Early-Age Properties of Concrete Based on Numerical Hydration Modelling: A Parametric Analysis

Abstract

1. Introduction

2. Modelling Approach

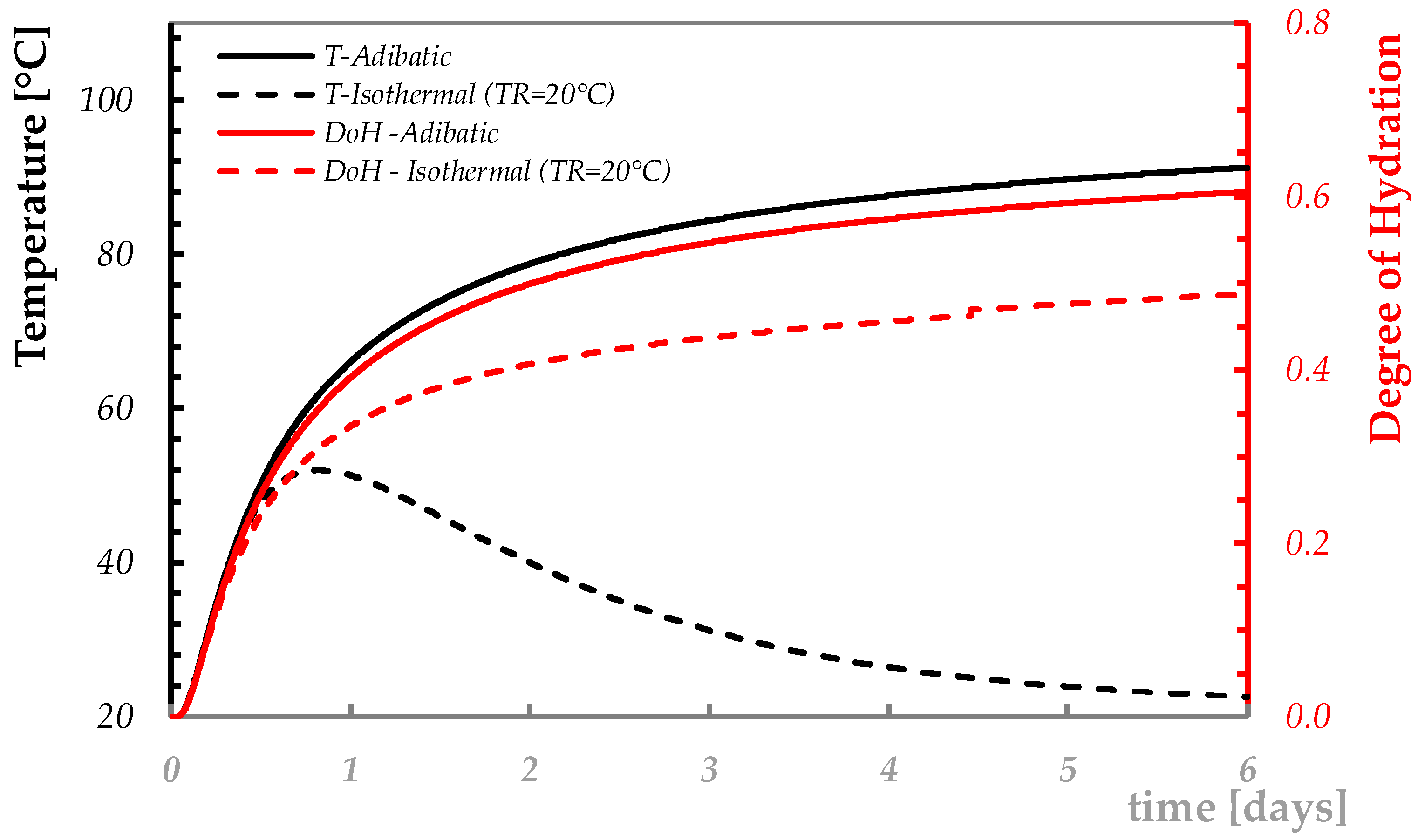

2.1. Hydration Processes

- -

- the reference temperature (TR) can be assumed “a priori” according to the direct measurements;

- -

- the “thermal” properties of the concrete (i.e., cc, ρc and λc) are evaluated as a function of the mixture composition;

