1. Introduction

Nowadays, the increased interest of manufacturing industry in welding is due to its great economical as well as technological advantages such as higher operating efficiency and reduction in fabrication cost. Hybrid welding shows a great future compared to stand-alone laser welding and arc welding techniques. Laser welding coupled with arc welding offers several advantages like increasing depth of weld, wider gap tolerance, higher welding speeds, narrow heat-affected zone (HAZ) and reduced welding defects [

1,

2]. There are many applications that have proved hybrid laser-arc welding to be a suitable technology to weld metals of different compositions and properties [

3].

The combination of different materials is often required to provide high-performing products [

4]. Among steels, high manganese twinning-induced plasticity (TWIP) steels and dual phase (DP) can be joined to austenitic stainless steels and they produce high strength, although high corrosion and oxidation resistance welds [

5,

6,

7,

8,

9,

10]. TWIP steel with austenitic microstructures at room temperature show high strength and ductility due to the formation of twins during deformation. DP steel, with a ferritic and martensitic microstructure, shows high tensile strength (from 500 to 1200 MPa) and formability. The formation of martensite microstructure increases the tensile strength [

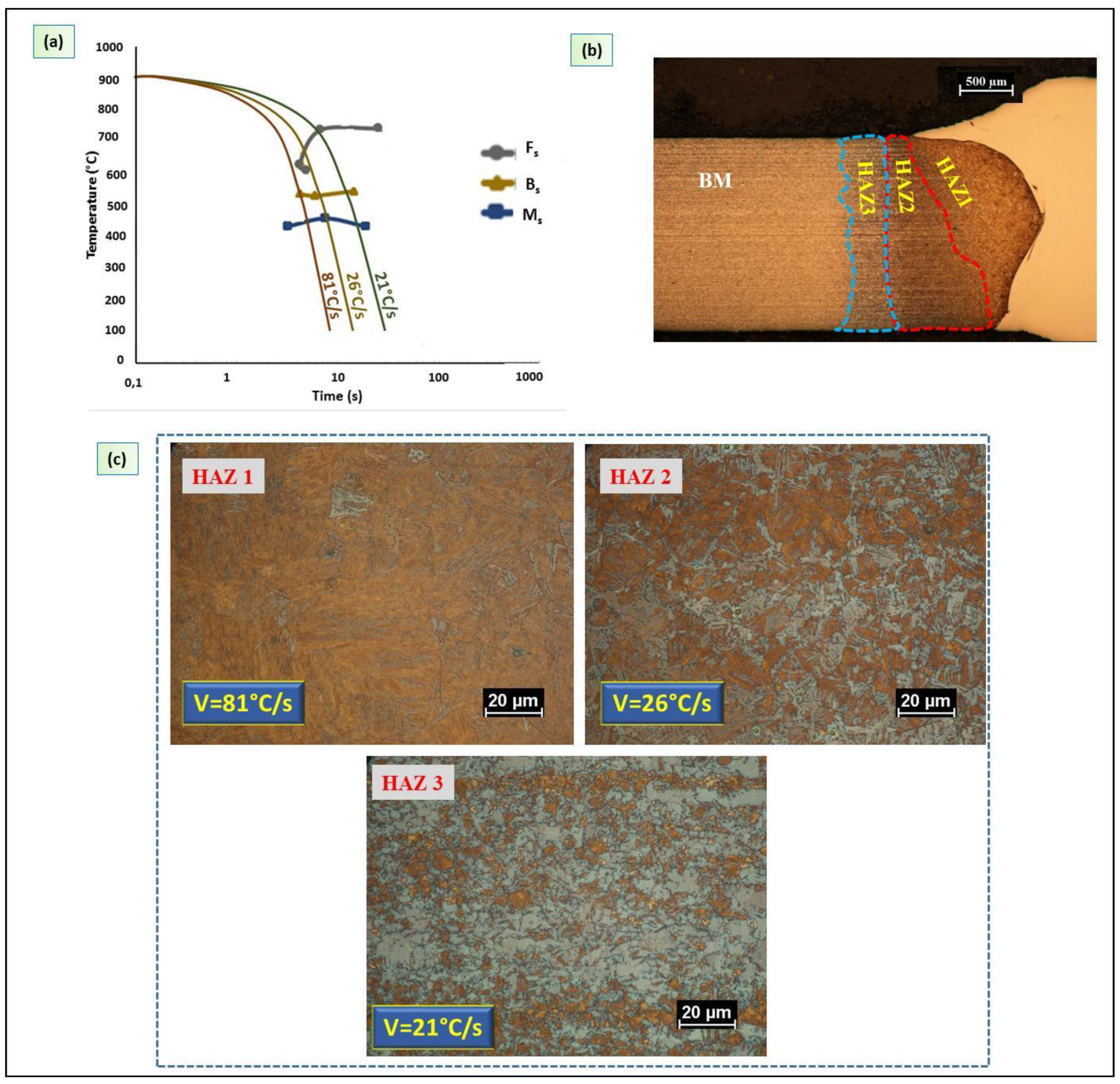

3]. Dissimilar joints must have adequate tensile strength and ductility, which requires avoiding the formation of unsuitable microstructures and second phases in the fusion and HAZ [

11]. Through finite element analysis, it is possible to develop time-saving numerical models that are suitable for better understanding the mechanisms of the welding process and avoiding the welding defects [

12]. Modeling the hybrid laser-arc welding seems to be a reliable way to investigate the physical phenomena of the process [

13]. In numerical simulation, it is important to ensure the accuracy of both thermal and mechanical analysis, which permits to evaluate the weldability and the structural deformation during the welding process [

14].

The heat source is one of the critical issues in thermal simulation. Moreover, temperatures are the necessary data that can be employed to define residual stress and distortion in the welded plates. Correct calibration of the model is a prerequisite to establish good correlations between numerical and experimental results. Consequently, the accurate prediction of the temperature distribution during the welding process depends on the heat source model. Rosenthal (1946) was the first researcher who suggested a mathematical model for the heat source [

15]. Since then, Dowden et al. (1983) proposed a three-dimensional mathematical model for the simulation of molten pool during laser beam welding [

16]. For arc welding, the double-ellipsoidal power density model proposed by Goldak (1984) proved to be extremely efficient in the simulation of the heat source [

17]. That movement of the heat source was described by Fourier’s law and the point, line, point and plane sources can be represented. One of the limits of Fourier’s law is the calculation of the transient temperature in the proximity of the fusion zone [

18]. More recently, researchers have been struggling with the modeling of the laser-arc hybrid welding process. Reutzel et al. [

19] used a volumetric double ellipsoidal heat source to represent laser/MIG (Metal Inert Gas) welding.

