1. Introduction

With the development of science and technology in the 21st century, light alloy forming and manufacturing technology has made a great contribution to the development of aerospace, automobile, major equipment, energy, weapons, shipbuilding and information industries [

1]. At present, light alloys mainly include aluminum, magnesium, titanium and other high-performance light alloys. Magnesium alloy is the lightest structural metal, with a density two thirds that of aluminum and one quarter that of iron. It has high strength, rigidity, damping, machining and thermal conductivity, and a high absorption of vibration and impact. It is used to improve resource optimization and emission reduction in the field of traffic engineering. Magnesium alloy is lighter, more environmentally friendly and safer. For ensuring automobile safety, the effect of magnesium alloy on reducing automobile mass and energy consumption is particularly significant. Magnesium and its alloy are widely used in automobile manufacturing enterprises. Magnesium alloy is used in the automobile industry instead of steel in engines, saving 0.25l/100 km fuel in carbon dioxide emissions, making the center of gravity of the automobile move backward, and improving the steering performance of the automobile [

2].

In the field of machinery, the screw connection is the most common connection mode in the assembly of parts, which is widely used in various industrial fields. In the machining process, 60% of the holes are machined, of which nearly 50% are threaded holes [

3]. The threaded connection can be assembled and disassembled quickly and accurately many times, while ensuring that the parts connected with each other will not be damaged [

4].

When traditional cutting tap is used to tap magnesium alloy, chips will be produced in the process of machining. It is difficult to clean a chip stuck on the inner wall of the thread, which affects the cleanliness of the product. In the processing and use of threaded holes, the phenomenon of broken teeth and sliding wires is common, which seriously affects the assembly quality [

5]. Therefore, in order to ensure that the thread will not be damaged when it is loaded and unloaded many times, the threaded hole to be processed must have high strength and rigidity. In this case, the technology of cold extrusion to process the threaded hole was born. In recent years, cold extrusion threading is becoming more and more important in the manufacturing industry [

6]. With the improvement of processing environments and the concept of “green manufacturing”, the application of extrusion threading in industry is increasing. As the tool life is prolonged, the machining accuracy, surface roughness, mechanical strength and reliability of the thread are improved, the process cleanliness is improved, and the production cost is reduced, so from an economic point of view, the extrusion of internal threads is also very important. The biggest advantage of the extrusion of the thread is that the thread is formed by plastic deformation, which not only has good deformation ability but also can maintain high mechanical strength [

7,

8]. Therefore, compared with the traditional tapping process, extrusion tapping is a good choice.

Most of the research on thread formation focuses on the processing technology. By analyzing the variables in the process, the complete thread profile is obtained. Carvalho et al. [

9] used factorial design and variance analysis to optimize the process parameters for AM60 magnesium alloy cold extrusion internal threads, and analyzed the influence of various factors such as initial hole diameter, forming speed and tool type on the thrust, torque, filling rate and hardness in the forming process. The goal was to reduce the bifurcation wave peak of the internal thread and finally obtain a better thread profile quality. Dias [

10] proposed a special process for machining magnesium alloy internal threads, analyzed the influence of forming speed and screw feeding rate on the forming process, and found that an increase in the screw feeding rate reduced the torque and thrust during the processing. Sérgio [

11] used coated and uncoated tools to extrude the internal thread of 7075 aluminum alloy, analyzed the causes of the formation of the burr at the inlet and outlet of the thread, and then optimized the process parameters in the extrusion process. The results show that a change in the initial diameter only affects the formation of the entrance burr, and the forming speed is the most important factor affecting the formation of the exit burr. Pereira [

12] studied the influence of each variable in the two manufacturing processes of cutting threads and extrusion thread formation on the forming process, and determined the rules of the influence of each cutting edge of the tool on the torque, and the compensation effect of a new fixture system on the synchronous error.

There is little research on the three-dimensional finite element analysis of the extrusion thread forming process. Domblesky and Feng [

13,

14] established two-dimensional and three-dimensional models of screw rolling using “deform 3D”, Warrington et al. [

15] established a finite element model under deform three-dimensional software, an equivalent tapping to linear scratch experiment to study the formation of split peaks in the tapping process, and then improved the tapping design and verified their models with experiments. Mathurin et al. [

16] used the three-dimensional finite element model of 45 degree sector (discrete rigid screw body) to determine the displacement and thread shape during the forming process. They also conducted parametric studies to determine the most influential process parameters. The results show that the diameter of the guide hole has an important influence on the tightening torque. Dinger [

17] used the method of numerical simulation and experiments to analyze the assembly process of screw thread formation. Through parametric study, the influence of the friction conditions and hole diameter on the tightening torque was determined, and it was concluded that the hole diameter has an important influence on tightening torque.

Most of the magnesium alloys have a closely packed hexagonal crystal structure with low symmetry. Their axial ratio is 1.632, which is close to the ideal packed value of 1.633. There are few slip systems at room temperature, and it is difficult to cold work [

18]. Among many magnesium alloy materials, cast magnesium alloy AZ91D is one of the most widely used magnesium alloy materials, which is widely used in the transmission systems, engine systems and chassis systems of automobile. In automobile parts, a thread machined by AZ91D material often has a slip thread and insufficient thread strength, while AZ91D is a cast magnesium alloy, which is difficult to be formed at room temperature and also unable to be processed by extrusion. Electromagnetic induction-assisted heating forming technology can realize the on-line real-time heating of components, and solve the technical problem of too-rapid cooling in the hot forming process for light material components [

19]. In this paper, a processing technology for the electromagnetic induction-assisted extrusion of AZ91D internal threads is proposed. The finite element model of electromagnetic induction-assisted extrusion is established by using the DEFORM software (Deform 3D V11, SFTC, Berkeley, CA, USA). The law of stress and strain and material flow in the process of processing is analyzed. The influence of process parameters on torque is discussed, so as to obtain high quality threads.

