Analysis of Magneto-Optical Hysteresis Loops of Amorphous and Surface-Crystalline Fe-Based Ribbons

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

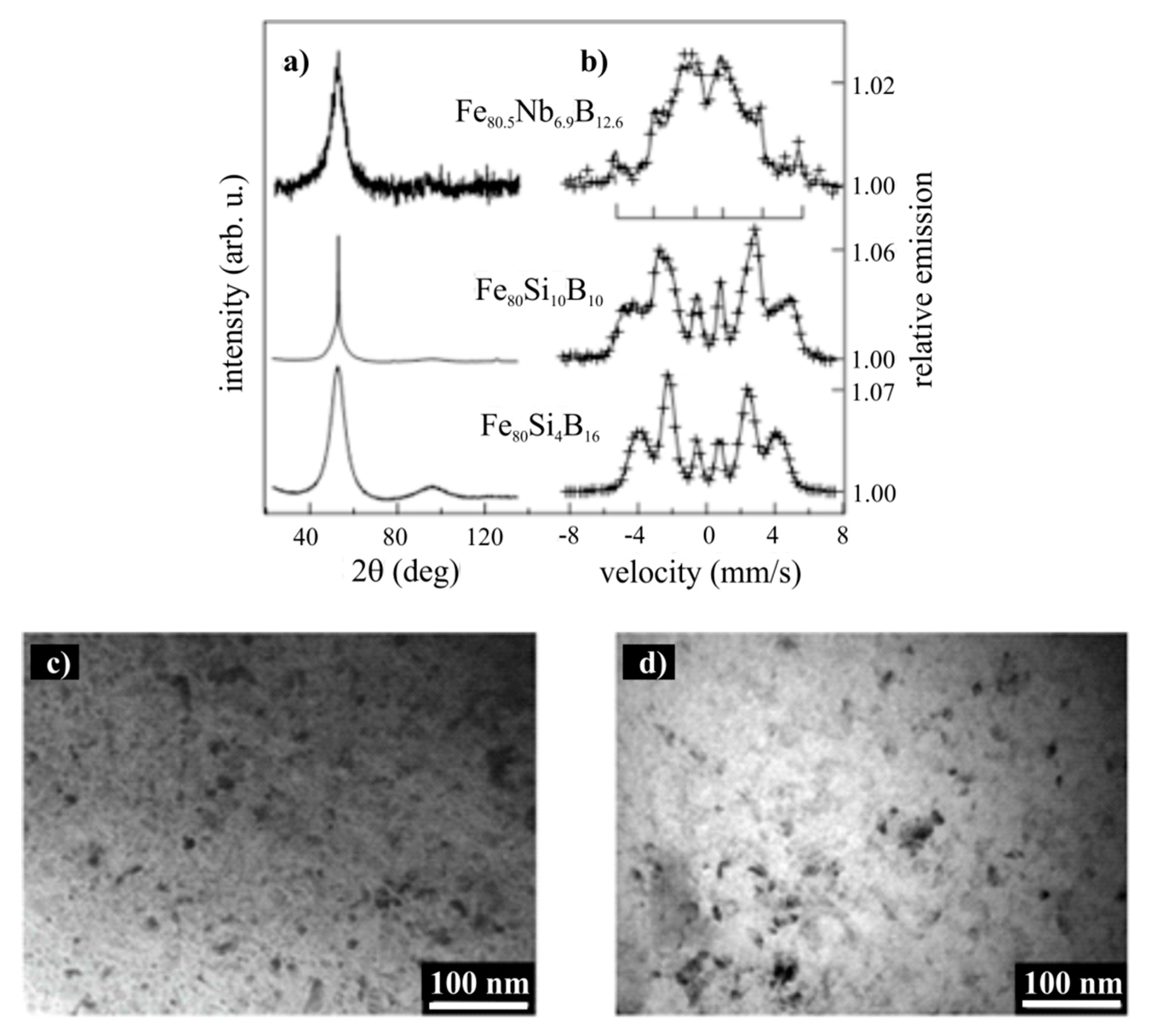

3.1. Microstructural and Bulk Magnetic Properties

