Design of Multi-Stage Roll Die Forming Process for Drum Clutch with Artificial Neural Network

Abstract

1. Introduction

2. Multi-Stage Roll Die Forming Process for Drum Clutch

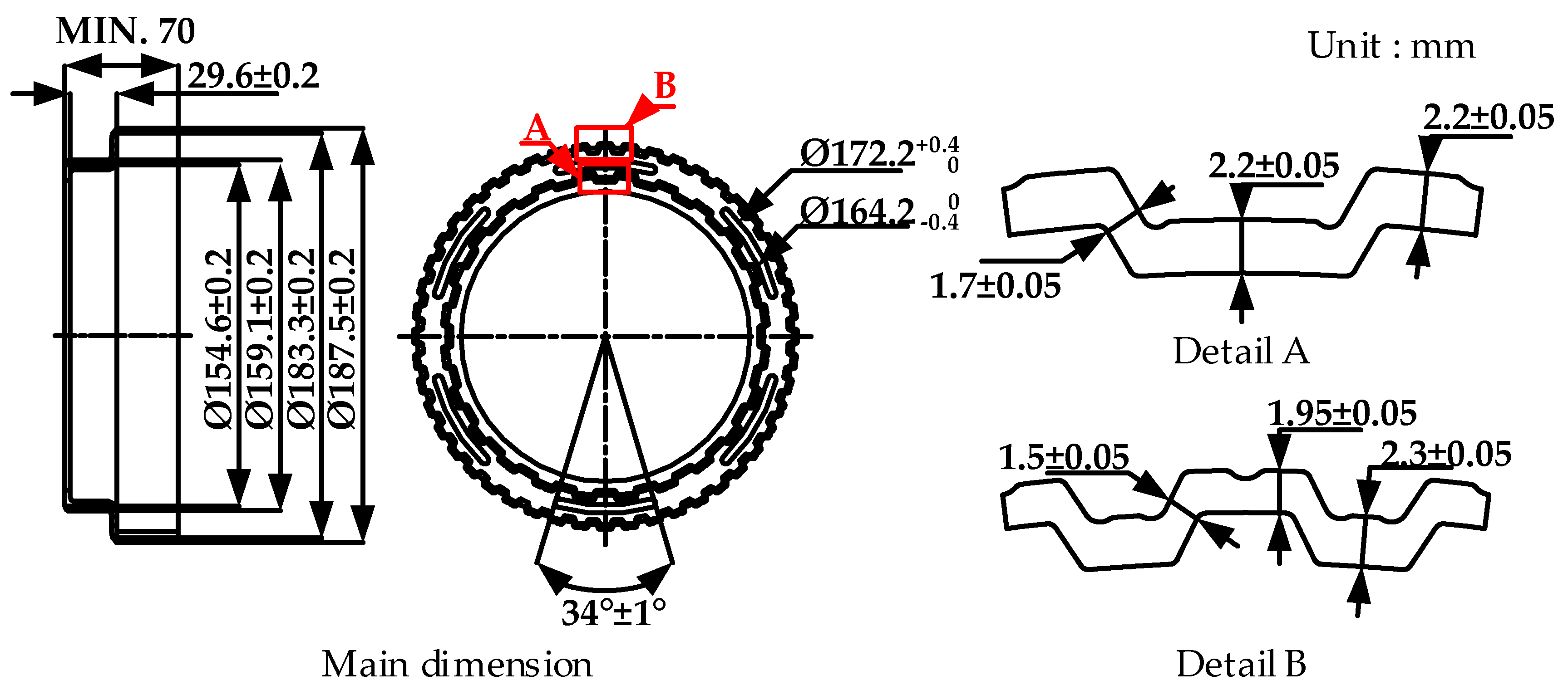

2.1. Drum Clutch

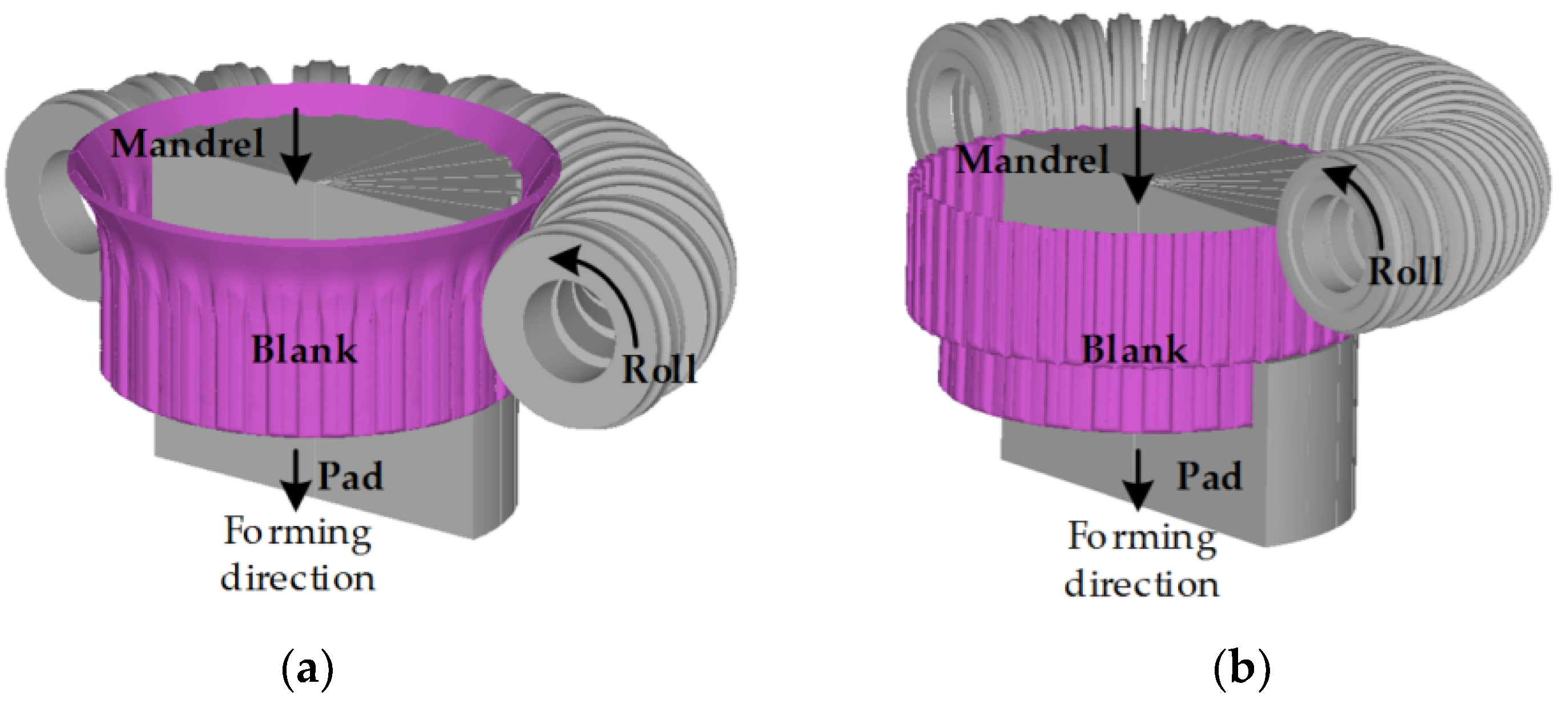

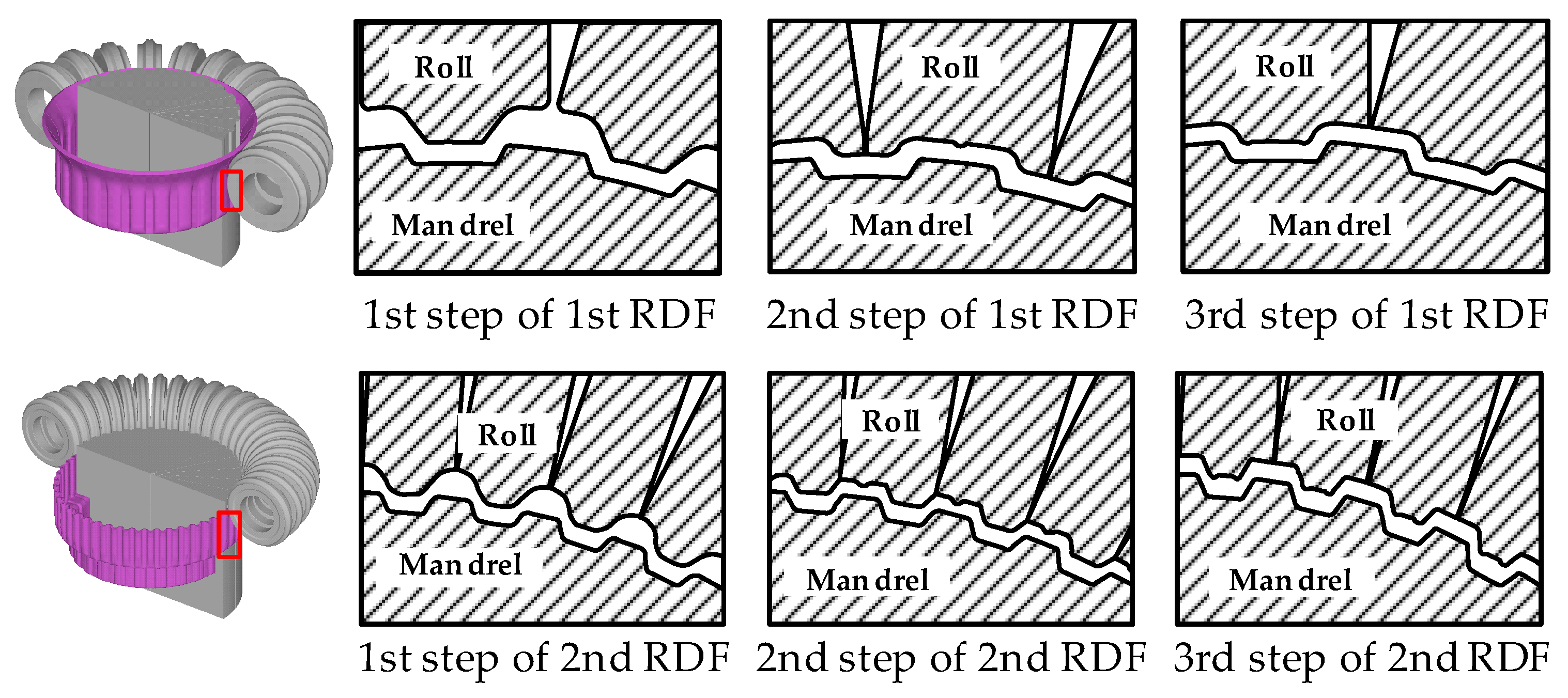

2.2. Application of Multi-Stage Roll Die Forming Process

3. FE Simulation of Multi-Stage Roll Die Forming Process

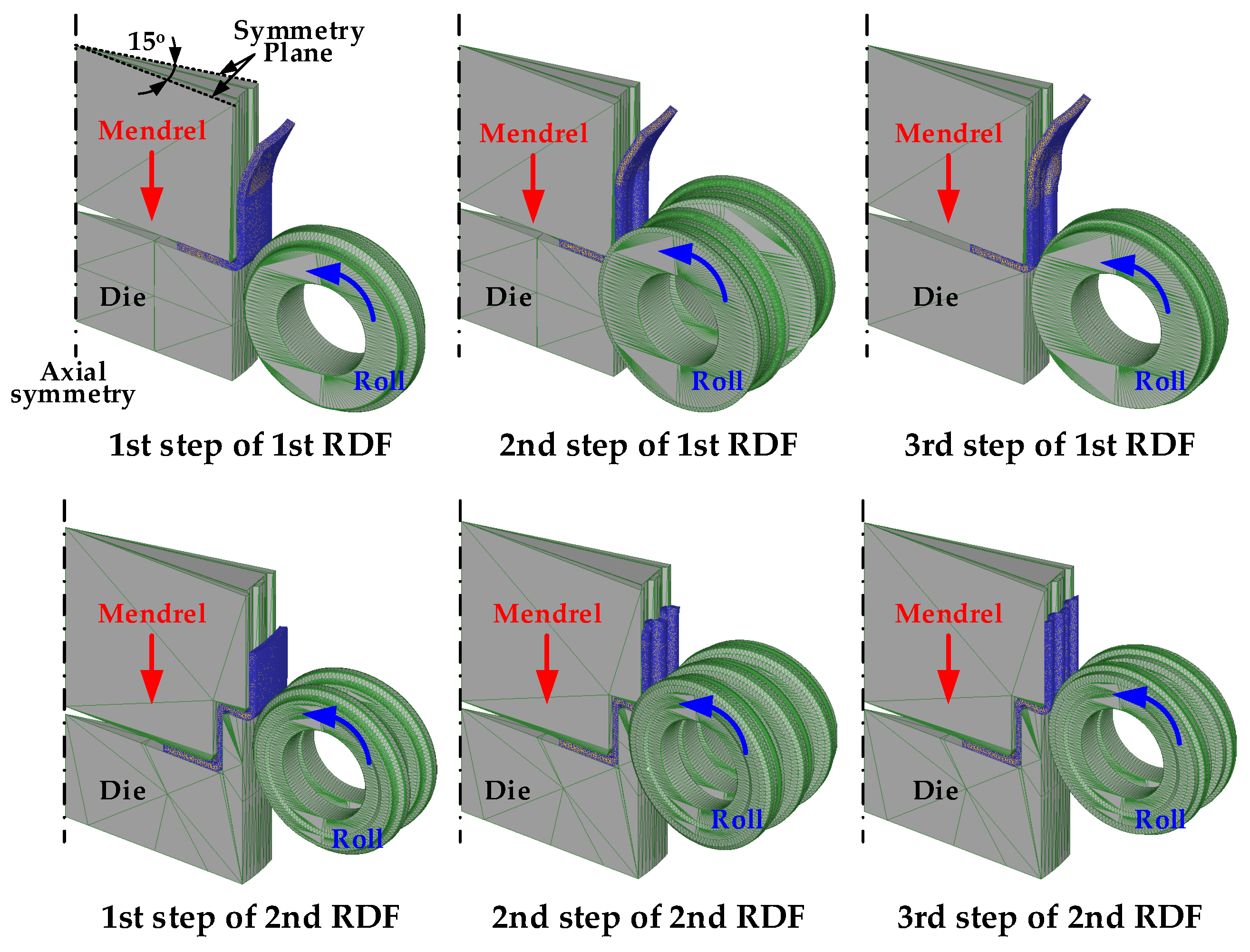

3.1. Construction of FE Model

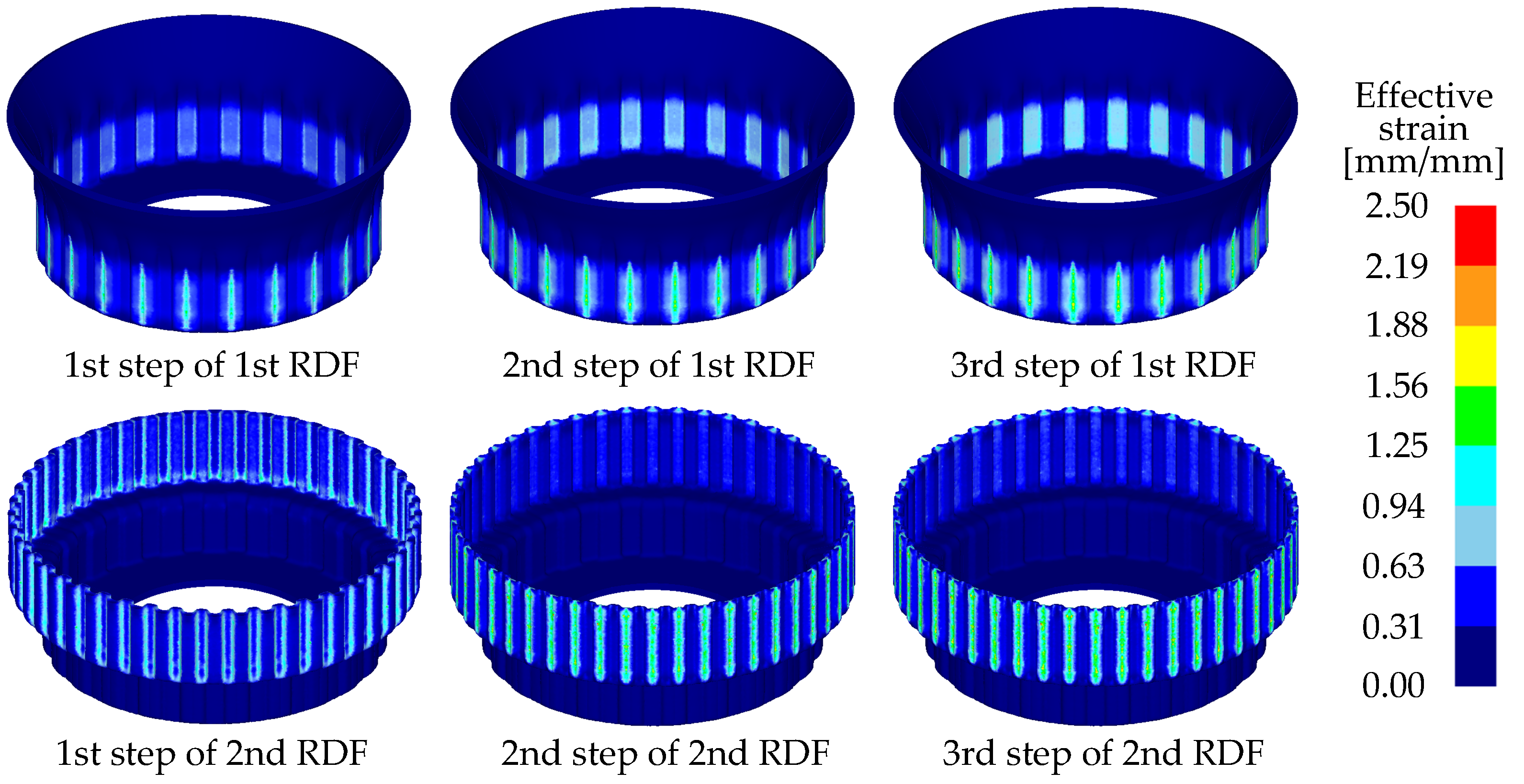

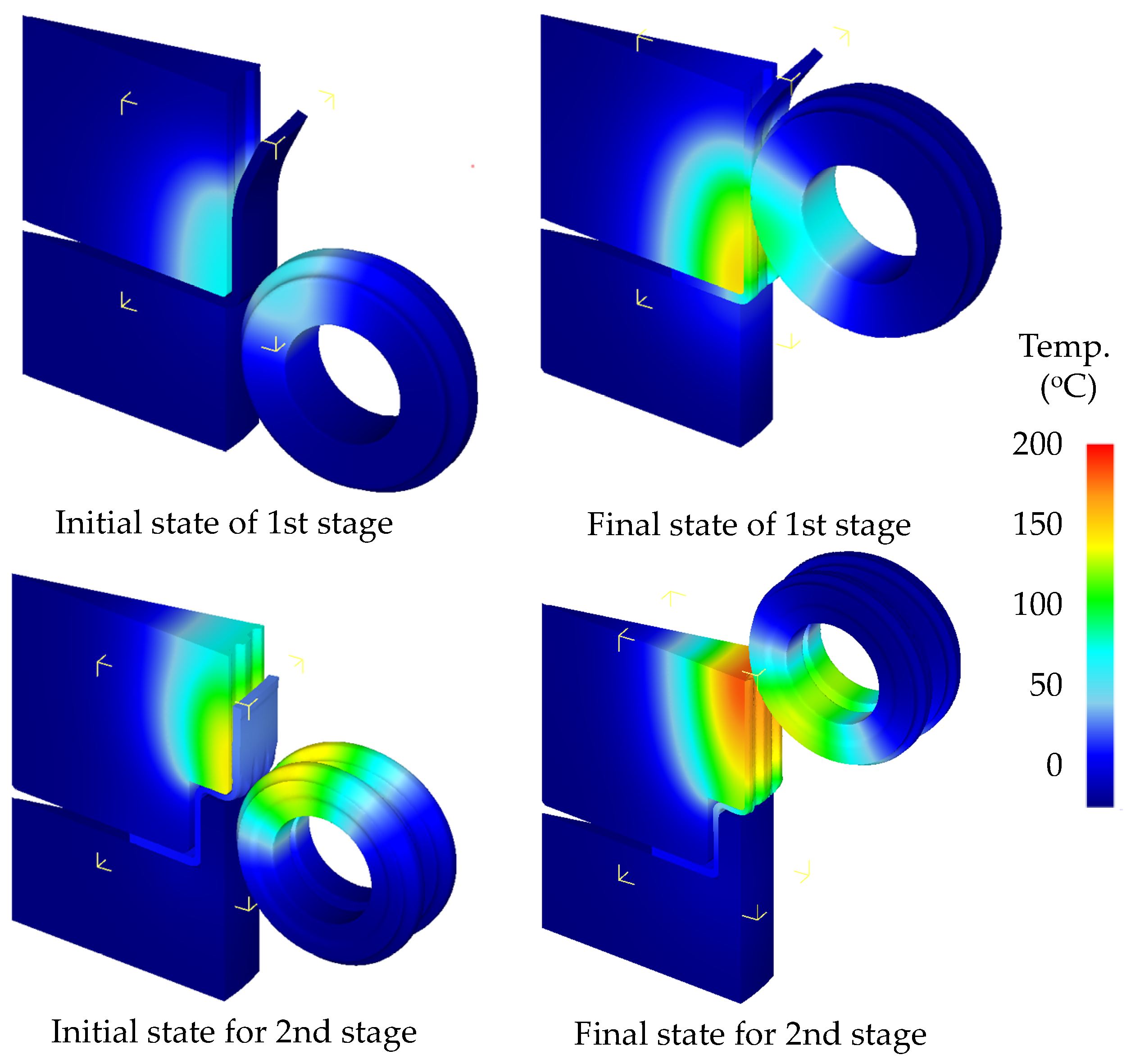

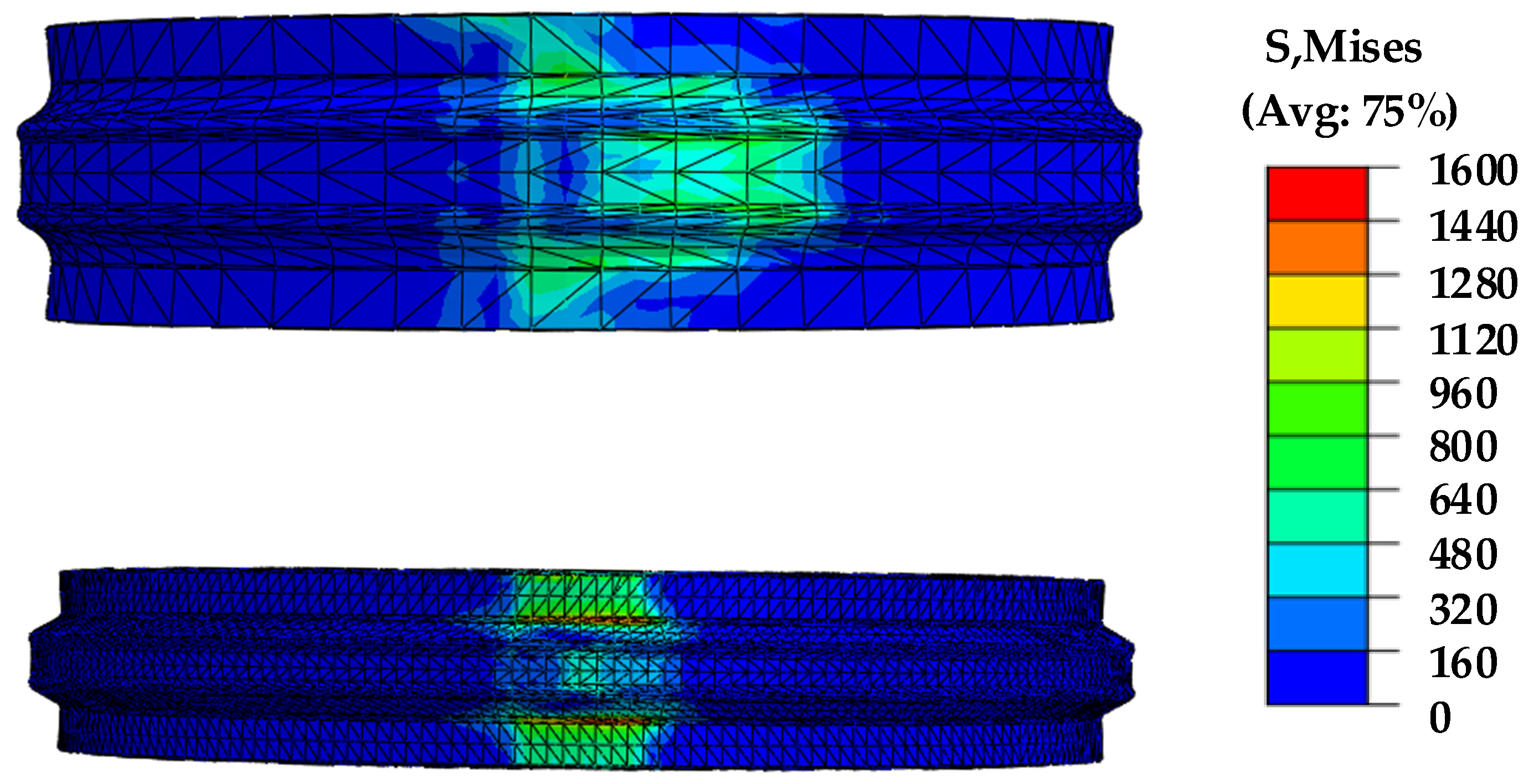

