1. Introduction

Hardness is a property that cannot be defined unequivocally. In fact, many other properties are measured in hardness tests. The tests can be classified depending on the material resistance observed during the testing. Static methods of hardness measurement consist of pushing the indenter into the tested material beyond the yield point to cause plastic strains. In such methods, hardness can be defined as the measure of the material strength to plastic strains arising due to the indenter pressing force.

During a traditional hardness measurement, the hardness testing machine indenter causes plastic strain to the surface domain where the measurement is performed. For some elements, such damage to the surface is unacceptable. For others, plastic deformation of the surface is not an operating problem but a diagnostic one: it is impossible to repeat the hardness test in exactly the same location under the same conditions. These obstacles can be overcome using so-called inverse problems of non-destructive testing, where mechanical properties are determined based on other physical quantities.

In the testing presented herein, this physical quantity is the Barkhausen noise (BN), which is created due to a time-variable impact of a magnetic field on a ferromagnetic. The variable magnetic field causes the stochastic displacement of domain walls, which involves a sudden change in magnetization detectable by the measuring sensor. More details about the theory of the Barkhausen noise can be found in several models [

1,

2,

3].

The Barkhausen noise is used as a diagnostic signal to determine the material stress-and-strain state [

4,

5,

6,

7], the state of the microstructure [

8], defects in surface treatment [

9], and hardness [

5,

9,

10,

11,

12,

13,

14,

15].

Ortega-Labra et al. [

4] presented a novel system for measuring stress applied to a pipe section using the rotational continuous magnetic Barkhausen noise (MBN). The presented results show that the shape and the amplitude of the MBN angular dependence change with an increase in applied stress. The outcome reveals that the applied stress value could be estimated using the amplitude of the angular dependence of the measured MBN signal. Additionally, the shape of the angular dependence is related to the applied stress direction. This suggests that using a proper procedure, the direction of the applied stress could also be estimated based on the MBN.

Liu et al. [

5] presented the application of a multifunctional magnetic testing technique in the quantitative prediction of tensile stress, surface hardness, and the case depth in medium-carbon steel rods. Simultaneous measurements were carried out on the MBN signal, the tangential magnetic field, and the magnetic hysteresis curve in tensioned steel rods with different depths of the surface-hardened layer. A total of 16 feature parameters were extracted from four types of signal patterns as candidate inputs of the back-propagation neural network. Very promising results were obtained, where the prediction model error was less than 5.3% for tensile stress, 5% for the case depth, and 0.22% for surface hardness.

In [

6], skewness is utilized as a feature for applied stress detection and compared with the root-mean-square (RMS) peak value and peak position, which are the most common features of the MBN signal. Different levels of compressive and tensile stresses are applied to En36 steel specimens to evaluate the new feature effectiveness. Its non-linear behavior and sensitivity are compared with the RMS peak value and peak position. The domain wall energy and the eddy current damping are discussed as the cause of the phenomenon.

In [

9], He et al. presented a review of non-destructive testing methods for the metallic grinding burn detection. One of them makes use of measurements of the magnetic Barkhausen noise (MBN) and the magnetoelastic acoustic emission (MAE). It is found that the BN method itself produces only relative results that need to be compared with calibration blocks to define certain limits for rejection. Several aspects for further investigation are defined, such as the relationship between the BN signal multiparameters and the measured material properties (stress state, hardness), the impact factors of BN measurements including microstructural domain walls, and macroscopic operations, such as the influence of the holding force, the contact angle between the probe and the workpiece, and the probe moving speed.

Wilson et al. [

10] studied P9 and T22 steel specimens subjected to different kinds of heat treatment used to modify the microstructure. Magnetic hysteresis loops and the Barkhausen noise were measured and compared to the Vickers hardness number. It is demonstrated that a rise in hardness involves a rise in coercivity, a change in the location of the maximum value of the Barkhausen noise envelope, and a drop in magnetic permeability.

Moorthy et al. [

11] examined the impact of a post-hardening change in the specimen structure on the Barkhausen noise envelope on the carburized layer of steel EN36. Several frequencies of the excitation field were applied, and a frequency analysis of the measured signal was conducted in different ranges. It is proved that the envelope maximum value correlates with the hardness measured in the layer to the depth of 100 μm.

The aim of the studies presented in [

12] was to use the Barkhausen noise to characterize hardness in steel AISI 4140 subjected to the Jominy test. Various types of time-frequency representations were used: the spectrogram, the Wigner–Ville distribution, the Capongram, the ARgram, the wavelet transform scalogram, and the Mellingram. It is proved that due to the Barkhausen noise non-stationary character, time-frequency representations are a rich source of information. A method is proposed of extracting information from these representations by creating an algorithm reducing the number of variables from 3 (time, frequency, amplitude) to 2 (time or frequency and amplitude).

In [

13], O’Sullivan et al. measured magnetoacoustic emission (MAE) and the Barkhausen noise (BN) to determine the properties of AISI 430 steel specimens subjected to heat treatment to change their microstructure. Parameters such as the RMS value of the Barkhausen noise and the magnetoacoustic emission absolute value proposed by the authors were compared e.g., to the Vickers hardness number. It is shown that a rise in plastic strain causes a drop in the BN and MAE and that the parameters are linearly dependent on the Vickers hardness number.

Franco et al. [

14] present relations between the Barkhausen noise parameters and Rockwell hardness using SAE 4140 and SAE 6150 steel specimens subjected to the Jominy hardenability test. The Barkhausen noise is described using the maximum value, the location, and the RMS value of the envelope. A linear relation is found between all parameters of the Barkhausen noise and Rockwell hardness.

In [

15], many properties of the Barkhausen noise are analyzed, and a method is proposed of their selection and mutual complementation for the purposes of hardness evaluation. An algorithm is presented for the analysis of the signal main properties. Combined with the method of the analysis of the correlations between them, the algorithm is used to select the optimal properties. Multidimensional linear regression with selected properties is applied, and a statistical linear model of merging BN properties is built to forecast the material hardness.

This paper presents the results of testing aiming to develop diagnostic correlations between hardness and the Barkhausen noise total number of events NoETOT BN. A good correlation between the two quantities would enable periodic and multiple measurements of hardness in the same location, which cannot be done using traditional hardness measurement methods. Two cases of differences in the material hardness are considered. One is a change in hardness due to cold plastic strain and the other is the change caused by thermochemical treatment.

NoETOT is selected as the diagnostic signal property to be analyzed because the authors already obtained promising results from their previous preliminary research on hardness evaluation [

16,

17] and from their comprehensive studies on the assessment of the state of active stresses in steel elements [

7]. The following quantities are analyzed in [

7,

16,

17]: the BN RMS value of voltage (

URMS) [

18,

19,

20], the BN energy (

EBN) [

20,

21], characteristic parameters related to the BN signal envelope [

22,

23], and the distribution of the BN total number of events (

NoETOT BN) [

24]. The best determination coefficients

R2 and the smallest standard deviations are obtained for the

NoETOT BN. Another issue, not taken up in this paper, is the analysis of the intensity of changes in the features describing the Barkhausen noise that occur due to changes in hardness or in the stress-and-strain state. The signal feature that changes the most intensely is the one best suited to enable the development of a diagnostic correlation. The issue is related to digital processing of the signal on the one hand, and to analysis of the variability of the signal individual features on the other. Such analyses are presented for example in [

25], where a comparison is made between changes in the Barkhausen noise profile skewness and the noise signal RMS value caused by active compressive and tensile stresses. Within certain stress ranges, the sensitivity of skewness is higher than that of the RMS value, which makes the former a better diagnostic signal.

Among others, the Barkhausen noise depends on the state of the material microstructure and on the material stress state. The impacts can be separated from each other assuming that the two factors are not changed at the same time. Changes in hardness due to strain hardening are accompanied by changes in internal (residual) stresses. Similarly, changes in hardness due to thermochemical treatment involve, apart from changes in the specimen microstructure, changes in the level of residual stresses. In the presented testing, the impact of internal stresses was not taken into consideration in the analysis of results. In consequence, the developed diagnostic correlations are less universal because they are related to the structural properties of specimens.

