Low-Frequency Dielectric Relaxation in Structures Based on Macroporous Silicon with Meso-Macroporous Skin-Layer

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

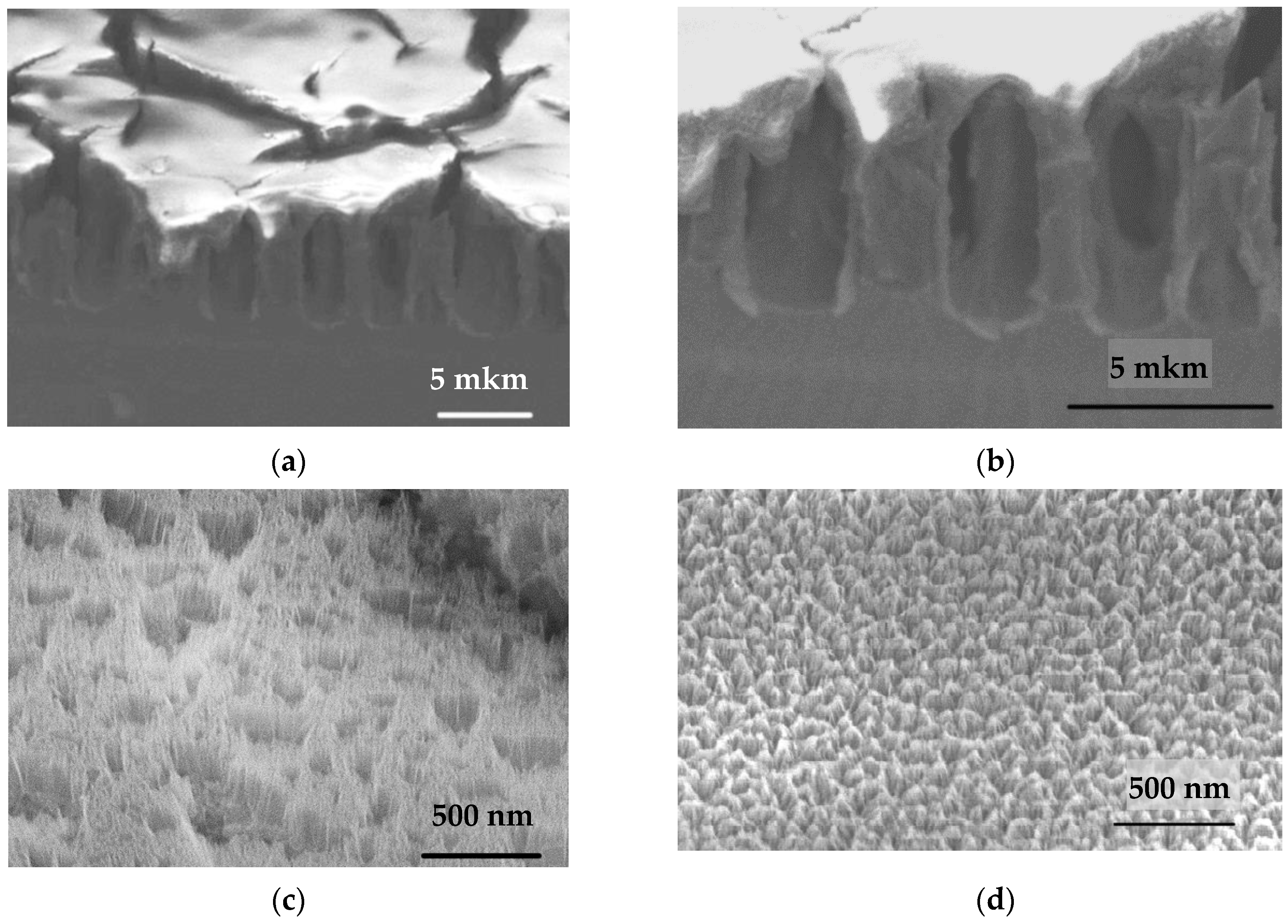

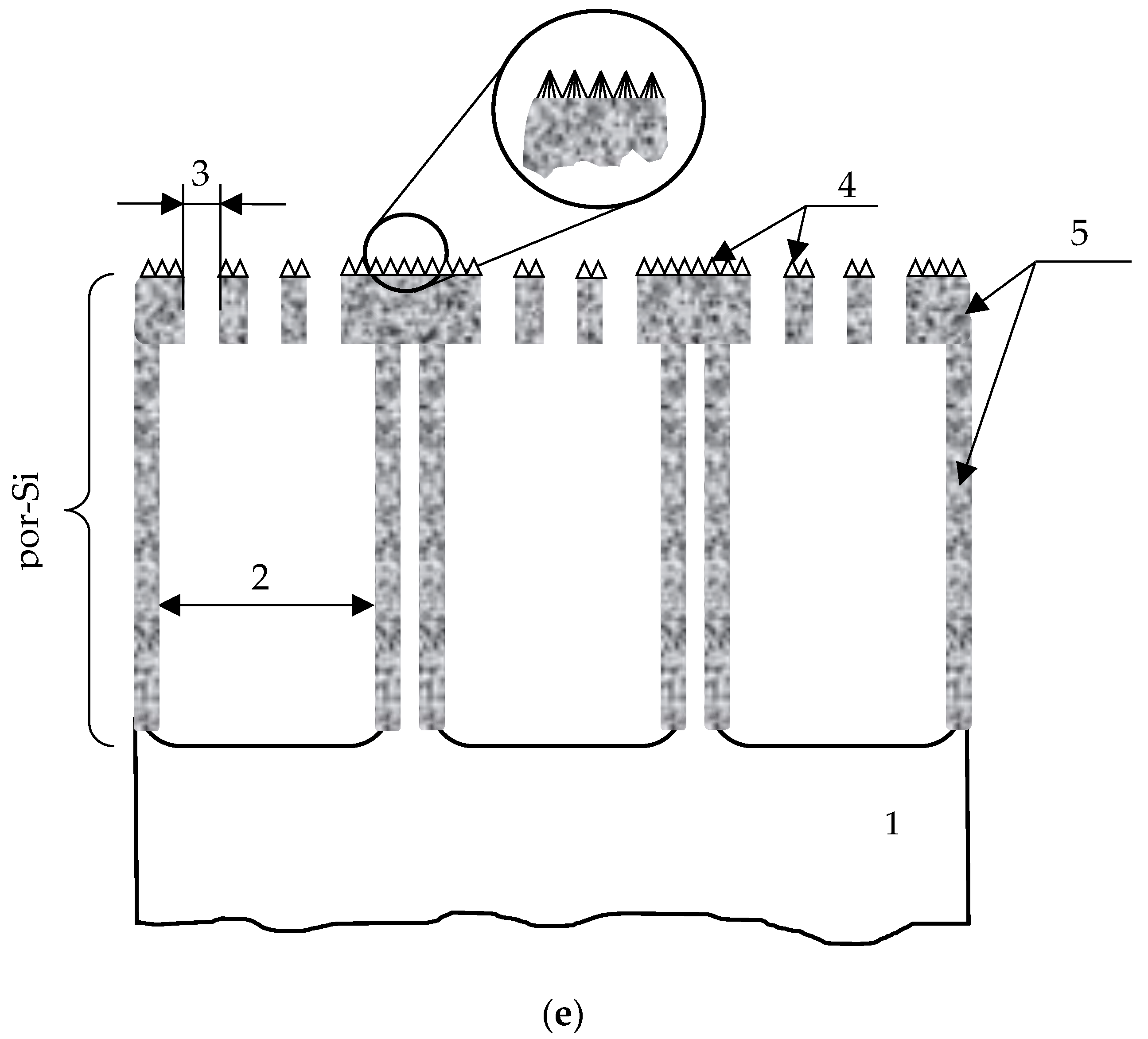

3.1. Microstructure Characterization

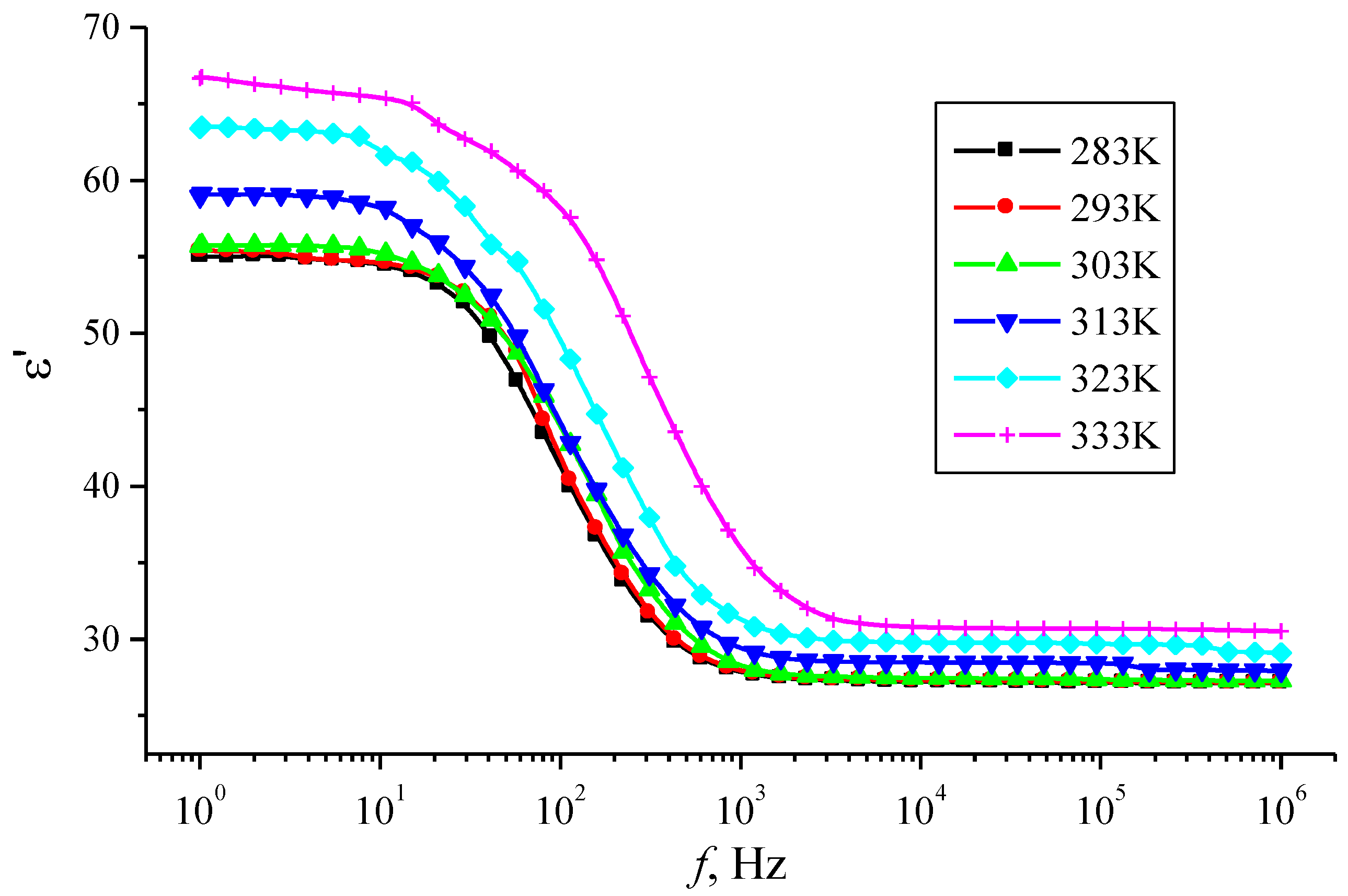

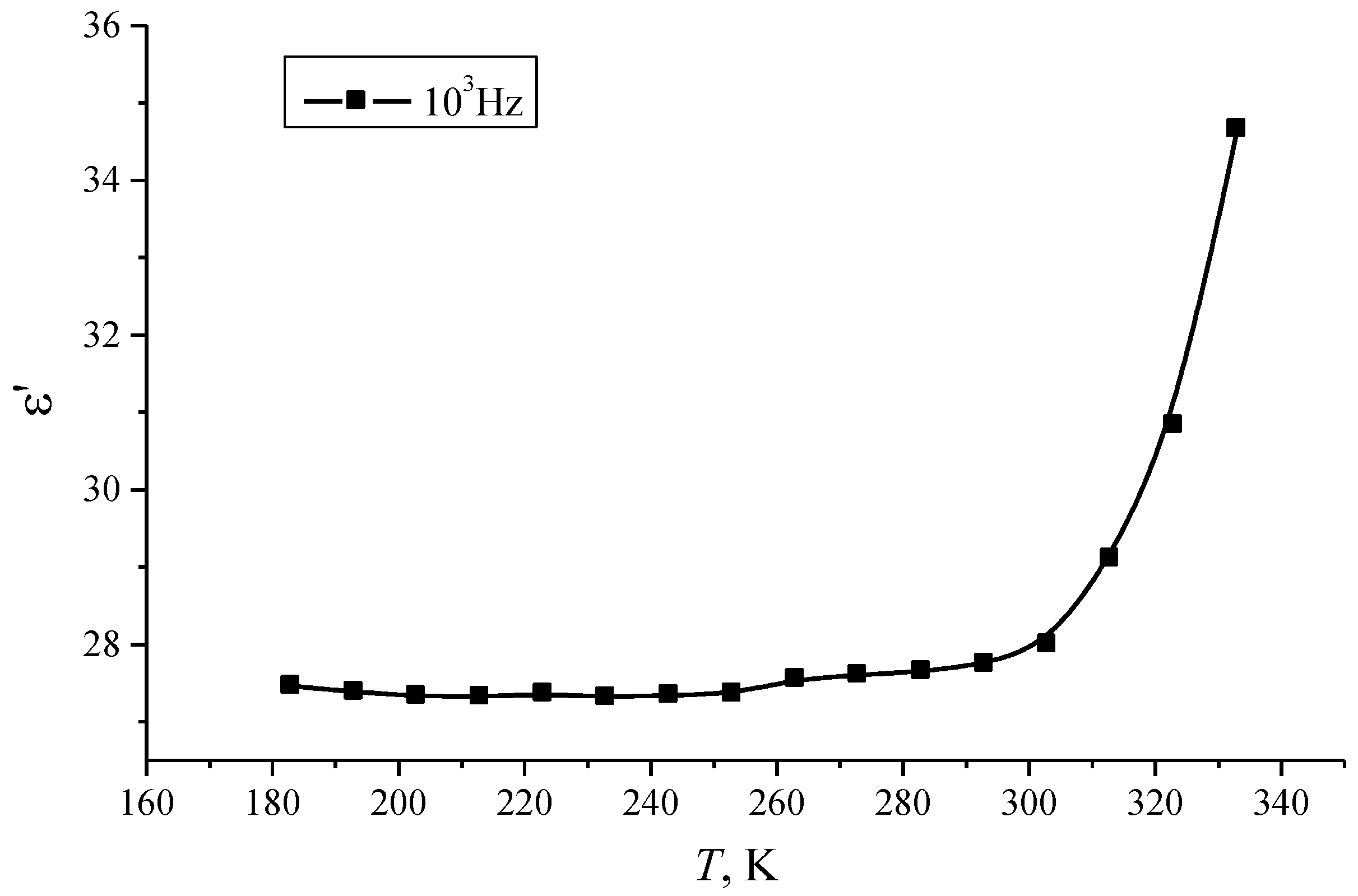

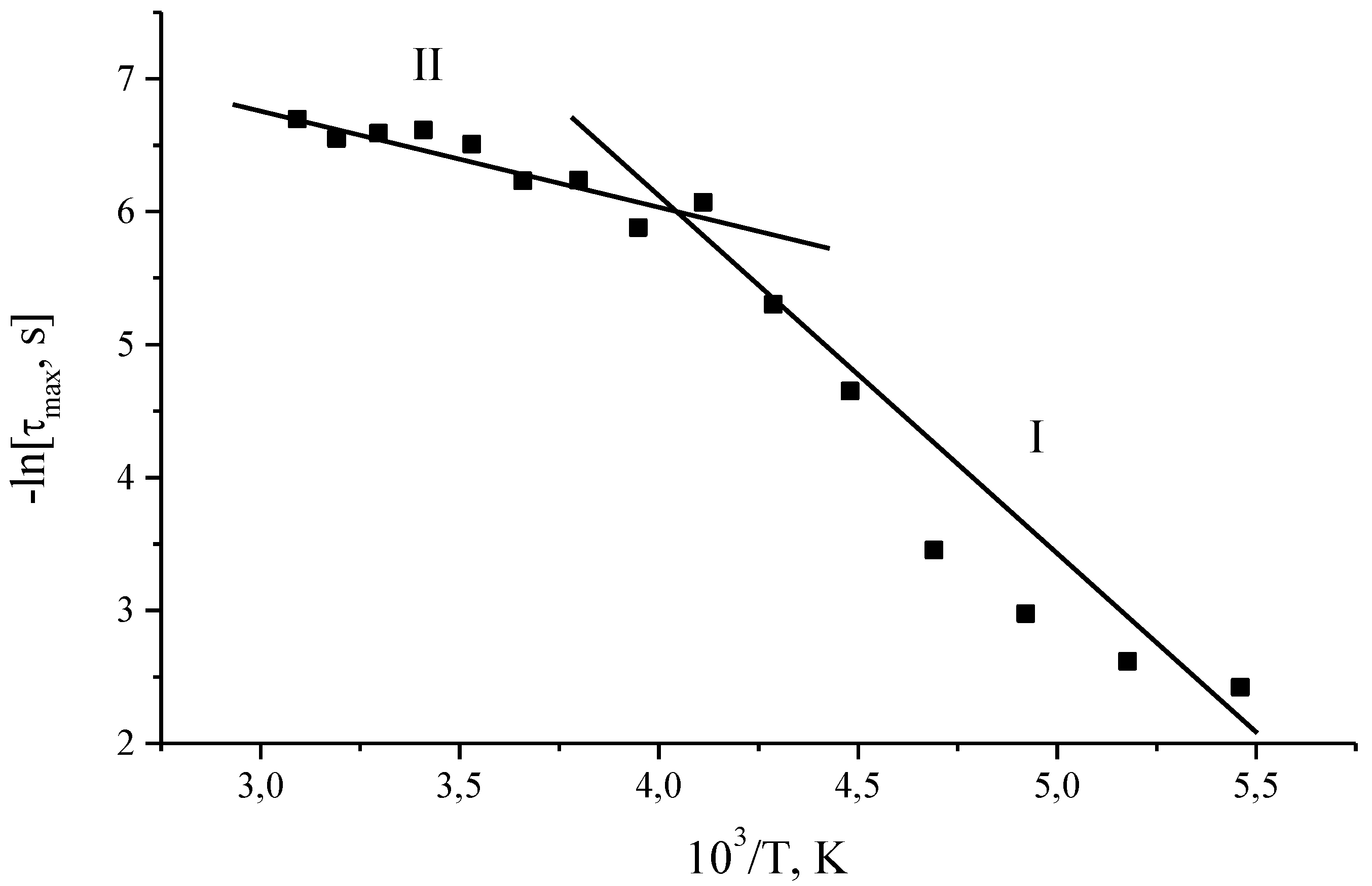

