Development of Coated Electrodes with Solid Wire and Flux-Cored Alloyed Wire for Microalloyed Steel Welding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Base Metal and Filler Materials

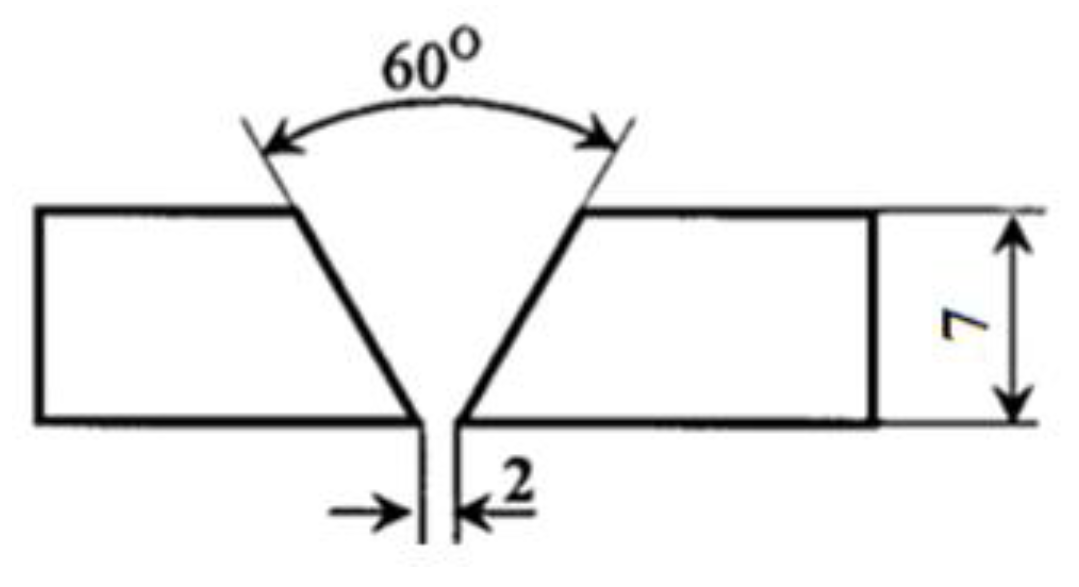

2.2. Experimental Welding

3. Results and Discussion

3.1. Testing of the Chemical Composition of Pure WM

3.2. Testing of Mechanical Properties of Welding Joints

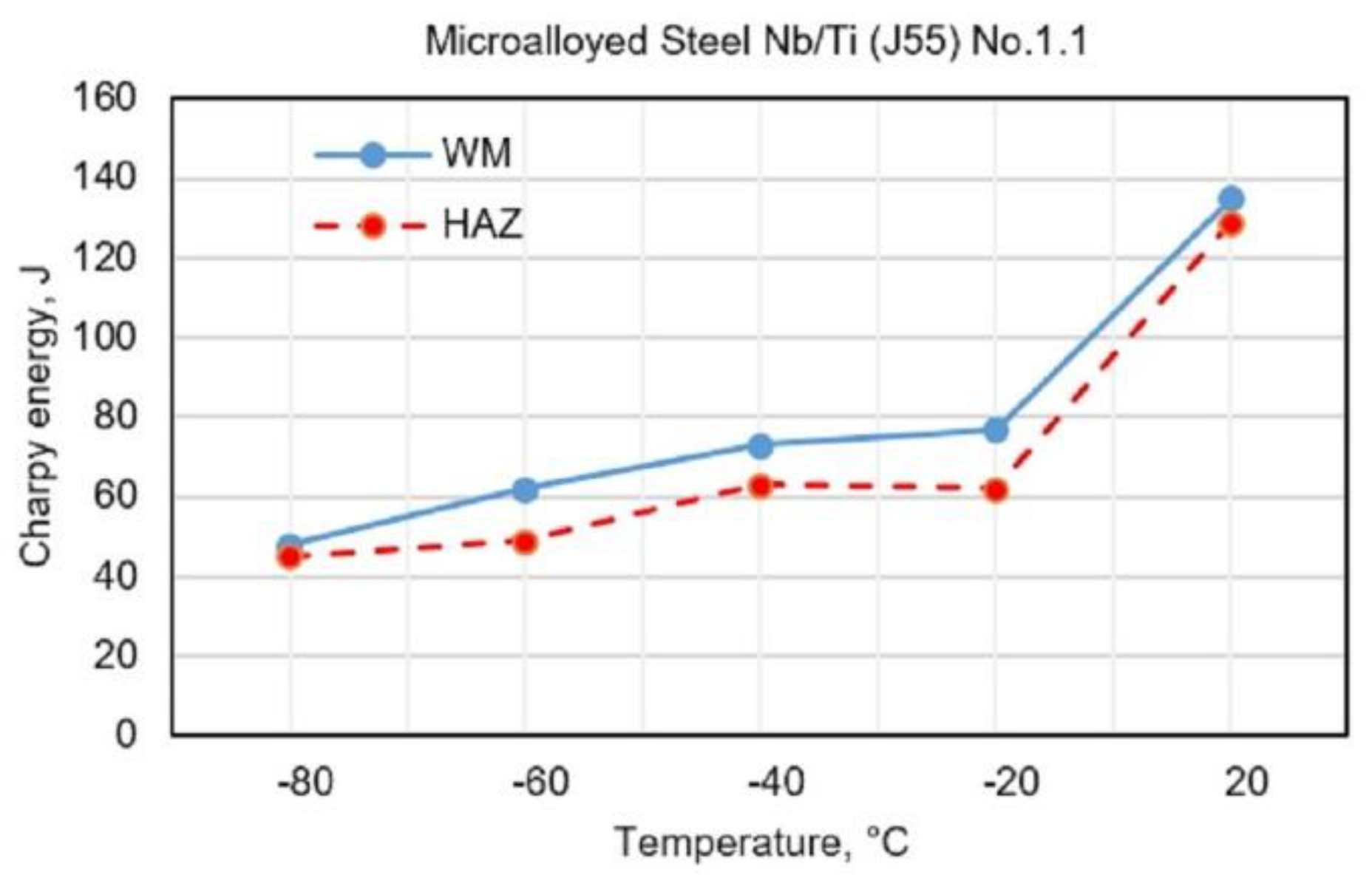

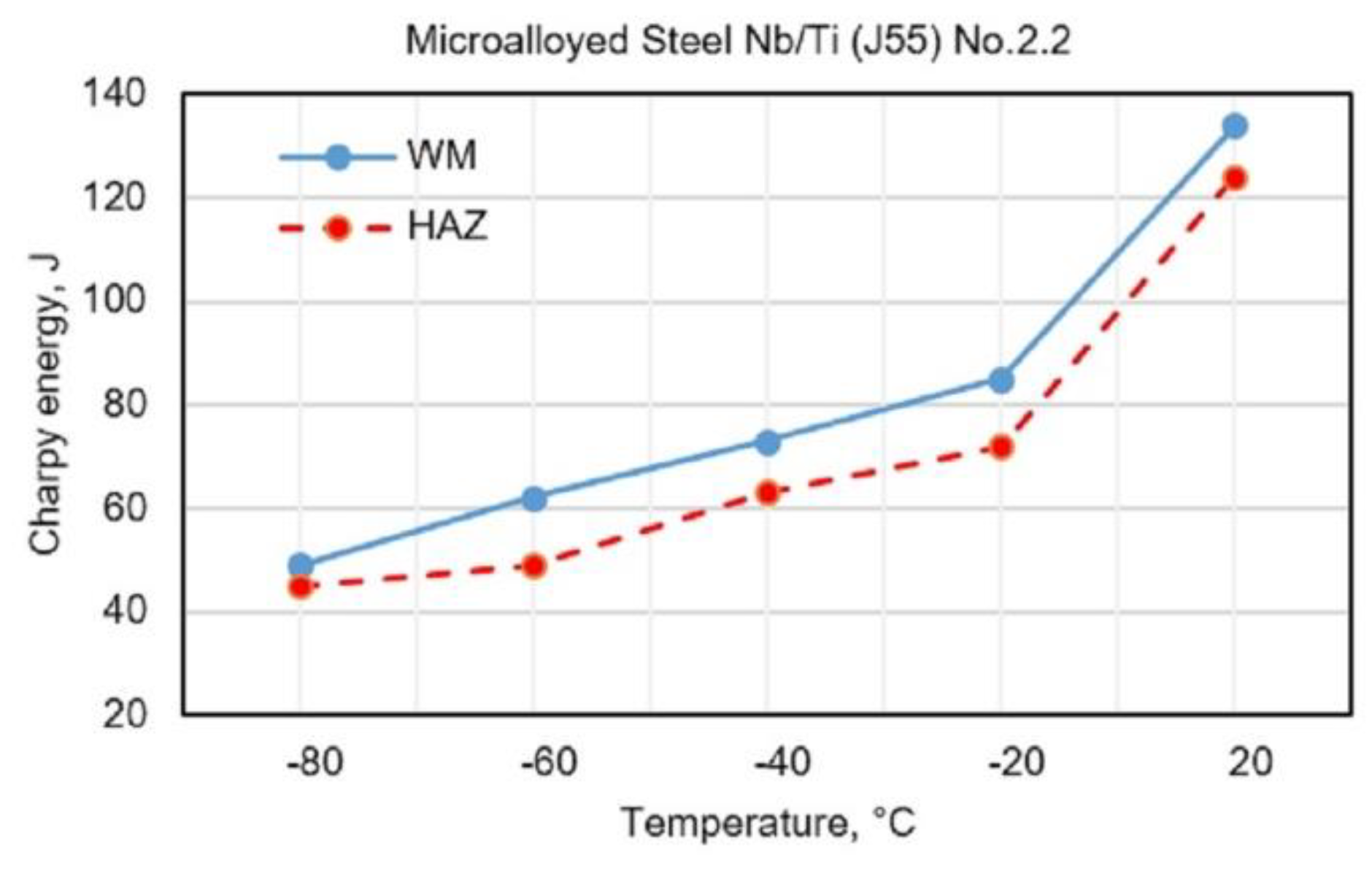

