Multi-Response Optimization of Ultrafine Cement-Based Slurry Using the Taguchi-Grey Relational Analysis Method

Abstract

1. Introduction

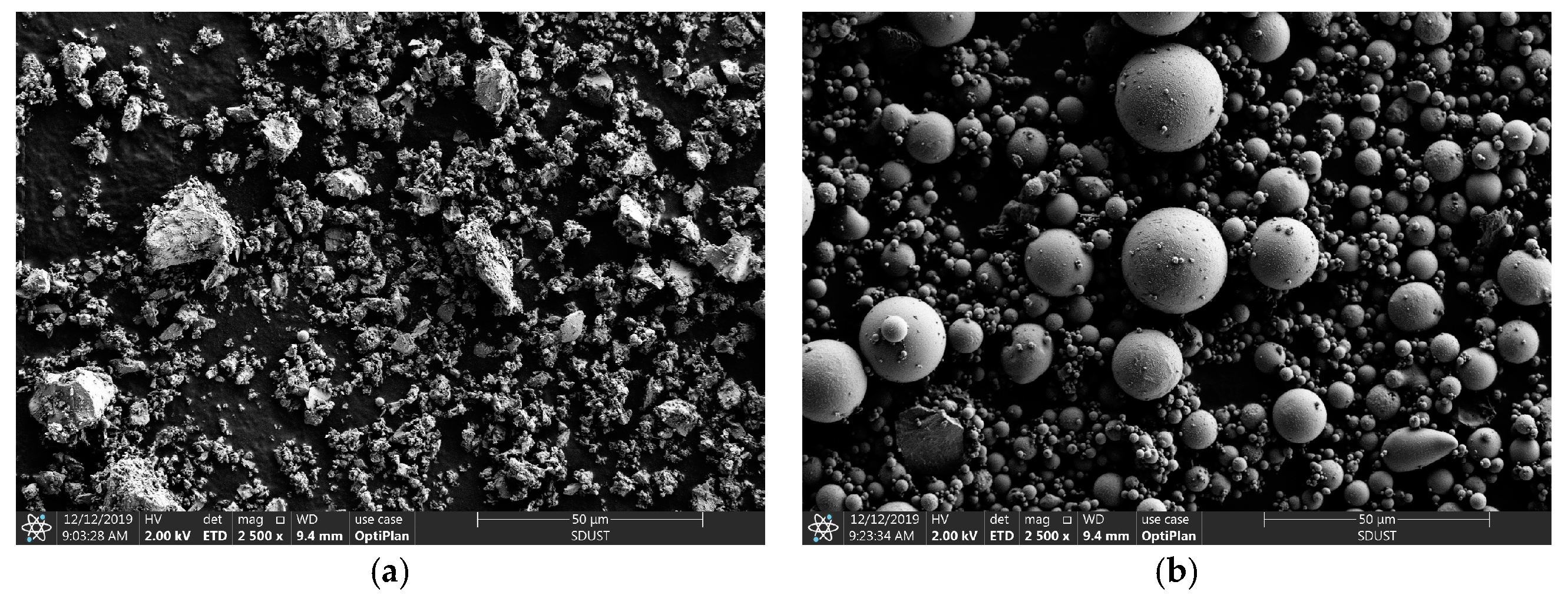

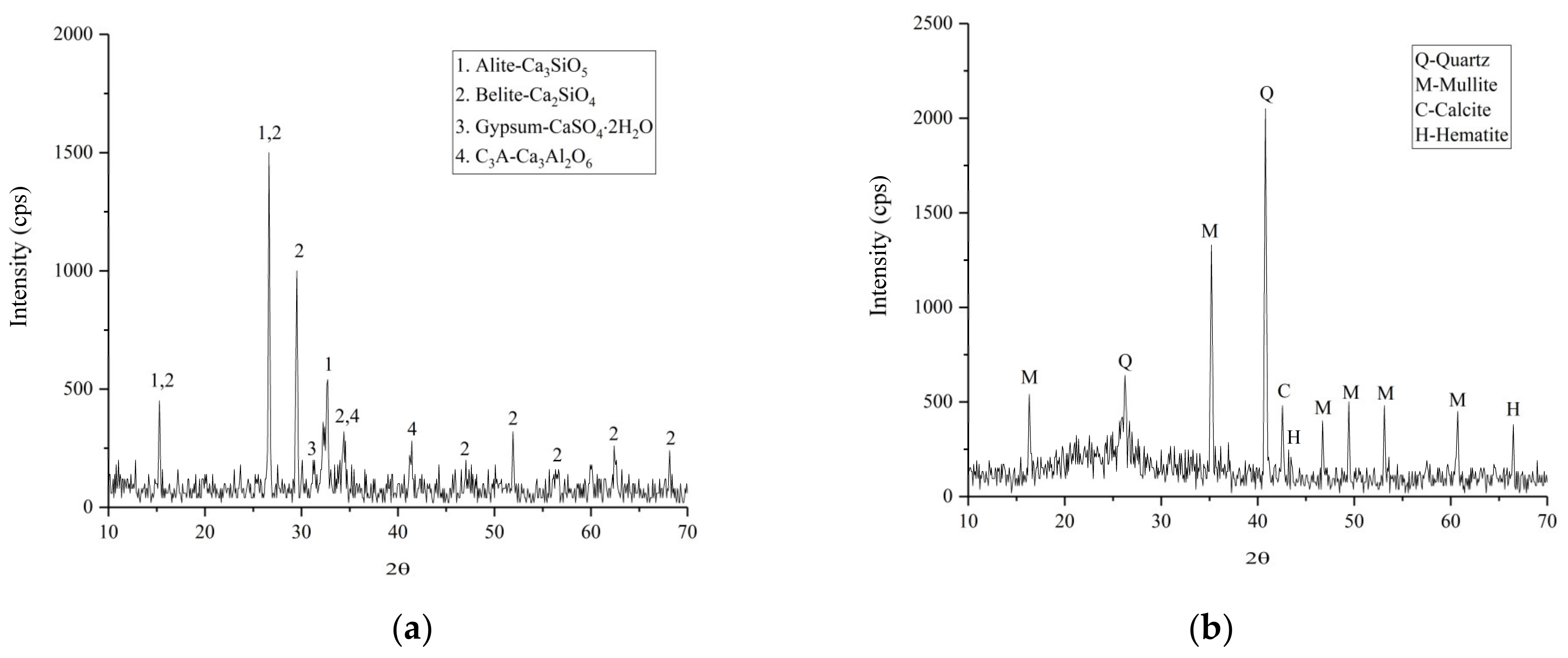

2. Materials

3. Experimental Methods

3.1. Orthogonal Arrays and Taguchi-Grey Relational Analysis Method

- Step 1: Select the orthogonal test parameters and their corresponding levels.

- Step 2: Select the suitable orthogonal table based on the Taguchi method, and arrange the orthogonal test parameters and their corresponding levels.

- Step 3: Carry out the tests on UC-based slurries according to the Taguchi experimental design method.

- Step 4: Calculate the S/N ratio of the orthogonal test results using the corresponding equation given by Equations (1)−(3) and analyze the variance in the S/N ratio.

- Step 5: Normalize the S/N ratios of each response using Equations (4)–(6):

- Step 6: Calculate the mass loss function using the following equation:

- Step 7: Calculate the grey relational coefficient (GRC) with the following equation:

- Step 8: Calculate the grey relational grade (GRG) with the following equation:

- yij is the S/N ratio value of ith experiment for the jth response;

- Zij is the ith normalized S/N ratio value for the jth response;

- Δij is the difference between the optimum value of the normalized S/N ratio and the ith normalized S/N ratio value for the jth response;

- λ is the identification coefficient that ranges from 0 to 1, and λ is generally set as 0.5;

- φj is the normalized nonnegative coefficient assigned to the jth response, and the sum of all φj is 1. All the responses (characteristics) considered in this research are equally weighted.