3.2. Impedance Spectroscopy Characterization

- for α = 0 and β = 1, Formula (1) transforms into the Debye model;

- for 1 > α > 0 and β = 1—the Cole-Cole model;

- for α = 0 and 1 > β > 1—Formula (1) turns into the Davidson-Cole model.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Y.; Li, L.-H.; Li, Y.; Rooke, J.; Sanchez, C.; Su, B.-L. Hierarchically porous materials: Synthesis strategies and structure design. Chem. Soc. Rev. 2017, 45, 481–558. [Google Scholar] [CrossRef]

- Martin-Martinez, F.J.; Jin, K.; Barreiro, D.L.; Buehler, M.J. The Rise of Hierarchical Nanostructured Materials from Renewable Sources: Learning from Nature. ACS Nano 2018, 12, 7425–7433. [Google Scholar] [CrossRef] [PubMed]

- Jia, H.; Li, X.; Song, J.; Zhang, X.; Luo, L.; He, Y.; Li, B.; Cai, Y.; Hu, S.; Xiao, X.; et al. Hierarchical porous silicon structures with extraordinary mechanical strength as high-performance lithium-ion battery anodes. Nat. Commun. 2020, 11, 1–9. [Google Scholar] [CrossRef]

- Fang, B.; Kim, J.H.; Kim, M.S.; Yu, J.S. Hierarchical nanostructured carbons with meso-macroporosity: Design, characteriza-tion, and applications. Acc. Chem. Res. 2013, 46, 1397–1406. [Google Scholar] [CrossRef] [PubMed]

