Design and Evaluation of a New Resin-Filled GFRP Pipe Connection System for Butt Splicing of FRP Bars

Abstract

1. Introduction

2. The Connection System Design

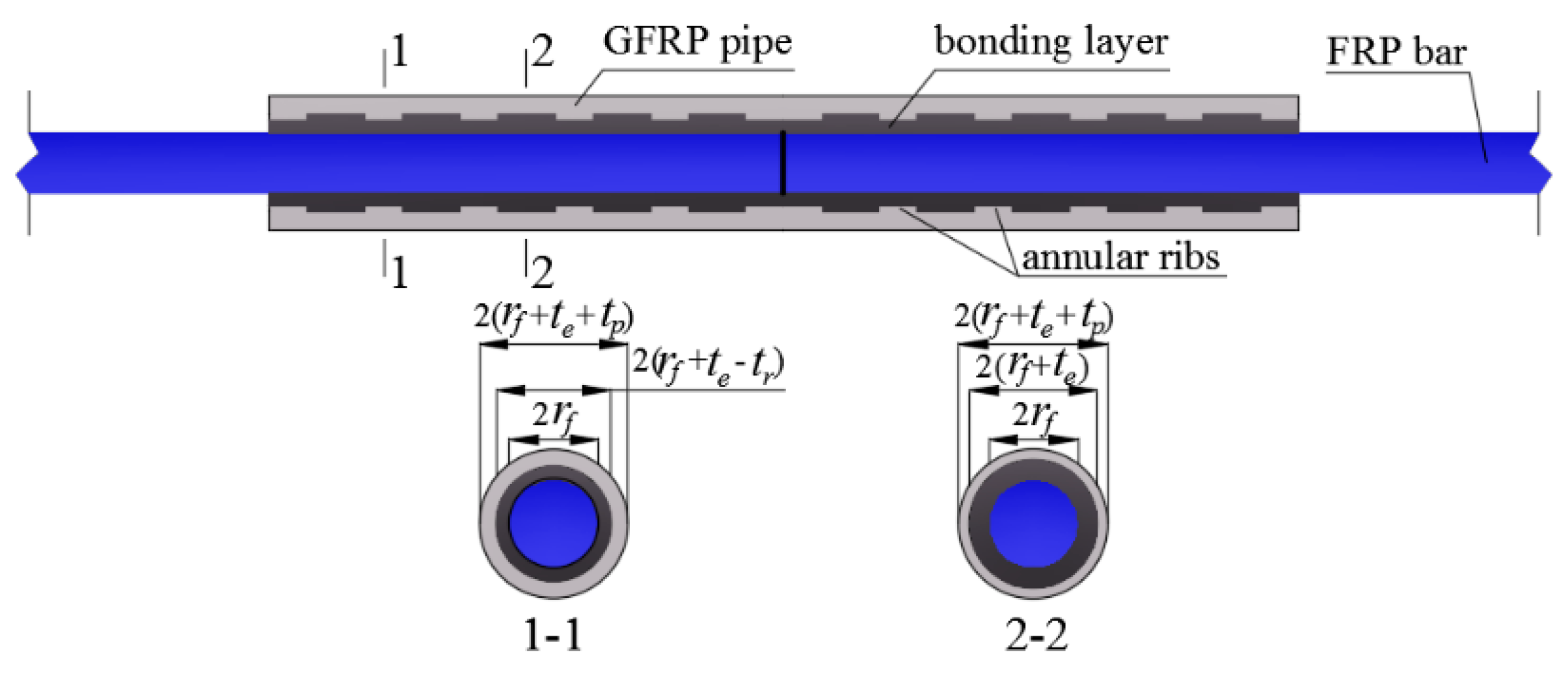

2.1. Prototype Design

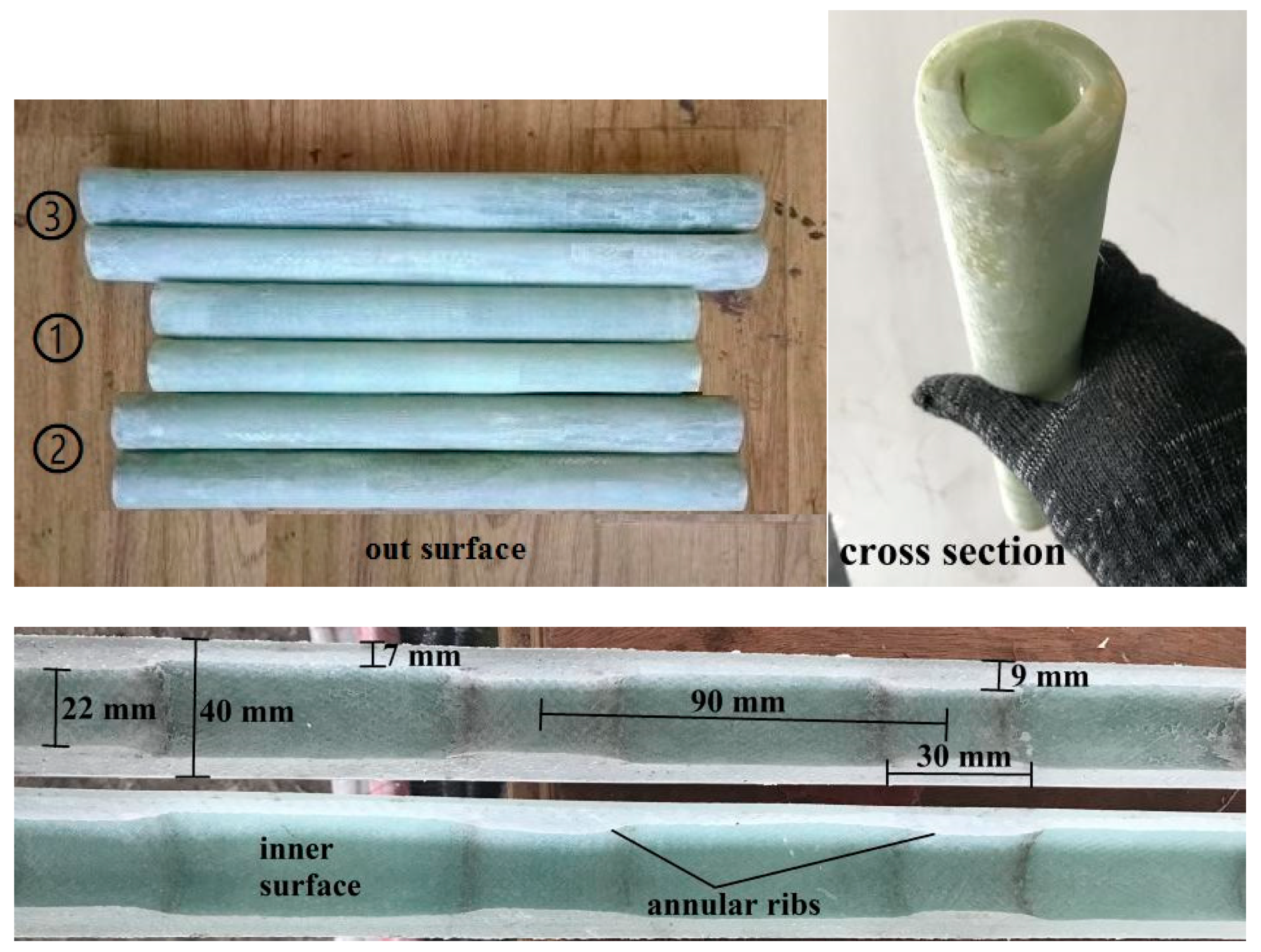