2. Materials and Methods

DEFORM-3D is a powerful process simulation and analysis software. It is a finite element system based on a process simulation system. It could be used to analyze the three-dimensional metal flow in various metal forming processes, providing valuable process analysis data and the relevant material and temperature flows in the forming process. The powerful simulation engine of DEFORM-3D can analyze the large deformation and thermal characteristics of many related objects in the metal forming process. The system integrates the functions of the automatic grid re-division generator and local grid subdivision to generate an optimized grid system, reduce the operation scale and improve the calculation efficiency [

20]. As the cold extrusion of internal threads belongs to the plastic forming category of large metal deformation, the plastic deformation is far greater than the elastic deformation, so the rigid plastic finite element method was used for analysis.

2.1. Rigid-Plastic Finite Element Mathematical Model

Neglecting the volume force and inertia force, the deformation area of material should meet the balance equation:

where

is the divergence of the stress tensor.

The speed

νi of the particle in the stress tensor deformation region needs to satisfy the geometric equation:

where

is strain rate tensor. According to the Mises yield criterion, the constitutive equation of rigid plastic materials is:

where

is the equivalent strain rate,

is the deviatoric Cauchy stress, and

is the equivalent stress.

2.2. Electromagnetic Induction Heating Simulation

2.2.1. Geometric Model

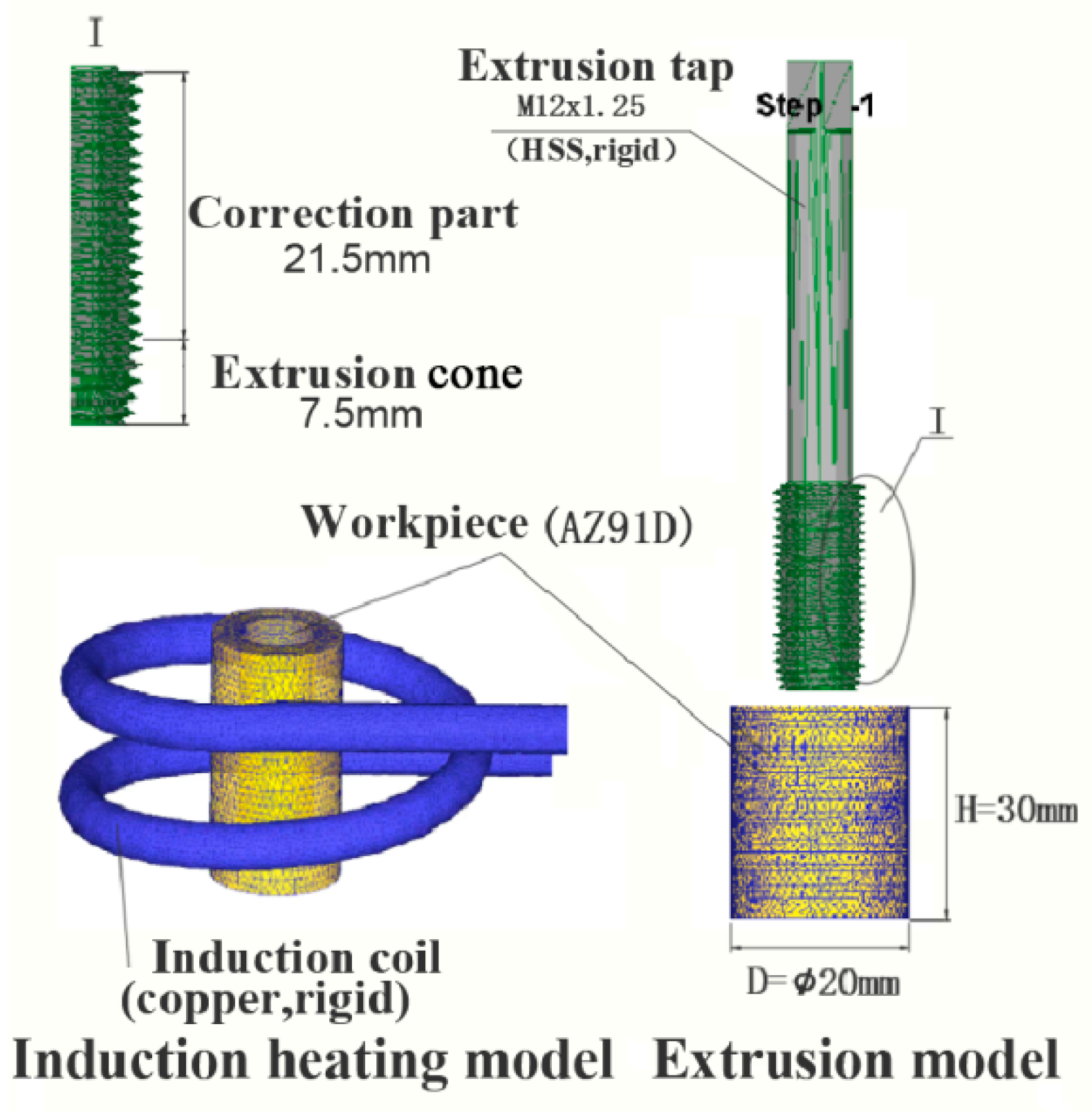

The research objective of this paper is to study the AZ91D magnesium alloy. The processing of AZ91D magnesium alloy-based extrusion of internal threads is based on high frequency induction heating. Before the processing of the extrusion internal thread, the AZ91D magnesium alloy workpiece is subjected to high frequency induction heating. The finite element model of induction heating is shown in

Figure 1.

2.2.2. Workpiece Material Properties Definition

In the simulation of high frequency induction heating, the finite element model is composed of the workpiece and coil. In the process of extruding the workpiece with tap, because of the high strain and strain rate of the workpiece material, the nonlinear characteristics of the material cannot be ignored. The rheological stress constitutive equation applicable to the establishment of the AZ91D magnesium alloy is as shown in Equation (4) [

21]:

where

is the strain rate;

A is the coefficient,

A = 1.15 × 10

16 s

−1;

σ is the rheological stress;

Q is the free diffusion activation energy;

α are the stress level parameters;

n is the stress exponent;

R is the gas constant; and

T is the absolute temperature.