- -

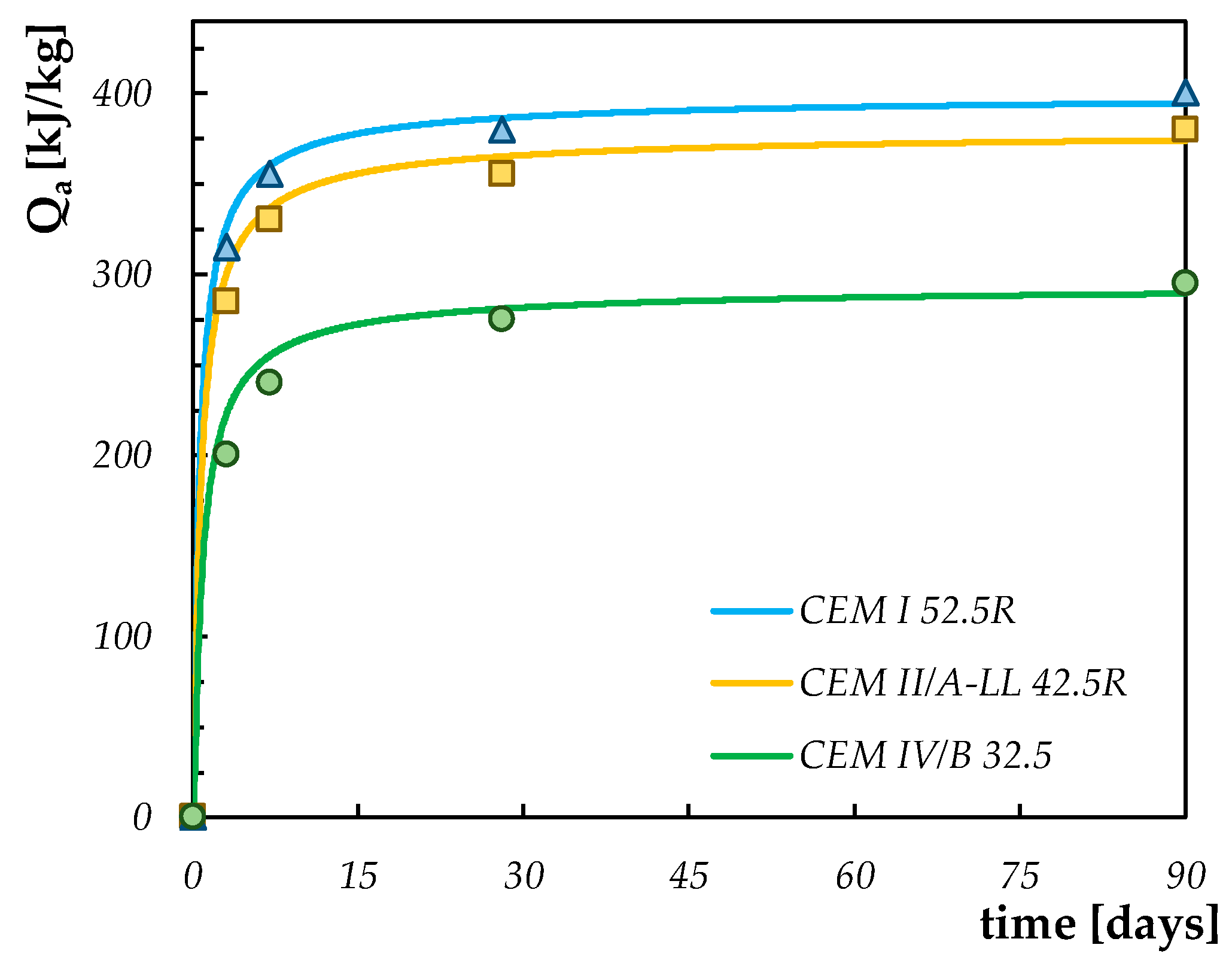

- the Qmax and αh,max values can be determined by the analytical correlations available in the literature, as a function of the cement type and the water-to-cement ratio [21];

- -

- the parameters τ and β are calibrated on adiabatic curves provided by recently released guidelines [22]: they depend on the cement type, as will be explained in Section 2.3;

- -

- the thermal conductivity λp depends on the insulation properties of the materials used for covering the concrete mixture during the setting and hardening processes.