3.3. The Charpy Impact Test

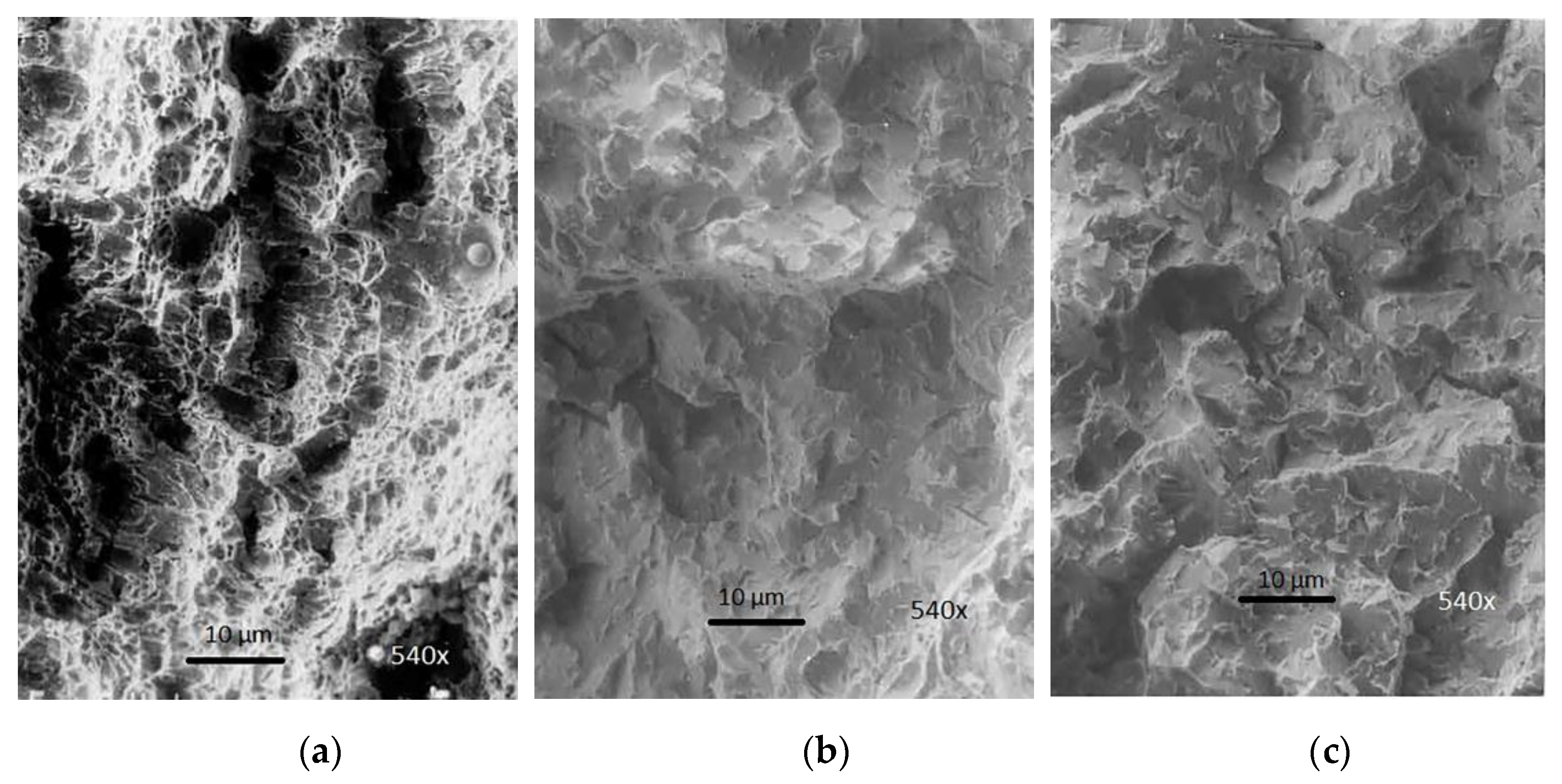

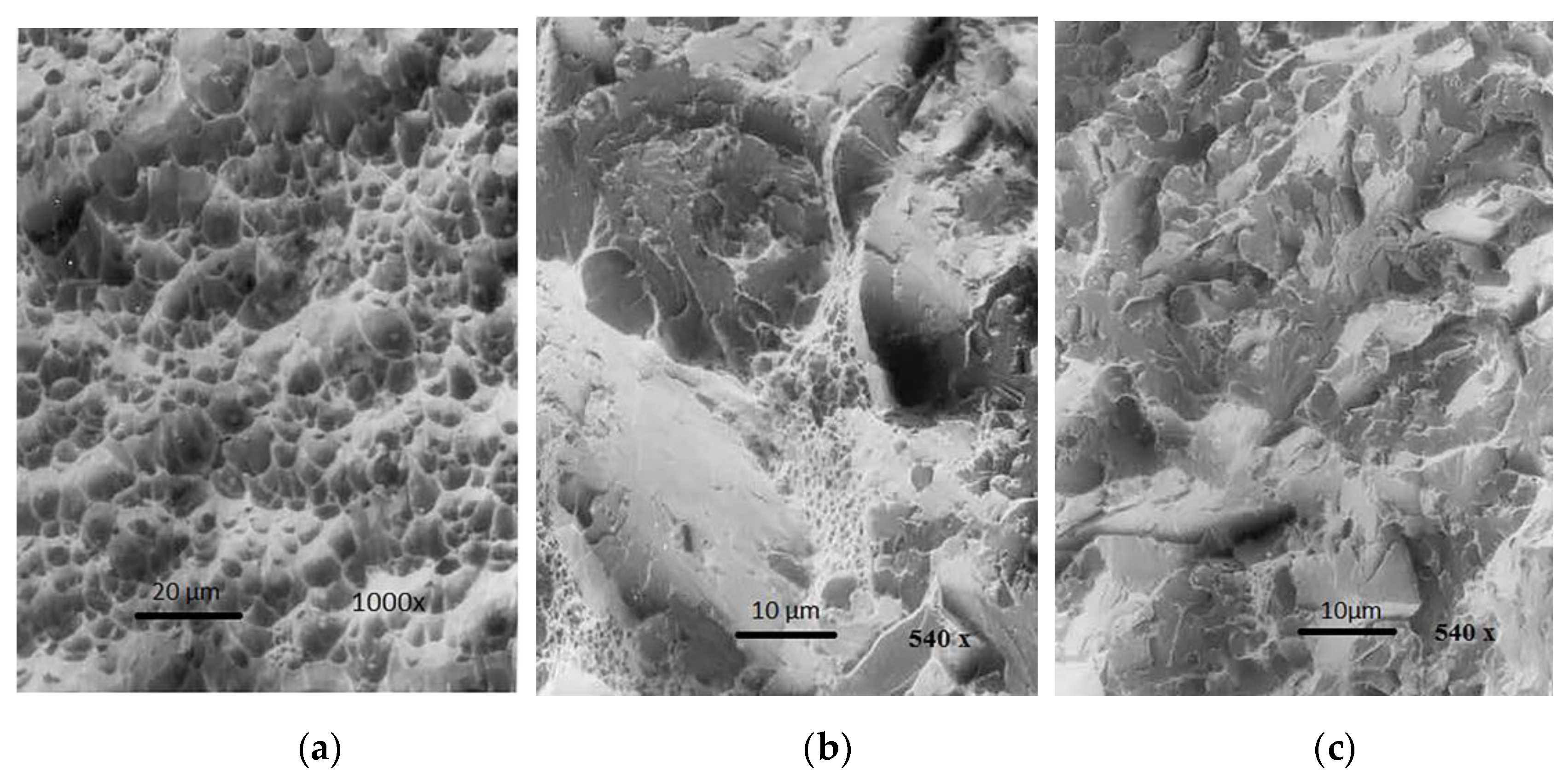

3.4. Fractographic Analysis of WM Toughness

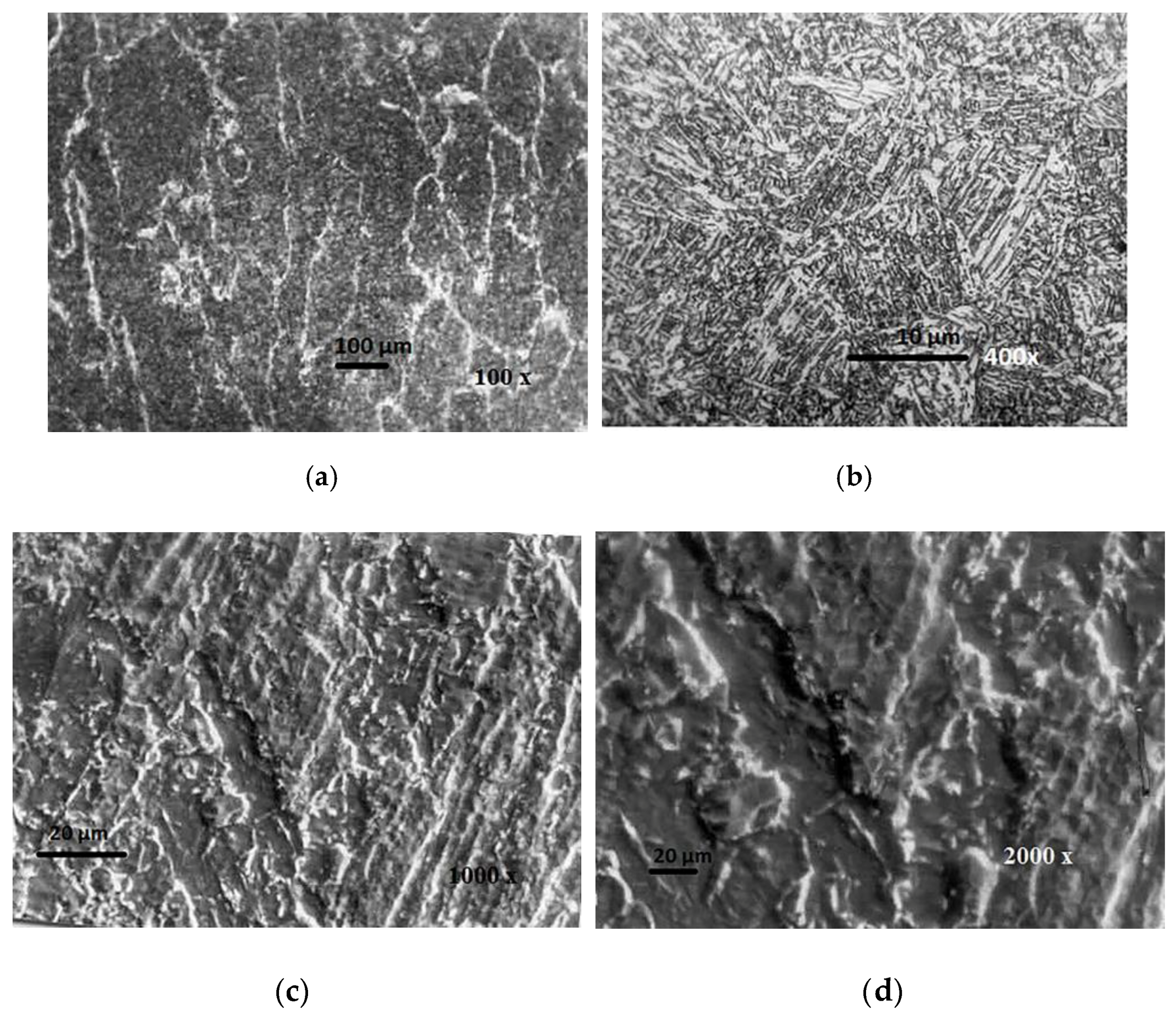

3.5. Base Metal Microstructure

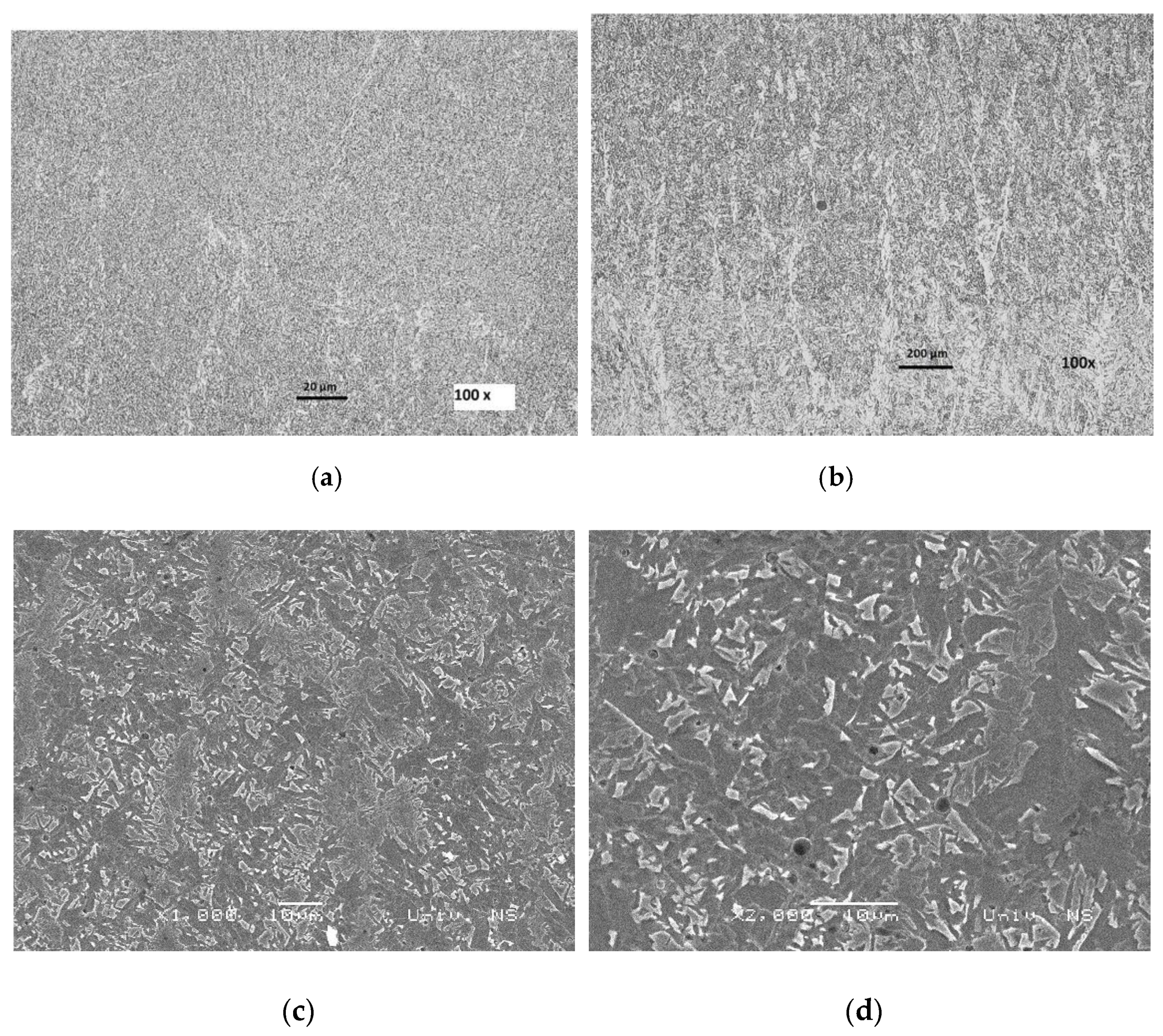

3.6. Microstructural Analysis of WM

4. Conclusions

- Mechanical–technological properties of WM are primarily characterized by the chemical composition of filler material, i.e., the amount