3. BN Signal Analysis

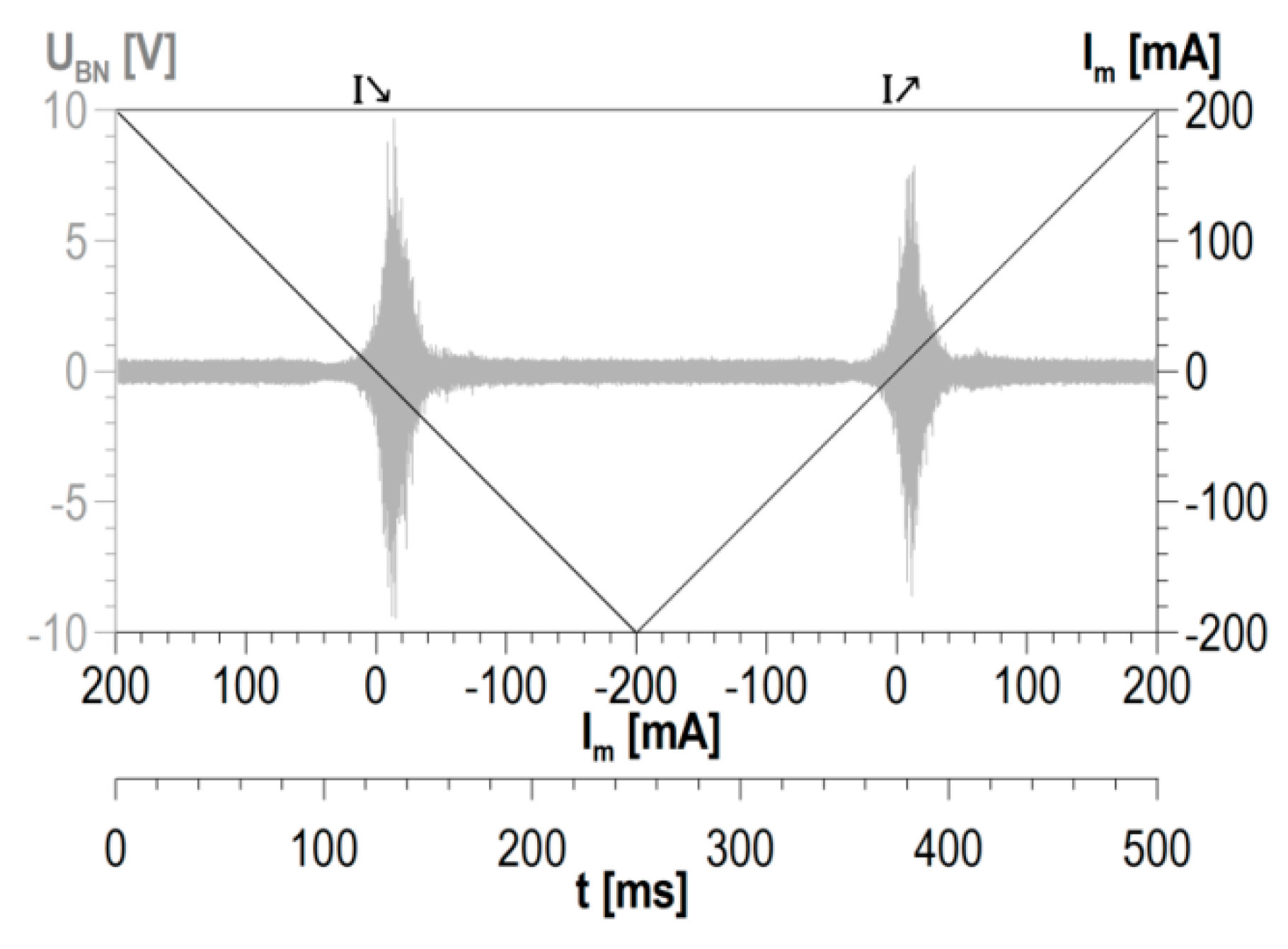

The basic unit of information is a single cycle of changes in magnetization. The cycle is presented in detail in

Figure 3. Two halves of such a full cycle can be distinguished: one in which the magnetization current intensity diminishes (marked as

I↘) and the other in which the current intensity rises (marked as

I↗).

To obtain information from a single cycle of changes in magnetization, the signal is processed in different ways. The processing method produces values of individual properties of the Barkhausen noise. For a multiple number of cycles of changes in magnetization, a multiple number is obtained of values of the quantity for which a statistical analysis has to be carried out. The analysis gives the average value of the quantity and the value of standard deviation being a variability measure of the BN signal analyzed properties.

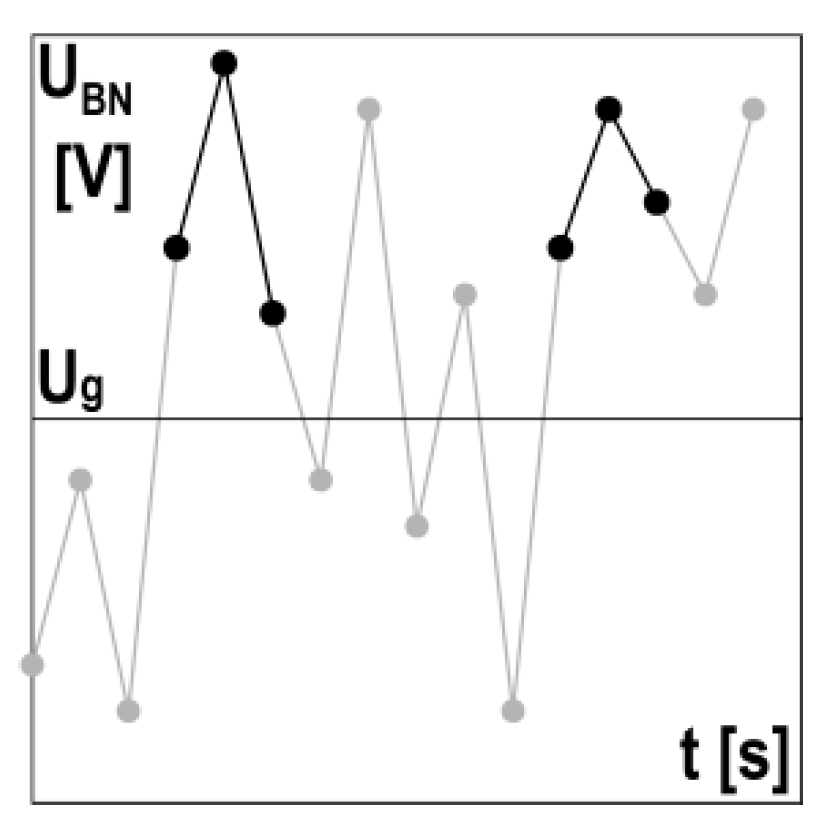

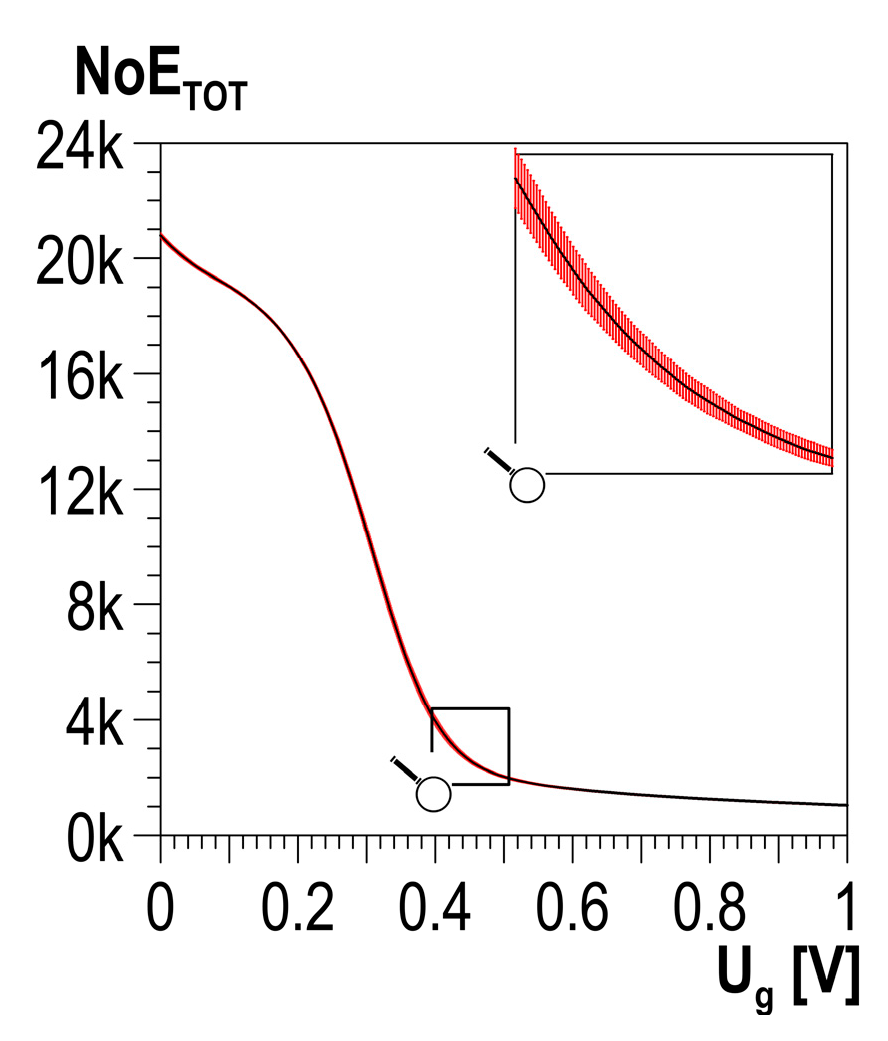

The measured signal of the Barkhausen noise is a set of voltage pulses, among which so-called events can be distinguished. It is assumed that for a set value of threshold voltage

Ug, the event occurrence is determined based on three subsequent signal samples with a value exceeding the threshold voltage, where the value of the second signal is higher than the value of the first and third (cf.

Figure 4). Detected events are summed up, which gives the distribution of the total number of events—

NoETOT—depending on threshold voltage

Ug (cf. the example presented in

Figure 5). The threshold voltage-dependent

NoETOT distribution is obtained for each cycle of changes in magnetization. In the case of a multiple number of cycles of changes in magnetization, averaged

NoETOT distributions are determined together with statistical features, such as standard deviation.

The relation between the number of events (NoETOT) and the corresponding values of hardness were analyzed for individual values of discrimination voltage using a linear regression model. The analysis resulted in the value of determination coefficient R2 for each value of discrimination voltage . The value reflects the quality of the goodness of fit of the linear model developed based on input data. A value of determination coefficient R2 equal or higher than 0.8 proves a good fit of the linear regression model.

Additionally, the resolution coefficient (

RECOF.) was defined. The coefficient makes it possible to find the discrimination voltage value for which the best resolution is obtained, where the resolution is defined for a given value of discrimination voltage

as the quotient of the difference between the maximum and the minimum value of the obtained total number of events (

and

, respectively) and the sum of the standard deviation values

corresponding to individual points of the hardness measurement.

To normalize the resolution coefficient (

RE) results with the determination coefficient (

R2) varying in interval <0,1>, the normalized coefficient of resolution (

RECOF.) was introduced. The coefficient is defined as:

The best correlation occurs for the discrimination voltage for which maximum values of R2 and RECOF are obtained.

4. Testing of Specimens with Plastic Strain

Cold plastic strain increases dislocation density (by 4 to 5 orders of magnitude) [

26], which involves the material hardening due to the decrease in distances between dislocations and the increasing forces of their interaction. Due to the smaller distance, the dislocations block each other, and their further displacement (further deformation of the material) is only possible if a higher external stress is applied; the phenomenon is referred to as strain hardening. A plastically deformed material is characterized by increased strength properties (hardness, yield point) with simultaneously decreased plastic properties (elongation, narrowing) [

26].

