Effect of Ground Waste Glass Addition on the Strength and Durability of Low Strength Concrete Mixes

Abstract

1. Introduction

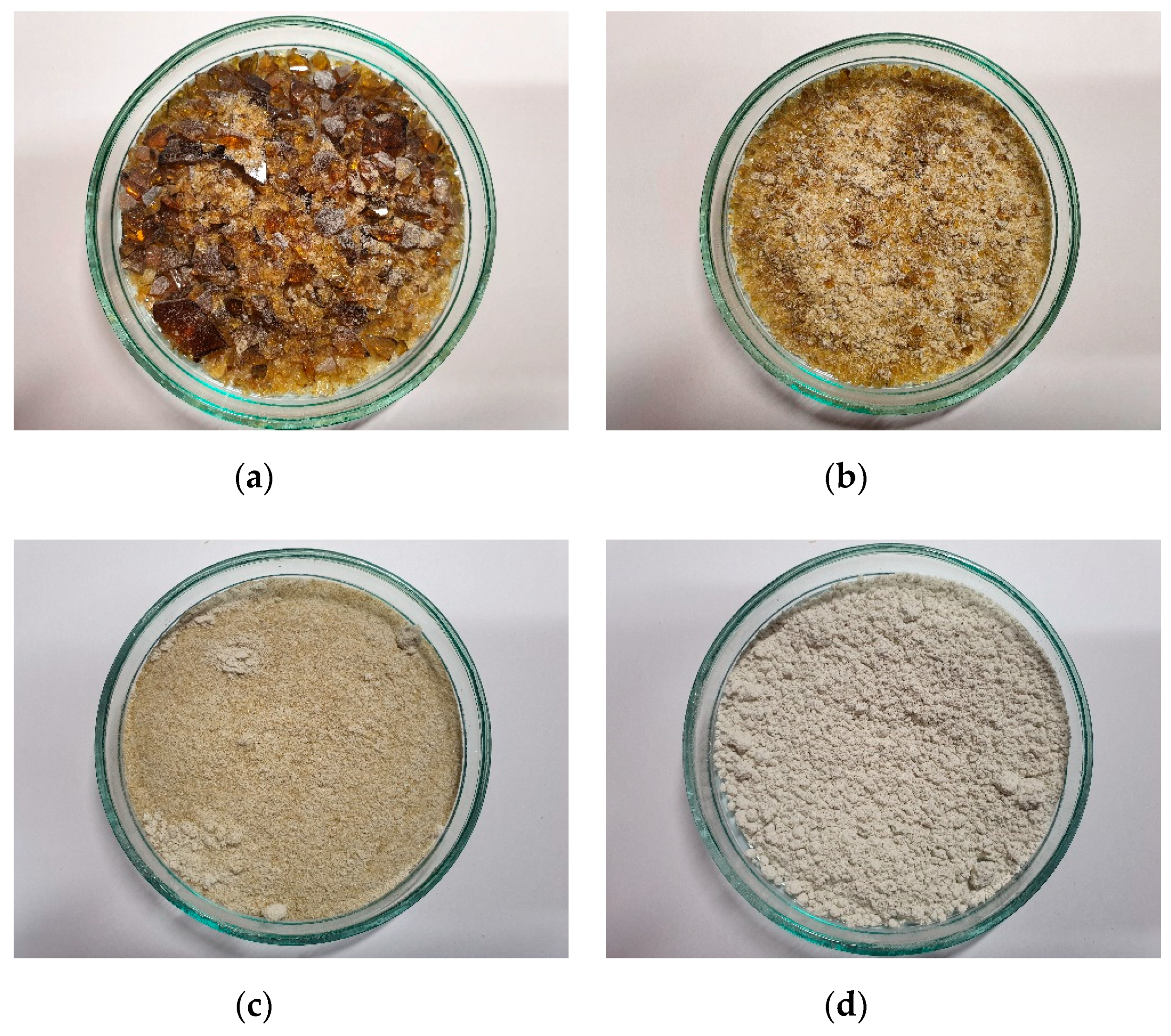

2. Materials and Methods

3. Results and Discussion

3.1. Fresh Properties

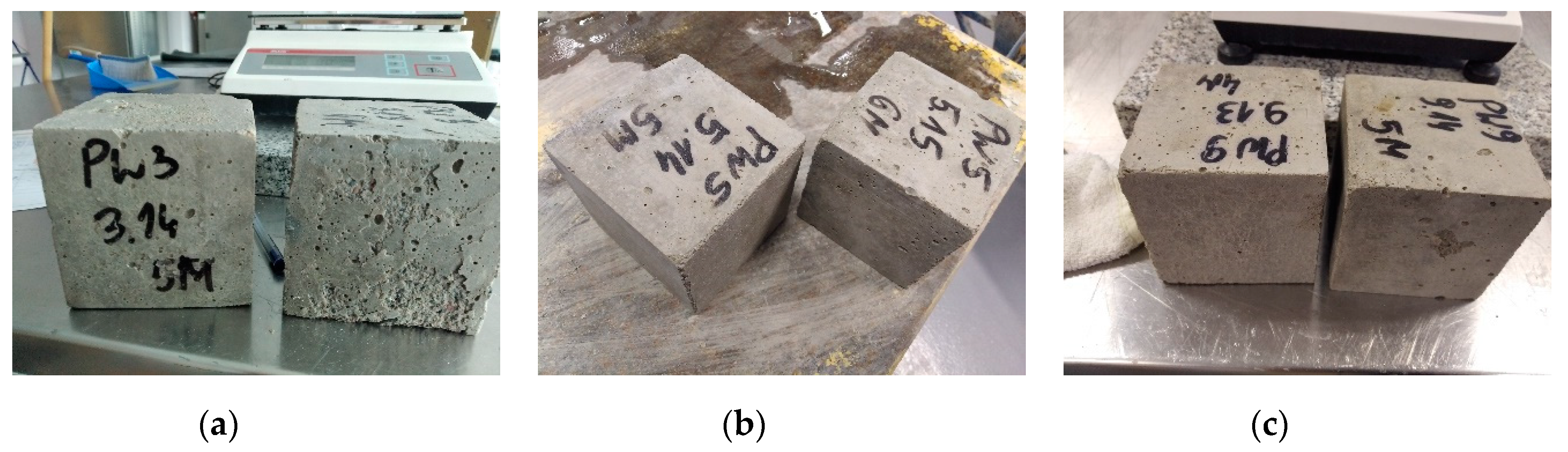

3.2. Hardened Properties

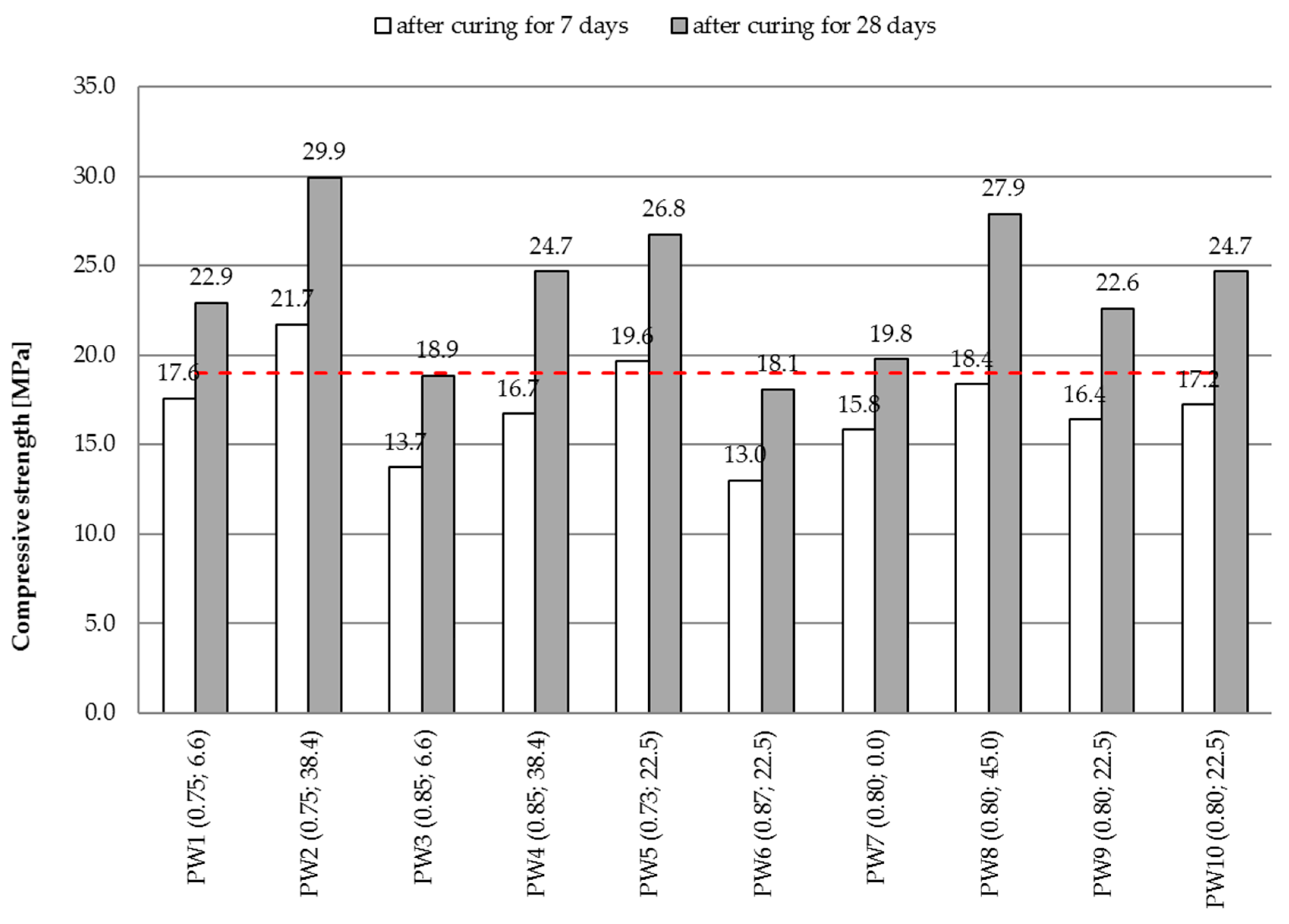

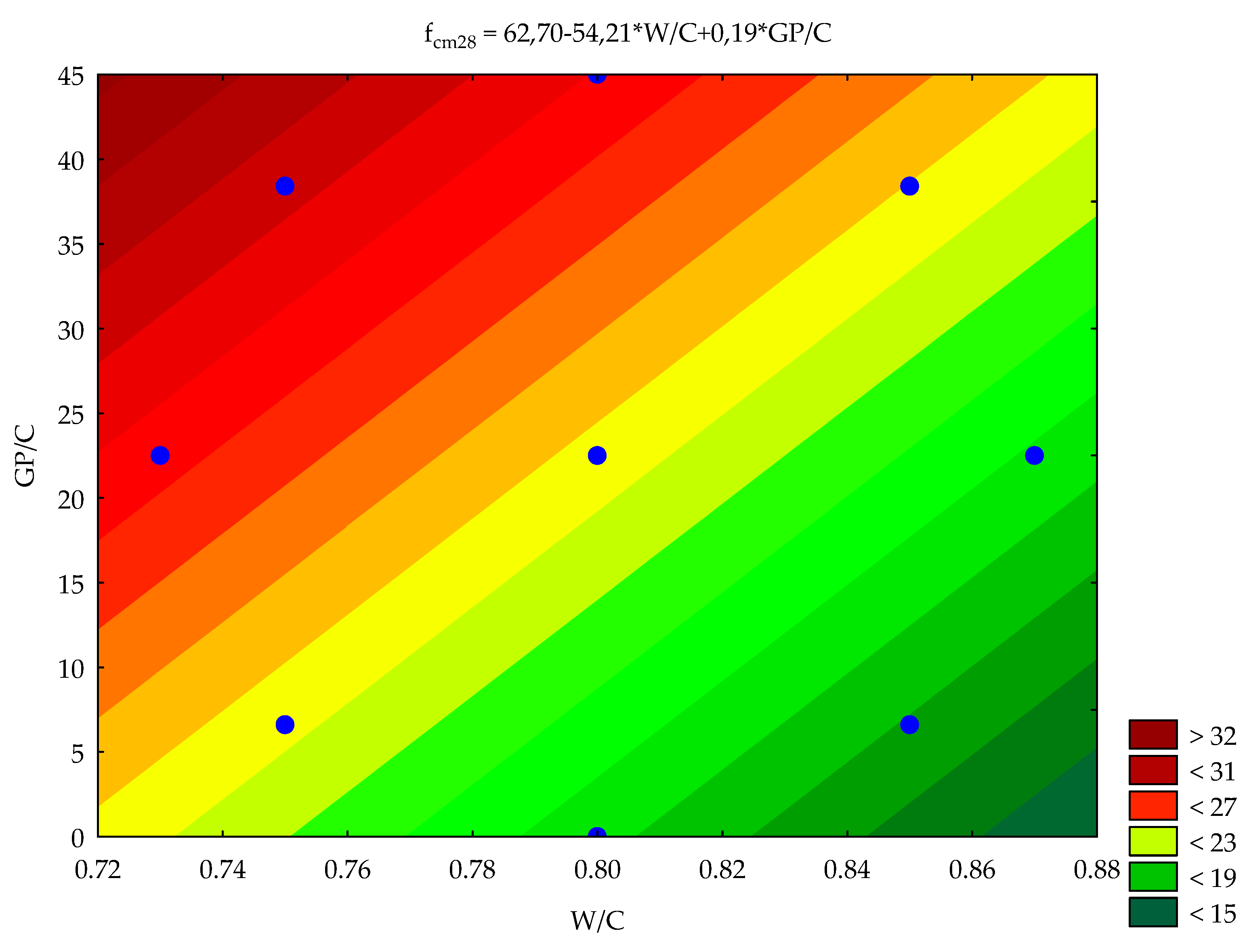

3.2.1. Compressive Strength

3.2.2. Water Absorption

3.2.3. Freeze–Thaw Resistance after Saturation in Water

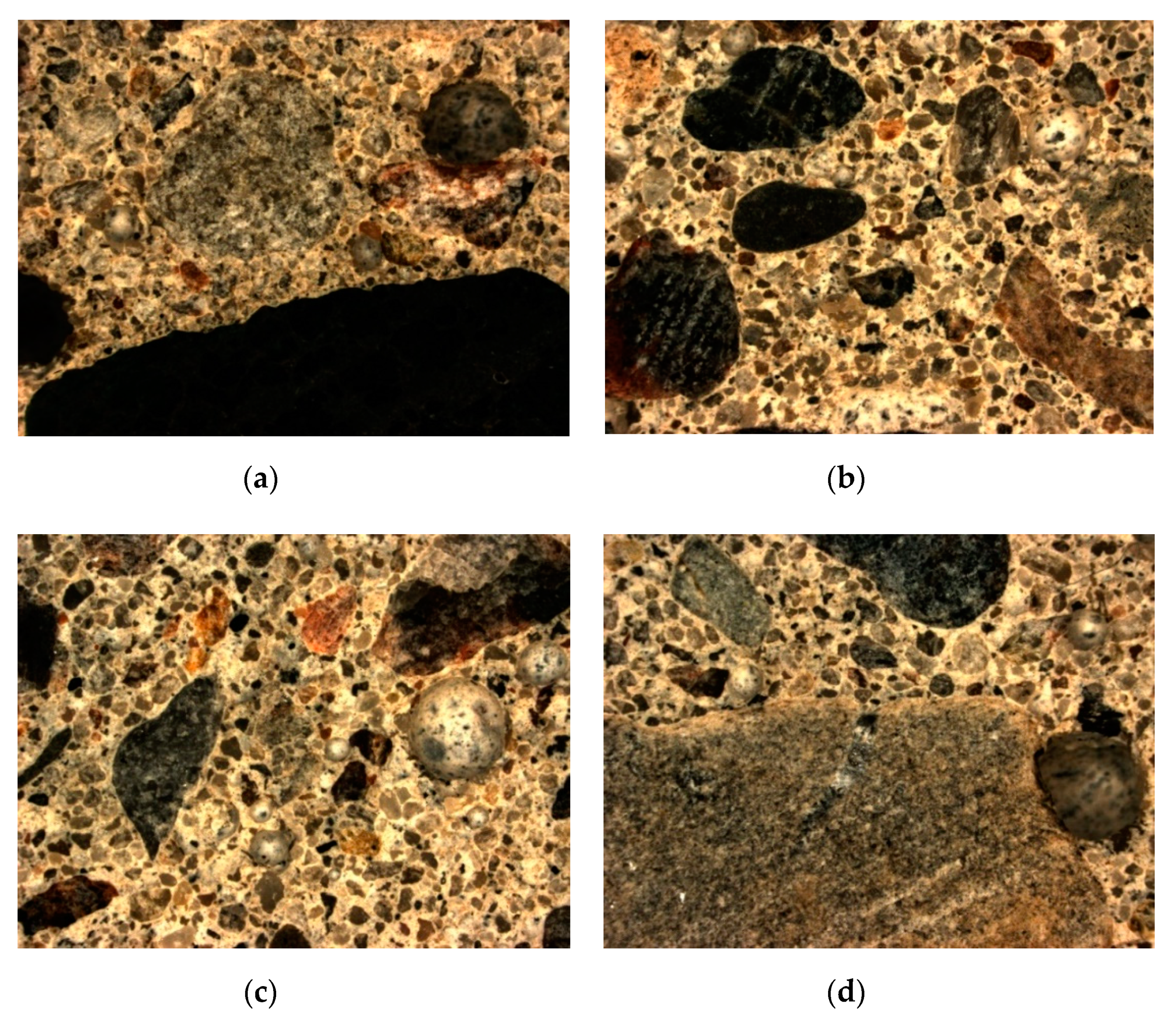

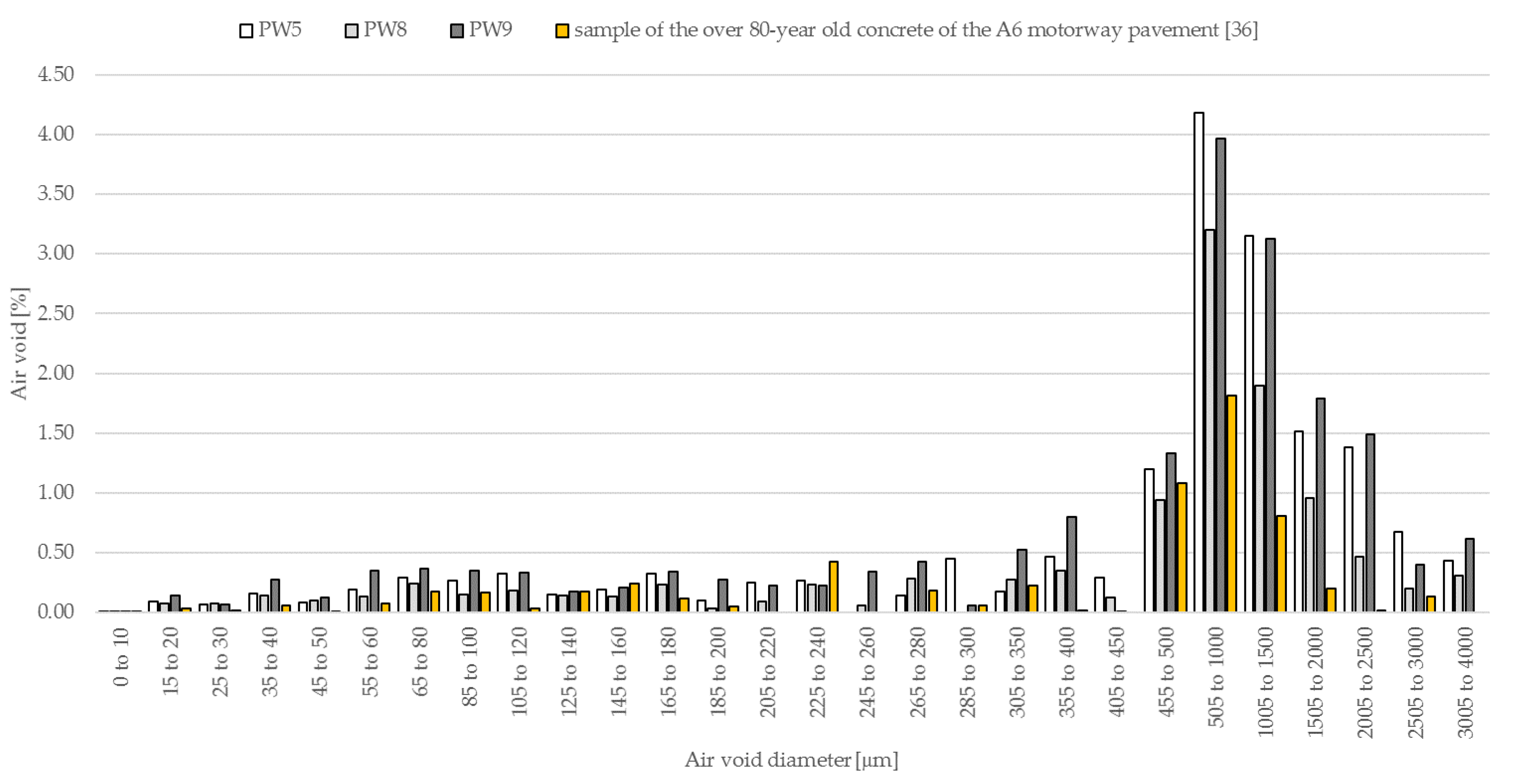

3.2.4. Air Void Analysis

3.3. The Effect of Glass Powder on the Compressive Strength and Durability of Concrete

4. Conclusions

