Effect of Different Shear Rates on Particle Microstructure of Cementitious Materials in a Wide Gap Vane-in-cup Rheometer

Abstract

1. Introduction

2. Materials and Methods

2.1. Aim and Concept of Investigations

2.2. Materials and Sample Preparation

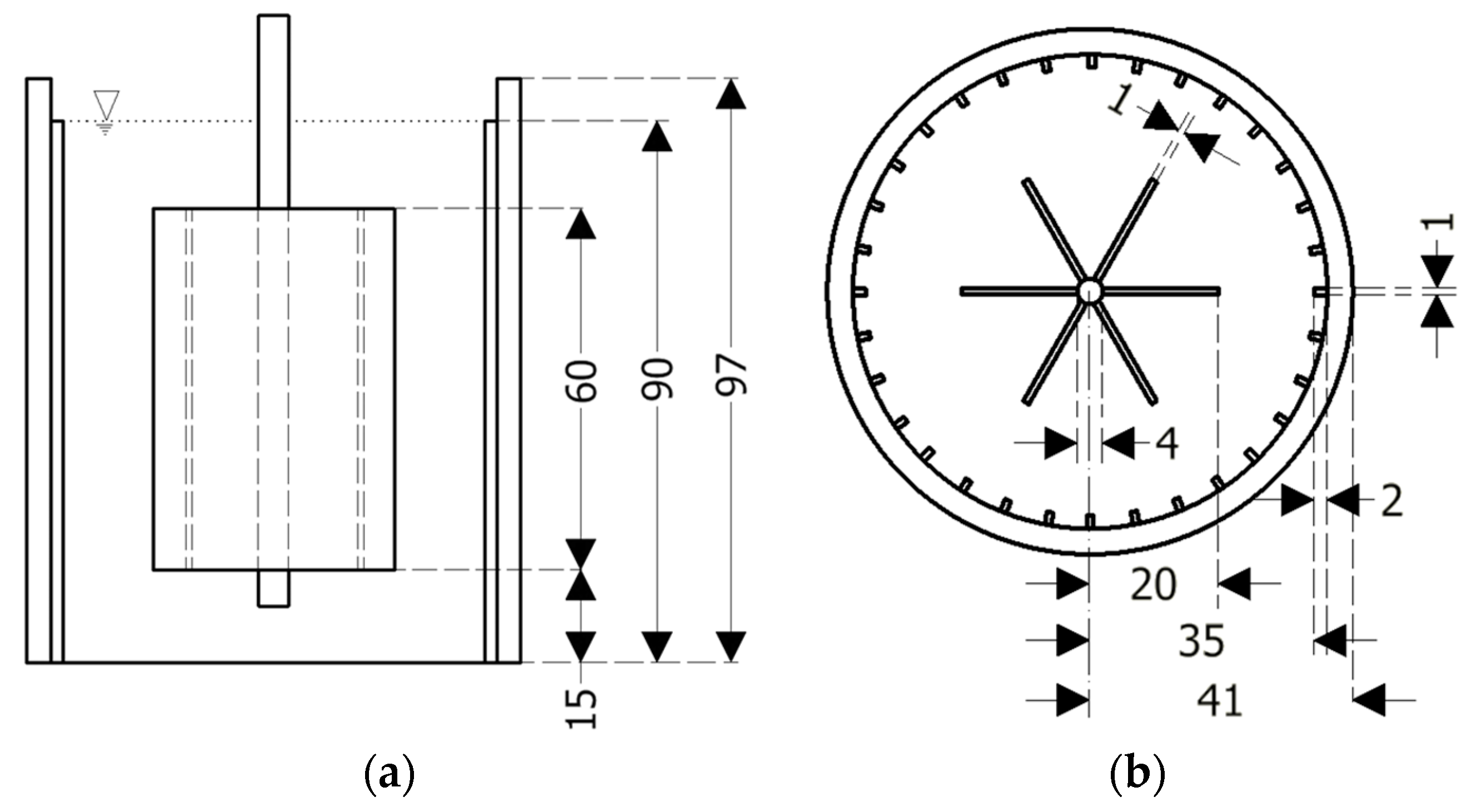

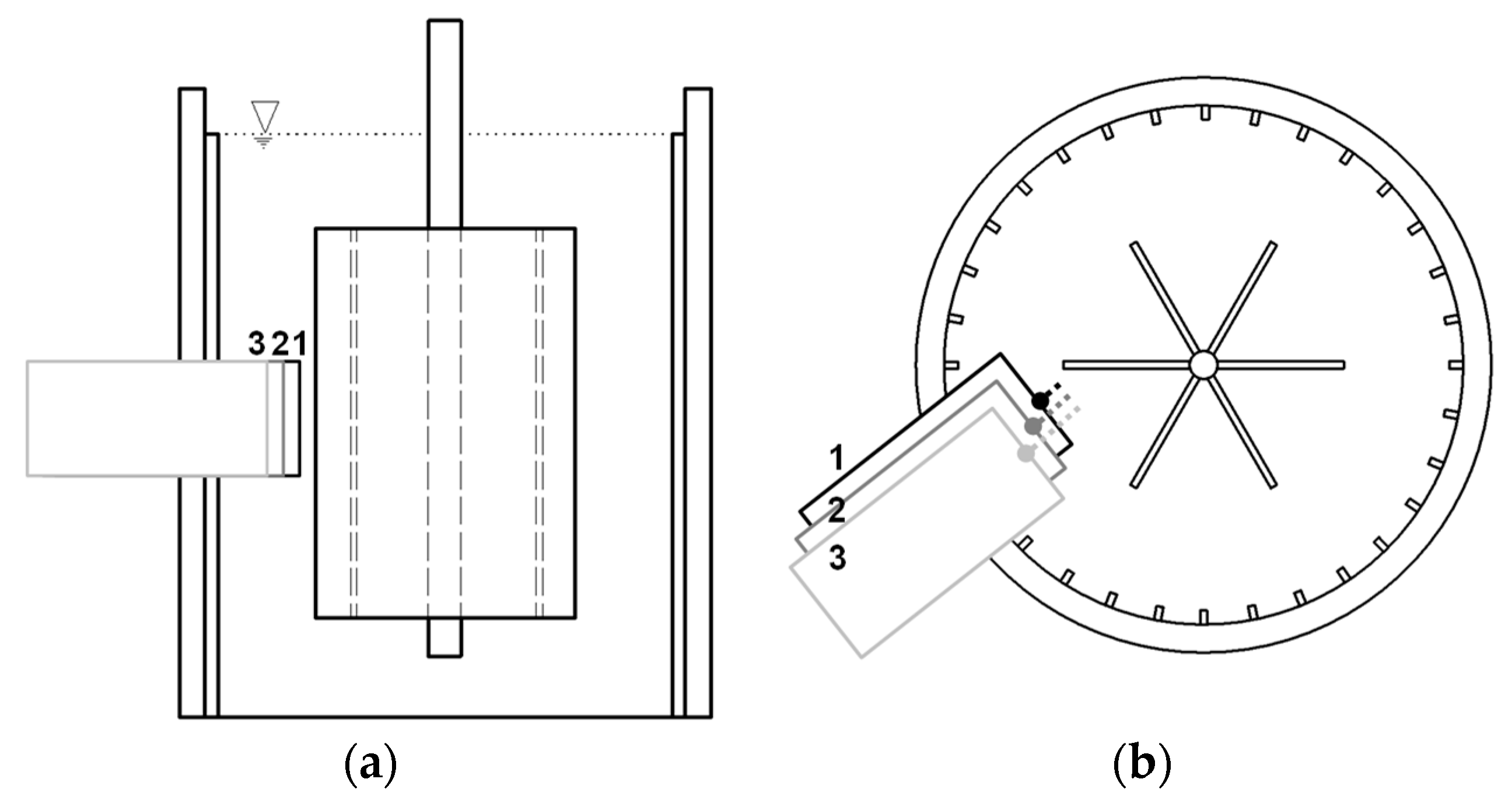

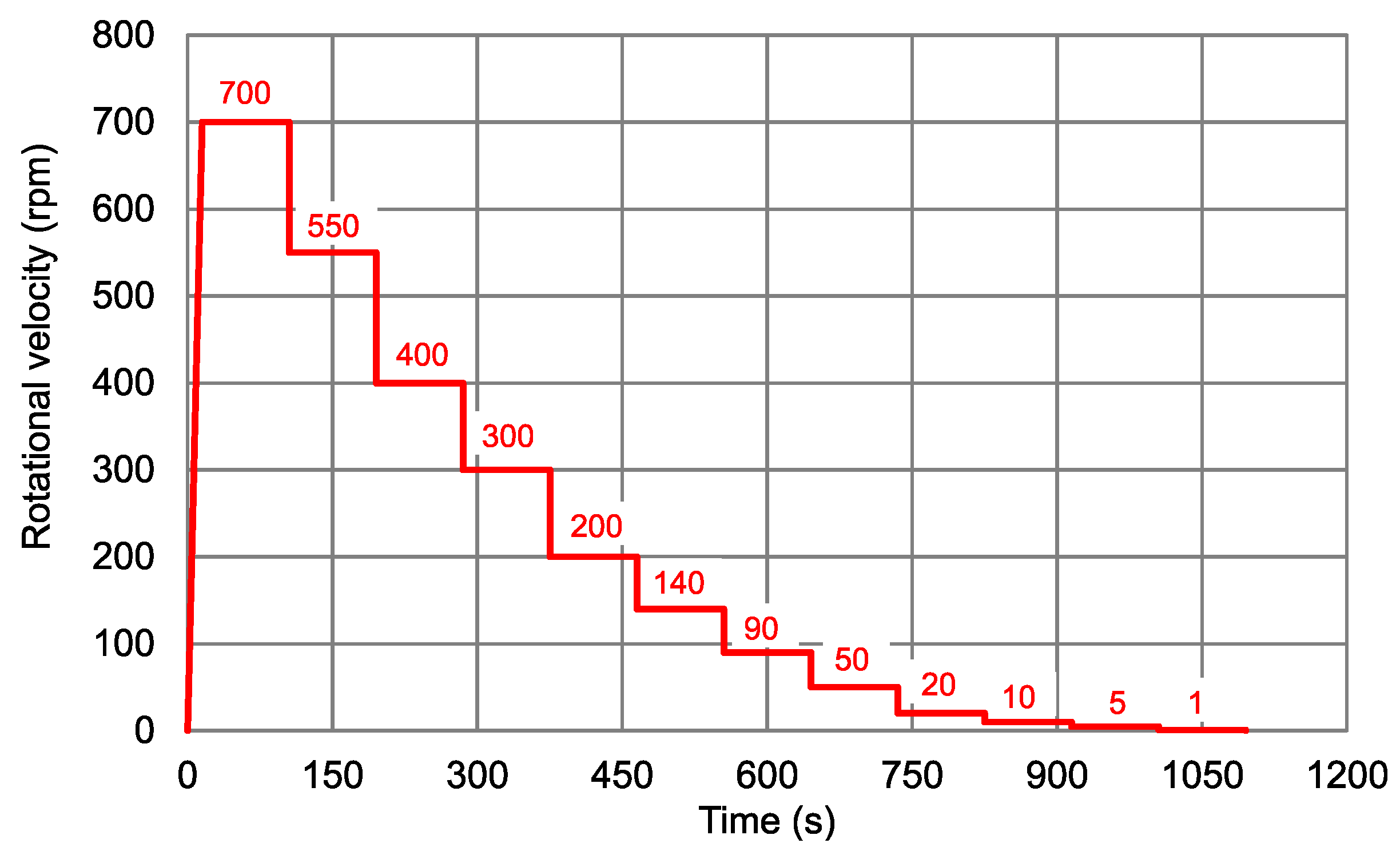

2.3. Experimental Setup and Program

2.4. CFD Simulations

2.5. Data Evaluation

2.5.1. Bingham Model

2.5.2. Shear Rate Calculation in the Shear Thickening Zone