Other parameters of the AZ91D magnesium alloy material are shown in

Table 1, and the data generated were added to the deform material library as material properties.

2.2.3. Mesh Generation

The mesh generation of deformable bodies using DEFORM is the basis of numerical simulation analysis. For the subsequent extrusion process for internal threads, which is equivalent to the complex deformation plastic forming numerical simulation problem, it is difficult to simulate the deformation process with only a fixed element mesh. The main reason is that the interference between the extrusion tap boundary and the mesh boundary will seriously distort the finite element mesh, and the distortion will lead to the distortion of the numerical simulation results. Therefore, when the mesh deforms to a certain extent, it is necessary to stop the calculation and adjust and subdivide the mesh. In order to improve the simulation speed and accuracy, mesh subdivision technology was used in the screw forming part. After mesh division, the total number of meshes was 57,951, and the number of cell nodes was 14,703.

2.2.4. Boundary Conditions and Parameters

Since the energized coil provides a magnetic field for the workpiece, the coil was set to Master and the workpiece, to Slave. The current frequency was set to 30,000 Hz, the current density was set to 50 A/mm2, and the heating temperature of workpiece was set to 533, 553, 573, 593 and 613 K in the simulation.

2.3. Numerical Simulation of Internal Thread Extrusion

2.3.1. Geometric Model and Settings

On the basis of high frequency induction heating, the movement simulation analysis of the internal thread of the workpiece was carried out. The Creao software was used to model the extrusion tap and generate an “STL” file, which was then imported into DEFORM-3D preprocessing for simulation analysis. The finite element model for the extrusion of the internal thread is shown in

Figure 1. The structure of the extrusion tap includes a working part and clamping part, and the working part includes an extrusion tap and a correction part. The internal thread extrusion test tap adopts an M12 × 1.25 hexagonal high-speed steel fine thread ordinary fine shank tap, the length of the extrusion tap is 7.5 mm, and the length of the correction part is 21.5 mm.

2.3.2. Establishment of Motion Model

The internal thread extrusion is completed in the machining center. In the actual machining, the main shaft of the machining center drives the tap to rotate at a certain speed, and the internal thread extrusion is completed according to a certain feed rate. In the DEFORM software, the tap was set as a rigid body, and the rotation speed of the machine tool in the actual processing was transformed into the axial speed and rotation angle speed when the tap was extruded. According to the pitch of the formed thread, the relationship between the machine speed and the axial speed and angular speed of the tap in the simulation was as follows:

where

f is the axial speed of the tap (m/s),

n is the machine speed (rpm),

P is the pitch of the extrusion thread (mm), and

ω is the Rotation angular velocity of the tap (rad/s).

2.3.3. Setting the Relationship between Objects

Friction is a common and complicated problem in metal forming. The proper treatment of friction boundary conditions and reasonable selection of the friction model directly affect the accuracy of finite element calculation. The inside screw extrusion forming process was modeled by taking into account the high contact stress of the plastic forming process, so the general Coulomb friction model for the extrusion tap edge state of the tooth profile and the extrusion friction between parts is no longer applicable for the extrusion tap part and the plastic deformation of the workpiece contact area for the shear friction model, as shown in Equation (7). According to the characteristics of this process, induction heating-assisted forming and no lubricating fluid are used, and the friction factor was set to 0.7. The heat conduction between the extrusion tap and the magnesium alloy is expressed by the thermal conductivity, which was set to 72 W·M

−1·K

−1.

where

τf is the frictional stress; m is the friction factor, 0 ≤

m ≤ 1; and

k is the shear yield limit,

.

In the process of finite element simulation, only the increase in the slip system for the magnesium alloy at 498 K was considered. The temperature dependence of the mechanical properties was not considered.

2.3.4. Setting of Boundary Conditions

According to the actual processing conditions, the workpiece was fixed on the worktable of the machining center, so all six degrees of freedom on the outer surface of the workpiece were fixed, and the temperature field was added to the workpiece. In the process of simulation, volume compensation was needed to prevent large deviations between the mesh volume and the workpiece volume after mesh division, which would result in large errors in simulation and inaccurate experimental data.

2.3.5. Setting of Simulation Control Parameters

Simulation control parameter setting includes setting the simulation type, step control, stop control, etc. In this work, the Lagrangian incremental method was selected for iterative control and calculation. The simulation type was set to forming mode, which means that the whole machining process only took plastic forming instead of cutting forming; the total number of simulation steps was set to 380 steps; and the data were stored once per step, which was set to 0.04 mm in the solution step definition, that is, one third of the minimum mesh size, and the others were selected as default values.

2.4. Experimental Method

In the experiment, the DHK32 machining center was used to carry out the auxiliary heating extrusion processing of the M12 × 1.25 mm internal thread. The experimental device used to study the forming process is shown in

Figure 2. The extrusion tap, 1, was installed in the spindle box of the machining center, and the magnesium alloy workpiece was installed in the special clamp, 3, and fixed on the workbench, 2, of the machining center. The induction coil, 6, was placed on the outside of the workpiece, and a 2 cm gap was maintained with the outer circle surface of the workpiece. The water pipe, 9, was cooled with cold water, and the relevant parameters for induction heating with the induction heater, 7, were adjusted. The workpiece temperature was measured with the temperature sensor, 5, and read on the thermometer, 8. The experimental parameters were the same as those of the finite element simulation.

The torque sensor was used to measure the torque produced in the process of internal thread extrusion. The torque sensor consisted of a measuring bridge, an amplifier and an interface circuit composed of a resistance strain gauge (BF-350HA).

After cutting the extruded magnesium alloy internal thread sample, the longitudinal section of the thread tooth was taken for grinding and polishing. The shape of thread was observed using an OLYMPUS-GX71-6230A metallographic microscope (OLYMPUS, Tokyo, Japan).