- Glass powder changes the properties of low-strength concrete mixes (as compared to the control mix PW7 with the same water–cement ratio and without ground waste glass addition) as follows:

- Improves the 28 day compressive strength by ca. 20% and 40% when added at the proportions of 22.5% and 45%, respectively;

- Does not increase water absorption;

- Improves the freeze–thaw durability of concrete (without the presence of de-icing agents), which is testified by compliance with the requirements given for F100 concretes designated PW8–PW10.

- Except for PW3 and PW6, all of the tested mixes satisfied the requirements of [25] in terms of the assumed strength class and can be used for casting of footings to support kerbs and road gutters placed aside the road pavements.

- Mixes PW2 and PW5, in addition to the above-mentioned requirements, also satisfy the compressive strength, water absorption and freeze–thaw resistance criteria defined for concrete class F25 in the Polish standard no. PN-S-96014:1997 [26], and thus can be used as road-base material under bus lay-bys and for bespoke design road pavements.

- The average parameters of the microstructure of air voids according to the standard [35] in specimens of concrete marked as PW5, PW8 and PW9 confirm that they meet the requirements that refer to the air void spacing factor and the content of micro-air-voids with a diameter lower than 300 μm for concrete utilized in an XF aggressive environment and correspond with the results of freeze–thaw resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Available online: https://feve.org/about-glass/statistics/ (accessed on 30 September 2020).