3. Results and Discussion

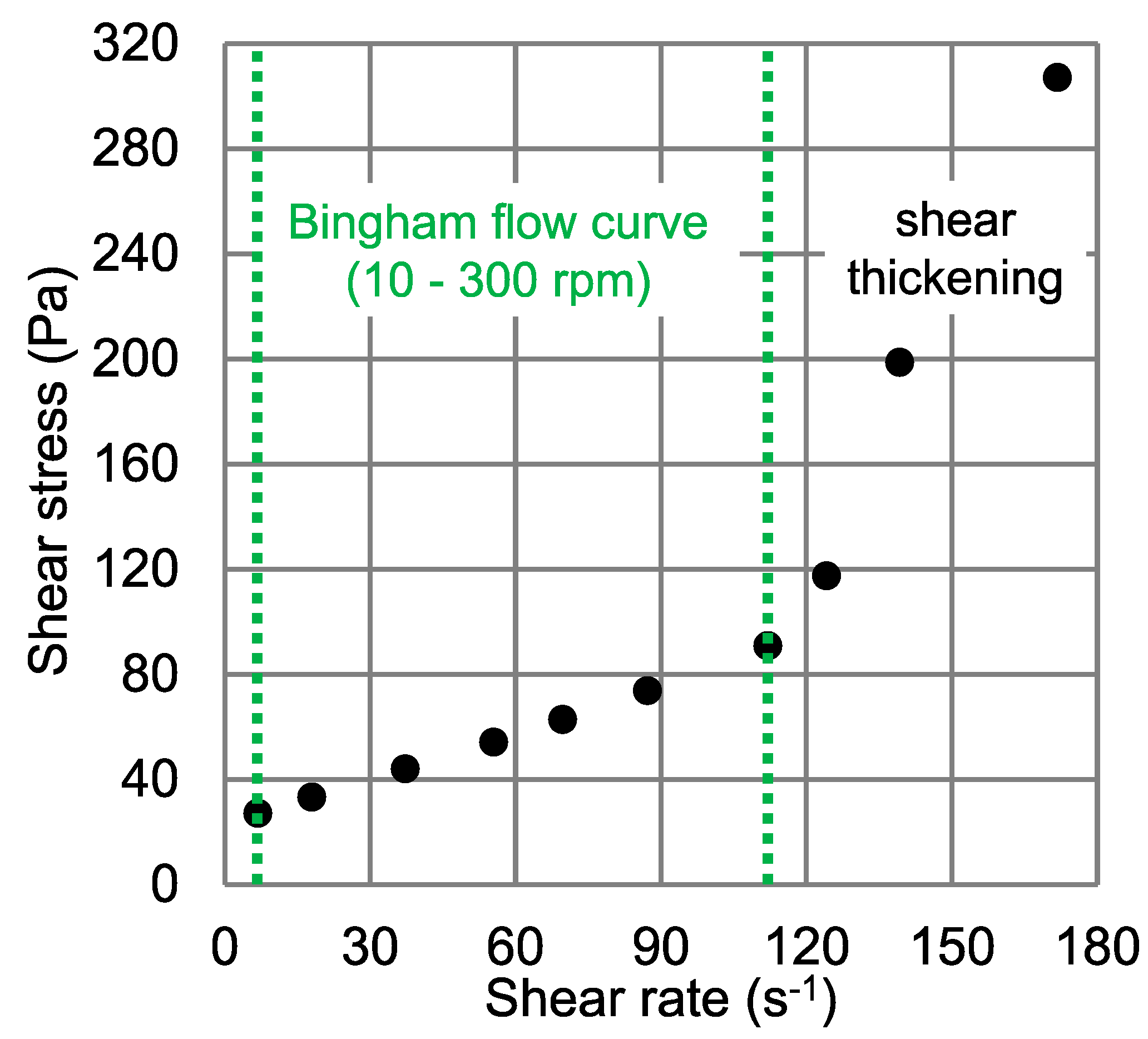

3.1. Rheological Properties

3.2. In-situ Chord Length Distributions

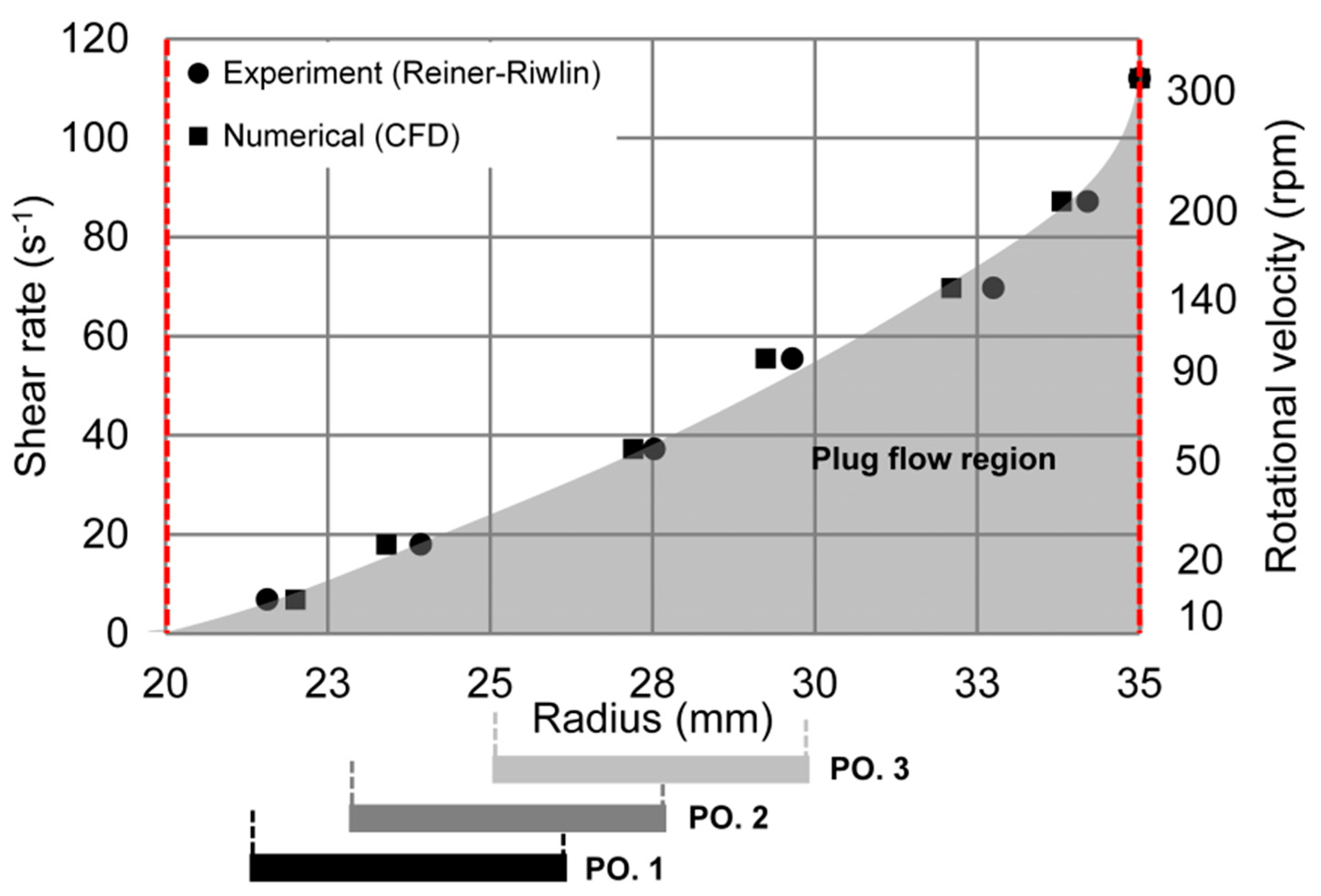

3.2.1. Determination of Plug Flow Radius at Different Rotational Velocities

3.2.2. Effect of Shear Rates on Median Chord Length

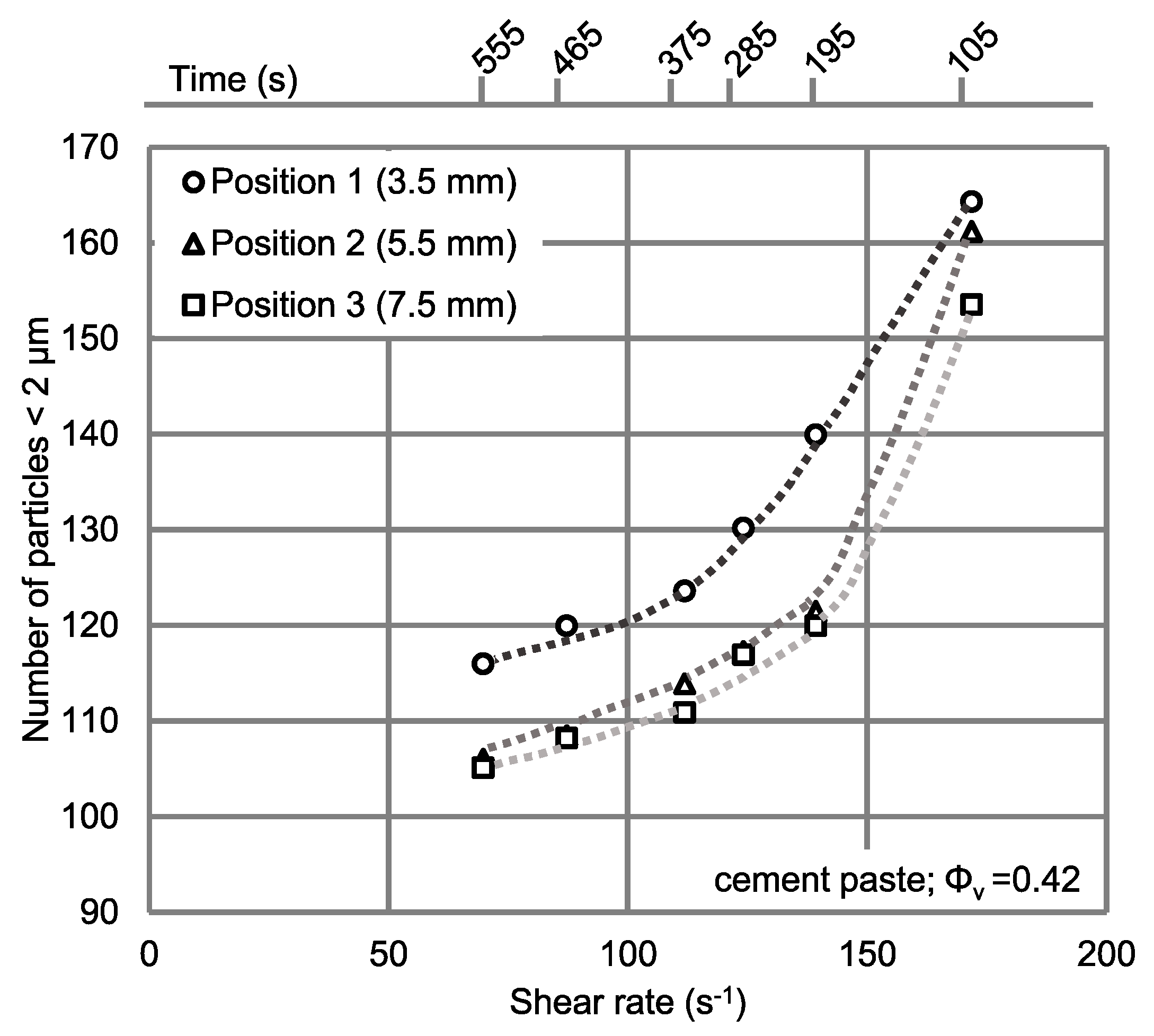

3.2.3. Effect of Shear Rates on Small Particles (≤ 2 μm)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Han, D.; Ferron, R.D. Influence