4.1. Testing Details

The tests were performed on plate specimens made of S235 steel (according to Standard EN 10025) and DC01 steel (according to Standard EN 10130). The steel grades properties are listed in

Table 1.

The specimens were loaded on a Galdabini Sun 10P tensile testing machine (Galdabini, Cardano al Campo (VA), Italy). They were repeatedly subjected to uniaxial tension in such a manner that with every loading cycle, there was a slight increment in plastic strain. When the ultimate strength value was exceeded, a narrowing started to form in the specimen. The loading process was discontinued the moment that the narrowing was visible enough to detect through a visual inspection. Due to the material hardening, a change in hardness occurs in the plastically deformed area. Non-uniform plastic strain leads to the creation of a specific hardness profile on the specimen surface.

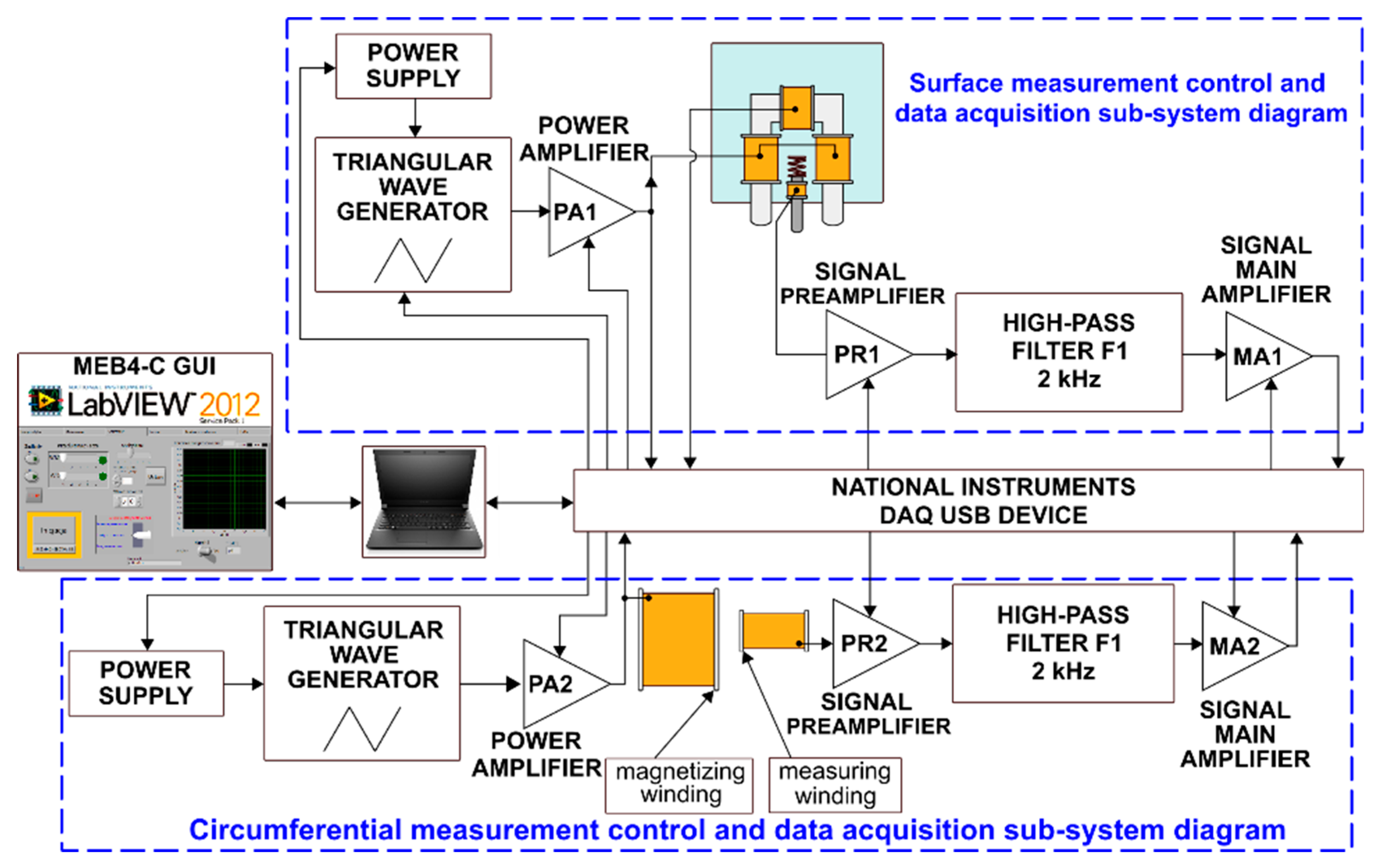

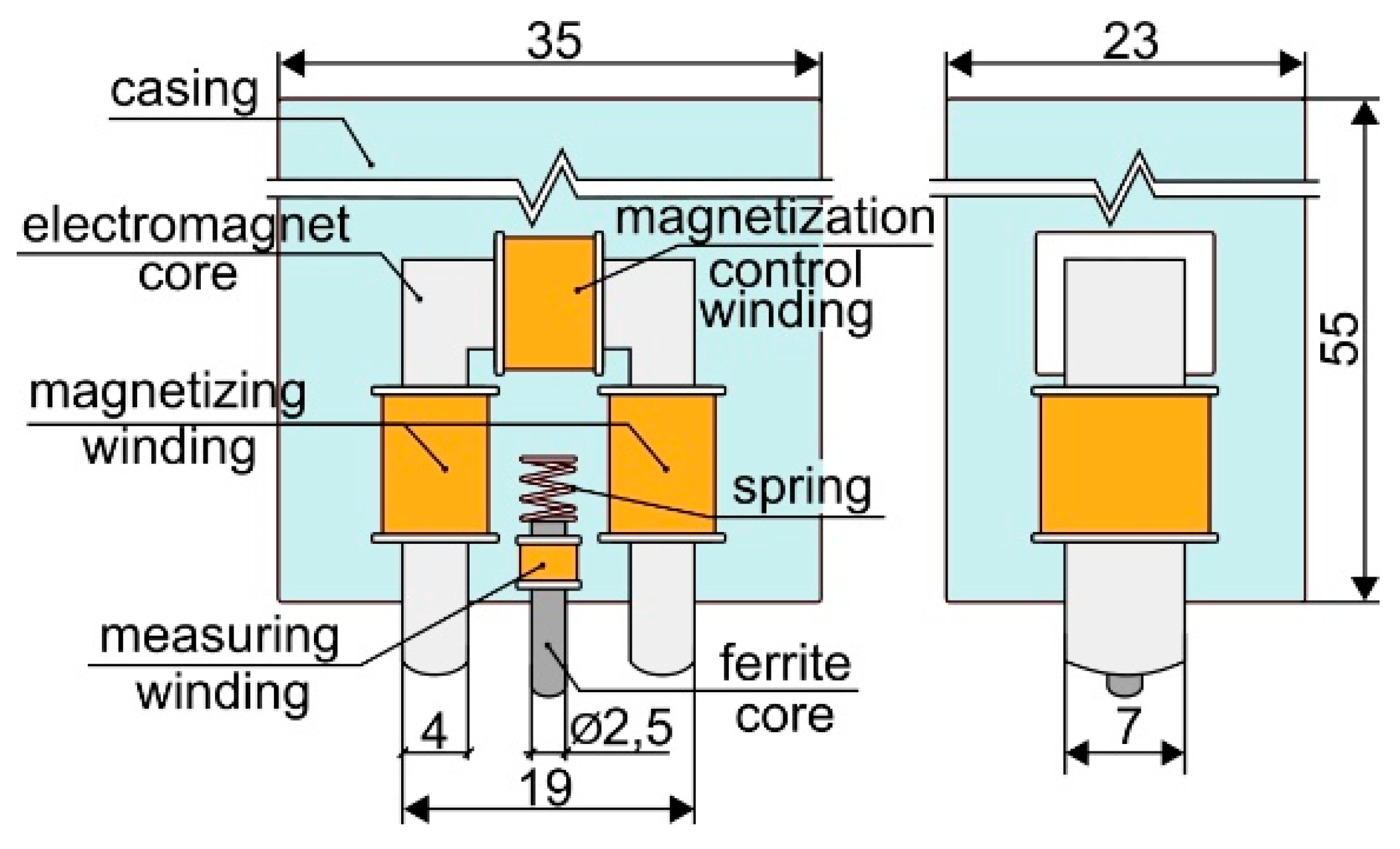

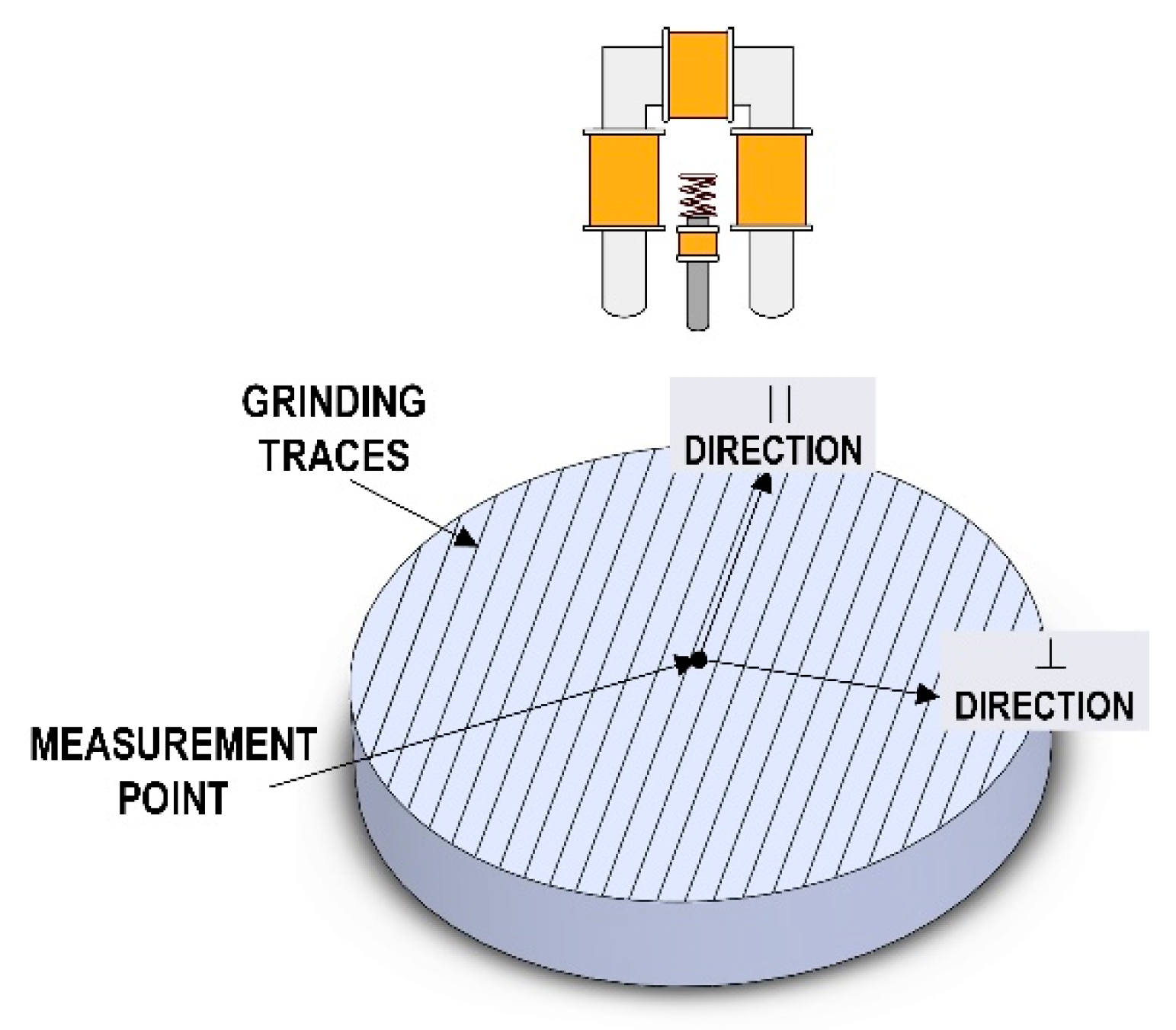

For the measuring apparatus described in

Section 2, the details of the configurations used during the BN measurements are presented in