An HXD-1000 microhardness tester (BAHENS, Shanghai, China) was used to test the microhardness of the samples. Before the test, the sample should be polished in accordance with the requirements of metallographic observation. The test parameters were: load, 50 g; pressure holding time, 20 s.

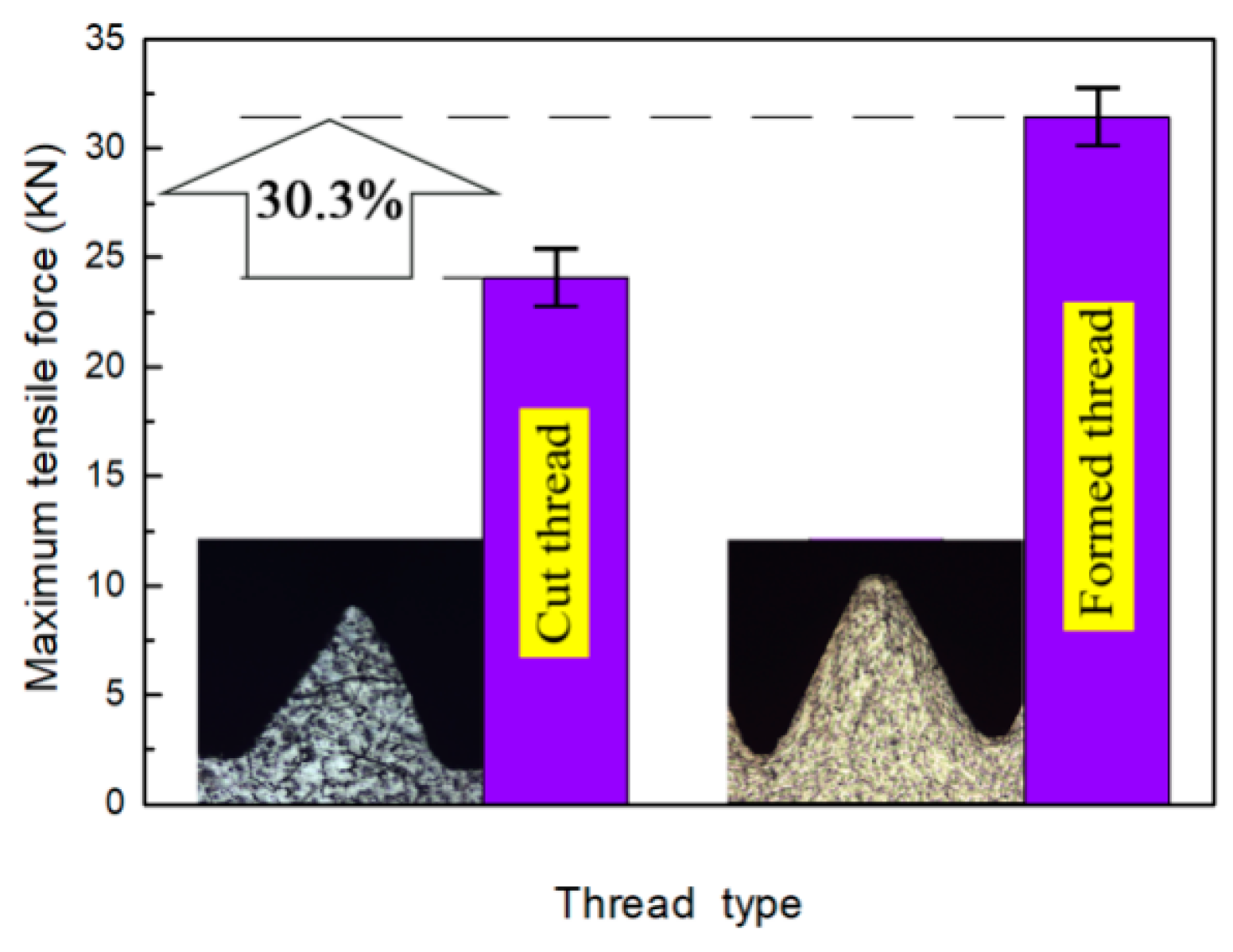

Through a quasi-static tensile test, the tensile strength tests for the cutting thread and cold extrusion thread formation were carried out respectively. As shown in

Figure 3, the magnesium alloy, 2, was put into the special tooling, 3, and the magnesium alloy from the top of the special tooling was screwed in with an M12 × 1.25 standard screw. They were put together on the cupping machine, 4, for the destructive test. The specifications of each thread are M12 × 1.25 mm, the screw length is 18 mm, and the tensile force values are the average values of six threads. The experimental results are all thread pull off values, and the maximum tensile force value is obtained.

4. Conclusions

In this paper, an extrusion-based process for forming AZ91D magnesium alloy internal threads is proposed. The key point of the process is to use an electromagnetic induction coil to assist in heating the magnesium alloy, so that the plasticity of the cast magnesium alloy can be improved compared with that made at room temperature.

