Fabrication of QFN-Packaged Miniaturized GaAs-Based Bandpass Filter with Intertwined Inductors and Dendritic Capacitor

Abstract

1. Introduction

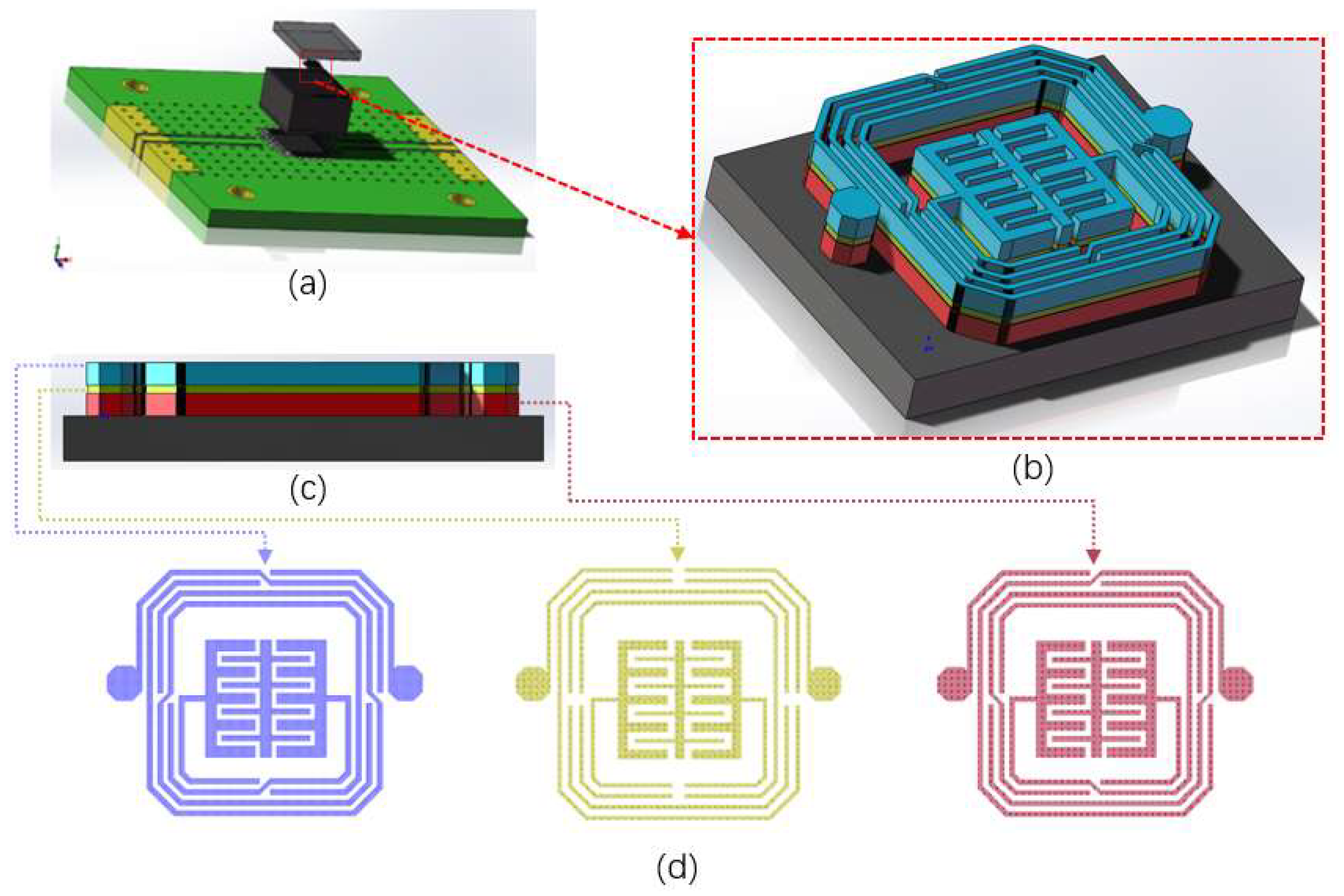

2. Design and Fabrication

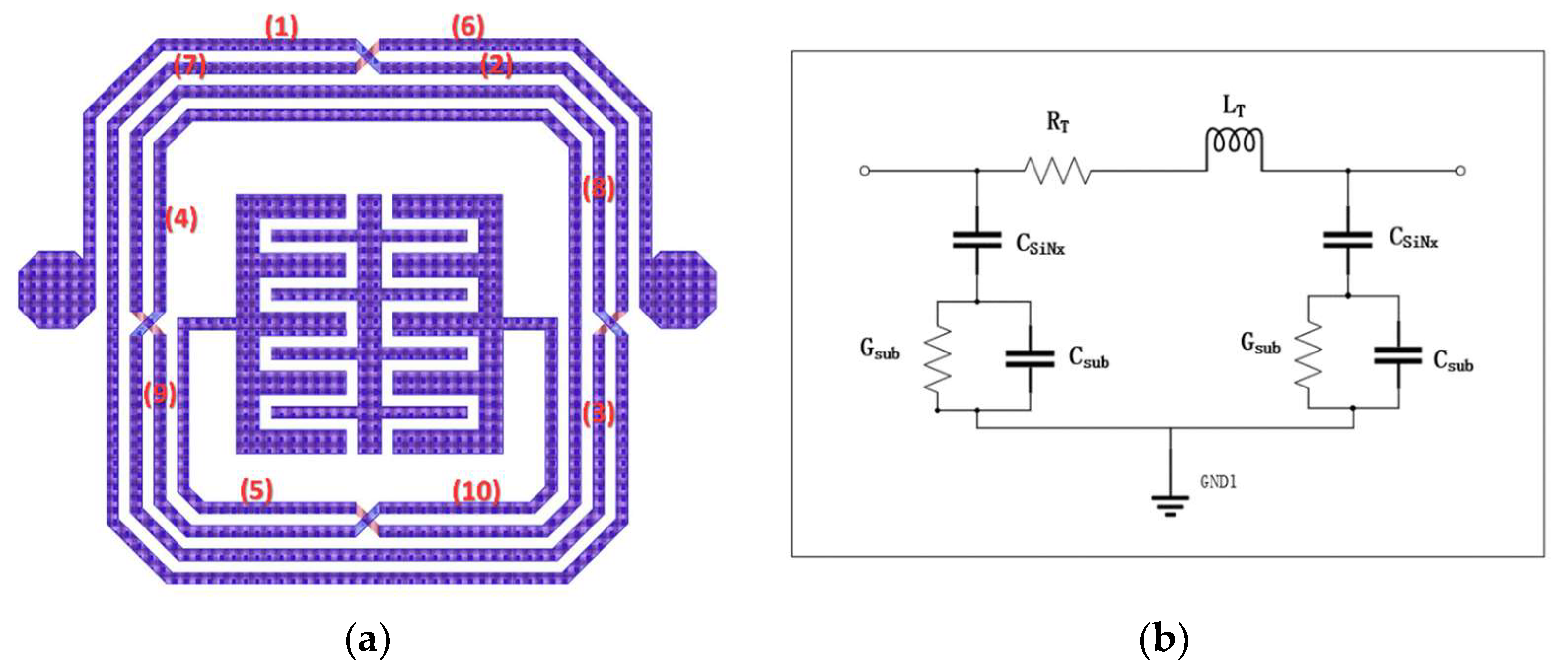

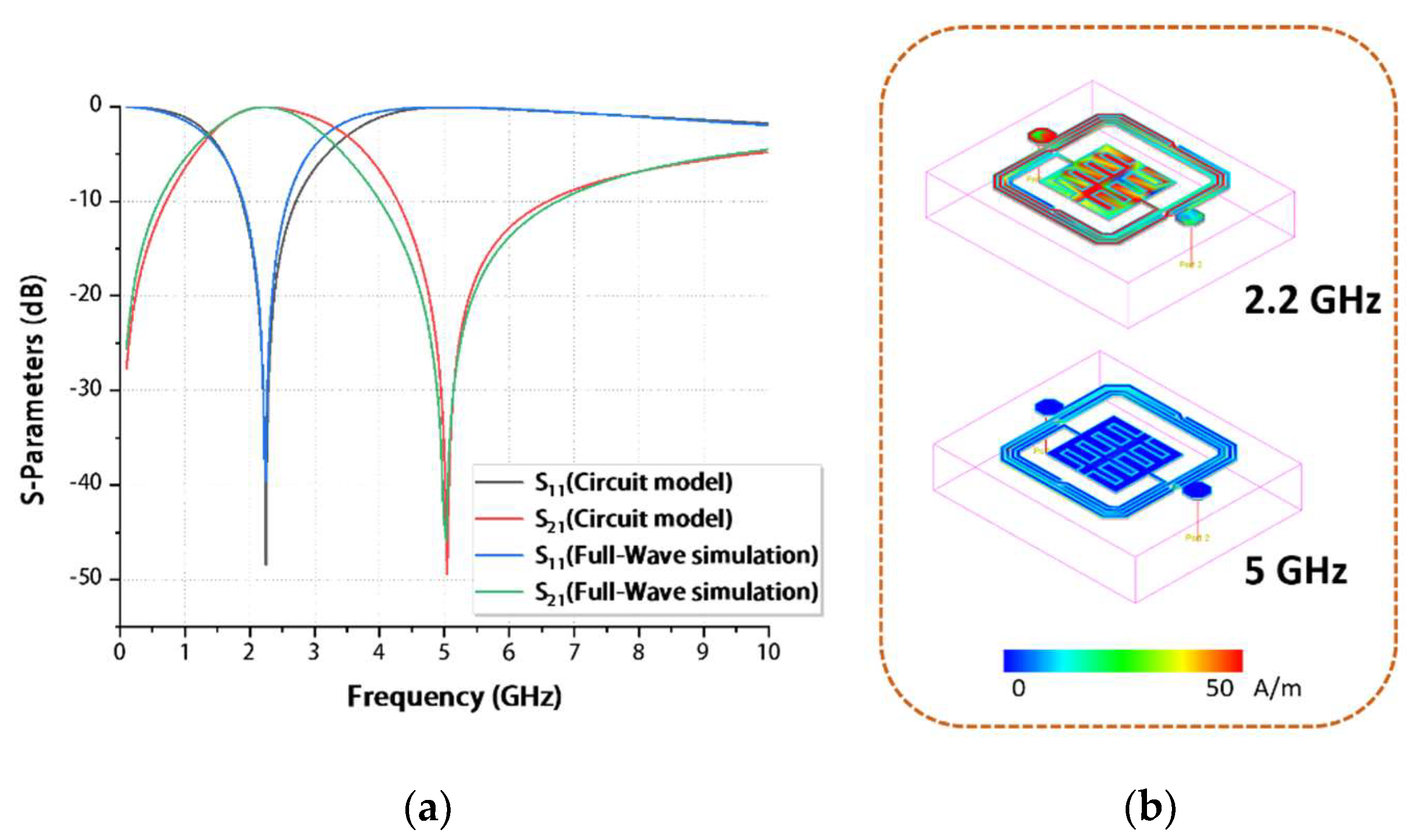

2.1. Design and Circuit Analysis

2.1.1. Model inside the Segment Box

2.1.2. Models outside the Segment Box

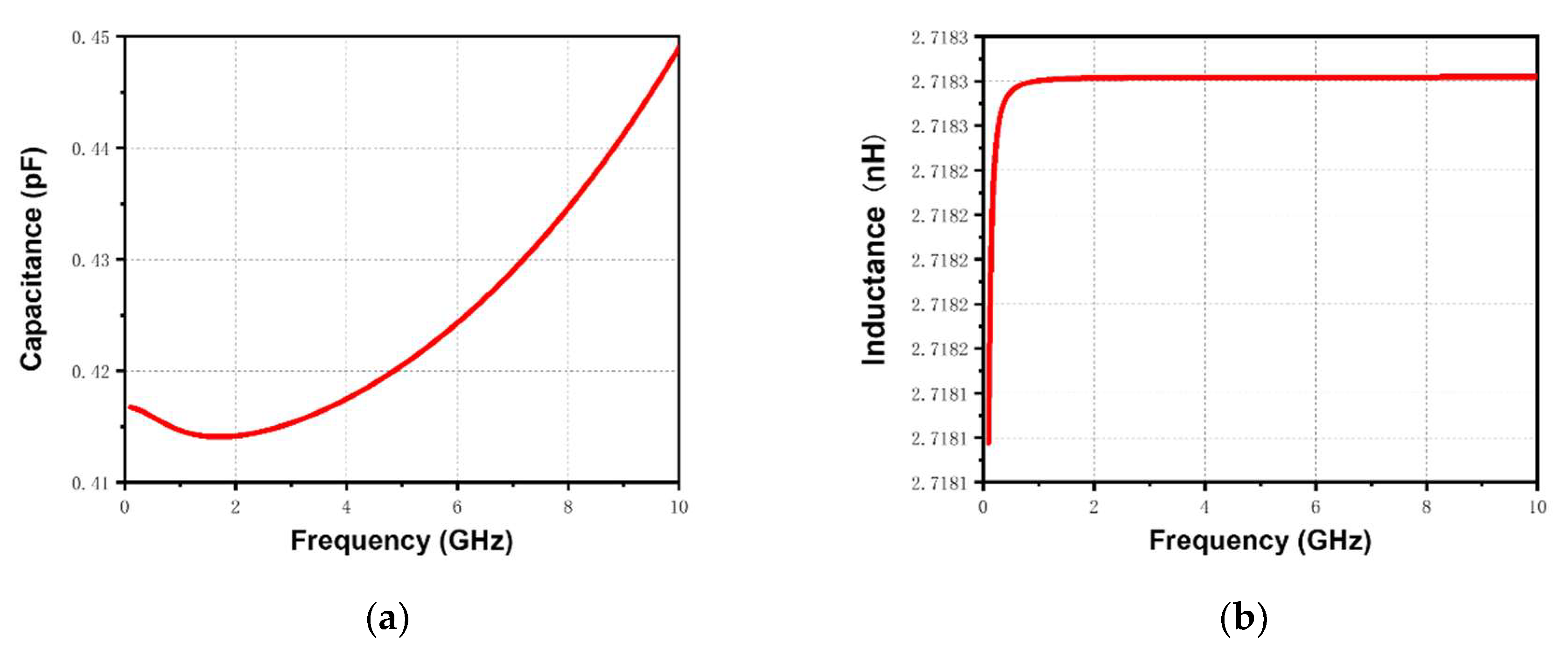

2.1.3. Embedded Capacitor

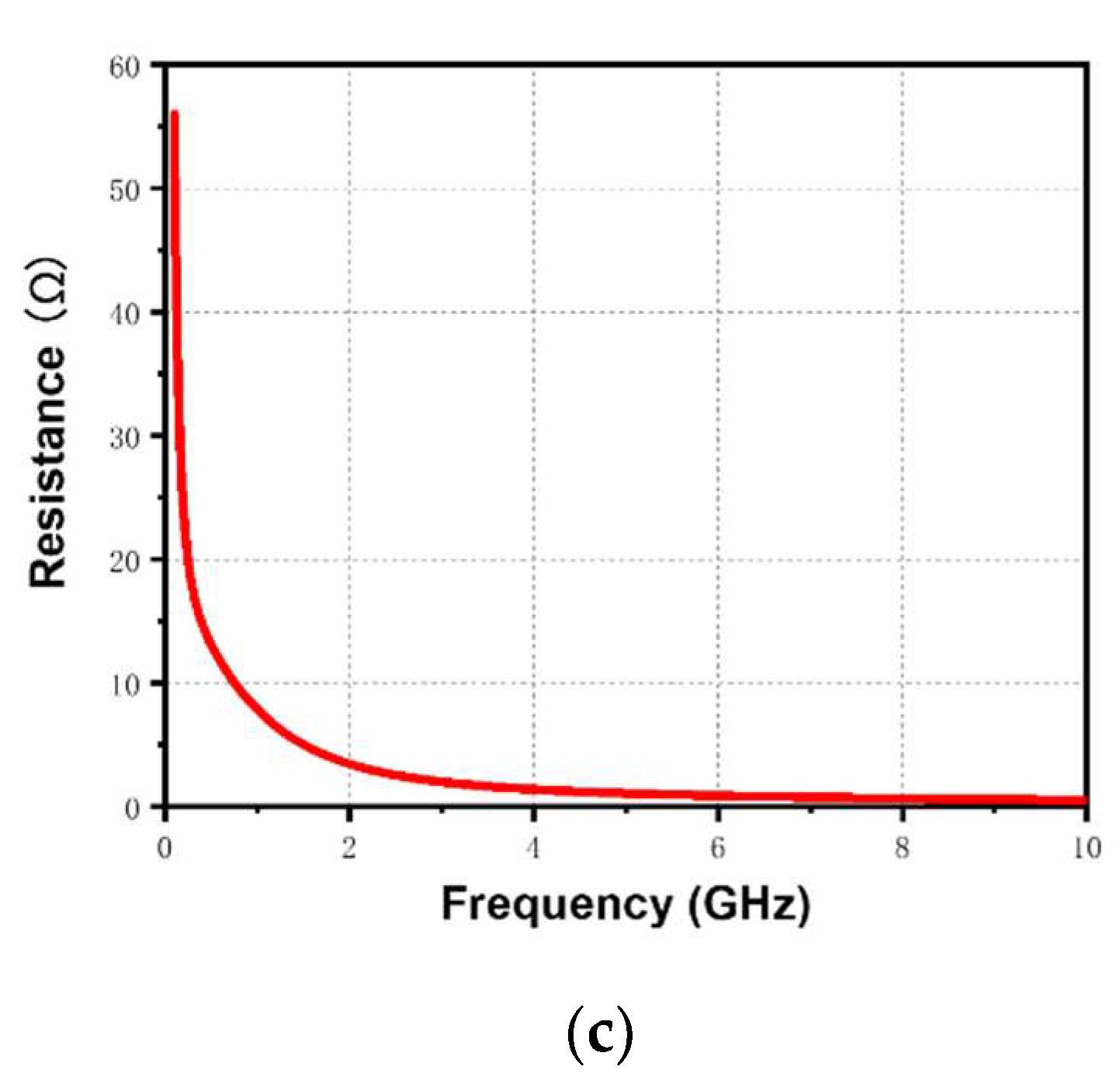

2.1.4. Substrate-Related Parasitic Effects

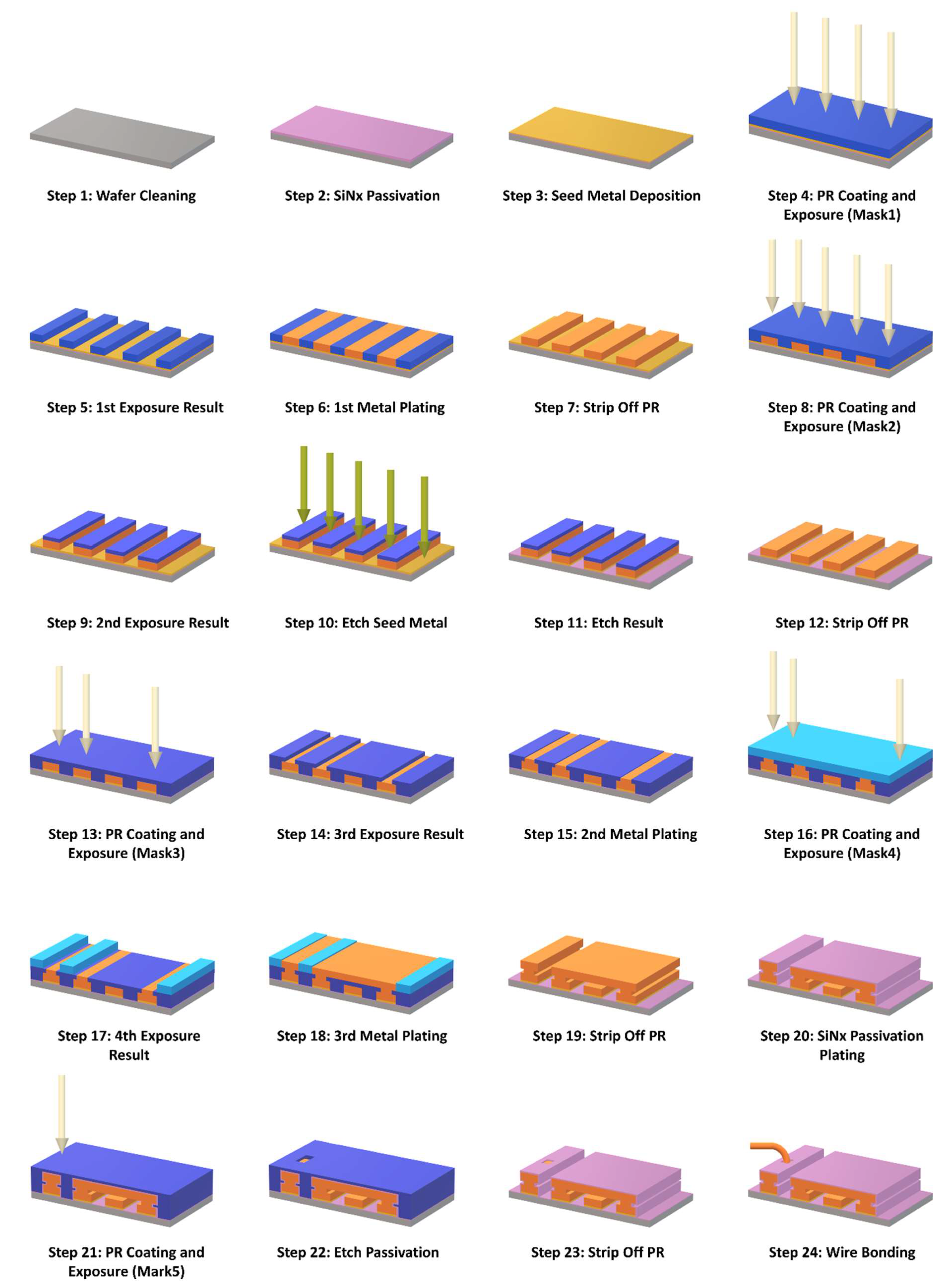