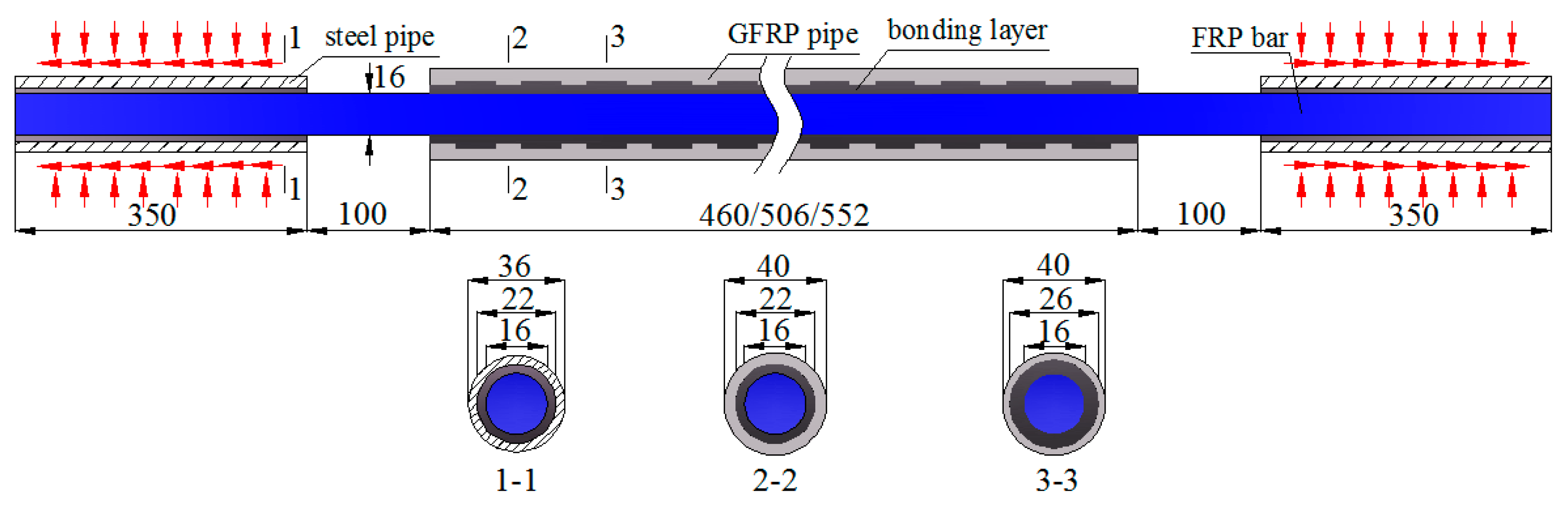

2.2. Configuration Design

2.2.1. The Net Bonding Layer Thickness Design

2.2.2. The Net GFRP Pipe Wall Thickness Design

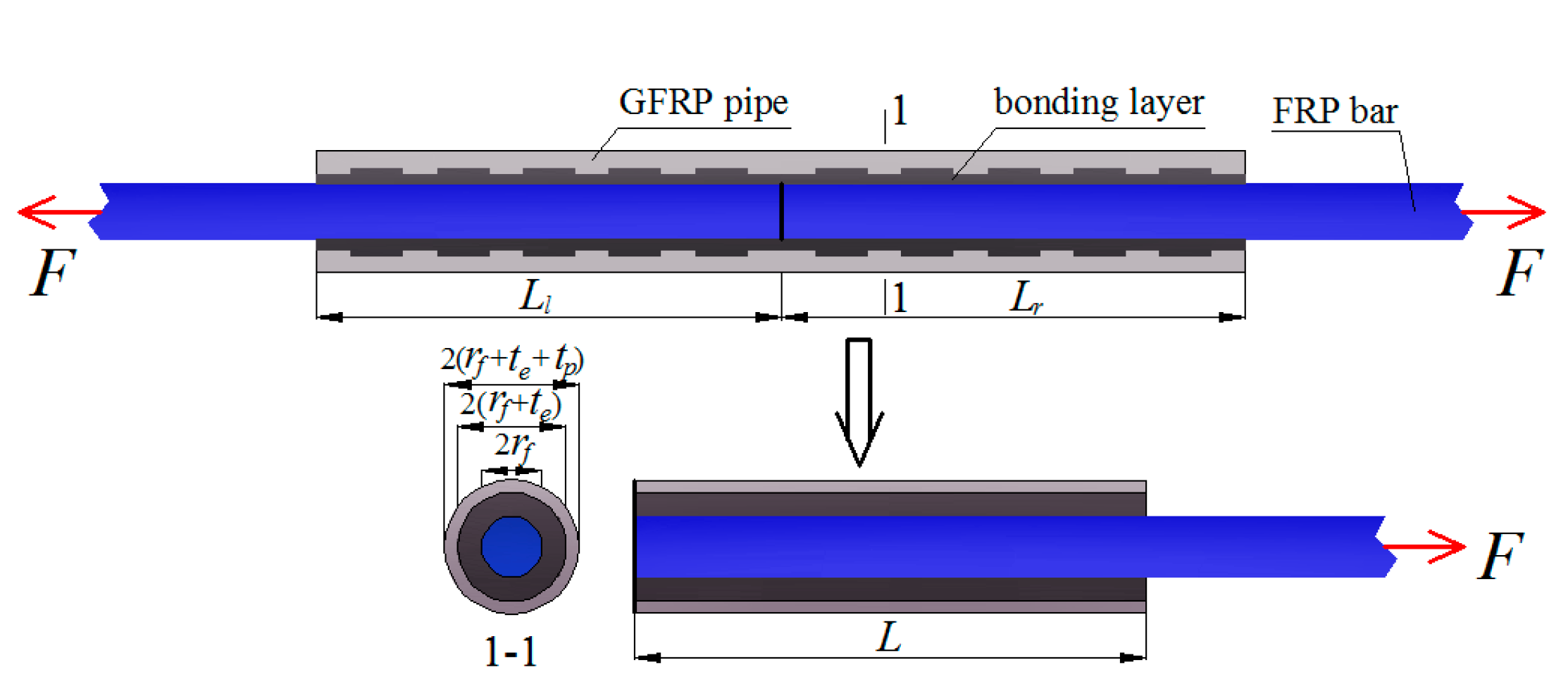

2.2.3. The FRP Bar Anchorage Length Design

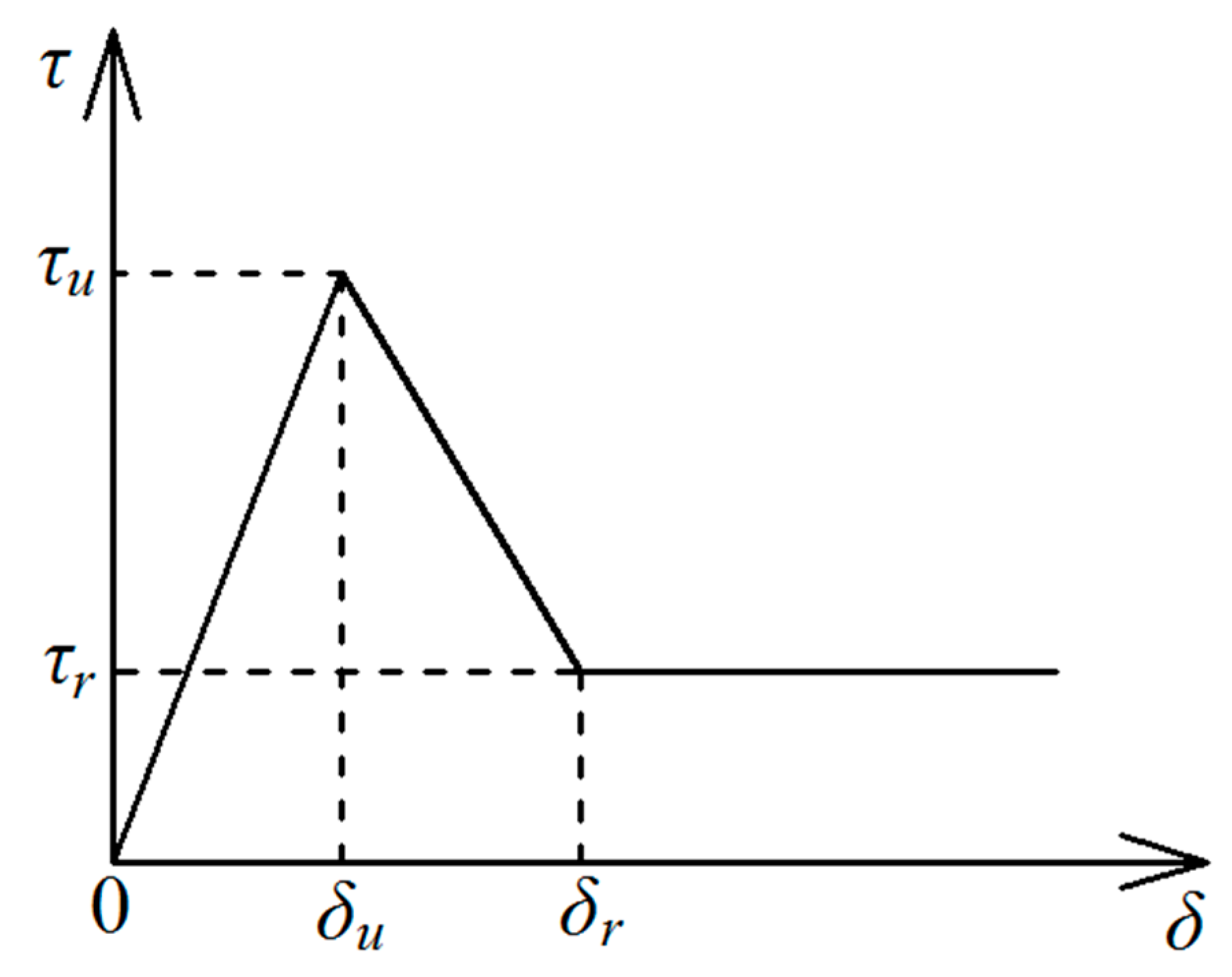

- Basic assumptions and equations

- 2.

- Theoretical solution

- (1)

- Elastic part

- (2)

- Softening part

- (3)

- Frictional part

- 3.

- The critical FRP bar anchorage length calculation

- (1)

- Case 1: for Ffu < Fc

- (2)

- Case 2: for Ffu = Fc

- (3)

- Case 3: for Ffu > Fc

- 4.

