Three-Dimensional Printed PLA and PLA/PHA Dumbbell-Shaped Specimens: Material Defects and Their Impact on Degradation Behavior

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. 3D Processing of Dumbbell-Shaped Specimens

2.3. Specimens Preparation and Conditioning Process (Annealing)

2.4. Hydrolytic Degradation Experiments

2.5. Characterization

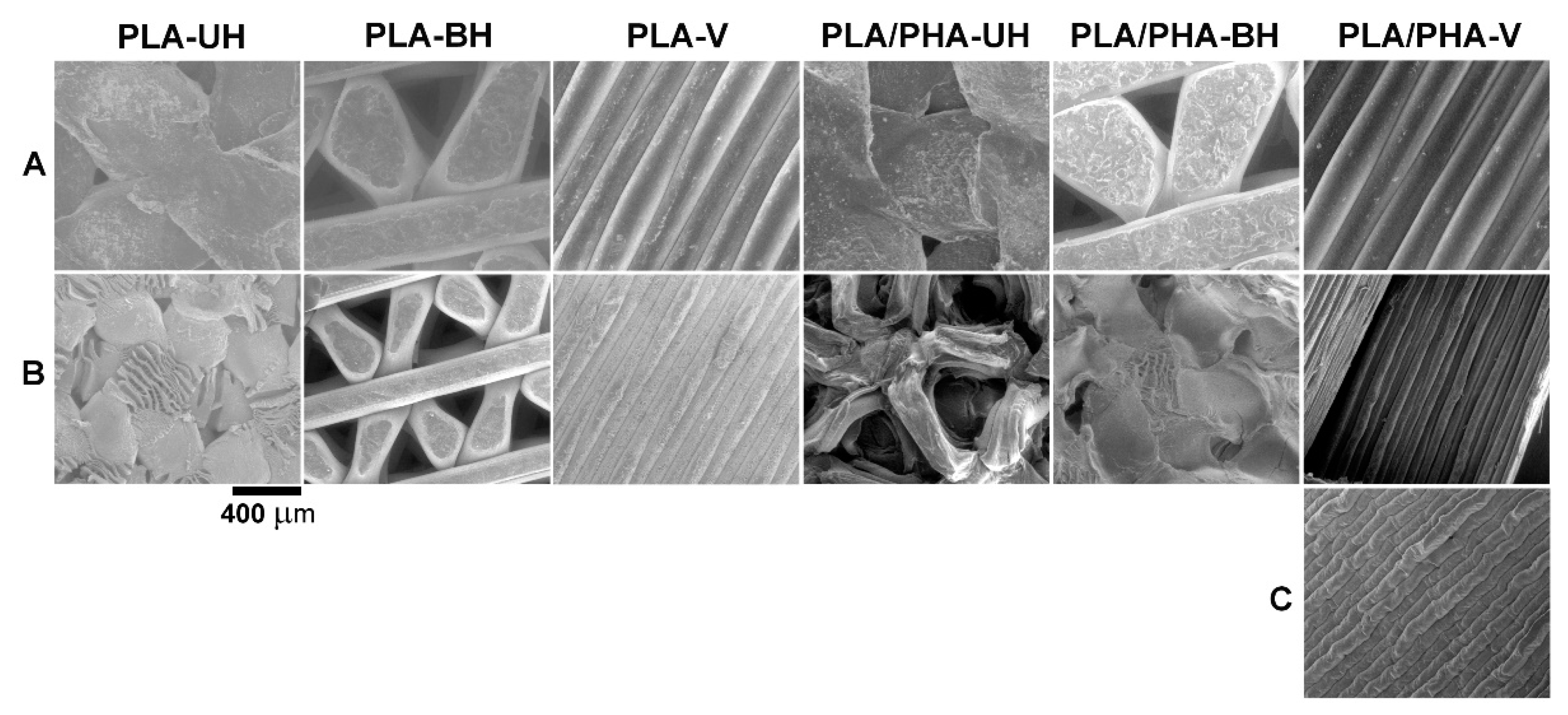

2.5.1. Scanning Electron Microscope (SEM)

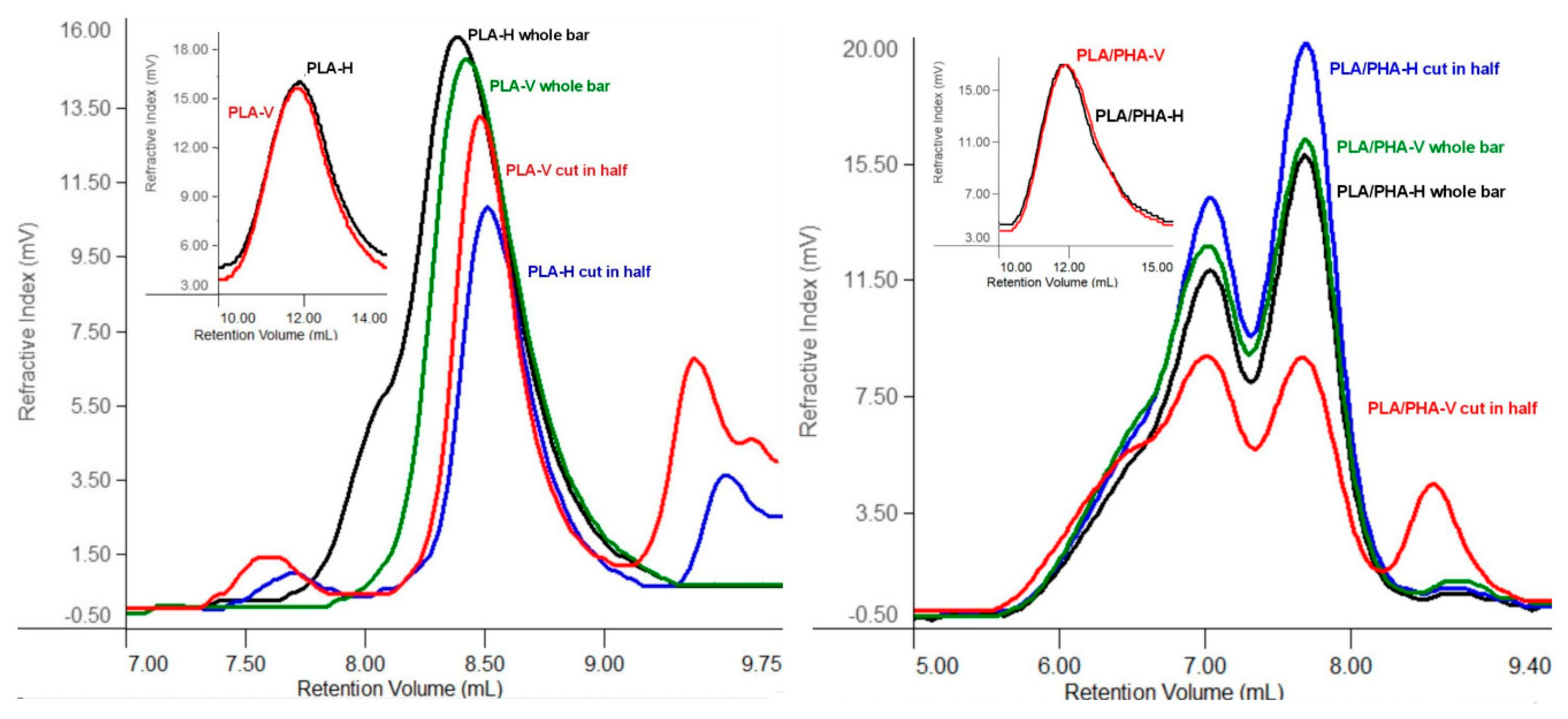

2.5.2. Gel Permeation Chromatography Analysis (GPC)

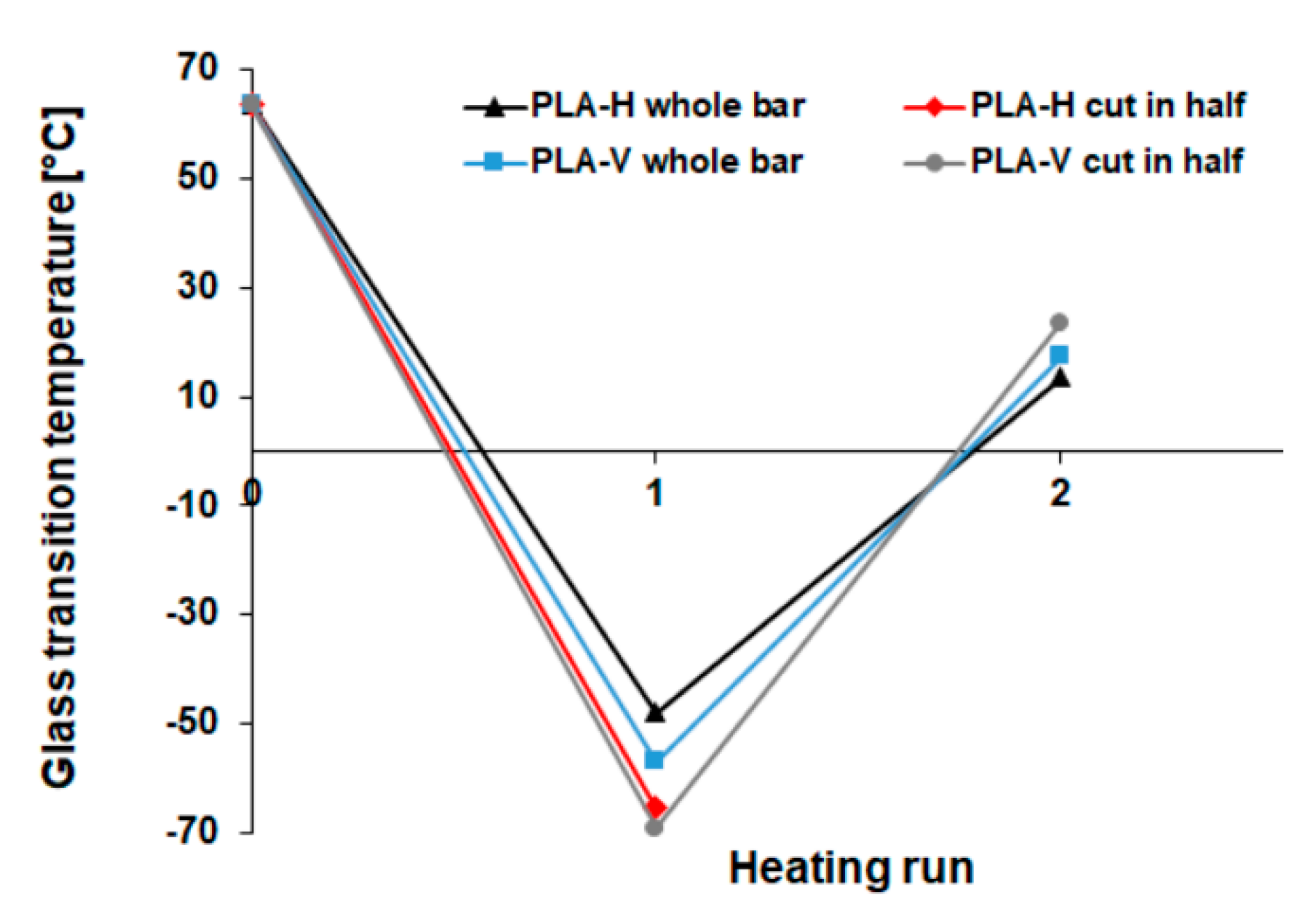

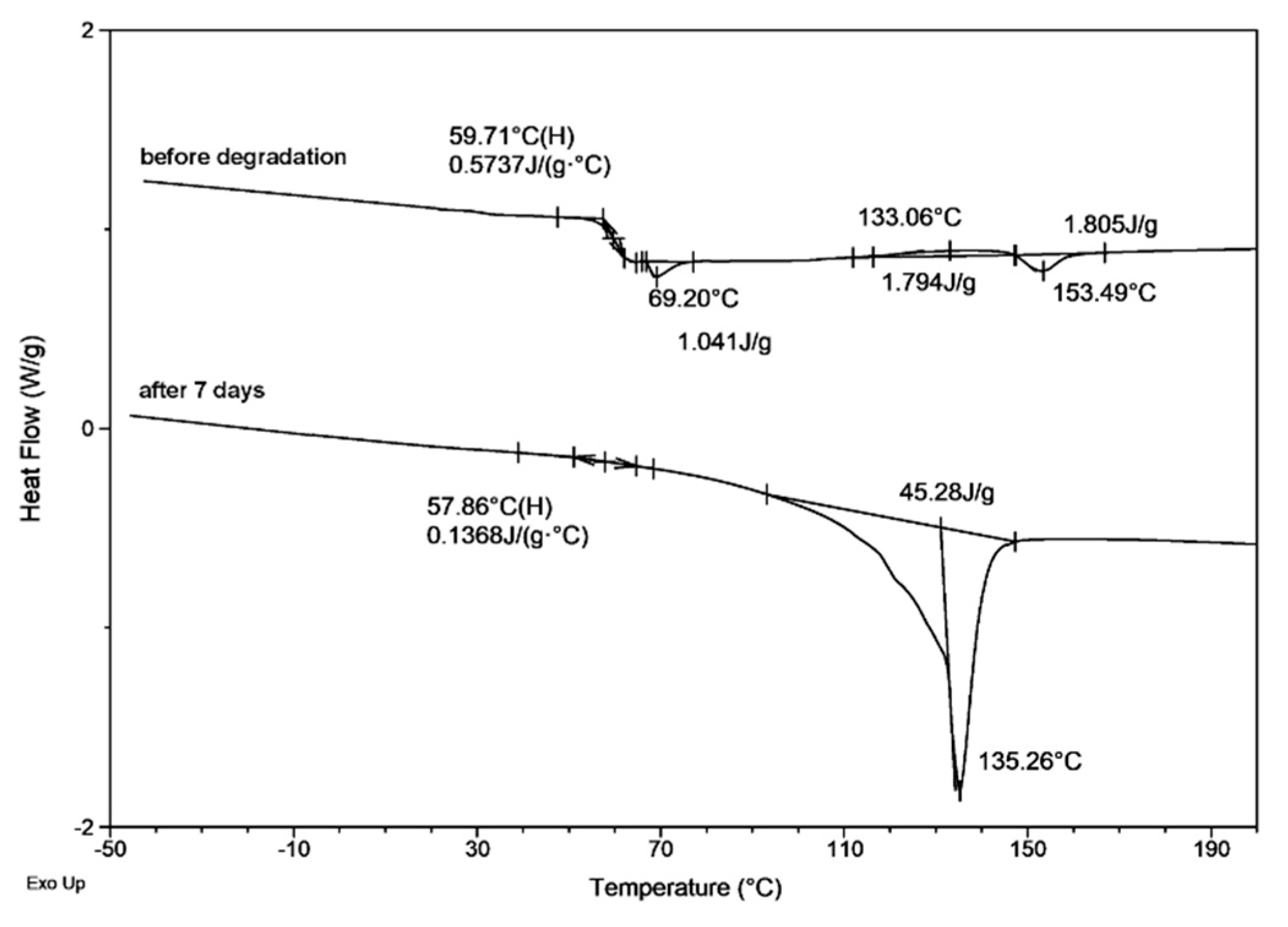

2.5.3. Differential Scanning Calorimetry (DSC)

