A Computational Geometry Generation Method for Creating 3D Printed Composites and Porous Structures

Abstract

1. Introduction

2. Materials and Methods

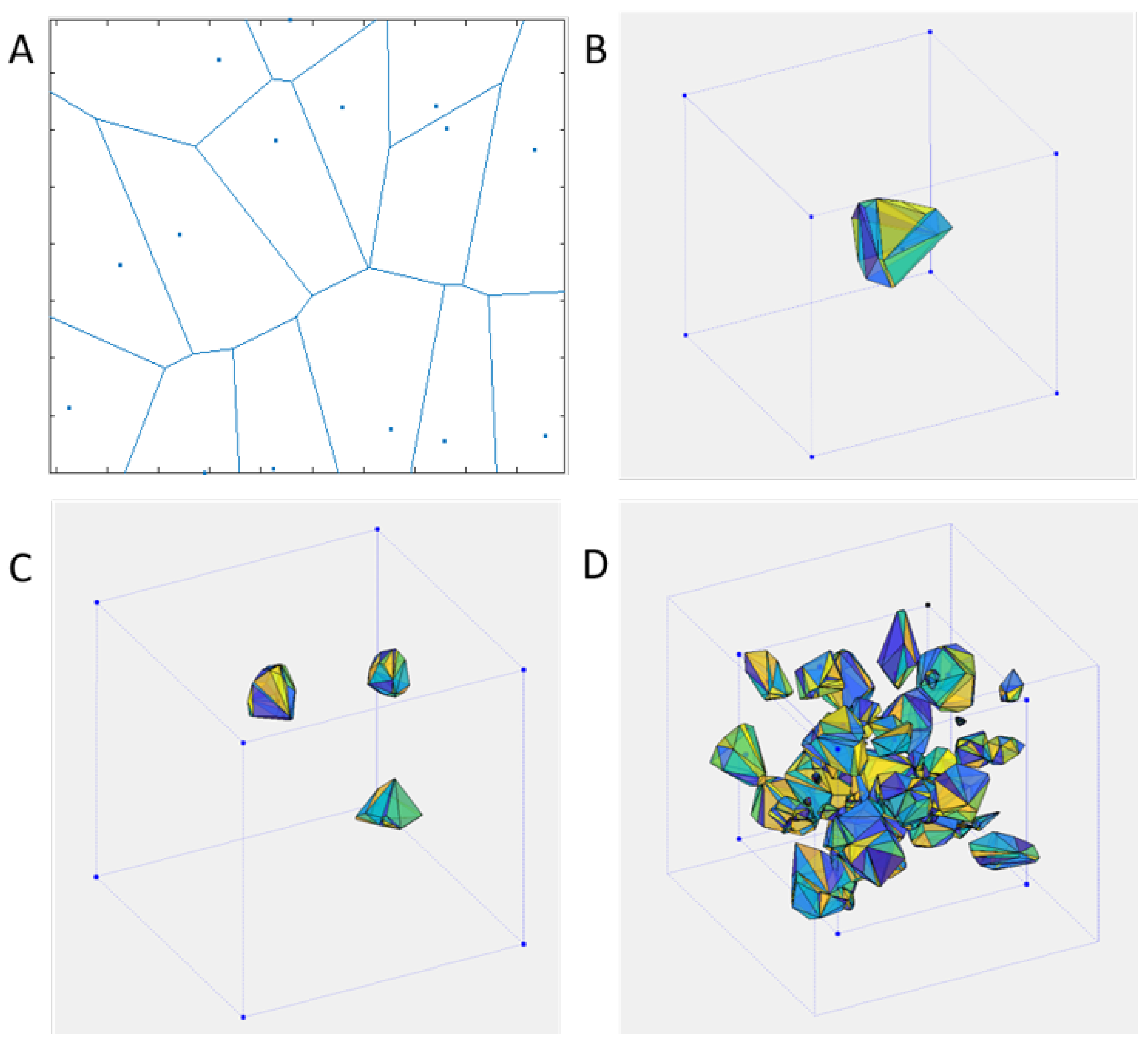

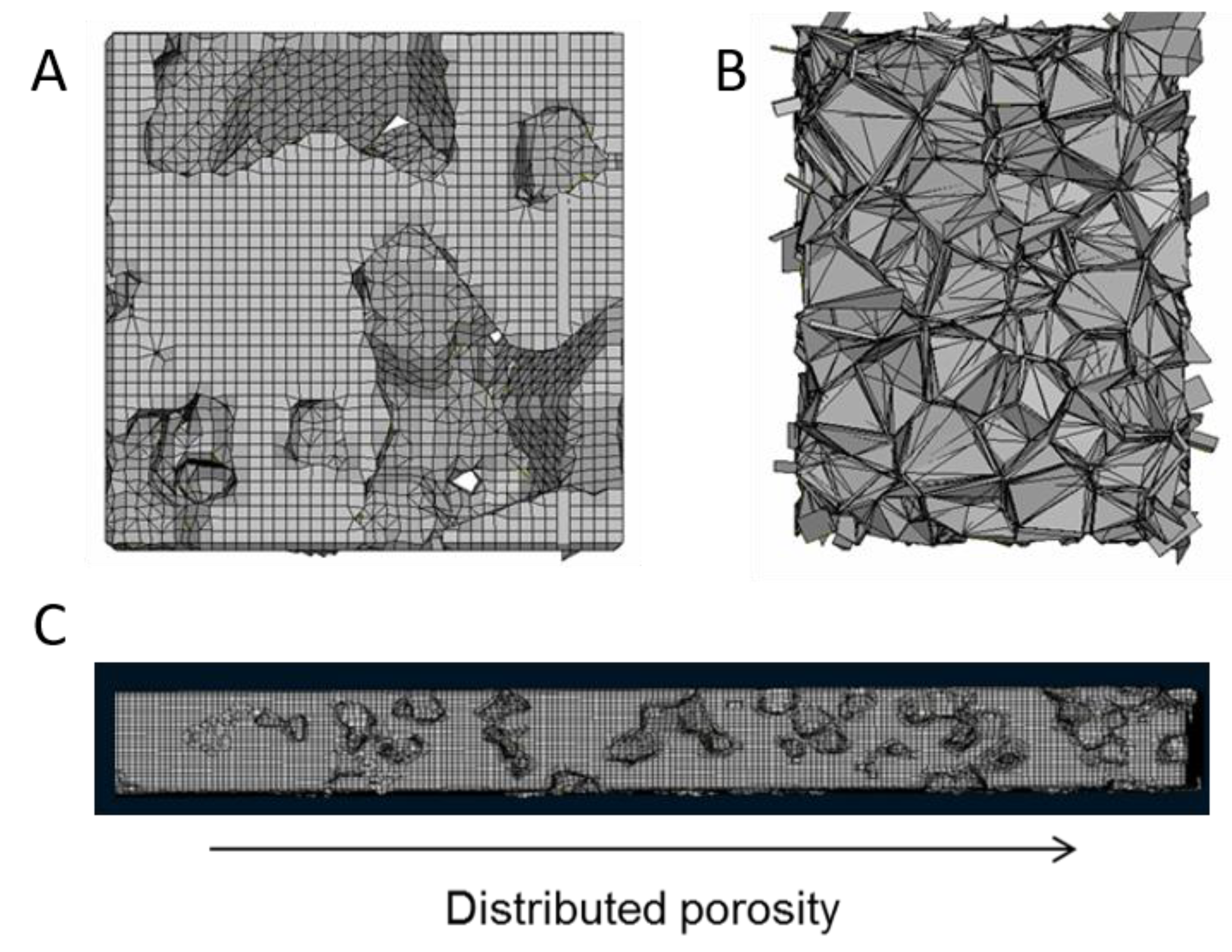

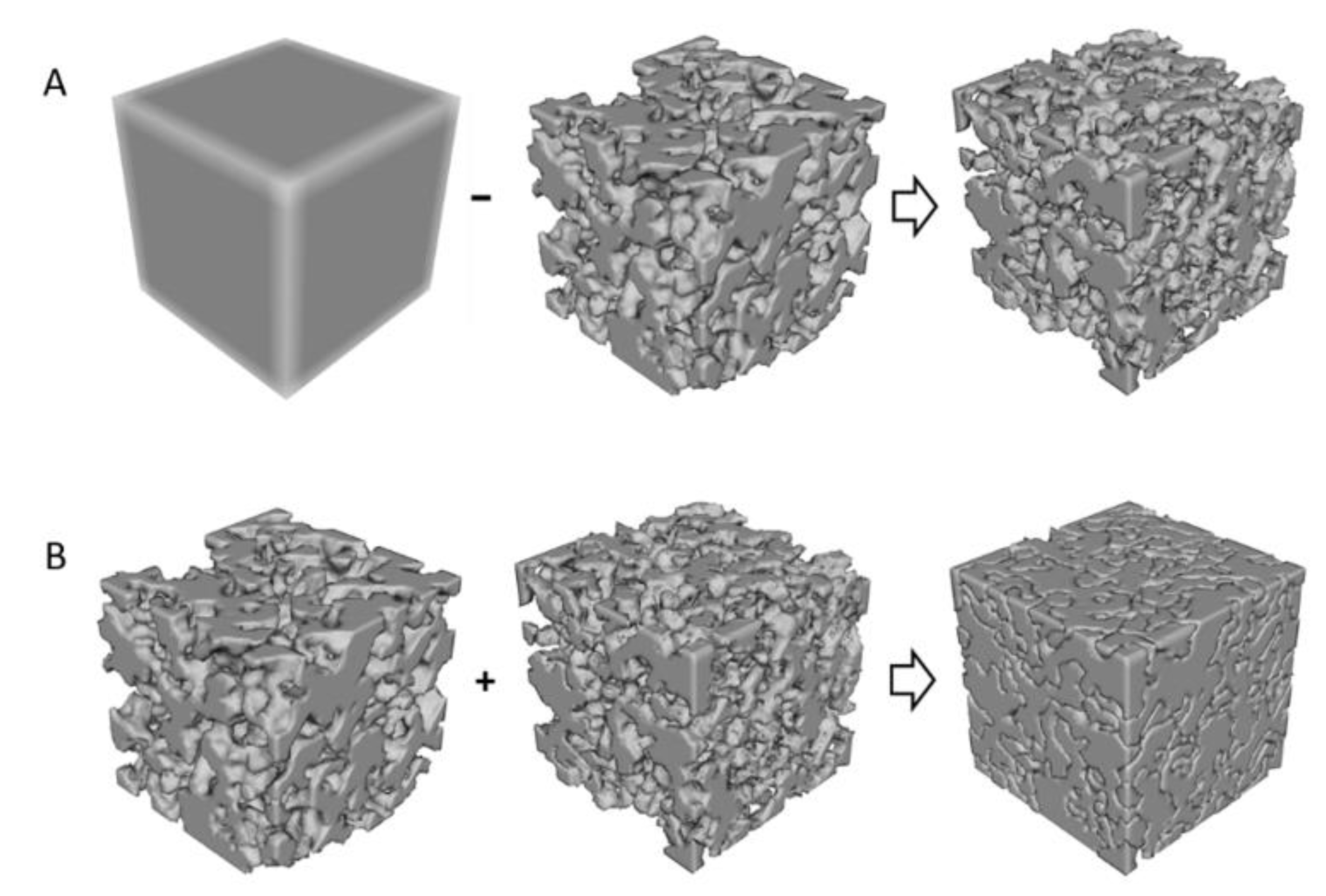

2.1. Virtual Geometry Generation

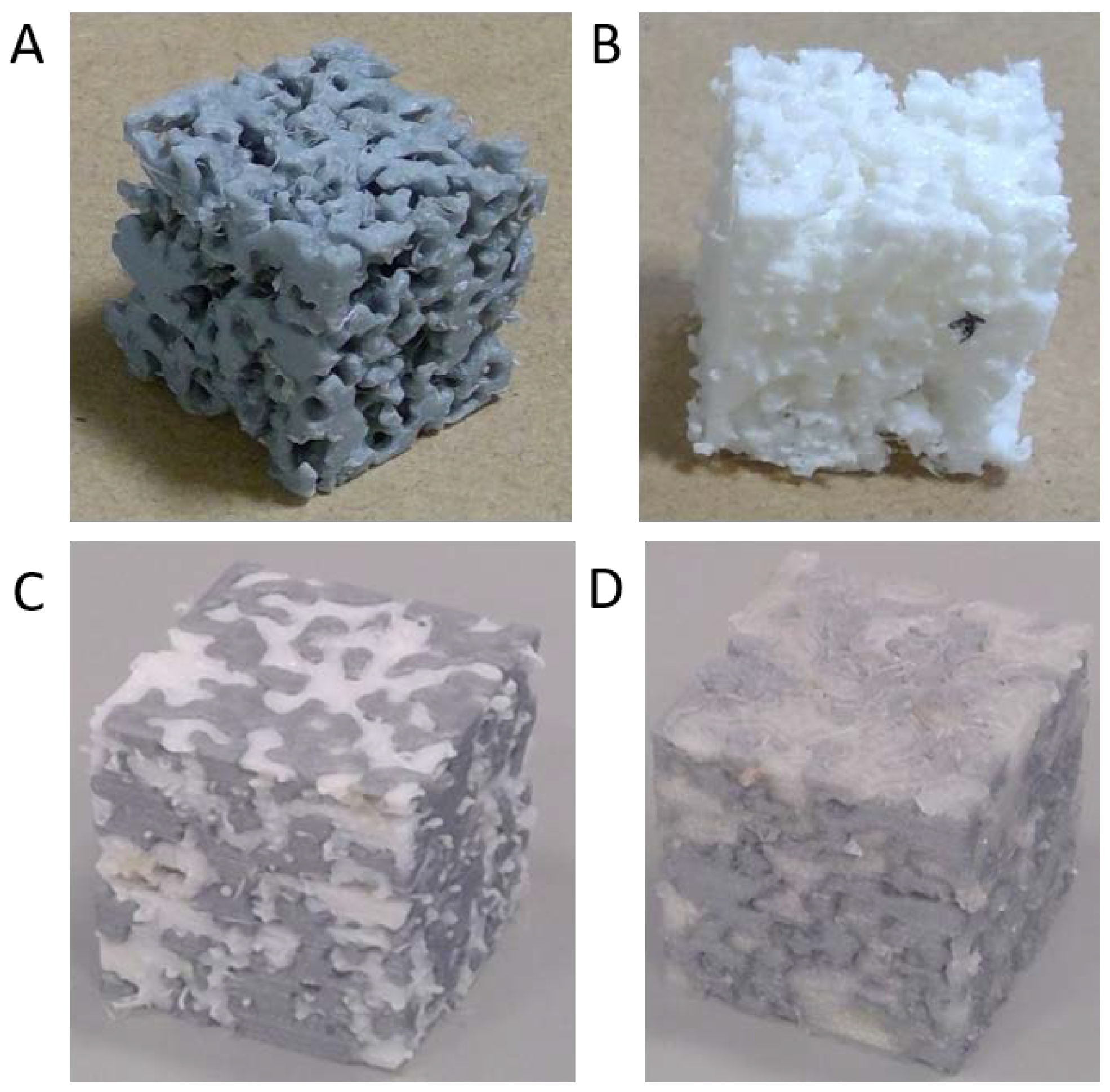

2.2. Specimen Preparation

2.3. Testing

3. Results-Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Serra, T.; Mateos-Timoneda, M.; Planell, J.A.; Navarro, M. 3D printed PLA-based scaffolds. Organogenesis 2013, 9, 239–244. [Google Scholar] [CrossRef]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Van Nieuwenhove, I.; Tytgat, L.; Ryx, M.; Blondeel, P.; Stillaert, F.; Thienpont, H.; Ottevaere, H.; Dubruel, P.; Van Vlierberghe, S. Soft tissue fillers for adipose tissue regeneration: From hydrogel development toward clinical applications. Acta Biomater. 2017, 63, 37–49. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.; Wang, J.; Tang, F.; Min, L.; Zhou, Y.; Zhang, W.; Tu, C. A three-dimensional printed porous implant combined with bone grafting following curettage of a subchondral giant cell tumour of the proximal tibia: A case report. BMC Surgery 2019, 19, 29. [Google Scholar] [CrossRef] [PubMed]

- Khoda, A.; Ozbolat, I.T.; Koc, B. Designing heterogeneous porous tissue scaffolds for additive manufacturing processes. Comput.-Aided Des. 2013, 45, 1507–1523. [Google Scholar] [CrossRef]