3.2. Experimental Methods of the Specimens

4. Results and Discussion

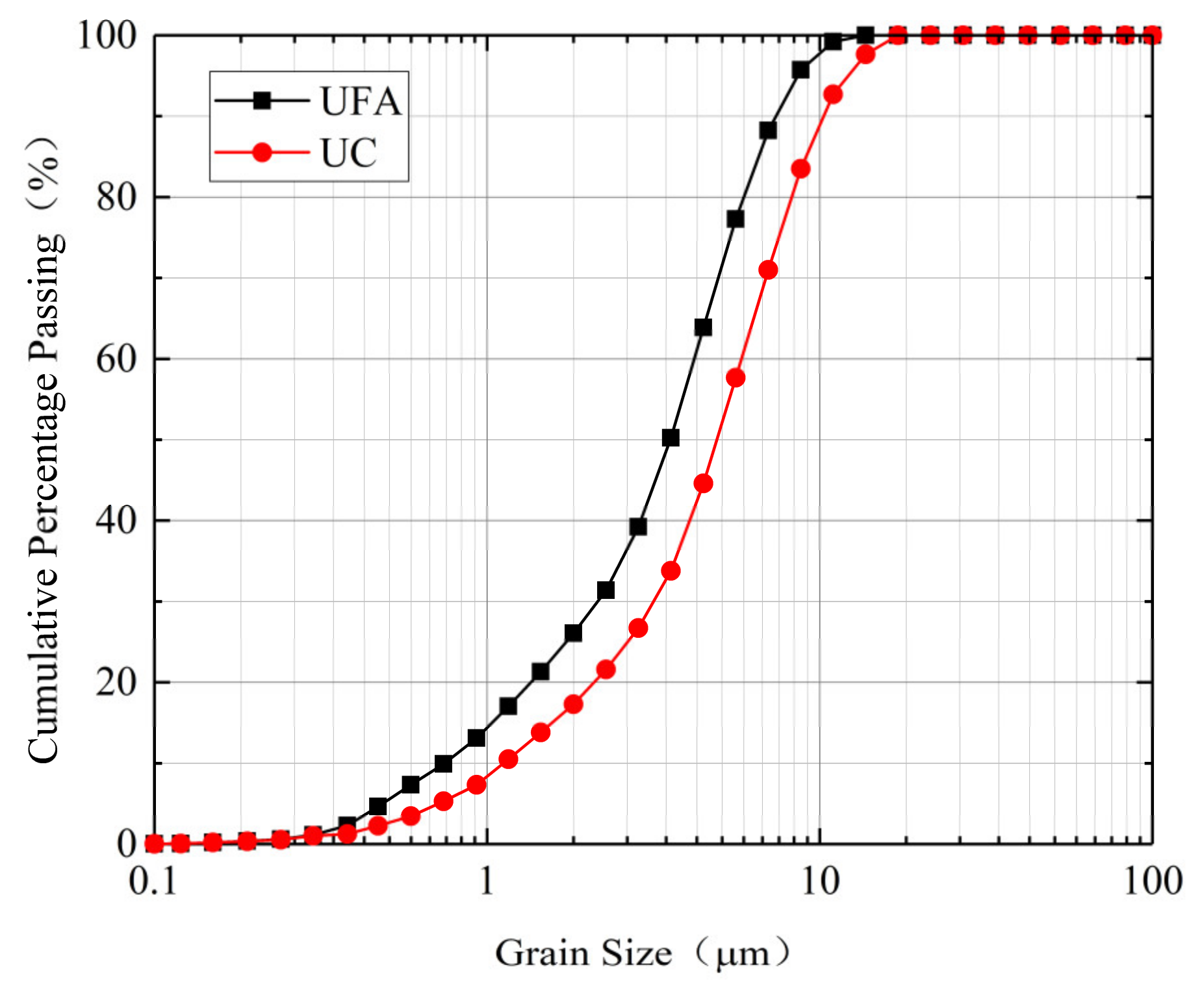

4.1. Grain Size Analysis

4.2. Analysis of the Orthogonal Test Results

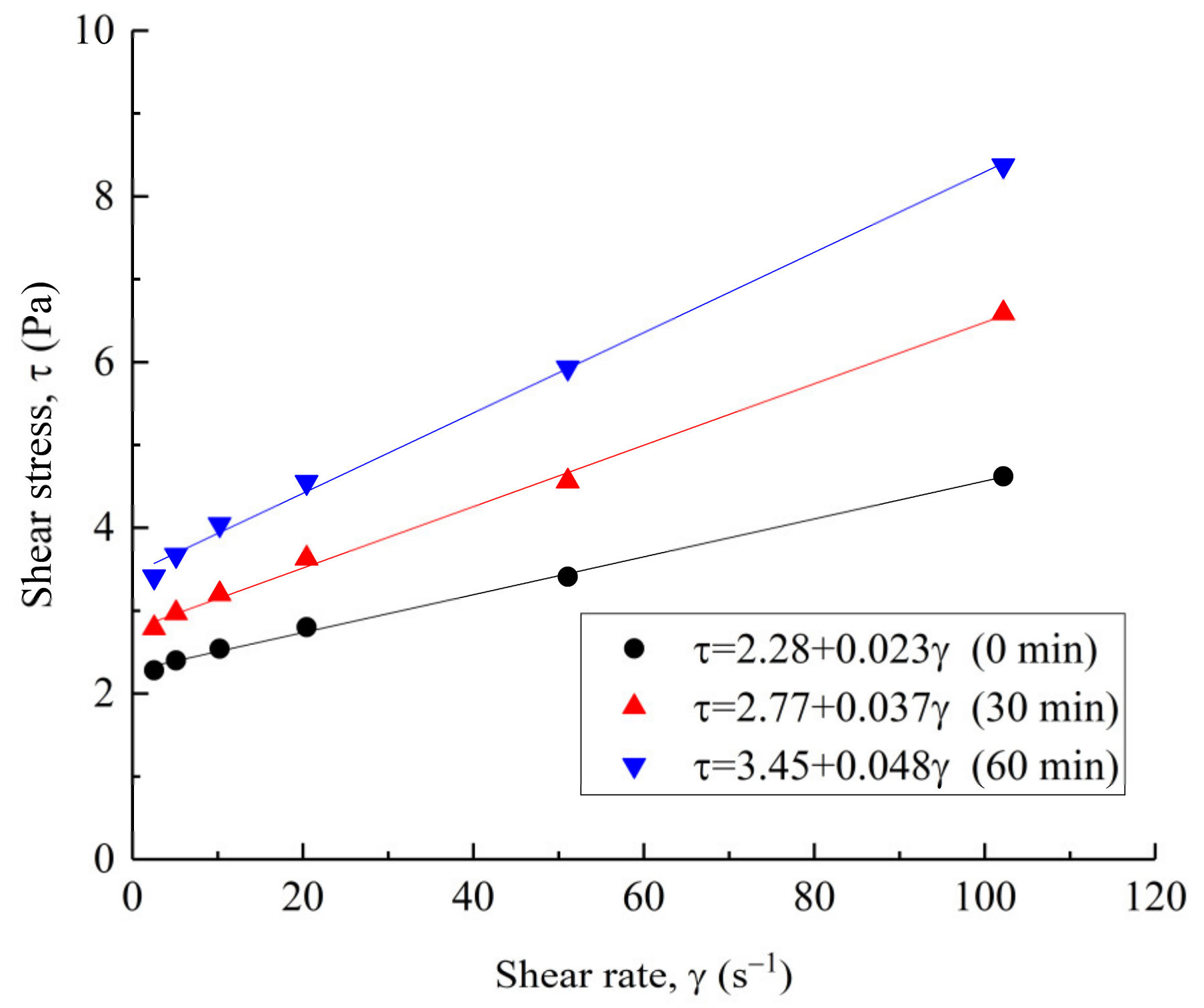

4.2.1. Rheological Model of the UC-Based Slurry

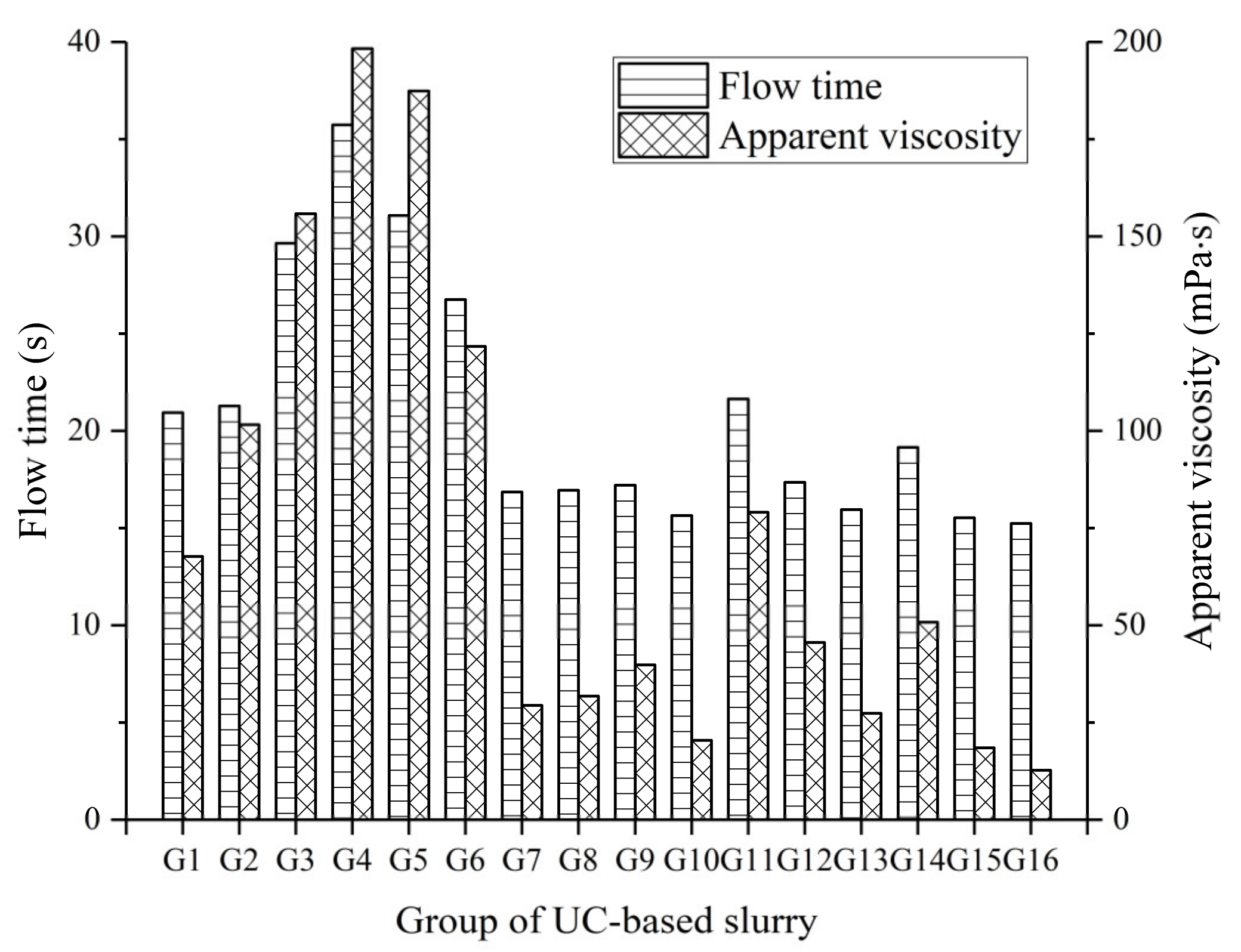

4.2.2. Flow Time and Apparent Viscosity of the UC-Based Slurry

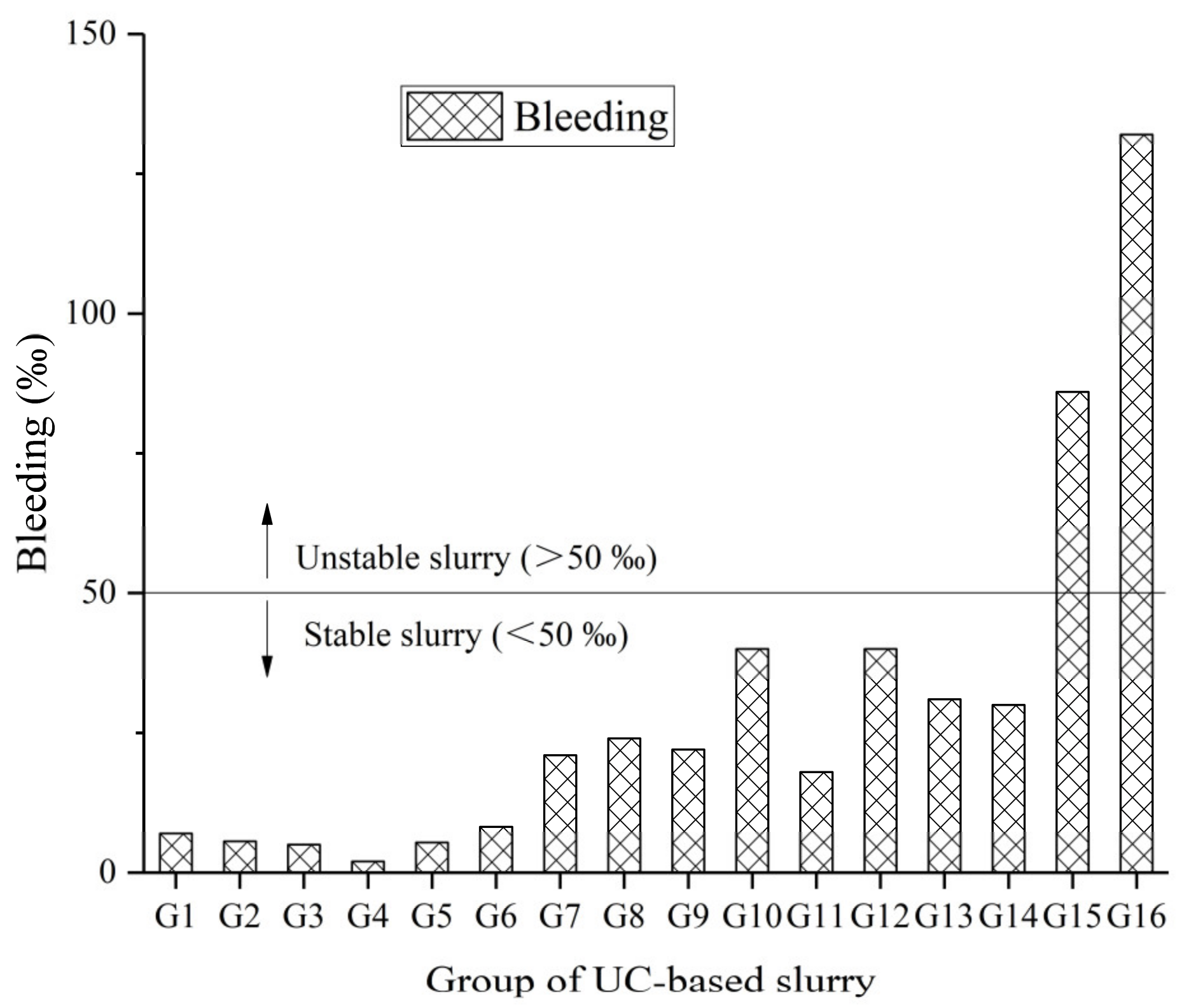

4.2.3. Bleeding of the UC-Based Slurry

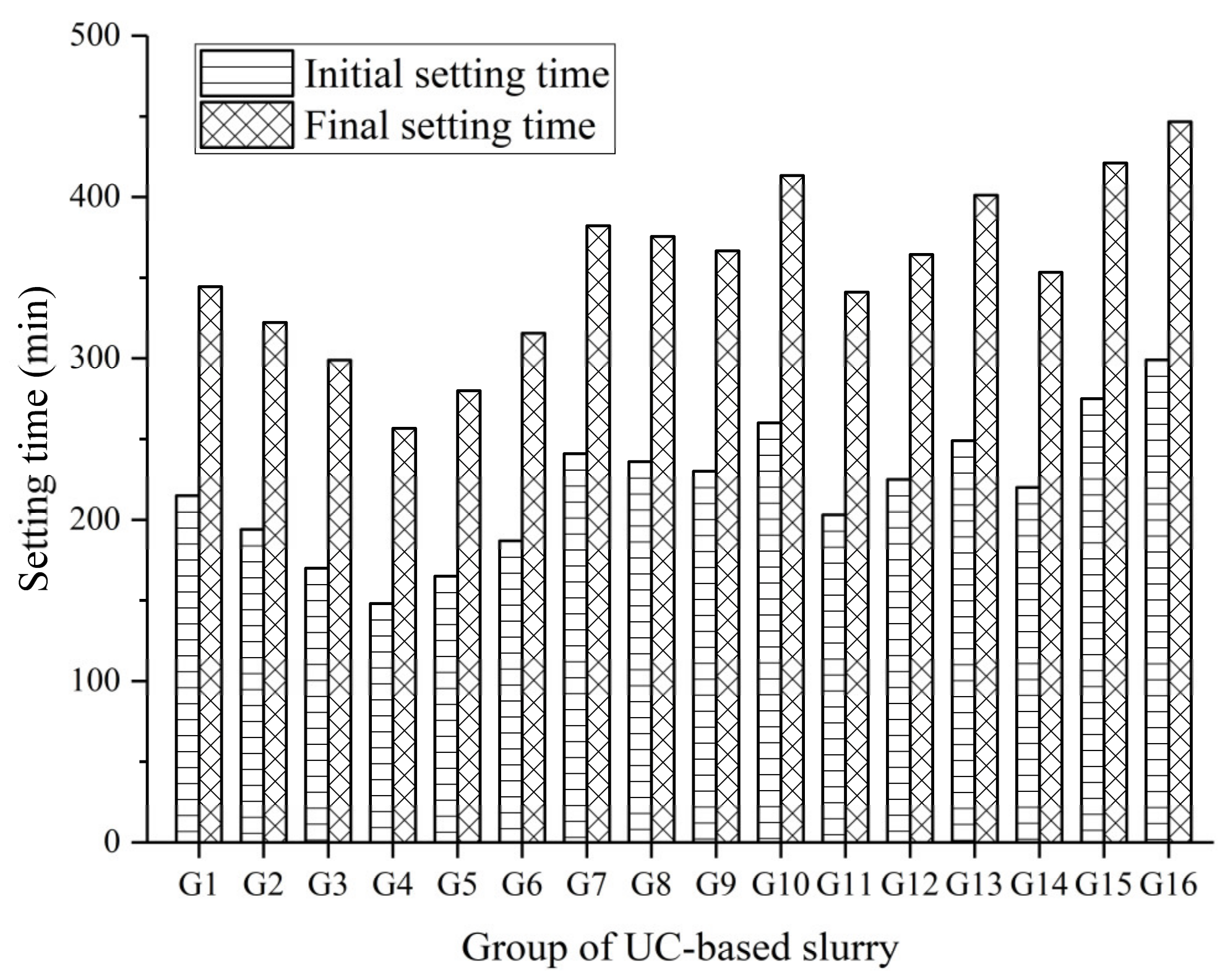

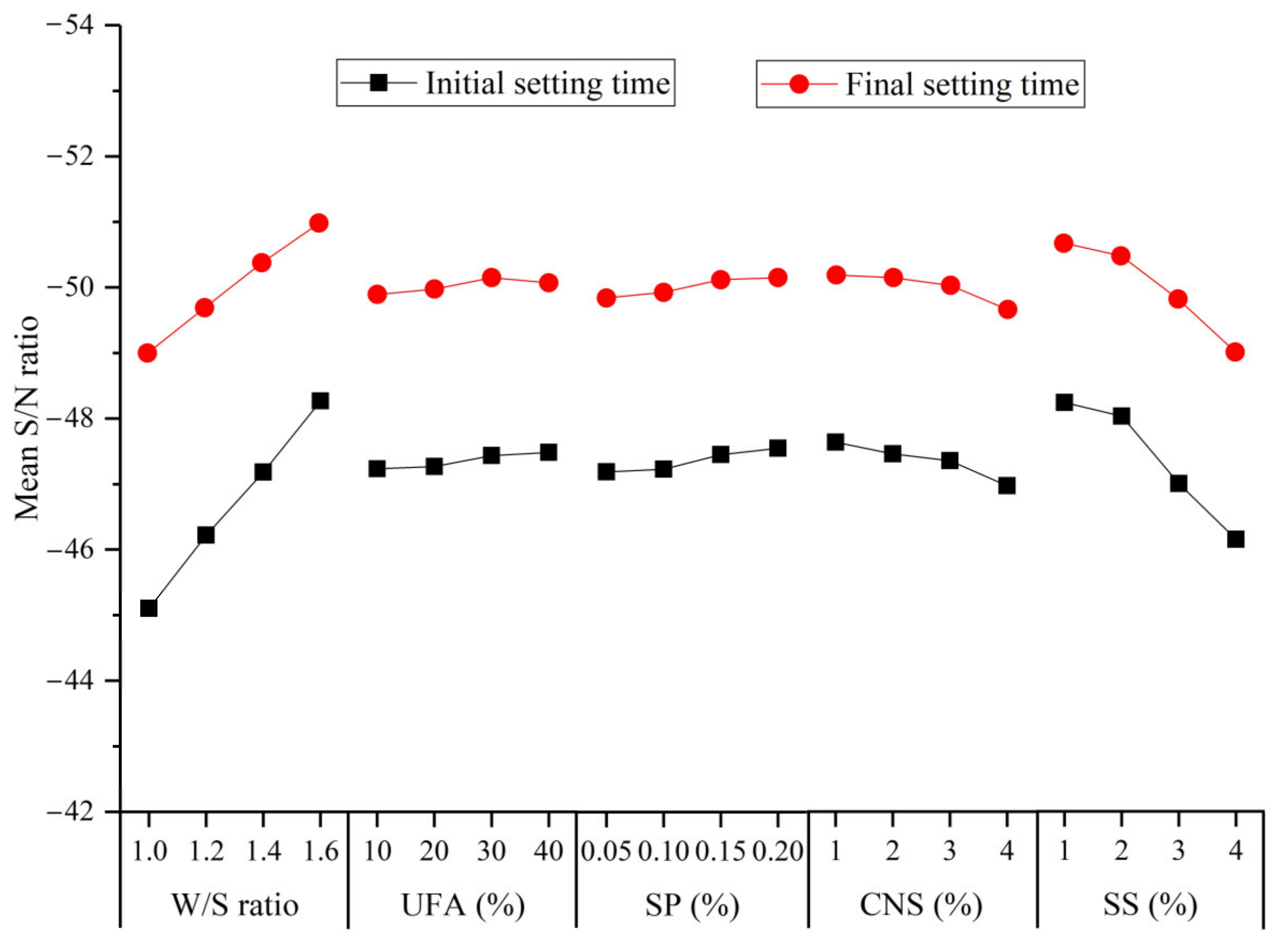

4.2.4. Setting Time of the UC-Based Slurry

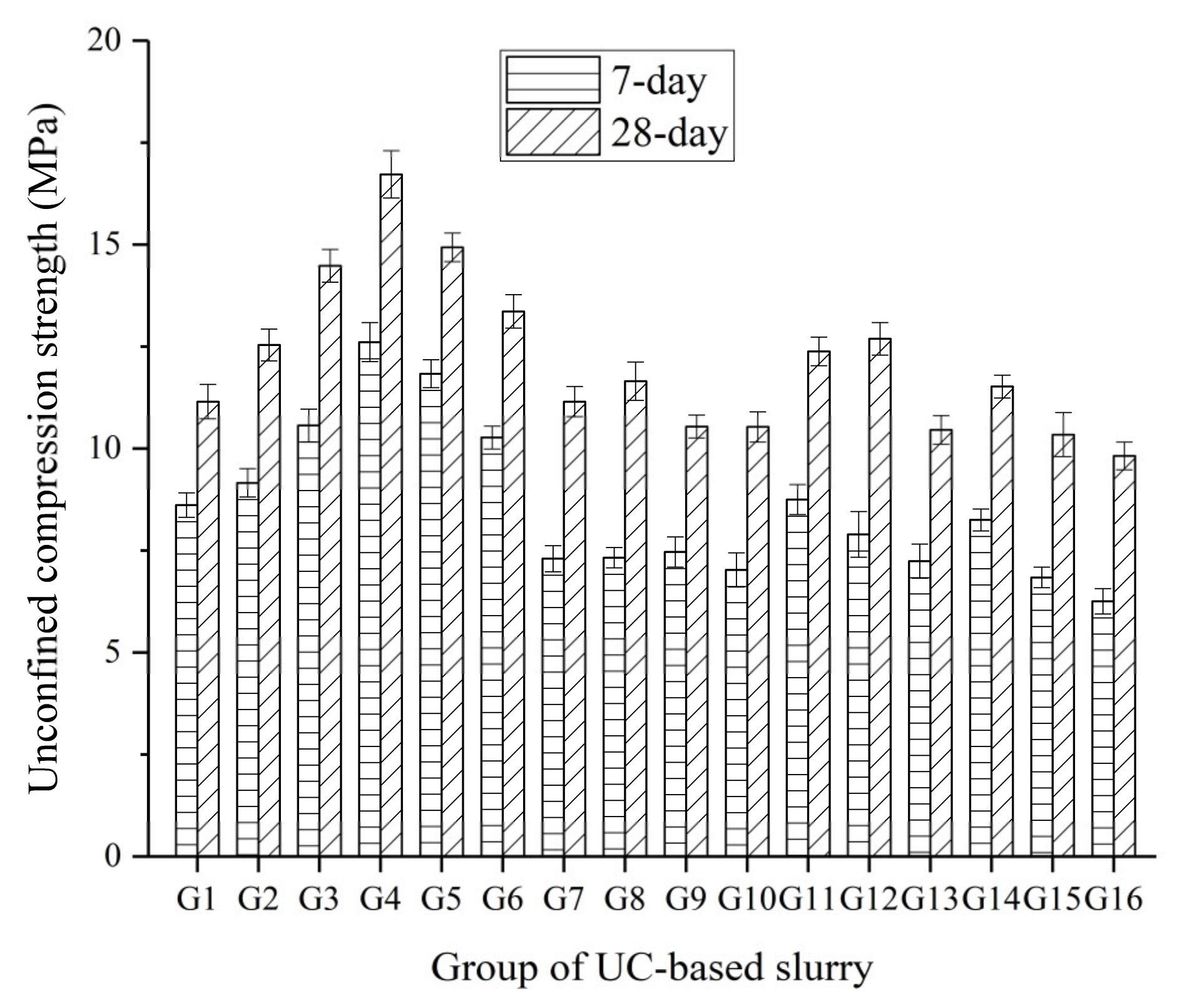

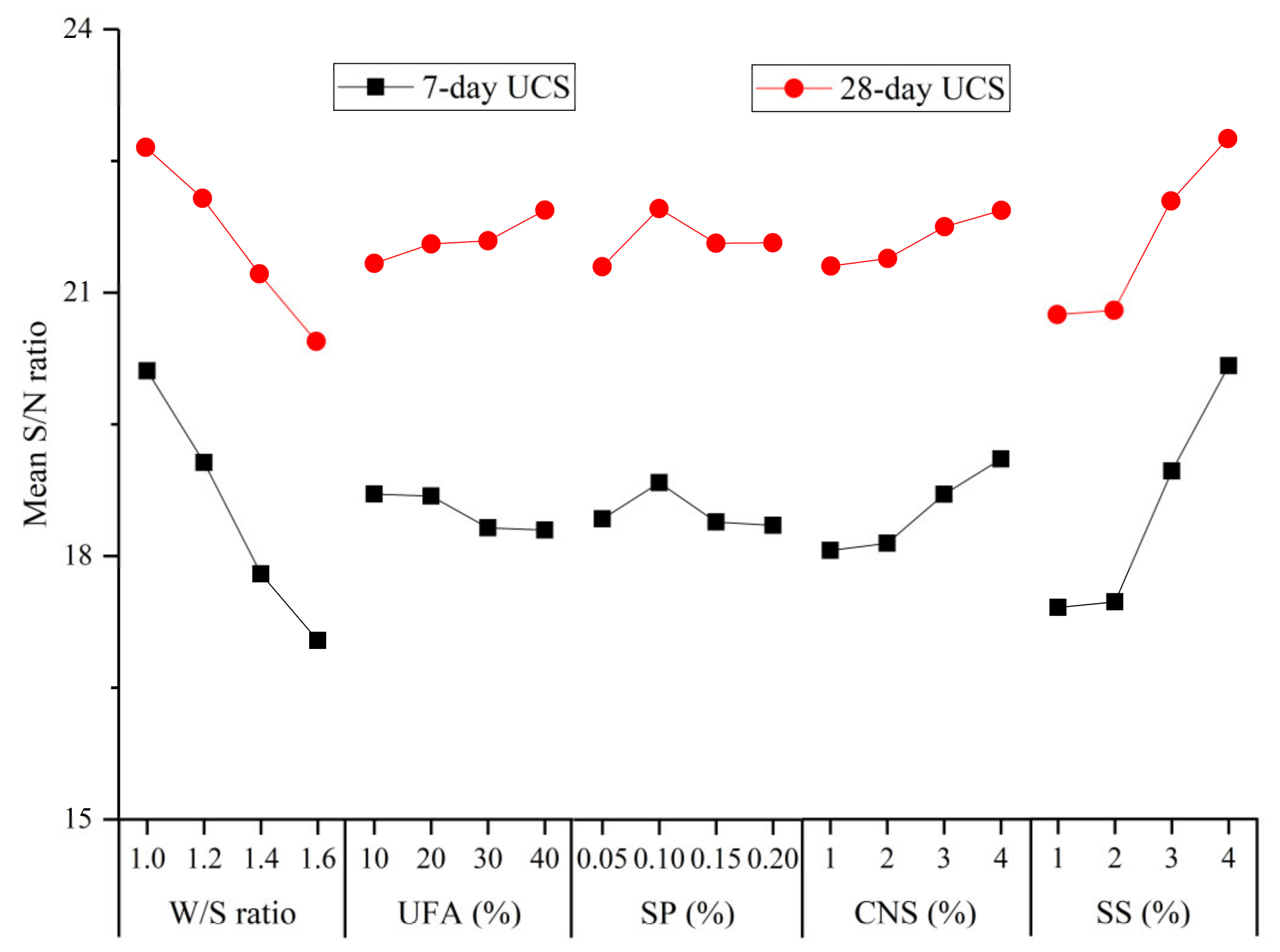

4.2.5. Unconfined Compression Strength of the UC-Based Slurry

4.2.6. Multi-Response Optimization of the Experimental Results Using the Taguchi Based Grey Relational Analysis Method

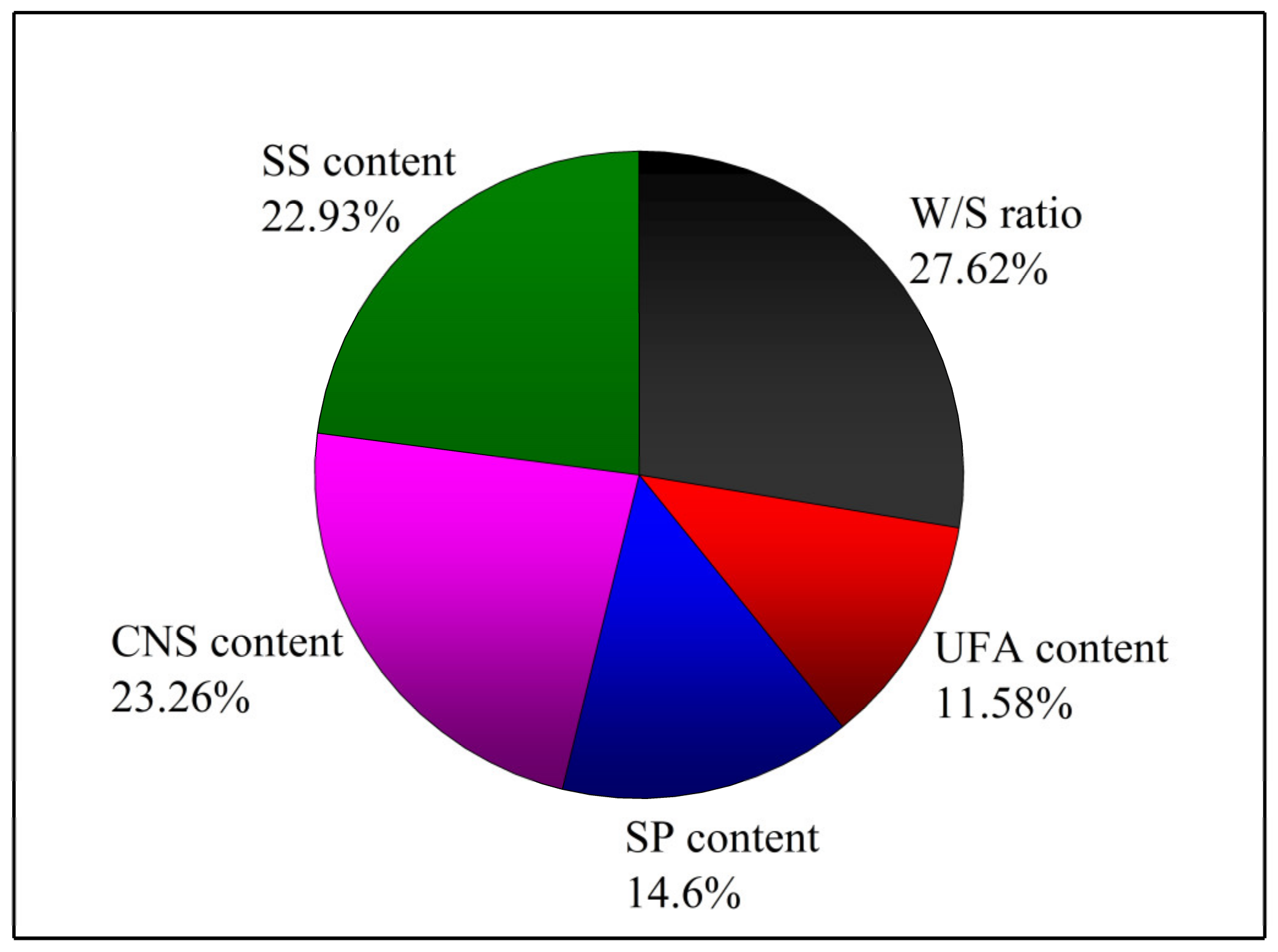

4.2.7. Analysis of Variance (ANOVA)

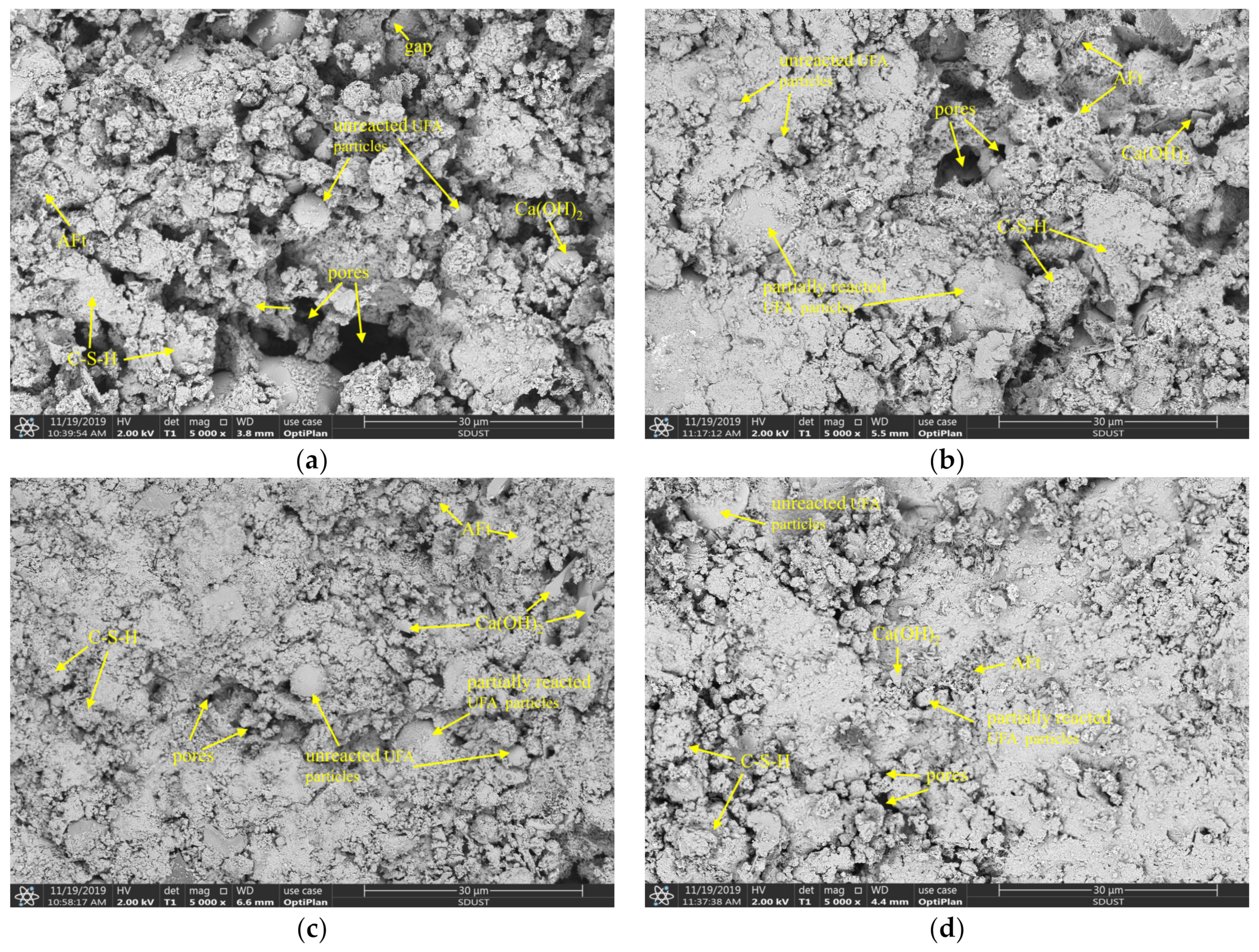

4.2.8. Microstructure Analysis of the Hydration Products by SEM

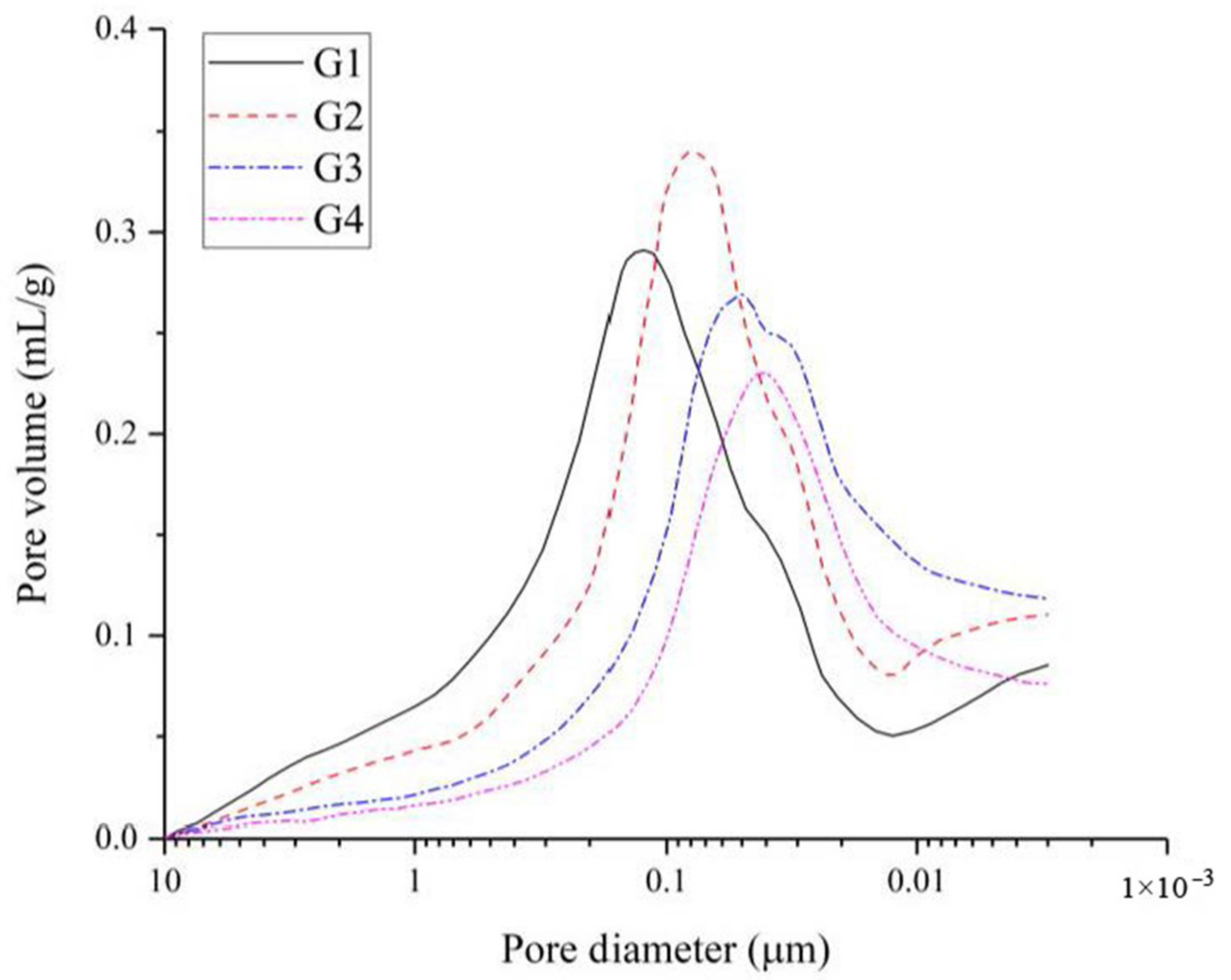

4.2.9. MIP Analysis of the Pore Structure of the Hardened UC-Based Slurry

5. Conclusions

- (1)

- The orthogonal test results showed that the degree of influence on the properties of UC-based slurries was as follows: W/S ratio > CNS content > SS content > SP content > UFA content.

- (2)

- For the rheological curves of UC-based slurry, prepared from 0 min to 60 min, can be described as Bingham fluid due to the correlation coefficients are 0.99 in all cases indicating a well fitting of Bingham model to test data.

