A Novel Approach to Discrete Representative Volume Element Automation and Generation-DRAGen

Abstract

1. Introduction

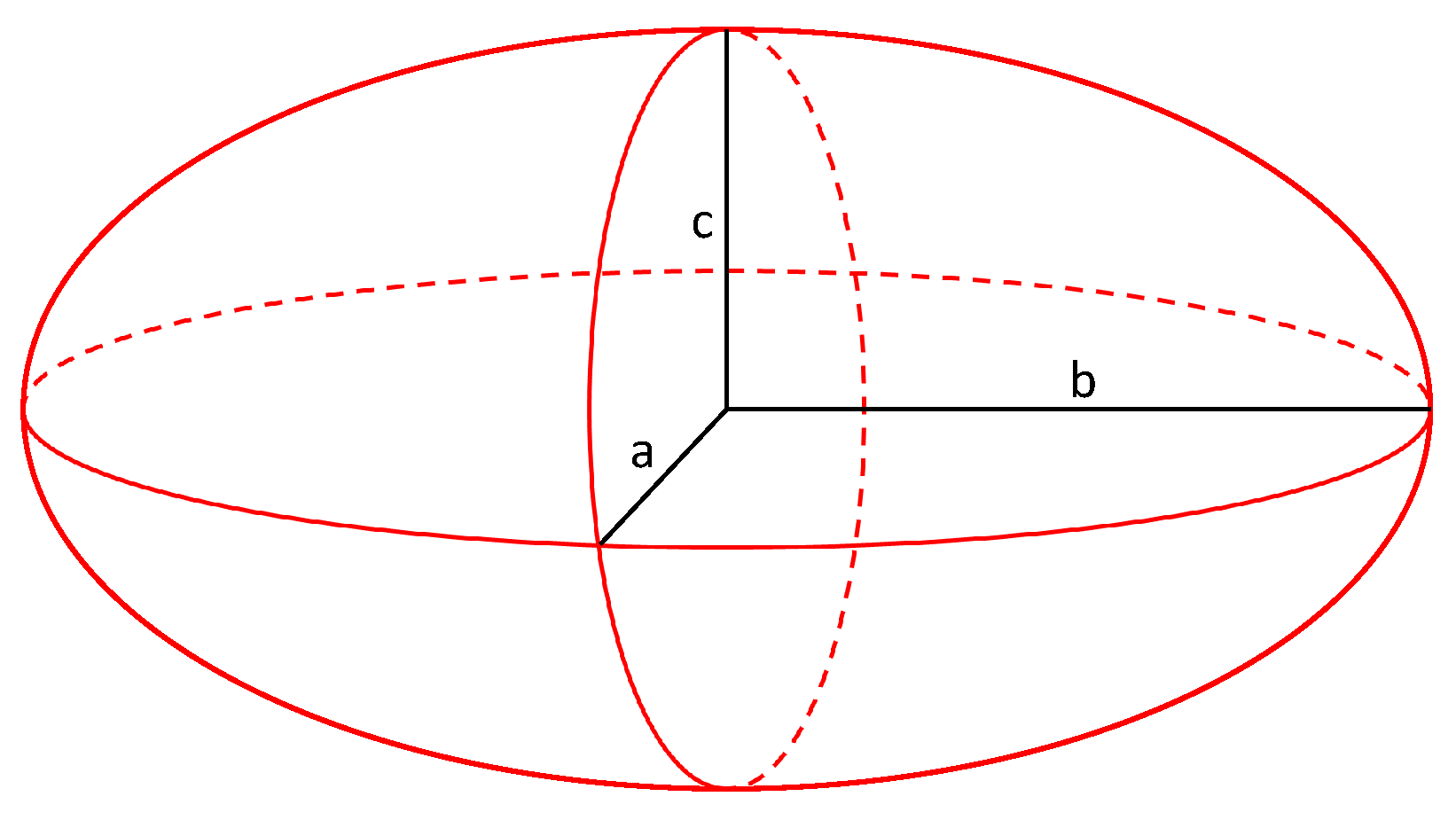

- Generation of spheres or ellipsoids in dependence of a distribution function from the statistical characterization

- Packing of the grain representing volumes (spheres or ellipsoids)

- Tessellation to fill empty spaces between the volumes

- Assignment of crystallographic orientation

- Spheres are not suitable as initial geometry for grains in a metallic polycrystal.

- Ellipsoids or even more complex bodies must be used as initial geometry.

- Tessellation must support a growth that keeps the initial geometry.

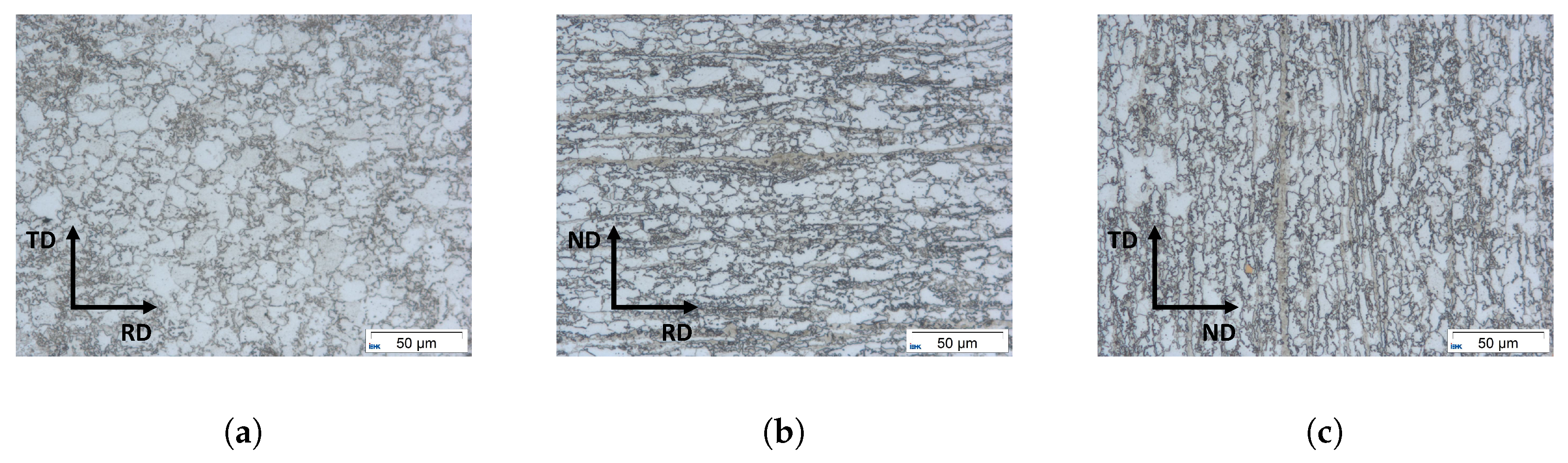

- Banding of second phases has to be considered during the modeling of the microstructure.

- Inclusions should be considered as well.

- RVEs must be periodic in order to represent the continuous space.