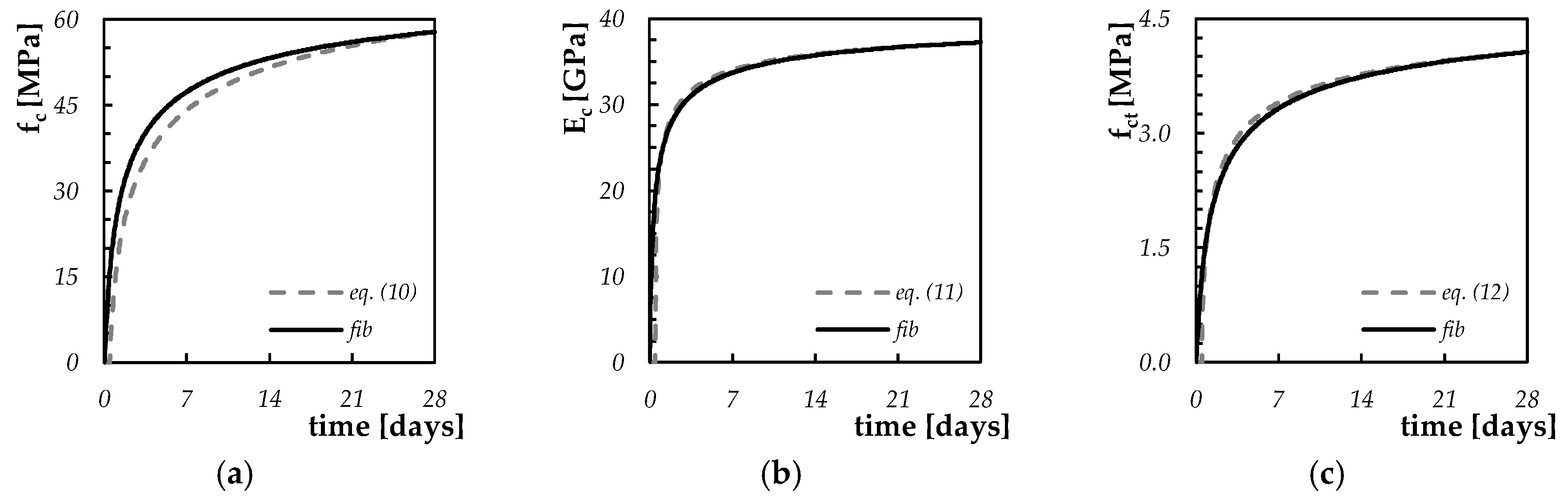

2.2. Time Evolution of the Mechanical Properties

2.3. Input Data for the Parametric Analysis

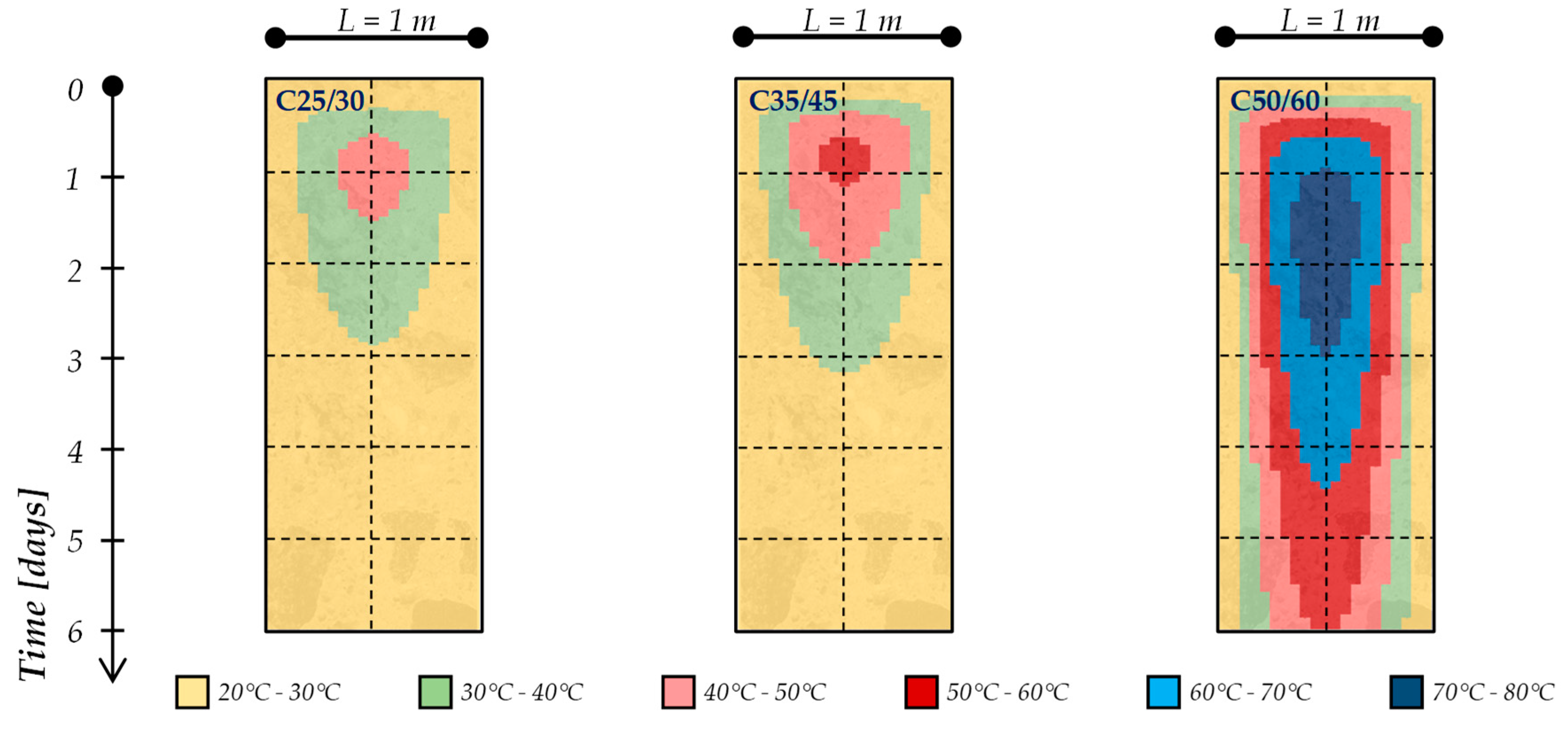

3. Temperature Profiles and Cracking Risk Assessment

- -

- Maximum concrete temperature ≤ 70 °C;

- -

- ΔTmax ≤ 20 °C between the various parts of the structure.