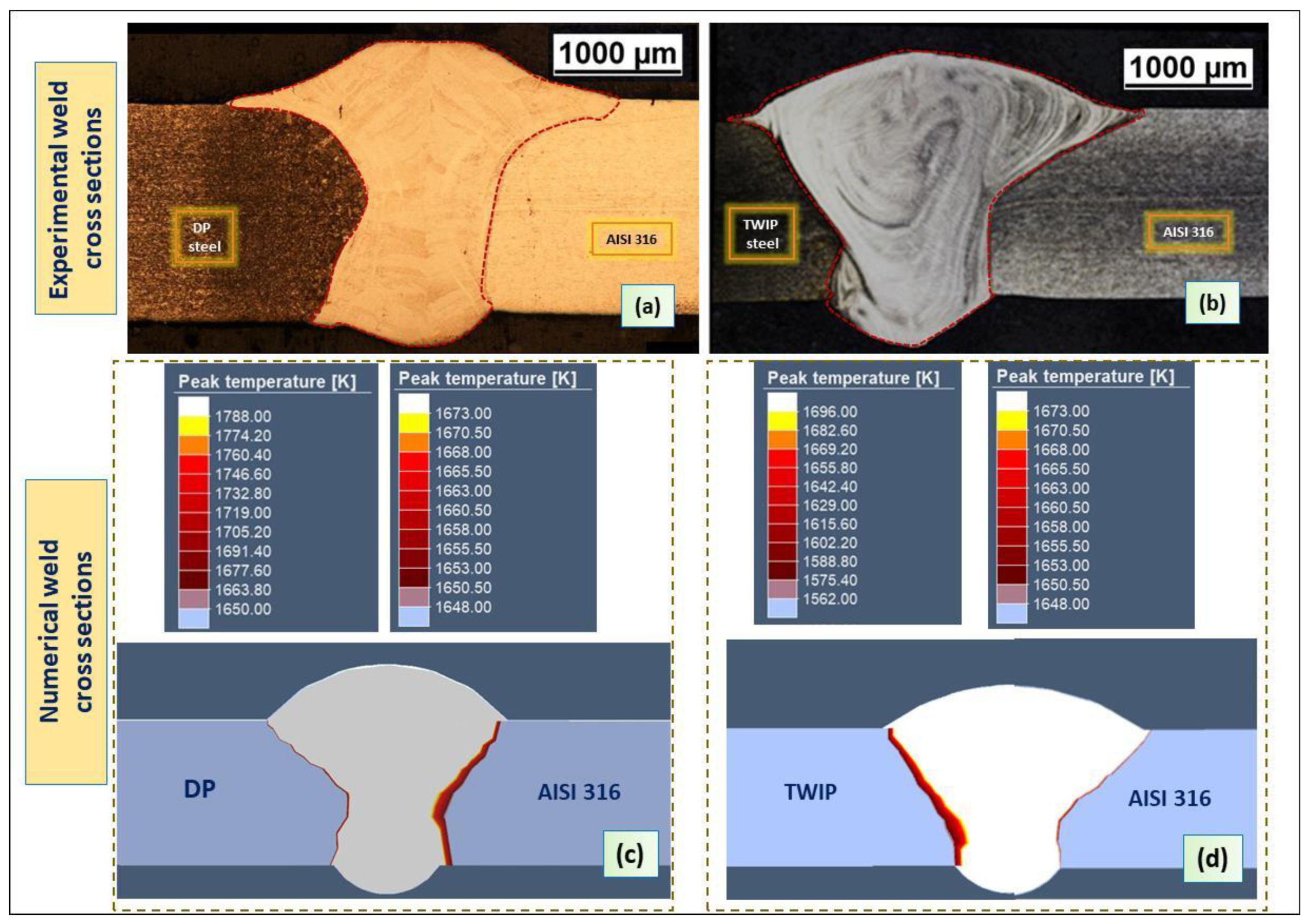

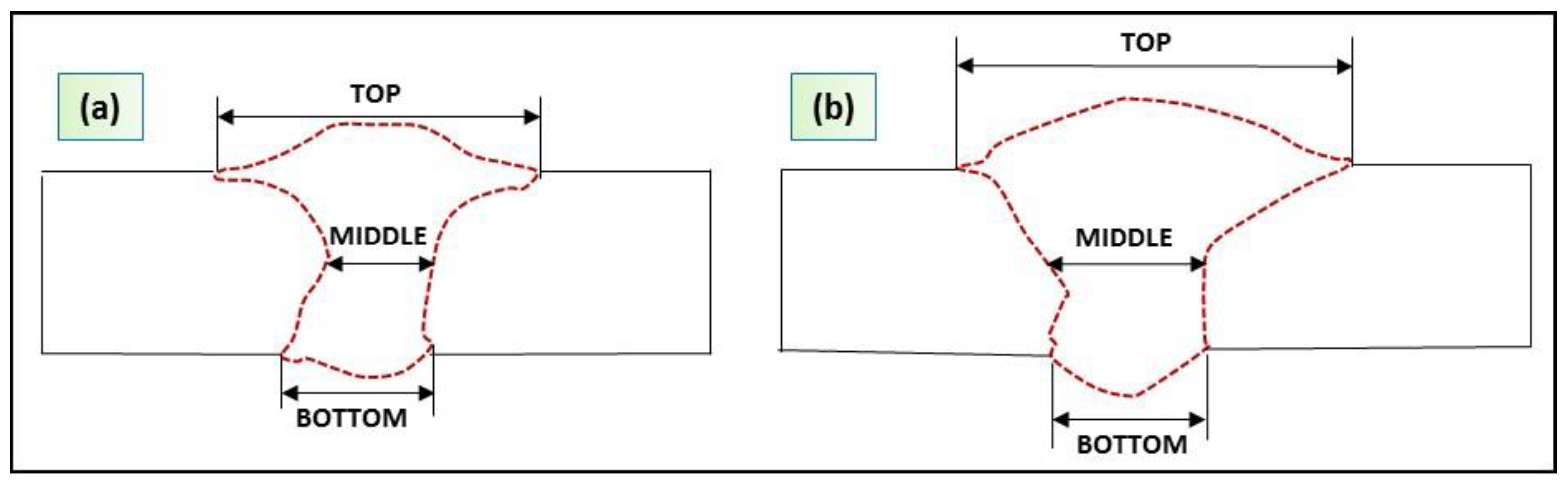

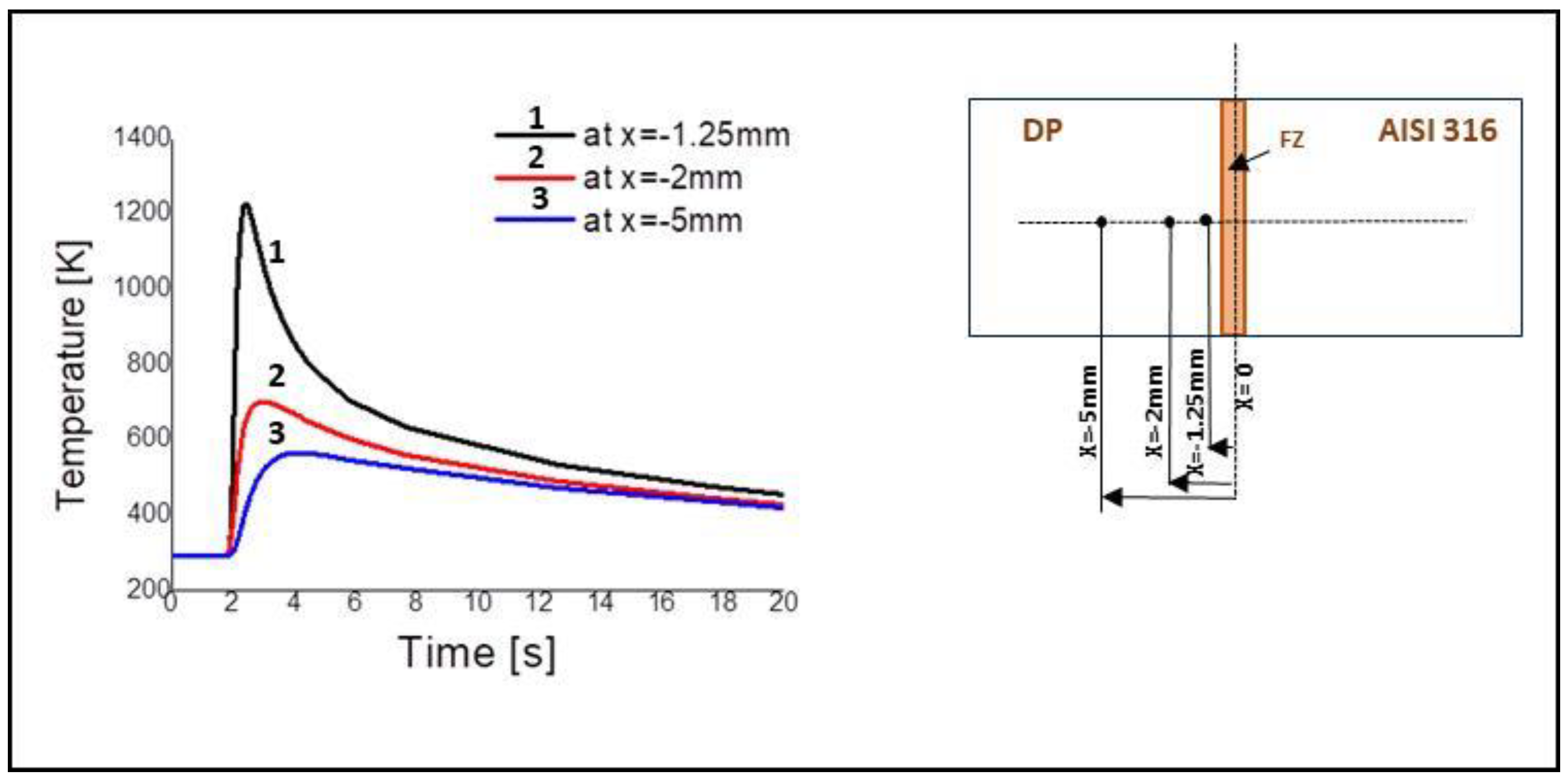

This paper presents a finite element model (FEM) for the thermal-mechanical simulation of the laser-arc hybrid welding process of DP/austenitic stainless steel (AISI 316) and TWIP/AISI 316 dissimilar steel welds. The heat input during the hybrid welding process was simulated by a three-dimensional moving heat source. This work focuses on the calibration and validation of the heat source by comparing the size and shape of the weld calculated by the numerical model and those obtained by the experiment. The metallurgical transformations for the DP steel were evaluated using the continuous cooling transformation (CCT) diagram and the calculated thermal cycle. This study is a novelty of the numerical modeling of a dissimilar steels weld obtained by a hybrid fiber laser-MAG welding system. Enhancing the weldability of dissimilar DP/AISI 316 and TWIP/AISI 316 steels can be a solution for the assembler of car body parts to reduce vehicle weight and, consequently, fuel consumption. Hence, it is important to have a model by which the welding parameters can be optimized.

2. Experimental Setup

Plates 1.5 mm thick of the DP/AISI 316 and TWIP/AISI 316 steels were welded in butt configuration, as shown in

Figure 1.

Table 1,

Table 2 and

Table 3 contain the chemical composition of those steels.

The welding system was a continuous ytterbium fiber laser (IPG YLS-4000) with power of 4 kW and wavelength of 1070.6 nm combined with a MAG (metal active gas) current generator. A mixture of argon (87%) and carbon dioxide (CO

2) (13%) was used as shielding gas to avoid the melt pool oxidation during the welding process. The MAG torch, tilted at an angle of 41°, with 94 A arc current and 20.2 V voltage was used. The laser beam with 250 mm focal distance lens created a spot diameter of 0.4 mm on the workpiece surface. The welding parameters included 1500 W power at 2.4 m/min welding speed. Austenitic filler wire with a diameter of 0.8 mm was used (316L-Si/SKR-Si).

Table 3 shows the chemical composition of the austenitic filler wire. As represented in

Figure 1, the laser-leading configuration was used during the welding process. The heat sources were spaced by 2 mm. The laser focus was put at the sheet’s surface.