- Determination of the GFRP pipe length

3. Experimental Verification

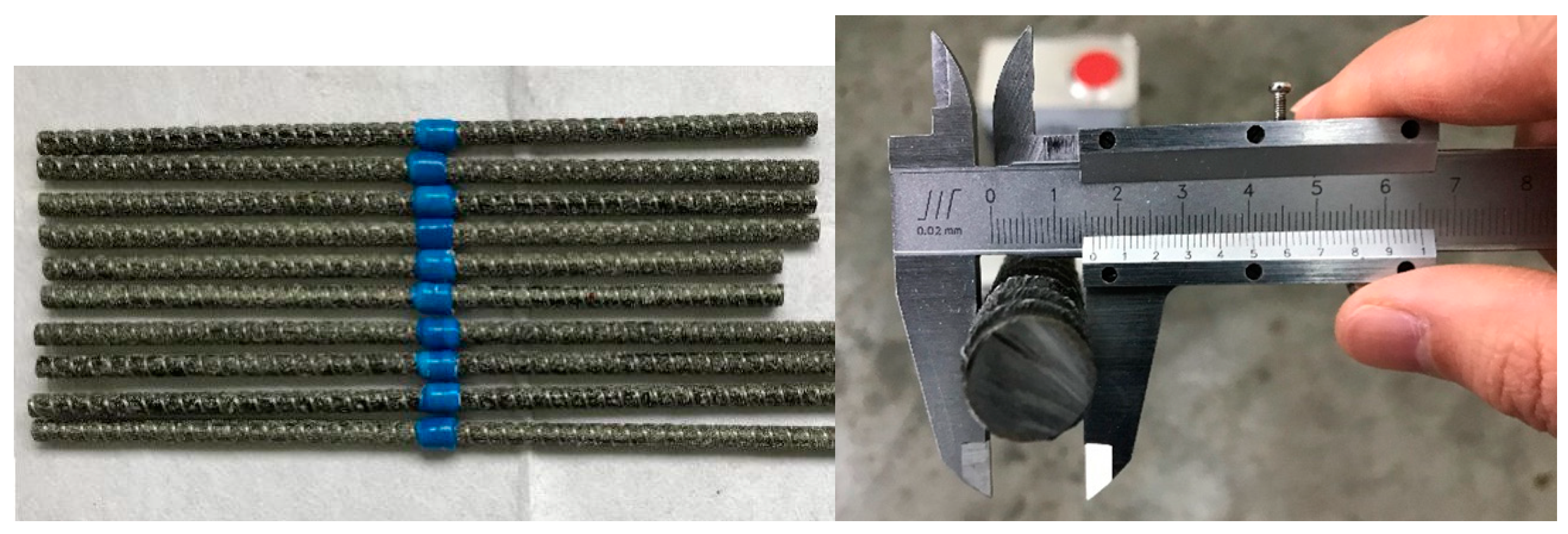

3.1. Specimen Design

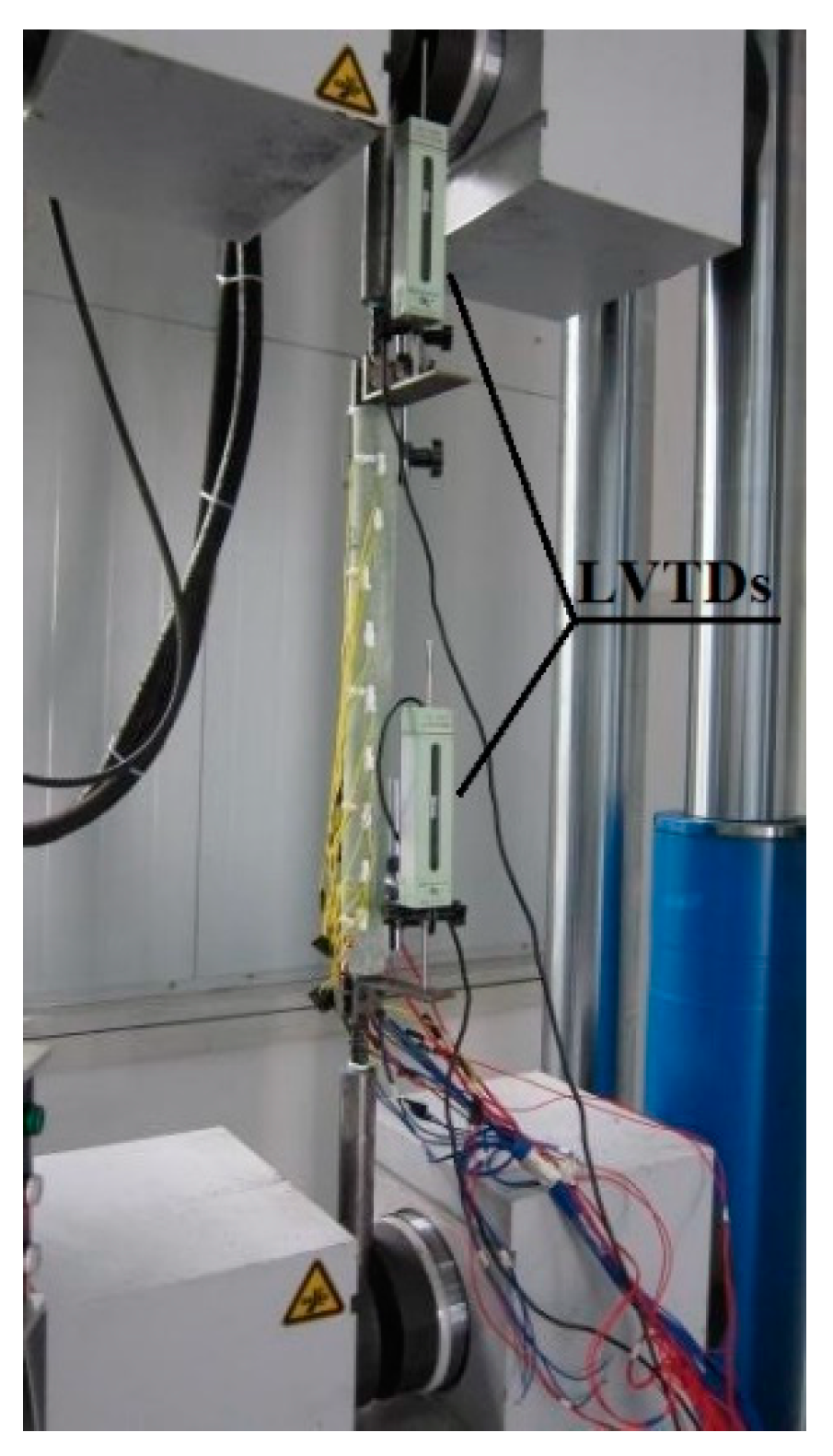

3.2. Measuring Points and Loading Equipment

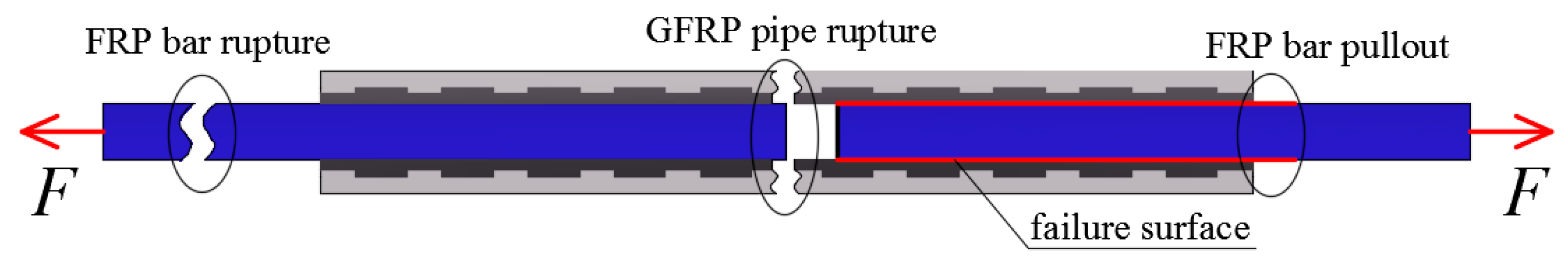

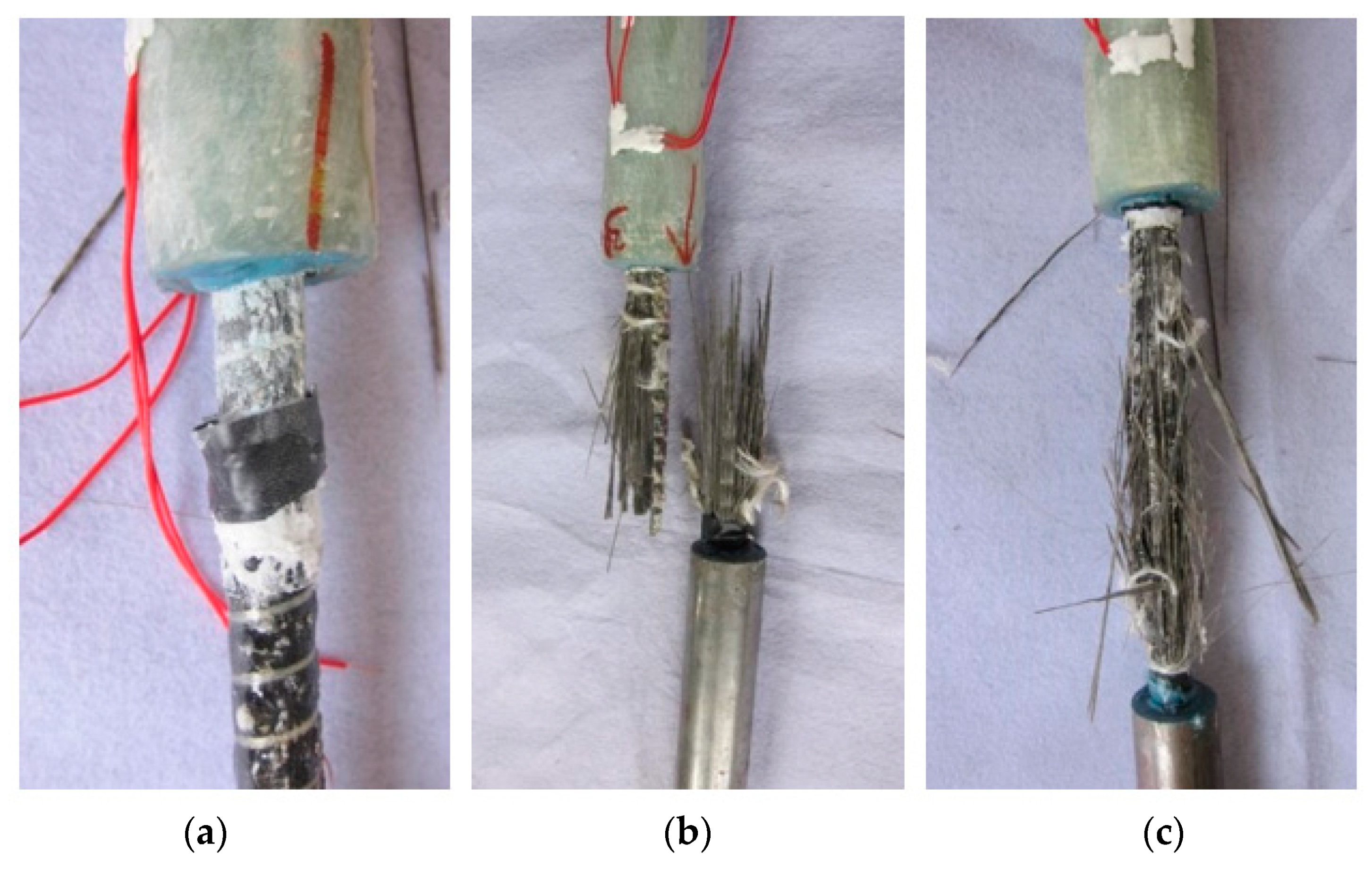

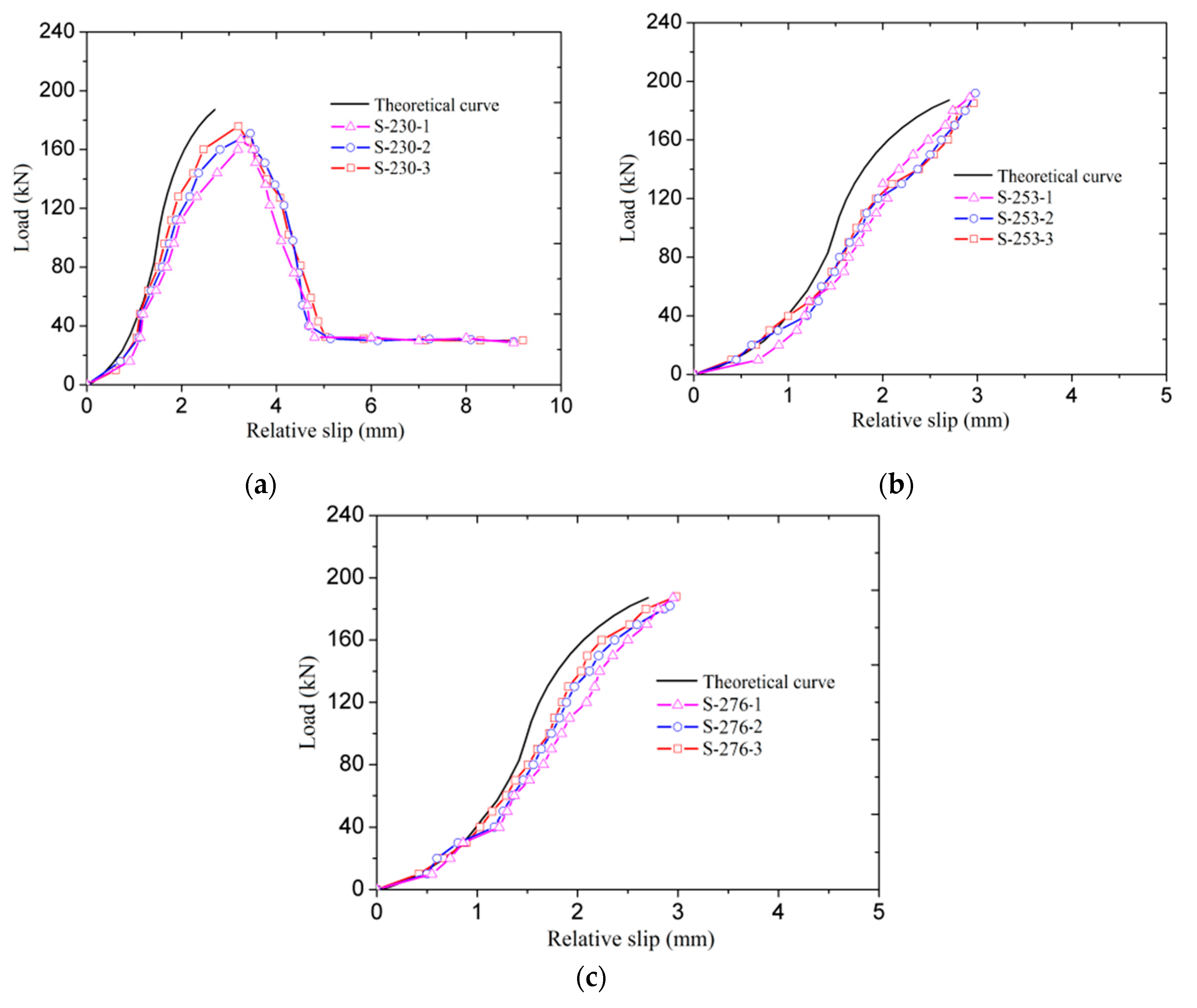

3.3. Test Results and Discussion

4. Conclusions

- Bond-type connection system is able to connect symmetrically placed FRP bars for splicing application. The proposed resin-filled GFRP pipe connection system can provide a sound connection and simple mechanism for the butt splicing of the BFRP bars studied herein.

- The derived design formulas can be used to determine the geometrical configuration of the proposed resin-filled GFRP pipe connection system for the given FRP bars. Besides, these formulas can also be reversely used to predict the load transfer performance of the splices with reasonable accuracy.