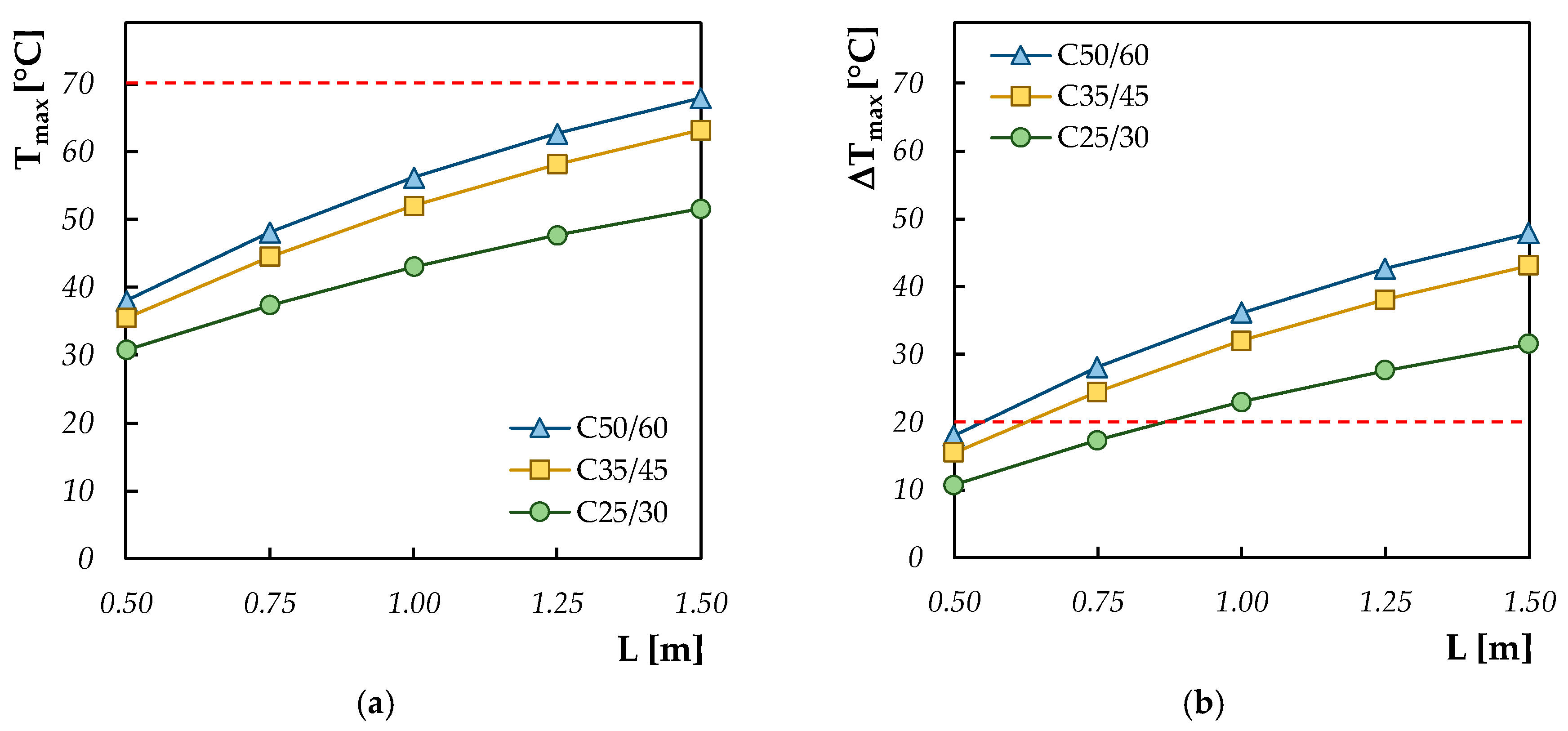

3.1. Influence of Concrete Element Geometry

- -

- Ambient temperature set to 20 °C;

- -

- Absence of thermal insulation protection;

- -

- Variable thickness between 0.50 and 1.50 m.

3.2. Influence of Thermal Isolation of the Formwork

- (i)

- Absence of thermal insulation (i.e., λp = ∞);

- (ii)

- Intermediate thermal insulation system (i.e., λp = 0.125 W/mK) realized with wooden formwork;

- (iii)

- High thermal insulation system (i.e., λp = 0.065 W/mK) realized with fir-mineralized wood bonded with Portland cement formworks. For both the thermal insulation systems, an equal thickness of the formwork’s panel (i.e., 2 cm) is considered.