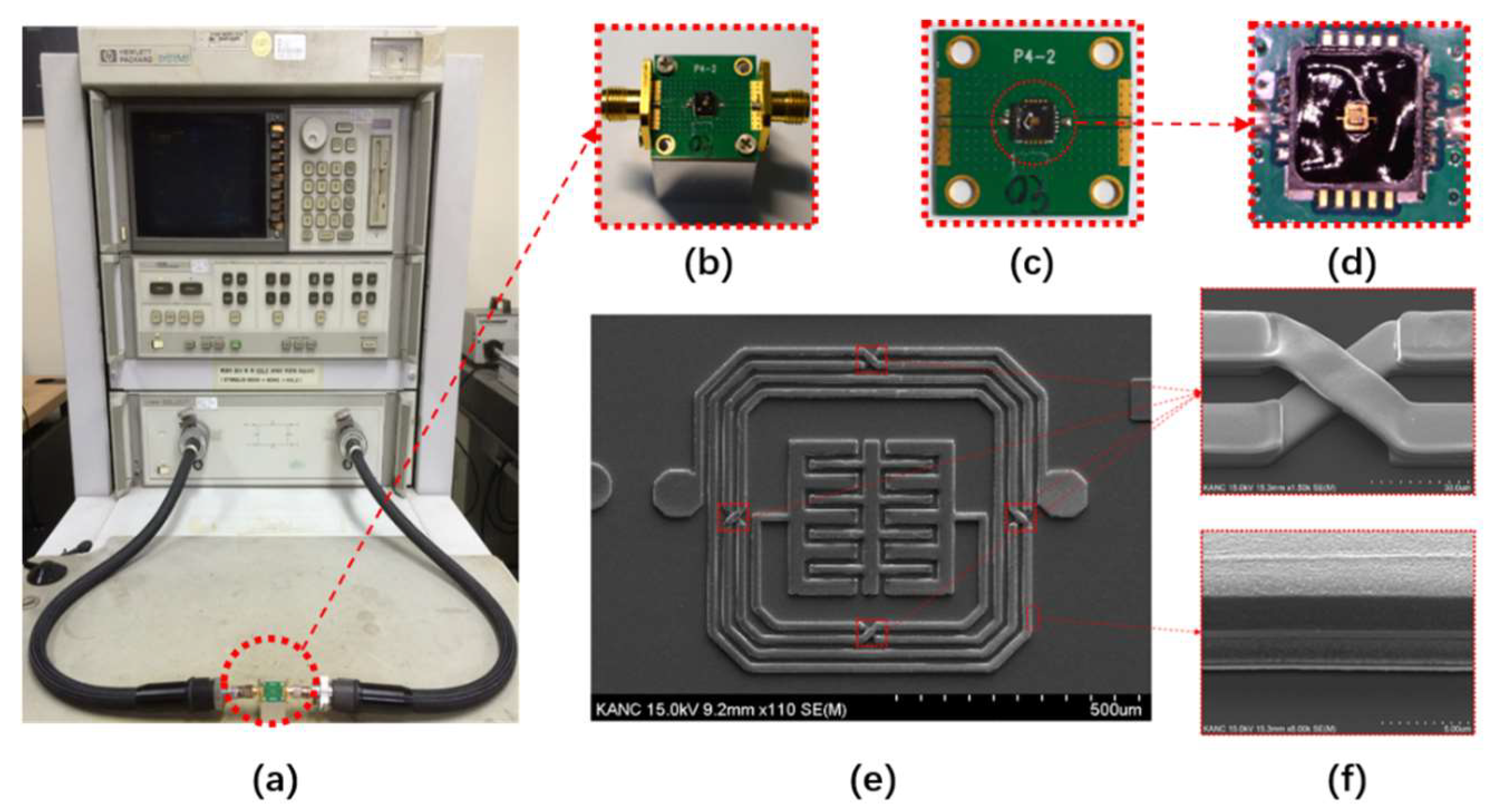

2.2. Fabrication

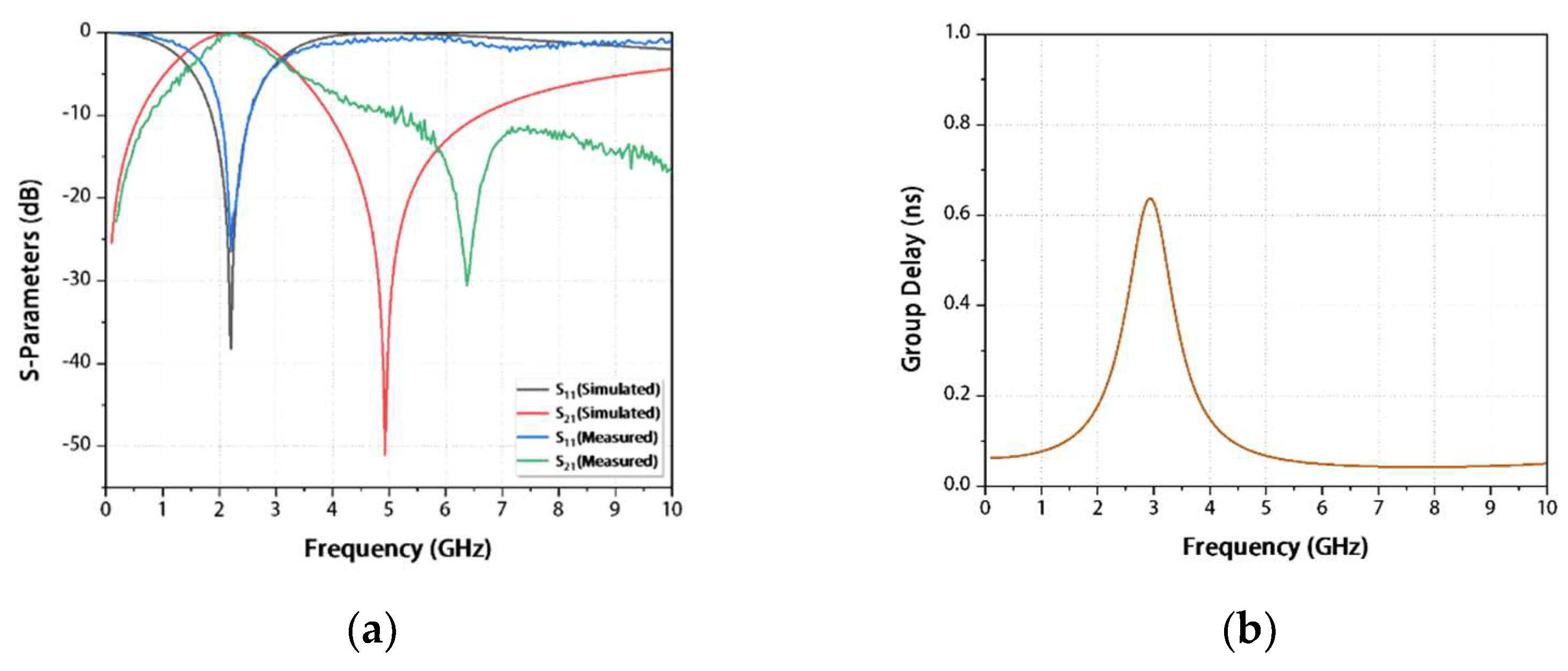

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lim, T.B.; Zhu, L. Highly selective differential-mode wideband bandpass filter for UWB application. IEEE Microw. Wirel. Compon. Lett. 2011, 21, 133–135. [Google Scholar] [CrossRef]

- Tang, C.W.; Shen, C.W.; Hsieh, P.J. Design of low-temperature co-fired ceramic bandpass filters with modified coupled inductors. IEEE Trans. Microw. Theory Tech. 2008, 57, 172–179. [Google Scholar] [CrossRef]