- Hollister, S.J. Porous scaffold design for tissue engineering. Nat. Mater. 2005, 4, 518–524. [Google Scholar] [CrossRef]

- Moroni, L.; De Wijn, J.R.; Van Blitterswijk, C.A. 3D fiber-deposited scaffolds for tissue engineering: Influence of pores geometry and architecture on dynamic mechanical properties. Biomaterials 2006, 27, 974–985. [Google Scholar] [CrossRef]

- Bose, S.; Roy, M.; Bandyopadhyay, A. Recent advances in bone tissue engineering scaffolds. Trends Biotechnol. 2012, 30, 546–554. [Google Scholar] [CrossRef]

- Davis, G.R.; Wong, F.S. X-ray microtomography of bones and teeth. Physiol. Meas. 1996, 17, 121. [Google Scholar] [CrossRef]

- Rubin, C.T.; Lanyon, L.E. Osteoregulatory nature of mechanical stimuli: Function as a determinant for adaptive remodeling in bone. J. Orthop. Res. 1987, 5, 300–310. [Google Scholar] [CrossRef] [PubMed]

- Lanyon, L.E. Functional strain in bone tissue as an objective, and controlling stimulus for adaptive bone remodelling. J. Biomech. 1987, 20, 1083–1093. [Google Scholar] [CrossRef]

- Gbureck, U.; Vorndran, E.; Müller, F.A.; Barralet, J.E. Low temperature direct 3D printed bioceramics and biocomposites as drug release matrices. J. Control. Release 2007, 122, 173–180. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, W.; Vo, A.Q.; Feng, X.; Ye, X.; Kim, D.W.; Repka, M.A. Hydroxypropyl methylcellulose-based controlled release dosage by melt extrusion and 3D printing: Structure and drug release correlation. Carbohydr. Polym. 2017, 177, 49–57. [Google Scholar] [CrossRef]

- Nyga, A.; Cheema, U.; Loizidou, M. 3D tumour models: Novel in vitro approaches to cancer studies. J. Cell Commun. Signal. 2011, 5, 239. [Google Scholar] [CrossRef] [PubMed]

- Cook, J.; Goodridge, R.D.; Siviour, C.R. Strain Rate Dependency of Laser Sintered Polyamide 12. In Proceedings of the 11th International Conference on the Mechanical and Physical Behaviour of Materials under Dynamic Loading, Lugano, Switzerland, 7–11 September 2015; EPJ Web of Conferences. EDP Sciences: Paris, France, 2015; Volume 94, p. 02019. [Google Scholar]

- Evans, A.G.; Hutchinson, J.W.; Fleck, N.A.; Ashby, M.F.; Wadley, H. The topological design of multifunctional cellular metals. Prog. Mater. Sci. 2001, 46, 309–327. [Google Scholar] [CrossRef]

- Soe, S.; Ryan, M.; McShane, G.; Theobald, P. Energy Absorbing Characteristics of Additively Manufactured TPE Cellular Structures. InImpact J. Innov. Impact 2016, 8, 145. [Google Scholar]

- Evans, A.G.; He, M.; Deshpande, V.S.; Hutchinson, J.W.; Jacobsen, A.J.; Carter, W.B. Concepts for enhanced energy absorption using hollow micro-lattices. Int. J. Impact Eng. 2010, 37, 947–959. [Google Scholar] [CrossRef]

- Compton, B.G.; Lewis, J.A. 3D-printing of lightweight cellular composites. Adv Mater 2014, 26, 5930–5935. [Google Scholar] [CrossRef] [PubMed]

- Schroeder, C.; Regli, W.C.; Shokoufandeh, A.; Sun, W. Computer-aided design of porous artifacts. Comput.-Aided Des. 2005, 37, 339–353. [Google Scholar] [CrossRef]

- Tran, P.; Ngo, T.D.; Ghazlan, A.; Hui, D. Bimaterial 3D printing and numerical analysis of bio-inspired composite structures under in-plane and transverse loadings. Compos. Part B Eng. 2017, 108, 210–223. [Google Scholar] [CrossRef]

- Bahr, R.A.; Fang, Y.; Su, W.; Tehrani, B.; Palazzi, V.; Tentzeris, M.M. Novel Uniquely 3D Printed Intricate Voronoi and Fractal 3D Antennas. In Proceedings of the 2017 IEEE MTT-S International Microwave Symposium (IMS), Honololu, HI, USA, 4–9 June 2017; IEEE: New York, NY, USA, 2017; pp. 1583–1586. [Google Scholar]