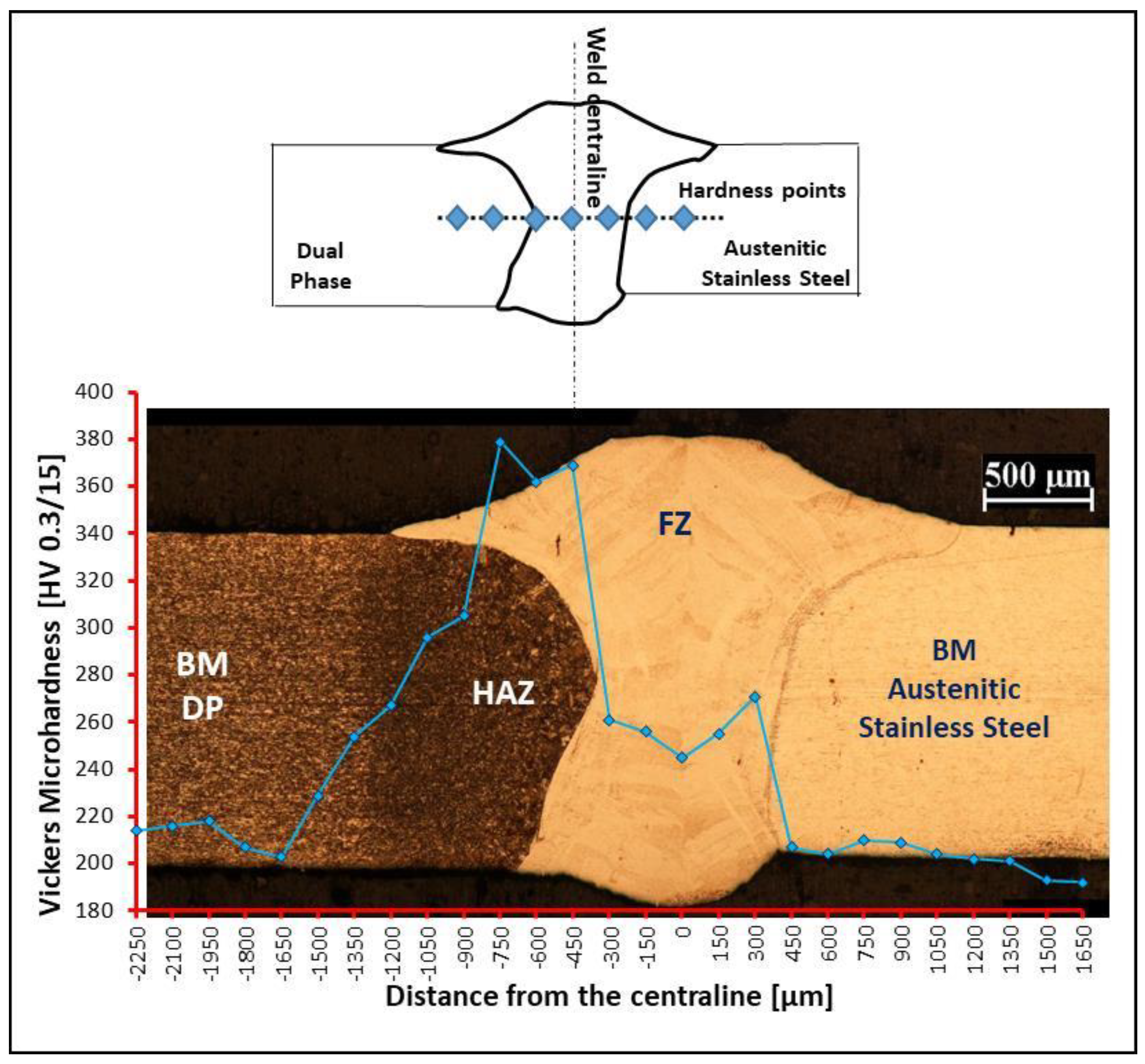

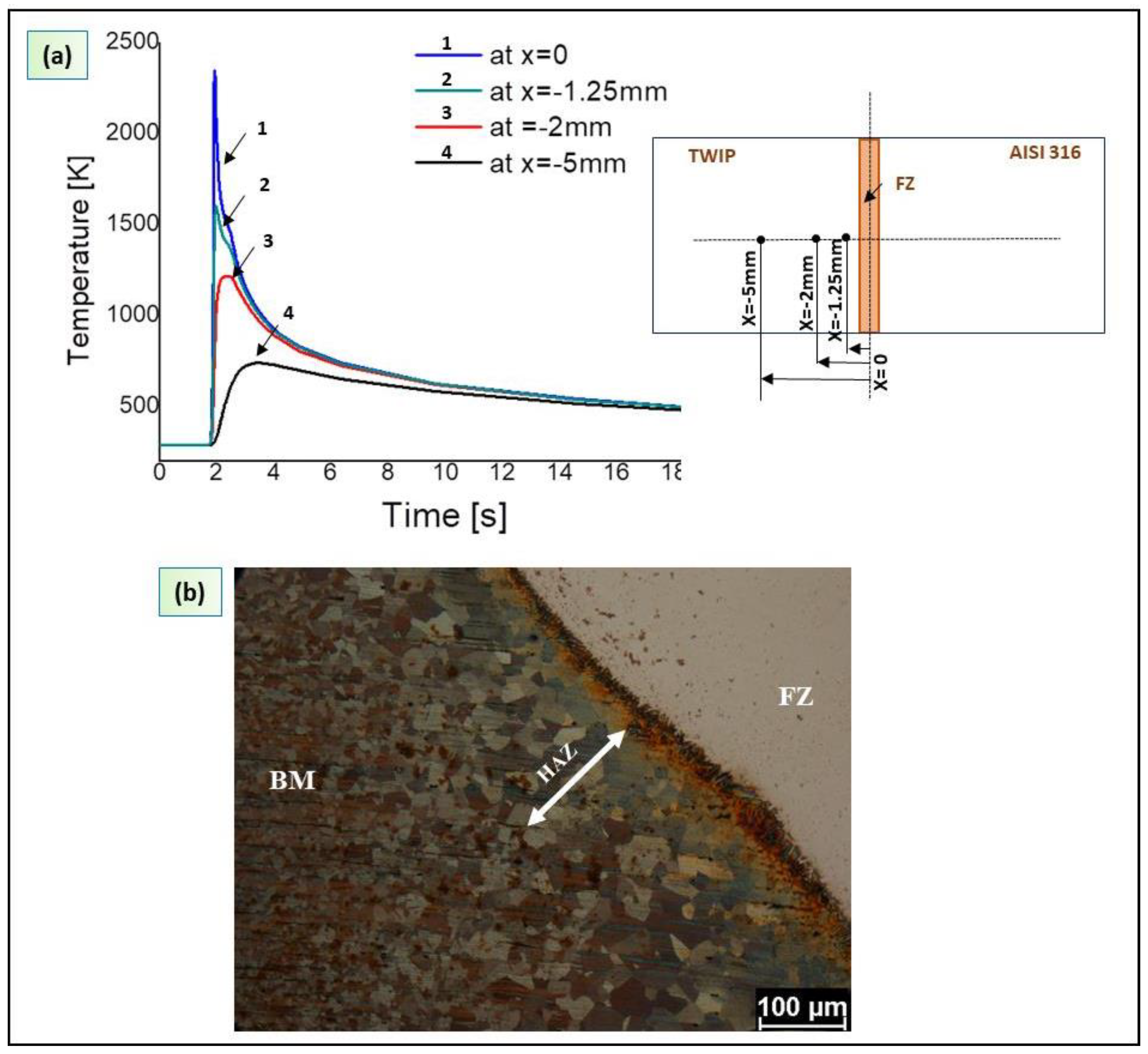

The cross section of the dissimilar joints was analyzed by optical microscopy (OM, Nikon Epiphot 200, Tokyo, Japan), after the standard metallographic grinding and polishing technique. The microstructure of the cross sections was etched using Glyceregia solution (15 mL HCl, 15 mL glycerol, 5 mL HNO3) for austenitic stainless steel and TWIP steel and LePera solution (1% metabisulfide in distilled water and 4% picric acid in ethyl alcohol) for DP steel.

3. Numerical Model

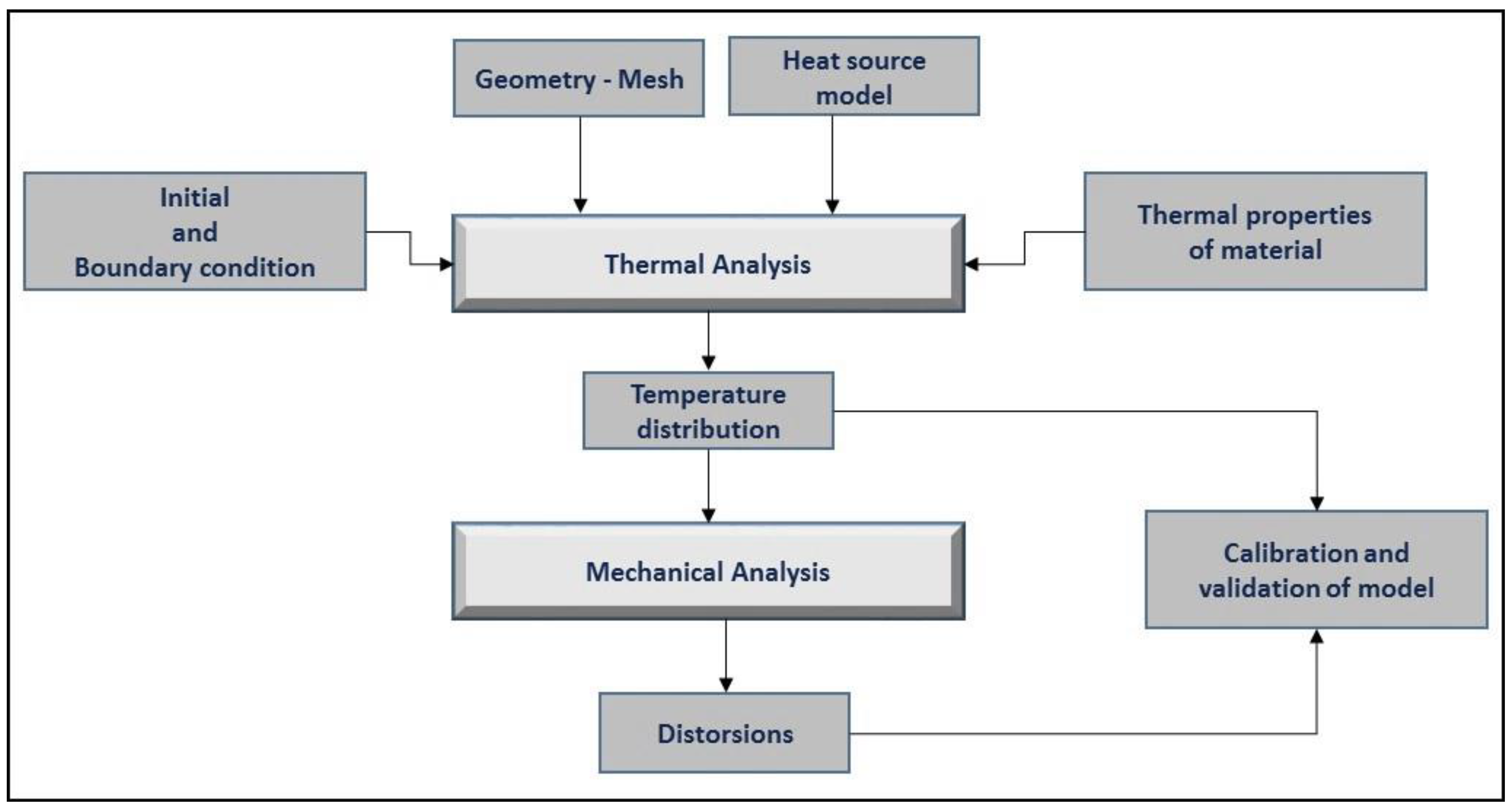

The finite element model was built using the Simufact Welding software (version 8.0, MSC. Software, Munich, Germany). Thermo-mechanical finite element calculation was performed for the prediction of the fusion zone and prediction of the temperature fields, thermal cycles and distortions of the plates. The flow chart in

Figure 2 describes the numerical procedure used in the FEM analysis: coupling thermal analysis was used as input for mechanical analysis step by step.

3.1. Geometry and Mesh

The dimensions of the plate were 150 mm × 50 mm × 1.5 mm. Hexahedral mesh was employed.

Figure 3a shows the mesh used in the model. The fine mesh is very important for the accuracy of the temperature calculation, which is the most important precaution in high-thermal gradient zones.

Mesh sizes were 3.2 mm × 0.5 mm × 0.1 mm at the contact surfaces of the plates in order to reproduce the high thermal gradient. The ratio in size between the last element and first element in the distribution was 0.1 (

Figure 3b). A coarse mesh was used far from the fusion zone to reduce the computational cost. The mapped mesh in the plats had 33,000 elements.

The top and bottom reinforcements produced during the welding processes requires a finer mesh. The tetrahedron mesh in the top and bottom material had 45,000 elements (see

Figure 3b).