of inserted alloying elements. The total amount of alloying elements inserted into the weld metal from the coated electrode No.1.1 amounted to 2.92%; No.1.2 amounted to 5.66%; No.2.1 amounted to 2.99%; and No.2.2 amounted to 5.13%. The above-mentioned percentages of alloying elements inserted during the technological process of weld metal formation hints at their possible impact on the quality of weld metal, taking into consideration the percentage of their mixture with base metal.

- Testing of weld metal toughness shows that the highest impact on the toughness can be attributed to the chemical composition of base metal and the reaction of elements during the welding procedure. The highest values for toughness were achieved with weld metals created by the No.1.2 and No.2.2 electrodes because, apart from the existence of Ni and Mo in weld metal, this led to the increase in Mn from base metal caused by mixing within the molten weld pool and the reduction in carbon due to its burn-out, which has a favorable impact on the formation of acicular ferrite within WM. It can be concluded that toughness, at lower temperatures, is higher than 25–40%.

- Fractographic analysis of fracture toughness of J55 weld metal created by No.1.1 and No.2.1 electrodes at +20 °C shows that the fracture is ductile along the whole cross-section. Weld metal brittle fracture increases in frequency with specimens which were fractured at −40 °C, where the transcrystalline fracture becomes more prevalent. With specimens that were fractured at −60 °C, the brittle fracture of transcrystalline and intercrystalline character become visible.

- The best quality of welding joints in terms of J55 microalloyed steel of increased strength was achieved by the electrodes No.1.2 (1.34% Mn + 2.850% Ni + 0.59% Mo) and No.2.2 (0.89% Mn + 3.245% Ni + 0.307% Mo), with low heat input (7.5–8.5 kJ/cm).