- Öncel, A.C.; Yaman, U. Generation of Optimized Voronoi Based Interior Structures for Improved Mechanical Properties. Procedia Manuf. 2019, 38, 42–51. [Google Scholar] [CrossRef]

- Wejrzanowski, T.; Skibinski, J.; Szumbarski, J.; Kurzydlowski, K.J. Structure of foams modeled by Laguerre–Voronoi tessellations. Comput. Mater. Sci. 2013, 67, 216–221. [Google Scholar] [CrossRef]

- Siegkas, P.; Petrinic, N.; Tagarielli, V.L. Measurements and micro-mechanical modelling of the response of sintered titanium foams. J. Mech. Behav. Biomed. Mater. 2016, 57, 365–375. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.; Hu, N.; Guo, X.; Dong, L.; Chen, Y.; Guo, Z. An Ultra-Simple Universal Model for the Effective Elastic Properties of Isotropic 3D Closed-Cell Porous Materials. Compos. Struct. 2020, 249, 112531. [Google Scholar] [CrossRef]

- Siegkas, P. Static and Dynamic Performance of Ti Foams. Ph.D. Thesis, University of Oxford, Oxford, UK, 2014. [Google Scholar]

- Brischetto, S.; Torre, R. Tensile and Compressive Behavior in the Experimental Tests for PLA Specimens Produced via Fused Deposition Modelling Technique. J. Compos. Sci. 2020, 4, 140. [Google Scholar] [CrossRef]

- Płatek, P.; Rajkowski, K.; Cieplak, K.; Sarzyński, M.; Małachowski, J.; Woźniak, R.; Janiszewski, J. Deformation Process of 3D Printed Structures Made from Flexible Material with Different Values of Relative Density. Polymers 2020, 12, 2120. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Assad, M.A.; Al-Rub, R.K.A. Mechanical properties of periodic interpenetrating phase composites with novel architected microstructures. Compos. Struct. 2017, 176, 9–19. [Google Scholar] [CrossRef]

- Elmrabet, N.; Siegkas, P. Dimensional considerations on the mechanical properties of 3D printed polymer parts. Polym. Test. 2020, 90, 106656. [Google Scholar] [CrossRef]

