Accelerated Life Testing of a Palladium-Doped Tin Oxide Electrode for Zn Electrowinning

Abstract

1. Introduction

2. Experimental Methods

2.1. Electrodes

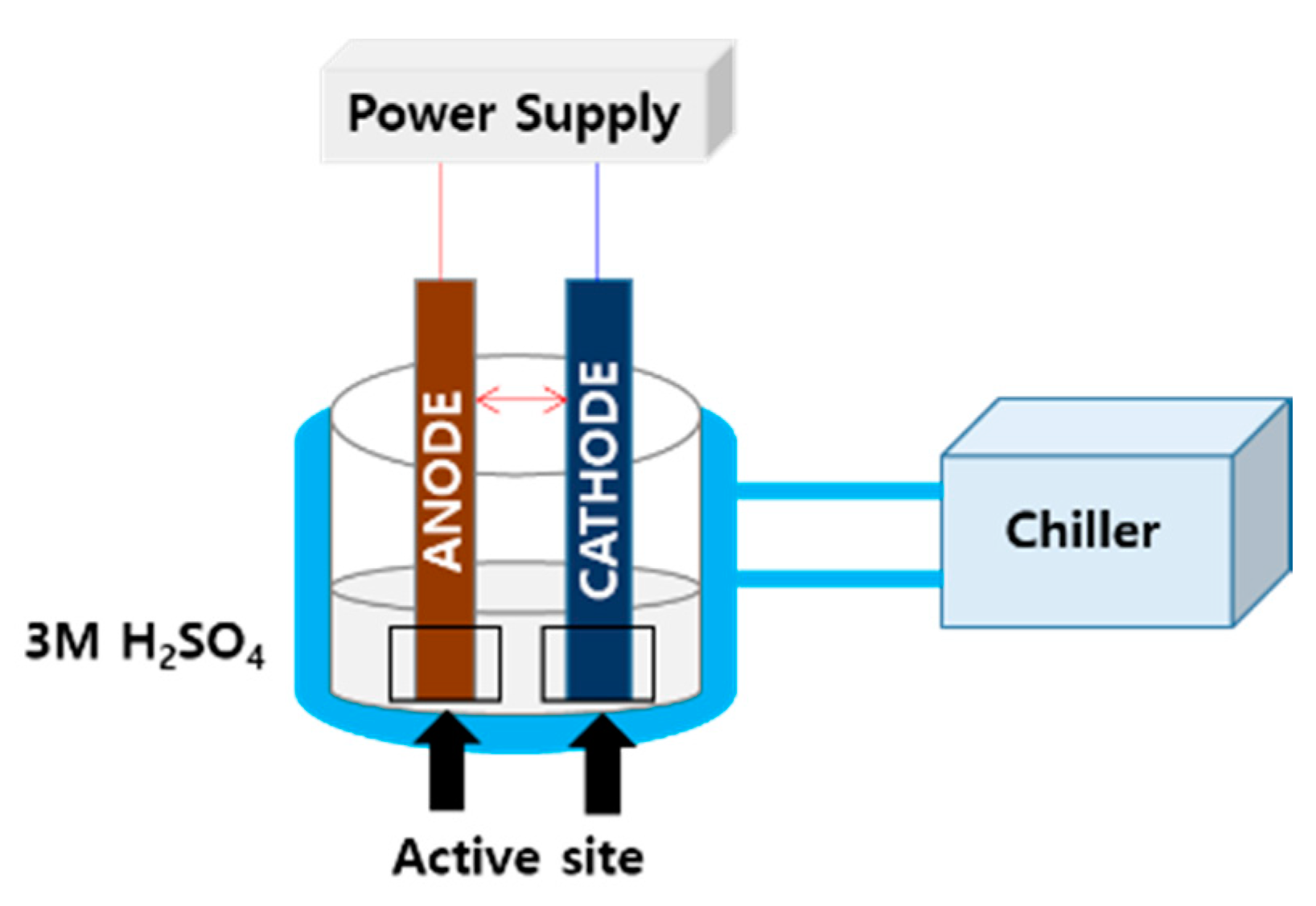

2.2. Accelerated Life Testing (ALT)

3. Results and Discussion

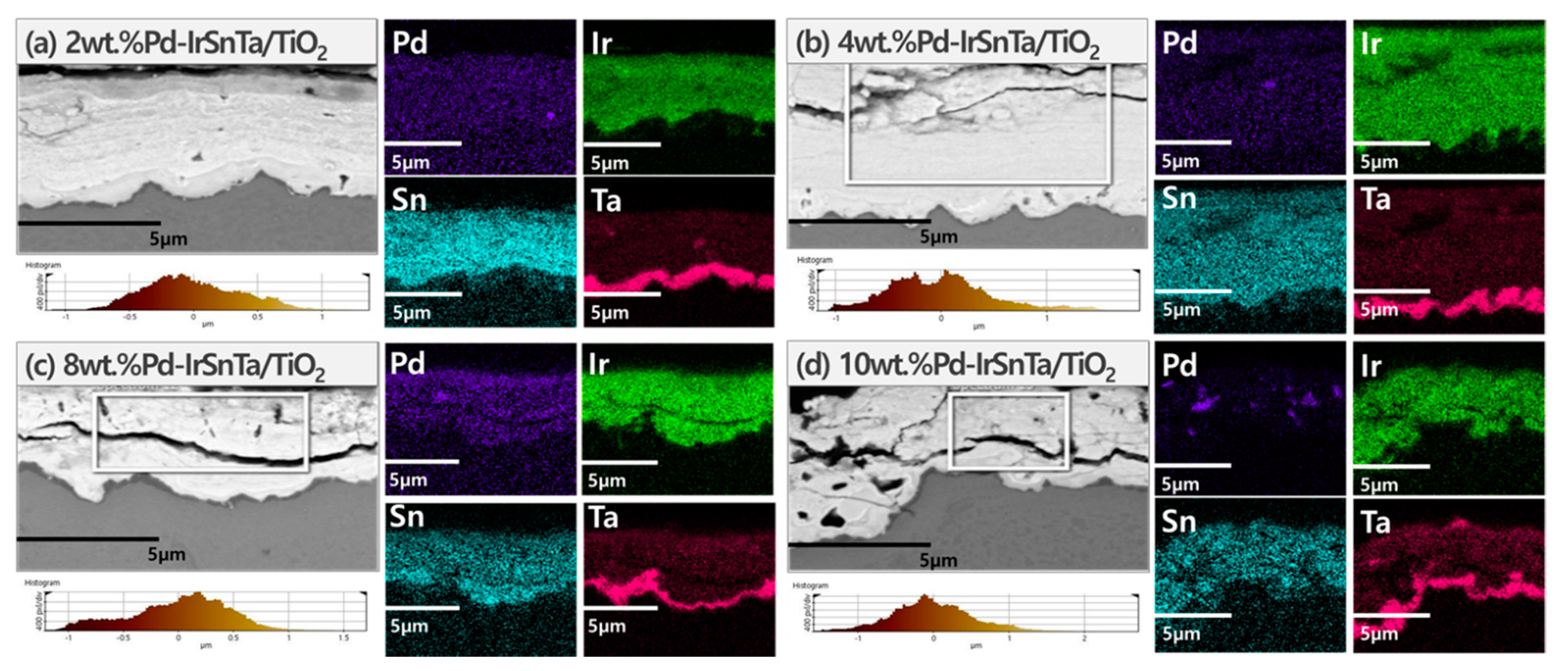

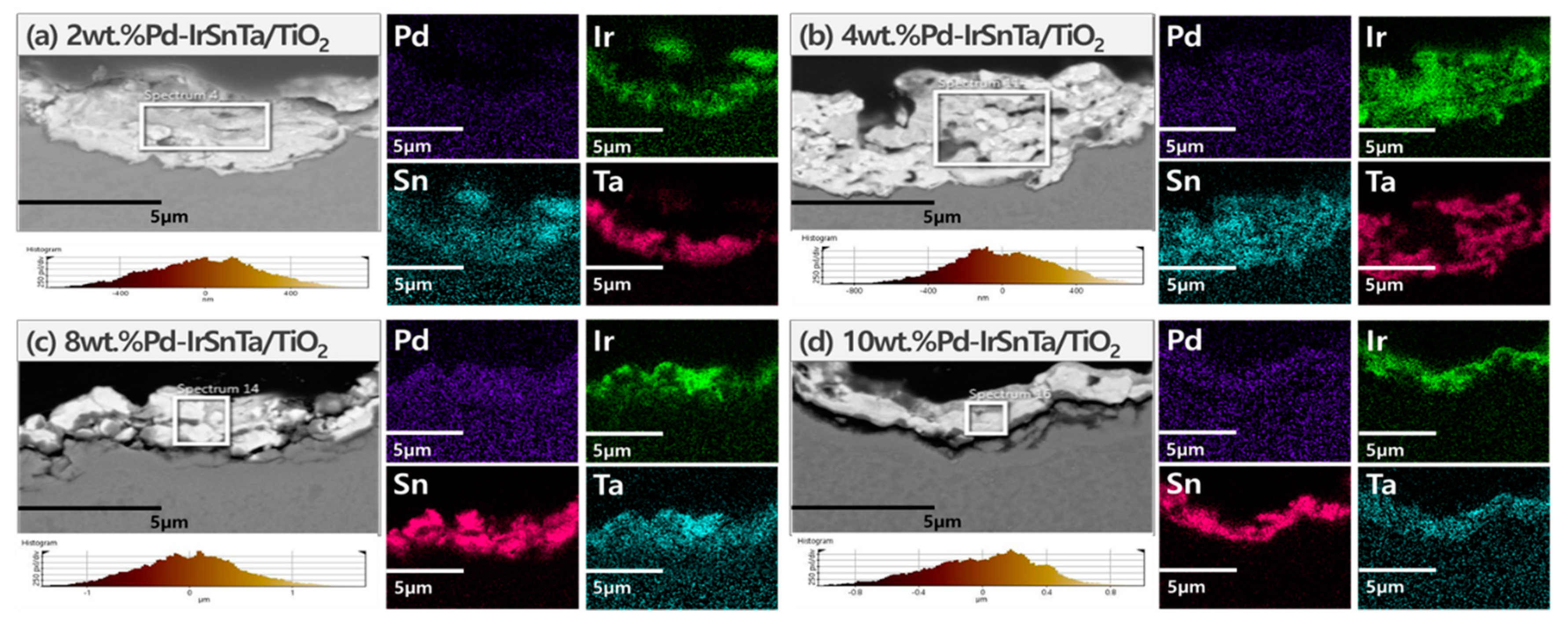

3.1. Characterization of the Pd-Based Electrodes

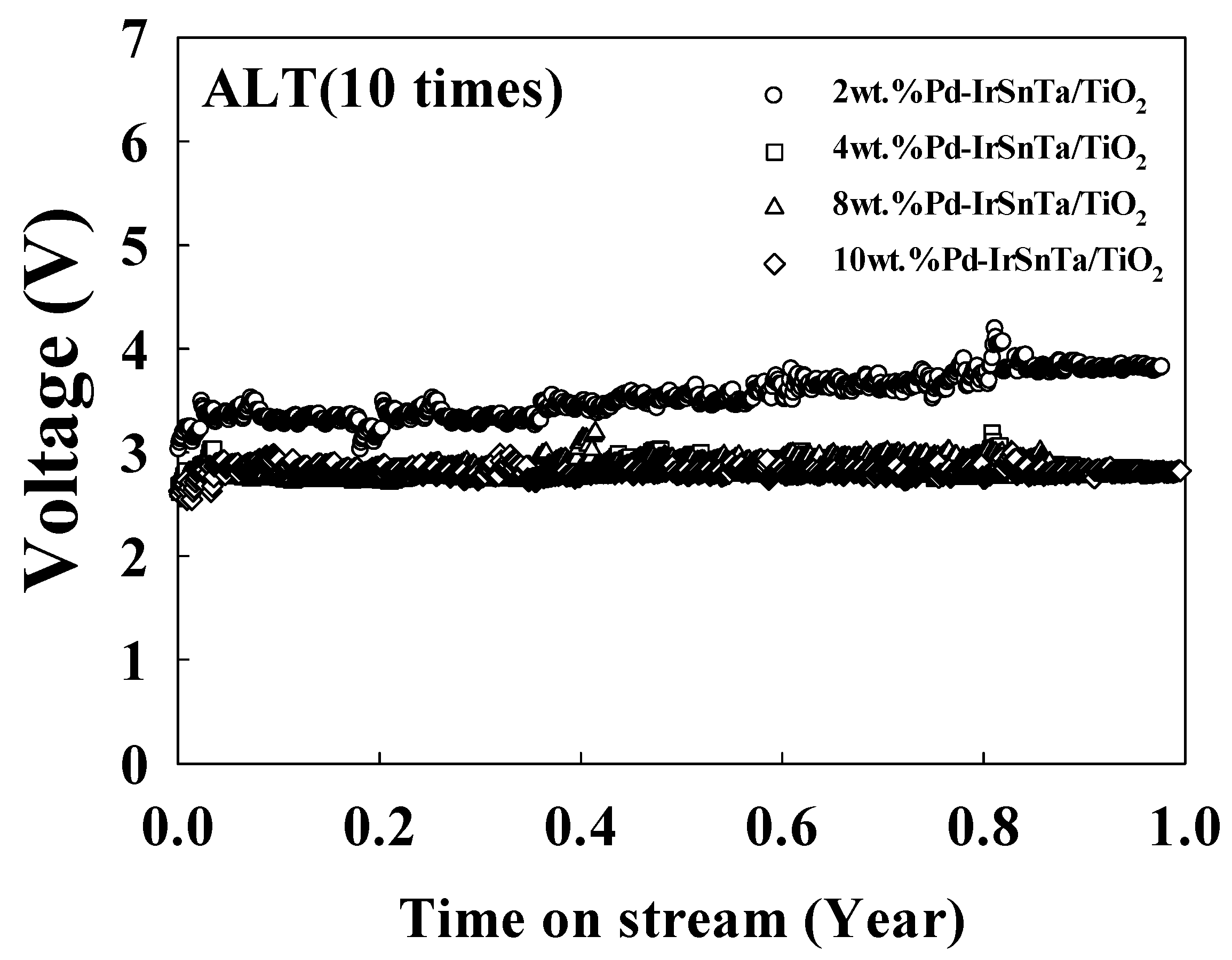

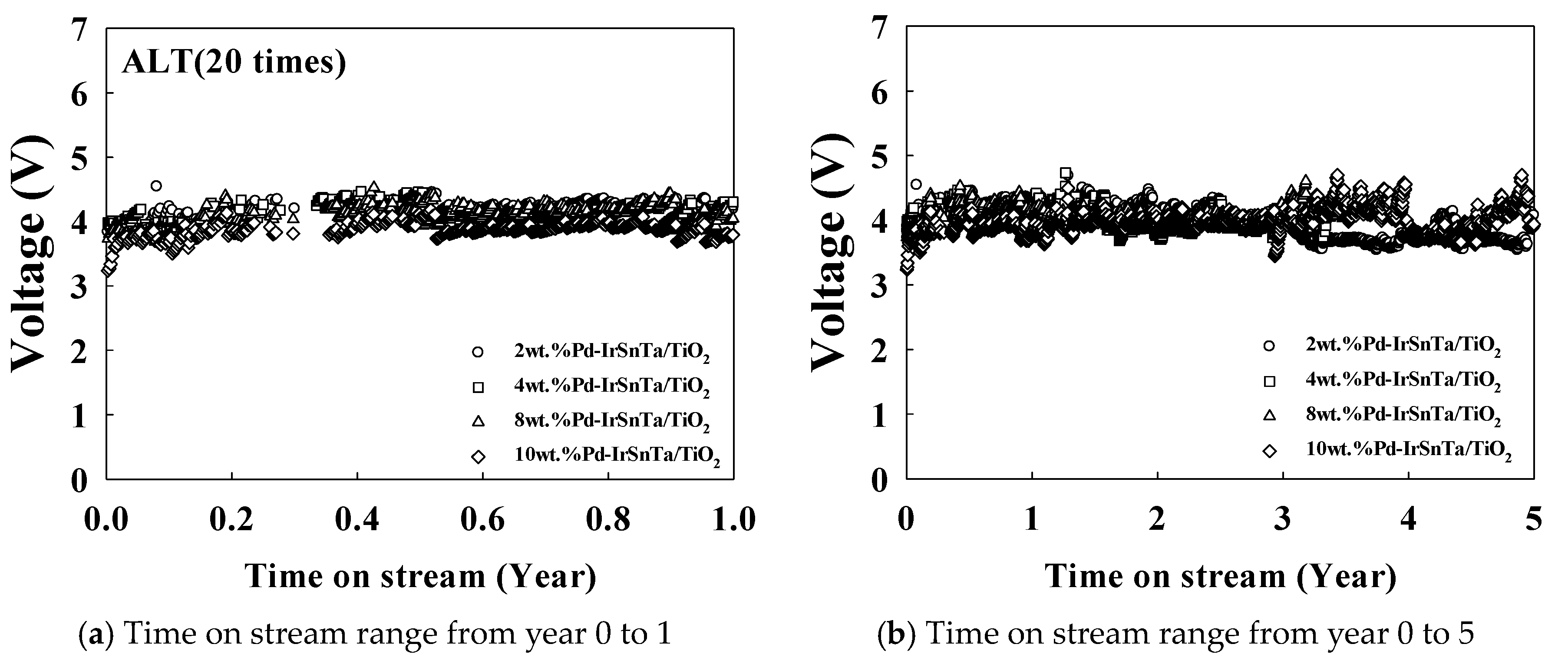

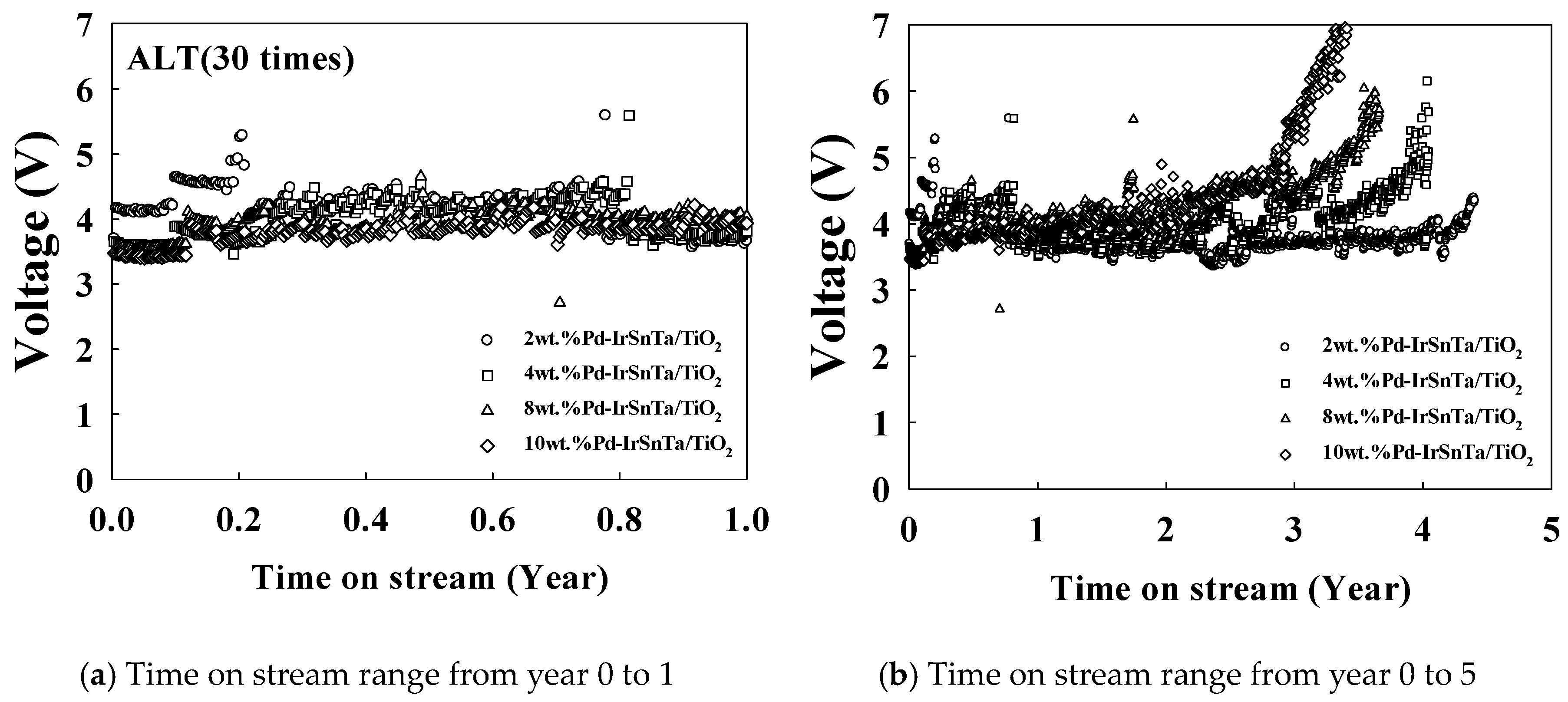

3.2. Accelerated Life Testing

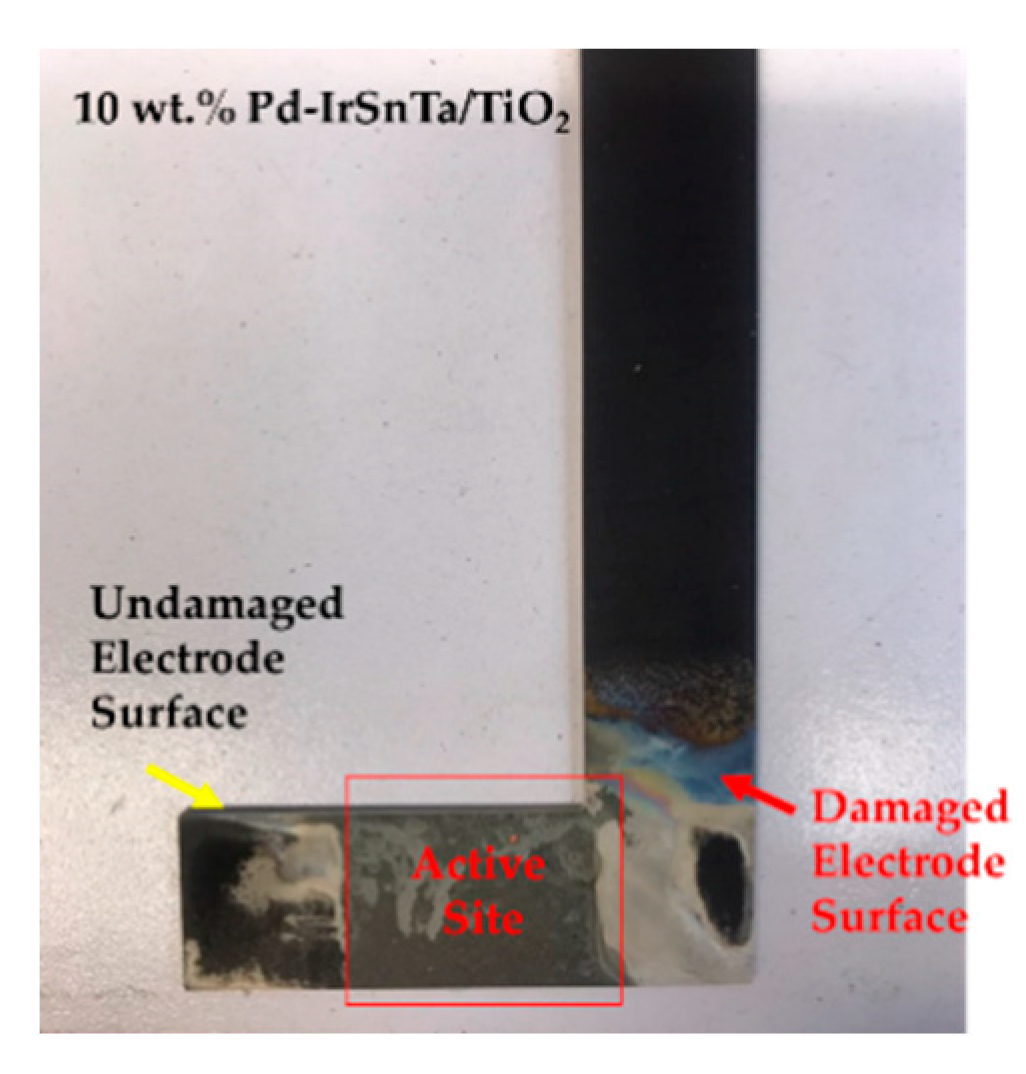