3. Results and Discussion

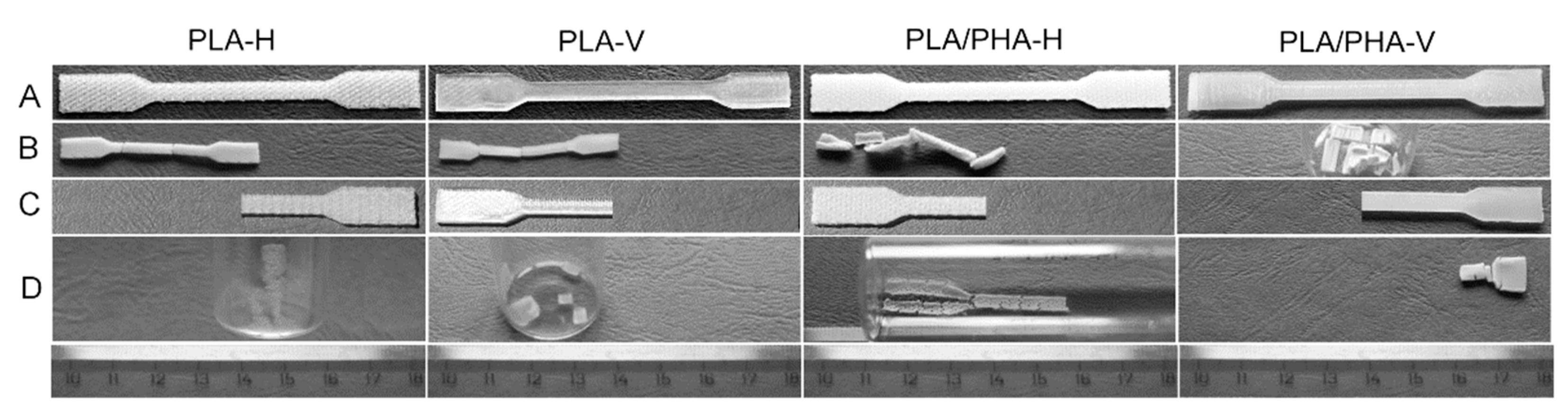

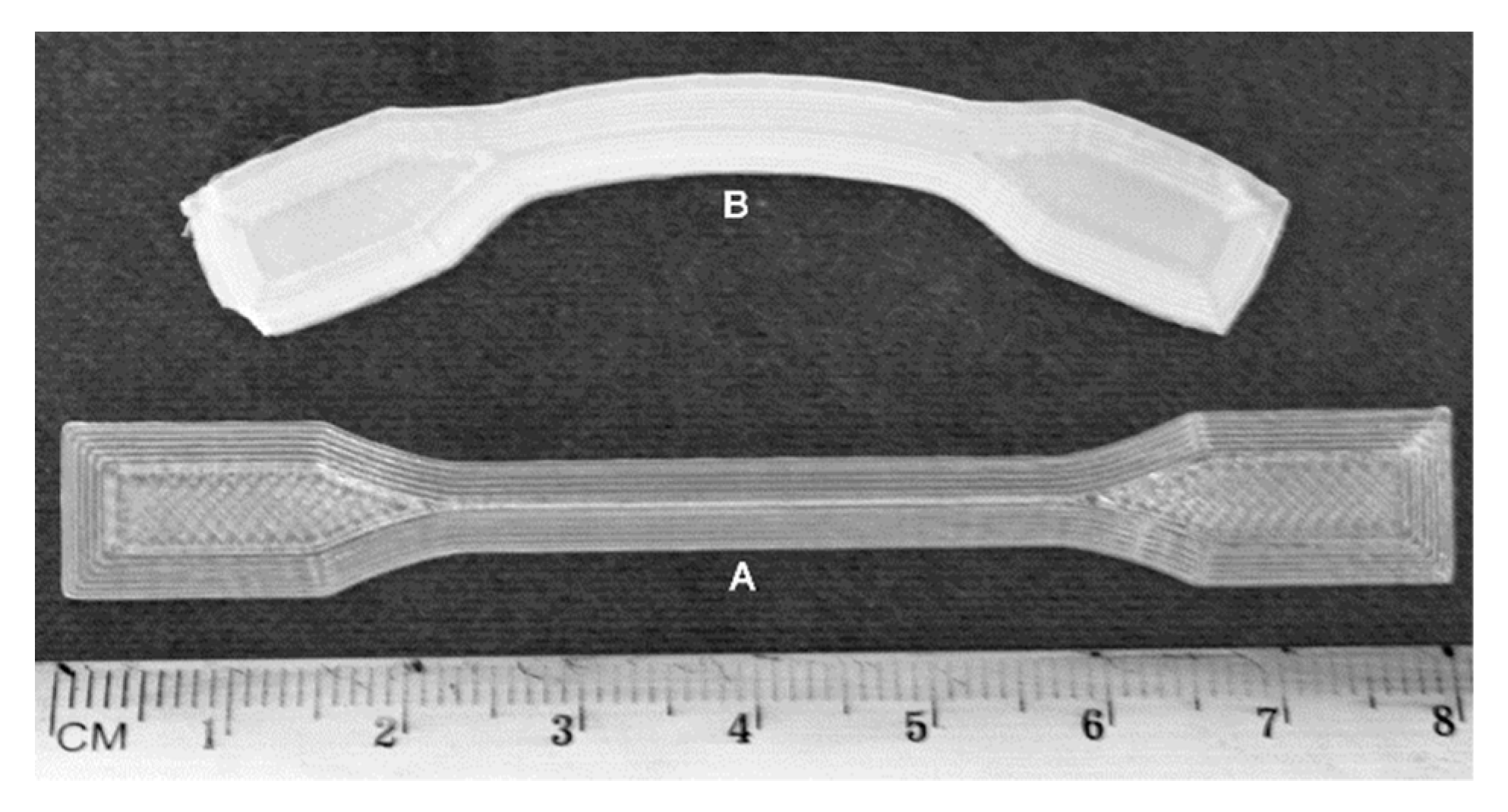

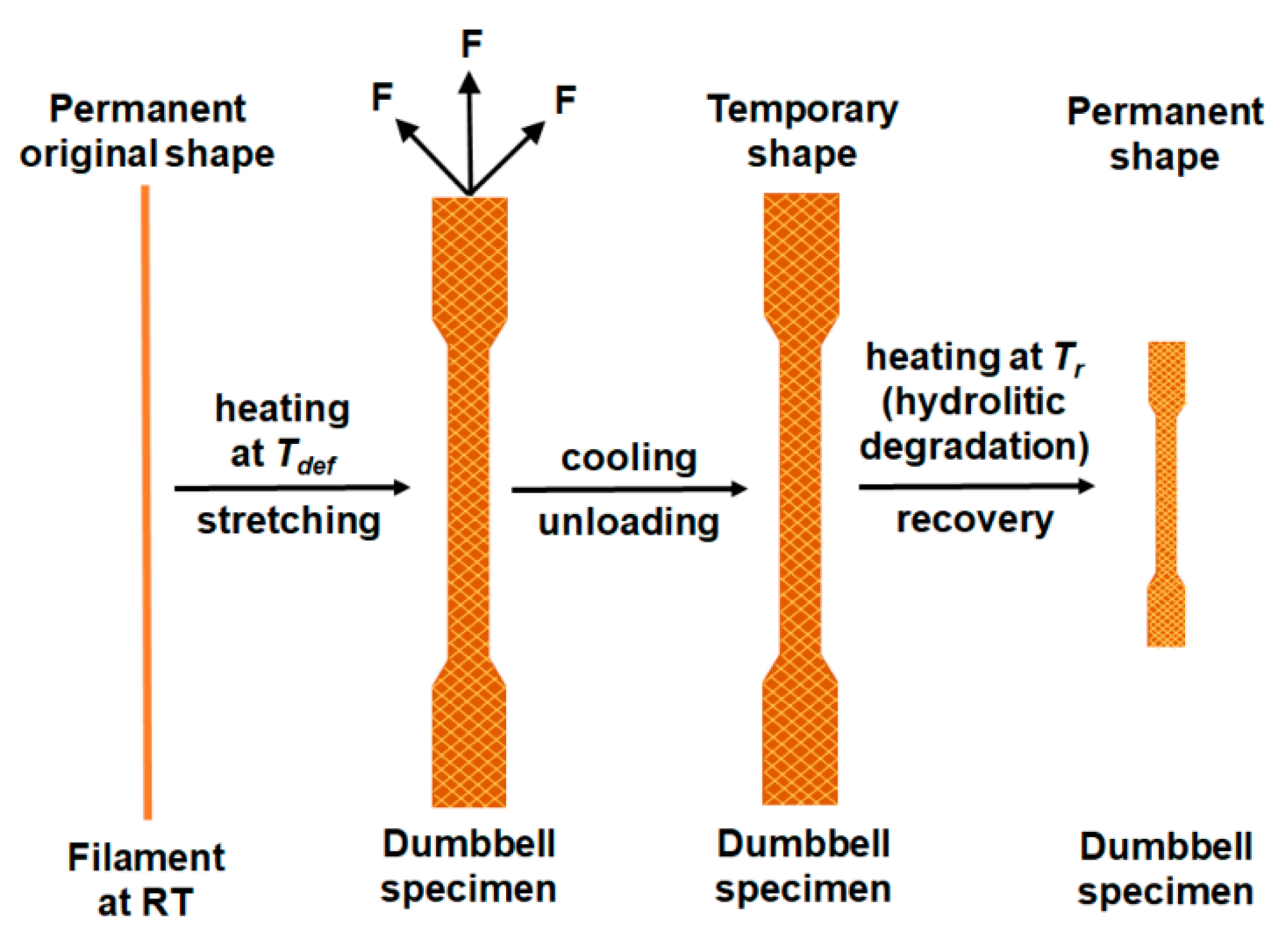

3.1. Failure Analysis and Characteristics of Dumbbell-Shaped Specimens with Unexpected Shrinkage Phenomena after Post-Processing Heat Treatment During Degradation Experiment

3.2. Impact of External Conditions During Printing

3.3. Impact of Printing Parameters: Times and Speeds of Printing

3.4. Impact of Conditioning and 3D Printer Parameters: Working Platform and Nozzle Temperatures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liang, F.; Todd, B.L.; Saini, R.K. Reinforcing amorphous PLA with solid particles for downhole applications. U.S. Patent 20130081821A1, 4 April 2013. [Google Scholar]

- Lee, R.E.; Guo, Y.; Tamber, H.; Planeta, M.; Leung, S.N.S. Thermoforming of polylactic acid foam sheets: Crystallization. Ind. Eng. Chem. Res. 2016, 55, 560–567. [Google Scholar] [CrossRef]

