Preparation of Plastics- and Foaming Agent-Free and Porous Bamboo Charcoal based Composites Using Sodium Silicate as Adhesives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of BC/SS Composites

2.3. Porosity and Average Pore Size Test

2.4. Formaldehyde Adsorption Performance Test

2.5. Mechanical Properties and Aging Resistance Test

2.6. Characterization

3. Results and Discussion

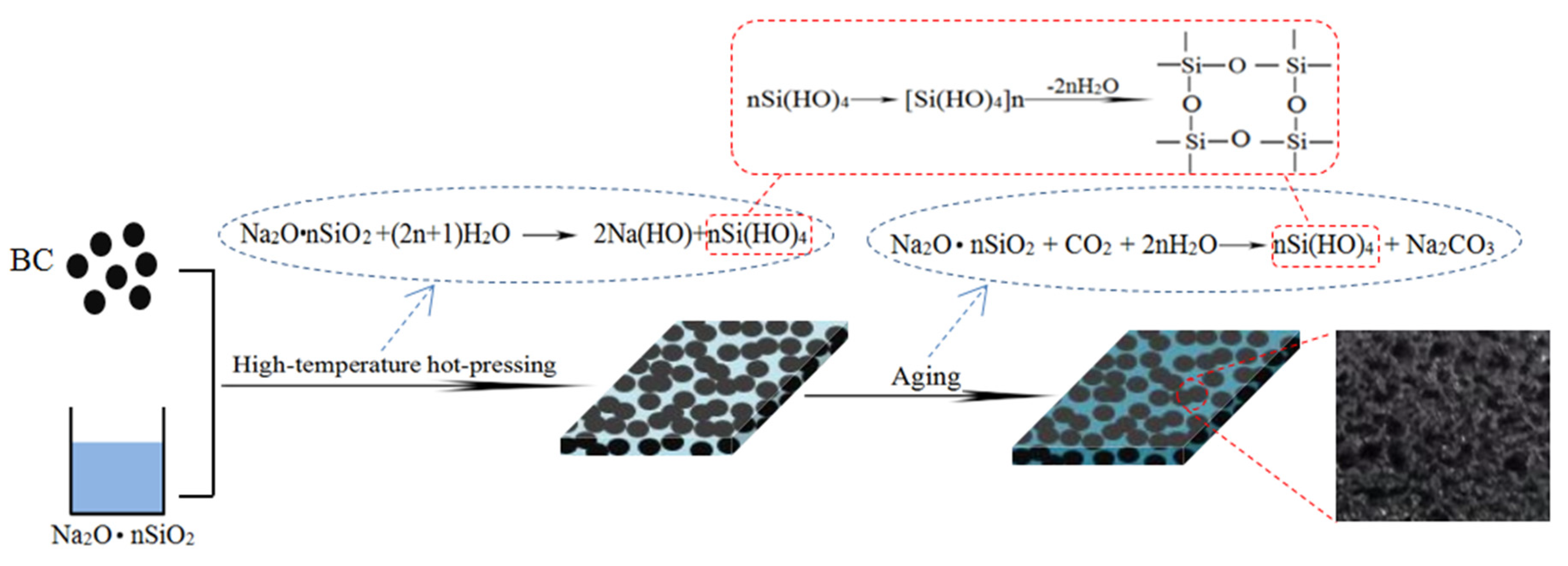

3.1. Forming Mechanism of BC/SS Composites

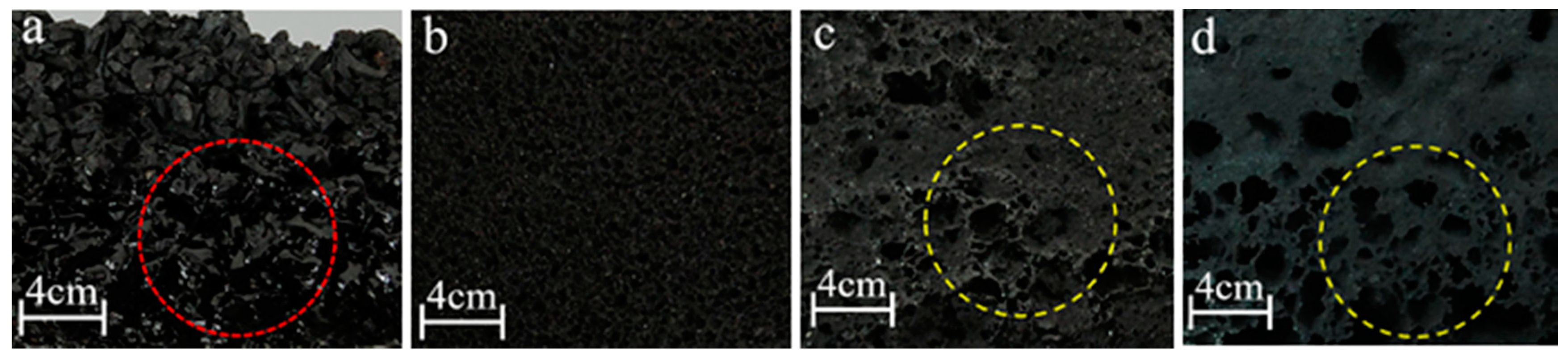