3.2. Material Properties

Table 4 shows the mechanical and thermo-physical properties at room temperature of DP, TWIP and stainless steel. Temperature dependent material properties were considered in the FEM analysis. The simulation strategy was to perform first the thermal analysis. The thermal simulation output was used for the mechanical analysis, which permitted the evaluation of the induced strain fields.

3.3. Boundary Conditions

In the welding simulation process is fundamental the temperature distribution in the workpiece. Equation (1) accounts for the heat transfer in the plates during the welding process [

25]:

In this equation, Q (W·m−3) represents the heat transfer in the work piece and ρ (kg·m−3) the density of the metal. Kx, Ky and Kz define the thermal conductivity in the x, y and z directions (W/m−1·K−1), c represents the specific heat capacity (J·kg−1 °C−1), while t is the time (s).

Heat losses due to the convection and radiation were also considered. The heat losses followed Equation (2) [

25]:

where ε is the emissivity of the surface, σ is the Stefan-Boltzmann constant,

Tr is the room temperature (293 K),

h is the heat transfer coefficient. It was estimated to 20 W/(m

2·K) for air and 200 W/(m

2·K) for the lower surface of the weld. The workpiece room temperature was 293 K at time t = 0. The boundary conditions in the mechanical analysis were applied in order to simulate the strain field. The plates were clamped to the worktable to prevent displacement: four edges of plates were fixed in order to avoid translation and rotation with appropriate clamping system.

3.4. Three-Dimensional (3D) Model for Laser Heat Source

Two different heat source models were defined and coupled to represent the arc and laser heat source in hybrid laser-arc simulation welding. A 3D model for the heat source was considered for both.

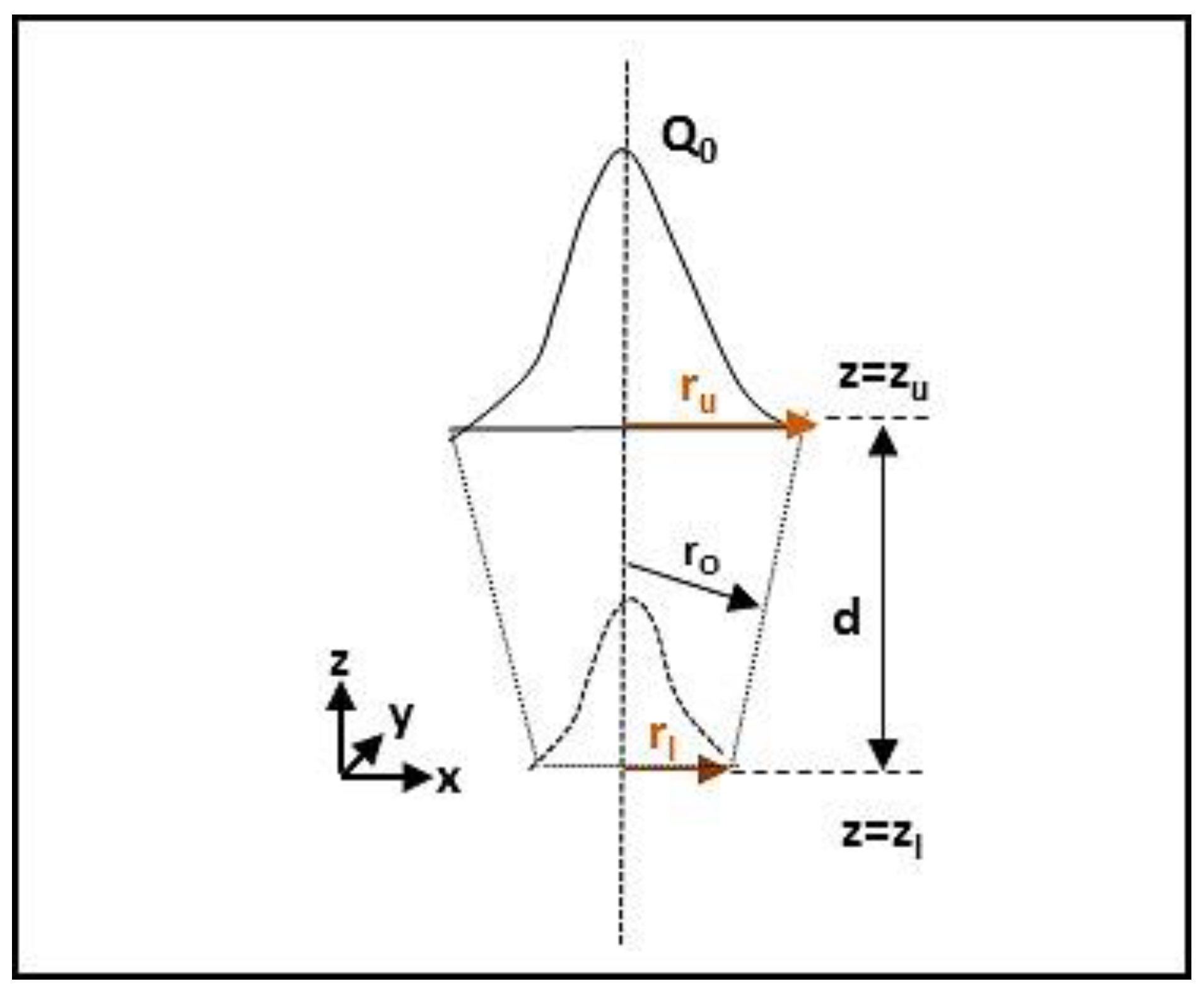

In the Gaussian distribution for the laser power density, the heat intensity decreases from the top to bottom of a truncated cone (

Figure 4).

The power distribution in welding direction can be mathematically expressed as follows (Equations (3) and (4)) [

26]:

The parameter

r0 decreases linearly and it can be expressed as Equation (5):

In particular, Qr represents the heat source intensity, Q0 is the maximum intensity, ru and rl describe upper and the lower radius in the upper plane at z = zu and in the lower plane at z = zl respectively.