| Settings | PLA | Nylon | TPU |

|---|---|---|---|

| Printing temperature (°C) | 200 | 245 | 223 |

| Layer height (mm) | 0.1 | 0.1 | 0.1 |

| Printing speed (mm·s−1) | 70 | 70 | 25 |

| Filament (mm) | 2.85 | 2.85 | 2.85 |

| Nozzle (mm) | 0.4 | 0.4 | 0.4 |

| Infill (%) | 20 | 20 | 20 |

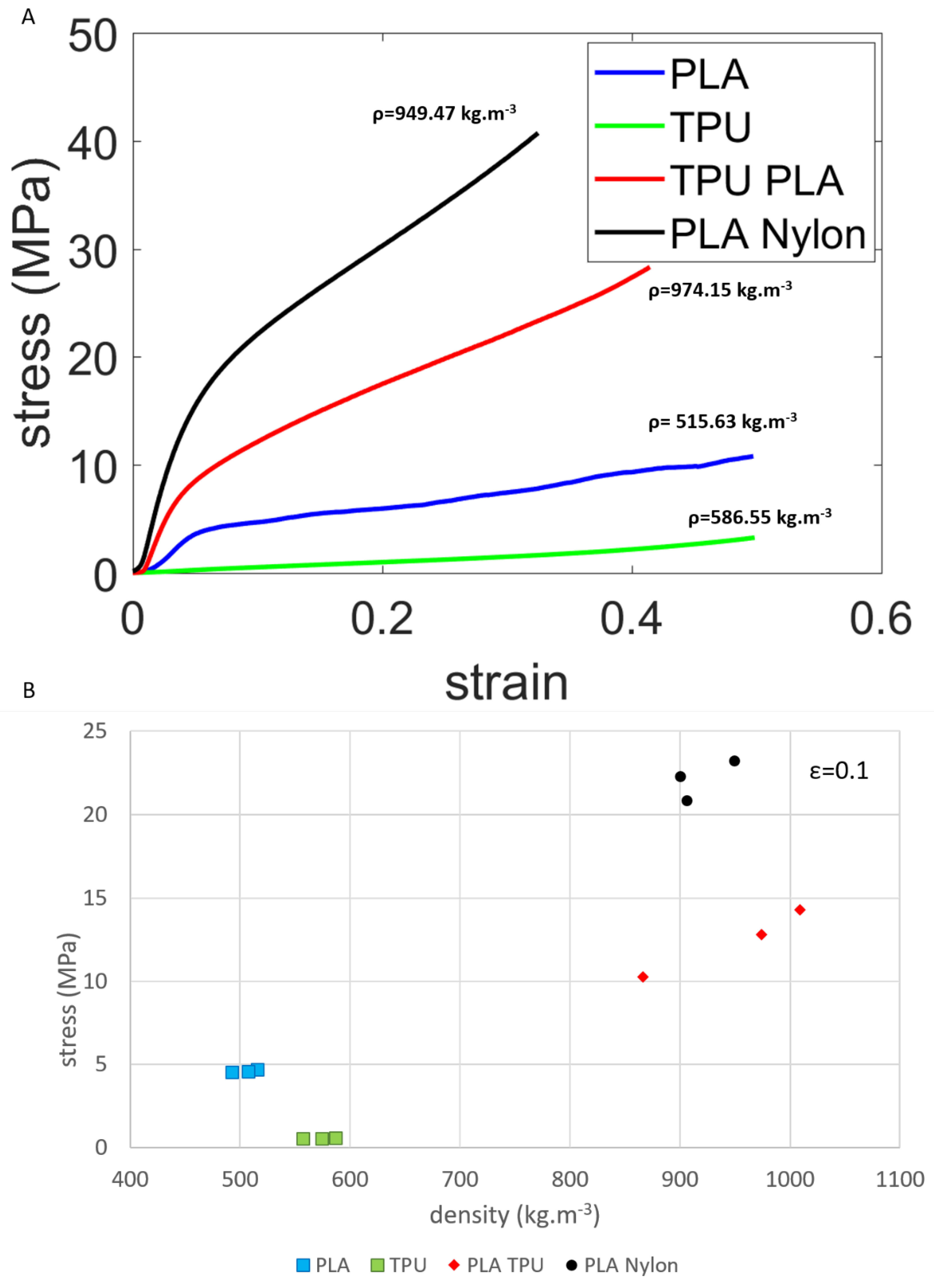

| Material | Density (kg·m−3) | Stress (MPa) at 0.1 Strain | Stress (MPa) at 0.2 Strain |

|---|---|---|---|

| PLA-Nylon composite | 949.47 | 23.25 | 31.39 |

| 905.79 | 20.87 | 29.74 | |

| 900.27 | 22.32 | 32.54 | |

| PLA-TPU composite | 974.15 | 12.79 | 18.03 |

| 866.64 | 10.27 | 15.21 | |

| 1.01 × 103 | 14.28 | 20.55 | |

| Porous TPU | 586.55 | 0.59 | 1.031 |

| 574.09 | 0.54 | 0.97 | |

| 557.39 | 0.55 | 0.94 | |

| Porous PLA | 515.52 | 4.7 | 6 |

| 507.44 | 4.6 | 6.7 | |

| 492.80 | 4.55 | 5.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siegkas, P. A Computational Geometry Generation Method for Creating 3D Printed Composites and Porous Structures. Materials 2021, 14, 2507. https://doi.org/10.3390/ma14102507

Siegkas P. A Computational Geometry Generation Method for Creating 3D Printed Composites and Porous Structures. Materials. 2021; 14(10):2507. https://doi.org/10.3390/ma14102507

Chicago/Turabian StyleSiegkas, Petros. 2021. "A Computational Geometry Generation Method for Creating 3D Printed Composites and Porous Structures" Materials 14, no. 10: 2507. https://doi.org/10.3390/ma14102507

APA StyleSiegkas, P. (2021). A Computational Geometry Generation Method for Creating 3D Printed Composites and Porous Structures. Materials, 14(10), 2507. https://doi.org/10.3390/ma14102507