3.2. Effect of BC Particle Size on Formation of Composites

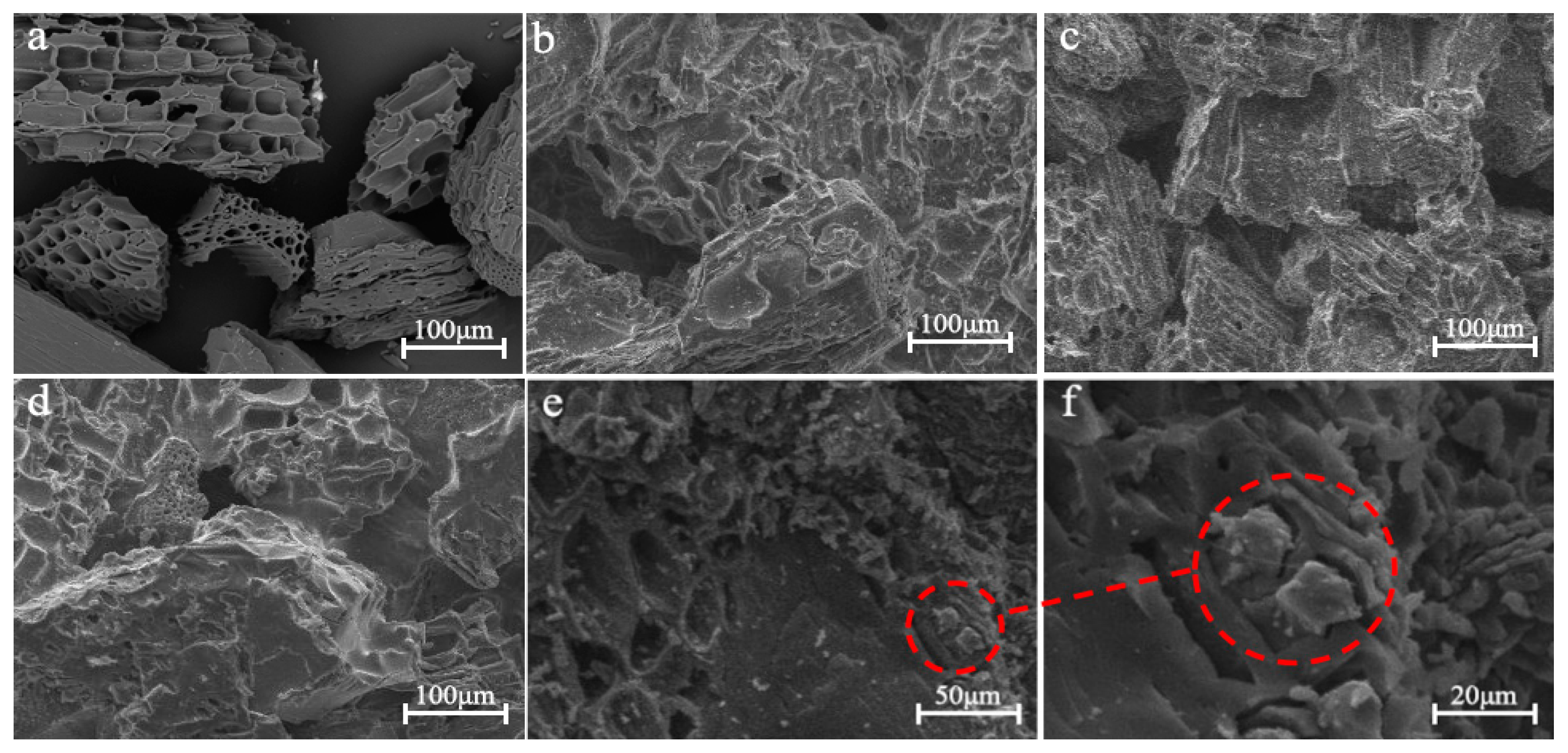

3.3. Surface Morphologies

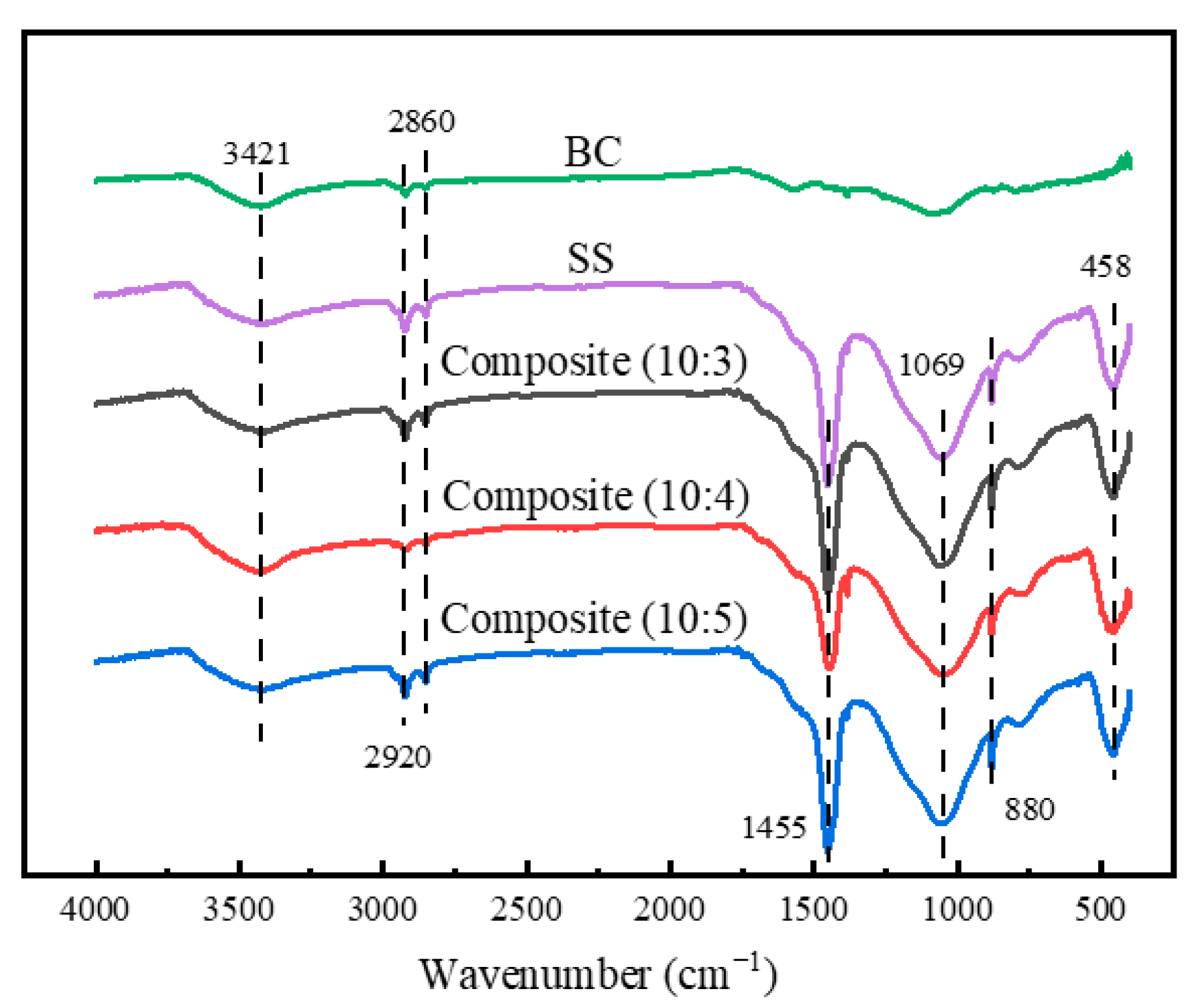

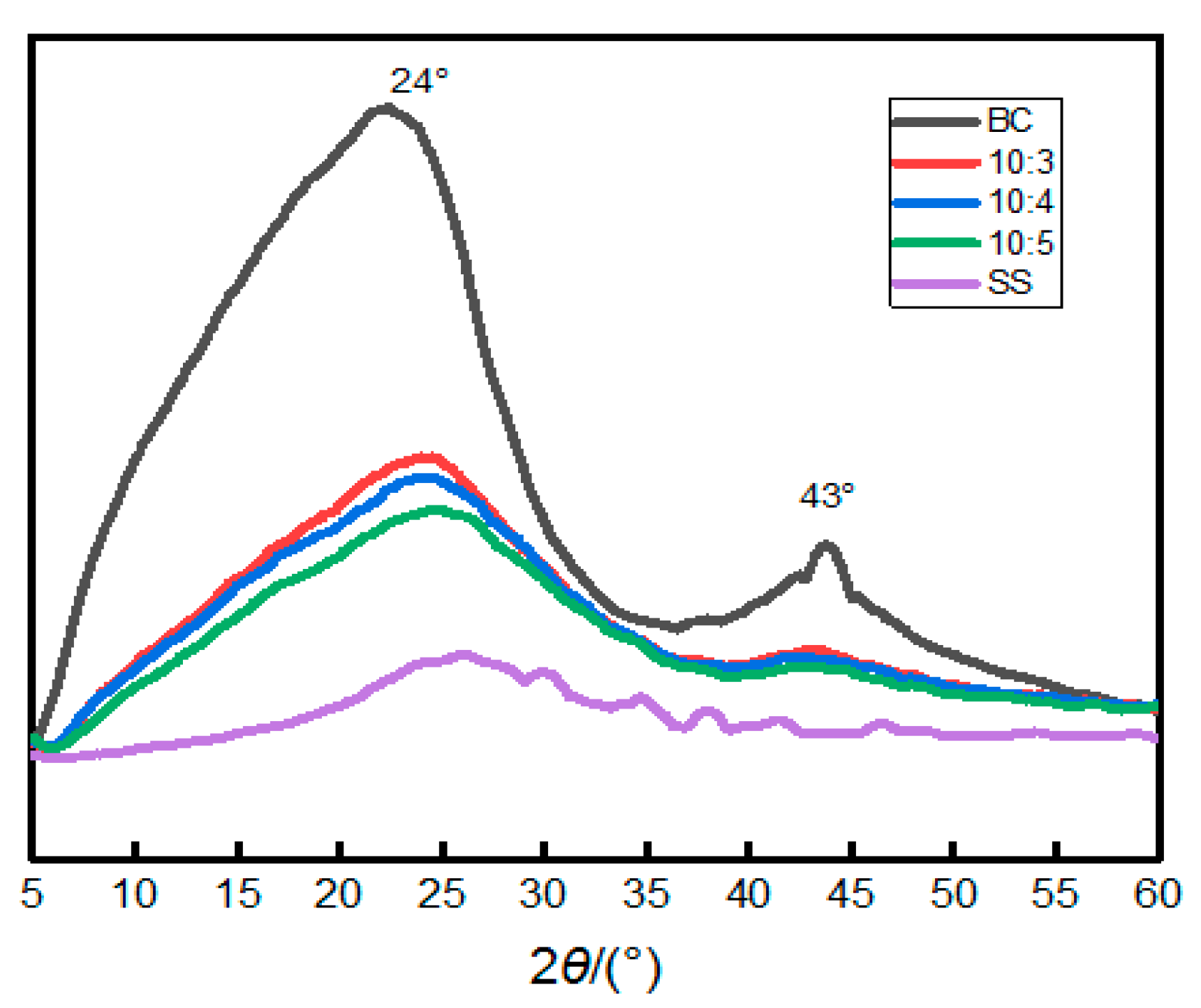

3.4. Chemical Component Analysis

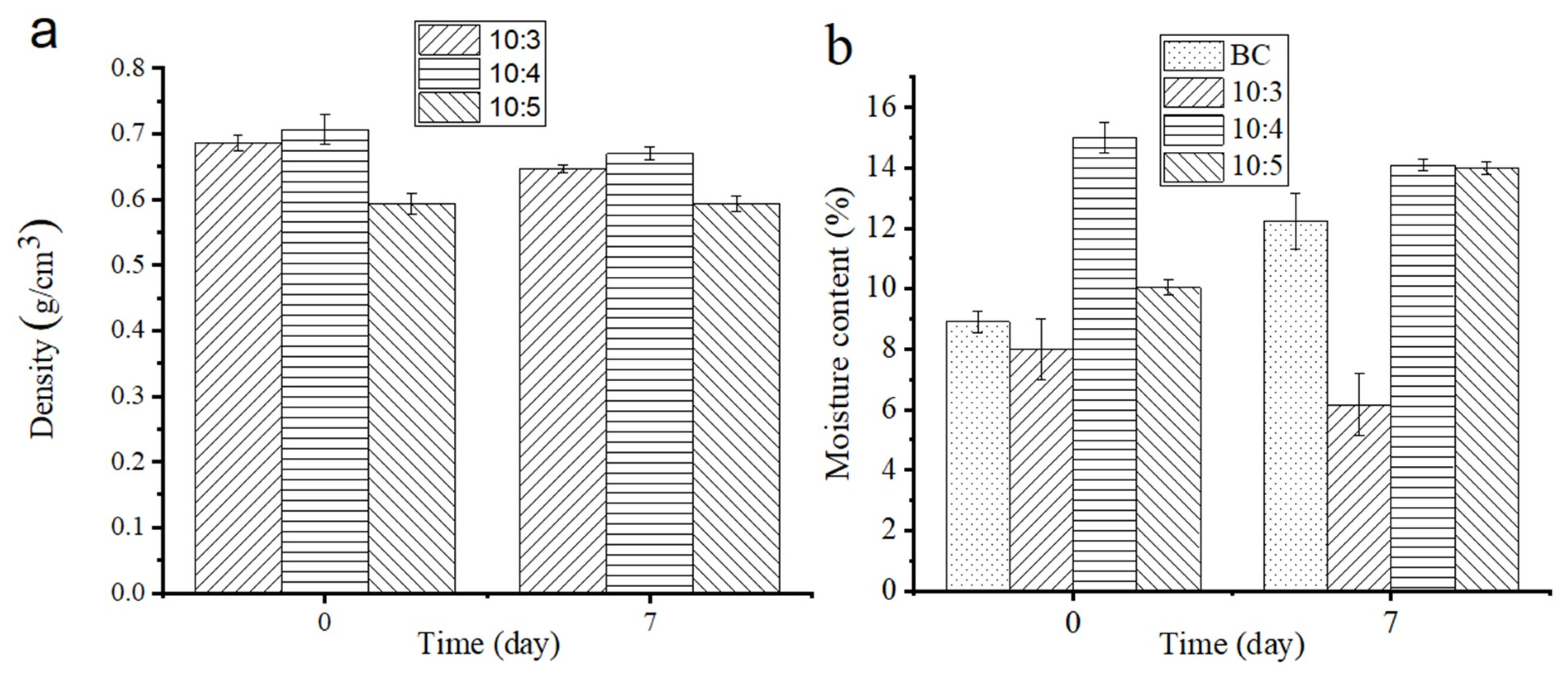