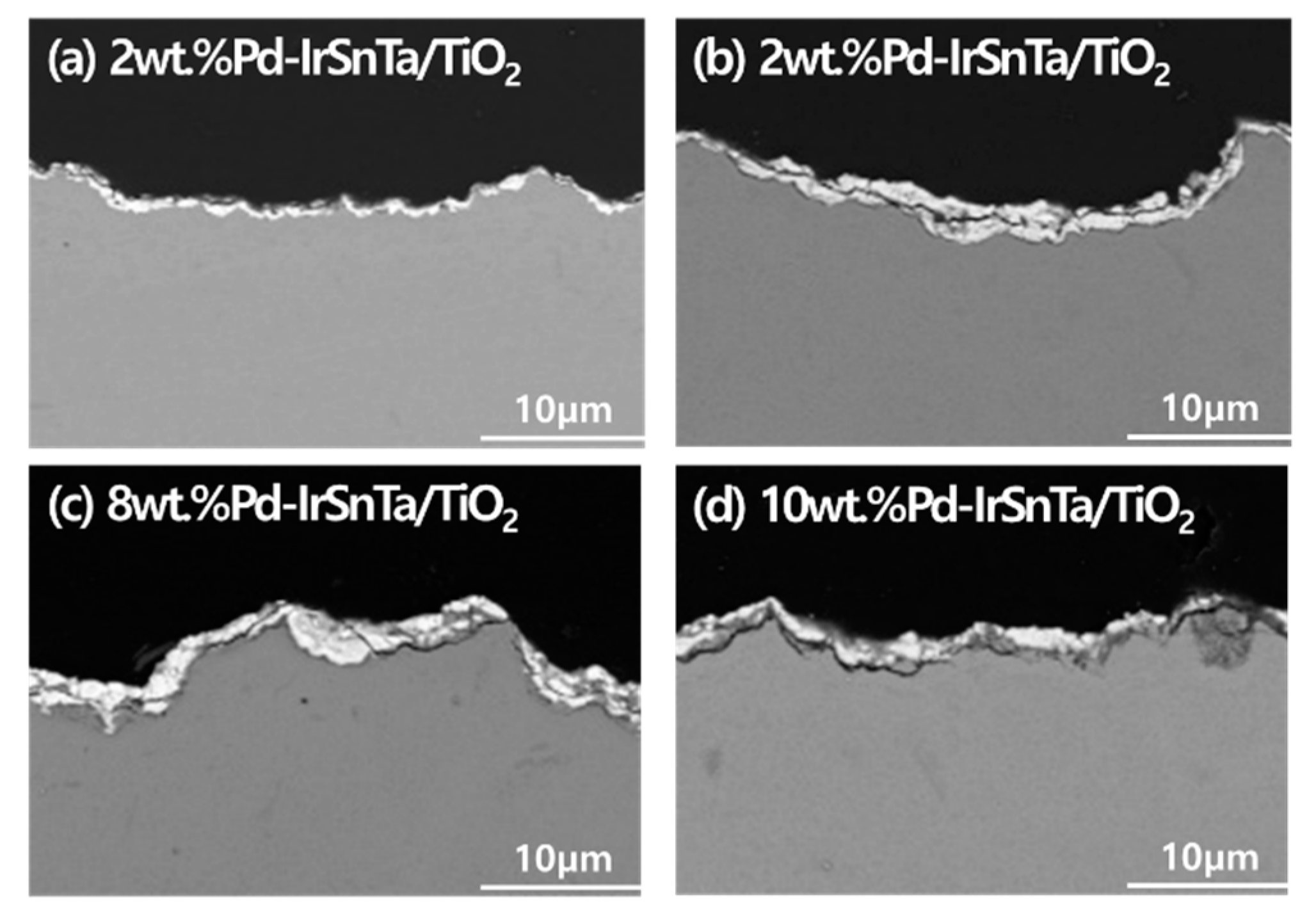

3.3. Pd-based Electrode after the Reactions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kirchhoff, M.M. Promoting sustainability through green chemistry. Resour. Conserv. Recycl. 2005, 44, 237–243. [Google Scholar] [CrossRef]

- Jha, M.K.; Kumari, A.; Panda, R.; Kumar, J.R.; Yoo, K.; Lee, J.-Y. Review on hydrometallurgical recovery of rare earth metals. Hydrometallurgy 2016, 165, 2–26. [Google Scholar] [CrossRef]

- Cachet, C.; Rérolle, C.; Wiart, R. Kinetics of Pb and Pb-Ag anodes for zinc electrowinning—II. Oxygen evolution at high polarization. Electrochim. Acta 1996, 41, 83–90. [Google Scholar] [CrossRef]