- Musioł, M.; Jurczyk, S.; Kwiecień, M.; Smola-Dmochowska, A.; Domański, M.; Janeczek, H.; Włodarczyk, J.; Klim, M.; Rydz, J.; Kawalec, M.; et al. The impact of shape memory test on degradation profile of a bioresorbable polymer. J. Mech. Behav. Biomed. Mater. 2018, 81, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez Ausejo, J.; Rydz, J.; Musioł, M.; Sikorska, W.; Sobota, M.; Włodarczyk, K.; Adamus, G.; Janeczek, H.; Kwiecień, I.; Hercog, A.; et al. A comparative study of three-dimensional printing directions: The degradation and toxicological profile of a PLA/PHA blend. Polym. Degrad. Stab. 2018, 152, 191–207. [Google Scholar] [CrossRef]

- Wu, W.; Ye, W.; Wu, Z.; Geng, P.; Wang, Y.; Zhao, J. Influence of layer thickness, raster angle, deformation temperature and recovery temperature on the shape-memory effect of 3D-printed polylactic acid samples. Materials 2017, 10, 970. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Yang, F.F.; Zhao, H.M.; Gao, Q.; Xia, B.; Fu, J.Z. Research on the printability of hydrogels in 3D bioprinting. Sci. Rep. 2016, 6, 29977. [Google Scholar] [CrossRef] [PubMed]

- Włodarczyk, J.; Sikorska, W.; Rydz, J.; Johnston, B.; Jiang, G.; Radecka, I.; Kowalczuk, M. 3D processing of PHA containing (bio)degradable materials. In Current Advances in Biopolymer Processing & Characterization; Biomaterials—Properties, Production and Devices Series; Koller, M., Ed.; Nova Science Publishers: New York, NY, USA, 2017. [Google Scholar]

- Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Lampman, S. Characterization and Failure Analysis of Plastics; ASM International: Materials Park, OH, USA, 2003. [Google Scholar]

- Frankland, J. Extrusion: How to Adjust for Shrinkage and Orientation. 2015. Available online: https://www.ptonline.com/columns/extrusion-how-to-adjust-for-shrinkage-and-orientation (accessed on 19 November 2019).

- Autodesk Inc. Dynamics that Affect the Shrinkage of Injection Molded Parts. Available online: https://www.autodesk.com/industry/manufacturing/resources/injection-molding/shrinkage-dynamics (accessed on 19 November 2019).

- Scalet, G.; Auricchio, F.; Bonetti, E.; Castellani, L.; Ferri, D.; Pachera, M.; Scavello, F. An experimental, theoretical and numerical investigation of shape memory polymers. Int. J. Plasticity 2015, 67, 127–147. [Google Scholar] [CrossRef]

- INEOS Olefins & Polymers USA. Polypropylene Processing Guide; Technical Center: Long Beach, CA, USA, 2007. [Google Scholar]

- ISO 527-2:2012. Tensile Testing of Moulding and Extrusion Plastics; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Gonzalez Ausejo, J.; Rydz, J.; Musioł, M.; Sikorska, W.; Janeczek, H.; Sobota, M.; Włodarczyk, J.; Szeluga, U.; Hercog, A.; Kowalczuk, M. Three-dimensional printing of PLA and PLA/PHA dumbbell-shaped specimens of crisscross and transverse patterns as promising materials in emerging application areas: Prediction study. Polym. Degrad. Stab. 2018, 156, 100–110. [Google Scholar] [CrossRef]

- Rydz, J.; Adamus, G.; Wolna-Stypka, K.; Marcinkowski, A.; Misiurska-Marczak, M.; Kowalczuk, M.M. Degradation of polylactide in paraffin and selected protic media. Polym. Degrad. Stab. 2013, 98, 316–324. [Google Scholar] [CrossRef]

- Sikorska, W.; Richert, J.; Rydz, J.; Musioł, M.; Adamus, G.; Janeczek, H.; Kowalczuk, M. Degradability studies of poly(L-lactide) after multi-reprocessing experiments in extruder. Polym. Degrad. Stab. 2012, 97, 1891–1897. [Google Scholar] [CrossRef]

- Grestenberger, G.; Potter, G.D.; Grein, C. Polypropylene/ethylene-propylene rubber (PP/EPR) blends for the automotive industry: Basic correlations between EPR-design and shrinkage. EXPRESS Polym. Lett. 2014, 8, 282–292. [Google Scholar] [CrossRef]

- Kwon, K.; Isayev, A.I.; Kim, K.H.; van Sweden, C. Theoretical and experimental studies of anisotropic shrinkage in injection moldings of semicrystalline polymers. Polym. Eng. Sci. 2006, 46, 712–728. [Google Scholar] [CrossRef]

- Puchalski, M.; Kwolek, S.; Szparaga, G.; Chrzanowski, M.; Krucińska, I. Investigation of the influence of PLA molecular structure on the crystalline forms (α’ and α) and mechanical properties of wet spinning fibres. Polymers 2017, 9, 18. [Google Scholar] [CrossRef] [PubMed]

- Moynihan, C.T.; Crichton, S.N.; Opalka, S.M. Linear and nonlinear structural relaxation. J. Non-Cryst. Solids 1991, 131, 420–434. [Google Scholar] [CrossRef]