Table 2.

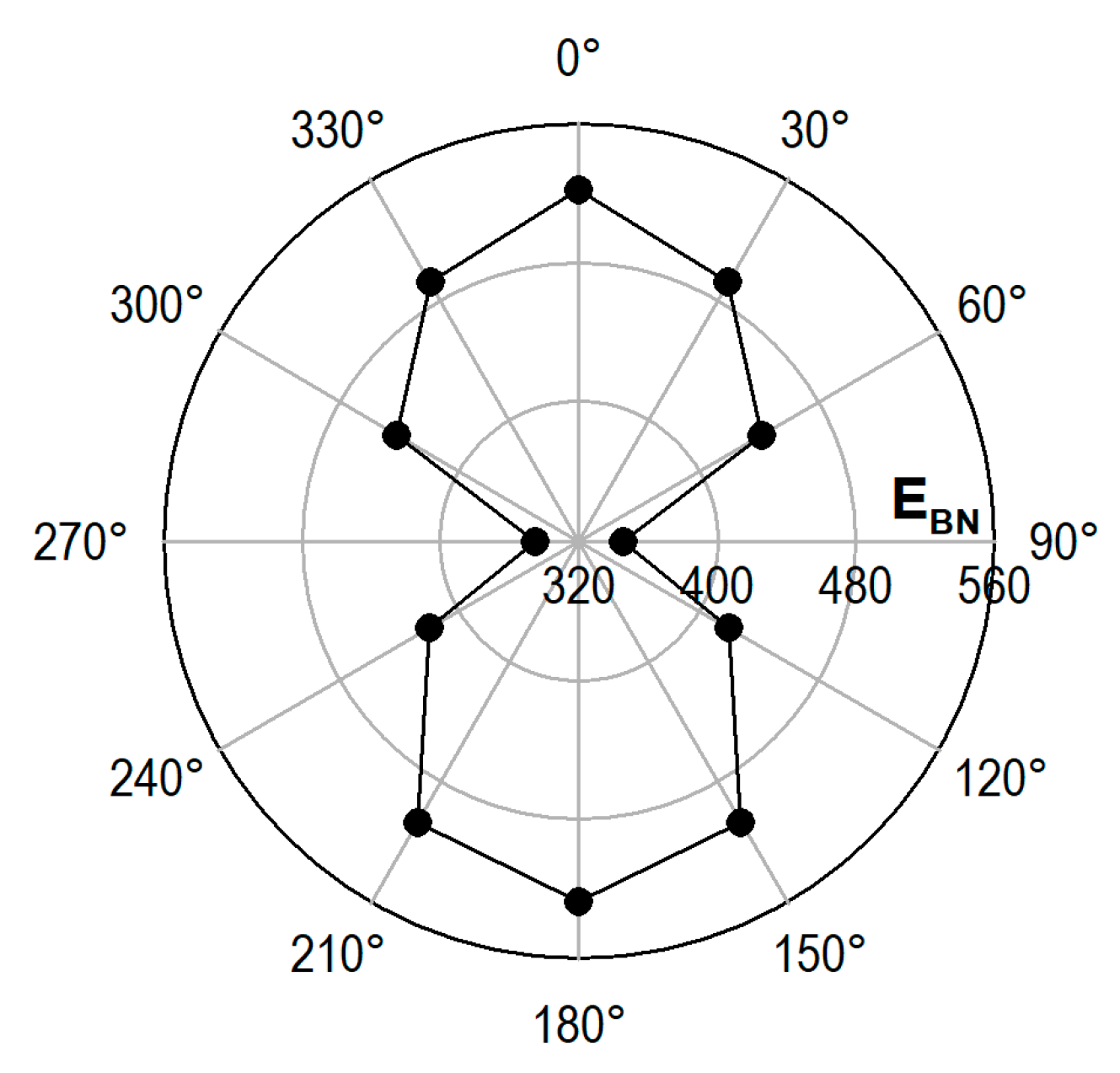

At the preliminary stage of the testing, measurements were carried out changing the magnetization direction every 30°; angles 0° and 180° correspond to the load direction. Example results are presented in

Figure 6. They confirm the literature data [

27,

28] that prove that the signal maximum and minimum values are obtained for the maximum strain direction and for the normal direction, respectively.

In the engineering practice, diagnostic correlations should be independent of the directions of principal residual stresses in the material, which are usually unknown. One proposal for a simplified solution is the absolute value of the Barkhausen noise properties:

where

VX and

VY, respectively, are the property values for two directions of the magnetizing field application (e.g.,

EBN or

NoETOT) for which the most extreme values are obtained.

Considering the above, the Barkhausen noise was measured only in two directions perpendicular to each other, i.e., in direction X, parallel to the load direction, and in direction Y, normal to the load direction.