- Regardless of the fact that the price of flux-cored electrode is higher than the solid wire electrode, it is still a better option, since it yields better weld metal properties related to microalloyed steel if other filler materials are of sufficient quality.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mrdak, M.; Bajić, N.; Rakin, M.; Stojadinović, S.; Veljić, D. Comparison of the microstructure of weld metals in welded joints made with rutile electrodes based on domestic raw materials and electrodes of a well-known manufacturer. Int. J. Eng. 2015, 8, 75–78. [Google Scholar]

- Mrdak, M.; Bajić, N.; Veljić, D.; Rakin, M.; Stojadinovic, S.; Karastojkovic, Z. Study of the possibility of applying alloyed fluxcored wire for production of cores for coated electrodes. Acta Tech. Corviniensis–Bull. Eng. 2016, 9, 20–22. [Google Scholar]

- Rakin, M.; Bajić, N.; Mrdak, M.; Veljić, D.; Arsić, M. Analysis of mechanical and structural properties of micro alloyed steel welded joints depending on quality of cored wire. Tech. Gaz. 2013, 20, 635–640. [Google Scholar]

- Bajić, N.; Sijacki-Zeravcic, V.; Bobic, B.; Cikara, D.; Arsić, M. Filler Metal Influence on Weld Metal Structure of Micro-Alloyed Steel. Weld. J. 2011, 90, 55–62. [Google Scholar]

- Potapov, N.N.; Baranov, D.N.; Kakovkin, O.S.; Vitman, D.B. Svaročnie provoloki i elektrodi; Mašinostrenie: Moskva, Russia, 1993; pp. 147–150. [Google Scholar]

- Wan, X.L.; Wei, R.; Wu, K.M. Effect of acicular ferrite formation on grain refinement in the coarse-grained region of heat affected zone. Mater. Charact. J. 2010, 61, 726–731. [Google Scholar] [CrossRef]

- Specification 5CT, Casing and Tubing, 10th ed.; American Petroleum Institute, Eighth Edition: Washington, DC, USA, 2005; p. 306.

- Evans, G.M. The Effect of Molybdenum on the Microstructure and Properties of C-Mn All Weld Metal Deposits; Oerlikon Schwieβmitteilungen: Zurich, Switzerlend, 1987; Volume 45, pp. 10–27. [Google Scholar]

- Powell, G.L.F.; Herfurth, G. Charpy V-Notch Properties and Microstructures of Narrow Gap Ferritic Welds of a Quenched and Tempered Steel Plate. Metall. Mater. Trans. A: Phys. Metall. Mater. Sci. 1998, 29, 2775–2784. [Google Scholar] [CrossRef]

- Ragu Nathan, S.; Balasubramanian, V.; Malarvizhi, S.; Rao, A.G. Effect of welding processes on mechanical and microstructural characteristics of high strength low alloy naval grade steel joints. Def. Technol. 2015, 11, 308–317. [Google Scholar] [CrossRef]

- Oldland, P.T.; Ramsy, C.W.; Matlock, D.K.; Olson, D.L. Significient Features of High-Strength Steel Weld Metal Microstructure. Weld. J. 1989, 68, 158–168. [Google Scholar]

- Wegrzyn, T. The Classification of Metal Weld Deposits In Terms of the Amount of Nitrogen. In Proceedings of the Tenth International Offshore and Polar Engineering Conference, Seattle, WA, USA, 28 May–2 June 2000. [Google Scholar]

- Tonkovič, M.P.; Gojić, M.; Karpe, B.; Kosec, L. Secondary ledeburite formation during various welding techniques. J. Min. Metall. B-Metall. 2015, 51, 117–123. [Google Scholar] [CrossRef]

- Schindleram, I.; Kawuloka, R.; Seilliera, Y.; Kawuloka, P.; Opěla, P.; Rusz, S.; Vodárek, V.; Turoň, R. Continuous cooling transformation diagrams of hsla Steel for seamless tubes production. J. Min. Metall. Sect. B Metall. 2019, 55, 413–426. [Google Scholar] [CrossRef] [Green Version]

- Evans, G.M. Effect of Manganese on the Microstructure and Properties of all Weld metal Deposits. Weld. J. Res. Suppl. 1990, 59, 67–75. [Google Scholar]

- Evans, G.M. The Effect of Nickel on the Microstructure and Properties of C-Mn All-weld metal Deposits. Weld. Res. Abroad 1991, 1, 2–13. [Google Scholar]