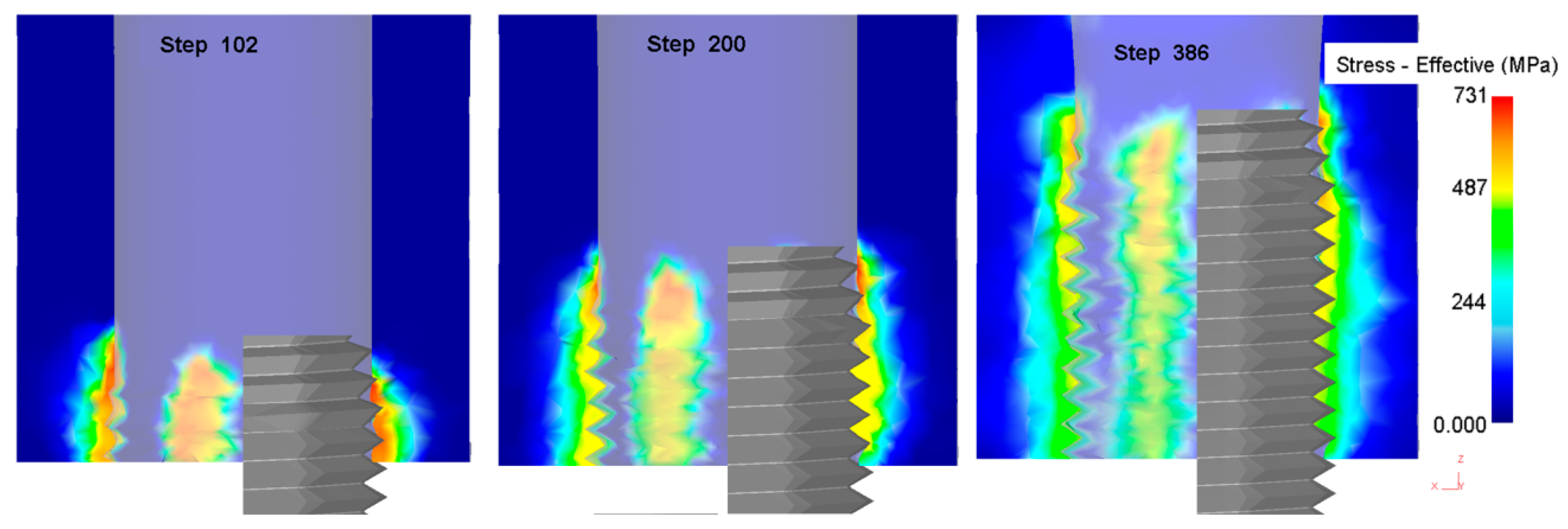

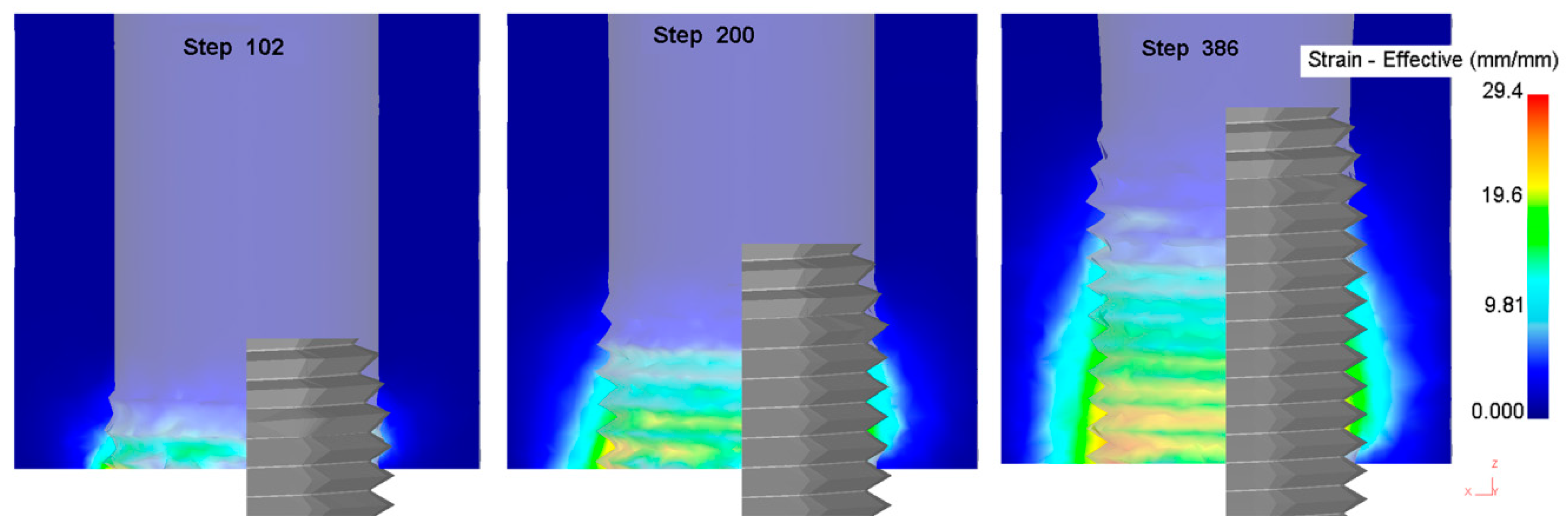

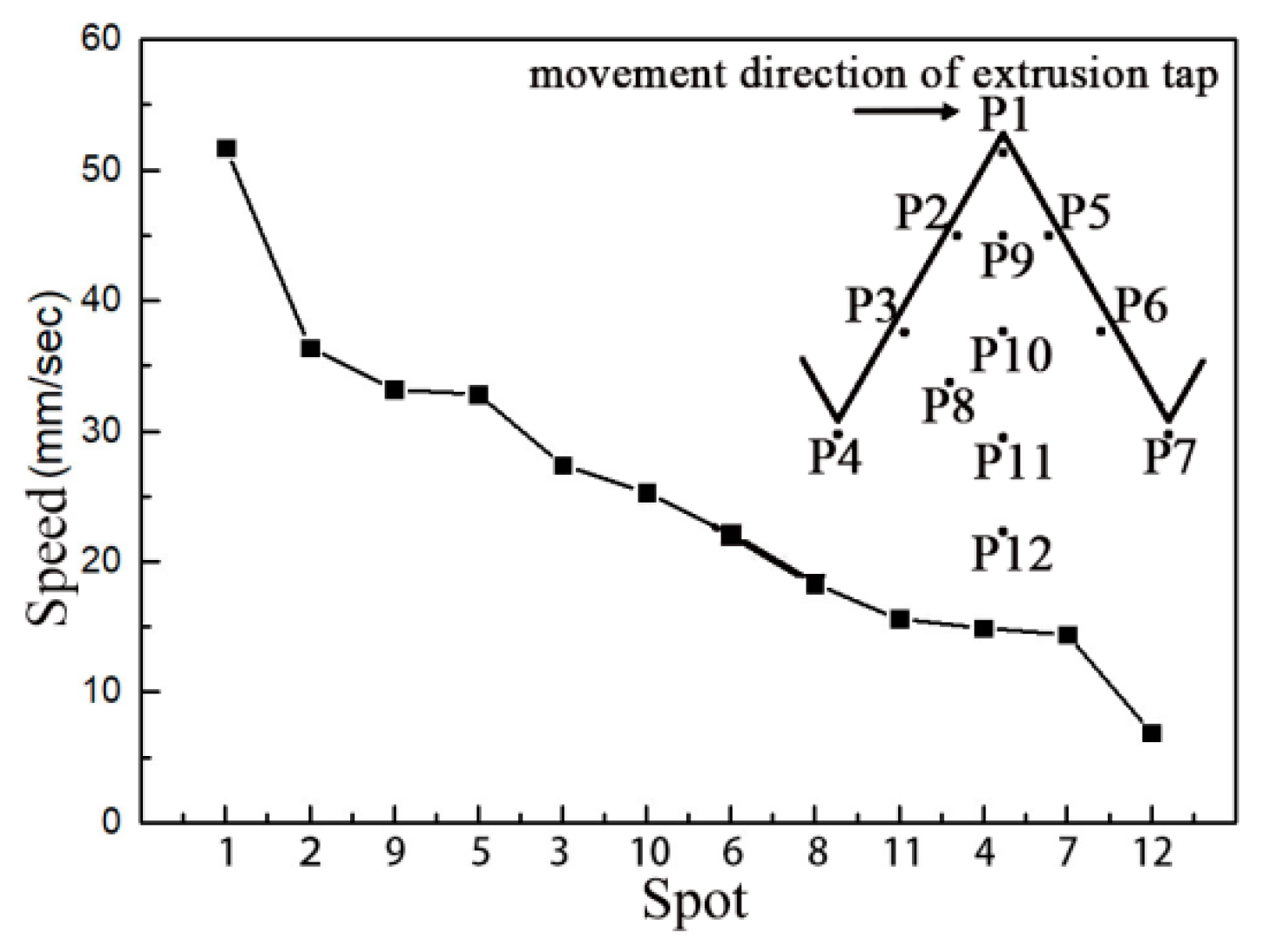

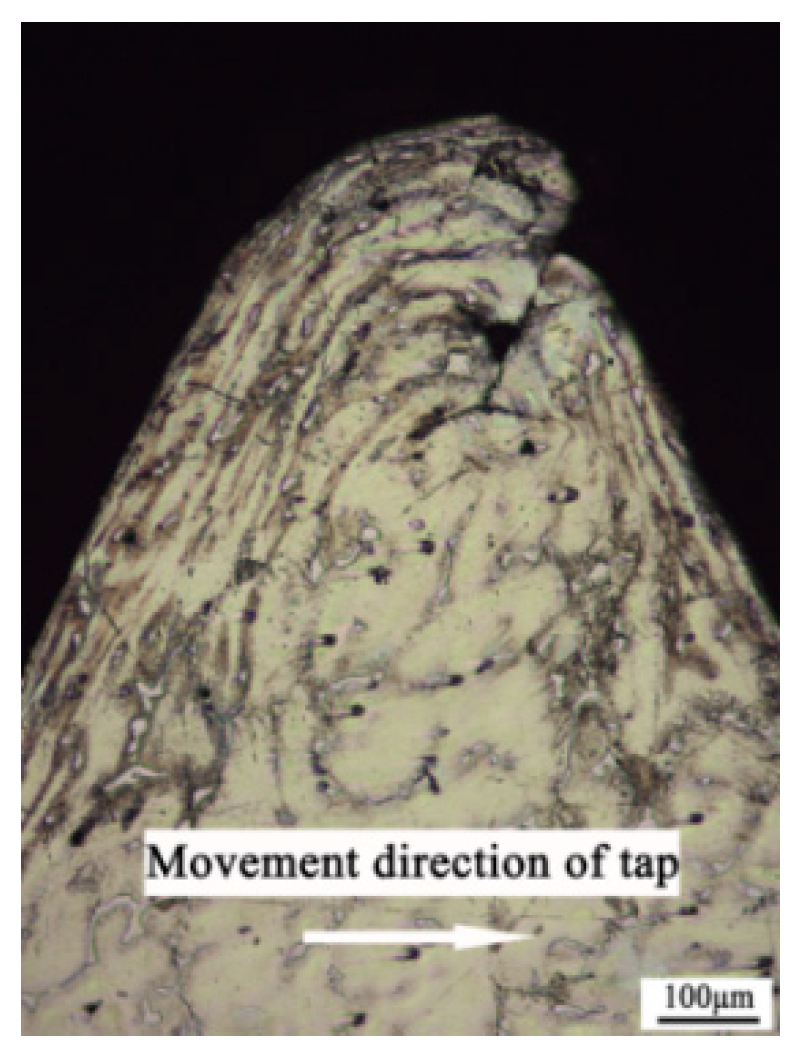

Through the simulation and analysis of the equivalent stress-strain and the law of metal flow in the forming process, it was found that the structure of the extrusion tap is also a relevant factor affecting the internal thread formation. The moving direction of the extrusion tap would cause different degrees of material accumulation on both sides of the thread profile.

The heating temperature is a key parameter in this process. The temperature range makes the deformation resistance of metal lower than that with cold working, the energy consumption less than that with cold working, and metal plasticity larger than that with cold working. With an increase in temperature, the yield strength of the metal decreases and the torque of the forming process decreases.