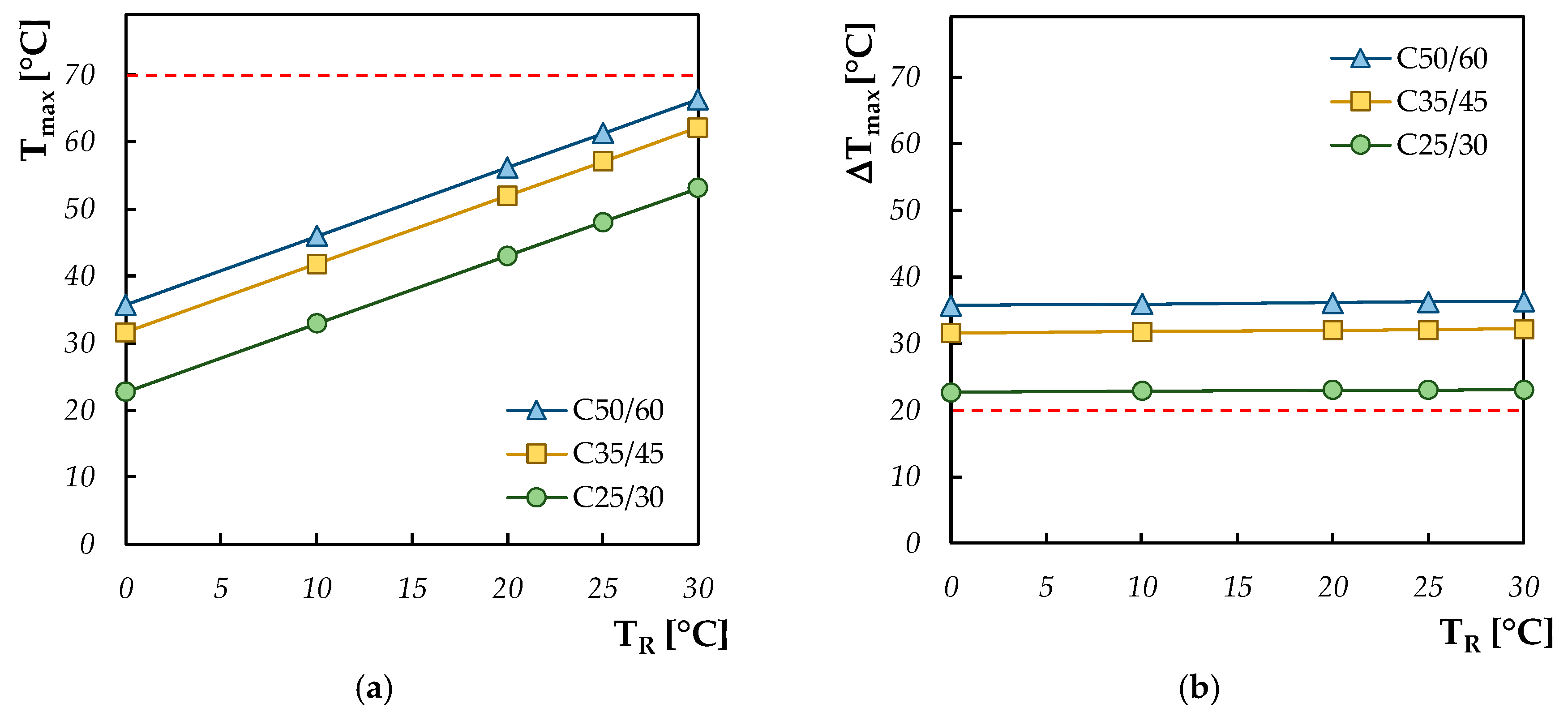

3.3. Influence of Ambient Temperature

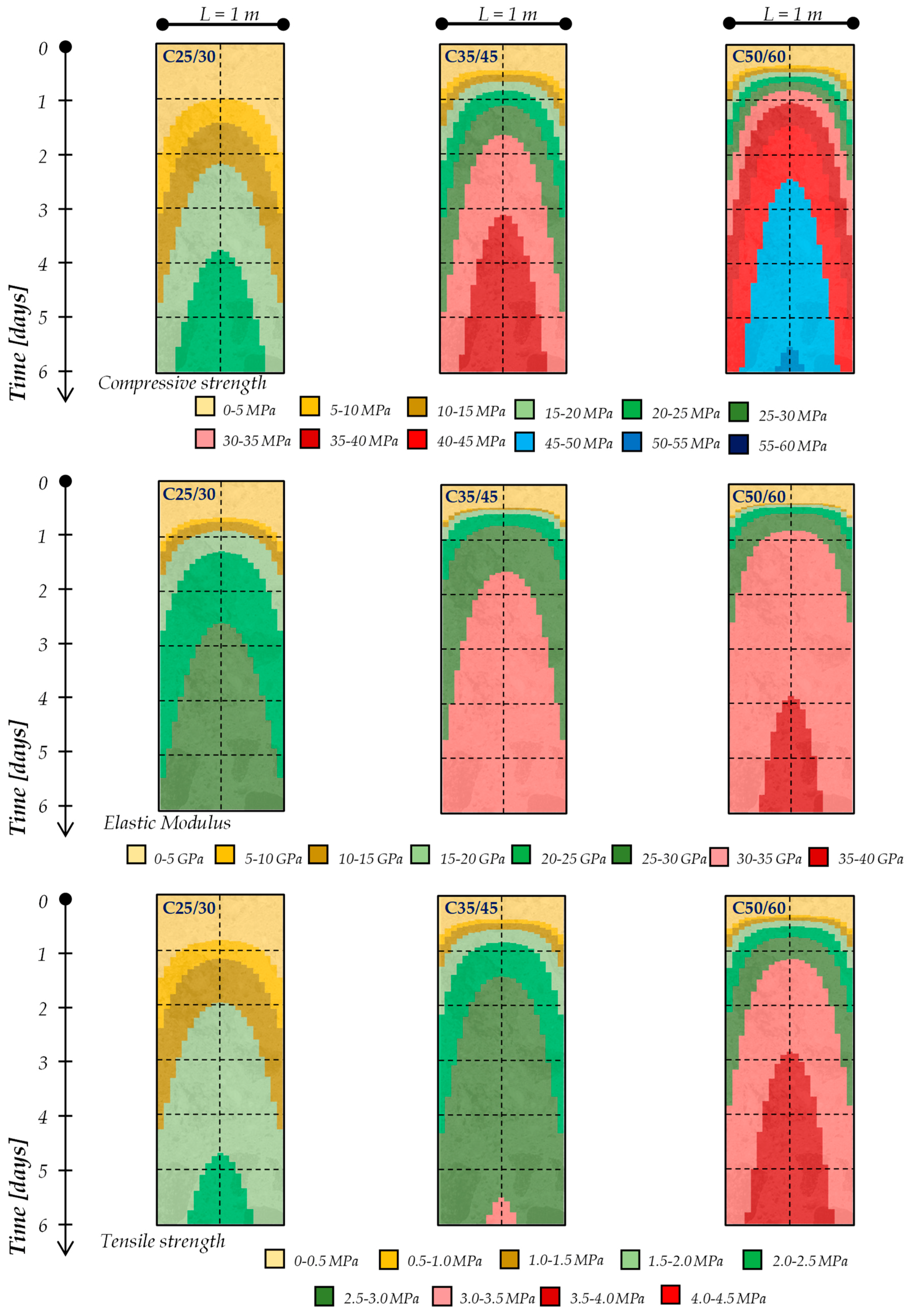

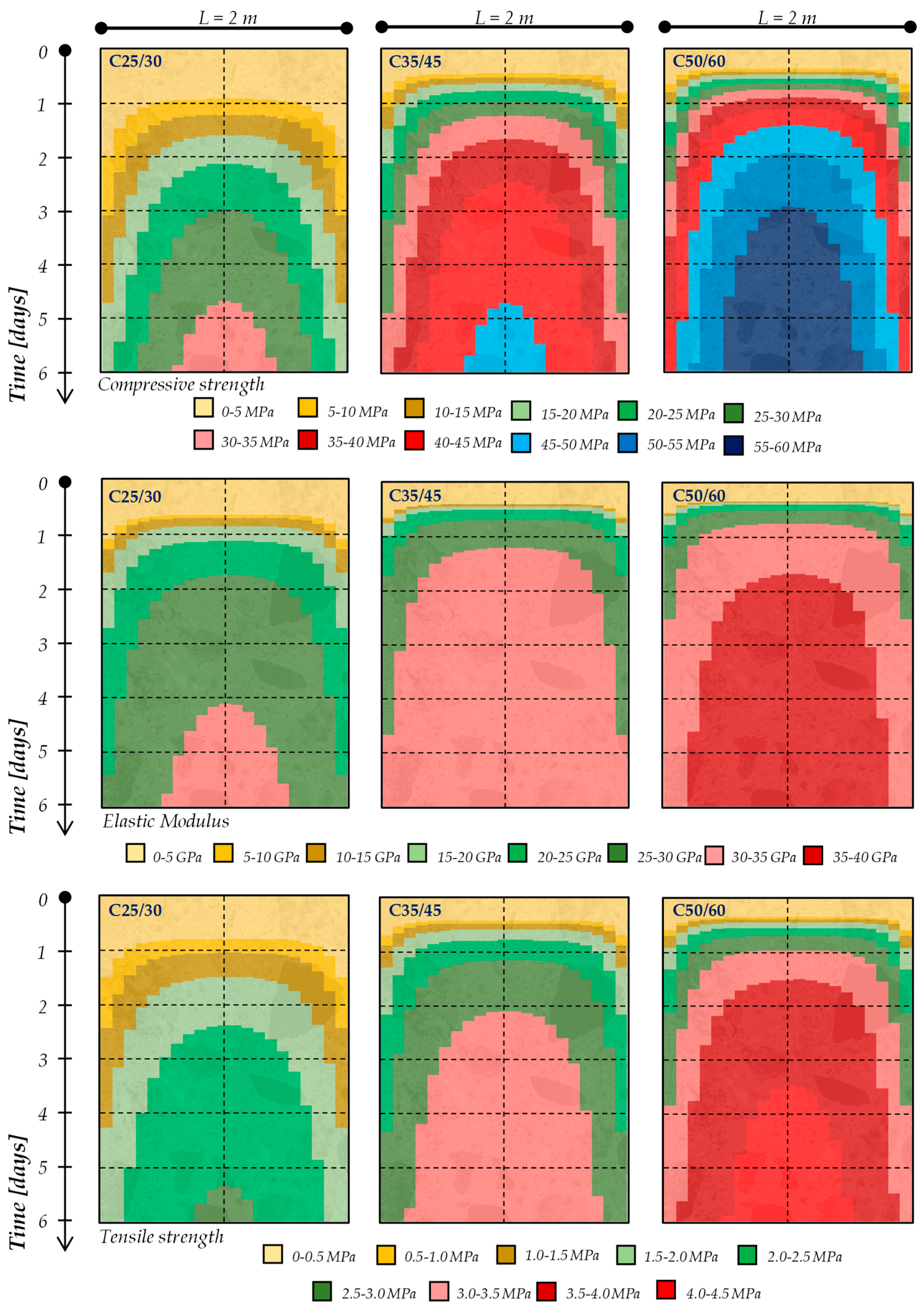

4. Mechanical Properties at Early-Age

5. Conclusions

- the proposed model is capable to simulate the time evolution of both the temperature and degree of hydration in concrete during the setting and hardening phases of the hydration processes;

- the proposed 1-D flow and hydration model turns out to be a useful tool for assessing the cracking risk due to thermal stresses;

- the parametric analysis proposed herein allows to quantify the influence of key parameters affecting the thermal crack formations, such as the geometry of the element, the type of formwork employed for the thermal protection and the ambient temperature;

- the figures derived from the parametric analysis can be employed as simplified design abaci for the optimization of both concrete mixtures as well as the construction phases aimed at mitigating the thermal cracking risk: similar simulations can be performed for other types of mixtures leading to a more comprehensive set of data that can be used for practical aspects;

- the model can be easily employed also for estimating the time evolution of mechanical properties such as the compressive strength, the tensile strength and the elastic modulus: this represents the first step toward a more advanced simulation tool for the “direct” verification of thermal crack formations.