2. Materials and Methods

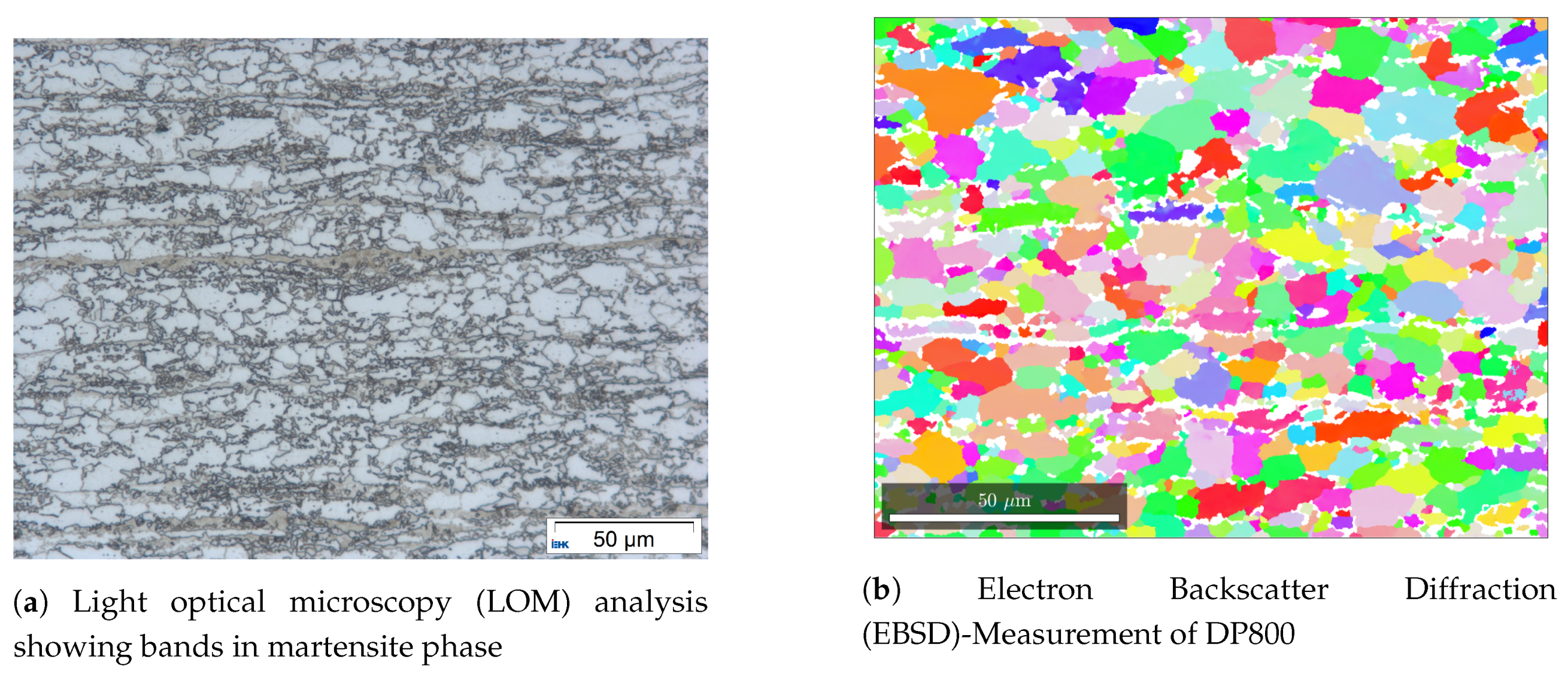

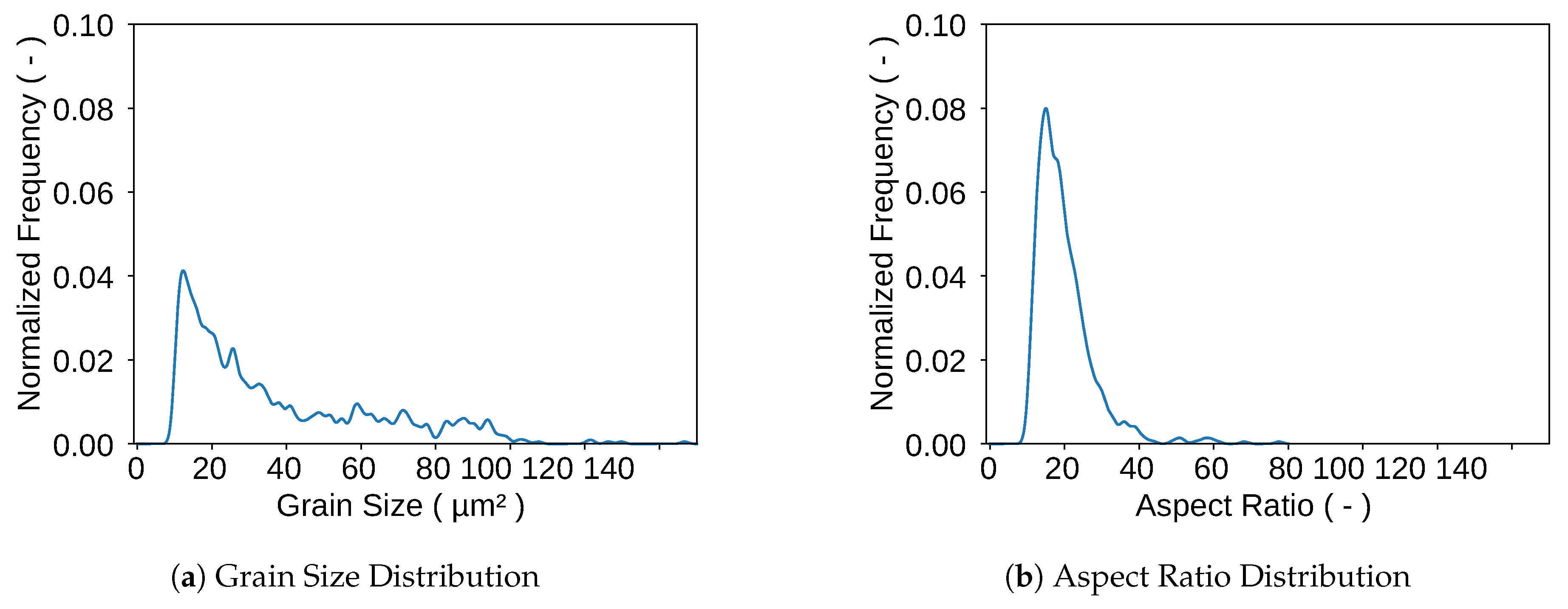

2.1. DP800

2.2. RVE-Generation

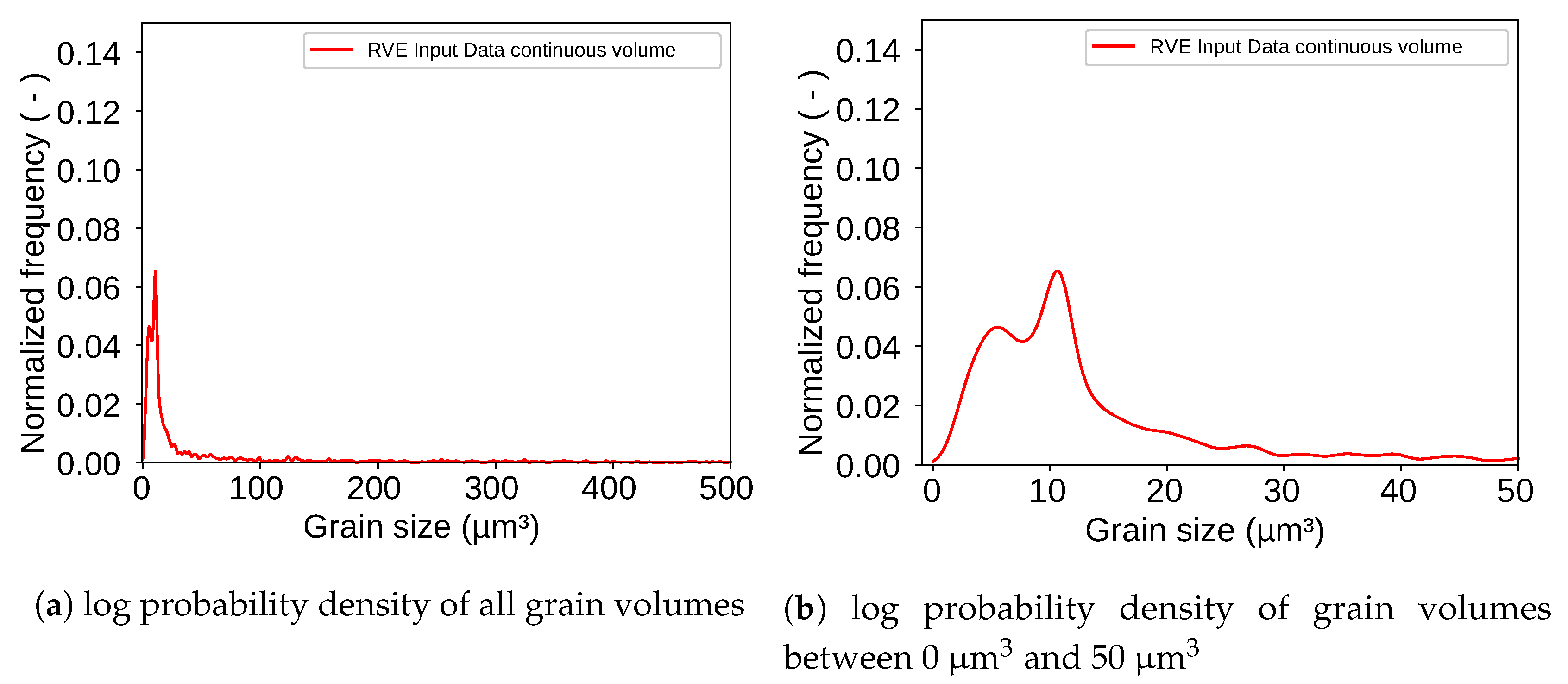