- Sordoń-Kulibaba, B. Management of glass waste and glass packaging. Glass Ceram. 2008, 59, 15–17. [Google Scholar]

- Shao, Y.; Lefort, T.; Moras, S.; Rodrigez, D. Studies on Concrete Containing Ground Waste Glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Islam, G.M.S.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Meena, M.K.; Gupta, J.; Nagar, B. Performance of concrete by using glass powder. Int. Res. J. Eng. Technol. 2018, 5, 840–844. [Google Scholar]

- Omran, A.F.; Morin, E.D.; Harbec, D.; Tagnit-Hamou, A. Long-term performance of glass-powder concrete in large-scale field applications. Constr. Build. Mater. 2017, 135, 43–58. [Google Scholar] [CrossRef]

- Serpa, D.; Silva, S.S.; de Brito, J.; Pontes, J.; Soares, D. ASR of mortars containing glass. Constr. Build. Mater. 2013, 47, 489–495. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Properties of high volume glass powder concrete. Cem. Concr. Compos. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Tamanna, N.; Tuladhar, R. Sustainable Use of Recycled Glass Powder as Cement Replacement in Concrete. Open Waste Manag. J. 2020, 13, 1–13. [Google Scholar] [CrossRef]

- Zidol, A.Z.; Tognonvi, M.T.; Tagnit-Hamou, A. Effect of Glass Powder on Concrete Sustainability. New J. Glass Ceram. 2017, 7, 34–47. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Constr. Build. Mater. 2015, 98, 407–416. [Google Scholar] [CrossRef]