3.5. Densities and Moisture Content

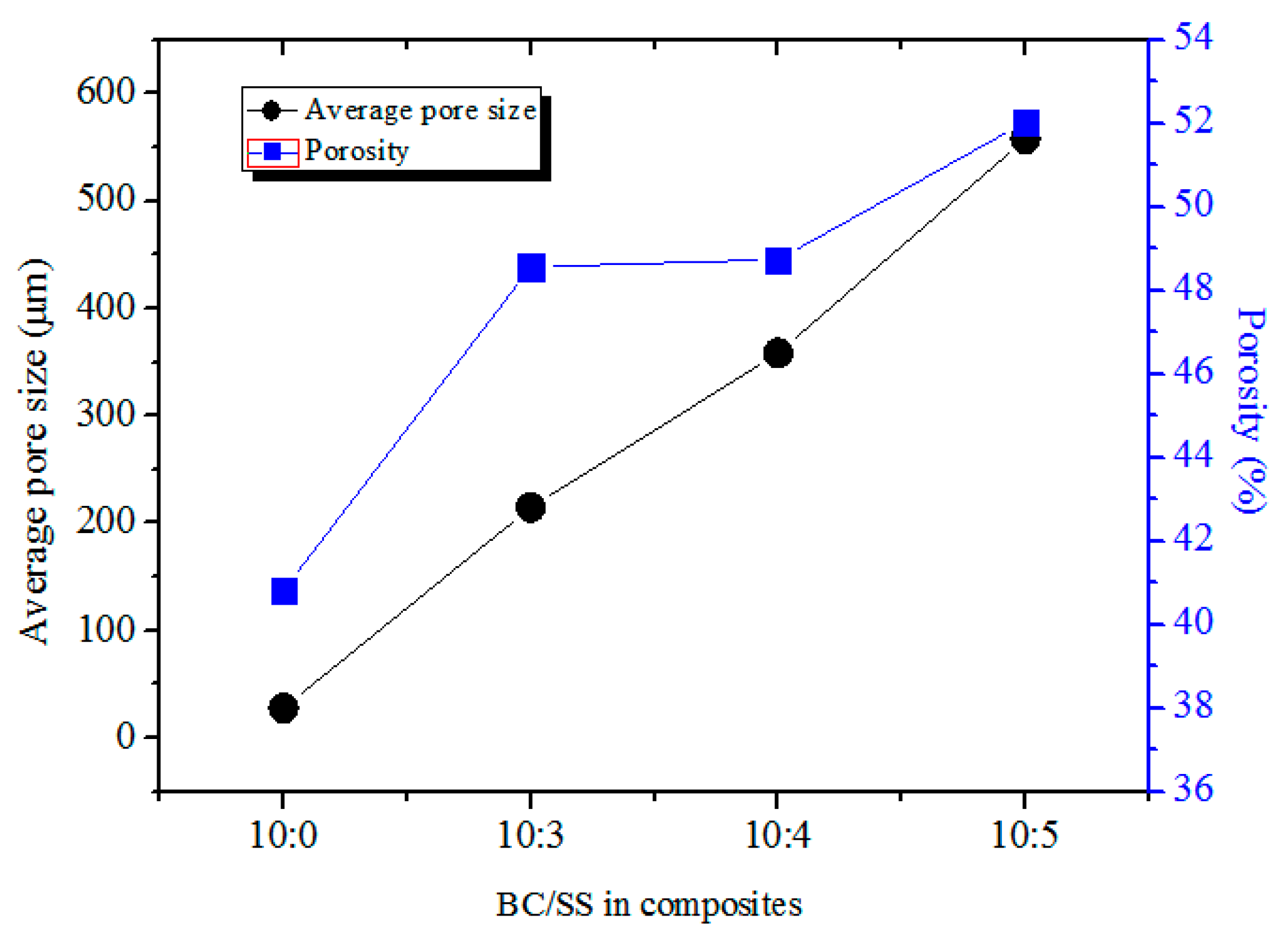

3.6. Porosity and Average Pore Size

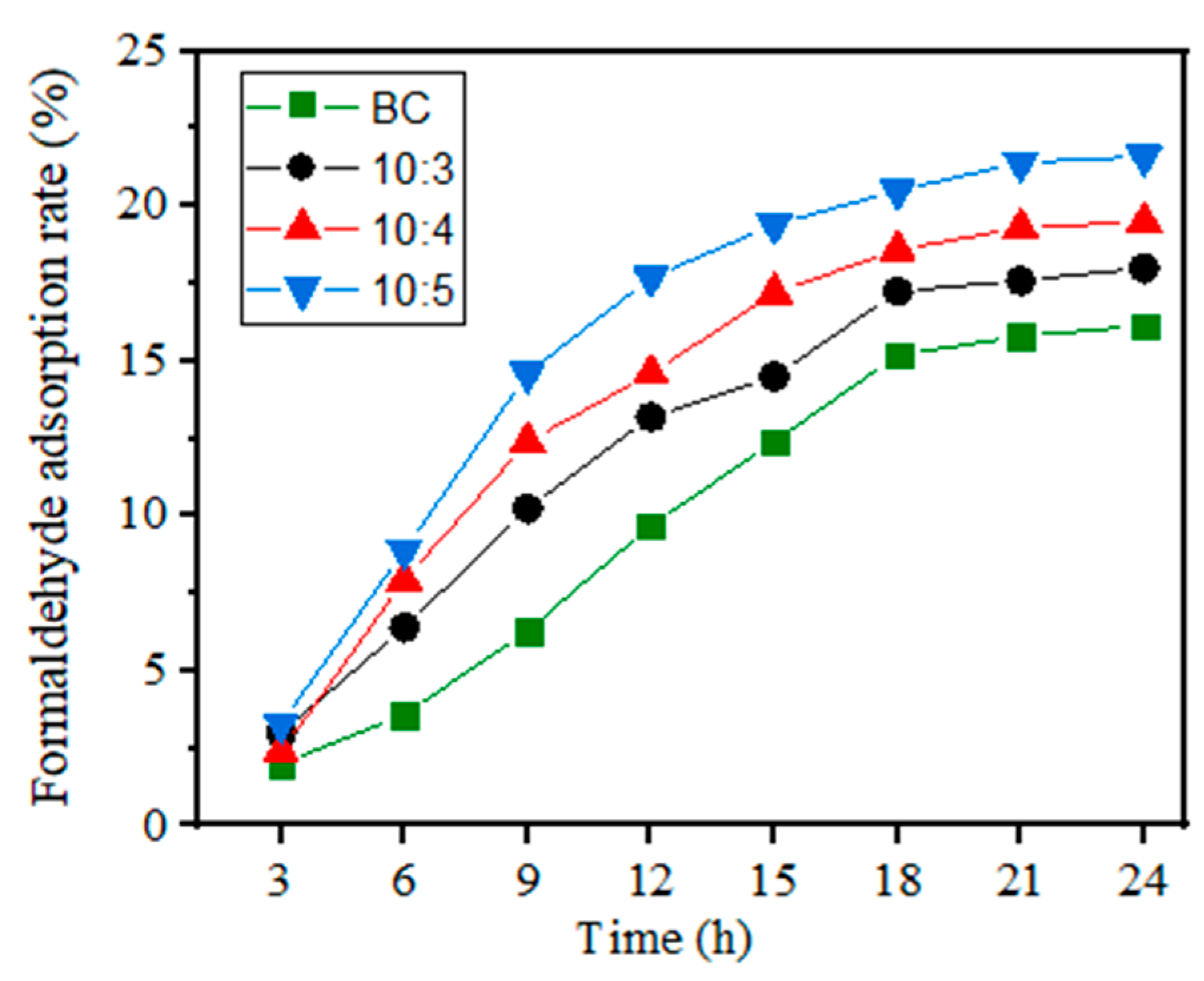

3.7. Formaldehyde Adsorption Performance

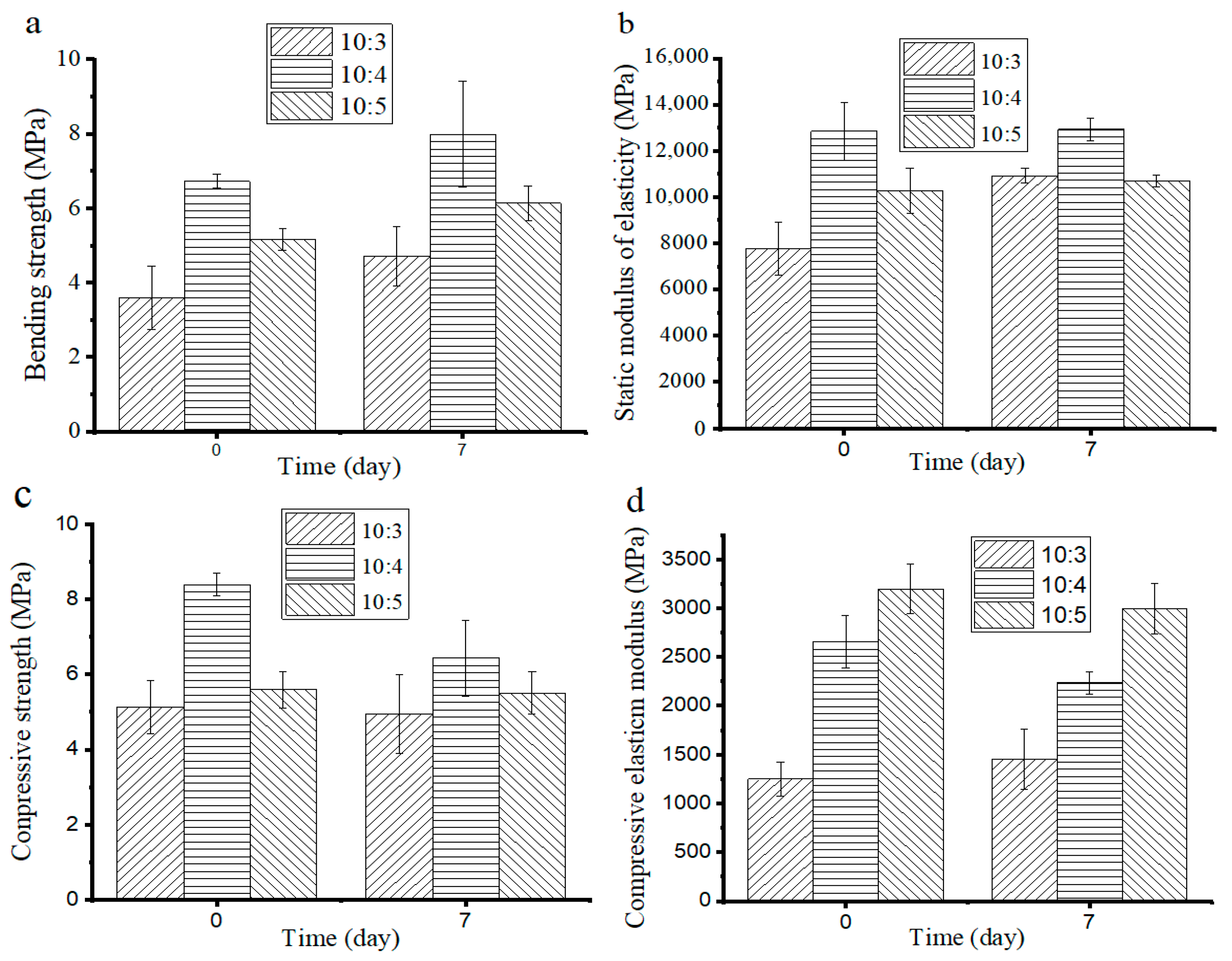

3.8. Mechanical Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohan, D.; Sarswat, A.; Ok, Y.S.; Pittman, C.U., Jr. Organic and inorganic contaminants removal from water with biochar, a renewable, low cost and sustainable adsorbent-a critical review. Bioresour. Technol. 2014, 160, 191–202. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Xing, B.; Ding, Y.; Han, X.; Wang, S. A critical review of the production and advanced utilization of biochar via selective pyrolysis of lignocellulosic biomass. Bioresour. Technol. 2020, 312, 123614. [Google Scholar] [CrossRef]