- Moynihan, C.T.; Easteal, J.; De Bolt, M.A.; Tucker, J. Dependence of fictive temperature of glass on cooling rate. J. Am. Ceram. Soc. 1976, 59, 12–16. [Google Scholar] [CrossRef]

- Plazek, D.J.; Ngai, K.L. Physical Properties of Polymer Handbook; Mark, J.E., Ed.; American Institute of Physics: Woodbury, New York, NY, USA, 1996. [Google Scholar]

- Rydz, J.; Sikorska, W.; Musioł, M.; Janeczek, H.; Włodarczyk, J.; Misiurska-Marczak, M.; Łęczycka, J.; Kowalczuk, M. 3D-Printed polyester-based prototypes for cosmetic applications—Future directions at the forensic engineering of advanced polymeric materials. Materials 2019, 12, 994. [Google Scholar] [CrossRef] [PubMed]

- Menczel, J.D.; Judovits, L.; Prime, R.B.; Bair, H.E.; Reading, M.; Swier, S. Differential scanning calorimetry (DSC). In Thermal Analysis of Polymers: Fundamentals and Applications; Menczel, J.D., Prime, R.B., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2009; pp. 208–216. [Google Scholar]

- Burgos, N.; Tolaguera, D.; Fiori, S.; Jiménez, A. Synthesis and characterization of lactic acid oligomers: Evaluation of performance as poly(lactic acid) plasticizers. J. Polym. Environ. 2014, 22, 227–235. [Google Scholar] [CrossRef]

- Mark, H.F. Encyclopedia of Polymer Science and Technology, 3th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

| Specimen | PLA-H | PLA-V | PLA/PHA-H | PLA/PHA-V | ||

|---|---|---|---|---|---|---|

| Upper Layer | Underside Layer | Upper Layer | Underside Layer | |||

| Average Filament Width (μm) (Width Loss (%)) | ||||||

| Before degradation | 664 ± 103 | 481 ± 117 | 213 ± 38 | 666 ± 116 | 488 ± 91 | 210 ± 33 |

| After degradation, the whole specimen | 394 ± 26 (41) | 221 ± 45 (54) | 96 ± 13 (55) | 386 ± 74 (58) | 196 ± 34 (40) | 71 ± 12 (66) |

| After degradation, cut in half specimen | N/A | N/A | N/A | 268 ± 54 (45) | 161 ± 40 (76) | 87 ± 18 (58) |

| Specimen | Dumbbell-Shaped Specimens before Degradation | Dumbbell-Shaped Specimens after 70 Days of Degradation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PLA-H | PLA-Va | PLA/ PHA-H | PLA/ PHA-Va | PLA-H Whole Specimen | PLA-H Cut in Half Specimen | PLA-V Whole Specimen | PLA-V Cut in Half Specimen | PLA/PHA-H Whole Specimen | PLA/PHA-H Cut in Half Specimen | PLA/PHA-V Whole Specimen | PLA/PHA-V Cut in Half Specimen | |

| First heating run | ||||||||||||

| Tg (°C) | 63.7 | 63.5 | 4.8/62.4 | 2.9/62.8 | −48.0 | −65.4/0.4 | −56.9 | −69.1/24.1 | −62.1/−4.4 | −63.4/2.5 | −64.0/18.1 | −61.6/31.5 |

| Δcp (J/g°C) | 0.53 | 0.46 | 0.06/0.47 | 0.05/0.47 | 0.17 | 0.42/0.08 | 0.41 | 0.45/0.19 | 0.11/0.06 | 0.13/0.10 | 0.26/0.13 | 0.41/0.13 |

| Enthalpic relaxation (°C) | 74.5 | 72.5 | 68.7 | 72.0 | – | – | – | – | – | – | – | – |

| Tm (°C) | 152.1 | 153.2 | 152.6/172.1 | 154.1/172.5 | 81.2/100.7 | 60.4 | 74.8/103.7 | 102.1 | 73.0/144.2 | 141.0 | 144.1 | 65.6/127.4/135.1 |

| ΔHm (J/g) | 0.51 | 1.29 | 18.10 | 13.32 | 52.6/0.05 | 52.41 | 63.69/3.01 | 2.95 | 72.82 | 86.8 | 80.06 | 4.29/53.11 |

| Tcc (°C) | – | – | 111.7 | 124.9 | – | – | – | – | – | – | – | – |

| ΔHcc (J/g) | – | – | −17.75 | −13.11 | – | – | – | – | – | – | – | – |

| Second heating run | ||||||||||||

| Tg (°C) | 62.4 | 61.9 | 2.0/59.5 | 3.0/60.8 | 13.6 | N/A | 17.4 | 23.5 | −8.6 | −4.6 | −26.2 | −21.1/27.8 |

| Δcp (J/g°C) | 0.49 | 0.52 | 0.06/0.50 | 0.06/0.43 | 0.57 | 0.55 | 0.36 | 0.32 | 0.24 | 0.34 | 0.41/0.02 | |

| Tm (°C) | – | – | 152.6/174.5 | 154.2/171.7 | 95.2 | 114.8 | 116.0 | 135.7 | 135.9 | 120.2/135.5 | 66.6/102.0/127.8 | |