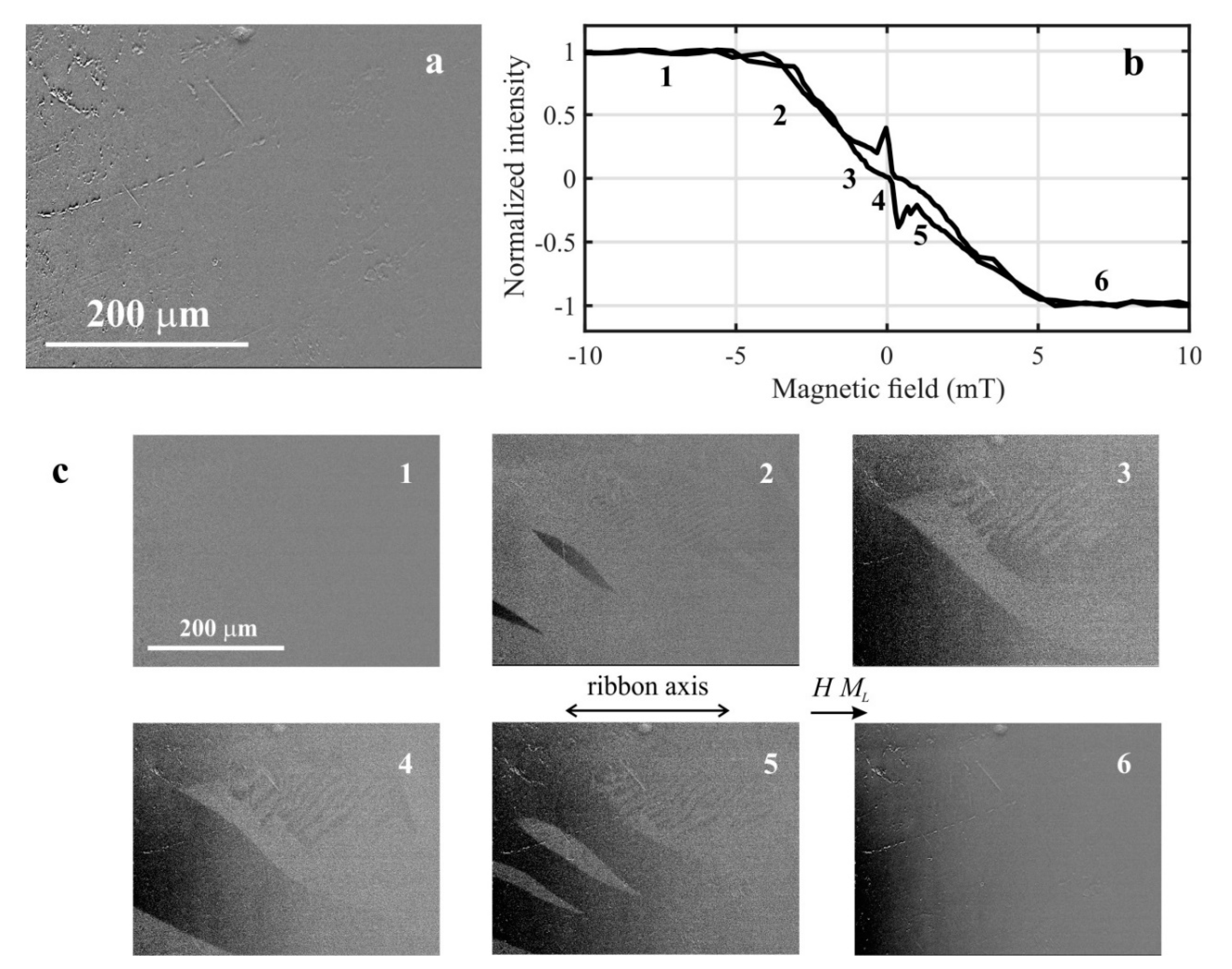

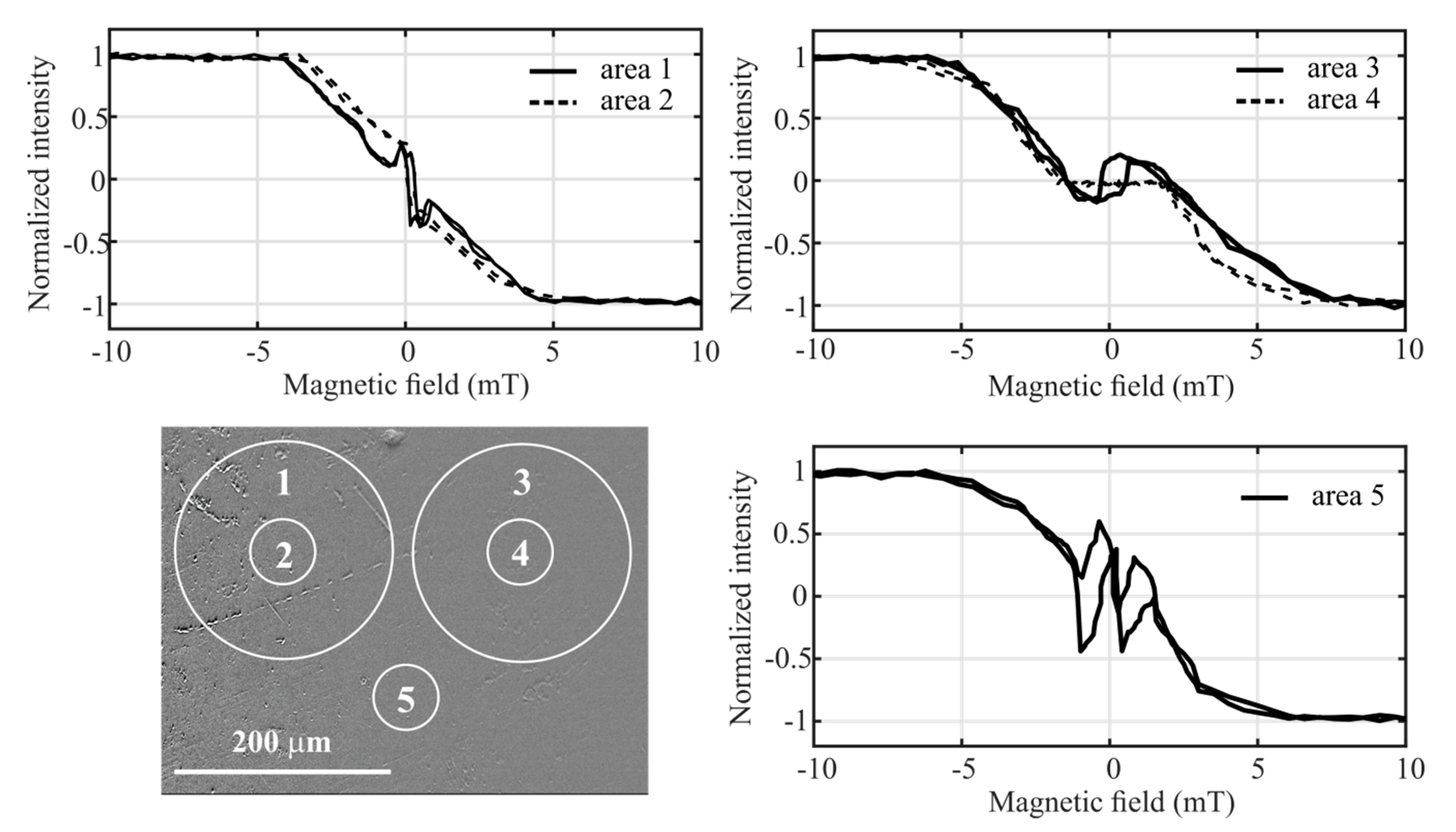

3.2. Surface Magnetic Properties—Amorphous Fe80Si4B16 Ribbon

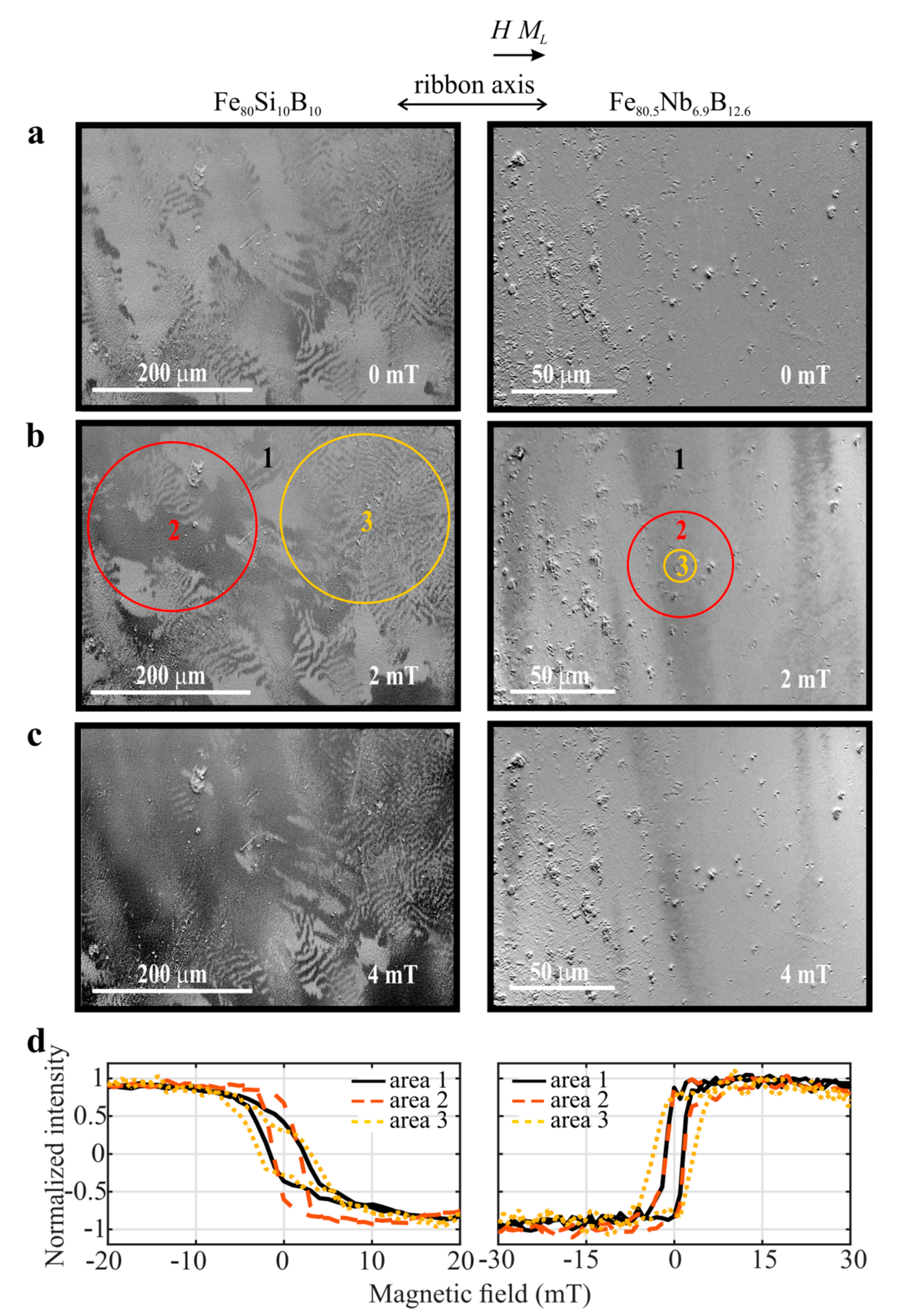

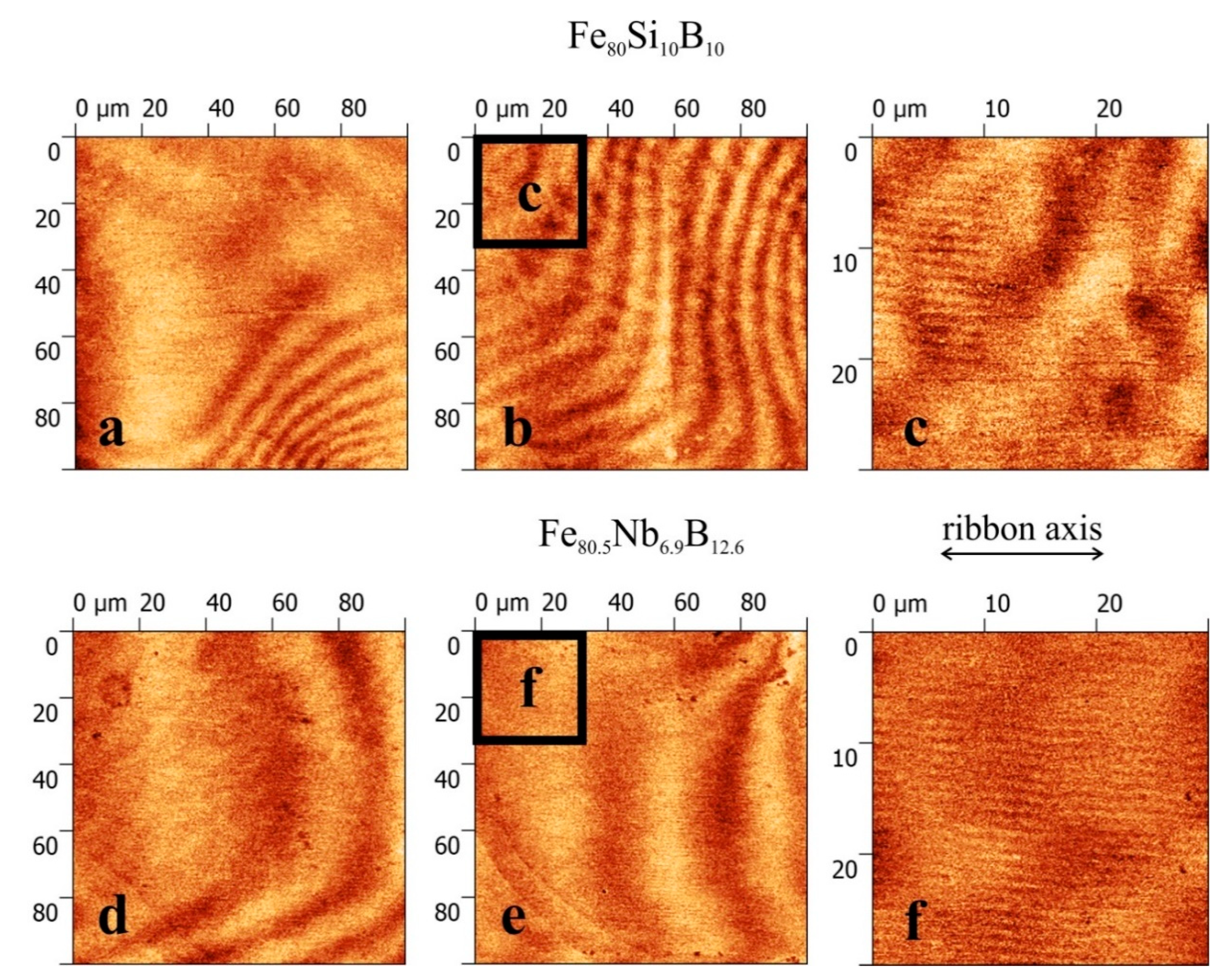

3.3. Surface Magnetic Properties—Surface-Crystalline Fe80Si10B10 and Fe80.5Nb6.9B12.6 Ribbons

4. Conclusions

- (1)

- XRD diffractograms and CEMS spectra confirmed an amorphous structure at the air-surface of the Fe80Si4B16 sample. The other two samples, Fe80Si10B10 and Fe80.5Nb6.9B12.6, are partially crystallized, as documented by small sharp peaks superimposed on a broad amorphous halo in diffractograms and additional component(s) in the Mössbauer spectra. The small surface crystallites are clearly seen in the TEM images;

- (2)

- The best bulk soft magnetic properties are observed in the case of the anamorphous Fe80Si4B16 ribbon. The crystallization of the other two samples is reflected by an increase in the coercivity;

- (3)