- Bobkov, A.A.; Kononova, I.E.; Moshnikov, V.A. Materials science of micro- and nanosystem. In Hierarchical Structures; SPbETU Publishing House: Saint Petersburg, Russia, 2017; p. 204. [Google Scholar]

- Wang, J.; Tang, J.; Ding, B.; Malgras, V.; Chang, Z.; Hao, X.; Wang, Y.; Dou, H.; Zhang, X.; Yamauchi, Y. Hierarchical porous carbons with layer-by-layer motif architectures from confined soft-template self-assembly in layered materials. Nat. Commun. 2017, 8, 15717. [Google Scholar] [CrossRef]

- Zhu, J.; Shan, Y.; Wang, T.; Sun, H.; Zhao, Z.; Mei, L.; Fan, Z.; Xu, Z.; Shakir, I.; Huang, Y.; et al. A hyperaccumulation pathway to three-dimensional hierarchical porous nanocomposites for highly robust high-power electrodes. Nat. Commun. 2016, 7, 13432. [Google Scholar] [CrossRef] [PubMed]

- Sohn, M.; Lee, D.G.; Park, H.-I.; Park, C.; Choi, J.-H.; Kim, H. Microstructure Controlled Porous Silicon Particles as a High Capacity Lithium Storage Material via Dual Step Pore Engineering. Adv. Funct. Mater. 2018, 28, 1800855. [Google Scholar] [CrossRef]

- Sun, M.-H.; Huang, S.-Z.; Chen, L.-H.; Li, Y.; Yang, X.-Y.; Yuan, Z.-Y.; Su, B.-L. Applications of hierarchically structured porous materials from energy storage and conversion, catalysis, photocatalysis, adsorption, separation, and sensing to biomedicine. Chem. Soc. Rev. 2016, 45, 3479–3563. [Google Scholar] [CrossRef]

- Zheng, B.; Lin, X.; Zhang, X.; Wu, D.; Matyjaszewski, K. Emerging Functional Porous Polymeric and Carbonaceous Materials for Environmental Treatment and Energy Storage. Adv. Funct. Mater. 2020, 30, 1907006. [Google Scholar] [CrossRef]

- Antunez, E.E.; Salazar-Kuri, U.; Estevez, J.O.; Campos, J.; Basurto, M.A.; Jimenez Sandoval, S.; Agarwal, V. Porous sili-con-VO2 based hybrids as possible optical temperature sensor: Wavelength-dependent optical switching from visible to near-infrared range. Appl. Phys. 2015, 118, 134503. [Google Scholar] [CrossRef]

- Pronin, I.; Yakushova, N.; Averin, I.; Moshnikov, V.; Donkova, B.; Dimitrov, D.; Georgieva, A.; Nalimova, S. A percolation model of semiconductor gas sensors with a hierarchical pore structure. EAI Endorsed Trans. Energy Web 2018, 6, 10. [Google Scholar] [CrossRef]

- Kononova, I.E.; Moshnikov, V.A.; Lenshin, A.S.; Gareev, K.G.; Soboleva, E.A.; Kuznetsov, V.V.; Olchowik, G.; Olchowik, J.M. The preparation and properties of "porous silicon-nickel ferrite" nanoheterocomposites for gas detectors. J. Sol-Gel Sci. Technol. 2014, 71, 234–240. [Google Scholar] [CrossRef]

- Arzumanyan, G.; Doroshkevich, N.; Mamatkulov, K.; Shashkov, S.; Girel, K.; Bandarenka, H.; Borisenko, V. Phospholipid detection by surface-enhanced Raman scattering using silvered porous silicon substrates. Phys. Status Solidi (a) 2017, 214, 1600915. [Google Scholar] [CrossRef]

- Ko, W.-Y.; Chen, Y.-S.; Li, M.-S.; Lai, J.-Y.; Lin, K.-J. A Novel Hydrogen Peroxide Amperometric Sensor Based on Hierarchical 3D Porous MnO2−TiO2 Composites. Electroanalysis 2019, 31, 797–804. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, X.; Huang, H.; Wang, H.; Lin, W.; Peng, Z. Full 3D Printing of Stretchable Piezoresistive Sensor with Hier-archical Porosity and Multimodulus Architecture. Adv. Fun. Mater. 2019, 29, 1807569. [Google Scholar] [CrossRef]

- Zou, S.; Zhang, M.; Mo, S.; Cheng, H.; Fu, M.; Chen, P.; Chen, L.; Shi, W.; Ye, D. Catalytic Performance of Toluene Combustion over Pt Nanoparticles Supported on Pore-Modified Macro-Meso-Microporous Zeolite Foam. Nanomaterials 2019, 10, 30. [Google Scholar] [CrossRef] [PubMed]

- Ayral, A. Sol-Gel Synthesis and Fine Characterization of Hierarchically Porous and Multifunctional Silica-Based Membranes. Chem. Rec. 2018, 18, 878–890. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.H.; Xu, S.T.; Li, X.Y.; Tian, G.; Li, Y.; Rooke, J.C.; Zhu, G.S.; Qiu, S.L.; Wei, Y.X.; Yang, X.Y.; et al. Multimodal Zr-Silicalite-1 zeolite nanocrystal aggregates with interconnected hierarchically micro-meso-macroporous architecture and enhanced mass transport property. J. Colloid Interface Sci. 2012, 377, 368–374. [Google Scholar] [CrossRef]