3.2. Results of the FE Simulation

4. Optimization of Multi-Stage Roll Die Forming Process

4.1. Artificial Neural Network

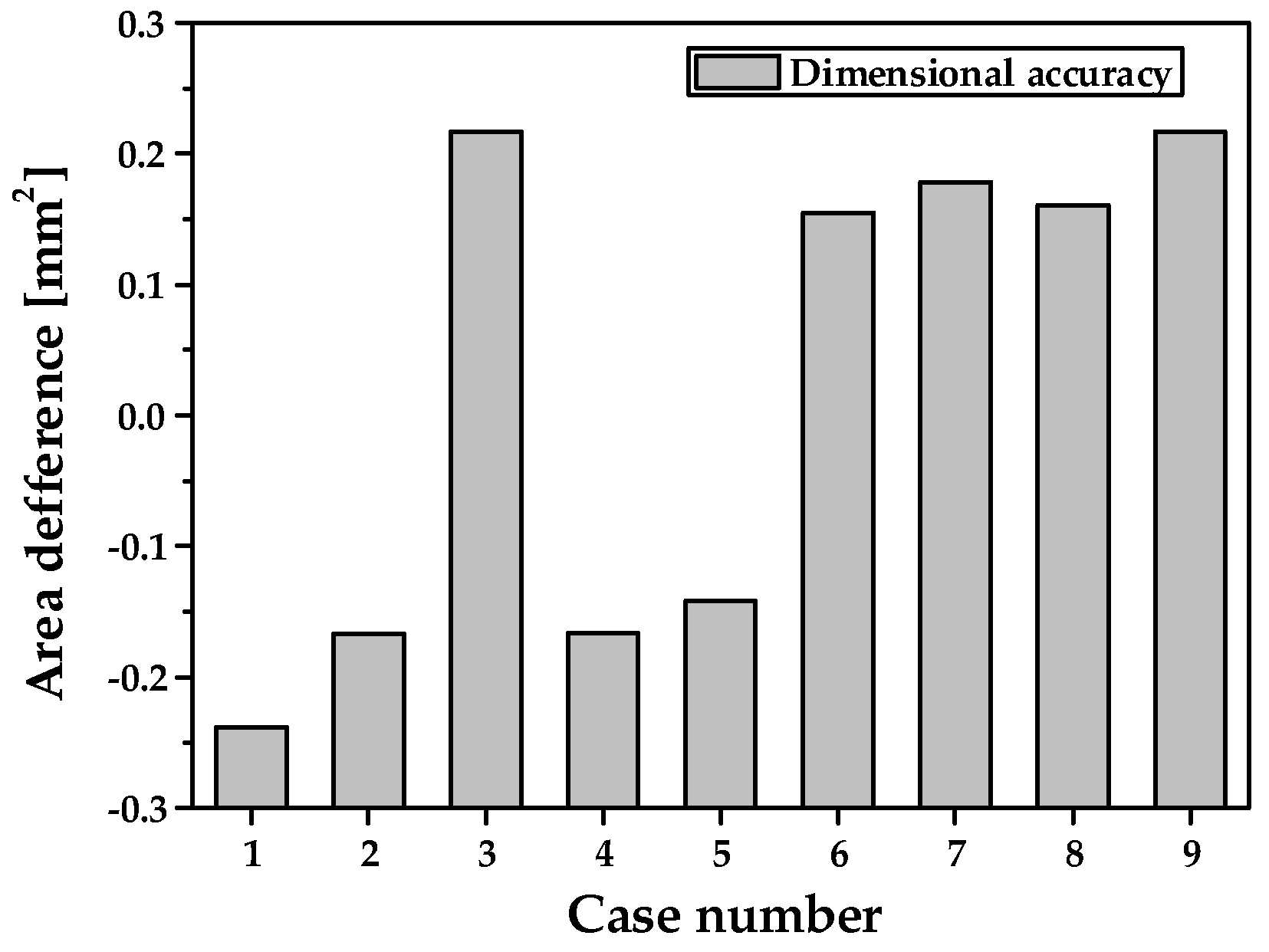

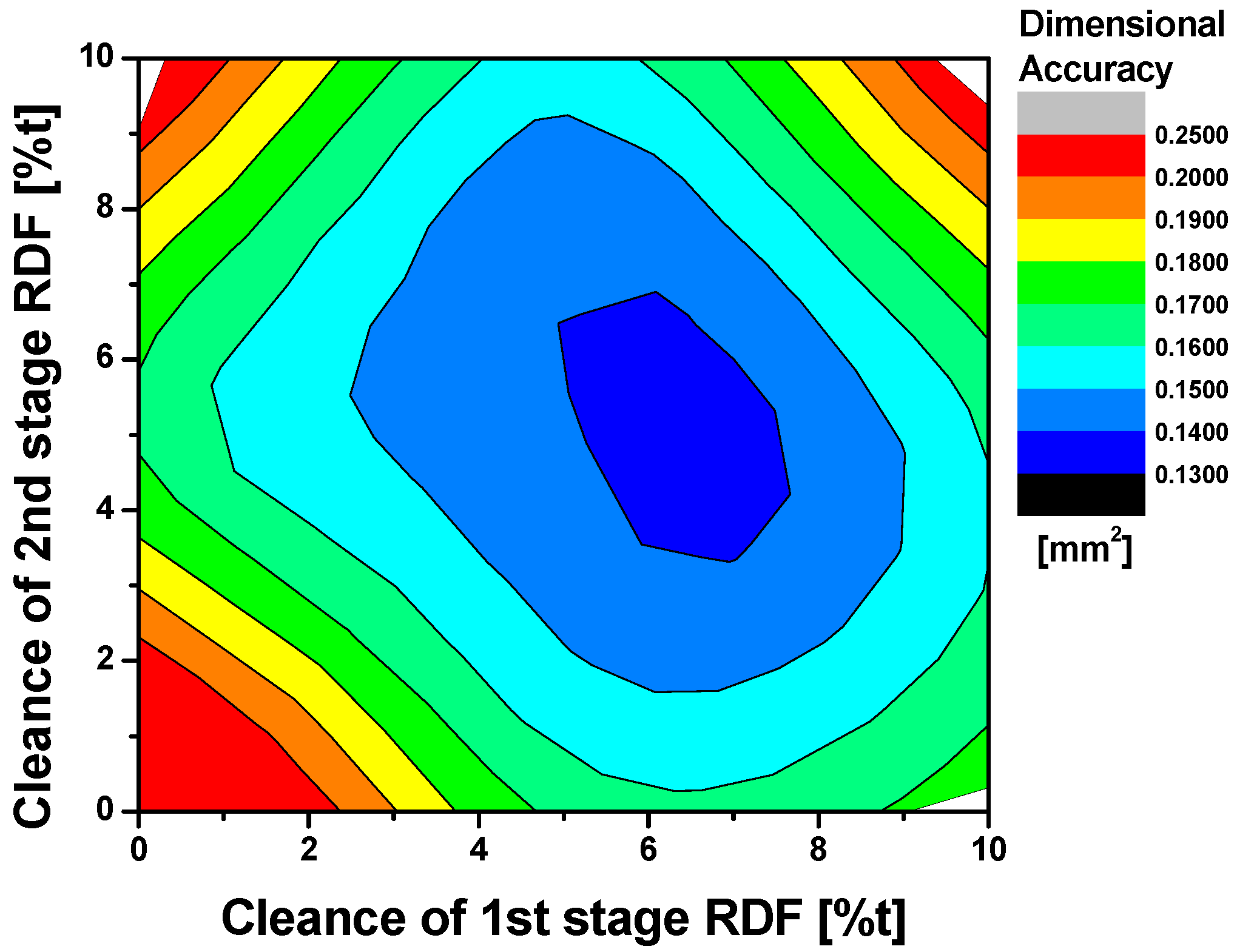

4.2. Optimization of Clearance with Artificial Neural Network

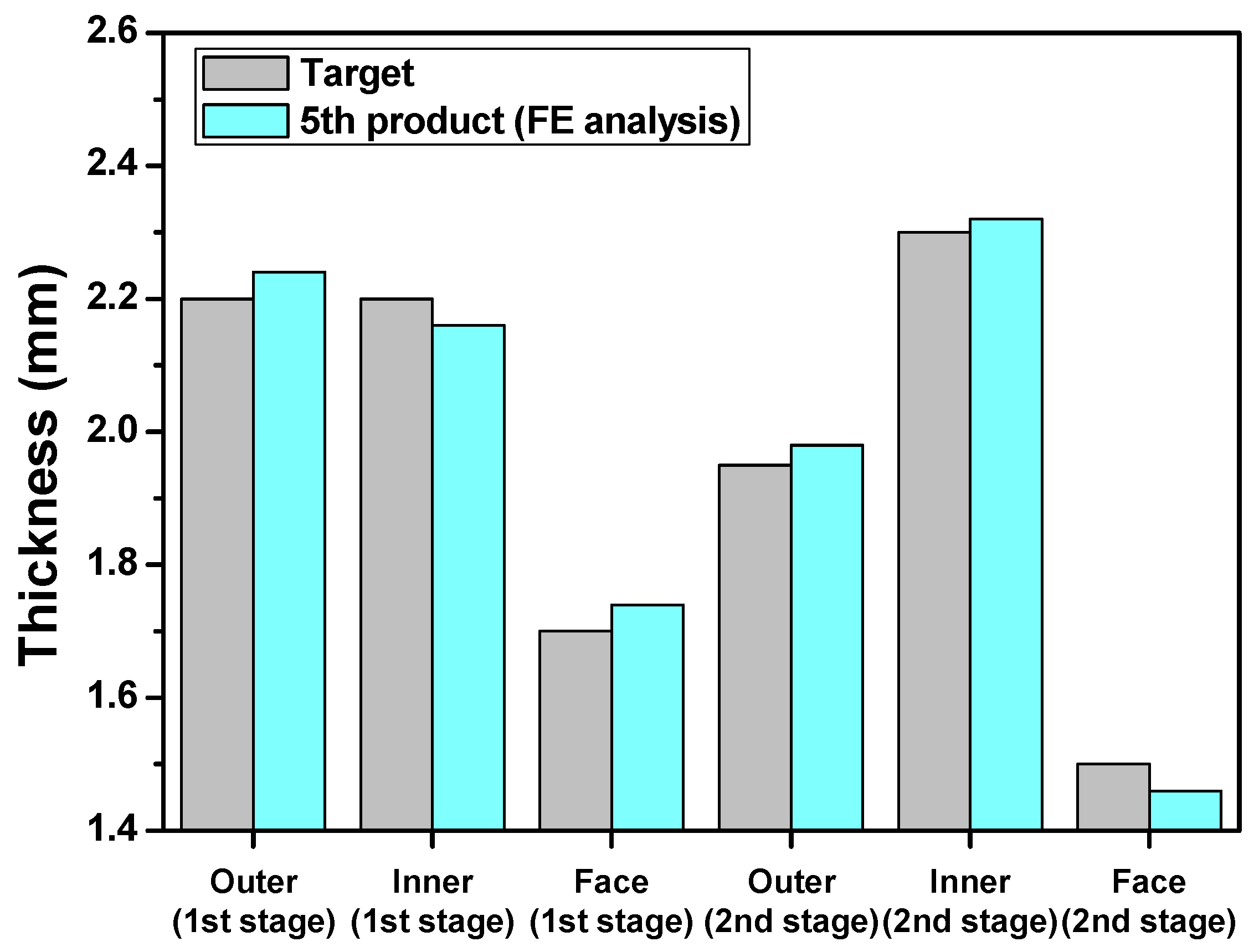

4.3. FE Simulation of the Manufacturing Process of the Drum Clutch with Optimized Clearance

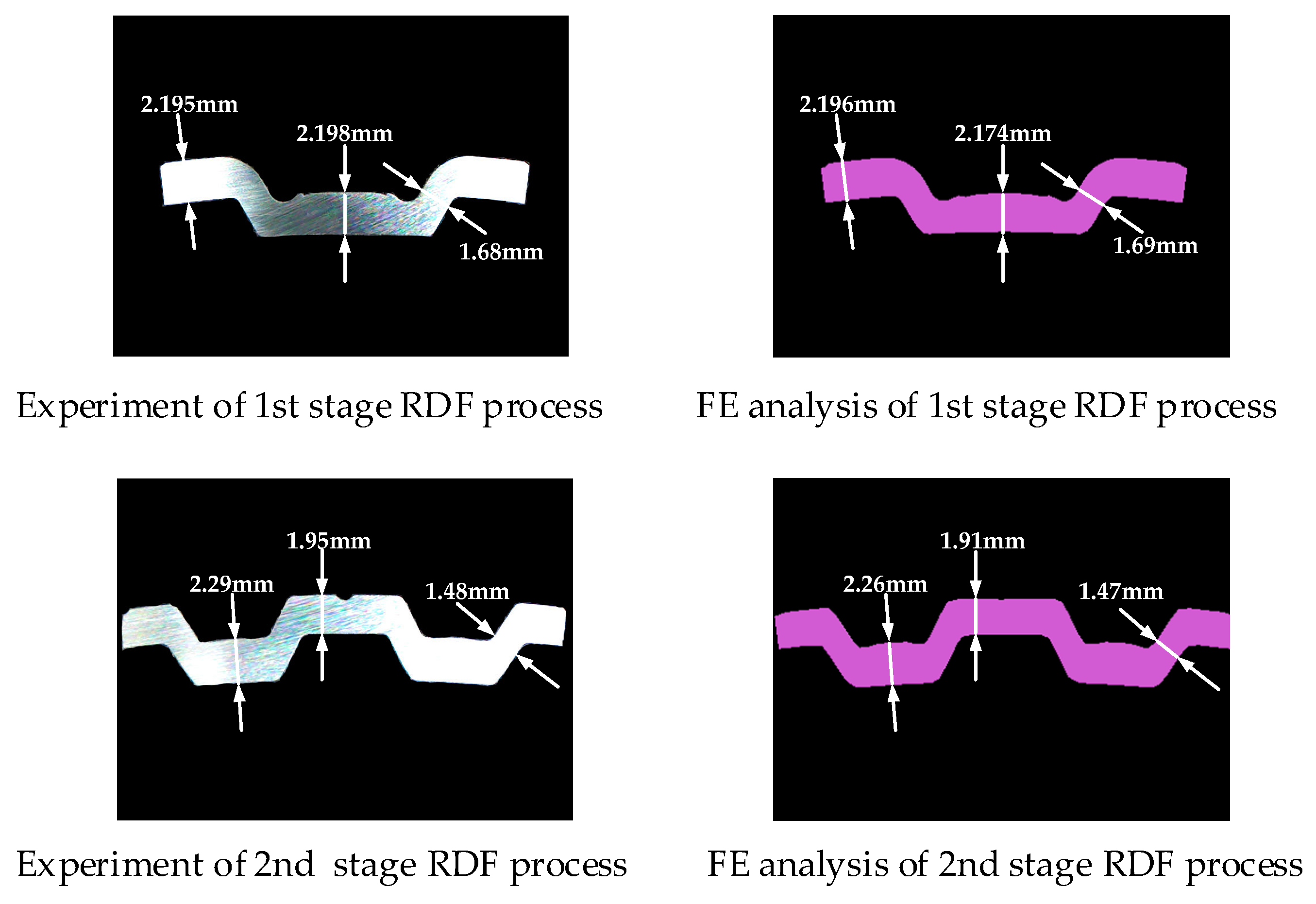

5. Experimental Verification

6. Conclusions

- (1)

- A multi-stage RDF process is suggested as a manufacturing method for the drum clutch to prevent decreases in the tooth strength and improve dimensional accuracy.