- (3)

- The addition of CNS and SS showed positive effects on bleeding, setting time and compressive strength of the UC-based slurries, while reducing the fluidity of fresh slurry. However, the detrimental effects of CNS and SS on the fluidity of slurry can be negated by adding UFA and SP.

- (4)

- The SEM test results showed that the microstructure improvement of the hardened slurry can be attributed to the addition of CNS and SS. Moreover, many hydration products covered the surface of the UFA spherical particles, which indicates that the pozzolanic activity of UFA was stimulated by the addition of CNS and SS.

- (5)

- The MIP test results indicated that the pores of the hardened slurry were refined due to the addition of CNS and SS. For the slurry with CNS addition, the volume of harmful and multi-harm pores was significantly reduced. The decrease in total porosity is due to the physical filling effect of the fly ash and the acceleration of the cement’s hydration process.

- (6)

- The results of the Taguchi-Grey relational analysis showed that the optimal mix proportion of the UC-based slurry was G4: W/S ratio of 1.0, 40% UFA, 0.2% SP, 4% CNS and 4% SS.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, C.; Li, X.; Li, S.D.; Zheng, B. Failure behavior of granite affected by confinement and water pressure and its influence on the seepage behavior by laboratory experiments. Materials 2017, 10, 798. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.X.; Sun, D.K.; Jing, H.W. Morphological features of shear-formed fractures developed in a rock bridge. Eng. Geol. 2020, 278, 105833. [Google Scholar] [CrossRef]