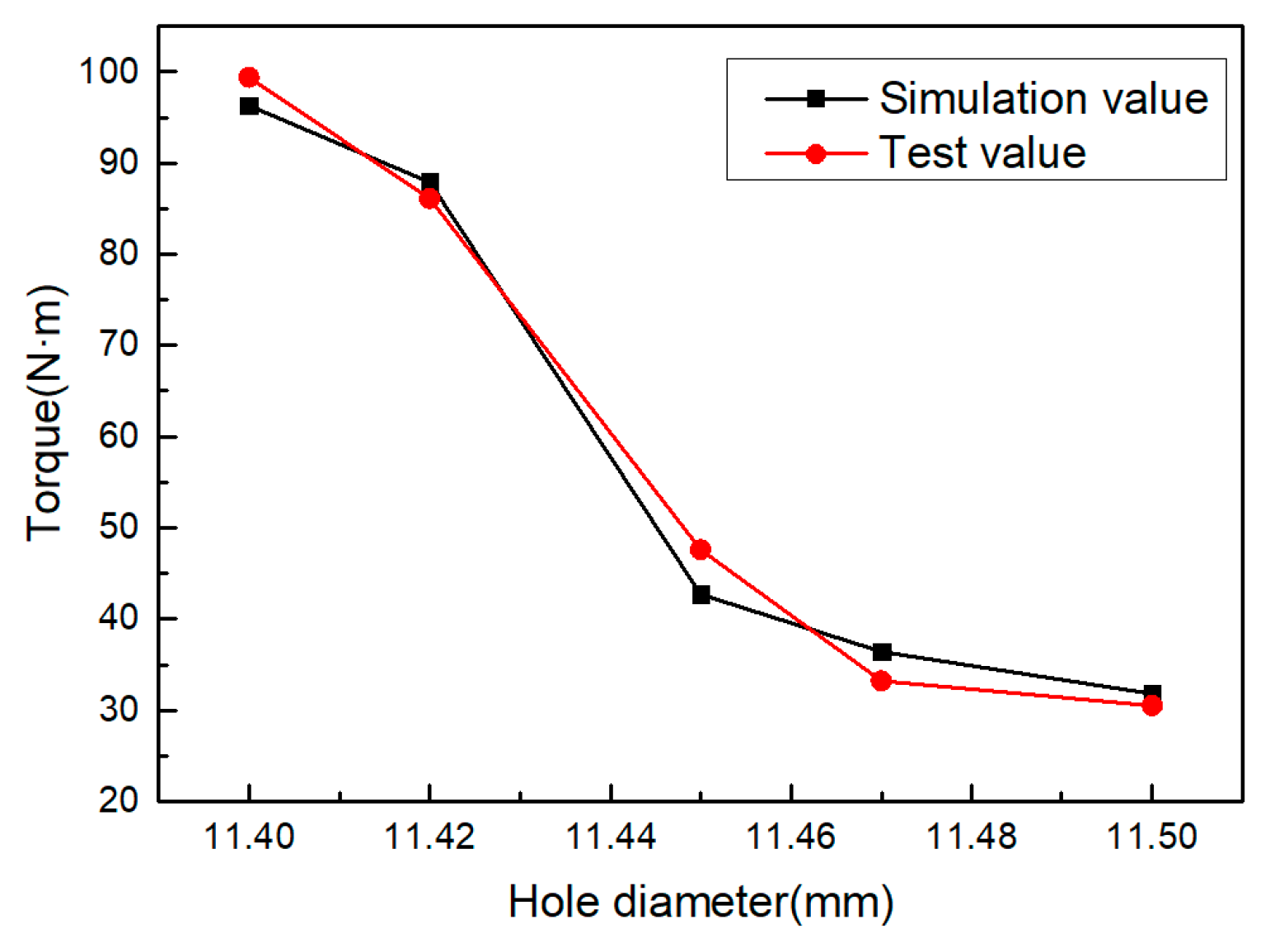

The hole diameter is an important factor in the extrusion internal thread formation process. With a decrease in the hole diameter, the torque increased, especially when the diameter of the hole changed from 11.45 to 11.40 mm.