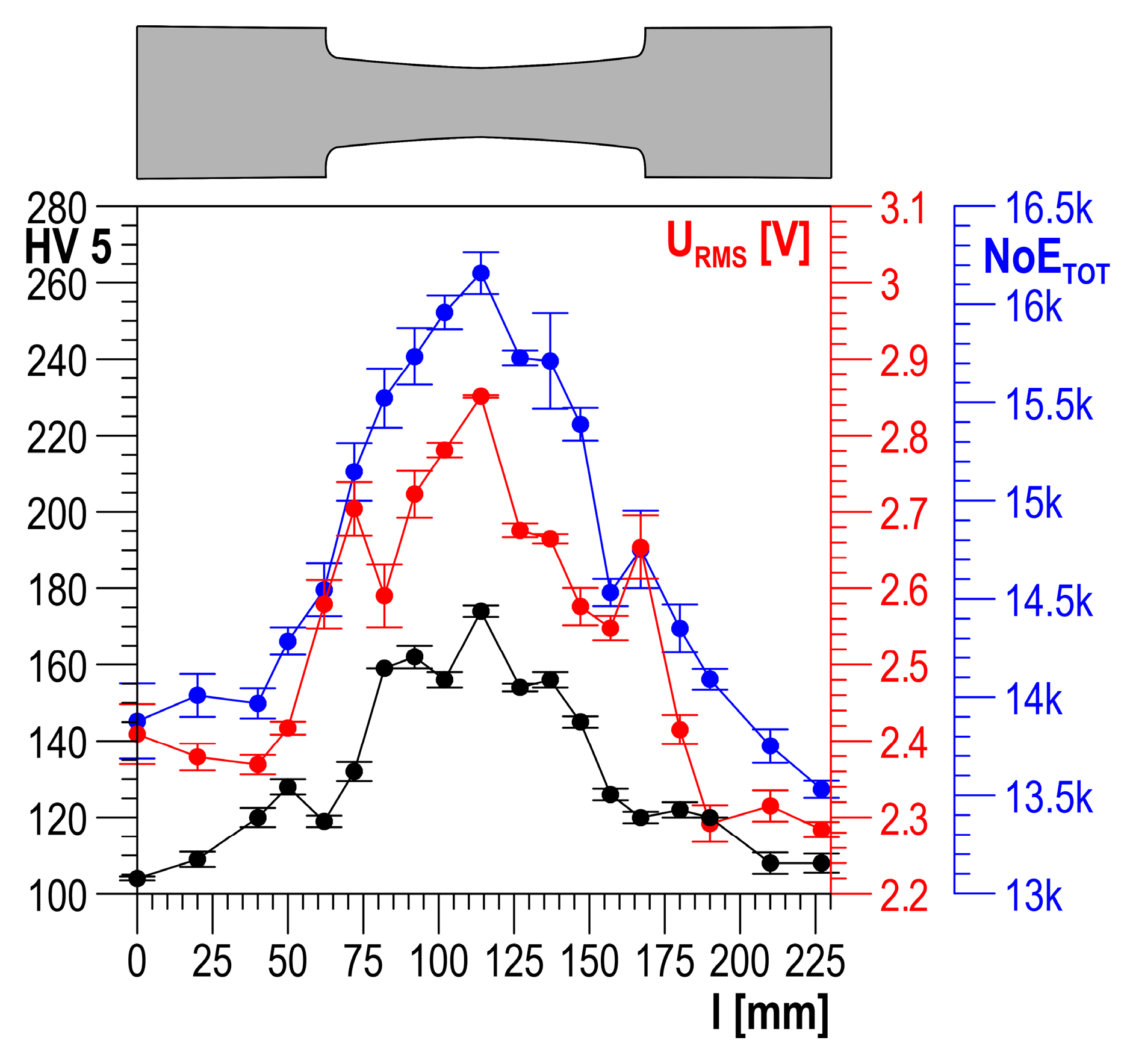

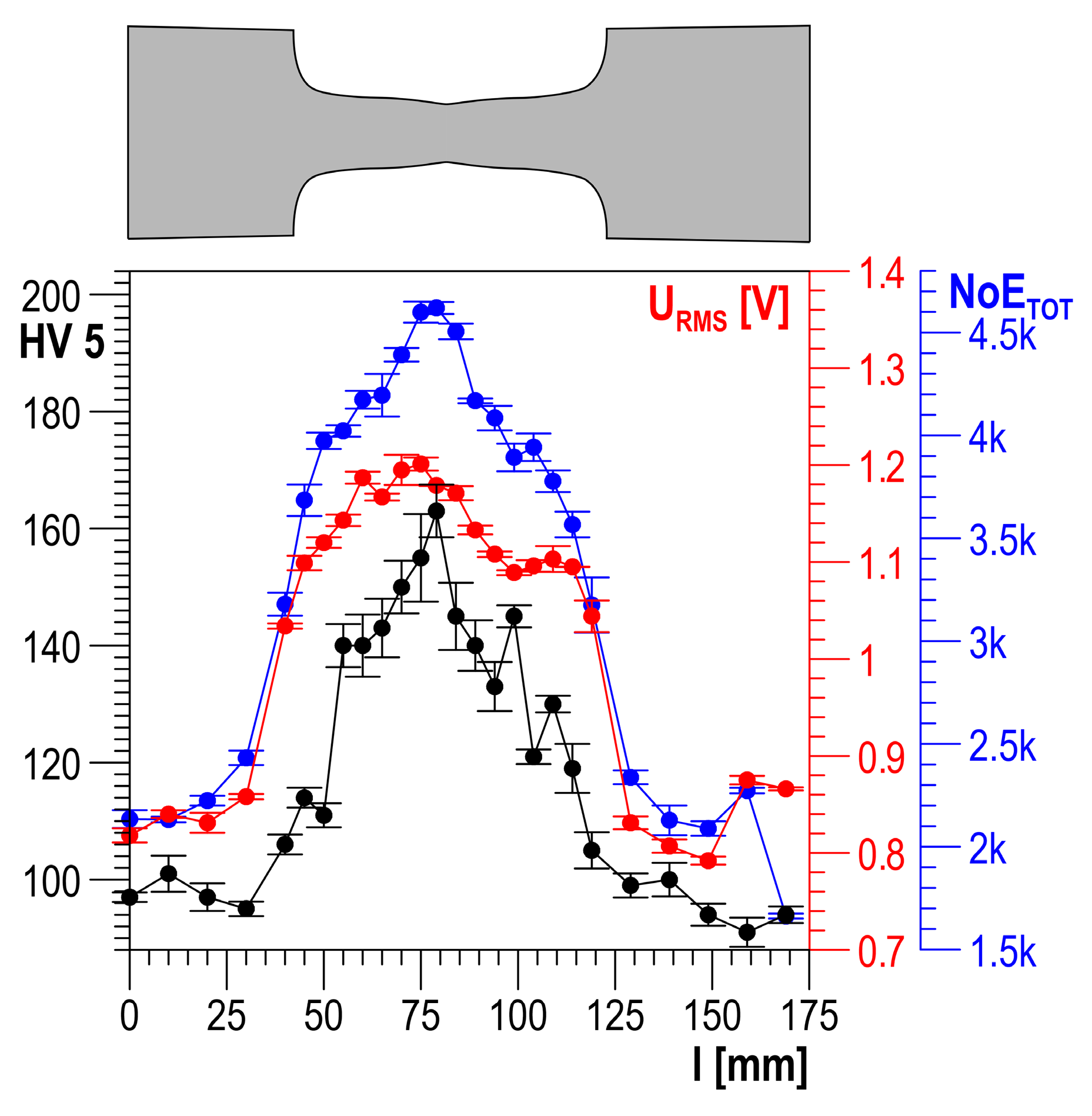

After the Barkhausen noise was measured in the same measuring points, HV5 hardness measurements were performed using the Krautkramer TIV hardness tester (General Electric, Boston, MA, USA). The measurements were carried out along a measurement line being the specimen axis of symmetry. Example testing results for plastically deformed specimens made of S235 and DC01 steel are shown in

Figure 7 and

Figure 8, respectively.