of high mixing intensity on rheology, hydration, and microstructure of fresh state cement paste. Cem. Concr. Res. 2016, 84, 95–106. [Google Scholar] [CrossRef]

- Ferron, R.D.; Shah, S.; Fuente, E.; Negro, C. Aggregation and breakage kinetics of fresh cement paste. Cem. Concr. Res. 2013, 50, 1–10. [Google Scholar] [CrossRef]

- Zhang, Y. Study on Microstructure and Rheological Properties of Cement-Chemical Admixtures-Water Dispersion System at Early Stage; Springer Singapore: Singapore, 2018; ISBN 978-981-10-4569-1. [Google Scholar]

- Roussel, N. Rheology of fresh concrete: From measurements to predictions of casting processes. Mater. Struct. 2007, 40, 1001–1012. [Google Scholar] [CrossRef]

- Coussot, P.; Nguyen, Q.D.; Huynh, H.T.; Bonn, D. Viscosity bifurcation in thixotropic, yielding fluids. J. Rheol. 2002, 46, 573–589. [Google Scholar] [CrossRef]

- Dongyeop, H. Flow Behavior and Microstructure of Cement-Based Materials. Ph. D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2014. [Google Scholar]

- Banfill, P.F.H. Rheology of Fresh Cement and Concrete; Taylor & Francis: Abingdon, UK, 1991; ISBN 978-0-203-24017-5. [Google Scholar]

- Lowke, D. Sedimentationsverhalten & Robustheit Selbstverdichtender Betone. Ph.D. Thesis, Technische Universität München, München, Germany, 2013; pp. 87–88. [Google Scholar]

- Haist, M. Zur Rheologie Zur Rheologie und den Physikalischen Wechselwirkungen bei Zementsuspensionen. Ph.D. Thesis, Fakultät für Bauingenieur-, Geo- und Umweltwissenschaften der Universität Fridericiana zu Karlsruhe (TH), Karlsruhe, Germany, 2019. [Google Scholar]

- Jae Hong, K.; Hong Jae, Y.; Ferron, R.D. In situ measurement of the rheological properties and agglomeration on cementitious pastes. Soc. Rheol. Inc. J. Rheol. 2016, 60, 695–704. [Google Scholar]

- Heinrich, J. Determination of Crystallization Kinetics Using In-Situ Measurement Techniques and Model-Based Experimental Design & Analysis. Ph.D. Thesis, Martin-Luther-Universität Halle-Wittenberg, Halle, Germany, 2008; pp. 41–45. [Google Scholar]