- Wang, K.X.; Liu, X.F.; Li, Y.C.; Lin, L.Z.; Zhao, X.L. LTCC filtering rat-race coupler based on eight-line spatially-symmetrical coupled structure. IEEE Access 2017, 6, 262–269. [Google Scholar] [CrossRef]

- McCulloch, M.A.; Melhuish, S.J.; Piccirillo, L. Enhancing the noise performance of monolithic microwave integrated circuit-based low noise amplifiers through the use of a discrete preamplifying transistor. J. Astron. Telesc. Instrum. Syst. 2014, 1, 016001. [Google Scholar] [CrossRef]

- Robertson, I.D.; Lucyszyn, S. (Eds.) RFIC and MMIC Design and Technology; No. 13. Iet; IET: London, UK, 2001; pp. 7–10. [Google Scholar]

- Tsukamoto, O.; Ogawa, J. Perspectives of elementary technologies for AC power applications of high temperature superconductors. J. Mater. Process. Technol. 2007, 181, 6–11. [Google Scholar] [CrossRef]

- Lei, D.; Wang, T.; Cao, D.; Fei, J. Adaptive dynamic surface control of MEMS gyroscope sensor using fuzzy compensator. IEEE Access 2016, 4, 4148–4154. [Google Scholar] [CrossRef]

- Adhikari, K.K.; Kim, N.Y. Ultrahigh-sensitivity mediator-free biosensor based on a microfabricated microwave resonator for the detection of micromolar glucose concentrations. IEEE Trans. Microw. Theory Tech. 2015, 64, 319–327. [Google Scholar] [CrossRef]

- Kim, N.Y.; Dhakal, R.; Adhikari, K.K.; Kim, E.S.; Wang, C. A reusable robust radio frequency biosensor using microwave resonator by integrated passive device technology for quantitative detection of glucose level. Biosens. Bioelectron. 2015, 67, 687–693. [Google Scholar] [CrossRef]

- Kim, E.; Kim, N. Micro-fabricated resonator based on inscribing a meandered-line coupling capacitor in an air-bridged circular spiral inductor. Micromachines 2018, 9, 294. [Google Scholar] [CrossRef]

- Wang, C.; Kim, N.Y. Analytical optimization of high-performance and high-yield spiral inductor in integrated passive device technology. Microelectron. J. 2012, 43, 176–181. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Kim, N.Y. A high performance compact Wilkinson power divider using GaAs-based optimized integrated passive device fabrication process for LTE application. Solid-State Electron. 2015, 103, 147–153. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Q.; Song, C.; Cheng, Y. Similarity-based difference analysis approach for remaining useful life prediction of GaAsbased semiconductor lasers. IEEE Access 2017, 5, 21508–21523. [Google Scholar] [CrossRef]