- Magneto-optical properties of the amorphous sample show a strong sensitivity to the type of the surface magnetic domains and to the size of the surface area from which the loop is averaged. In both cases, the measured hysteresis loops exhibit different magnetization reversals at lower magnetic fields. It is experimentally demonstrated that contributions of both wide-curved and fingerprint-like magnetic domains can be distinguished on the measured loop due to the magneto-optical material sensitivity;

- (4)

- The prevailing contribution of the irregular wide-curve domains only enlarging with an increasing magnetic field and causing a simple magnetization reversal without significant dependence on the selected area size was observed in the case of the surface-crystalline ribbons. Magnetic force microscopy evidenced that the domain bands are in reality formed by finer structures. In some places, these domains are combined with the amorphous fingerprint domains, slowing down the magnetization reversal, and both contributions are again visible on the measured magneto-optical hysteresis loop.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, F.C.; Liu, T.; Zhang, J.Y.; Shuang, S.; Wang, Q.; Wang, A.D.; Wang, J.G.; Yang, Y. Amorphous–nanocrystalline alloys: Fabrication, properties, and applications. Mater. Today Adv. 2019, 4, 100027. [Google Scholar] [CrossRef]

- Mattson, J.; Theisen, E.; Steen, P. Rapid solidification forming of glassy and crystalline ribbons by planar flow casting. Chem. Eng. Sci. 2018, 192, 1198–1208. [Google Scholar] [CrossRef]

- Cao, C.C.; Wang, Y.G.; Zhu, L.; Meng, Y.; Zhai, X.B.; Dai, Y.D.; Chen, J.K.; Pan, F.M. Local structure, nucleation sites and crystallization behavior and their effects on magnetic properties of Fe81SixB10P8−xCu1 (x = 0~8). Sci. Rep. 2018, 8, 1243. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.; Bai, G.; Yi, S.; Yan, M. Effect of CO gas on surface profile and magnetic properties of Fe–Si–B amorphous ribbons. J. Mater. Sci. Mater. Electron. 2019, 30, 11843. [Google Scholar] [CrossRef]

- Zhang, J.; Wan, F.; Li, Y.; Zheng, J.; Wang, A.; Song, J.; Tian, M.; He, A.; Chang, C. Effect of surface crystallization on magnetic properties of Fe82Cu1Si4B11.5Nb1.5 nanocrystalline alloy ribbons. J. Magn. Magn. Mater. 2017, 438, 126. [Google Scholar] [CrossRef]

- Mansourian, S.; Bakhshayeshi, A.; Taghavi mendi, R. Giant magneto-impedance variation in amorphous CoFeSiB ribbons as a function of tensile stress and frequency. Phys. Lett. A 2020, 384, 126657. [Google Scholar] [CrossRef]

- Gazda, P.; Szewczyk, R. Novel Giant Magnetoimpedance Magnetic Field Sensor. Sensors 2020, 20, 691. [Google Scholar] [CrossRef]

- Malátek, M.; Kraus, L. Off-diagonal GMI sensor with stress-annealed amorphous ribbon. Sens. Actuators A Phys. 2010, 164, 41–45. [Google Scholar] [CrossRef]

- Beato-López, J.J.; Urdániz-Villanueva, J.G.; Pérez-Landazábal, J.I.; Gómez-Polo, C. Giant Stress Impedance Magnetoelastic Sensors Employing Soft Magnetic Amorphous Ribbons. Materials 2020, 13, 2175. [Google Scholar] [CrossRef] [PubMed]

- Hrabovská, K.; Životský, O.; Rojíček, J.; Fusek, M.; Mareš, V.; Jirásková, Y. Surface Magnetostriction of FeCoB Amorphous Ribbons Analyzed Using Magneto-Optical Kerr Microscopy. Materials 2020, 13, 257. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, D.; Briley, C.; Schubert, E.; Schubert, M. Vector magneto-optical generalized ellipsometry for sculptured thin films. Appl. Phys. Lett. 2013, 102, 123109. [Google Scholar] [CrossRef]

- Postava, K.; Sveklo, I.; Tekielak, M.; Mazalski, P.; Maziewski, A.; Stupakiewicz, A.; Urbaniak, M.; Szymanski, B.; Stobiecki, E. Material selective sensitivity of magneto-optical Kerr effect in NiFe/Au/Co/Au periodic multilayers. IEEE Trans. Magn. 2008, 44, 3261. [Google Scholar] [CrossRef]