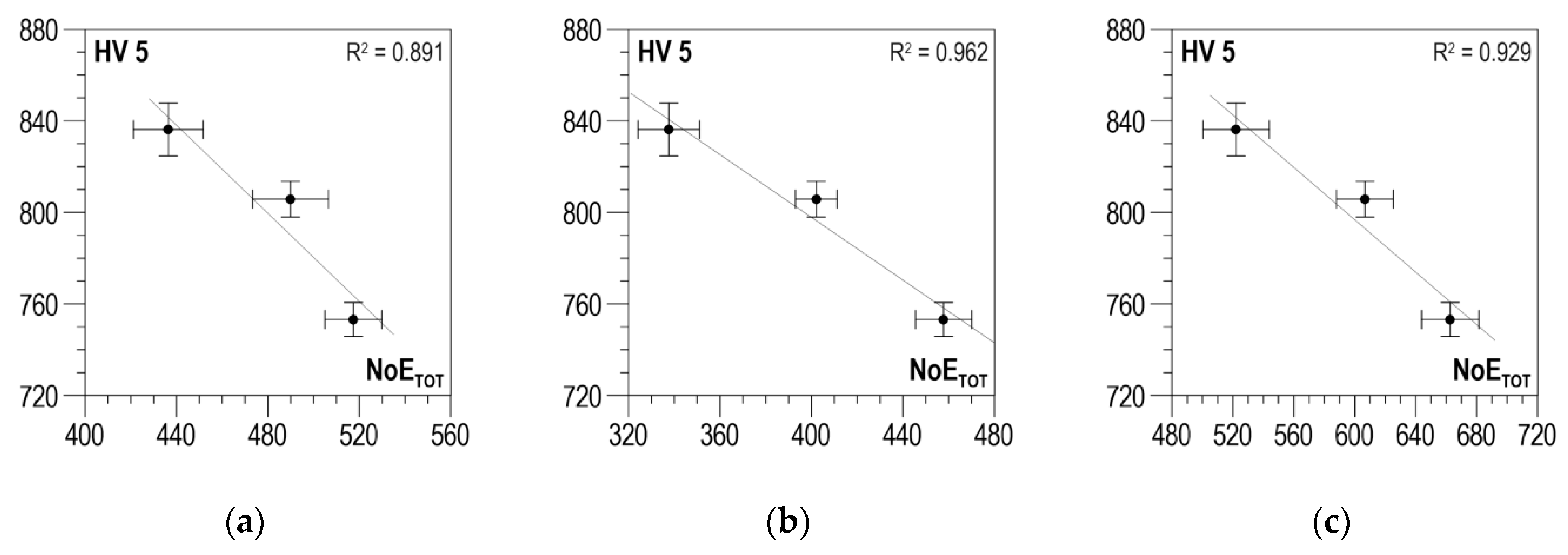

4.2. Analysis of Results

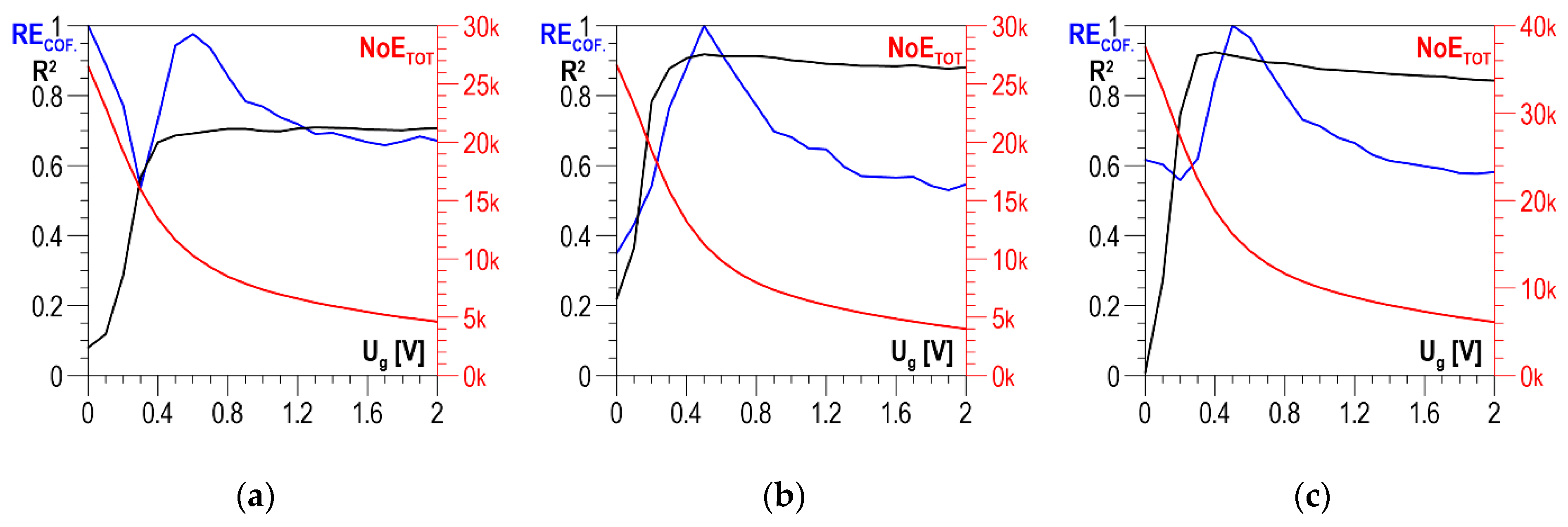

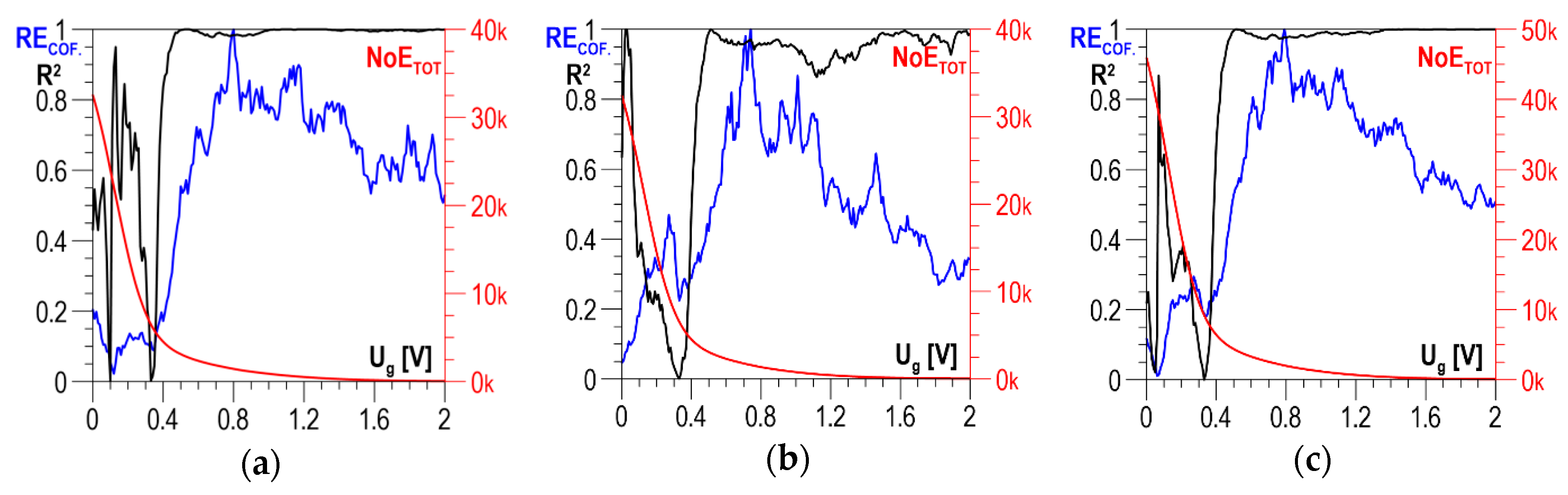

According to the measurement methodology presented in

Section 3, the analysis covers the results obtained in two directions perpendicular to each other and their absolute value. The distributions of determination coefficient

R2 of the linear correlation between

HV5 hardness and the total number of events

NoETOT and of resolution coefficient

RECOF as a function of threshold voltage

Ug for S235 steel are presented in

Figure 9a–c for the parallel direction, the normal direction, and the absolute value, respectively. In all three charts (

Figure 9a–c), the curves illustrating the history of determination coefficient

R2, after the initial phase of a clear increase (in the range of

Ug from 0 to about 0.4 V), look quite similar; for higher voltage values, there are no essential changes. The distributions of coefficient

RECOF are characterized by a global maximum falling on

Ug values ranging from 0.5 to 0.6 V. These maxima decide the selection of the discrimination voltage for which the linear correlations between

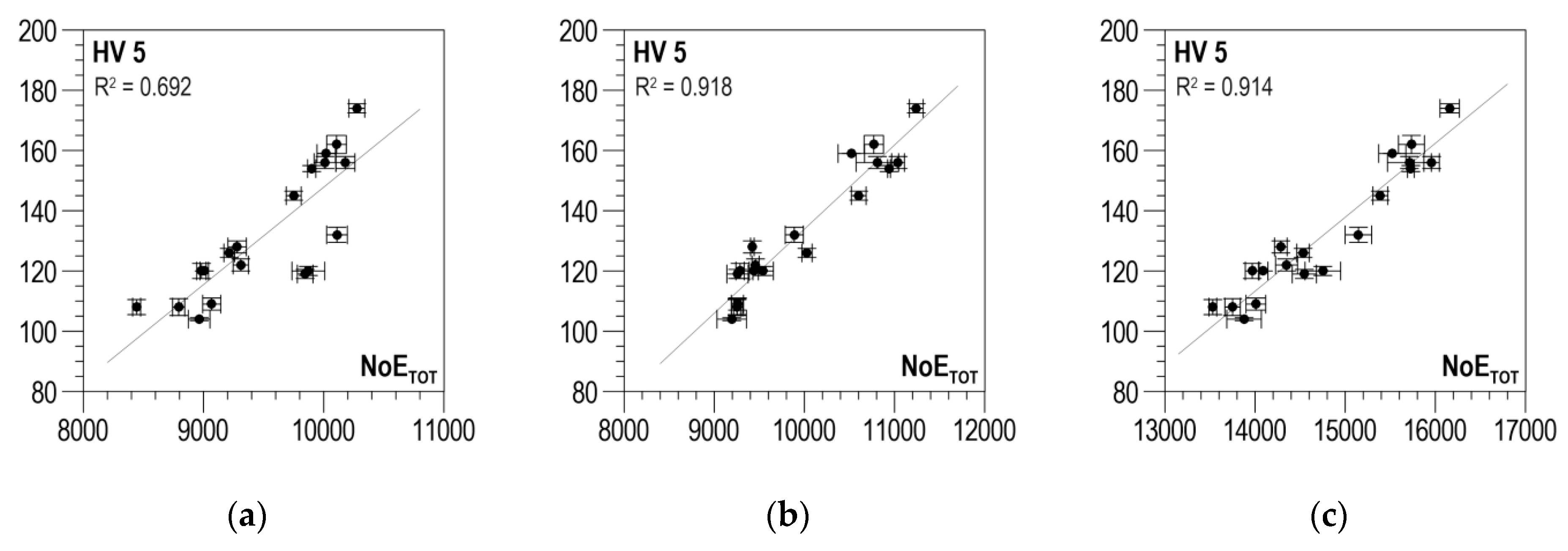

NoETOT and HV5 are developed and presented in

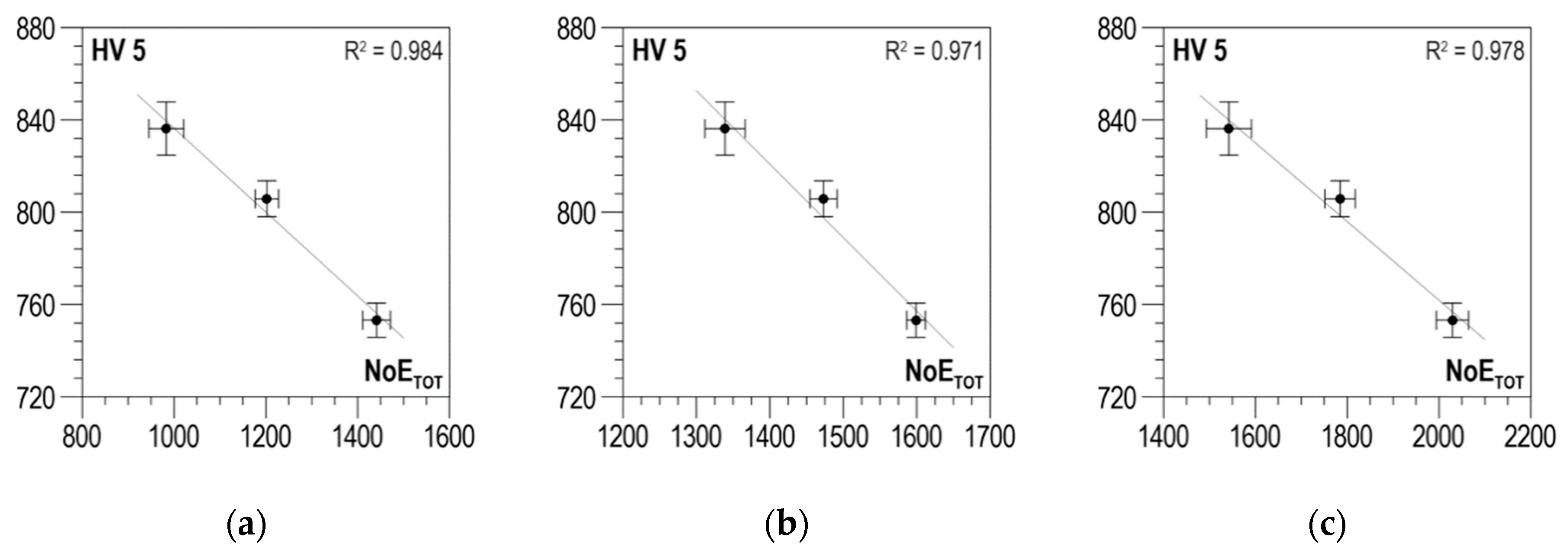

Figure 10a for the parallel direction, in

Figure 10b for the normal direction, and in

Figure 10c for the absolute value. The values of determination coefficient

R2 differ considerably for the two directions and total about 0.7 for the parallel direction (which is too low for practical use) and about 0.92 for the normal direction. However, in the analyzed case, the impact of the parallel direction of magnetization on the value of the linear correlation determination coefficient

R2 for the absolute value (

R2 = 0.914) is very slight, and the correlation can be used in practice.

