Hot Deformation Behavior and Strain-Compensated Constitutive Equation of Nano-Sized SiC Particle-Reinforced Al-Si Matrix Composites

Abstract

1. Introduction

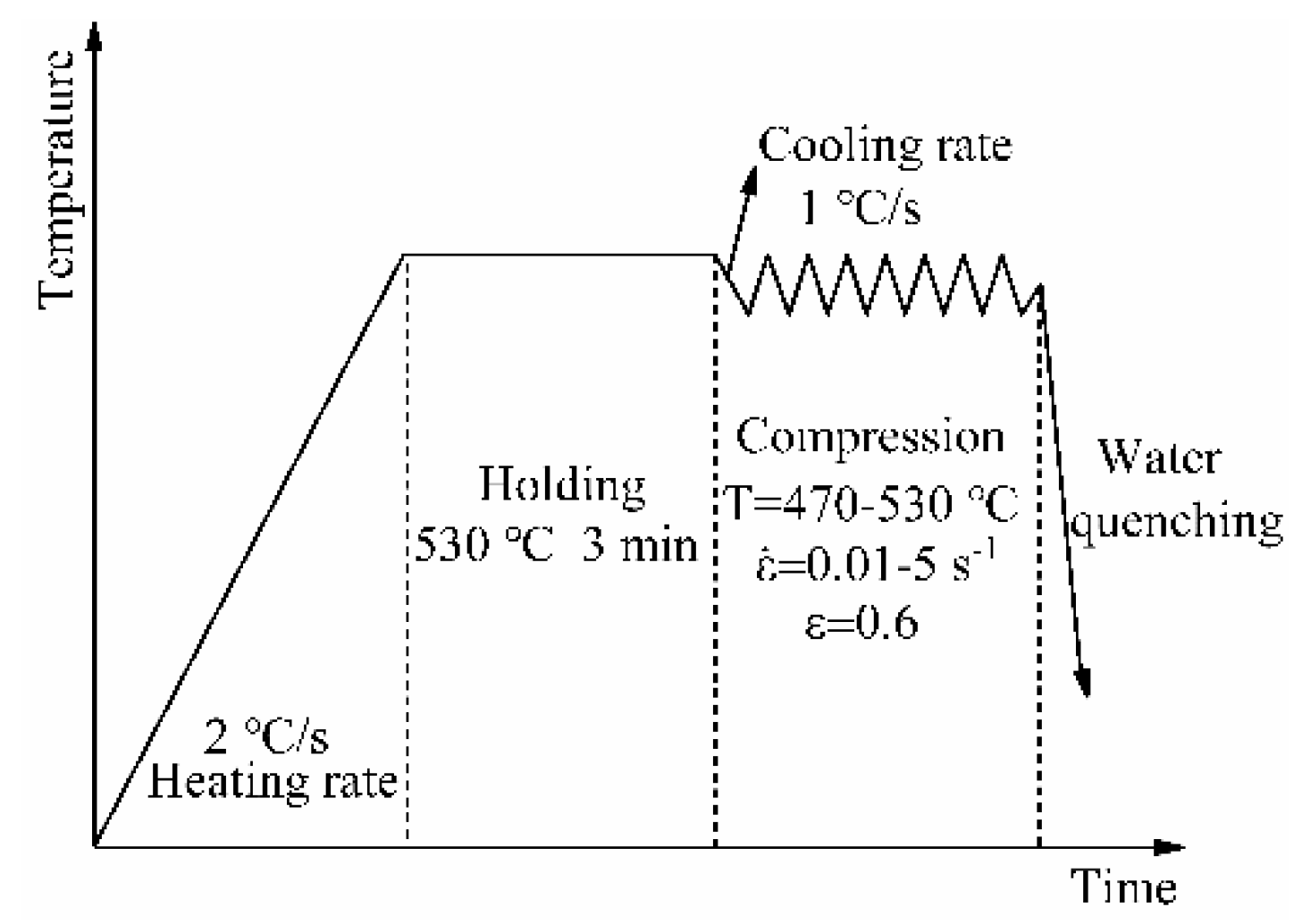