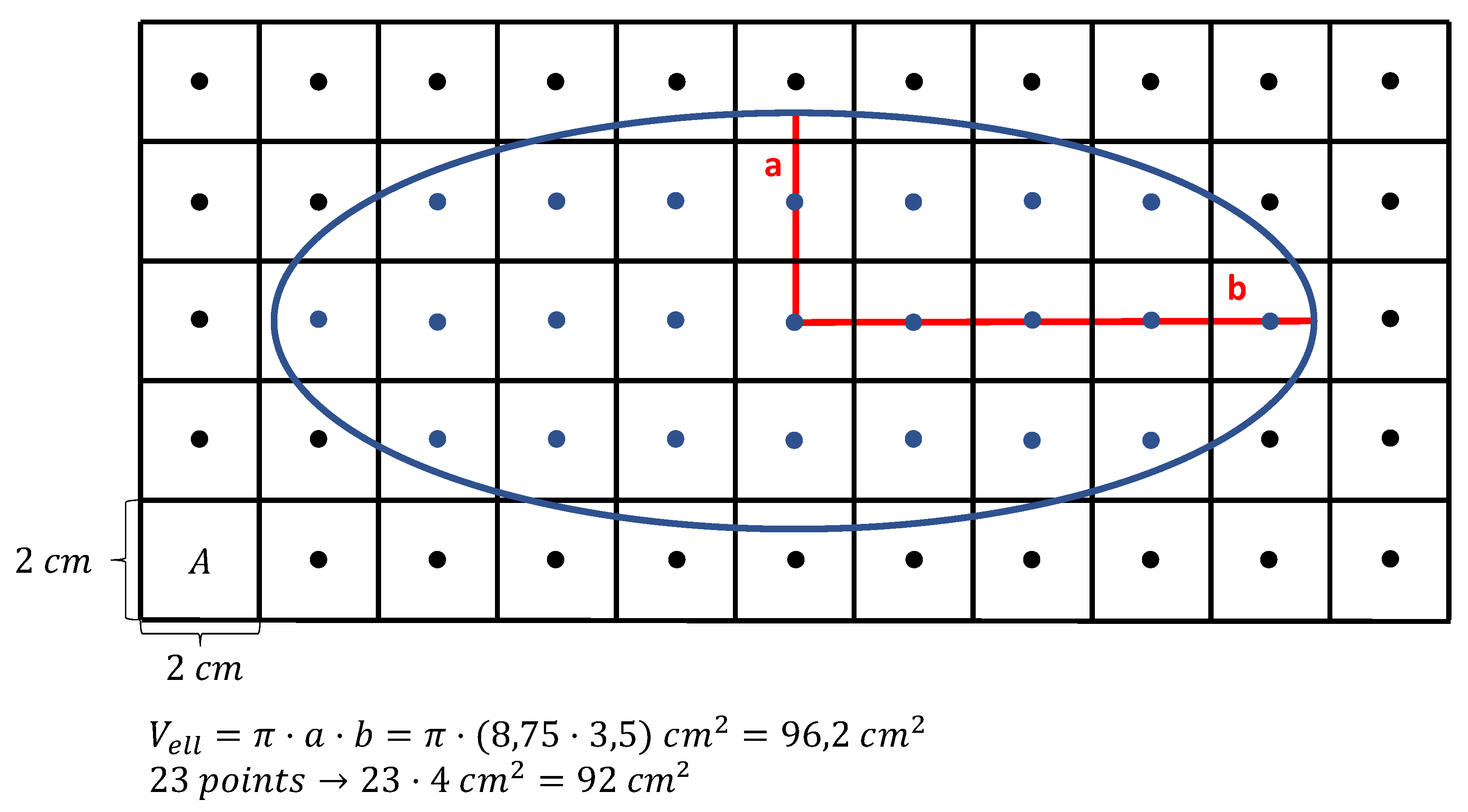

- Generation of input data

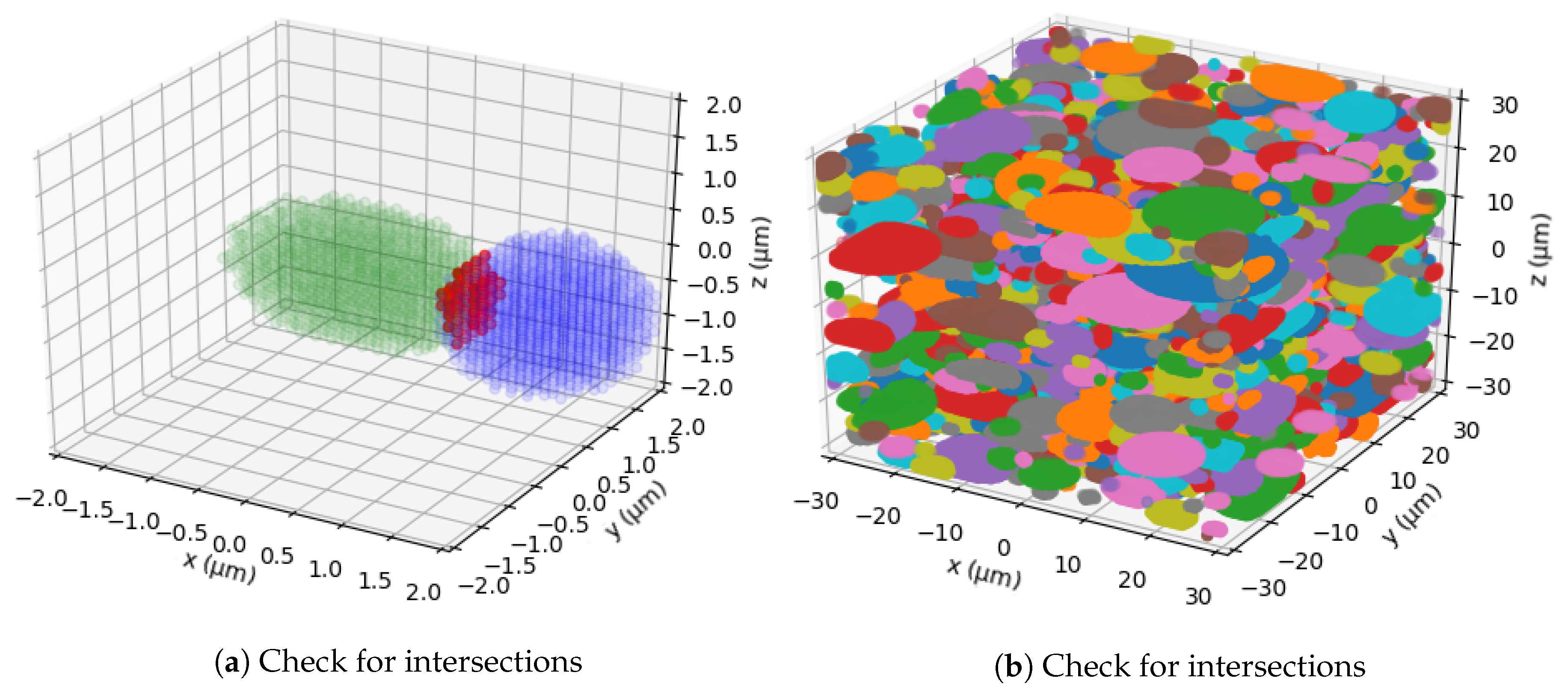

- Placing ellipsoids in volume (RSA)

- Filling empty spaces between ellipsoids (Discrete Tessellation)