Author Contributions

Funding

Conflicts of Interest

References

- Carette, J.; Staquet, S. Monitoring and modelling the early age and hardening behaviour of eco-concrete through continuous non-destructive measurements: Part I. Hydration and apparent activation energy. Cem. Concr. Compos. 2016, 73, 10–18. [Google Scholar] [CrossRef]

- Fairbairn, E.M.; Azenha, M. (Eds.) Thermal Cracking of Massive Concrete Structures: State of the Art Report of the RILEM Technical Committee 254-CMS; RILEM State-of-the-Art Reports; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Schmid, M.; Pichler, C.; Lackner, R. Engineering hydration model for ordinary Portland cement based on heat flow calorimetry data. J. Therm. Anal. Calorim. 2019, 138, 2283–2288. [Google Scholar] [CrossRef]

- Jung, S.H.; Choi, Y.C.; Choi, S. Use of ternary blended concrete to mitigate thermal cracking in massive concrete structures—A field feasibility and monitoring case study. Constr. Build. Mater. 2017, 137, 208–215. [Google Scholar] [CrossRef]

- Alnaggar, M.; Di Luzio, G.; Cusatis, G. Modeling Time-Dependent Behavior of Concrete Affected by Alkali Silica Reaction in Variable Environmental Conditions. Materials 2017, 10, 471. [Google Scholar] [CrossRef] [PubMed]