- Considering the fabrication error-induced load transfer capacity reduction of the FRP bar-bonding layer interface, a correction factor should be introduced in the connection system design to compensate for the reduced load transfer capacity of the interface by enlarging the FRP bar anchorage length. Thus, in designing the proposed connection system for the butt splicing of FRP bars, external experimental tests should be conducted to determine the reasonable correction factor for determining the final GFRP pipe length. For the BFRP bars studied in this paper, a minimum correction factor of 1.1 was found to ensure that the interface provides a load transfer capacity beyond the tensile capacity of the BFRP bars.

- Although the resin-filled GFRP pipe connection system showed good mechanical performance under unidirectional tension, the behaviors under reversal, dynamic, and sustained loads should be further studied before field application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, W.W.; Dai, J.G.; Harries, K.A.; Bao, Q.H. Prestress losses and flexural behavior of reinforced concrete beams strengthened with post-tensioned CFRP sheets. J. Compos. Constr. 2012, 16, 207–216. [Google Scholar] [CrossRef]

- Wang, W.W.; Dai, J.G.; Harries, K.A. Performance evaluation of RC beams strengthened with an externally bonded FRP system under simulated vehicles loads. J. Bridge. Eng. 2013, 18, 76–82. [Google Scholar] [CrossRef]

- Xu, X.; Huang, Q.; Ren, Y.; Zhao, D.Y.; Zhang, D.Y.; Sun, H.B. Condition evaluation of suspension bridges for maintenance, repair and rehabilitation: A comprehensive framework. Struct. Infrastruct. E 2019, 15, 555–567. [Google Scholar] [CrossRef]