- Krauss, H.-W.; Dreßler, I.; Budelmann, H. Experimentelle Bestimmung der Zusammenhänge zwischen rheologischen Eigenschaften von feststoffreichen Suspensionen und deren Mikrostruktur. Chem. Ing. Tech. 2018, 90, 881–887. [Google Scholar] [CrossRef]

- Qian, Y.; Lesage, K.; El Cheikh, K.; de Schutter, G. Effect of polycarboxylate ether superplasticizer (PCE) on dynamic yield stress, thixotropy and flocculation state of fresh cement pastes in consideration of the Critical Micelle Concentration (CMC). Cem. Concr. Res. 2018, 107, 75–84. [Google Scholar] [CrossRef]

- Qian, Y.; de Schutter, G. Enhancing thixotropy of fresh cement pastes with nanoclay in presence of polycarboxylate ether superplasticizer (PCE). Cem. Concr. Res. 2018, 111, 15–22. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Li, H.; Zhou, X.; Wang, X. Using Coupled Rheometer-FBRM to Study Rheological Properties and Microstructure of Cemented Paste Backfill. Adv. Mater. Sci. Eng. 2019, 2019, 6813929. [Google Scholar] [CrossRef]

- Eslami Pirharati, M.; Ivanov, D.; Krauss, H.-W.; Schilde, C.; Lowke, D. Numerical simulation of the flow behavior of Newtonian fluids in a wide gap rheometer by CFD. In Rheology and Processing of Construction Materials; RheoCon2 & SCC9; RheoCon2019/SCC9; RILEM Bookseries 23; Mechtcherine, V., Khayat, K.H., Secrieru, E., Eds.; Springer: Cham, Switzerland, 2019; pp. 588–595. [Google Scholar]

- Lu, Z.C.; Haist, M.; Ivanov, D.; Jakob, C.; Jansen, D.; Leinitz, S.; Link, J.; Mechtcherine, V.; Neubauer, J.; Plank, J.; et al. Characterization data of reference cement CEM I 42.5 R used for priority program DFG SPP 2005 “Opus Fluidum Futurum—Rheology of reactive, multiscale, multiphase construction materials”. Data Brief 2019, 27, 104699. [Google Scholar] [CrossRef] [PubMed]

- DIN-Normenausschuss Bauwesen (NABau). Prüfverfahren für Zement–Teil 1: Bestimmung der Festigkeit; Deutsche Fassung EN 196-1; Comite Europeen de Normalisation: Brussels, Belgium, 2016. [Google Scholar]

- Mettler-Toledo Garvens GmbH, Mettler-Toledo AutoChem, I. ParticleTrack G400 Hardware Manual; Renesas Electronics: Tokyo, Japan, 2015; pp. 54–55. [Google Scholar]

- Normenausschuss Bauwesen (NABau) im DIN. Prüfverfahren für Mörtel für Mauerwerk–Teil 6: Bestimmung der Rohdichte von Frischmörtel; Deutsche Fassung EN 1015-6: 1998 + A1; Comite Europeen de Normalisation: Brussels, Belgium, 2006. [Google Scholar]

- DIN-Normenausschuss Erdöl- und Erdgasgewinnung (NÖG). Erdöl- und Erdgasindustrie–Zemente und Materialien für die Zementation von Tiefbohrungen–Teil 2: Prüfung von Bohrloch-Zemente (ISO/DIS 10426-2); International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- Normenausschuss Bauwesen (NABau) im DIN. Prüfverfahren für Mörtel für Mauerwerk – Teil 3: Bestimmung der Konsistenz von Frischmörtel (mit Ausbreittisch); Deutsche Fassung EN 1015-3:1999 + A1:2004 + A2; Comite Europeen de Normalisation: Brussels, Belgium, 2006. [Google Scholar]

- Worlitschek, J. Monitoring, Modeling and Optimization of Batch Cooling Crystallization. Ph.D. Thesis, ETH Zurich, Zürich, Switzerland, 2003. [Google Scholar]

- Koehler, E.P.; Fowler, D.W. Development of a Portable Rheometer for Fresh Portland Cement Conceret; International Center for Aggregates Research: Austin, TX, USA, 2004. [Google Scholar]

- Estellé, P.; Lanos, C.; Perrot, A.; Amziane, S. Processing the vane shear flow data from Couette analogy. Appl. Rheol. 2008, 18, 34037. [Google Scholar] [CrossRef][Green Version]