- (2)

- The clearance between the roll and the mandrel is selected as the main design parameter. An ANN with FE simulation is performed to determine the optimal parameters of the 1st and 2nd stages of the RDF process. The process window is also constructed to obtain the relationship between the process parameters and the dimensional accuracy and could predict dimensional accuracy for all combinations within a whole range of process parameters without additional FE simulation.

- (3)

- FE simulation considering a continuous multi-stage RDF confirms the feasibility of the suggested manufacturing process and parameters. The temperature increase and maximum stress were within the permitted safety tolerances of the actual manufacturing process. The fatigue life of tool could be improved by prevention of stress concentration during RDF process because of the rotational roll.

- (4)

- The optimized conditions were successfully utilized to manufacture the drum clutch. The calculated dimensional accuracy of the product was in good agreement with that of the manufactured drum clutch, and the object dimensions were within an allowable tolerance. The suggested process window can be used efficiently for determination of process parameters in multi-stage RDF process to manufacture drum clutch.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Merklein, M.; Johannes, M.; Lechner, M.; Kuppert, A. A Review on Tailored Blanks-Production, Applications and Evaluation. J. Mater. Process. Technol. 2014, 214, 151–164. [Google Scholar] [CrossRef]

- Turetta, A.; Bruschi, S.; Ghiotti, A. Investigation of 22MnB5 Formability in Hot Stamping Operations. J. Mater. Process. Technol. 2006, 177, 396–400. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Friderikos, O.; Tsiafis, I. FEM-supported simulation of chip formation and flow in gear hobbing of spur and helical gears. CIRP J. Manuf. Sci. Technol. 2008, 1, 18–26. [Google Scholar] [CrossRef]