- Ivanov, I.; Stefanov, Y.; Noncheva, Z.; Petrova, M.; Dobrev, T.; Mirkova, L.; Vermeersch, R.; Demaerel, J.-P. Insoluble anodes used in hydrometallurgy. Hydrometallurgy 2000, 57, 109–124. [Google Scholar] [CrossRef]

- Yoon, H.-S.; Kim, C.-J.; Chung, K.-W.; Kim, S.-D.; Lee, J.-Y.; Kumar, J.R. Solvent extraction, separation and recovery of dysprosium (Dy) and neodymium (Nd) from aqueous solutions: Waste recycling strategies for permanent magnet processing. Hydrometallurgy 2016, 165, 27–43. [Google Scholar] [CrossRef]

- Cardoso, C.E.D.; Almeida, J.; Lopes, C.; Trindade, T.; Vale, C.; Pereira, E. Recovery of Rare Earth Elements by Carbon-Based Nanomaterials-A Review. Nanomaterials 2019, 9, 814. [Google Scholar] [CrossRef]

- Lixandru, A.; Venkatesan, P.; Jönsson, C.; Poenaru, I.; Hall, B.; Yang, Y.; Walton, A.; Güth, K.; Gauß, R.; Gutfleisch, O. Identification and recovery of rare-earth permanent magnets from waste electrical and electronic equipment. Waste Manag. 2017, 68, 482–489. [Google Scholar] [CrossRef]

- Charalampides, G.; Vatalis, K.I.; Apostoplos, B.; Ploutarch-Nikolas, B. Rare Earth Elements: Industrial Applications and Economic Dependency of Europe. Procedia Econ. Finance 2015, 24, 126–135. [Google Scholar] [CrossRef]

- Ojebuoboh, F.; Wang, S.; Maccagni, M. Refining primary lead by granulation-leaching-electrowinning. JOM 2003, 55, 19–23. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, J.; Sun, Y.; Feng, Y.; Niu, H. An energy saving and fluorine-free electrorefining process for ultrahigh purity lead refining. Chin. J. Chem. Eng. 2019, 27, 1191–1199. [Google Scholar] [CrossRef]

- Owais, A. Effect of electrolyte characteristics on electrowinning of copper powder. J. Appl. Electrochem. 2009, 39, 1587–1595. [Google Scholar] [CrossRef]

- Deen, K.; Asselin, E. Integration of Cu extraction and Zn electrowinning processes for energy storage. J. Clean. Prod. 2020, 253, 119779. [Google Scholar] [CrossRef]

- Karbasi, M.; Keshavarz, E.; Elaheh, A.; Dehko, A. Electrochemical performance of Pb-Co composite anode during Zincelectrowinning. Hydrometallurgy 2019, 183, 51–59. [Google Scholar] [CrossRef]

- Panda, B.; Das, S.C. Electrowinning of copper from sulfate electrolyte in presence of sulfurous acid. Hydrometallurgy 2001, 59, 55–67. [Google Scholar] [CrossRef]