- Wang, W.W.; Dai, J.G.; Huang, C.K.; Bao, Q.H. Strengthening multiple span simply-supported girder bridges using post-tensioned negative moment connection technique. Eng. Struc. 2011, 33, 663–673. [Google Scholar] [CrossRef]

- Wang, W.W.; Dai, J.G.; Li, G.; Huang, C.K. Long-term behavior of prestressed old-new concrete composite beams. J. Bridge. Eng. 2011, 16, 275–285. [Google Scholar] [CrossRef]

- Wang, W.W.; Dai, J.G. Self-stressed steel fiber reinforced concrete as negative moment connection for strengthening of multi-span simply-supported girder bridges. Adv. Struct. Eng. 2013, 16, 1113–1127. [Google Scholar] [CrossRef]

- Huang, H.; Wang, W.W.; Dai, J.G.; Brigham, J.C. Fatigue behavior of reinforced concrete beams strengthened with externally bonded prestressed CFRP sheets. J. Compos. Constr. 2016, 21, 04016108. [Google Scholar] [CrossRef]

- Davies, P.; Verbouwe, W. Evaluation of Basalt Fiber Composites for Marine Applications. Appl. Compos. Mater. 2017, 1, 1–10. [Google Scholar]

- Dong, Z.Q.; Wu, G.; Zhao, X.L.; Zhu, H.; Lian, J.L. Durability test on the flexural performance of seawater sea-sand concrete beams completely reinforced with FRP bars. Constr. Build. Mater. 2018, 192, 671–682. [Google Scholar] [CrossRef]

- Wang, Y.L.; Cai, G.C.; Li, Y.Y.; Waldmann, D.; Larbi, A.S.; Tsavdaridis, K.D. Behavior of circular fiber-reinforced polymer-steel-confined concrete columns subjected to reversed cyclic loads: Experimental studies and finite-element analysis. J. Struct. Eng. 2019, 145, 04019085. [Google Scholar] [CrossRef]

- Wang, Y.L.; Chen, G.P.; Wan, B.L.; Cai, G.C.; Zhang, Y.W. Behavior of circular ice-filled self-luminous FRP tubular stub columns under axial compression. Constr. Build. Mater. 2020, 232, 117287. [Google Scholar] [CrossRef]

- Cascardi, A.; Dell’Anna, R.; Micelli, F.; Lionetto, F.; Aiello, M.A.; Maffezzoli, A. Reversible techniques for FRP-confinement of masonry columns. Constr. Build. Mater. 2019, 225, 415–428. [Google Scholar] [CrossRef]

- Henault, J.M.; Quiertant, M.; Delepine-Lesoille, S.; Salin, J.; Moreau, G.; Taillade, F.; Benzarti, K. Quantitative strain measurement and crack detection in RC structures using a truly distributed fiber optic sensing system. Constr. Build. Mater. 2012, 37, 916–923. [Google Scholar] [CrossRef]

- Huang, M.H.; Zhou, Z.; Huang, Y.; Ou, Y.; Ou, J.P. A distributed self-sensing FRP anchor rod with built-in optical fiber sensor. Measurement 2013, 46, 1363–1370. [Google Scholar] [CrossRef]

- Chen, Q.J.; Cai, J.; Bradford, M.A.; Liu, X.P.; Zuo, Z.L. Seismic behaviour of a through-beam connection between concrete-filled steel tubular columns and reinforced concrete beams. Eng. Struct. 2014, 80, 24–39. [Google Scholar] [CrossRef]

- Roure, F.; Somalo, M.R.; Casafont, M.; Pastor, M.M.; Bonada, J.; Pekaz, T. Determination of beam-to-column connection characteristics in pallet rack structures: A comparison of the EN and ANSI methods and an analysis of the influence of the moment-to-shear ratios. Steel Constr. 2013, 6, 132–138. [Google Scholar] [CrossRef]

- Alam, M.S.; Youssef, M.A.; Nehdi, M.L. Exploratory investigation on mechanical anchors for connecting SMA bars to steel or FRP bars. Mater. Struct. 2020, 43, 91–107. [Google Scholar] [CrossRef]

- Huang, H.; Jia, B.; Lian, J.; Wang, W.W. Experimental investigation on the tensile performance of resin-filled steel pipe splices of BFRP bars. Constr. Build. Mater. 2020, 242, 118018. [Google Scholar] [CrossRef]

- Mckay, K.S.; Erki, M.A. Grouted anchorages for aramid fibre reinforced plastic prestressing tendons. Can. J. Civil. Eng. 1993, 20, 1065–1069. [Google Scholar] [CrossRef]

- Benmokrane, B.; Zhang, B.R.; Chennouf, A. Tensile properties and pullout behaviour of AFRP and CFRP rods for grouted anchor applications. Constr. Build. Mater. 2000, 14, 157–170. [Google Scholar] [CrossRef]

- Zhang, B.R.; Benmokrane, B.; Chennouf, A.; Mukhopadhyaya, P.; El-Safty, A. Tensile behaviour of FRP tendons for prestressed grouted anchors. J. Compos. Constr. 2001, 5, 85–93. [Google Scholar] [CrossRef]

- Zhang, B.R.; Benmokrane, B. Design and evaluation of a new bond-type anchorage system for fiber reinforced polymer tendons. Can. J. Civ. Eng. 2004, 31, 14–26. [Google Scholar] [CrossRef]

- Zhang, B.R.; Benmokrane, B.; Ebead, U.A.A. Design and evaluation of fiber-reinforced polymer bond-type anchorages and ground anchors. Int. J. Geomech. 2006, 6, 166–175. [Google Scholar] [CrossRef]

- Zhu, H.H.; Yin, J.H.; Yeung, A.T.; Jin, W. Field pullout testing and performance evaluation of GFRP soil nails. J. Geotech. Geoenviron. 2011, 137, 633–642. [Google Scholar] [CrossRef]