- Nitesh, R.S.; Rajendran, J.; Ramiah, H.; Manaf, A.A. A 700 MHz to 2.5 GHz cascode GaAs power amplifier for multi-band pico-cell achieving 20 dB Gain, 40 dBm to 45 dBm OIP3 and 66% Peak PAE. IEEE Access 2018, 6, 818–829. [Google Scholar] [CrossRef]

- Khubchandani, S.; Hodkiewicz, M.R.; Keating, A. Characterizing the performance of LED reflective distance sensors. IEEE Access 2017, 5, 14289–14297. [Google Scholar] [CrossRef]

- Kim, N.Y.; Adhikari, K.K.; Dhakal, R.; Chuluunbaatar, Z.; Wang, C.; Kim, E.S. Rapid, sensitive, and reusable detection of glucose by a robust radiofrequency integrated passive device biosensor chip. Sci. Rep. 2015, 5, 1–9. [Google Scholar] [CrossRef]

- Dhakal, R.; Wang, C.; Kim, E.S.; Kim, N.Y. Complex permittivity characterization of serum with an air-bridge enhanced capacitor for quantifiable detection of glucose. Appl. Phys. Lett. 2015, 106, 073702073706. [Google Scholar] [CrossRef]

- Chen, J.; Liou, J.J. Improved and physical-based model for symmetrical spiral inductors. IEEE Trans. Electron. Devices 2006, 53, 1300–1309. [Google Scholar] [CrossRef]

- Bahl, I.J. Lumped Elements for RF and Microwave Circuit, 1st ed.; Artech House: London, UK, 2003; pp. 17–36. [Google Scholar]

- Chen, J. On-Chip Spiral Inductor Transformer Design and Modeling for RF Applications. Ph.D. Thesis, University of Central Florida, Orlando, FL, USA, 2006. [Google Scholar]

- Matthaei, G.L.; Chinn, G.C.; Plott, C.H.; Dagli, N. A simplified means for computation for interconnect distributed capacitances and inductances. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 1992, 11, 513–524. [Google Scholar] [CrossRef]

- Cao, Y.; Groves, R.A.; Zamdmer, N.D.; Plouchart, J.O.; Wachnik, R.A.; Huang, X.J.; King, T.J.; Hu, C.M. Frequency-independent equivalent-circuit model for on-chip spiral inductors. IEEE J. Solid-State Circuits 2003, 38, 419–426. [Google Scholar] [CrossRef]

- Yuan, J.S.; Eisenstadt, W.R.; Liou, J.J. A novel lossy and dispersive interconnect model for integrated circuit simulation. IEEE Trans. Comp. Hybrids. Manuf. Technol. 1990, 13, 275–280. [Google Scholar] [CrossRef]

- Lim, K.; Pinel, S.; Davis, M.F.; Sutono, A.; Lee, C.H.; Heo, D.; Obatoynbo, A.; Laskar, J.; Tentzeris, E.M.; Tummala, R. RF-system-on-package (SOP) for wireless communications. IEEE Microw. Mag. 2002, 3, 88–99. [Google Scholar]

- Nirmalathas, A.; Lim, C.; Novak, D.; Castleford, D.; Waterhouse, R.; Smith, G. Millimeter-wave fiber-wireless access systems incorporating wavelength division multiplexing. In Proceedings of the 2000 Asia-Pacific Microwave Conference, Sydney, Australia, 3–6 December 2000. [Google Scholar]

- Hong, J.S. Microstrip Filters for RF/Microwave Applications, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 203–263. ISBN 978-0-470-40877-3. [Google Scholar]

- Nooshnab, V.; Ahmadivand, A. Optothermally Functional Charge Transfer Plasmon Modulator. IEEE Photon. Technol. Lett. 2017, 29, 1556–1559. [Google Scholar] [CrossRef]

- Kruger, B.A.; Joushaghani, A.; Poon, J.K.S. Design of electrically driven hybrid vanadium dioxide (VO2) plasmonic switches. Opt. Express 2012, 20, 23598–23609. [Google Scholar] [CrossRef] [PubMed]

- Quan, C.H.; Wang, Z.J.; Lee, J.C.; Kim, E.S.; Kim, N.Y. A Highly Selective and Compact Bandpass Filter with a Circular Spiral Inductor and an Embedded Capacitor Structure Using an Integrated Passive Device Technology on a GaAs Substrate. Electronics 2019, 8, 73. [Google Scholar] [CrossRef]

- Ahmadivand, A.; Gerislioglu, B.; Ramezani, Z. Gated graphene island-enabled tunable charge transfer plasmon terahertz metamodulator. Nanoscale 2019, 11, 8091–8095. [Google Scholar] [CrossRef]

- Wu, Z.; Shim, Y.; Rais-Zadeh, M. Miniaturized UWB filters integrated with tunable notch filters using a silicon-based integrated passive device technology. IEEE Trans. Microw. Theory Tech. 2012, 60, 518–527. [Google Scholar] [CrossRef]

- Pan, J.; Wang, H.; Tian, G.; Cao, L.; Yu, D. Design of a compact silicon-based integrated passive band-pass filter with two tunable finite transmission zeros. Microelectron. J. 2016, 49, 43–48. [Google Scholar] [CrossRef]

- Wong, K.W.; Mansour, R.R.; Weale, G. Reconfigurable bandstop and bandpass filters with wideband balun using IPD technology for frequency agile applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 610–620. [Google Scholar] [CrossRef]