- Gong, Q.M.; Zhao, Y.; Zhou, J.H.; Zhou, S.H. Uplift resistance and progressive failure mechanisms of metro shield tunnel in soft clay. Tunn. Undergr. Space Technol. 2018, 82, 222–234. [Google Scholar] [CrossRef]

- Wang, Y.F.; Liu, S.H.; Xuan, D.X.; Guan, X.M.; Zhang, H.B. Improving the mechanical properties of sulfoaluminate cement-based grouting material by incorporating limestone powder for a double fluid system. Materials 2020, 13, 4854. [Google Scholar] [CrossRef]

- Mirza, J.; Saleh, K.; Langevin, M.A.; Mirza, S.; Bhutta, M.A.R.; Tahir, M.M. Properties of microfine cement grouts at 4 °C, 10 °C and 20 °C. Constr. Build. Mater. 2013, 47, 1145–1153. [Google Scholar] [CrossRef]

- Mozumder, R.A.; Laskar, A.I.; Hussain, M. Penetrability prediction of microfine cement grout in granular soil using Artificial Intelligence techniques. Tunn. Undergr. Space Technol. 2018, 72, 131–144. [Google Scholar] [CrossRef]

- Li, S.C.; Sha, F.; Liu, R.T.; Li, Z.F.; Zhang, Q.S. Investigation of viscous behaviour and strength of microfine-cement-based grout mixed with microfine fly ash and superplasticizer. Adv. Cem. Res. 2017, 29, 206–215. [Google Scholar] [CrossRef]

- Markou, I.N.; Christodoulou, D.N.; Papadopoulos, B.K. Penetrability of microfine cement grouts: Experimental investigation and fuzzy regression modeling. Can. Geotech. J. 2015, 52, 868–882. [Google Scholar] [CrossRef]