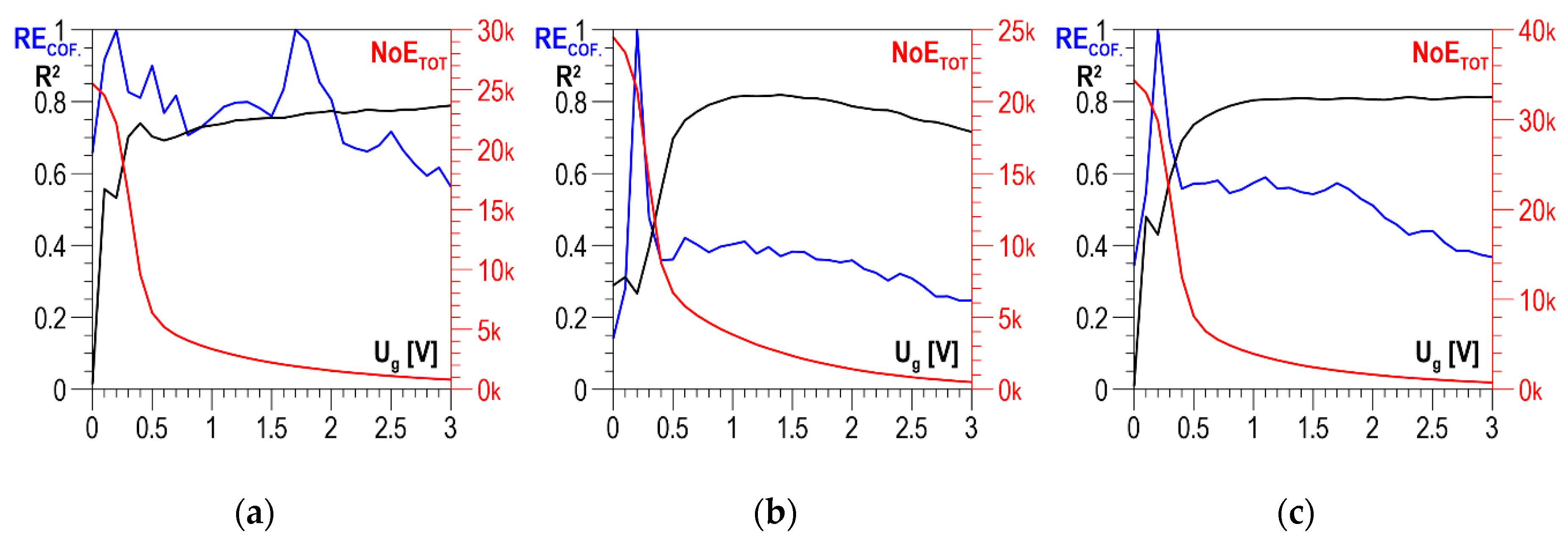

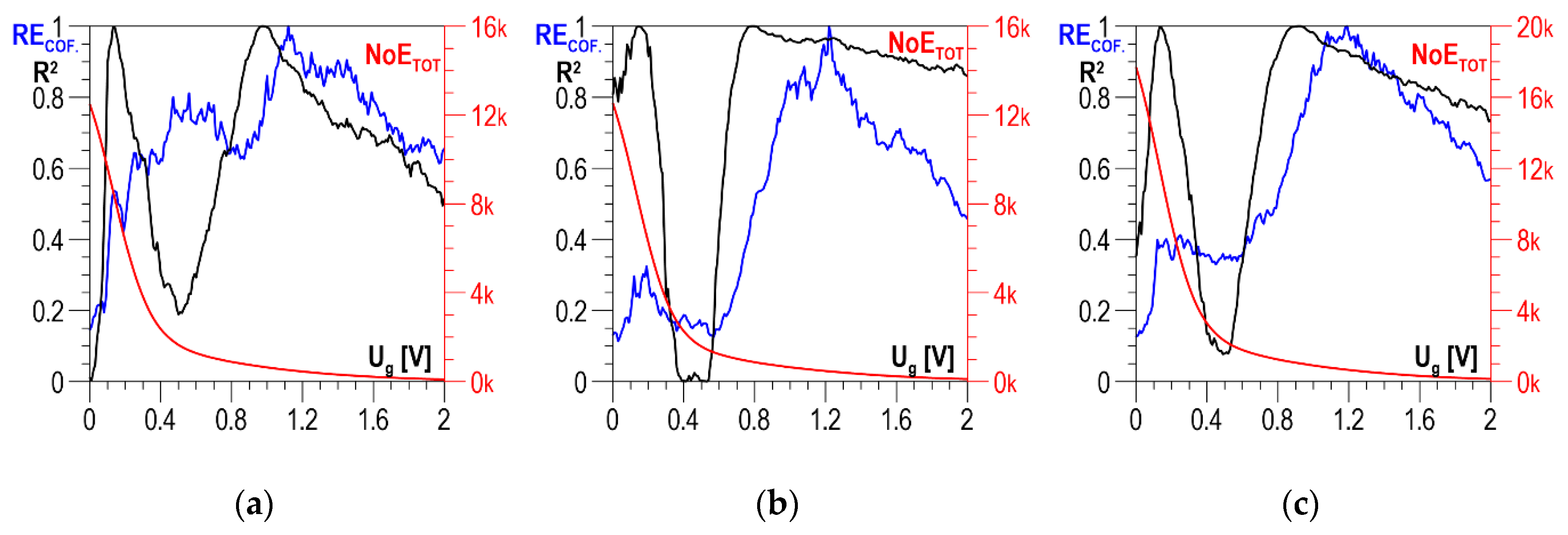

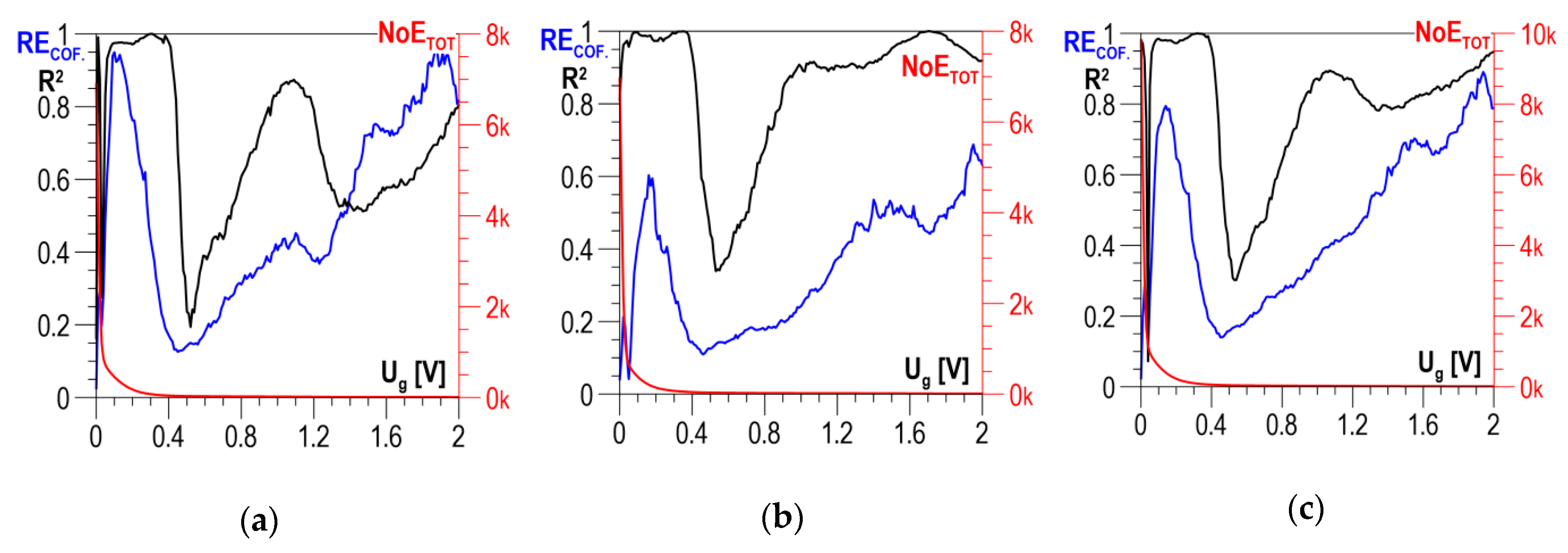

The distributions of determination coefficient

R2 of the linear correlation between

HV5 hardness and the total number of events

NoETOT and of resolution coefficient

RECOF as a function of threshold voltage

Ug for DC01 steel are presented in

Figure 11a–c for the parallel direction, the normal direction, and the absolute value, respectively. In all three charts below, the curves illustrating the history of determination coefficient

R2, after the initial phase of a clear increase (in the range of

Ug from 0 to about 0.5 V), look quite similar; for higher voltage values, there are no essential changes. A characteristic feature of the

RECOF. distributions is that the first local maximum falls within the range of voltage