| ΔHm (J/g) | – | – | 0.08/0.22 | 0.73 | 0.74 | 1.77 | 1.41 | 65.72 | 67.58 | 69.59 | 0.08/39.61 | |

| Tcc (°C) | – | – | 145.7 | 143.1 | – | 72.6 | – | 79.3 | – | – | – | |

| ΔHcc (J/g) | – | – | −0.32 | −0.65 | – | −1.54 | – | −12.10 | – | – | – | |

| Parameters | Overall Length (mm) | Overall Width (mm) | Thickness (mm) | Overall Length (mm) | Overall Width (mm) | Thickness (mm) |

|---|---|---|---|---|---|---|

| Before | After 72 h | |||||

| Cooling 2/2/2a | 87.9 ± 0.3 | 10.3 ± 0.2 | 2.39 ± 0.1 | 84.0 ± 0.8 | 9.94 ± 0.3 | 2.35 ± 0.2 |

| Without cooling 2/2/2a | 88.0 ± 0.4 | 10.0 ± 0.2 | 2.27 ± 0.06 | 82.3 ± 0.7 | 9.71 ± 0.2 | 2.38 ± 0.1 |

| Cooling 0/0/0b | 87.7 ± 0.3 | 10.0 ± 0.2 | 2.38 ± 0.1 | 83.1 ± 0.6 | 9.62 ± 0.1 | 2.27 ± 0.1 |

| Without cooling 0/0/0b | 87.4 ± 0.2 | 9.7 ± 0.1 | 2.19 ± 0.1 | 82.6 ± 0.7 | 9.47 ± 0.2 | 2.24 ± 0.07 |

| Specimen | Printing Speed (mm/s) | Printing Time (min) | Nozzle Temperature (°C) | Overall Length (mm) | Thickness (mm) | Mass (g) |

|---|---|---|---|---|---|---|

| Dumbbell-shaped specimens with shrinkage phenomena during degradation experiment | ||||||

| PLA-H and PLA/PHA-H | 50 | 15 | 200 | 88 ± 0.4 | 1.80 ± 0.01 | 0.99 ± 0.01 |

| PLA-V and PLA/PHA-V | 70 | 40 | 195 | 90 ± 0.4 | 2.07 ± 0.01 | 1.36 ± 0.03 |

| Dumbbell-shaped specimens printed with various times and speeds of printing | ||||||

| PLA-1/210H | 1 | 210 | 200 | 87 ± 0.3 | 1.52 ± 0.01 | 1.21 ± 0.04 |

| PLA-1/165V | 1 | 165 | 195 | 91 ± 0.4 | 1.00 ± 0.06 | 0.90 ± 0.01 |

| PLA-50/5H | 50 | 5 | 200 | 87 ± 0.3 | 1.59 ± 0.07 | 1.26 ± 0.04 |

| PLA-50/15V | 50 | 15 | 195 | 91 ± 0.4 | 1.71 ± 0.20 | 1.44 ± 0.03 |

| PLA-50/14H | 50 | 14 | 200 | 88 ± 0.3 | 1.69 ± 0.01 | 1.31 ± 0.04 |

| PLA-70/36V | 70 | 36 | 195 | 93 ± 0.5 | 2.06 ± 0.03 | 1.66 ± 0.03 |

| Specimen | Working Platform Temperature (°C) | Nozzle Temperature (°C) |

|---|---|---|

| PLA-60/200 | 60 | 200 |

| PLA-70/220 | 70 | 220 |

| PLA-80/210 | 80 | 210 |

| PLA-90/220 | 90 | 220 |

| PLA-100/230 | 100 | 230 |

| PLA-120/240 | 120 | 240 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rydz, J.; Włodarczyk, J.; Gonzalez Ausejo, J.; Musioł, M.; Sikorska, W.; Sobota, M.; Hercog, A.; Duale, K.; Janeczek, H. Three-Dimensional Printed PLA and PLA/PHA Dumbbell-Shaped Specimens: Material Defects and Their Impact on Degradation Behavior. Materials 2020, 13, 2005. https://doi.org/10.3390/ma13082005

Rydz J, Włodarczyk J, Gonzalez Ausejo J, Musioł M, Sikorska W, Sobota M, Hercog A, Duale K, Janeczek H. Three-Dimensional Printed PLA and PLA/PHA Dumbbell-Shaped Specimens: Material Defects and Their Impact on Degradation Behavior. Materials. 2020; 13(8):2005. https://doi.org/10.3390/ma13082005

Chicago/Turabian StyleRydz, Joanna, Jakub Włodarczyk, Jennifer Gonzalez Ausejo, Marta Musioł, Wanda Sikorska, Michał Sobota, Anna Hercog, Khadar Duale, and Henryk Janeczek. 2020. "Three-Dimensional Printed PLA and PLA/PHA Dumbbell-Shaped Specimens: Material Defects and Their Impact on Degradation Behavior" Materials 13, no. 8: 2005. https://doi.org/10.3390/ma13082005

APA StyleRydz, J., Włodarczyk, J., Gonzalez Ausejo, J., Musioł, M., Sikorska, W., Sobota, M., Hercog, A., Duale, K., & Janeczek, H. (2020). Three-Dimensional Printed PLA and PLA/PHA Dumbbell-Shaped Specimens: Material Defects and Their Impact on Degradation Behavior. Materials, 13(8), 2005. https://doi.org/10.3390/ma13082005