- Hussain, P.B.; Cheon, J.S.; Kwak, D.Y.; Kim, S.Y.; Im, Y.T. Simulation of clutch-hub forging process using CAMPform. J. Mater. Process. Technol. 2002, 123, 120–132. [Google Scholar] [CrossRef]

- Wu, H.C.; Altan, T. Process optimization in stamping-a case study for flanging a clutch hub from steel plate. J. Mater. Process. Technol. 2004, 146, 8–19. [Google Scholar] [CrossRef]

- Shim, D.S.; Yang, D.Y.; Chung, S.W.; Han, M.S. Optimization of Forming Steps in the Incremental Forming of Twisted Shapes using a Line Array Roll Set (LARS). Int. J. Precis. Eng. Manuf. 2010, 11, 715–723. [Google Scholar] [CrossRef]

- Chang, Y.C.; Hu, Z.M.; Kang, B.S.; Dean, T.A. A study of cold ironing as a post-process for net-shape manufacture. Int. J. Mach. Tools Manuf. 2002, 42, 945–952. [Google Scholar] [CrossRef]

- Domblesky, J.P.; Feng, F. A parametric study of process parameters in external thread rolling. J. Mater. Process. Technol. 2002, 121, 341–349. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, S.G.; Kang, J.H.; Park, Y.C.; Kim, S.H.; Seo, S.R.; Park, K.H. Preform Design for Manufacturing of Automobile Drum Clutch Hub Products. J. Kor. Soc. Precis. Eng. 2008, 25, 33–38. [Google Scholar]