2. Materials and Methods

3. Results and Discussion

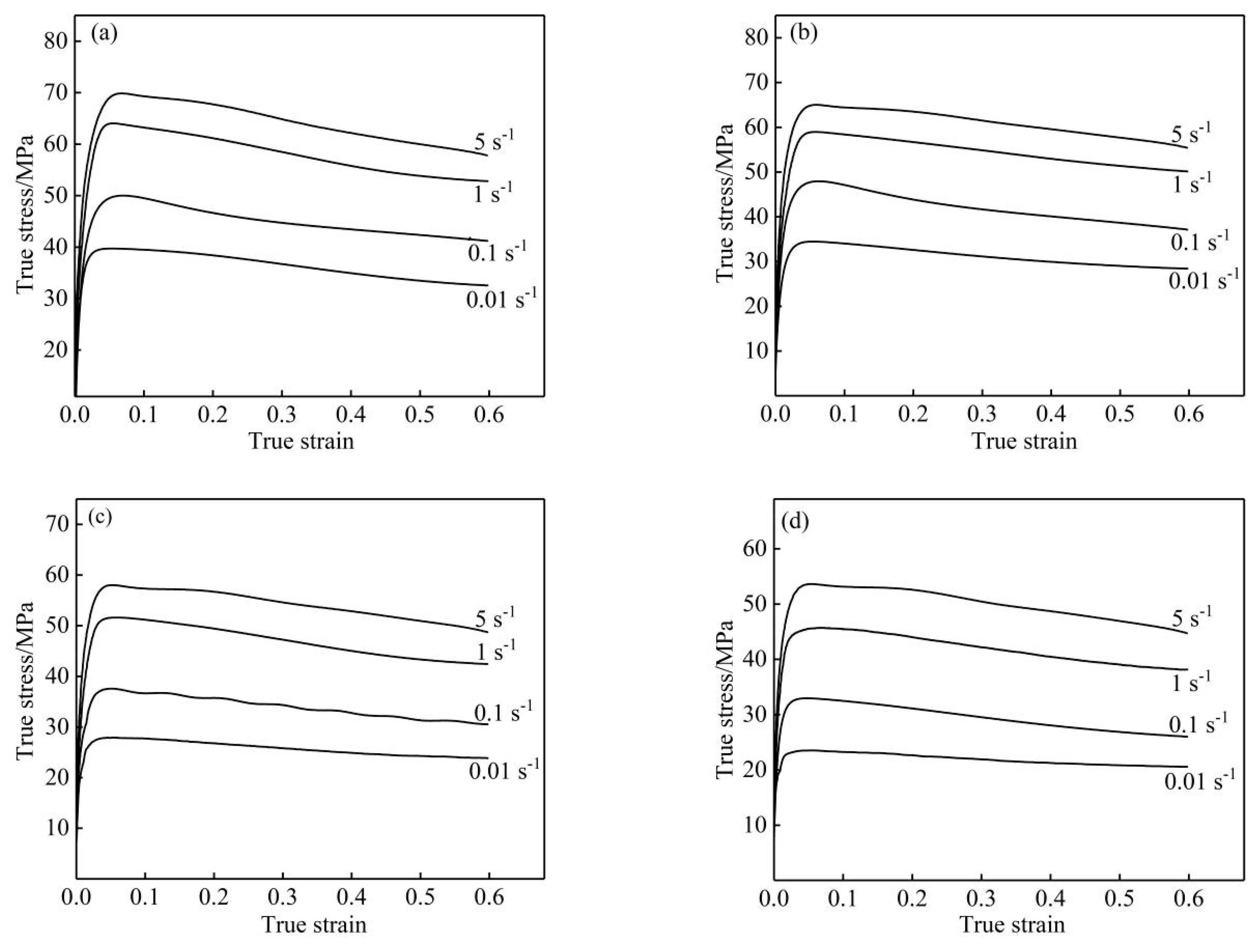