- Zhang, W.; Ghali, E.; Houlachi, G. Review of oxide coated catalytic titanium anodes performance for metal electrowinning. Hydrometallurgy 2017, 169, 456–467. [Google Scholar] [CrossRef]

- Zhang, W.; Robichaud, M.; Ghali, E.; Houlachi, G. Electrochemical behavior of mesh and plate oxide coated anodes during zinc electrowinning. Trans. Nonferrous Met. Soc. China 2016, 26, 589–598. [Google Scholar] [CrossRef]

- Kim, K.-W.; Lee, E.-H.; Kim, J.-S.; Shin, K.-H.; Jung, B.-I. A study on performance improvement of Ir oxide-coated titanium electrode for organic destruction. Electrochim. Acta 2002, 47, 2525–2531. [Google Scholar] [CrossRef]

- Song, Y.; Wei, G.; Xiong, R. Structure and properties of PbO2–CeO2 anodes on stainless steel. Electrochim. Acta 2007, 52, 7022–7027. [Google Scholar] [CrossRef]

- Jia, J.; Li, X.; Chen, G. Stable spinel type cobalt and copper oxide electrodes for O2 and H2 evolutions in alkaline solution. Electrochim. Acta 2010, 55, 8197–8206. [Google Scholar] [CrossRef]

- Maskalick, N.J. Accelerated Life Testing of Lead-Acid Industrial Motive Power Cells. J. Electrochem. Soc. 1975, 122, 19–25. [Google Scholar] [CrossRef]

- Chen, X.; Chen, G.; Yue, P.L. Stable Ti/IrOx−Sb2O5−SnO2 Anode for O2 Evolution with Low Ir Content. J. Phys. Chem. B 2001, 105, 4623–4628. [Google Scholar] [CrossRef]

- Chen, X.; Chen, G. Stable Ti/RuO2–Sb2O5–SnO2 electrodes for O2 evolution. Electrochim. Acta 2005, 50, 4155–4159. [Google Scholar] [CrossRef]

- Ding, H.-Y.; Feng, Y.; Lu, J.-W. Study on the service life and deactivation mechanism of Ti/SnO2-Sb electrode by physical and electrochemical methods. Russ. J. Electrochem. 2010, 46, 72–76. [Google Scholar] [CrossRef]

- Bi, Q.; Guan, W.; Gao, Y.; Cui, Y.; Ma, S.; Xue, J. Study of the mechanisms underlying the effects of composite intermediate layers on the performance of Ti/SnO2-Sb-La electrodes. Electrochim. Acta 2019, 306, 667–679. [Google Scholar] [CrossRef]

- Kim, D.-S.; Park, Y.-S. A Basic Study on Accelerated Life Test Method and Device of DSA (Dimensionally Stable Anode) Electrode. J. Environ. Sci. Int. 2018, 27, 467–475. [Google Scholar] [CrossRef]

- Park, J.E.; Kim, E.J.; Park, M.-J.; Lee, E.S. Adsorption Capacity of Organic Compounds Using Activated Carbons in Zinc Electrowinning. Energies 2019, 12, 2169. [Google Scholar] [CrossRef]

- Park, J.E.; Yang, S.K.; Kim, J.-H.; Park, M.-J.; Lee, E.S. Electrocatalytic Activity of Pd/Ir/Sn/Ta/TiO2 Composite Electrodes. Energies 2018, 11, 3356. [Google Scholar] [CrossRef]

- Rajska, D.; Motyka, K.; Koziel, M.; Chlebda, D.; Brzozka, A.; Sulka, G.D. Influence of synthesis parameters on composition and morphology of electrodeposited Zn-Sb thin films. J. Ind. Eng. Chem. 2020, 84, 202–216. [Google Scholar] [CrossRef]

- Li, L.; Huang, Z.; Fan, X.; Zhang, Z.; Dou, R.; Wen, S.; Chen, Y.; Chen, Y.; Hu, Y. Preparation and Characterization of a Pd modified Ti/SnO2-Sb anode and its electrochemical degradation of Ni-EDTA. Electrochim. Acta 2017, 231, 354–362. [Google Scholar] [CrossRef]

- Chen, S.; Chen, B.; Wang, S.; Yan, W.; He, Y.; Guo, Z.; Xu, R. Ag doping to boost the electrochemical performance and corrosion resistance of Ti/Sn–Sb-RuOx/α-PbO2/β-PbO2 electrode in zinc electrowinning. J. Alloy. Compd. 2020, 815, 152551. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Ma, J.; Li, J. Investigation on electrochemical properties of cerium lead dioxide anode and application for elimination of nitrophenol. Electrochim. Acta 2011, 56, 1352–1360. [Google Scholar] [CrossRef]

- Yi, Z.; Kangning, C.; Wei, W.; Wang, J.; Leem, S. Effect of IrO2 loading on RuO2-IrO2-TiO2 anodes: A Study of microstructure working life for the chlorine evolution reaction. Ceram. Int. 2007, 33, 1087–1091. [Google Scholar] [CrossRef]