- Königsberger, M.; Carette, J. Validated hydration model for slag-blended cement based on calorimetry measurements. Cem. Concr. Res. 2020, 128, 105950. [Google Scholar] [CrossRef]

- Kang, S.-H.; Lee, J.-H.; Hong, S.-G.; Moon, J. Microstructural Investigation of Heat-Treated Ultra-High Performance Concrete for Optimum Production. Materials 2017, 10, 1106. [Google Scholar] [CrossRef] [PubMed]

- Ukrainczyk, N.; Matusinović, T. Thermal properties of hydrating calcium aluminate cement pastes. Cem. Concr. Res. 2010, 40, 128–136. [Google Scholar] [CrossRef]

- Shen, D.; Jiang, J.; Shen, J.; Yao, P.; Jiang, G. Influence of curing temperature on autogenous shrinkage and cracking resistance of high-performance concrete at an early age. Constr. Build. Mater. 2016, 103, 67–76. [Google Scholar] [CrossRef]

- Liu, W.; Cao, W.; Yan, H.; Ye, T.; Jia, W. Experimental and numerical studies of controlling thermal cracks in mass concrete foundation by circulating water. Appl. Sci. 2016, 6, 110. [Google Scholar] [CrossRef]

- Pan, Y.; Prado, A.; Porras, R.; Hafez, O.M.; Bolander, J.E. Lattice Modeling of Early-Age Behavior of Structural Concrete. Materials 2017, 10, 231. [Google Scholar] [CrossRef] [PubMed]

- Chu, I.; Lee, Y.; Amin, M.N.; Jang, B.S.; Kim, J.K. Application of a thermal stress device for the prediction of stresses due to hydration heat in mass concrete structure. Constr. Build. Mater. 2013, 45, 192–198. [Google Scholar] [CrossRef]