3.5. Three-Dimensional (3D) Heat Source Model for the Electric Arc

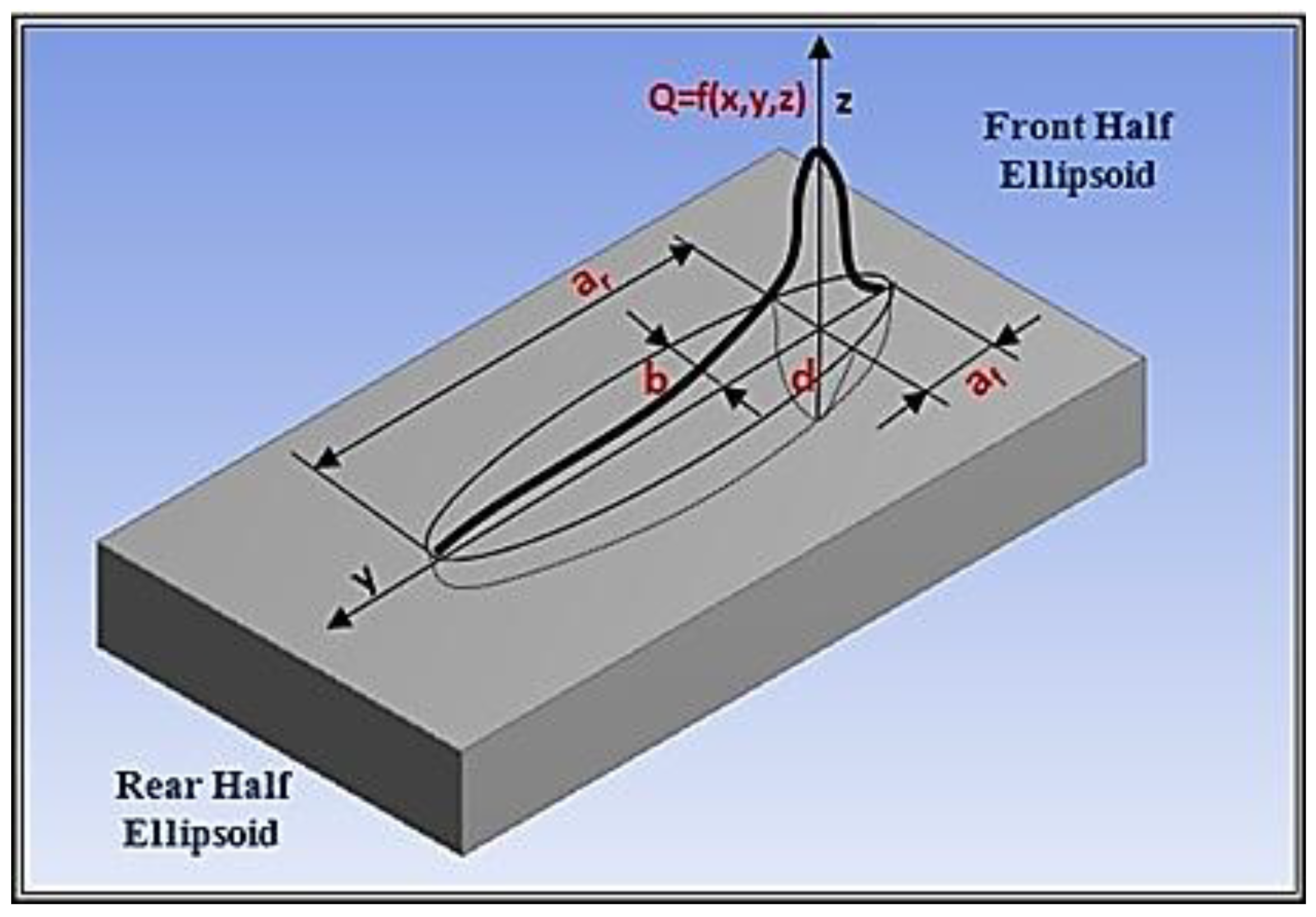

After Goldak, the double-ellipsoidal heat source can describe the arc power, which causes the molten pool [

26]. The heat source model is shown in

Figure 5; it combines two different ellipses, i.e., one in the front quadrant of the power distribution (

qf) and the other in the rear quadrant (

qr) [

27].

Moving arc heat source in the plates can be mathematically defined as [

28,

29,

30]:

The mathematical definition of the power distribution of the two different ellipses is defined by power distribution inside the front quadrant (Equation (7)) and for the rear quadrant (Equation (8)), respectively.

In particular,

af represent the front length,

ar is the rear length,

b and

d are the width and depth, respectively (see

Figure 5). The welding speed is

v and

ff and

fr are the proportion coefficients at front and rear ellipsoids.

Q is arc power that was calculated by Equation (9):

where

I is to the arc current and

U represents the arc voltage and η

a is the arc heat efficiency. The heat source parameters are employed in the calibration process of the model.