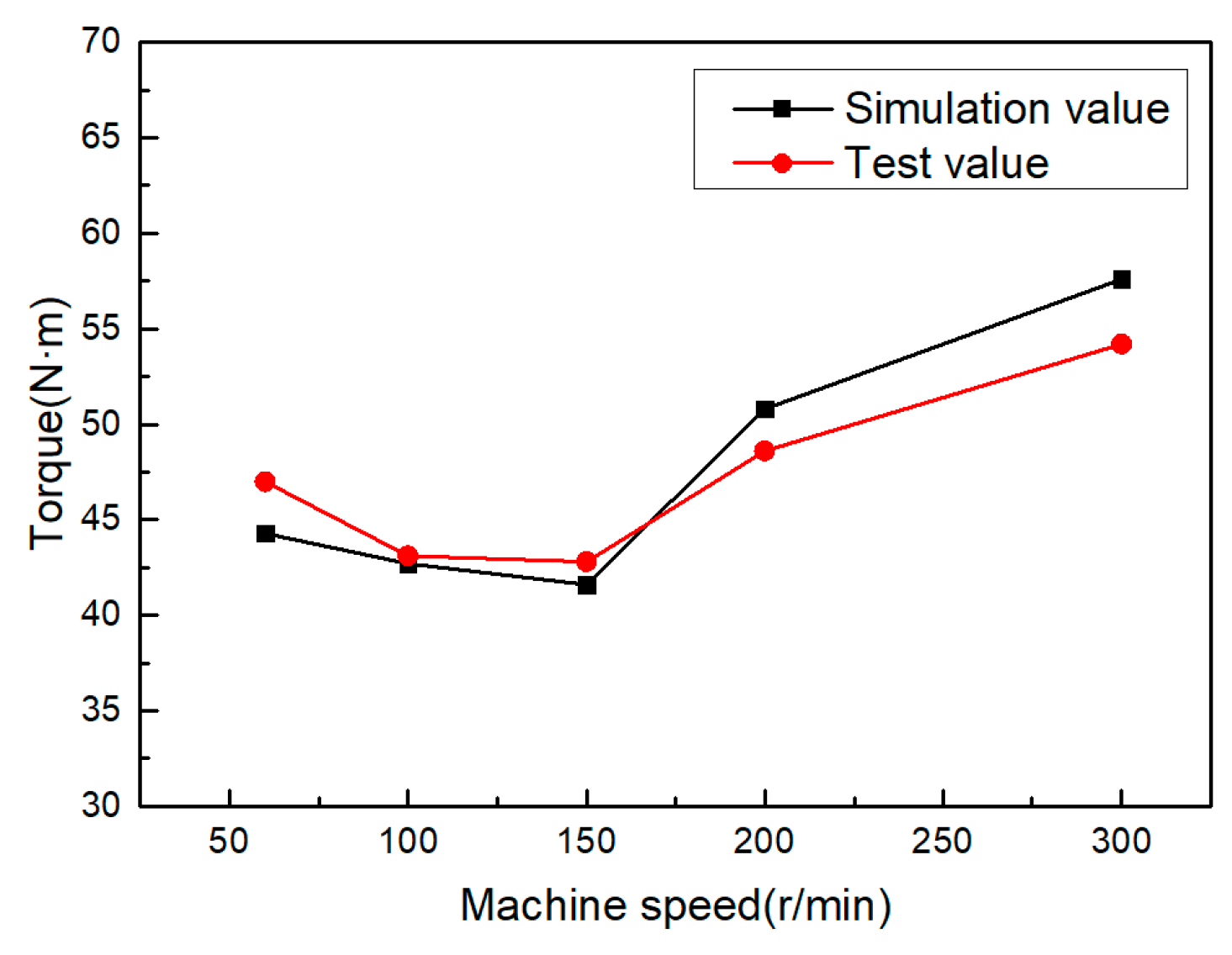

This process is not suitable for high-speed machining. When the machine speed exceeds 200 rpm, the deformation of the workpiece material is not sufficient, resulting in an increase in the torque.

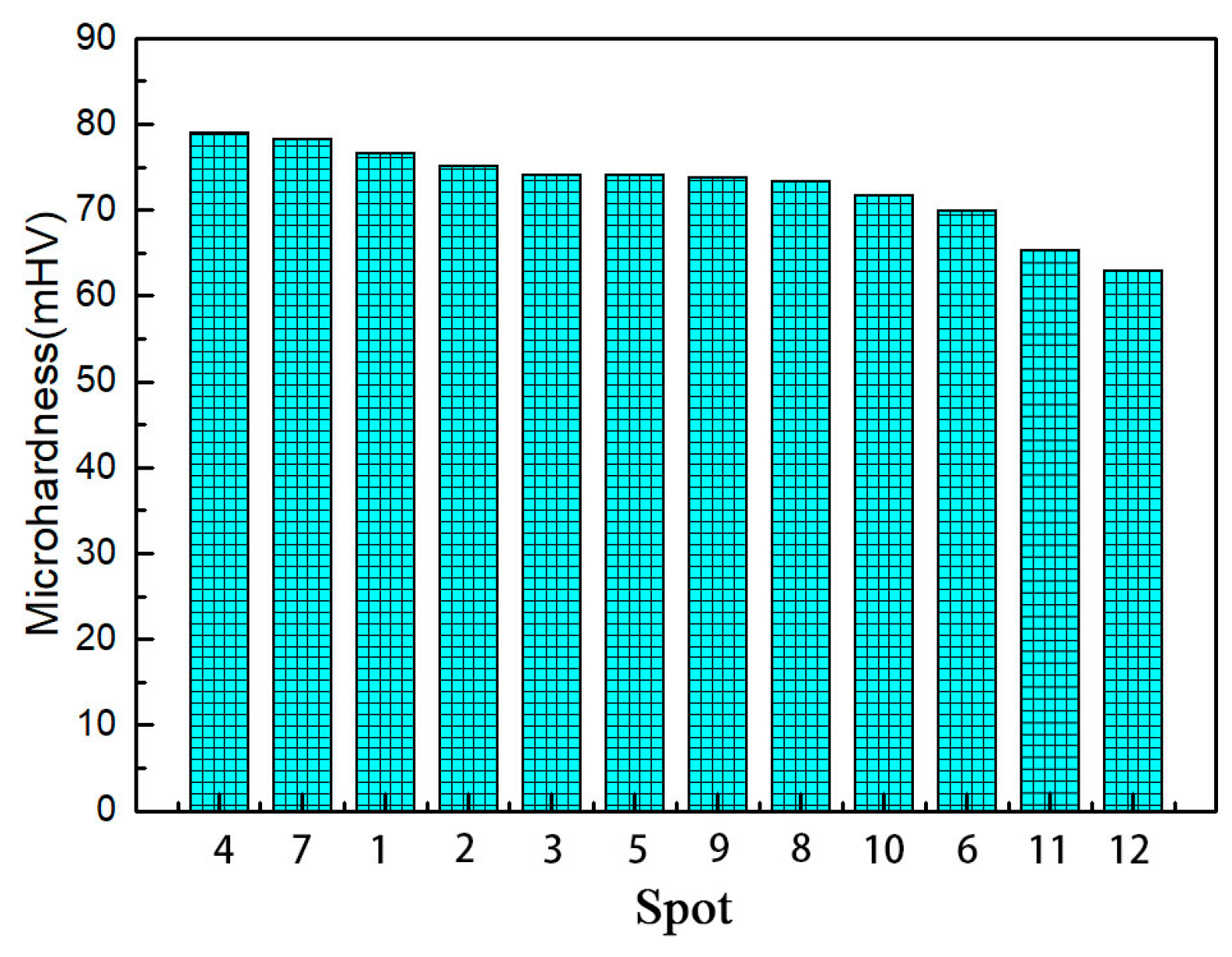

Strain hardening is the root cause of internal threads in extrusion, which is caused by the plastic flow of metal under the interaction of the extrusion tap and workpiece. The hardened layer formed on the thread surface will improve the mechanical properties of the thread. The maximum tensile force of the thread formed by this process is 30.3% higher than that formed by thread cutting.

The process in this paper can be applied to the extrusion processing of other alloy materials with poor plasticity. Future research should take into account the optimization of process parameters and more complex friction and contact models.