- Kwon, Y.N.; Kim, S.W.; Kim, B.J.; Park, E.S.; Cha, D.J. Development of Flow Forming Process for Hollow Shaped Parts from Seamless Steel Tube. Trans. Mater. Process. 2011, 20, 611–618. [Google Scholar] [CrossRef][Green Version]

- Ko, D.H.; Lee, S.K.; Kwon, Y.N.; Kim, S.W.; Lee, H.S.; Park, E.S.; Kim, B.M.; Ko, D.C. Roll Die Forming Process for Manufacturing Clutch Hub in Automotive Transmission. Trans. Mater. Process. 2011, 22, 154–159. [Google Scholar] [CrossRef][Green Version]

- Kim, D.H.; Ko, D.C.; Lee, S.H.; Byun, H.S.; Kim, B.M. Development of Press Forming Technology for the Multistage Fine Tooth Hub Gear. J. Kor. Soc. Precis. Eng. 2008, 23, 44–51. [Google Scholar]

- Kang, J.Y.; Kim, B.M.; Kim, Y.H.; Kim, D.H. Development of Forming Technology for Clutch Gear Using Artificial Neural Network. J. Kor. Soc. Precis. Eng. 2011, 28, 827–833. [Google Scholar]

- Lee, K.O.; Kim, J.M.; Je, J.S.; Kang, S.S. Development of precise clutch gear for automobile transmission by compound forging process. J. Kor. Soc. Precis. Eng. 2006, 23, 185–192. [Google Scholar]

- Ko, D.H.; Lee, S.K.; Kwon, Y.N.; Kim, S.W.; Kim, B.H.; Kim, B.M.; Ko, D.C. Improvement in Dimensional Accuracy of Roll-Die-Formed Clutch Hub Used in Automotive Transmission. Int. J. Precis. Eng. Manuf. 2012, 13, 237–243. [Google Scholar] [CrossRef]

- Kuo, Y.Y.; Yang, T.; Huang, G.W. The use of a grey-based Taguchi method for optimizing multi-response simulation problems. Eng. Optim. 2008, 40, 517–528. [Google Scholar] [CrossRef]

- Designation, E. 8M—04. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Kwak, T.S.; Kim, Y.J.; Bae, W.B. Finite element analysis on the effect of die clearance on shear planes in fine blanking. J. Mater. Process. Technol. 2002, 130, 462–468. [Google Scholar] [CrossRef]

- Kim, D.H. An Innovative Scheme for Process Design in Metal Forming Using FEM and Intelligent Computational Optimization. Ph.D. Thesis, Pusan National University, Busan, Korea, 2002; pp. 27–46. [Google Scholar]

- Sobajic, D.J.; Pao, Y.H. Artificial Neural-Net based Dynamic Security Assessment for Electric Power Systems. IEEE Trans. Power Syst. 1989, 4, 220–228. [Google Scholar] [CrossRef]

- Jin, G. Galling Mechanism of Cold Work Tool Steel by Frictional Heat Generation in Stamping of UHSS. Master’s Thesis, Pusan National University, Busan, Korea, 2015; p. 52. [Google Scholar]

- Pavlina, E.J.; Van Tyne, C.J. Correlation of yield strength and tensile strength with hardness for steels. J. Mater. Eng. Perform. 2008, 17, 888–893. [Google Scholar] [CrossRef]

| Mechanical Properties | Values |

|---|---|

| Yield strength | 315 MPa |

| Tensile strength | 436 MPa |

| Strength coefficient (K) | 722.2 MPa |

| Strain hardening exponent (n) | 0.198 |

| Material model (Hollomon equation) |

| Process Condition | Values | |

|---|---|---|

| Material | SAPH440 | |

| Punch(mandrel) speed | 500 [mm/s] | |

| Friction factor (m) | Blank with die and mandrel | 0.12 |

| Blank with roll | 0.02 | |

| Case | Clearance of 1st Stage [%t] | Clearance of 2nd Stage [%t] | Case | Clearance of 1st Stage [%t] | Clearance of 2nd Stage [%t] |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 2 | 0 | 5 |

| 3 | 0 | 10 | 4 | 5 | 0 |

| 5 | 5 | 5 | 6 | 5 | 10 |

| 7 | 10 | 0 | 8 | 10 | 5 |

| 9 | 10 | 10 |

| Experiment [mm] | FE Simulation [mm] | Error [%] | ||

|---|---|---|---|---|

| 1st stage of RDF process | Thickness of inner tooth | 2.20 | 2.17 | 1.38 |

| Thickness of outer tooth | 2.20 | 2.20 | 0.00 | |

| Thickness of face | 1.68 | 1.69 | 0.59 | |

| Internal diameter | 154.62 | 154.46 | 0.10 | |

| External diameter | 159.19 | 159.08 | 0.07 | |

| 2nd stage of RDF process | Thickness of inner tooth | 2.29 | 2.26 | 1.32 |

| Thickness of outer tooth | 1.95 | 1.91 | 2.09 | |

| Thickness of face | 1.48 | 1.47 | 0.68 | |

| Internal diameter | 183.41 | 183.20 | 0.11 | |

| External diameter | 187.65 | 187.44 | 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Ryu, J.-C.; Jang, W.-S.; Park, J.-H.; Moon, Y.-H.; Ko, D.-C. Design of Multi-Stage Roll Die Forming Process for Drum Clutch with Artificial Neural Network. Materials 2021, 14, 69. https://doi.org/10.3390/ma14010069

Kim J-H, Ryu J-C, Jang W-S, Park J-H, Moon Y-H, Ko D-C. Design of Multi-Stage Roll Die Forming Process for Drum Clutch with Artificial Neural Network. Materials. 2021; 14(1):69. https://doi.org/10.3390/ma14010069

Chicago/Turabian StyleKim, Jae-Hong, Jae-Chang Ryu, Woo-Sik Jang, Joon-Hong Park, Young-Hoon Moon, and Dae-Cheol Ko. 2021. "Design of Multi-Stage Roll Die Forming Process for Drum Clutch with Artificial Neural Network" Materials 14, no. 1: 69. https://doi.org/10.3390/ma14010069

APA StyleKim, J.-H., Ryu, J.-C., Jang, W.-S., Park, J.-H., Moon, Y.-H., & Ko, D.-C. (2021). Design of Multi-Stage Roll Die Forming Process for Drum Clutch with Artificial Neural Network. Materials, 14(1), 69. https://doi.org/10.3390/ma14010069