- Olofinnade, O.M.; Ede, A.N.; Ndambuki, J.M.; Ngene, B.U.; Akinwumi, I.I.; Ofuyatan, O. Strength and microstructure of eco-concrete produced using waste glass as partial and complete replacement for sand. Cogent Eng. 2018, 5, 1483860. [Google Scholar] [CrossRef]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of Waste Glass Addition as a Replacement for Fine Aggregate on Properties of Mortar. Materials 2020, 13, 1–19. [Google Scholar]

- Drzymała, T.; Zegardło, B.; Tofilo, P. Properties of Concrete Containing Recycled Glass Aggregates Produced of Exploded Lighting Materials. Materials 2020, 13, 3189. [Google Scholar] [CrossRef] [PubMed]

- Sikora, P.; Horszczaruk, E.; Rucińska, T.; Straszyńska, A. The influence of elevated temperature on the mechanical properties of cement mortars with waste glass. Build. Mater. 2015, 5, 116–118. [Google Scholar]

- Rutkowska, G.; Wichowski, P.; Lipiński, R. Impact of crushed glass waste on chosen properties of concrete made with its addition. Sci. Rev. Eng. Environ. Sci. 2018, 27, 463–475. [Google Scholar]

- Sičáková, A.; Špak, M. The Effect of a High Amount of Micro-Fillers on the Long-Term Properties of Concrete. Materials 2019, 12, 3421. [Google Scholar] [CrossRef]

- Jackiewicz-Rek, W.; Kopytko, M.; Opłocka, E. The impact of glass cullet from recycling on the strength and durability of concrete. Eng. Constr. 2019, 9, 429–434. [Google Scholar]

- Czapik, P. Microstructure and Degradation of Mortar Containing Waste Glass Aggregate as Evaluated by Various Microscopic Techniques. Materials 2020, 13, 2186. [Google Scholar] [CrossRef]

- Bhandari, P.S.; Tajne, K.M. Use of waste glass in cement mortar. Int. J. Civ. Struct. Eng. 2013, 4, 704–711. [Google Scholar]

- Najduchowska, M.; Pabiś, E.; Rolka, G.; Baran, T. The properties of concrete containing glass cullet. In Monografie Technologii Betonu, Proceedings of the Dni Betonu, Wisła, Poland, 10–12 October 2016; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2016. [Google Scholar]

- Gołek, Ł.; Kapeluszna, E. Using glass cullet and fluidal ashes for the production of binders. Word Glass 2013, 5, 42–44. [Google Scholar]

- Catalogue of Typical Structures of Flexible and Semi-Rigid Pavements; GDDKiA: Warszawa, Poland, 2014. Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/d/dokumenty-techniczne_8162/Dokumenty%20techniczne/KTKNPiP.pdf (accessed on 30 September 2020).

- Catalogue of Typical Structures of Rigid Pavements; GDDKiA: Warszawa, Poland, 2014. Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/d/dokumenty-techniczne_8162/Dokumenty%20techniczne/KTKNS.pdf (accessed on 30 September 2020).

- Conditions of Execution and Acceptance of Construction Works. D-08.01.01 Concrete kerbs; GDDKiA: Warszawa, Poland, 2019. Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/d/dokumentytechniczne_8162/WWiORB/punkt%208/D-08.01.01_KRAWĘŻNIKI%20BETONOWE_V01.pdf (accessed on 30 September 2020).

- PN-S-96014:1997. Roads – Cement concrete base course – Requirements and Test; PKN: Warsaw, Poland, 1997. [Google Scholar]

- TIBCO Software Inc. Statistica Version 13. 2017. [Google Scholar]

- EN 12350-2:2019 Testing fresh concrete – Part 2: Slump test; Comite Europeen de Normalisation: Brussels, Belgium, 2019.

- EN 12350-7:2019- Testing fresh concrete. Air content. Pressure Methods; Comite Europeen de Normalization: Brussels, Belgium, 2019. [Google Scholar]

- EN 12350-6:2019 Testing fresh concrete. Density; Comite Europeen de Normalisation: Brussels, Belgium, 2019. [Google Scholar]

- EN 12390-3:2019 Testing Hardened Concrete. Compressive Strength of Test Specimens; Comite Europeen de Normalisation: Brussels, Belgium, 2019. [Google Scholar]

- EN 206:2014 Concrete—Specification, Performance, Production and Conformity; Comite Europeen de Normalisation: Brussels, Belgium, 2014.

- PN-B-06250:1988 Polish Standard Normal Concrete (in Polish); PKN: Warsaw, Poland, 1988.

- EN 480-11:2008 Admixtures for Concrete, Mortar and Grout-Test Methods—Part 11: Determination of Air Void Characteristics in Hardened Concrete; Comite Europeen de Normalisation: Brussels, Belgium, 2008.

- Conditions of Execution and Acceptance of Construction Works. D-05.03.04 Cement Concrete Pavement; GDDKiA: Warszawa, Poland, 2019. Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/d/dokumenty-techniczne_8162/WWiORB/punkt%205/D05.03.04_NAWIERZCHNIA%20Z%20BETONU%20CEMENTOWEGO_V02.pdf (accessed on 30 September 2020).