- Fang, Z.; Zhang, K.Y.; Tu, B. Experimental investigation of a bond-type anchorage system for multiple FRP tendons. Eng. Struct. 2013, 57, 364–373. [Google Scholar] [CrossRef]

- Zheng, J.J.; Dai, J.G. Analytical solution for the full-range pull-out behavior of FRP ground anchors. Constr. Build. Mater. 2014, 58, 129–137. [Google Scholar] [CrossRef]

- Zheng, J.J.; Dai, J.G. Prediction of the nonlinear pull-out response of FRP ground anchors using an analytical transfer matrix method. Eng. Struct. 2014, 81, 377–385. [Google Scholar] [CrossRef]

- Campbell, T.I.; Shrive, N.G.; Soudki, K.A.; Mayah, A.A.; Keatley, J.P.; Reda, M.M. Design and evaluation of a wedge-type anchor for fiber reinforced polymer tendons. Can. J. Civ. Eng. 2000, 27, 985–992. [Google Scholar] [CrossRef]

- Evernden, M.C.; Mottram, J.T. A case for houses to be constructed of fiber reinforced polymer components. Proc. Inst. Civil Eng. Constr. Mater. 2010, 163, 3–13. [Google Scholar]

- Schmidt, J.W.; Bennitz, A.; Toljsten, B.; Goltermann, P.; Pedersen, H. Mechanical anchorage of FRP tendons—A literature review. Constr. Build. Mater. 2012, 32, 110–121. [Google Scholar] [CrossRef]

- Schesser, D.; Yang, Q.D.; Nanni, A.; Giancaspro, J.W. Expansive grout-based gripping systems for tensile testing of large-diameter composite bars. J. Mater. Civil. Eng. 2014, 26, 250–258. [Google Scholar] [CrossRef]

- Benmokrane, B.; Xu, H.X.; Bellavance, E. Bond strength of cement grouted glass fiber reinforced plastic (GFRP) anchor bolts. Int. J. Rock. Mech. Min. 1996, 33, 455–465. [Google Scholar] [CrossRef]

- Wu, Z.M.; Yang, S.T.; Zheng, J.J.; Hu, X.Z. Analytical solution for the pull-out response of FRP rods embedded in steel tubes filled with cement grout. Mater. Struct. 2010, 43, 597–609. [Google Scholar] [CrossRef]

- CNSC (China National Standardization Committee). Standard Test Method for Mechanical Properties of Fiber Reinforced Polymer Bar. GB/T 30022-2013; CNSC: Beijing, China, 2013. (In Chinese) [Google Scholar]

- CNSC (China National Standardization Committee). General Testing Methods for Construction Adhesives. GB/T 12954-2008; CNSC: Beijing, China, 2008. (In Chinese) [Google Scholar]

| Material | Elastic Modulus /GPa | Ultimate Tensile Strength /MPa | Compressive Strength /MPa | Shear Strength /MPa | Poisson’s Ratio | Elongation |

|---|---|---|---|---|---|---|

| GFRP pipe | 26.4 ± 0.5 | 420.7 ± 7.5 | - | - | 0.31 | 1.61 ± 0.05% |

| BFRP bar | 54.1 ± 0.8 | 930.2 ± 14.3 | - | - | 0.29 | 1.72 ± 0.05% |

| Epoxy resin | 2.3 ± 0.1 | 63.6 ± 2.7 | 124.5 ± 3.8 | 35.3 ± 2.1 | 0.38 | 2.75 ± 0.07% |

| Epoxy Resin | τu/MPa | τr/MPa | δu/mm | δr/mm |

|---|---|---|---|---|

| JGN | 25.7 ± 0.6 | 2.8 ± 0.2 | 1.4 ± 0.2 | 3.2 ± 0.3 |

| Group Number | Specimen ID | BFRP Bar Anchorage Length/mm | GFRP Pipe Length/mm | Tested Ultimate Tensile Capacity/kN | Theoretical Ultimate Load Transfer Capacity/kN | Tested Relative Slip at Failure/mm | Theoretical Relative Slip at Failure/mm | Failure Mode |

|---|---|---|---|---|---|---|---|---|

| Group 1 | S-230-1 | 230 | 460 | 176.3 | 187.4 | 3.20 | 3.10 | BFRP bar Pullout |

| S-230-2 | 171.5 | 3.45 | ||||||

| S-230-3 | 167.9 | 3.25 | ||||||

| Group 2 | S-253-1 | 253 | 506 | 185.4 | 201.7 | 2.96 | 2.91 | BFRP bar rupture |

| S-253-2 | 192.1 | 2.98 | ||||||

| S-253-3 | 189.5 | 2.92 | ||||||

| Group 3 | S-276-1 | 276 | 552 | 188.3 | 208.6 | 2.88 | 2.82 | BFRP bar rupture |

| S-276-2 | 182.2 | 2.92 | ||||||

| S-276-3 | 187.6 | 2.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.; Lian, J.; Li, J.; Jia, B.; Meng, D.; Wu, Z. Design and Evaluation of a New Resin-Filled GFRP Pipe Connection System for Butt Splicing of FRP Bars. Materials 2021, 14, 161. https://doi.org/10.3390/ma14010161

Huang H, Lian J, Li J, Jia B, Meng D, Wu Z. Design and Evaluation of a New Resin-Filled GFRP Pipe Connection System for Butt Splicing of FRP Bars. Materials. 2021; 14(1):161. https://doi.org/10.3390/ma14010161

Chicago/Turabian StyleHuang, Hui, Jie Lian, Jiaxing Li, Bin Jia, Dong Meng, and Zhizhong Wu. 2021. "Design and Evaluation of a New Resin-Filled GFRP Pipe Connection System for Butt Splicing of FRP Bars" Materials 14, no. 1: 161. https://doi.org/10.3390/ma14010161

APA StyleHuang, H., Lian, J., Li, J., Jia, B., Meng, D., & Wu, Z. (2021). Design and Evaluation of a New Resin-Filled GFRP Pipe Connection System for Butt Splicing of FRP Bars. Materials, 14(1), 161. https://doi.org/10.3390/ma14010161