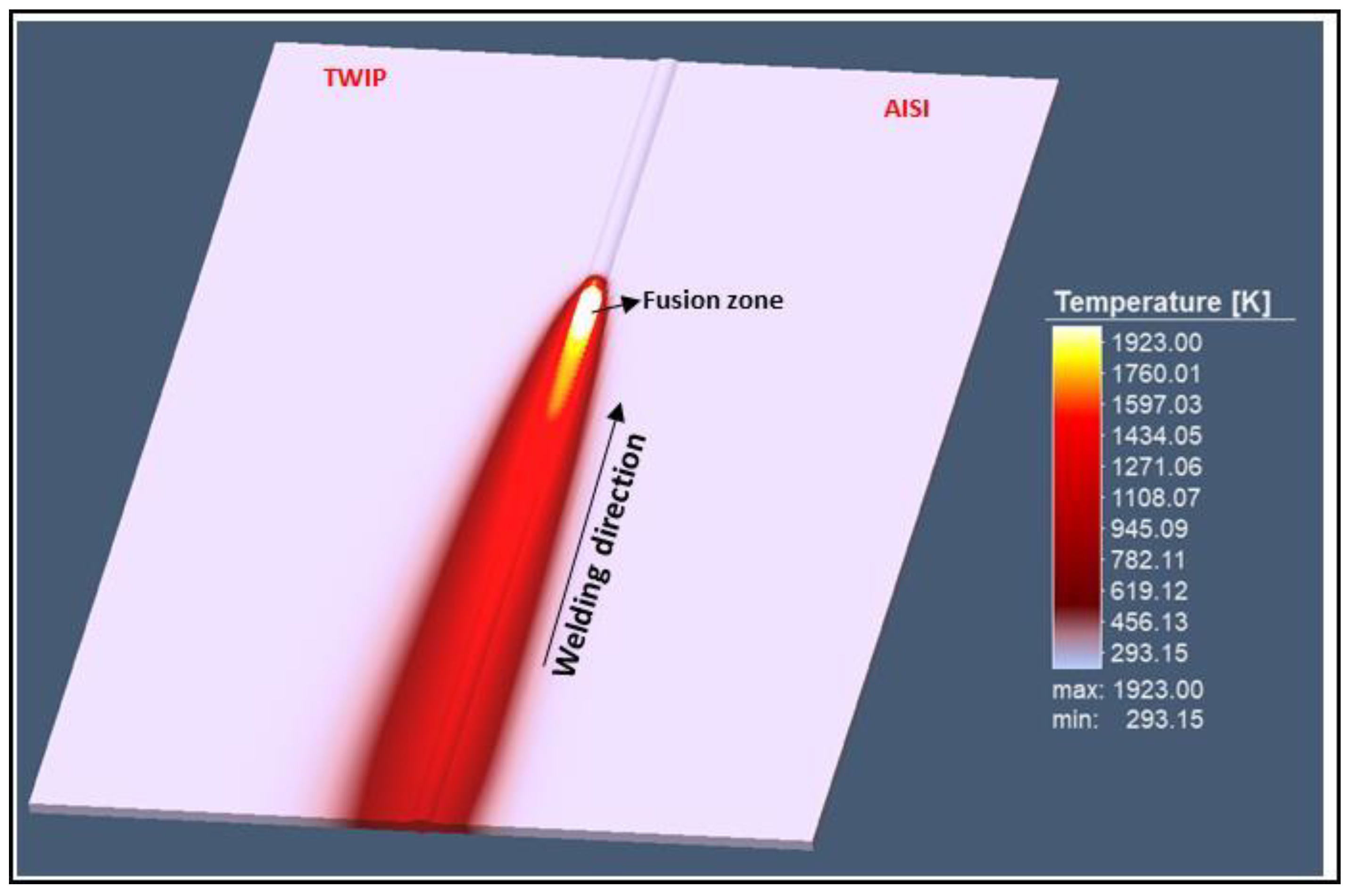

The temperature during the simulation analysis has reached 1923 K by ensuring the material fusion (

Figure 6).

3.6. Mechanical Analysis

Thermal analysis results were input for the mechanical analysis. During the mechanical analysis, the same mesh size as during the thermal analysis was employed. Temperature-dependent mechanical properties of the material such as, Poisson’s ratio, Young’s modulus, and yield strength were used for the simulation.

The total strain is described by the following general Equation (10) [

31,

32]:

where (Δε

E) is the elastic strain, (Δε

p)) is the plastic component and (Δε

T) represents the thermal loading.

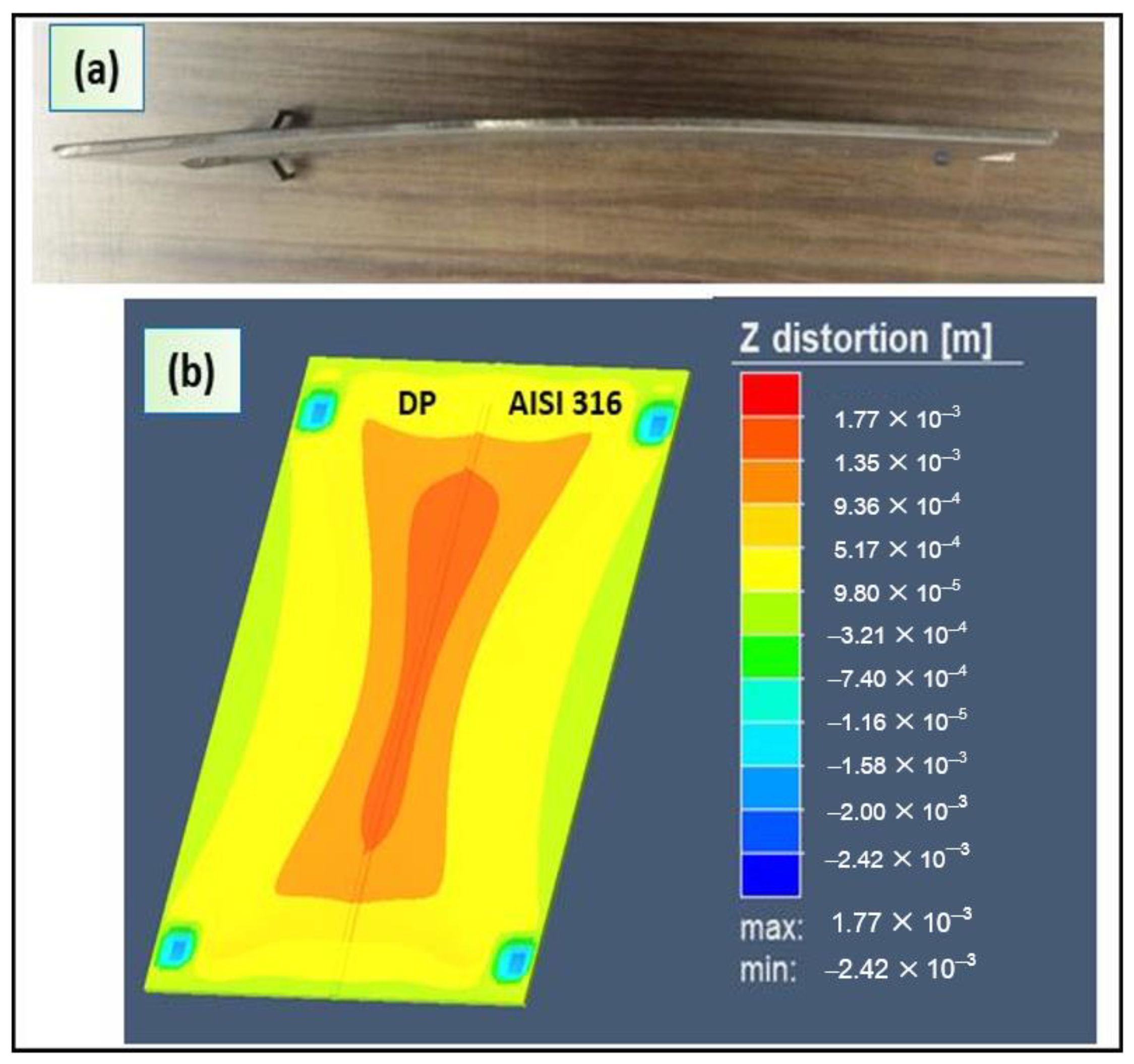

Another boundary condition assumed that the plates were clamped to the worktable to avoid translation and rotation. The buckling of the plates due to the expansion and contraction of the weld material during the welding processes was measured as the distortion.