- Sitaraman, S.; Sukumaran, V.; Pulugurtha, M.R.; Wu, Z.; Suzuki, Y.; Kim, Y.; Sundaram, V.; Kim, J.; Tummala, R.R. Miniaturized bandpass filters as ultrathin 3-D IPDs and embedded thinfilms in 3-D glass modules. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 1410–1418. [Google Scholar] [CrossRef]

- Wu, S.M.; Hsu, R.F.; Yu, P.H. Signal integrity and electromagnetic broadband packaging model extraction of full differential bandpass filter on IPD with BGA packaging. Prog. Electromagn. Res. 2013, 141, 201–217. [Google Scholar] [CrossRef][Green Version]

- Lu, D.; Barker, N.S.; Tang, X.H. Miniaturized two-pole lumped BPF with four controllable TZs using multiple coupling paths. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 563–565. [Google Scholar] [CrossRef]

- Liu, H.W.; Ren, B.P.; Liu, F.; Guan, X.H.; Wen, P.; Ma, Z.W. Dual-Band High-Temperature Superconducting Bandpass Filter Using Dual-Mode Hairpin Ring Resonator. IEEE Trans. Appl. Supercond. 2016, 26, 1501704. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Yang, Y.J.; Chen, J.X. High-performance bandpass filter using HTCC stepped-impedance resonators. IET Microw. Antennas Propag. 2018, 12, 56–62. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Dai, X.; Kao, H.L.; Wei, B.H.; Cai, Z.Y.; Xue, Q. Compact LTCC Bandpass Filter With Wide Stopband Using Discriminating Coupling. IEEE Trans. Microw. Theory Technol. 2014, 4, 656–663. [Google Scholar] [CrossRef]

| Fabrication Objective | Technique | Material |

|---|---|---|

| Passivation layer | PECVD | SiNx |

| Photoresistor | Spin-coating | Negative/positive PR |

| PR removal | Lift-off | Acetone |

| Seed metal | Sputtering | Ti/Au |

| Metal layer | Electroplating | Cu/Au |

| Via | ICP etching | SF6/O6 |

| References | Technology | Fractional Band Width (%) | Passband (GHz) | Insertion Loss (dB) | Return Loss (dB) | Circuit Area |

|---|---|---|---|---|---|---|

| [31] | Silicon IPD | 107.63 (3 dB) | 6.5 | 1.1 | 15 | 0.219 λ0 × 0.181 λ0 |

| [32] | Silicon IPD | 33.33 (3 dB) | 2.4 | 2.3 | 10 | 0.024 λ0 × 0.024 λ0 |

| [33] | Silicon IPD | 16 (10 dB) | 1.7 | 2.56 | 12 | 0.039 λ0 × 0.037 λ0 |

| [34] | Glass IPD | 49.62 (3 dB) | 2.6 | 0.6 | 30 | 0.018 λ0 × 0.009 λ0 |

| [35] | Glass IPD | 36.73 (10 dB) | 2.1 | 3.2 | 22 | 0.019 λ0 × 0.019 λ0 |

| This work | GaAs IPD | 71.94 (3 dB) | 2.21 | 0.38 | 26.45 | 0.021 λ0 × 0.021 λ0 (0.8 × 0.8 mm2) |

| References | Technology | Fractional Band Width (%) | Insertion Loss (dB) | Return Loss (dB) | Passband (GHz) | Circuit Area |

|---|---|---|---|---|---|---|

| [36] | Microstrip | 13.3 | 1.1 | > 20 | 0.975 | 0.094 λ0 × 0.08 λ0 |

| [37] | HTS | 2.6/2.4 | 0.18/0.32 | > 16 | 1.9/2.6 | 0.182 λ0 × 0.156 λ0 |

| [38] | HTCC | 5.5 | 1.8 | > 15 | 2.25 | 6.9 × 39.9 mm2 |

| [39] | LTCC | 12.5 | 2.4 | 15 | 2.4 | 0.058 λ0 × 0.058 λ0 |

| This work | GaAs IPD | 71.94 | 0.38 | 26.45 | 2.21 | 0.021 λ0 × 0.021 λ0 (0.8 × 0.8 mm2) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wang, Z.-J.; Zhu, B.-H.; Kim, E.-S.; Kim, N.-Y. Fabrication of QFN-Packaged Miniaturized GaAs-Based Bandpass Filter with Intertwined Inductors and Dendritic Capacitor. Materials 2020, 13, 1932. https://doi.org/10.3390/ma13081932

Chen J, Wang Z-J, Zhu B-H, Kim E-S, Kim N-Y. Fabrication of QFN-Packaged Miniaturized GaAs-Based Bandpass Filter with Intertwined Inductors and Dendritic Capacitor. Materials. 2020; 13(8):1932. https://doi.org/10.3390/ma13081932

Chicago/Turabian StyleChen, Jian, Zhi-Ji Wang, Bao-Hua Zhu, Eun-Seong Kim, and Nam-Young Kim. 2020. "Fabrication of QFN-Packaged Miniaturized GaAs-Based Bandpass Filter with Intertwined Inductors and Dendritic Capacitor" Materials 13, no. 8: 1932. https://doi.org/10.3390/ma13081932

APA StyleChen, J., Wang, Z.-J., Zhu, B.-H., Kim, E.-S., & Kim, N.-Y. (2020). Fabrication of QFN-Packaged Miniaturized GaAs-Based Bandpass Filter with Intertwined Inductors and Dendritic Capacitor. Materials, 13(8), 1932. https://doi.org/10.3390/ma13081932