- Postava, K.; Hamrle, J.; Hamrlová, J.; Hrabovský, D.; Životský, O.; Pištora, J.; Lukáš, D. Depth and material sensitivity in magneto-optic nanostructures. Int. J. Nanotechnol. 2012, 9, 784. [Google Scholar] [CrossRef]

- Chizhik, A.; Vega, V.; Mohamed, A.; Prida, V.M.; Sanchez, T.; Hernando, B.; Ipatov, M.; Zhukova, V.; Zhukov, A.P.; Stupakiewicz, A.; et al. Surface magnetic properties and giant magnetoimpedance effect in Co-based amorphous ribbons. Intermatellics 2017, 86, 15. [Google Scholar] [CrossRef]

- Životský, O.; Hendrych, A.; Klimša, L.; Jirásková, Y.; Buršík, J.; Gómez, J.A.M.; Janičkovič, D. Surface microstructure and magnetic behavior in FeSiB amorphous ribbons from magneto-optical Kerr effect. J. Magn. Magn. Mater. 2012, 324, 569. [Google Scholar] [CrossRef]

- Životský, O.; Postava, K.; Kraus, L.; Jirásková, Y.; Juraszek, J.; Teillet, J.; Barčová, K.; Švec, P.; Janičkovič, D.; Pištora, J. Surface and bulk magnetic properties of as-quenched FeNbB ribbons. J. Magn. Magn. Mater. 2008, 320, 1535. [Google Scholar] [CrossRef]

- Kraus, L.; Životský, O.; Postava, K.; Švec, P.; Janičkovič, D. Exchange bias in surface-crystalline Fe-Nb-B ribbons. IEEE Trans. Magn. 2008, 44, 3875–3878. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A.; Makino, A.; Masumoto, T. Soft and hard magnetic properties of nanocrystalline Fe-M-B (M = Zr, Nd) base alloys containing intergranular amorphous phase. Sci. Rep. Ritu A 1996, 42, 143–156. [Google Scholar]

- Hirotsu, A. High resolution electron microscopy of medium-range order in amorphous alloys. Mat. Sci. Eng. A 1994, 180, 97–101. [Google Scholar] [CrossRef]

- Aykol, M.; Mekhrabov, A.O.; Akdeniz, M.V. Nano-scale phase separation in amorphous Fe–B alloys: Atomic and cluster ordering. Acta Mater. 2009, 57, 171–181. [Google Scholar] [CrossRef]

| Ribbon | Js (T) | Jr (T) | Hc (A/m) |

|---|---|---|---|

| Fe80Si4B16 | 2.32 | 0.02 | 14.97 |

| Fe80Si10B10 | 1.70 | 0.03 | 49.97 |

| Fe80.5Nb6.9B12.6 | 0.66 | 0.01 | 21.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Životský, O.; Markov, D.; Hrabovská, K.; Buršík, J.; Jirásková, Y. Analysis of Magneto-Optical Hysteresis Loops of Amorphous and Surface-Crystalline Fe-Based Ribbons. Materials 2021, 14, 141. https://doi.org/10.3390/ma14010141

Životský O, Markov D, Hrabovská K, Buršík J, Jirásková Y. Analysis of Magneto-Optical Hysteresis Loops of Amorphous and Surface-Crystalline Fe-Based Ribbons. Materials. 2021; 14(1):141. https://doi.org/10.3390/ma14010141

Chicago/Turabian StyleŽivotský, Ondřej, Dmitry Markov, Kamila Hrabovská, Jiří Buršík, and Yvonna Jirásková. 2021. "Analysis of Magneto-Optical Hysteresis Loops of Amorphous and Surface-Crystalline Fe-Based Ribbons" Materials 14, no. 1: 141. https://doi.org/10.3390/ma14010141

APA StyleŽivotský, O., Markov, D., Hrabovská, K., Buršík, J., & Jirásková, Y. (2021). Analysis of Magneto-Optical Hysteresis Loops of Amorphous and Surface-Crystalline Fe-Based Ribbons. Materials, 14(1), 141. https://doi.org/10.3390/ma14010141