- Li, Z.; He, Y.; Klausen, L.H.; Yan, N.; Liu, J.; Chen, F.; Song, W.; Dong, M.; Zhang, Y. Growing vertical aligned mesoporous silica thin film on nanoporous substrate for enhanced degradation, drug delivery and bioactivity. Bioact. Mater. 2021, 6, 1452–1463. [Google Scholar] [CrossRef]

- Balasubramanian, V.; Domanskyi, A.; Renko, J.-M.; Sarparanta, M.; Wang, C.-F.; Correia, A.; Mäkilä, E.; Alanen, O.S.; Salonen, J.; Airaksinen, A.J.; et al. Engineered antibody-functionalized porous silicon nanoparticles for therapeutic targeting of pro-survival pathway in endogenous neuroblasts after stroke. Biomaterials 2020, 227, 119556. [Google Scholar] [CrossRef]

- Fontana, F.; Lindstedt, H.; Correia, A.; Chiaro, J.; Kari, O.; Ndika, J.; Alenius, H.; Buck, J.; Sieber, S.; Mäkilä, E.; et al. Influence of Cell Membrane Wrapping on the Cell−Porous Silicon Nanoparticle Interactions. Adv. Healthc. Mater. 2020, 9, 2070056. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Li, W.; Xiao, C.; Liu, D.; Dong, C.; Zhang, M.; Mäkilä, E.; Kemell, M.; Salonen, J.; et al. Multifunctional Nanohybrid Based on Porous Silicon Nanoparticles, Gold Nanoparticles, and Acetalated Dextran for Liver Regeneration and Acute Liver Failure Theranostics. Adv. Mater. 2017, 30, 1703393. [Google Scholar] [CrossRef] [PubMed]

- Franco, S.; Noureddine, A.; Guo, J.; Keth, J.; Paffett, M.L.; Brinker, C.J.; Serda, R.E. Direct Transfer of Mesoporous Silica Nanoparticles between Macrophages and Cancer Cells. Cancers 2020, 12, 2892. [Google Scholar] [CrossRef]

- Spivak, Y.M.; Belorus, A.O.; Panevin, A.A.; Zhuravskii, S.G.; Moshnikov, V.A.; Bespalova, K.; Somov, P.A.; Zhukov, Y.M.; Komolov, A.S.; Chistyakova, L.V.; et al. Porous silicon as a nanomaterial for disperse transport systems of targeted drug delivery to the inner ear. Tech. Phys. 2018, 63, 1352–1360. [Google Scholar] [CrossRef]

- Kang, S.; Lee, J.; Lee, S.; Kim, S.; Kim, J.-K.; Algadi, H.; Al-Sayari, S.; Kim, D.-E.; Lee, T. Highly Sensitive Pressure Sensor Based on Bioinspired Porous Structure for Real-Time Tactile Sensing. Adv. Electron. Mater. 2016, 2, 1600356. [Google Scholar] [CrossRef]

- Davoodi, E.; Montazerian, H.; Haghniaz, R.; Rashidi, A.; Ahadian, S.; Sheikhi, A.; Chen, J.; Khademhosseini, A.; Milani, A.S.; Hoorfar, M.; et al. 3D-Printed Ultra-Robust Surface-Doped Porous Silicone Sensors for Wearable Biomonitoring. ACS Nano 2020, 14, 1520–1532. [Google Scholar] [CrossRef]

- He, Z.; Chen, W.; Liang, B.; Liu, C.; Yang, L.; Lu, D.; Mo, Z.; Zhu, H.; Tang, Z.; Gui, X. Capacitive Pressure Sensor with High Sensitivity and Fast Response to Dynamic Interaction Based on Graphene and Porous Nylon Networks. ACS Appl. Mater. Interfaces 2018, 10, 12816–12823. [Google Scholar] [CrossRef]

- Zhao, T.; Li, T.; Chen, L.; Yuan, L.; Li, X.; Zhang, J. Highly Sensitive Flexible Piezoresistive Pressure Sensor Developed Using Biomimetically Textured Porous Materials. ACS Appl. Mater. Interfaces 2019, 11, 29466–29473. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, X.; Chu, R.; Wang, S.; Zeng, W.; Qu, L.; Zhao, Y.; Yan, F.; Xing, G. Rapid-Response, Low Detection Limit, and High-Sensitivity Capacitive Flexible Tactile Sensor Based on Three-Dimensional Porous Dielectric Layer for Wearable Electronic Skin. ACS Appl. Mater. Interfaces 2019, 11, 40716–40725. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, L.; Chen, C.; Yu, H.; Bai, H.; Wang, L.; Qin, M.; Feng, Y.; Feng, W. Liquid metal-created macroporous com-posite hydrogels with self-healing ability and multiple sensations as artificial flexible sensors. Mater. Chem. A 2020, 9, 875–883. [Google Scholar] [CrossRef]

- Shilova, O.A. Fractals, morphogenesis and triply periodic minimal surfaces in sol–gel-derived thin films. J. Sol-Gel Sci. Technol. 2020, 95, 599–608. [Google Scholar] [CrossRef]