- Feys, D.; Wallevik, J.E.; Yahia, A.; Khayat, K.; Wallevik, H.; Olafur, H. Extension of the Reiner–Riwlin equation to determine modified Bingham parameters measured in coaxial cylinders rheometers. Mater. Struct. 2013, 46, 289–311. [Google Scholar] [CrossRef]

- Wallevik, O.H.; Feys, D.; Wallevik, J.E.; Khayat, K.H. Avoiding inaccurate interpretations of rheological measurements for cement-based materials. Cem. Concr. Res. 2015, 78, 100–109. [Google Scholar] [CrossRef]

- Heirman, G.; Vandewalle, L.; van Gemert, D.; Wallevik, Ó. Integration approach of the Couette inverse problem of powder type self-compacting concrete in a wide-gap concentric cylinder rheometer. J. Non-Newton. Fluid Mech. 2008, 150, 93–103. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Boger, D.V. Characterization of yield stress fluids with concentric cylinder viscometers. Rheol. Acta 1987, 508–515. [Google Scholar] [CrossRef]

- De Hoog, F.R.; Anderssen, R.S. Simple and Accurate Formulas for Flow-Curve Recovery from Couette Rheometer Data. Appl. Rheol. 2006, 16, 321–328. [Google Scholar] [CrossRef]

- Billon, H.H. Shear Rate Determination in a Concentric Cylinder Viscometer; DSTO Aeronautiocal and Maritime Research Laboratory: Victoria, Australia, 1996. [Google Scholar]

- Steffe, J.F. Rheological Methods in Food Process Engineering, 2nd ed.; Freeman Press: East Lansing, MI, USA, 1996. [Google Scholar]

- Feys, D.; Schutter, G.D.; Verhoeven, R. The Rheological Behaviour of Fresh Self-Compacting Concrete in the High Shear Rate Range; RILEM Bookseries 2; Springer: Dordrecht, The Netherlands, 2010; pp. 491–501. [Google Scholar]

| Process | Mixing Intensity | Duration |

|---|---|---|

| Dry homogenization of raw material | Level 1 (140 min−1) | 60 s |

| Addition of water during mixing | Level 1 (140 min−1) | 15 s |

| Mixing at lower speed | Level 1 (140 min−1) | 45 s |

| Rest, manual homogenization | − | 90 s |

| Mixing at higher speed | Level 2 (285 min−1) | 60 s |

| Rest, manual homogenization | − | 30 s |

| Mixing at higher speed | Level 2 (285 min−1) | 120 s |

| Position of the FBRM Probe | No. Experiment | Bingham Model | |

|---|---|---|---|

| Yield Stress (Pa) | Plastic Viscosity (Pa.s) | ||

| 1 | 1 | 25.6 | 0.5 |

| 2 | 24.1 | 0.5 | |

| 3 | 20.3 | 0.7 | |

| 2 | 1 | 24.2 | 0.6 |

| 2 | 20.4 | 0.7 | |

| 3 | 19.6 | 0.7 | |

| 3 | 1 | 23.4 | 0.6 |

| 2 | 21.9 | 0.6 | |

| 3 | 21.8 | 0.6 | |

| − | Average | 22.4 | 0.61 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eslami Pirharati, M.; Krauss, H.-W.; Schilde, C.; Lowke, D. Effect of Different Shear Rates on Particle Microstructure of Cementitious Materials in a Wide Gap Vane-in-cup Rheometer. Materials 2020, 13, 2035. https://doi.org/10.3390/ma13092035

Eslami Pirharati M, Krauss H-W, Schilde C, Lowke D. Effect of Different Shear Rates on Particle Microstructure of Cementitious Materials in a Wide Gap Vane-in-cup Rheometer. Materials. 2020; 13(9):2035. https://doi.org/10.3390/ma13092035

Chicago/Turabian StyleEslami Pirharati, Mahmoud, Hans-W. Krauss, Carsten Schilde, and Dirk Lowke. 2020. "Effect of Different Shear Rates on Particle Microstructure of Cementitious Materials in a Wide Gap Vane-in-cup Rheometer" Materials 13, no. 9: 2035. https://doi.org/10.3390/ma13092035

APA StyleEslami Pirharati, M., Krauss, H.-W., Schilde, C., & Lowke, D. (2020). Effect of Different Shear Rates on Particle Microstructure of Cementitious Materials in a Wide Gap Vane-in-cup Rheometer. Materials, 13(9), 2035. https://doi.org/10.3390/ma13092035