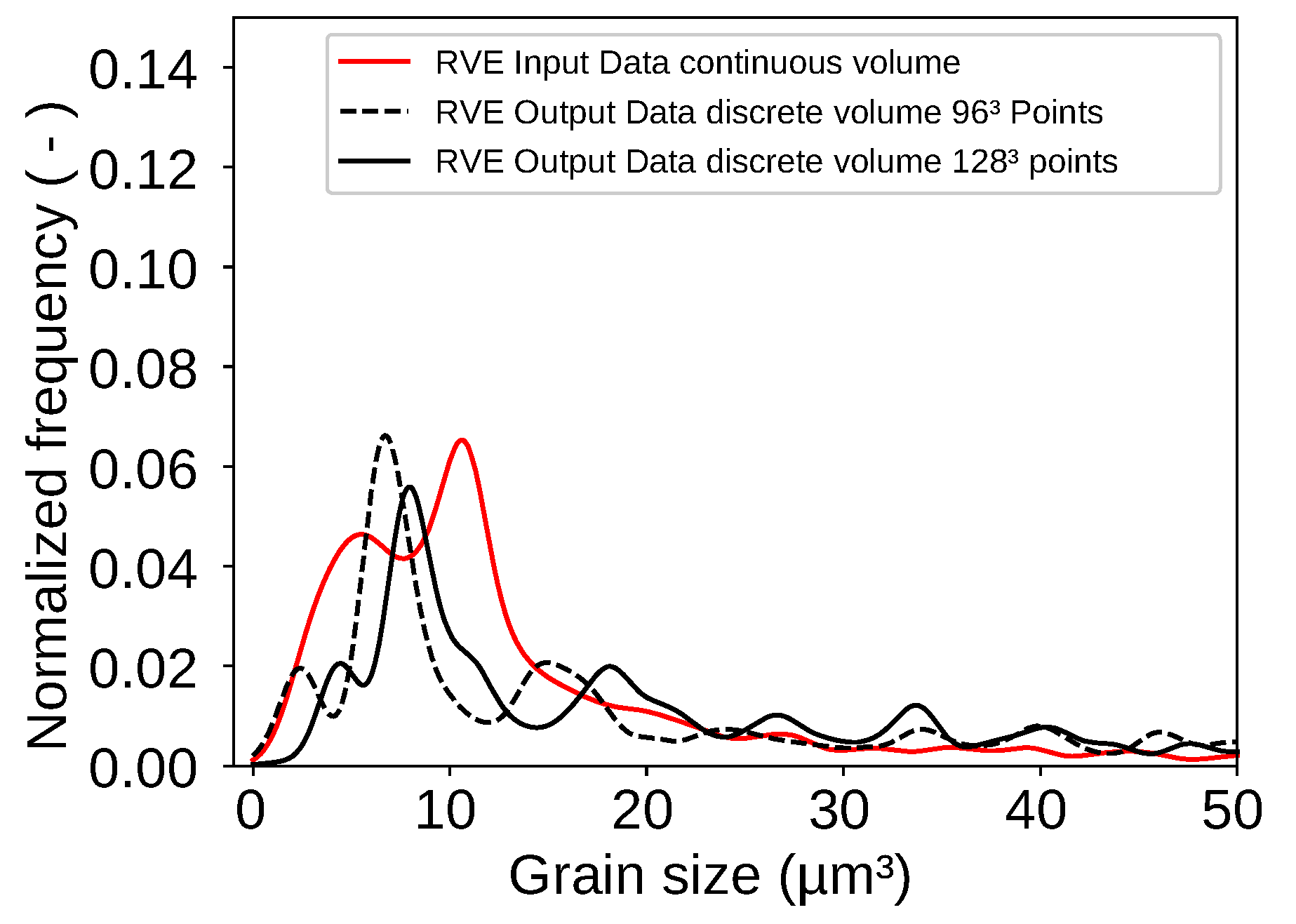

- Validation of output with input

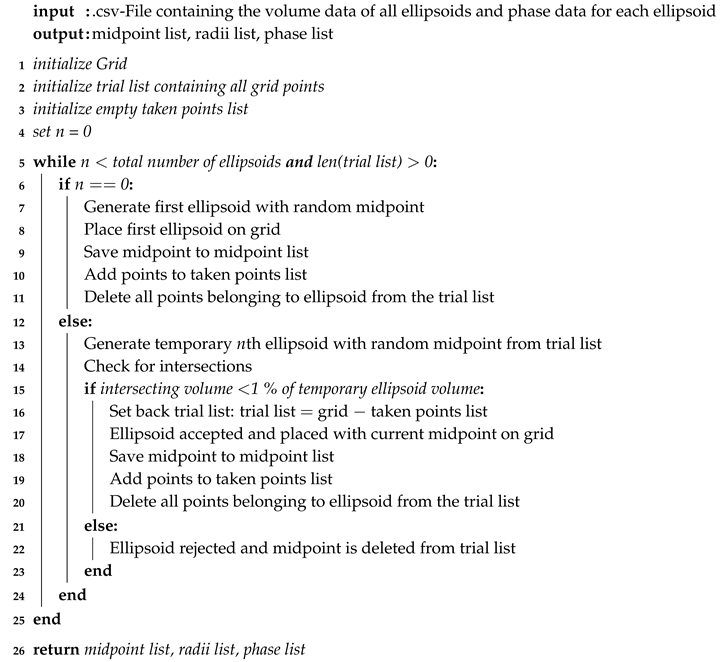

2.2.1. Discrete RSA Algorithm

| Algorithm 1: Discrete Random Sequential Addition Algorithm |

|

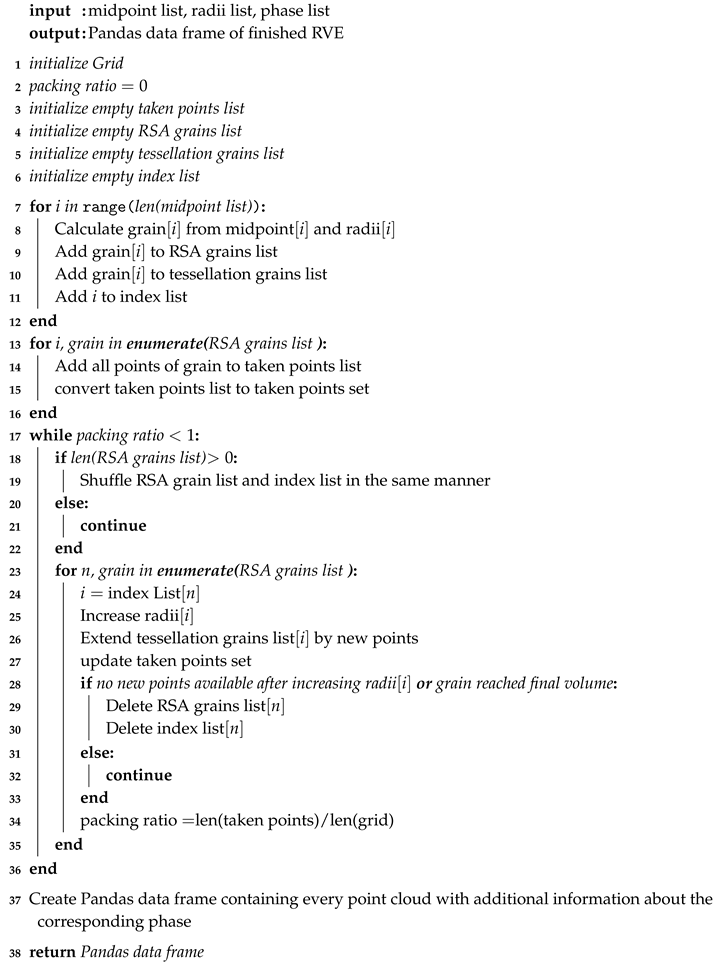

2.2.2. Discrete Tessellation

| Algorithm 2: Discrete Random Sequential Addition Algorithm |

|

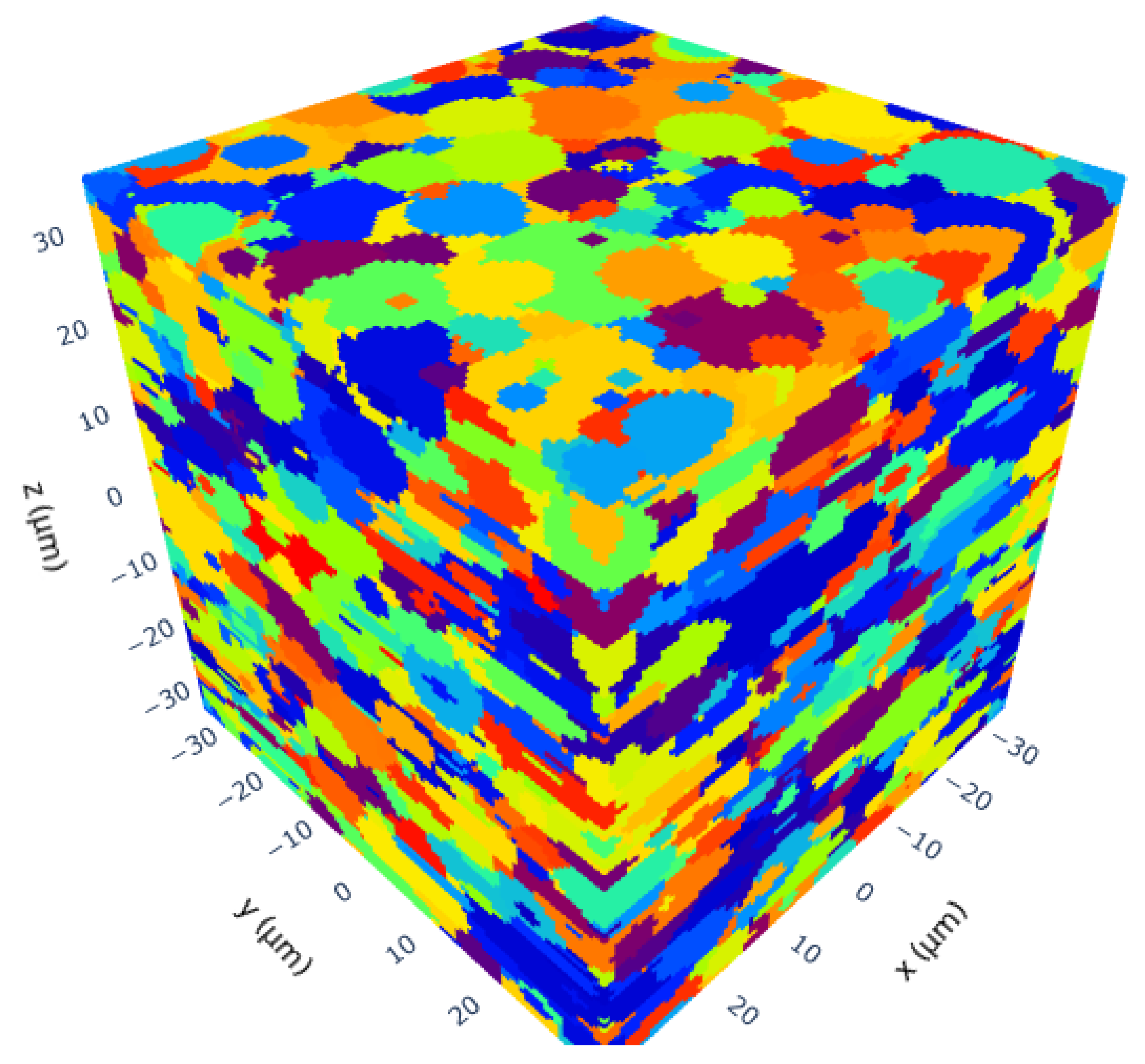

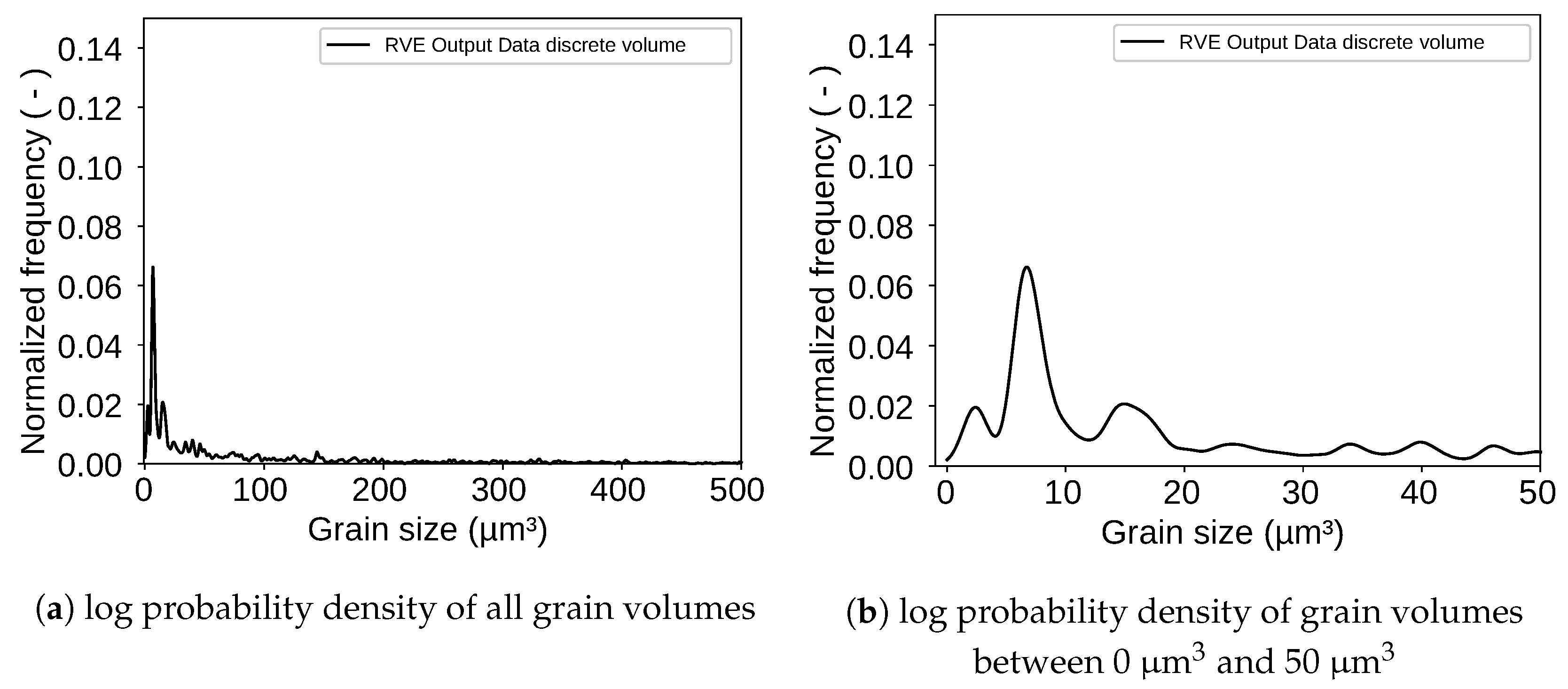

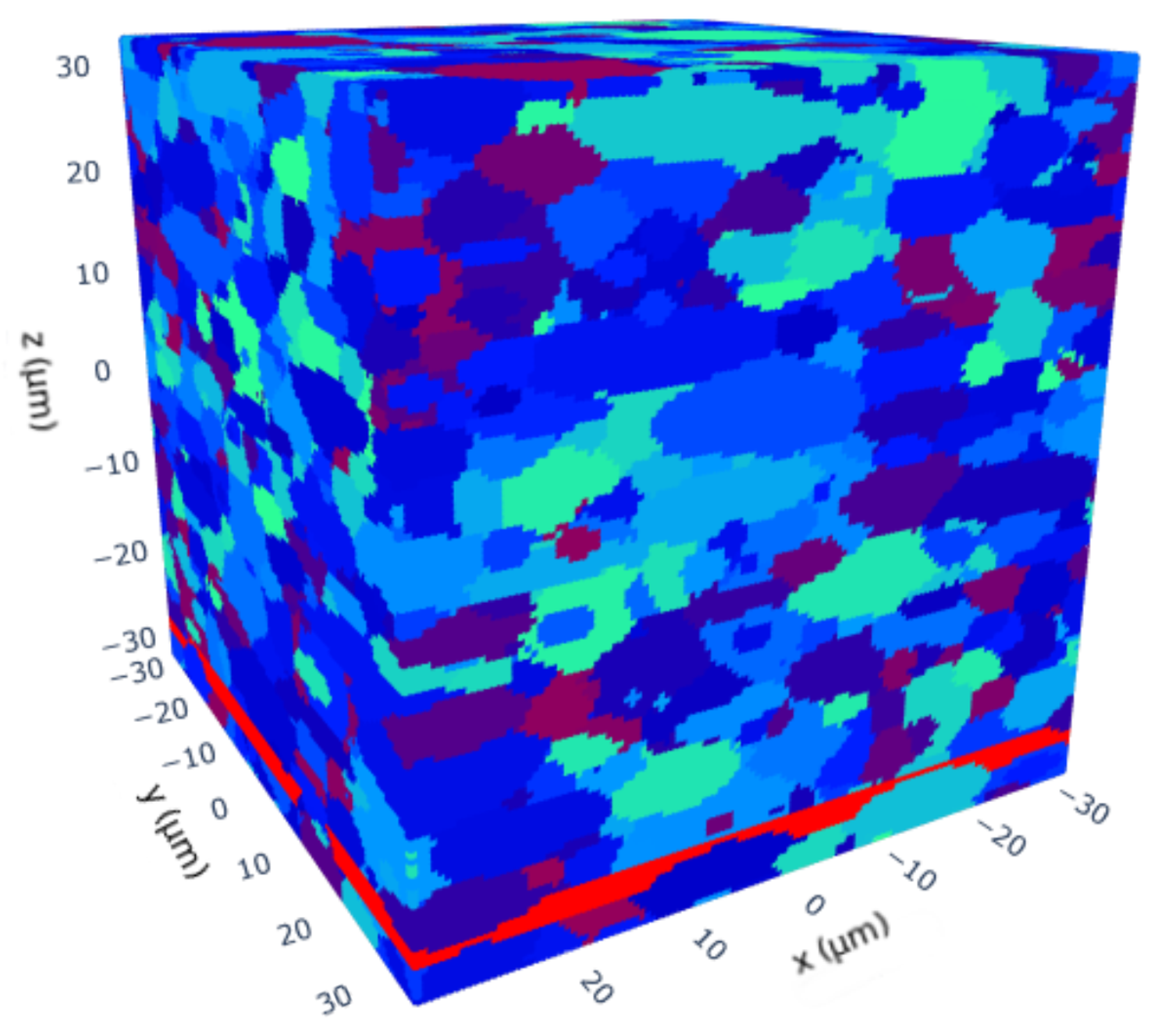

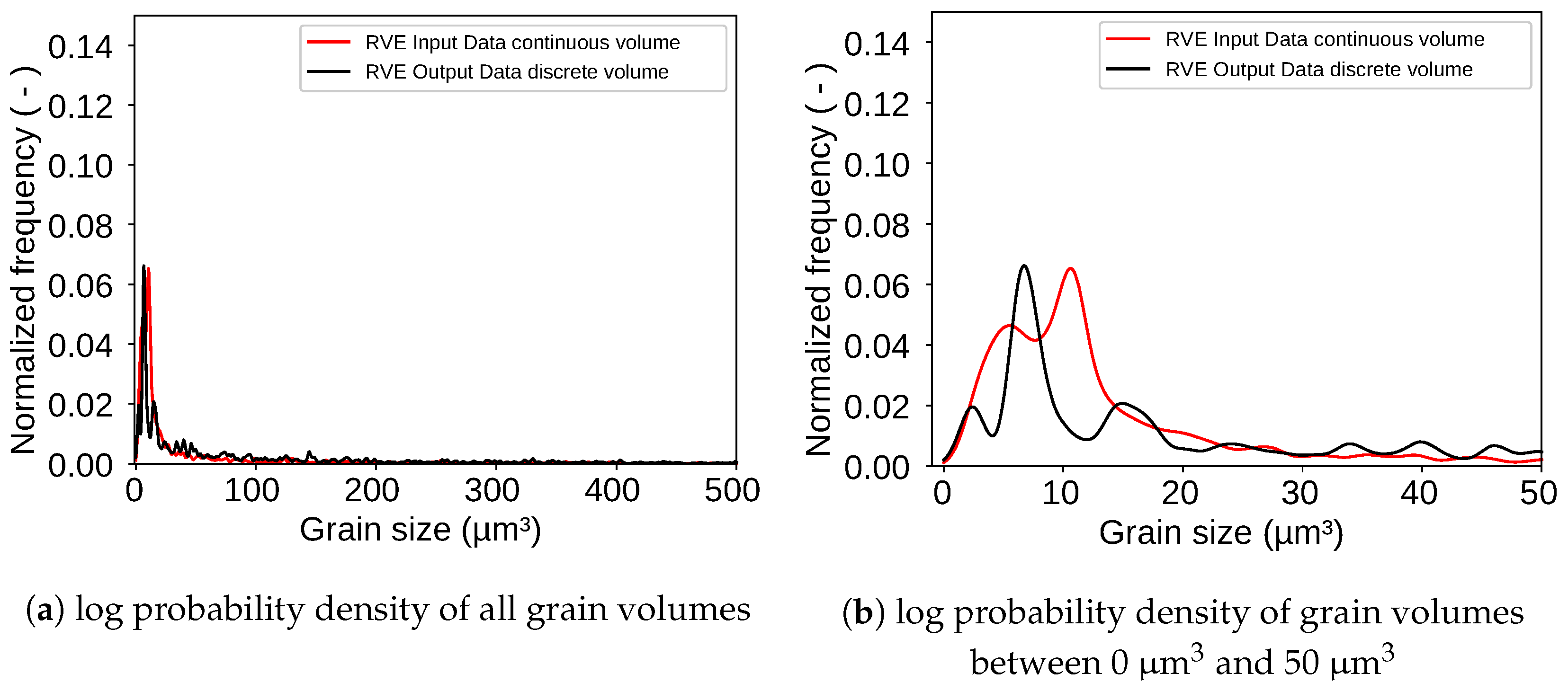

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AHSS | Advanced High Strength Steels |