- Thomou, E.; Diamanti, E.K.; Enotiadis, A.; Spyrou, K.; Mitsari, E.; Boutsika, L.G.; Sapalidis, A.; Alfonsín, E.M.; De Luca, O.; Gournis, D.; et al. New Porous Heterostructures Based on Organo-Modified Graphene Oxide for CO2 Capture. Front. Chem. 2020, 8, 840. [Google Scholar] [CrossRef]

- Khamkeaw, A.; Asavamongkolkul, T.; Perngyai, T.; Jongsomjit, B.; Phisalaphong, M. Interconnected Micro, Meso, and Macro Porous Activated Carbon from Bacterial Nanocellulose for Superior Adsorption Properties and Effective Catalytic Perfor-mance. Molecules 2020, 25, 4063. [Google Scholar] [CrossRef]

- Wu, L.; Li, Y.; Fu, Z.; Su, B.-L. Hierarchically structured porous materials: Synthesis strategies and applications in energy storage. Natl. Sci. Rev. 2020, 7, 1667–1701. [Google Scholar] [CrossRef]

- Li, B.; Li, X.; Shao, C.; Li, X.; Liu, H.; Yang, S.; Tao, R.; Liu, Y. Hierarchically Porous In2O3/In2S3 Heterostructures as Mi-cronano Photocatalytic Reactors Prepared by a Novel Polymer-Assisted Sol–Gel Freeze-Drying Method. Ind. Eng. Chem. Res. 2019, 58, 14106–14114. [Google Scholar] [CrossRef]

- Lenshin, A.S.; Kashkarov, V.M.; Spivak, Y.M.; Moshnikov, V.A. Investigations of nanoreactors on the basis of p-type porous silicon: Electron structure and phase composition. Mate. Chem. Phys. 2012, 135, 293–297. [Google Scholar] [CrossRef]

- Sidorov, A.I.; Nashchekin, A.V.; Kastro, R.A.; Anfimova, I.N.; Antropova, T.V. Optical and dielectric properties of nano-composites on base nanoporous glasses with silver and silver iodide nanowires. Phys. B Condens. Matter 2021, 603, 412764. [Google Scholar] [CrossRef]

- Kononov, A.A.; Kastro, R.A.; Glavnaya, D.D.; Anisimova, N.I.; Bordovsky, G.A.; Kolobov, A.V.; Saito, Y.; Fons, P. Dielectric relaxation and charge transfer in amorphous MoS2 thin films. Phys. Status Solidi B 2020, 257, 2000114. [Google Scholar] [CrossRef]

- Castro, R.A.; Bordovskiĭ, V.A.; Grabko, G.I.; Bordovskii, V.A. Temperature dependence of the dielectric parameters of thin arsenic triselenide layers with high bismuth content. Tech. Phys. Lett. 2010, 36, 966–968. [Google Scholar] [CrossRef]

- Iravani, M.A.; Deparis, J.; Davarzani, H.; Colombano, S.; Guérin, R.; Maineult, A. The influence of temperature on the dielectric permittivity and complex electrical resistivity of porous media saturated with DNAPLs: A laboratory study. Appl. Geophys. 2020, 172, 103921. [Google Scholar] [CrossRef]

- Baibarac, M.; Nila, A.; Smaranda, I.; Stroe, M.; Stingescu, L.; Cristea, M.; Cercel, R.; Lorinczi, A.; Ganea, P.; Mercioniu, I.; et al. Optical, Structural, and Dielectric Properties of Composites Based on Thermoplastic Polymers of the Polyolefin and Polyurethane Type and BaTiO3 Nanoparticles. Materials 2021, 14, 753. [Google Scholar] [CrossRef] [PubMed]

- Barsoukov, E.; Macdonald, J.R. Impedance Spectroscopy: Theory, Experiment, and Applications, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2005. [Google Scholar]

- Spivak, Y.M.; Castro, R.A.; Sevryugina, M.P.; Kuznetsova, M.A.; Moshnikov, V.A. Dielectric relaxation in por-Si layers at low frequencies. Phys. Chem. Asp. Study Clust. Nanostruct. Nanometer. 2020, 12, 170–179. [Google Scholar]

- Lenshin, A.S.; Kashkarov, V.M.; Spivak, Y.M.; Moshnikov, V.A. Study of electronic structure and phase composition of porous silicon. Glas. Phys. Chem. 2012, 38, 315–321. [Google Scholar] [CrossRef]

- Imai, K.; Unno, H. FIPOS technology and its application to LSI’s. IEEE Trans. Electron. Dev. 1984, 31, 297–302. [Google Scholar] [CrossRef]

- Chubenko, E.B.; Redko, S.V.; Sherstnyov, A.I.; Petrovich, V.A.; Kotov, D.A.; Bondarenko, V.P. Influence of the Surface Layer on the Electrochemical Deposition of Metals and Semiconductors into Mesoporous Silicon. Semiconductors 2016, 50, 372–376. [Google Scholar] [CrossRef]

- Zhao, M.; Balachandran, R.; Allred, J.; Keswani, M. Synthesis of porous silicon through interfacial reactions and measurement of its electrochemical response using cyclic voltammetry. RSC Adv. 2015, 5, 79157–79163. [Google Scholar] [CrossRef][Green Version]