- Lu, X.-R.; Ding, M.-H.; Zhang, C.; Tang, W.-Z. Investigation on microstructure evolution and failure mechanism of boron doped diamond coated titanium electrode during accelerated. Thin Solid Films 2018, 660, 306–313. [Google Scholar] [CrossRef]

| Electrode | Thickness (um) | Composition (%) ± R.S.D | Roughness | ||||

|---|---|---|---|---|---|---|---|

| Pd | Ir | Sn | Ta | Rq (µm) | Ra (µm) | ||

| 2wt.%Pd-IrSnTa/TiO2 | 10.06 ± 2.18 | 1.33 ± 0.39 | 34.64 ± 9.35 | 13.71 ± 0.12 | 10.08 ± 0.86 | 0.384 | 0.308 |

| 4wt.%Pd-IrSnTa/TiO2 | 7.69 ± 0.05 | 3.30 ± 1.50 | 30.49 ± 6.87 | 21.89 ± 3.25 | 9.72 ± 0.42 | 0.498 | 0.388 |

| 8wt.%Pd-IrSnTa/TiO2 | 4.9 ± 0.60 | 7.41 ± 1.41 | 34.54 ± 6.95 | 9.86 ± 3.99 | 10.22 ± 2.82 | 0.517 | 0.460 |

| 10wt.%Pd-IrSnTa/TiO2 | 4.3 ± 1.20 | 12.17 ± 3.74 | 33.43 ± 2.67 | 13.92 ± 2.26 | 11.86 ± 3.13 | 0.567 | 0.433 |

| Initial Voltage | Final Voltage at Year 1 | Resistance (ohm) | |

|---|---|---|---|

| 2 wt.%Pd-IrSnTa/TiO2 | 3.35 | 4.05 | 2.02 |

| 4 wt.%Pd-IrSnTa/TiO2 | 2.87 | 2.95 | 1.43 |

| 8 wt.%Pd-IrSnTa/TiO2 | 2.79 | 2.80 | 1.49 |

| 10 wt.%Pd-IrSnTa/TiO2 | 2.76 | 2.77 | 1.49 |

| Initial Voltage | Final Voltage at Year 1 | Final Voltage at Year 5 | |

|---|---|---|---|

| 2 wt.%Pd-IrSnTa/TiO2 | 3.84 | 3.96 | 4.17 |

| 4 wt.%Pd-IrSnTa/TiO2 | 3.88 | 4.01 | 4.25 |

| 8 wt.%Pd-IrSnTa/TiO2 | 3.79 | 4.01 | 4.30 |

| 10 wt.%Pd-IrSnTa/TiO2 | 3.62 | 3.99 | 4.02 |

| Initial Voltage | Final Voltage at Year 1 | |

|---|---|---|

| 2 wt.%Pd-IrSnTa/TiO2 | 4.17 | 4.30 |

| 4 wt.%Pd-IrSnTa/TiO2 | 3.61 | 3.73 |

| 8 wt.%Pd-IrSnTa/TiO2 | 3.52 | 3.92 |

| 10 wt.%Pd-IrSnTa/TiO2 | 3.46 | 3.94 |

| Electrode | Thickness (µm) | Composition (%) ± R.S.D | Roughness | ||||

|---|---|---|---|---|---|---|---|

| Pd | Ir | Sn | Ta | Rq (µm) | Ra (µm) | ||

| 2wt.%Pd-IrSnTa/TiO2 | 1.8–2.6 | 0.41 ± 0.14 | 5.36 ± 0.63 | 4.99 ± 0.90 | 13.44 ± 3.17 | 0.256 | 0.207 |

| 4wt.%Pd-IrSnTa/TiO2 | 1.7–2.8 | 0.37 ± 0.05 | 6.31 ± 4.03 | 3.43 ± 1.58 | 12.19 ± 1.21 | 0.275 | 0.223 |

| 8wt.%Pd-IrSnTa/TiO2 | 1.7–2.9 | 0.42 ± 0.02 | 3.10 ± 0.34 | 1.73 ± 0.12 | 10.68 ± 0.69 | 0.304 | 0.248 |

| 10wt.%Pd-IrSnTa/TiO2 | 1.8–2.2 | 0.18 ± 0.01 | 3.92 ± 2.62 | 1.10 ± 0.40 | 8.63 ± 0.28 | 0.336 | 0.274 |

| Pd | Ir | Sn | Ta | |

|---|---|---|---|---|

| Raw materials | 7.41 ± 1.41 | 34.54 ± 6.95 | 9.86 ± 3.99 | 10.22 ± 2.82 |

| 20 times | 0.60 ± 0.34 | 13.61 ± 4.72 | 4.67 ± 1.23 | 8.96 ± 1.16 |

| 30 times | 0.18 ± 0.01 | 3.92 ± 2.62 | 1.10 ± 0.40 | 8.63 ± 0.28 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.E.; Kim, H.; Lee, E.S. Accelerated Life Testing of a Palladium-Doped Tin Oxide Electrode for Zn Electrowinning. Materials 2020, 13, 1969. https://doi.org/10.3390/ma13081969

Park JE, Kim H, Lee ES. Accelerated Life Testing of a Palladium-Doped Tin Oxide Electrode for Zn Electrowinning. Materials. 2020; 13(8):1969. https://doi.org/10.3390/ma13081969

Chicago/Turabian StylePark, Jung Eun, Ho Kim, and Eun Sil Lee. 2020. "Accelerated Life Testing of a Palladium-Doped Tin Oxide Electrode for Zn Electrowinning" Materials 13, no. 8: 1969. https://doi.org/10.3390/ma13081969

APA StylePark, J. E., Kim, H., & Lee, E. S. (2020). Accelerated Life Testing of a Palladium-Doped Tin Oxide Electrode for Zn Electrowinning. Materials, 13(8), 1969. https://doi.org/10.3390/ma13081969