- Menendez, E.; Argiz, C.; Sanjuan, M.A. Chloride induced reinforcement corrosion in mortars containing coal bottom ash and coal fly ash. Materials 2019, 12, 1933. [Google Scholar] [CrossRef]

- Park, J.; Park, C.; Joh, S.; Lee, H. Effect of curing condition on resistance to chloride ingress in concrete using ground granulated blast furnace slag. Materials 2019, 12, 3233. [Google Scholar] [CrossRef]

- Shafigh, P.; Nomeli, M.A.; Alengaram, U.J.; Bin Mahmud, H.; Jumaat, M.Z. Engineering properties of lightweight aggregate concrete containing limestone powder and high volume fly ash. J. Clean. Prod. 2016, 135, 148–157. [Google Scholar] [CrossRef]

- Zhang, M.H.; Islam, J. Use of nano-silica to reduce setting time and increase early strength of concretes with high volumes of fly ash or slag. Constr. Build. Mater. 2012, 29, 573–580. [Google Scholar] [CrossRef]

- Peng, Y.M.; Ma, K.L.; Long, G.C.; Xie, Y.J. Influence of nano-SiO2, nano-CaCO3 and nano-Al2O3 on rheological properties of cement-fly ash paste. Materials 2019, 12, 2598. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.Y.; Chen, L.; Liu, A.H.; Wang, X.R. Effect of nano-CaCO3 on properties of cement paste. Energy Procedia 2012, 16, 991–996. [Google Scholar] [CrossRef]

- Abd Elrahman, M.; Chung, S.Y.; Sikora, P.; Rucinska, T.; Stephan, D. Influence of nanosilica on mechanical properties, sorptivity, and microstructure of lightweight concrete. Materials 2019, 12, 3078. [Google Scholar] [CrossRef]