- Slimani, A.; Iratni, A.; Henry, H.; Plapp, M.; Chazalviel, J.-N.; Ozanam, F.; Gabouze, N. Macropore formation in p-type silicon: Toward the modeling of morphology. Nanoscale Res. Lett. 2014, 9, 585. [Google Scholar] [CrossRef]

- Spivak, Y.M.; Myakin, S.V.; Moshnikov, V.A.; Panov, M.F.; Belorus, A.O.; Bobkov, A.A. Surface functionality features of porous silicon prepared and treated in different conditions. J. Nanomaterials 2016, 2016, 2629582. [Google Scholar] [CrossRef]

- Lenshin, A.S.; Kashkarov, V.M.; Seredin, P.V.; Spivak, Y.M.; Moshnikov, V.A. XANES and IR spectroscopy study of the electronic structure and chemical composition of porous silicon on n- and p-type substrates. Semiconductors 2011, 45, 1183–1188. [Google Scholar] [CrossRef]

- Smerdov, R.; Spivak, Y.; Bizyaev, I.; Somov, P.; Gerasimov, V.; Mustafaev, A.; Moshnikov, V. Advances in Novel Low-Macroscopic Field Emission Electrode Design Based on Fullerene-Doped Porous Silicon. Electronics 2020, 10, 42. [Google Scholar] [CrossRef]

- Zimina, T.M.; Luchinin, V.V. Microsystems for express analysis. J. Anal. Chem. 2011, 66, 1136–1158. [Google Scholar] [CrossRef]

- Lenshin, A.S. Formation and Functional Properties of Nanostructures Based on Porous Silicon. Ph.D. Thesis, Voronezh State University, Voronezh, Russia, 2021. [Google Scholar]

- Canham, L.T.; Barret, C.P.; Cox, T.I.; Wright, P.J.; Bowditch, A.P. Mesoporous Implants for Administering Substances and Methods of Producing Implants. U.S. Patent US 8,361,491 B2, 29 January 2013. [Google Scholar]

- Fonthal, F.; Trifonov, T.; Rodriguez, A.; Marsal, L.F.; Pallares, J. AC impedance analysis of Au/porous silicon contacts. Microelectron. Eng. 2006, 83, 2381–2385. [Google Scholar] [CrossRef]

- Kremer, F.; Schönhals, A. Broadband Dielectric Spectroscopy; Springer: Berlin/Heidelberg, Germany, 2003; p. 729. [Google Scholar]

- Nigmatullin, R.R.; Ryabov, Y.E. Cole-Davidson dielectric relaxation as a self-similar relaxation process. Phys. Solid State 1997, 39, 87–90. [Google Scholar] [CrossRef]

- Volkov, A.S.; Koposov, G.D.; Perfiliev, R.O. On the Physical Meaning of Disperse Parameters of Frequency Dependence of Dielectric Permittivity in the Havriliak–Negami Model. Opt. Spectrosc. 2018, 125, 379–382. [Google Scholar] [CrossRef]

- Zimin, S.P. Hopping conductivity in low-porosity mesoporous silicon formed on p + -Si:B. Semiconductors 2006, 40, 1350–1352. [Google Scholar] [CrossRef]

- Olenych, I.; Girnyk, I.; Orovcik, L. Electrical Properties of Porous Silicon Nanocrystals in a Dielectric Matrix. J. Nano-Electron. Phys. 2019, 11, 05016-1. [Google Scholar] [CrossRef]

- Azim-Araghi, M.; Ashrafabadi, S.; Kanjuri, F. Electrical Behaviour of Nanostructured Porous Silicon. Acta Phys. Pol. A 2012, 122, 170–173. [Google Scholar] [CrossRef]

| Geometric Elements of Por-Si Texture | Thickness, µm | Pore Diameter, nm | Size of Skeletal Part, nm |

|---|---|---|---|

| Macropores 1 | 7.8–8.2 | 2200–2700 | 0600–1200 |

| Macropores 2 | 0.1–0.2 | 190–310 | - |

| Mesopores | 0.1–0.2 | 13–25 | 35–40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castro, R.; Spivak, Y.; Shevchenko, S.; Moshnikov, V. Low-Frequency Dielectric Relaxation in Structures Based on Macroporous Silicon with Meso-Macroporous Skin-Layer. Materials 2021, 14, 2471. https://doi.org/10.3390/ma14102471

Castro R, Spivak Y, Shevchenko S, Moshnikov V. Low-Frequency Dielectric Relaxation in Structures Based on Macroporous Silicon with Meso-Macroporous Skin-Layer. Materials. 2021; 14(10):2471. https://doi.org/10.3390/ma14102471

Chicago/Turabian StyleCastro, Rene, Yulia Spivak, Sergey Shevchenko, and Vyacheslav Moshnikov. 2021. "Low-Frequency Dielectric Relaxation in Structures Based on Macroporous Silicon with Meso-Macroporous Skin-Layer" Materials 14, no. 10: 2471. https://doi.org/10.3390/ma14102471

APA StyleCastro, R., Spivak, Y., Shevchenko, S., & Moshnikov, V. (2021). Low-Frequency Dielectric Relaxation in Structures Based on Macroporous Silicon with Meso-Macroporous Skin-Layer. Materials, 14(10), 2471. https://doi.org/10.3390/ma14102471