- Dolado, J.S.; Van Breugel, K. Recent advances in modeling for cementitious materials. Cem. Concr. Res. 2011, 41, 711–726. [Google Scholar] [CrossRef]

- Feng, X.; Garboczi, E.J.; Bentz, D.P.; Stutzman, P.E.; Mason, T.O. Estimation of the degree of hydration of blended cement pastes by a scanning electron microscope point-counting procedure. Cem. Concr. Res. 2004, 34, 1787–1793. [Google Scholar] [CrossRef]

- Nybo, E.; Maier, R.S.; Lauchnor, E.G.; Seymour, J.D.; Codd, S.L. Electrophoretic nuclear magnetic resonance measurement of electroosmotic flow and dispersion in hydrating cement paste. Cem. Concr. Res. 2019, 116, 11–18. [Google Scholar] [CrossRef]

- Jakob, C.; Jansen, D.; Ukrainczyk, N.; Koenders, E.; Pott, U.; Stephan, D.; Neubauer, J. Relating Ettringite Formation and Rheological Changes during the Initial Cement Hydration: A Comparative Study Applying XRD Analysis, Rheological Measurements and Modeling. Materials 2019, 12, 2957. [Google Scholar] [CrossRef] [PubMed]

- Martinelli, E.; Koenders, E.A.B.; Caggiano, A. A numerical recipe for modelling hydration and heat flow in hardening concrete. Cem. Concr. Compos. 2013, 40, 48–58. [Google Scholar] [CrossRef]

- Koenders, E.A.B.; Pepe, M.; Martinelli, E. Compressive strength and hydration processes of concrete with recycled aggregates. Cem. Concr. Res. 2014, 56, 203–212. [Google Scholar] [CrossRef]

- Pepe, M. A Conceptual Model for Designing Recycled Aggregate Concrete for Structural Applications; Springer Theses; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Van Breugel, K. Simulation of Hydration and Formation of Structure in Hardening Cement-Based Materials. Ph.D. Thesis, Delft University of Technology, Delft (NL), The Netherlands, 1991; 171p. [Google Scholar]

- Hansen, T.C. Physical structure of hardened cement paste. A classical approach. Mater. Struct. 1986, 19, 423–436. [Google Scholar] [CrossRef]

- Italian Ministry of Infrastructure and Transport. Linee Guida Per La Messa in Opera Del Calcestruzzo Strutturale (in Italian); Superior Council of Public Works: Rome, Italy, 2017.

- European Committee for Standardization (CEN). EN 1992-1-1: Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; European Committee for Standardization (CEN): Bruxelles, Belgium, 2004. [Google Scholar]

- European Committee for Standardization (CEN). EN 197-1. Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Standards Specifications; European Committee for Standardization (CEN): Bruxelles, Belgium, 2011. [Google Scholar]

- De Schutter, G.; Tearwe, L. Degree of hydration-based description of mechanical properties of early age concrete. Mater. Struct. 1996, 29, 335–344. [Google Scholar] [CrossRef]

- Breitenbucher, R. Zwangspannungen Und Rissbildung Infolge Hydratationswarme. Ph.D. Thesis, Technischen Universitat Munchen, Munchen, Germany, 1989. [Google Scholar]

- Fib, Model Code 2010; Model code for Concrete Structures 2010; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2013.

| Description | C25/30 | C35/45 | C50/60 |

|---|---|---|---|

| Cement type | CEM IV/B 32.5 | CEM II/A-LL 42.5R | CEM I 52.5R |

| Rck,28 [MPa] | 32.00 | 45.00 | 60.00 |

| fcm,28 [MPa] | 34.56 | 45.35 | 57.80 |

| Q*max [kJ/kg] | 295 | 380 | 400 |

| τ [h] | 15.0 | 12.0 | 10.0 |

| β | 0.80 | 0.80 | 0.80 |

| α0 | 0.25 | 0.20 | 0.20 |

| A | 1.40 | 0.86 | 0.84 |

| B | 0.47 | 0.29 | 0.28 |

| C | 0.88 | 0.55 | 0.55 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pepe, M.; Lima, C.; Martinelli, E. Early-Age Properties of Concrete Based on Numerical Hydration Modelling: A Parametric Analysis. Materials 2020, 13, 2112. https://doi.org/10.3390/ma13092112

Pepe M, Lima C, Martinelli E. Early-Age Properties of Concrete Based on Numerical Hydration Modelling: A Parametric Analysis. Materials. 2020; 13(9):2112. https://doi.org/10.3390/ma13092112

Chicago/Turabian StylePepe, Marco, Carmine Lima, and Enzo Martinelli. 2020. "Early-Age Properties of Concrete Based on Numerical Hydration Modelling: A Parametric Analysis" Materials 13, no. 9: 2112. https://doi.org/10.3390/ma13092112

APA StylePepe, M., Lima, C., & Martinelli, E. (2020). Early-Age Properties of Concrete Based on Numerical Hydration Modelling: A Parametric Analysis. Materials, 13(9), 2112. https://doi.org/10.3390/ma13092112