- Sato, T.; Beaudoin, J.J. Effect of nano-CaCO3 on hydration of cement containing supplementary cementitious materials. Adv. Cem. Res. 2011, 23, 33–43. [Google Scholar] [CrossRef]

- Seifan, M.; Mendoza, S.; Berenjian, A. Mechanical properties and durability performance of fly ash based mortar containing nano- and micro-silica additives. Constr. Build. Mater. 2020, 252, 119121. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M.; Sarker, P.K. A study on the effect of nano silica on compressive strength of high volume fly ash mortars and concretes. Mater. Design 2014, 60, 433–442. [Google Scholar] [CrossRef]

- Xi, B.; Zhou, Y.W.; Yu, K.Q.; Hu, B.; Huang, X.X.; Sui, L.L.; Xing, F. Use of nano-SiO2 to develop a high performance green lightweight engineered cementitious composites containing fly ash cenospheres. J. Clean. Prod. 2020, 262, 121274. [Google Scholar] [CrossRef]

- Zhang, S.; Qiao, W.G.; Chen, P.C.; Xi, K. Rheological and mechanical properties of microfine-cement-based grouts mixed with microfine fly ash, colloidal nanosilica and superplasticizer. Constr. Build. Mater. 2019, 212, 10–18. [Google Scholar] [CrossRef]

- Shi, C.J.; Day, R.L. Acceleration of the reactivity of fly ash by chemical activation. Cem. Concr. Res. 1995, 25, 15–21. [Google Scholar] [CrossRef]

- Bui, P.T.; Ogawa, Y.; Kawai, K. Effect of sodium sulfate activator on compressive strength and hydration of fly-ash cement pastes. J. Mater. Civ. Eng. 2020, 32, 04020117. [Google Scholar] [CrossRef]