| CGP | Constrained Grain Packer |

| CP | Crystal Plasticity |

| EBSD | Electron Backscatter Diffraction |

| FEM | Finite Element Method |

| IMS | Integrity of Materials and Structures |

| MBW | Modified Bai-Wierzbicki model |

| RSA | Random Sequential Addition |

| RVE | Representative Volume Element |

| SEM | Scanning Electron Microscopy |

References

- Bleck, W. Cold-rolled, high-strength sheet steels for auto applications. JOM 1996, 48, 26–30. [Google Scholar] [CrossRef]

- Davies, R.G.; Magee, C.L. Physical Metallurgy of Automotive High-Strength Steels. JOM 1979, 31, 17–23. [Google Scholar] [CrossRef]

- Bieler, T.R.; Eisenlohr, P.; Roters, F.; Kumar, D.; Mason, D.E.; Crimp, M.A.; Raabe, D. The role of heterogeneous deformation on damage nucleation at grain boundaries in single phase metals. Int. J. Plast. 2009, 25, 1655–1683. [Google Scholar] [CrossRef]

- Gillner, K.; Henrich, M.; Münstermann, S. Numerical study of inclusion parameters and their influence on fatigue lifetime. Int. J. Fatigue 2018, 111, 70–80. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.; Diehl, M.; Yan, D.; Roters, F.; Raabe, D. Strain localization and damage in dual phase steels investigated by coupled in-situ deformation experiments and crystal plasticity simulations. Int. J. Plast. 2014, 63, 198–210. [Google Scholar] [CrossRef]

- Murakami, Y.; Nomoto, T.; Ueda, T. On the mechanism of fatigue failure in the superlong life regime (N>107 cycles). Part II: Influence of hydrogen trapped by inclusions. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 903–910. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, C.; Hong, Y. Crack growth rates and microstructure feature of initiation region for very-high-cycle fatigue of a high-strength steel. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1717–1732. [Google Scholar] [CrossRef]