Ug variability where the determination coefficient

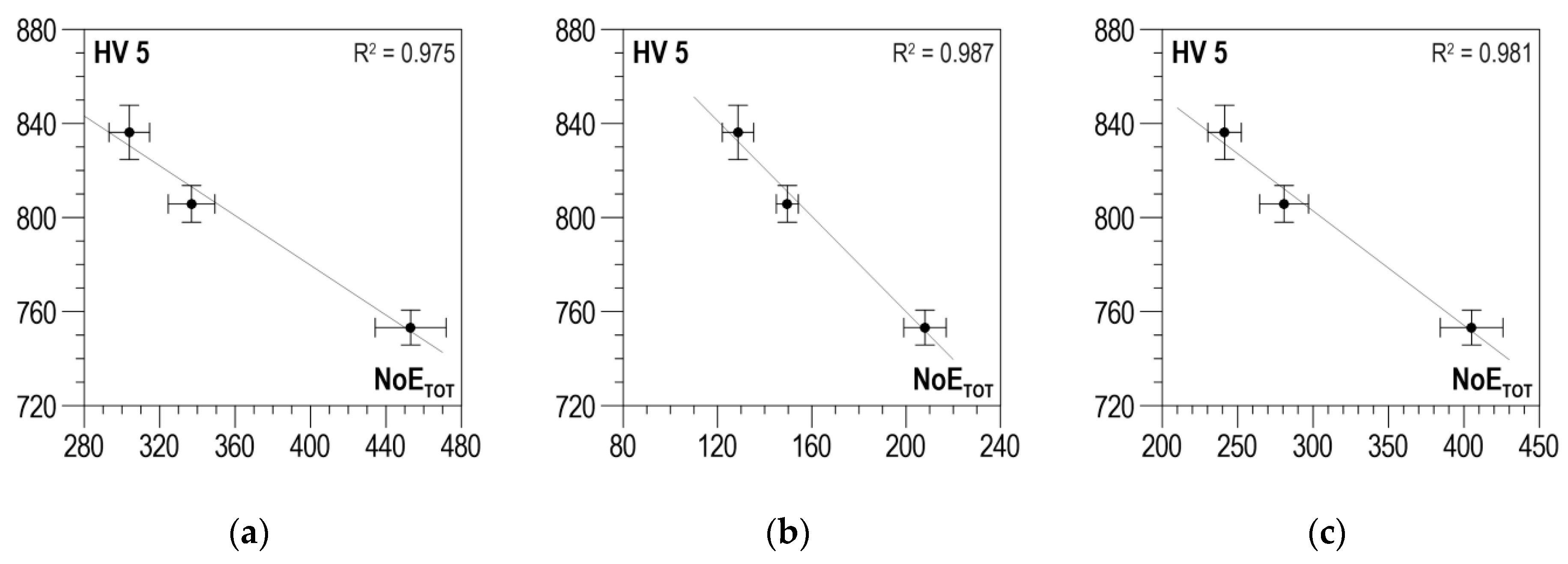

R2 takes low values. It is only the values of the second local maximum that decide the selection of the discrimination voltage for which the linear correlations between

NoETOT and

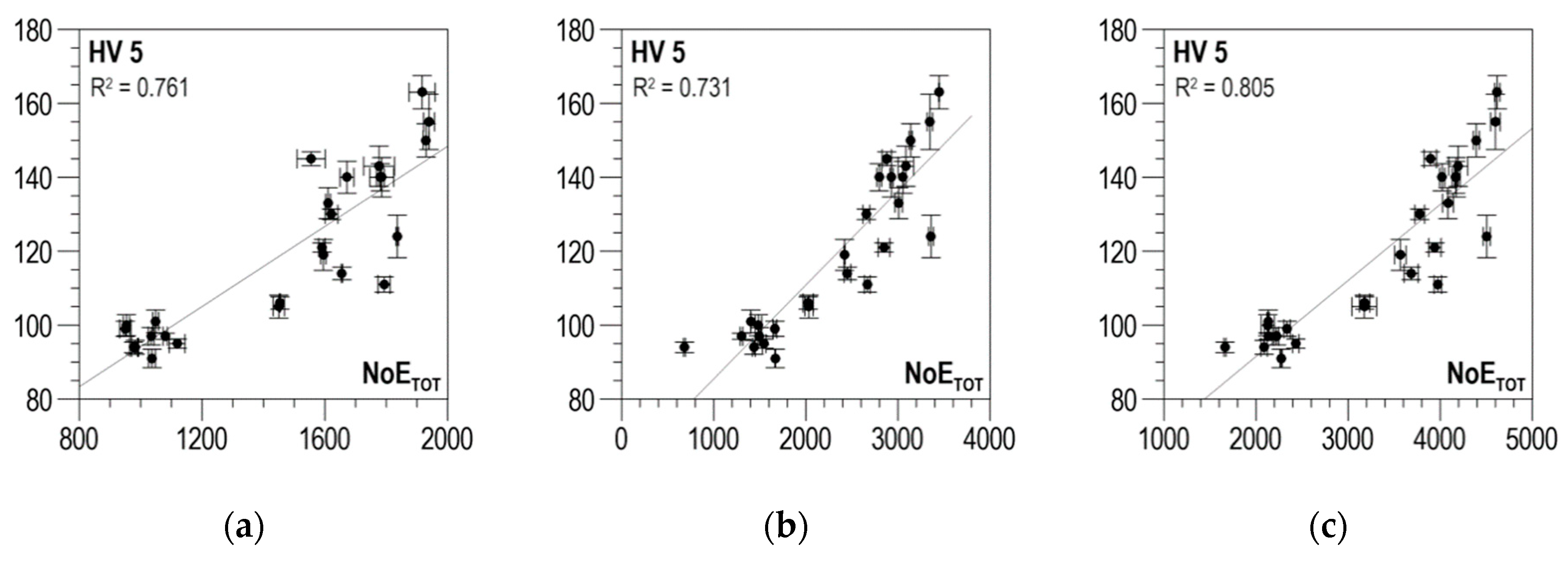

HV5 are developed and presented in

Figure 12a for the parallel direction, in

Figure 12b for the normal direction, and in

Figure 12c for the absolute value.

The values of determination coefficient R2 for the two directions of magnetization vary from about 0.73 to about 0.8, which is too low to use in practice. Finding the absolute value improves the situation only slightly, raising coefficient R2 for optimal discrimination voltage Ug to about 0.8, which is still just on the limit of possible practical use.

In the presented results of the testing, higher

NoETOT values correspond to higher hardness (higher degree of plastic strain), which is also observed for the values of other properties of the Barkhausen noise (

Figure 7 and

Figure 8) [

7,

16,

17]. However, this is not a permanent trend that occurs for every material. S235JRG2 steel is investigated in [

29], and it is found that a rise in the plastic strain degree involves a decrease in the BN

URMS value measured in the load direction and an increase in the value determined in the normal direction. It is also found that the main reason for the observed changes is the number of dislocations causing non-homogeneous microdeformations. The stress field around dislocations interacts with all suitably oriented displacements of domain walls. If the number of displacements is reduced, the values of the BN properties are reduced, too. The authors of [

29] state that this makes it possible to account for the drop in the BN property value measured in the load direction, but it still cannot explain the rise of the value in the normal direction. A similar trend of changes is observed in [

13]. In [

30], Fe–2%Si alloy is investigated using an enveloping coil, which allows the assumption that the magnetization direction is the same as the direction of the load. It is found that a rise in plastic strain involves a rise in the integrals of

Ub voltage. This trend is opposite to the one observed in [

29]. The results of the testing of plastically deformed Armco iron presented in [

31] show a non-uniform trend of changes in

Ub voltage integrals. After an initial increase with a rise in plastic strain, if the strain value exceeds about 10%, a further rise in strain involves a decrease in the values. Another essential factor is additionally found in [

32]: the impact of the specimen loading history (the method of achieving plastic strain). In the case of specimens for which plastic strain was achieved in a single loading cycle, the BN properties decreased with a rise in plastic strain. For specimens where subsequent plastic strain values were achieved gradually to the value of about 1%, the values of the BN properties increased. A further rise in strain caused a gradual drop in the values of the BN properties. However, the drop never reached the level measured for specimens where strain was achieved in a single loading cycle.

The analysis of the phenomena of interaction between a change in the degree of plastic strain and dislocation density is a complex process that requires many more microscopic and macroscopic studies on the changes that arise in the domain structure of polycrystalline ferromagnetic materials due to a complex state of stresses and strains.

6. Summary and Conclusions

The Barkhausen noise and HV hardness were tested in specimens subjected to plastic strain and thermochemical treatment. The measurement data were processed numerically, which resulted in distributions of the total number of events (NoETOT) as a function of discrimination voltage Ug. Next, the linear correlation determination coefficient (R2) and the resolution coefficient (RECOF.) introduced by the authors were analyzed in parallel to find the optimal correlation. The obtained results prove the great potential of using the Barkhausen noise total number of events (NoETOT BN) for the development of correlations enabling hardness determination. Distributions of the total number of events (NoETOT) in selected intervals of threshold voltage Ug make it possible to develop correlations characterized by a high determination coefficient R2 in the case of changes in hardness due to both strain hardening and thermochemical treatment.

A new methodology was developed for the determination of diagnostic correlations to solve inverse problems of non-destructive testing consisting of hardness evaluation based on the Barkhausen noise total number of events (

NoETOT BN). However, it has to be emphasized that if these correlations are to be applied, factors that affect the diagnostic signal, such as the surface shape and roughness or the element edge impact, must be taken into account. The factors are described in detail in [

7,

17]. The sampling frequency can also play a significant role, because some pulses could overlap in the time scale.

Compared to classic static and dynamic methods of hardness evaluation using an indenter, the developed method of measuring hardness based on the total number of events (NoETOT) of the Barkhausen noise causes no plastic strain on the tested surface and makes it possible to perform hardness measurements in the same place repeatedly.

Additionally, it is possible to utilize other properties of the Barkhausen noise to develop multi-property correlations [

15], where each property will have a specific weight established based on an analysis of the determination coefficient (

R2) and the resolution coefficient introduced by the authors (

RECOF.).

The authors, as well as other scientists [

37], are aware of the deficit in basic research on the relations between changes in a broadly understood state of the material and changes in electromagnetic properties, both at the micro and macroscopic scale. Another important research issue that emerged while analyzing the testing results is the impact of the plastic strain process (whether it proceeds continuously or in stages) on changes in parameters of the Barkhausen noise quantitative description. The results of such research would enable more confident actions in inverse problems of non-destructive testing using electromagnetic phenomena.