- Lymperopoulou, T.; Georgiou, P.; Tsakanika, L.A.; Hatzilyberis, K.; Ochsenkuehn-Petropoulou, M. Engineering properties of engineered cementitious composite and multi-response optimization using PCA-based Taguchi method. Materials 2019, 12, 2402. [Google Scholar]

- Kelestemur, O.; Arıcı, E. Analysis of some engineering properties of mortars containing steel scale using Taguchi based grey method. J. Build. Eng. 2020, 29, 101015. [Google Scholar] [CrossRef]

- Guria, C.; Kumar, R.; Mishra, P. Rheological analysis of drilling fluid using Marsh Funnel. J. Petrol. Sci. Eng. 2013, 105, 62–69. [Google Scholar] [CrossRef]

- Le, H.T.; Ludwig, H.M.; Parkinson, S. The influence of bleeding of cement suspensions on their rheological properties. Materials 2020, 13, 1609. [Google Scholar]

- Miltiadou-Fezans, A.; Tassios, T.P. Fluidity of hydraulic grouts for masonry strengthening. Mater. Struct. 2012, 45, 1817–1828. [Google Scholar] [CrossRef]

- Xu, S.H.; Xing, L.L.; Wang, G.Q.; Han, Q. Experimental research on grouting of superfine cement slurry in micro-fissured rock body. J. Saf. Sci. Technol. 2014, 10, 96–102. [Google Scholar]

- He, S.; Luo, P.P.; Chen, Z. Discussion on the groutability of fissured rock mass. Mine. Construct. Technol. 2005, 26, 33–35, 39. [Google Scholar]

- Garcia-Taengua, E.; Sonebi, M.; Hossain, K.M.A.; Lachemi, M.; Khatib, J. Effects of the addition of nanosilica on the rheology, hydration and development of the compressive strength of cement mortars. Compos. B Eng. 2015, 81, 120–129. [Google Scholar] [CrossRef]

- Long, W.J.; Tao, J.L.; Lin, C.; Gu, Y.C.; Mei, L.; Duan, H.B.; Xing, F. Rheology and buildability of sustainable cement-based composites containing micro-crystalline cellulose for 3D-printing. J. Clean. Prod. 2019, 239, 118054. [Google Scholar] [CrossRef]

- Pantazopoulos, I.A.; Markou, I.N.; Christodoulou, D.N.; Droudakis, A.I.; Atmatzidis, D.K.; Antiohos, S.K.; Chaniotakis, E. Development of microfine cement grouts by pulverizing ordinary cements. Cem. Concr. Compos. 2012, 34, 593–603. [Google Scholar] [CrossRef]

- Hou, P.K.; Kawashima, S.; Wang, K.J.; Corr, D.J.; Qian, J.S.; Shah, S.P. Effects of colloidal nanosilica on rheological and mechanical properties of fly ash-cement mortar. Cem. Concr. Compos. 2013, 35, 12–22. [Google Scholar] [CrossRef]

- Roshani, A.; Fall, M. Flow ability of cemented pastefill material that contains nano-silica particles. Powder. Technol. 2020, 373, 289–300. [Google Scholar] [CrossRef]

- Jiang, H.Q.; Fall, M.; Yilmaz, E.; Li, Y.H.; Yang, L. Effect of mineral admixtures on flow properties of fresh cemented paste backfill: Assessment of time dependency and thixotropy. Powder Technol. 2020, 372, 258–266. [Google Scholar] [CrossRef]

- Dejaeghere, I.; Sonebi, M.; De Schutter, G. Influence of nano-clay on rheology, fresh properties, heat of hydration and strength of cement-based mortars. Constr. Build. Mater. 2019, 222, 73–85. [Google Scholar] [CrossRef]

- Stephanie, P.; Danielle, P.; Gerard, B. Rheological behavior and setting time of microfine cement-based grouts. ACI Mater. J. 2000, 97, 472–478. [Google Scholar]

- Mei, J.P.; Tan, H.B.; Li, H.N.; Ma, B.G.; Liu, X.H.; Jiang, W.B.; Zhang, T.; Li, X. Effect of sodium sulfate and nano-SiO2 on hydration and microstructure of cementitious materials containing high volume fly ash under steam curing. Constr. Build. Mater. 2018, 163, 812–825. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.; Wang, K.; Wu, H.F.; Cui, B.Q. Effects of accelerator-water reducer admixture on performance of cemented paste backfill. Constr. Build. Mater. 2020, 242, 118187. [Google Scholar] [CrossRef]

- Rivera, R.A.; Sanjuan, M.A.; Martin, D.A. Granulated blast-furnace slag and coal fly ash ternary Portland cements optimization. Sustainability 2020, 12, 5783. [Google Scholar] [CrossRef]

- Hou, P.K.; Wang, K.J.; Qian, J.S.; Kawashima, S.; Kong, D.Y.; Shah, S.P. Effects of colloidal nano-SiO2 on fly ash hydration. Cem. Concr. Compos. 2012, 34, 1095–1103. [Google Scholar] [CrossRef]

- Wu, Z.W. An approach to the recent trends of concrete science and technology. J. Chin. Ceram. Soc. 1979, 7, 262–270. [Google Scholar]

| Chemical Composition | UC (wt%) | UFA (wt%) |

|---|---|---|

| CaO | 62.51 | 3.98 |

| SiO2 | 21.53 | 40.55 |

| Al2O3 | 4.08 | 17.83 |

| Fe2O3 | 2.89 | 28.98 |

| MgO | 3.31 | 1.56 |

| Na2O | 0.21 | 0.98 |

| K2O | 0.57 | 1.43 |

| TiO2 | 0.30 | 0.93 |

| SO3 | 3.04 | 1.32 |

| LOI | 1.56 | 2.44 |

| Average particle size | 5.06 µm | 3.56 µm |

| Specific surface (m2/kg) | 920 | 1033 |

| Aspect | Specific Gravity | pH | SiO2 (%) | Na2O (%) | Average Particle Size (nm) |

|---|---|---|---|---|---|

| milky white | 1.2 | 10 | 30 | 0.34 | 30 |

| Level | Factors | ||||

|---|---|---|---|---|---|

| W/S Ratio | UFA Content (%) | SP Content (%) | CNS Content (%) | SS Content (%) | |

| 1 | 1.0 | 10 | 0.05 | 1 | 1 |

| 2 | 1.2 | 20 | 0.1 | 2 | 2 |

| 3 | 1.4 | 30 | 0.15 | 3 | 3 |

| 4 | 1.6 | 40 | 0.2 | 4 | 4 |

| Group | W/S Ratio | UFA Content (%) | SP Content (%) | CNS Content (%) | SS Content (%) |

|---|---|---|---|---|---|

| G1 | 1.0 | 10 | 0.05 | 1 | 1 |

| G2 | 1.0 | 20 | 0.1 | 2 | 2 |

| G3 | 1.0 | 30 | 0.15 | 3 | 3 |

| G4 | 1.0 | 40 | 0.2 | 4 | 4 |

| G5 | 1.2 | 10 | 0.1 | 3 | 4 |

| G6 | 1.2 | 20 | 0.05 | 4 | 3 |

| G7 | 1.2 | 30 | 0.2 | 1 | 2 |

| G8 | 1.2 | 40 | 0.15 | 2 | 1 |

| G9 | 1.4 | 10 | 0.15 | 4 | 2 |

| G10 | 1.4 | 20 | 0.2 | 3 | 1 |

| G11 | 1.4 | 30 | 0.05 | 2 | 4 |

| G12 | 1.4 | 40 | 0.1 | 1 | 3 |

| G13 | 1.6 | 10 | 0.2 | 2 | 3 |

| G14 | 1.6 | 20 | 0.15 | 1 | 4 |

| G15 | 1.6 | 30 | 0.1 | 4 | 1 |

| G16 | 1.6 | 40 | 0.05 | 3 | 2 |

| Materials | Grain Sizes (µm) | Specific Surface (m2/kg) | |||

|---|---|---|---|---|---|

| dmax | d95 | d50 | d10 | ||

| UC | 17.46 | 12.49 | 5.06 | 1.1 | 920 |

| UFA | 13.74 | 7.28 | 3.56 | 0.9 | 1033 |

| Test Time (min) | τ0 (Pa) | η (mPa·s) | R2 |

|---|---|---|---|

| 0 | 2.28 | 23 | 0.99 |

| 30 | 2.77 | 37 | 0.99 |

| 60 | 3.45 | 48 | 0.99 |

| Group | Flow Time | Apparent Viscosity | Bleeding | Initial Setting Time | Final Setting Time | 7-Day UCS 1 | 28-Day UCS 1 |