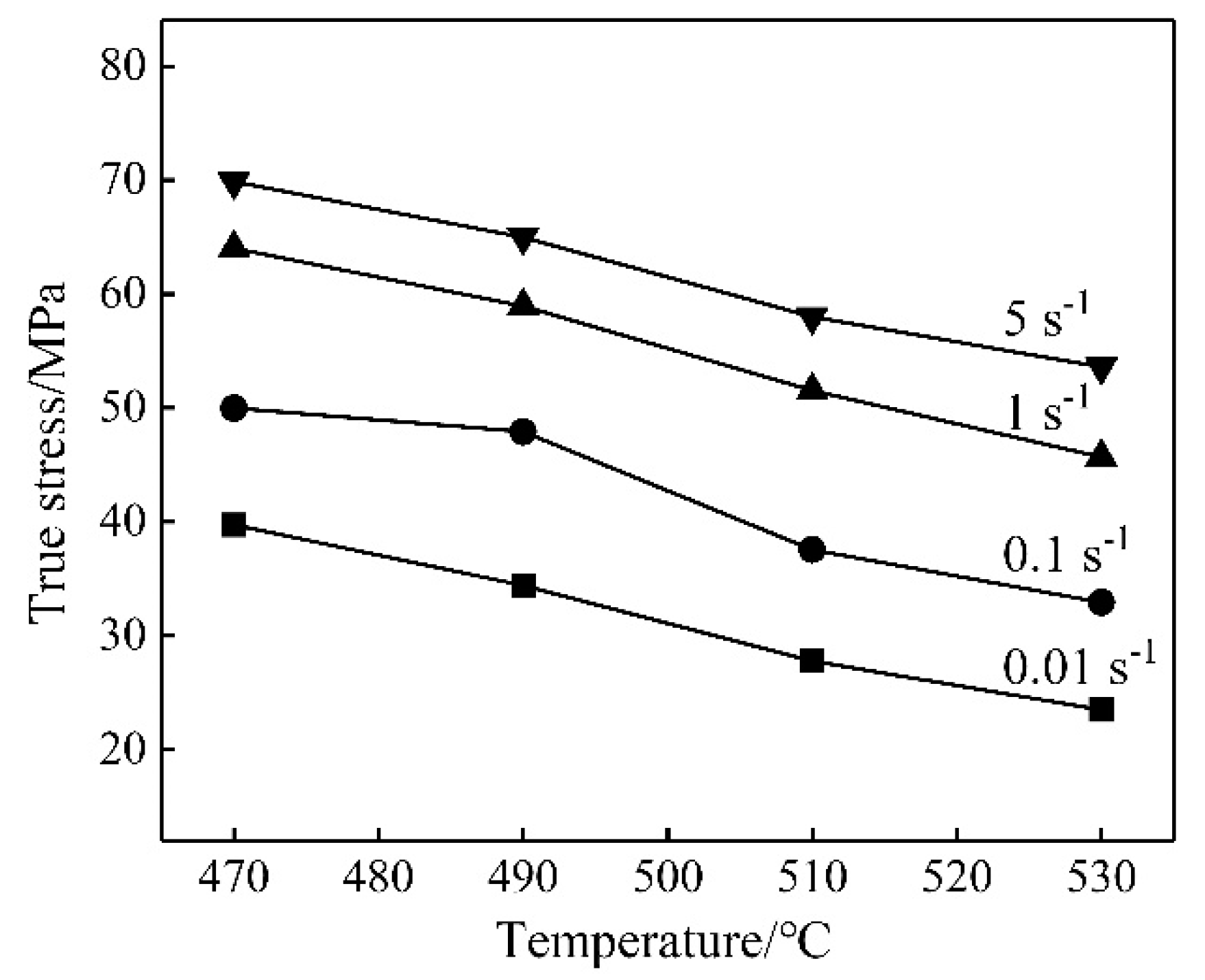

3.1. Hot Deformation Behavior

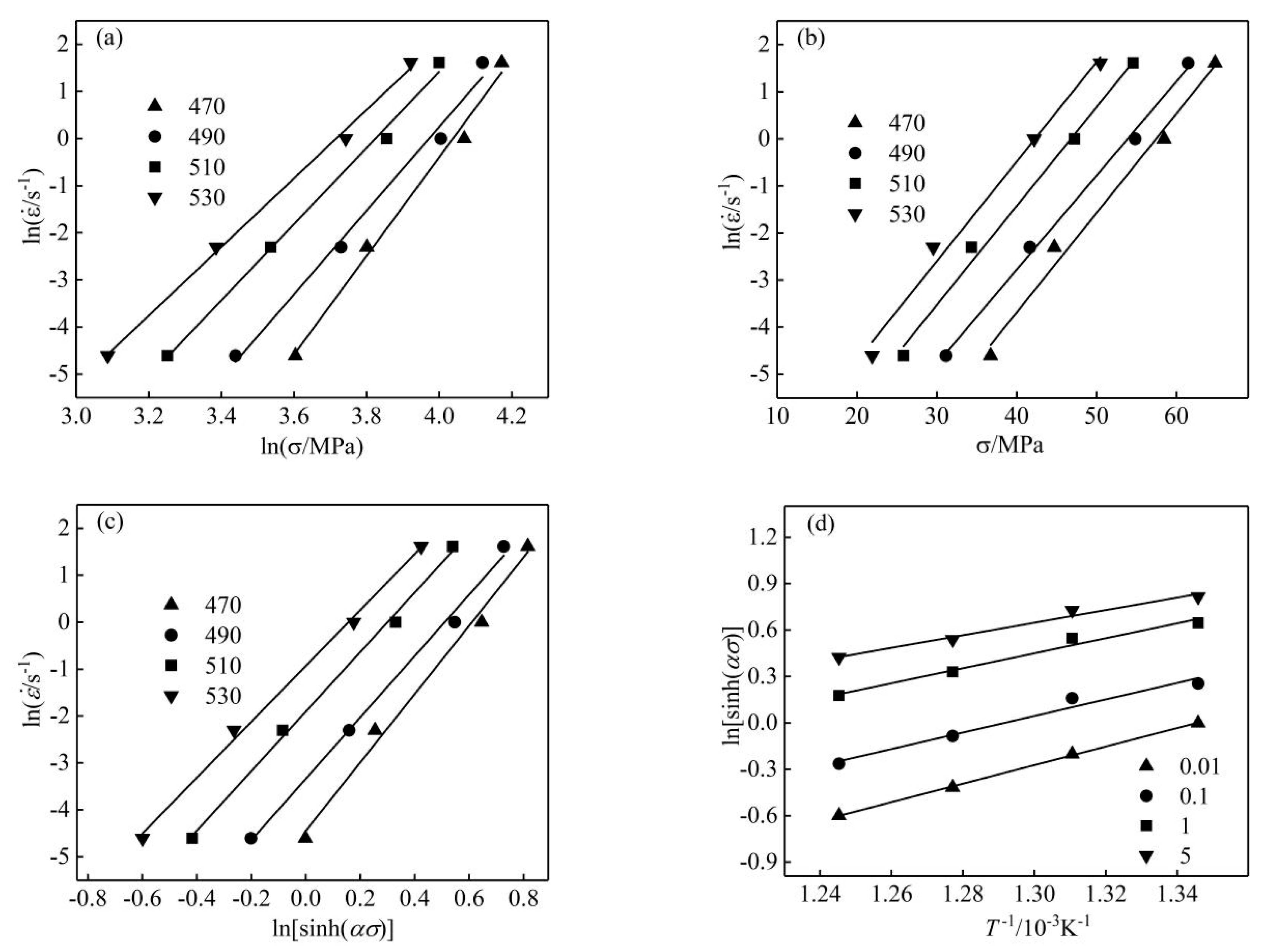