- Li, Z.; Wang, C.; Lei, T.; Ma, H.; Su, J.; Ling, S.; Wang, W. Arched bamboo charcoal as interfacial solar steam generation integrative device with enhanced water purification capacity. Adv. Sustain. Syst. 2019, 3, 1800144. [Google Scholar] [CrossRef]

- Li, S.; Wang, H.; Chen, C.; Li, X.; Deng, Q.; Li, D. Mechanical, electrical, and thermal properties of highly filled bamboo charcoal/ultra-high molecular weight polyethylene composites. Polym. Compos. 2018, 39, E1858–E1866. [Google Scholar] [CrossRef]

- Khandaker, S.; Toyohara, Y.; Kamida, S.; Kuba, T. Adsorptive removal of cesium from aqueous solution using oxidized bamboo charcoal. Water Resour. Ind. 2018, 19, 35–46. [Google Scholar] [CrossRef]

- Ye, Y.J.; Zhang, Z.F. Research progress of the properties and application of bamboo charcoal. Appl. Mech. Mater. 2013, 395–396, 646–649. [Google Scholar] [CrossRef]

- Wu, F.; Liu, W.; Qiu, J.; Li, J.; Zhou, W.; Fang, Y.; Zhang, S.; Li, X. Enhanced photocatalytic degradation and adsorption of methylene blue via TiO2 nanocrystals supported on graphene-like bamboo charcoal. Appl. Surf. Sci. 2015, 358, 425–435. [Google Scholar] [CrossRef]

- Chen, Q.; Zhu, W.; Li, X.; Lai, S. Study on photocatalytic degradation of formaldehyde by TiO2 loaded on bamboo charcoal. J. Fujian Norm. Univ. 2009, 25, 72–75. [Google Scholar]

- Lin, J.H.; Lin, C.M.; Huang, C.C.; Lin, C.C.; Hsieh, C.T.; Liao, Y.C. Evaluation of the manufacture of sound absorbent sandwich plank made of PET/TPU honeycomb grid/PU foam. J. Compos. Mater. 2011, 45, 1355–1362. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, L.; Semple, K.; Zhang, M.; Zhang, W.; Dai, C. Development of biodegradable flame-retardant bamboo charcoal composites, Part I: Thermal and elemental analyses. Polymers 2020, 12, 2217. [Google Scholar] [CrossRef]

- LI, S.; Wang, H.; Chen, C. Size effect of charcoal particles on the properties of bamboo charcoal/ultra-high molecular weight polyethylene composites. J. Appl. Polym. Sci. 2017, 134, 45530. [Google Scholar] [CrossRef]

- Zhang, H.; Yao, W.; Qian, S.; Sheng, K. Fabrication and reinforcement of ternary composites based on polypropylene matrix with bamboo particle/ultrafine bamboo-char. Polym. Compos. 2018, 39, 4364–4371. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, R.; Qin, D.; Feng, Z.; Wang, Y. Modification of the physical-mechanical properties of bamboo-plastic composites with bamboo charcoal after hydrothermal aging. BioResources 2018, 13, 1661–1677. [Google Scholar] [CrossRef]

- Ho, M.P.; Lau, K.T.; Wang, H.; Hui, D. Improvement on the properties of polylactic acid (PLA) using bamboo charcoal particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Li, S.; Li, X.; Chen, C.; Wang, H.; Deng, Q.; Gong, M.; Li, D. Development of electrically conductive nano bamboo charcoal/ultra- high molecular weight polyethylene composites with a segregated network. Compos. Sci. Technol. 2016, 132, 31–37. [Google Scholar] [CrossRef]

- Lou, C.W.; Lin, C.W.; Lei, C.H.; Su, K.H.; Hsu, C.H.; Liu, Z.H.; Lin, J.H. PET/PP blend with bamboo charcoal to produce functional composites. J. Mater. Process. Technol. 2002, 192-193, 428–433. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Burmeister, M.; Eilks, I. A lesson plan to develop structured discussion of the benefits and disadvantages of selected plastics using the product-testing method. Sch. Sci. Rev. 2014, 95, 47–54. [Google Scholar]

- Zaretskiy, L. Modified silicate binders new developments and applications. Int. J. Met. 2016, 10, 88–99. [Google Scholar] [CrossRef]

- Burchenkova, T.; Slavkina, V.; Nelyub, V. Modern technologies for the production of composites Based on inorganic binders. Mater. Today Proc. 2019, 11, 112–117. [Google Scholar] [CrossRef]

- Rusati, P.K.; Song, K.I. Magnesium chloride and sulfate attacks on gravel-sand-cement-inorganic binder mixture. Constr. Build. Mater. 2018, 187, 565–571. [Google Scholar] [CrossRef]