|---|---|---|---|---|---|---|---|

| G1 | −26.42 | −37.92 | −16.90 | −48.46 | −49.83 | 18.71 | 20.95 |

| G2 | −26.56 | −40.05 | −14.96 | −47.75 | −49.25 | 19.24 | 21.97 |

| G3 | −29.44 | −43.85 | −13.98 | −46.85 | −48.60 | 20.48 | 23.22 |

| G4 | −31.06 | −45.95 | −6.02 | −45.93 | −47.27 | 22.01 | 24.46 |

| G5 | −29.85 | −45.46 | −14.65 | −46.65 | −48.03 | 21.46 | 23.48 |

| G6 | −28.55 | −43.03 | −18.28 | −47.49 | −49.07 | 20.23 | 22.52 |

| G7 | −24.53 | −29.37 | −26.44 | −49.28 | −50.73 | 17.27 | 20.95 |

| G8 | −24.58 | −30.05 | −27.60 | −49.13 | −50.58 | 17.30 | 21.33 |

| G9 | −24.72 | −32.00 | −26.85 | −48.94 | −50.37 | 17.46 | 20.46 |

| G10 | −23.88 | −26.19 | −32.04 | −49.83 | -51.41 | 16.93 | 20.45 |

| G11 | −26.71 | −39.56 | −25.11 | −48.06 | −49.74 | 18.84 | 21.85 |

| G12 | −24.79 | −32.38 | −32.04 | −48.79 | −50.32 | 17.95 | 22.07 |

| G13 | −24.06 | −28.76 | −29.83 | −49.51 | −51.15 | 17.19 | 20.39 |

| G14 | −25.64 | −34.12 | −29.54 | −48.63 | −50.05 | 18.33 | 21.23 |

| G15 | −23.82 | −25.34 | −38.69 | −50.24 | −51.57 | 16.70 | 20.29 |

| G16 | −23.66 | −23.92 | −42.41 | −50.86 | −52.08 | 15.92 | 19.84 |

| Group | Flow Time | Apparent Viscosity | Bleeding | Initial Setting Time | Final Setting Time | 7-Day UCS | 28-Day UCS |

|---|---|---|---|---|---|---|---|

| G1 | 0.63 | 0.36 | 0.70 | 0.47 | 0.47 | 0.46 | 0.24 |

| G2 | 0.61 | 0.27 | 0.75 | 0.62 | 0.59 | 0.54 | 0.46 |

| G3 | 0.22 | 0.10 | 0.78 | 0.80 | 0.72 | 0.75 | 0.73 |

| G4 | 0.00 | 0.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| G5 | 0.16 | 0.02 | 0.76 | 0.85 | 0.84 | 0.91 | 0.79 |

| G6 | 0.34 | 0.13 | 0.66 | 0.67 | 0.63 | 0.71 | 0.58 |

| G7 | 0.88 | 0.75 | 0.44 | 0.31 | 0.28 | 0.22 | 0.24 |

| G8 | 0.88 | 0.72 | 0.41 | 0.34 | 0.31 | 0.23 | 0.32 |

| G9 | 0.86 | 0.63 | 0.43 | 0.37 | 0.36 | 0.25 | 0.13 |

| G10 | 0.97 | 0.90 | 0.28 | 0.20 | 0.14 | 0.17 | 0.13 |

| G11 | 0.59 | 0.29 | 0.48 | 0.55 | 0.49 | 0.48 | 0.44 |

| G12 | 0.85 | 0.62 | 0.28 | 0.40 | 0.37 | 0.33 | 0.48 |

| G13 | 0.95 | 0.78 | 0.35 | 0.26 | 0.19 | 0.21 | 0.12 |

| G14 | 0.73 | 0.54 | 0.35 | 0.44 | 0.42 | 0.40 | 0.30 |

| G15 | 0.98 | 0.94 | 0.10 | 0.12 | 0.11 | 0.13 | 0.10 |

| G16 | 1.00 | 1.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Group | Flow Time | Apparent Viscosity | Bleeding | Initial Setting Time | Final Setting Time | 7-Day UCS | 28-Day UCS |

|---|---|---|---|---|---|---|---|

| G1 | 0.37 | 0.64 | 0.30 | 0.53 | 0.53 | 0.54 | 0.76 |

| G2 | 0.39 | 0.73 | 0.25 | 0.38 | 0.41 | 0.46 | 0.54 |

| G3 | 0.78 | 0.90 | 0.22 | 0.20 | 0.28 | 0.25 | 0.27 |

| G4 | 1.00 | 1.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| G5 | 0.84 | 0.98 | 0.24 | 0.15 | 0.16 | 0.09 | 0.21 |

| G6 | 0.66 | 0.87 | 0.34 | 0.33 | 0.37 | 0.29 | 0.42 |

| G7 | 0.12 | 0.25 | 0.56 | 0.69 | 0.72 | 0.78 | 0.76 |

| G8 | 0.12 | 0.28 | 0.59 | 0.66 | 0.69 | 0.77 | 0.68 |

| G9 | 0.14 | 0.37 | 0.57 | 0.63 | 0.64 | 0.75 | 0.87 |

| G10 | 0.03 | 0.10 | 0.72 | 0.80 | 0.86 | 0.83 | 0.87 |

| G11 | 0.41 | 0.71 | 0.52 | 0.45 | 0.51 | 0.52 | 0.56 |

| G12 | 0.15 | 0.38 | 0.72 | 0.60 | 0.63 | 0.67 | 0.52 |

| G13 | 0.05 | 0.22 | 0.65 | 0.74 | 0.81 | 0.79 | 0.88 |

| G14 | 0.27 | 0.46 | 0.65 | 0.56 | 0.58 | 0.60 | 0.70 |

| G15 | 0.02 | 0.06 | 0.90 | 0.88 | 0.89 | 0.87 | 0.90 |

| G16 | 0.00 | 0.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Group | GRC Values | Grey Relational Grade | ||||||

|---|---|---|---|---|---|---|---|---|

| Flow Time | Apparent Viscosity | Bleeding | Initial Setting Time | Final Setting Time | 7-Day UCS | 28-Day UCS | ||

| G1 | 0.573 | 0.440 | 0.626 | 0.485 | 0.485 | 0.480 | 0.397 | 0.498 |

| G2 | 0.561 | 0.406 | 0.670 | 0.565 | 0.549 | 0.523 | 0.481 | 0.536 |

| G3 | 0.390 | 0.356 | 0.696 | 0.718 | 0.645 | 0.665 | 0.650 | 0.589 |

| G4 | 0.333 | 0.333 | 1.000 | 1.002 | 1.000 | 1.001 | 1.002 | 0.810 |

| G5 | 0.374 | 0.338 | 0.678 | 0.764 | 0.761 | 0.848 | 0.702 | 0.638 |

| G6 | 0.431 | 0.366 | 0.598 | 0.601 | 0.573 | 0.631 | 0.543 | 0.535 |

| G7 | 0.809 | 0.669 | 0.471 | 0.419 | 0.410 | 0.391 | 0.397 | 0.509 |

| G8 | 0.800 | 0.643 | 0.457 | 0.430 | 0.421 | 0.392 | 0.424 | 0.510 |

| G9 | 0.778 | 0.577 | 0.466 | 0.444 | 0.437 | 0.401 | 0.366 | 0.496 |

| G10 | 0.943 | 0.829 | 0.412 | 0.384 | 0.367 | 0.375 | 0.365 | 0.525 |

| G11 | 0.549 | 0.413 | 0.488 | 0.527 | 0.493 | 0.490 | 0.470 | 0.490 |

| G12 | 0.767 | 0.566 | 0.412 | 0.456 | 0.441 | 0.428 | 0.491 | 0.509 |

| G13 | 0.903 | 0.695 | 0.433 | 0.403 | 0.383 | 0.387 | 0.362 | 0.509 |

| G14 | 0.651 | 0.519 | 0.436 | 0.470 | 0.464 | 0.453 | 0.417 | 0.487 |

| G15 | 0.958 | 0.886 | 0.358 | 0.362 | 0.359 | 0.365 | 0.357 | 0.521 |

| G16 | 1.000 | 1.000 | 0.333 | 0.333 | 0.333 | 0.333 | 0.333 | 0.524 |

| Factor | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| W/S ratio | 0.608 * | 0.548 | 0.505 | 0.510 |

| UFA content | 0.535 | 0.521 | 0.527 | 0.588 * |

| SP content | 0.512 | 0.551 | 0.520 | 0.589 * |

| CNS content | 0.501 | 0.511 | 0.569 | 0.590 * |

| SS content | 0.513 | 0.516 | 0.535 | 0.606 * |

| Factor | DOF 1 | SOS 2 | MS 3 | Percentage Contribution (%) |

|---|---|---|---|---|

| W/S ratio | 3 | 0.0272 | 0.0091 | 27.62 |

| UFA content | 3 | 0.0114 | 0.0038 | 11.58 |

| SP content | 3 | 0.0144 | 0.0048 | 14.6 |

| CNS content | 3 | 0.0229 | 0.0076 | 23.26 |

| SS content | 3 | 0.0226 | 0.0075 | 22.93 |

| Error | - | - | - | - |

| Total | 15 | 0.0985 | 100 |

| Group | 7-Day | 28-Day |

|---|---|---|

| G1 | 21.8 | 17.9 |

| G2 | 19.7 | 16.8 |

| G3 | 16.2 | 13.4 |

| G4 | 15.3 | 12.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Qiao, W.; Wu, Y.; Fan, Z.; Zhang, L. Multi-Response Optimization of Ultrafine Cement-Based Slurry Using the Taguchi-Grey Relational Analysis Method. Materials 2021, 14, 117. https://doi.org/10.3390/ma14010117

Zhang S, Qiao W, Wu Y, Fan Z, Zhang L. Multi-Response Optimization of Ultrafine Cement-Based Slurry Using the Taguchi-Grey Relational Analysis Method. Materials. 2021; 14(1):117. https://doi.org/10.3390/ma14010117

Chicago/Turabian StyleZhang, Shuai, Weiguo Qiao, Yue Wu, Zhenwang Fan, and Lei Zhang. 2021. "Multi-Response Optimization of Ultrafine Cement-Based Slurry Using the Taguchi-Grey Relational Analysis Method" Materials 14, no. 1: 117. https://doi.org/10.3390/ma14010117

APA StyleZhang, S., Qiao, W., Wu, Y., Fan, Z., & Zhang, L. (2021). Multi-Response Optimization of Ultrafine Cement-Based Slurry Using the Taguchi-Grey Relational Analysis Method. Materials, 14(1), 117. https://doi.org/10.3390/ma14010117