- Liu, X.; Chen, E.; Zeng, F.; Cong, T.; Domblesky, J.P. Mechanisms of interior crack initiation in very-high-cycle fatigue of high-strength alloys. Eng. Fract. Mech. 2019, 212, 153–163. [Google Scholar] [CrossRef]

- Gillner, K.; Münstermann, S. Numerically predicted high cycle fatigue properties through representative volume elements of the microstructure. Int. J. Fatigue 2017, 105, 219–234. [Google Scholar] [CrossRef]

- Murakami, Y.; Kawakami, K.; Duckworth, W. Quantitative evaluation of effects of shape and size of artificially introduced alumina particles on the fatigue strength of 1.5Ni Cr Mo En24 steel. Int. J. Fatigue 1991, 13, 489–499. [Google Scholar] [CrossRef]

- Speich, G.R.; Spitzig, W.A. Effect of volume fraction and shape of sulfide inclusions on through-thickness ductility and impact energy of high-strength 4340 plate steels. Metall. Trans. A 1982, 13, 2239–2258. [Google Scholar] [CrossRef]

- Lian, J.; Yang, H.; Vajragupta, N.; Münstermann, S.; Bleck, W. A method to quantitatively upscale the damage initiation of dual-phase steels under various stress states from microscale to macroscale. Comput. Mater. Sci. 2014, 94, 245–257. [Google Scholar] [CrossRef]

- Wu, B.; Vajragupta, N.; Lian, J.; Hangen, U.; Wechsuwanmanee, P.; Münstermann, S. Prediction of plasticity and damage initiation behaviour of C45E + N steel by micromechanical modelling. Mater. Des. 2017, 121, 154–166. [Google Scholar] [CrossRef]

- Cruzado, A.; Gan, B.; Jiménez, M.; Barba, D.; Ostolaza, K.; Linaza, A.; Molina-Aldareguia, J.M.; Llorca, J.; Segurado, J. Multiscale modeling of the mechanical behavior of IN718 superalloy based on micropillar compression and computational homogenization. Acta Mater. 2015, 98, 242–253. [Google Scholar] [CrossRef]

- Segurado, J.; Llorca, J. Simulation of the deformation of polycrystalline nanostructured Ti by computational homogenization. Comput. Mater. Sci. 2013, 76, 3–11. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Scheunemann, L.; Balzani, D.; Brands, D.; Schröder, J. Design of 3D statistically similar Representative Volume Elements based on Minkowski functionals. Mech. Mater. 2015, 90, 185–201. [Google Scholar] [CrossRef]

- van den Eijnden, A.P.; Bésuelle, P.; Chambon, R.; Collin, F. A FE2 modelling approach to hydromechanical coupling in cracking-induced localization problems. Int. J. Solids Struct. 2016, 97–98, 475–488. [Google Scholar] [CrossRef]

- Gitman, I.M.; Askes, H.; Sluys, L.J. Representative volume: Existence and size determination. Eng. Fract. Mech. 2007, 74, 2518–2534. [Google Scholar] [CrossRef]

- Pelissou, C.; Baccou, J.; Monerie, Y.; Perales, F. Determination of the size of the representative volume element for random quasi-brittle composites. Int. J. Solids Struct. 2009, 46, 2842–2855. [Google Scholar] [CrossRef]

- Bargmann, S.; Klusemann, B.; Markmann, J.; Schnabel, J.E.; Schneider, K.; Soyarslan, C.; Wilmers, J. Generation of 3D representative volume elements for heterogeneous materials: A review. Prog. Mater. Sci. 2018, 96, 322–384. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Grain detection from 2d and 3d EBSD data–specification of the MTEX algorithm. Ultramicroscopy 2011, 111, 1720–1733. [Google Scholar] [CrossRef] [PubMed]

- Grober, M. A framework for automated analysis and simulation of 3D polycrystalline microstructures. Part 1: Statistical characterization. Acta Mater. 2008, 56, 1257–1273. [Google Scholar] [CrossRef]

- Grober, M. A framework for automated analysis and simulation of 3D polycrystalline microstructures. Part 2: Synthetic structure generation. Acta Mater. 2008, 56, 1274–1287. [Google Scholar] [CrossRef]

- Quey, R.; Dawson, P.R.; Barbe, F. Large-scale 3D random polycrystals for the finite element method: Generation, meshing and remeshing. Comput. Methods Appl. Mech. Eng. 2011, 200, 1729–1745. [Google Scholar] [CrossRef]

- Rycroft, C.H. VORO++: A three-dimensional voronoi cell library in C++. Chaos 2009, 19, 041111. [Google Scholar] [CrossRef]

- Uthaisangsuk, V.; Muenstermann, S.; Prahl, U.; Bleck, W.; Schmitz, H.P.; Pretorius, T. A study of microcrack formation in multiphase steel using representative volume element and damage mechanics. Comput. Mater. Sci. 2011, 50, 1225–1232. [Google Scholar] [CrossRef]

- Pütz, F.; Shen, F.; Könemann, M.M.; Münstermann, S. The Differences of Damage Initiation and Accumulation of DP Steels: A Numerical and Experimental Analysis. Int. J. Fract. 2020. submitted. [Google Scholar]

- Nygårds, M.; Gudmundson, P. Three-dimensional periodic Voronoi grain models and micromechanical FE-simulations of a two-phase steel. Comput. Mater. Sci. 2002, 24, 513–519. [Google Scholar] [CrossRef]

- Ledl, T. Kernel Density Estimation: Theory and Application in Discriminant Analysis. Austrian J. Stat. 2016, 33, 267. [Google Scholar] [CrossRef]

- Lewiner, T.; Lopes, H.; Vieira, A.W.; Tavares, G. Efficient Implementation of Marching Cubes’ Cases with Topological Guarantees. J. Graph. Tools 2003, 8, 1–15. [Google Scholar] [CrossRef]

- Geuzaine, C.; Remacle, J.F. Gmsh: A 3-D finite element mesh generator with built-in pre- and post-processing facilities. Int. J. Numer. Methods Eng. 2009, 79, 1309–1331. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Henrich, M.; Pütz, F.; Münstermann, S. A Novel Approach to Discrete Representative Volume Element Automation and Generation-DRAGen. Materials 2020, 13, 1887. https://doi.org/10.3390/ma13081887

Henrich M, Pütz F, Münstermann S. A Novel Approach to Discrete Representative Volume Element Automation and Generation-DRAGen. Materials. 2020; 13(8):1887. https://doi.org/10.3390/ma13081887

Chicago/Turabian StyleHenrich, Manuel, Felix Pütz, and Sebastian Münstermann. 2020. "A Novel Approach to Discrete Representative Volume Element Automation and Generation-DRAGen" Materials 13, no. 8: 1887. https://doi.org/10.3390/ma13081887

APA StyleHenrich, M., Pütz, F., & Münstermann, S. (2020). A Novel Approach to Discrete Representative Volume Element Automation and Generation-DRAGen. Materials, 13(8), 1887. https://doi.org/10.3390/ma13081887