- Chen, T.; Wu, Z.; Wang, X.A.; Wang, W.; Huang, D.; Wei, Q.; Wu, B.; Xie, Y. Hierarchical lamellar aluminophosphate materials with porosity as ecofriendly inorganic adhesive for wood-based boards. ACS Sustain. Chem. Eng. 2018, 6, 6273–6280. [Google Scholar] [CrossRef]

- Qiao, J.; Wang, A.; Li, X. Preparation and performance of wheat-straw composite board with inorganic adhesive. BioResources 2016, 11, 819–826. [Google Scholar] [CrossRef]

- Ding, Z.; Lu, Z.X.; Li, Y. Feasibility of basalt fiber reinforced inorganic adhesive for concrete strengthening. In Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2011; Volume 287, pp. 1197–1200. [Google Scholar]

- Polat, A.; Makaraci, M.; Usta, M. Influence of SS concentration on structural and tribological properties of microarc oxidation coatings on 2017A aluminum alloy substrate. J. Alloys Compd. 2010, 504, 519–526. [Google Scholar] [CrossRef]

- Morsy, M.S.; Alsayed, S.H.; Al-Salloum, Y.; Almusallam, T. Effect of SS to sodium hydroxide ratios on strength and microstructure of fly ash geopolymer binder. Arab. J. Sci. Eng. 2014, 39, 4333–4339. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Leung, C.; Wan, K. Application of sodium silicate solution as self-healing agent in cementitious materials. In Proceedings of the International RILEM Conference on Advances in Construction Materials through Science and Engineering, Hong Kong, China, 5–7 September 2011; pp. 530–536. [Google Scholar]

- Phoo-ngernkham, T.; Maegawa, A.; Mishima, N.; Hatanaka, S.; Chindaprasirt, P. Effects of sodium hydroxide and SS solutions on compressive and shear bond strengths of FA–GBFS geopolymer. Constr. Build. Mater. 2015, 91, 1–8. [Google Scholar] [CrossRef]

- GB/T17657-2013, Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels; Standards Press of China: Beijing, China, 2013.

- Li, X.; Song, W.; Yang, K.; Krishnan, N.A.; Wang, B.; Smedskjaer, M.M.; Mauro, J.C.; Sant, G.; Balonis, M.; Bauchy, M. Cooling rate effects in sodium silicate glasses: Bridging the gap between molecular dynamics simulations and experiments. J. Chem. Phys. 2017, 147, 074501. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Lu, A.; Qu, G. Preparation and characterization of foam ceramics from red mud and fly ash using sodium silicate as foaming agent. Ceram. Int. 2013, 39, 1923–1929. [Google Scholar] [CrossRef]

- Koohestani, B.; Mokhtari, P.; Yilmaz, E.; Mahdipour, F.; Darban, A.K. Geopolymerization mechanism of binder-free mine tailings by sodium silicate. Constr. Build. Mater. 2021, 268, 121217. [Google Scholar] [CrossRef]

- Rao, A.P.; Rao, A.V.; Pajonk, G.M. Hydrophobic and physical properties of the ambient pressure dried silica aerogels with sodium silicate precursor using various surface modification agents. Appl. Surf. Sci. 2007, 253, 6032–6040. [Google Scholar] [CrossRef]

- Innocenzi, P. Infrared spectroscopy of sol-gel derived silica-based films: A spectra-microstructure overview. J. Non-Cryst. Solids 2003, 316, 309–319. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, X.; Cao, W.; Gong, L.; Zhang, R.; Zhang, H. Fabrication of adiabatic foam at low temperature with sodium silicate as raw material. Mater. Des. 2015, 88, 1008–1014. [Google Scholar] [CrossRef]

- Chen, Y.; Hong, Y.; Zheng, F.; Li, J.; Wu, Y.; Li, L. Preparation of silicate stalagmite from sodium silicate. J. Alloys Compd. 2009, 478, 411–414. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Q.; You, C. Biochar effect on water evaporation and hydraulic conductivity in sandy soil. Pedosphere 2016, 26, 265–272. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, W.; Zhang, L.; Li, W.; Zhang, M.; Huang, J.; Zhang, W. Preparation of Plastics- and Foaming Agent-Free and Porous Bamboo Charcoal based Composites Using Sodium Silicate as Adhesives. Materials 2021, 14, 2468. https://doi.org/10.3390/ma14102468

Chai W, Zhang L, Li W, Zhang M, Huang J, Zhang W. Preparation of Plastics- and Foaming Agent-Free and Porous Bamboo Charcoal based Composites Using Sodium Silicate as Adhesives. Materials. 2021; 14(10):2468. https://doi.org/10.3390/ma14102468

Chicago/Turabian StyleChai, Weisheng, Liang Zhang, Wenzhu Li, Min Zhang, Jingda Huang, and Wenbiao Zhang. 2021. "Preparation of Plastics- and Foaming Agent-Free and Porous Bamboo Charcoal based Composites Using Sodium Silicate as Adhesives" Materials 14, no. 10: 2468. https://doi.org/10.3390/ma14102468

APA StyleChai, W., Zhang, L., Li, W., Zhang, M., Huang, J., & Zhang, W. (2021). Preparation of Plastics- and Foaming Agent-Free and Porous Bamboo Charcoal based Composites Using Sodium Silicate as Adhesives. Materials, 14(10), 2468. https://doi.org/10.3390/ma14102468