- Rudnicki, T.; Jurczak, R. Recycling of a Concrete Pavement after over 80 Years in Service. Materials 2020, 13, 2262. [Google Scholar] [CrossRef] [PubMed]

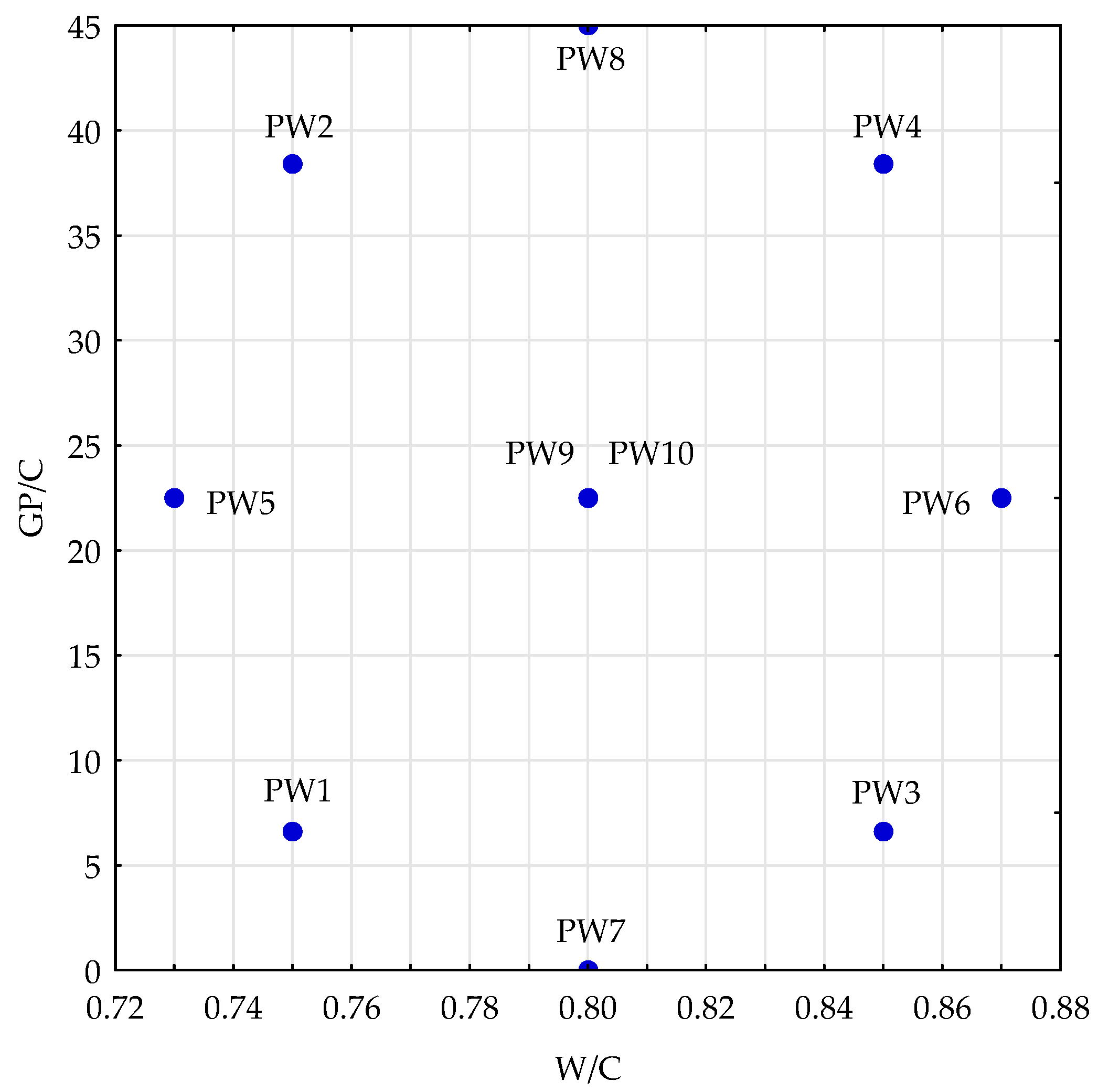

| Mix Symbol | Coded Variables | Actual Variables | ||

|---|---|---|---|---|

| W/C (x1) | GP/C (x2) | |||

| PW1 | −1 | −1 | 0.75 | 6.6 |

| PW2 | −1 | 1 | 0.75 | 38.4 |

| PW3 | 1 | −1 | 0.85 | 6.6 |

| PW4 | 1 | 1 | 0.85 | 38.4 |

| PW5 | −1.414 | 0 | 0.73 | 22.5 |

| PW6 | 1.414 | 0 | 0.87 | 22.5 |

| PW7 | 0 | −1.414 | 0.80 | 0.0 |

| PW8 | 0 | 1.414 | 0.80 | 45.0 |

| PW9 | 0 | 0 | 0.80 | 22.5 |

| PW10 | 0 | 0 | 0.80 | 22.5 |

| Mix Symbol | The Composition of the Concrete Mix According to the Adopted Plan [kg] | |||||