- dos Santos, J.F.; dos Santos, V.R.; Jorge, J.C. Properties of a Ferritic Metal Cored Wire Weld Metal Deposited in the Pressure Range from 51 bar to 110 bar. In Proceedings of the Sixth International Offshore and Polar Engineering Conference, Los Angeles, CA, USA, 26–31 May 1996. [Google Scholar]

| Steel API 5CT | Chemical Composition, wt.% | Mechanical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Al | Cu | Ti | Nb | Re, MPa | Rm, MPa | A5, % | |

| J 55 | 0.06 | 0.26 | 1.18 | 0.02 | 0.007 | 0.031 | 0.045 | 0.013 | 0.035 | 497 | 578 | 32 |

| API 5CT Standard | 379–552 | >517 | >22.5 | |||||||||

| Designation | Comparative Nomenclature with Other Manufactures | Chemical Composition, wt % | Mechanical Properties of WM | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Ni | Mo | Re, MPa | Rm, MPa | A5, % | KV, J (−40 °C) | ||

| IHIS 1.1Ni Mo B | Jesenice, Slovenia: EVB NiMo | 0.06 | 0.40 | 0.90 | 1.10 | 0.35 | 510 | 580–710 | 22 | 47 |

| IHIS 2.5Ni Mo B | Plužine, Montenegro: PIVA255BMo | 0.08 | 0.5 | 0.95 | 2.5 | 0.35 | 550–640 | 650–750 | 22–26 | 60–90 |

| IHIS 1.1Ni Mo B-pp | Jesenice, Slovenia: Galeb70 | 0.06 | 0.40 | 0.90 | 1.1 | 0.35 | 510 | 580–710 | 22 | 47 |

| IHIS 3.3Ni Mo B-pp | Jesenice, Slovenia: EVB 2,5NiMo | 0.06 | 0.45 | 1.15 | 2.30 | 0.40 | 590 | 650–750 | 20 | 47 |

| Electrode Designation | Electrode Diameter, mm | Welding Current I, A | Arc Voltage U, V |

|---|---|---|---|

| IHIS 1.1Ni Mo B | 3.25–smw | 120 | 25 |

| IHIS 2.5Ni Mo B | 3.25–smw | 120 | 25 |

| IHIS 1.1Ni Mo B-pp | 3.25–fce | 80 | 25 |

| IHIS 3.3Ni Mo B-pp | 3.25–fce | 120 | 30 |

| No. | Chemical Composition of Clear WM, wt % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cu | Mo | Ni | Cr | S | P | V | Ti | Nb | |

| 1.1 | 0.04 | 0.32 | 0.95 | 0.13 | 0.31 | 1.04 | 0.09 | 0.010 | 0.013 | / | / | / |

| 1.2 | 0.09 | 0.59 | 1.34 | 0.08 | 0.59 | 2.85 | 0.073 | 0.02 | 0.023 | / | / | / |

| 2.1 | 0.015 | 0.111 | 0.68 | 0.067 | 0.241 | 1.868 | / | / | / | <0.003 | <0.003 | <0.003 |

| 2.2 | 0.026 | 0.546 | 0.89 | 0.090 | 0.307 | 3.245 | / | / | / | 0.014 | 0.009 | <0.003 |

| No. | Electrode Designation | Mechanical Properties of WM | Welding Joint | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Re, MPa | Rm, MPa | A5, % | KV, J (−40 °C) | Rm, MPa | Fracture Location | Bending Angle α, ° | |||

| Weld Face | Weld Root | ||||||||

| 1.1. | IHIS 1.1Ni Mo B | 510 | 580–710 | 22 | 47 | 510 | BM | 180 | 140 |

| 1.2. | IHIS 2.5Ni Mo B | 550–640 | 650–750 | 22–26 | 60–90 | 550–640 | BM | 180 | 180 |

| 2.1. | IHIS 1.1Ni Mo B-pp | 510 | 580–710 | 22 | 47 | 510 | BM | 180 | 180 |

| 2.2. | IHIS 3.3Ni Mo B-pp | 590 | 650–750 | 20 | 47 | 590 | BM | 180 | 180 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bajić, D.; Mrdak, M.; Bajić, N.; Veljić, D.; Rakin, M.; Radosavljević, Z. Development of Coated Electrodes with Solid Wire and Flux-Cored Alloyed Wire for Microalloyed Steel Welding. Materials 2020, 13, 2152. https://doi.org/10.3390/ma13092152

Bajić D, Mrdak M, Bajić N, Veljić D, Rakin M, Radosavljević Z. Development of Coated Electrodes with Solid Wire and Flux-Cored Alloyed Wire for Microalloyed Steel Welding. Materials. 2020; 13(9):2152. https://doi.org/10.3390/ma13092152

Chicago/Turabian StyleBajić, Darko, Mihailo Mrdak, Nikola Bajić, Darko Veljić, Marko Rakin, and Zoran Radosavljević. 2020. "Development of Coated Electrodes with Solid Wire and Flux-Cored Alloyed Wire for Microalloyed Steel Welding" Materials 13, no. 9: 2152. https://doi.org/10.3390/ma13092152