|---|---|---|---|---|---|---|

| CEM I 42.5 R | Sand 0/2 | Gravel 2/8 | Gravel 8/16 | Water | Glass Powder | |

| PW1 | 200 | 900 | 430 | 450 | 150 | 13.2 |

| PW2 | 150 | 76.8 | ||||

| PW3 | 170 | 13.2 | ||||

| PW4 | 170 | 76.8 | ||||

| PW5 | 146 | 45.0 | ||||

| PW6 | 174 | 45.0 | ||||

| PW7 | 160 | 0.0 | ||||

| PW8 | 160 | 90.0 | ||||

| PW9 | 160 | 45.0 | ||||

| PW10 | 160 | 45.0 | ||||

| Mix Symbol | W/C Ratio | GP/C Ratio | Slump Cone [mm] | Air Content, [%] | Density, [kg/m3] |

|---|---|---|---|---|---|

| PW1 | 0.75 | 6.6 | 20 | 4.0 | 2244 |

| PW2 | 0.75 | 38.4 | 10 | 4.9 | 2245 |

| PW3 | 0.85 | 6.6 | 20 | 5.0 | 2219 |

| PW4 | 0.85 | 38.4 | 50 | 4.1 | 2242 |

| PW5 | 0.73 | 22.5 | 10 | 4.8 | 2260 |

| PW6 | 0.87 | 22.5 | 70 | 4.2 | 2237 |

| PW7 | 0.80 | 0.0 | 20 | 4.7 | 2241 |

| PW8 | 0.80 | 45.0 | 30 | 5.1 | 2273 |

| PW9 | 0.80 | 22.5 | 30 | 5.0 | 2237 |

| PW10 | 0.80 | 22.5 | 30 | 4.8 | 2245 |

| Mix Symbol | Freeze–Thaw Resistance Criteria According to PN-B-06250:1988 [33] | ||

|---|---|---|---|

| Average Decrease of Strength ΔR, % | Weight Variation after Freeze–Thaw Cycles ΔG, % | Appearance, Presence of Cracks | |

| PW1 | 5.9 | 0.04 | none |

| PW2 | 2.7 | 0.03 | none |

| PW3 | 1.0 | 0.05 | none |

| PW4 | 9.0 | 0.01 | none |

| PW5 | 2.0 | 0.04 | none |

| PW6 | 4.9 | 0.05 | none |

| PW7 | 2.3 | 0.08 | none |

| PW8 | 6.8 | 0.02 | none |

| PW9 | 1.5 | 0.06 | none |

| PW10 | 0.4 | 0.05 | none |

| Mix Symbol | Freeze–Thaw Resistance Criteria According to PN-B-06250:1988 [33] | ||

|---|---|---|---|

| Average Decrease of Strength ΔR, % | Weight Variation after Freeze–Thaw Cycles ΔG, % | Appearance, Presence of Cracks | |

| PW1 | 8.6 | −0.21 | hairline cracks |

| PW2 | 5.6 | −0.04 | none |

| PW3 | 22.5 | −0.12 | scaling and spalling |

| PW4 | 45.0 | −0.92 | partial and full depth cracking |

| PW5 | 3.0 | −0.06 | none |

| PW6 | 24.6 | −0.33 | cracking |

| PW7 | 24.1 | -0.35 | scaling and cracking |

| PW8 | 5.0 | −0.15 | hairline cracks |

| PW9 | 12.3 | −0.18 | spalling |

| PW10 | 10.5 | −0.17 | spalling |

| Parameter | Unit | PW5 | PW8 | PW9 |

|---|---|---|---|---|

| Total air content, A | % | 16.58 | 10.85 | 18.20 |

| Specific surface of the air void system, α | mm−1 | 18.73 | 21.93 | 22.13 |

| Spacing factor, L | mm | 0.09 | 0.11 | 0.07 |

| Micro air-void content, A300 | % | 3.37 | 2.30 | 4.31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jurczak, R.; Szmatuła, F.; Rudnicki, T.; Korentz, J. Effect of Ground Waste Glass Addition on the Strength and Durability of Low Strength Concrete Mixes. Materials 2021, 14, 190. https://doi.org/10.3390/ma14010190

Jurczak R, Szmatuła F, Rudnicki T, Korentz J. Effect of Ground Waste Glass Addition on the Strength and Durability of Low Strength Concrete Mixes. Materials. 2021; 14(1):190. https://doi.org/10.3390/ma14010190

Chicago/Turabian StyleJurczak, Robert, Filip Szmatuła, Tomasz Rudnicki, and Jacek Korentz. 2021. "Effect of Ground Waste Glass Addition on the Strength and Durability of Low Strength Concrete Mixes" Materials 14, no. 1: 190. https://doi.org/10.3390/ma14010190

APA StyleJurczak, R., Szmatuła, F., Rudnicki, T., & Korentz, J. (2021). Effect of Ground Waste Glass Addition on the Strength and Durability of Low Strength Concrete Mixes. Materials, 14(1), 190. https://doi.org/10.3390/ma14010190