3.2. Constitutive Equation

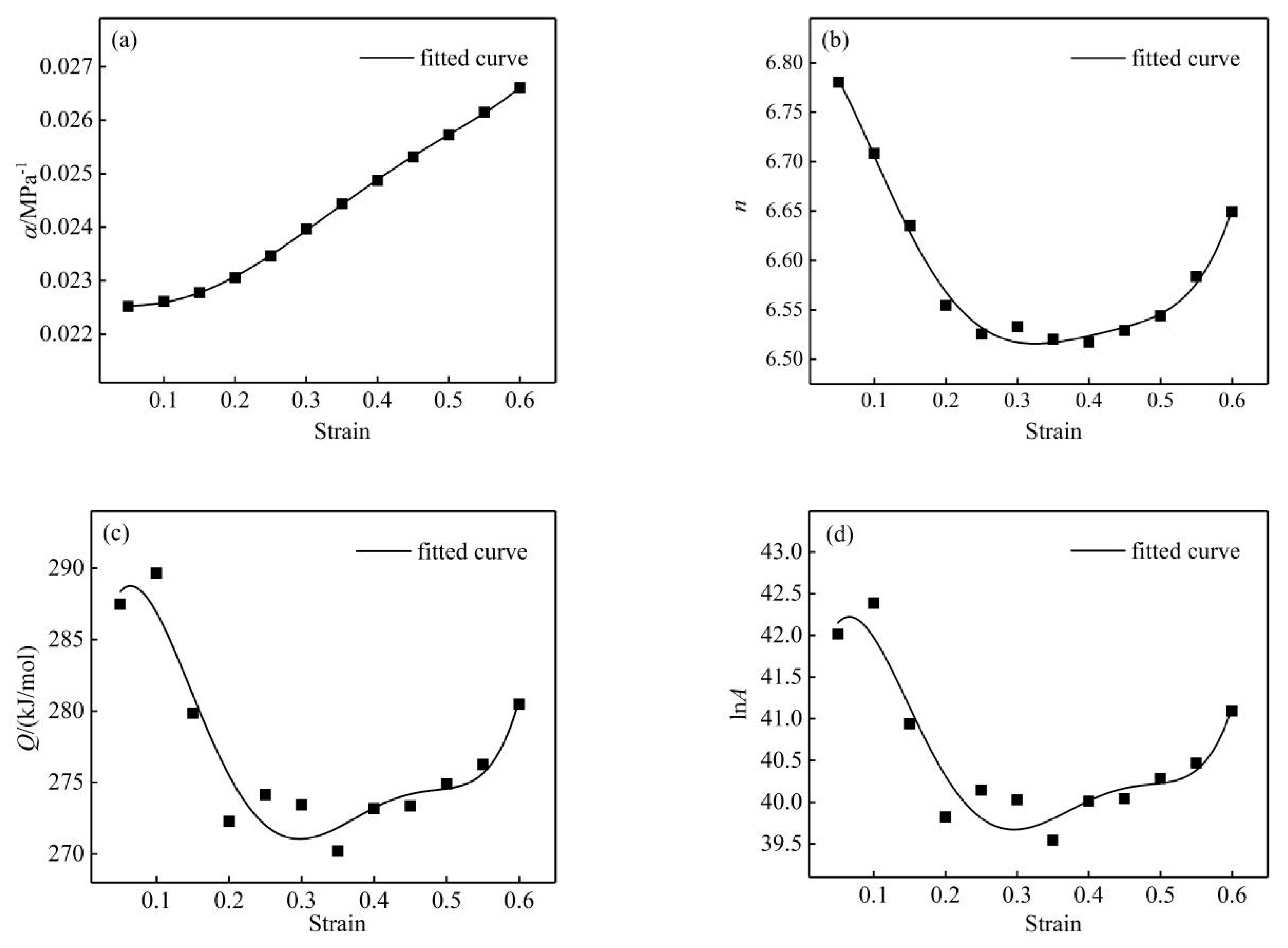

3.3. Strain Compensation

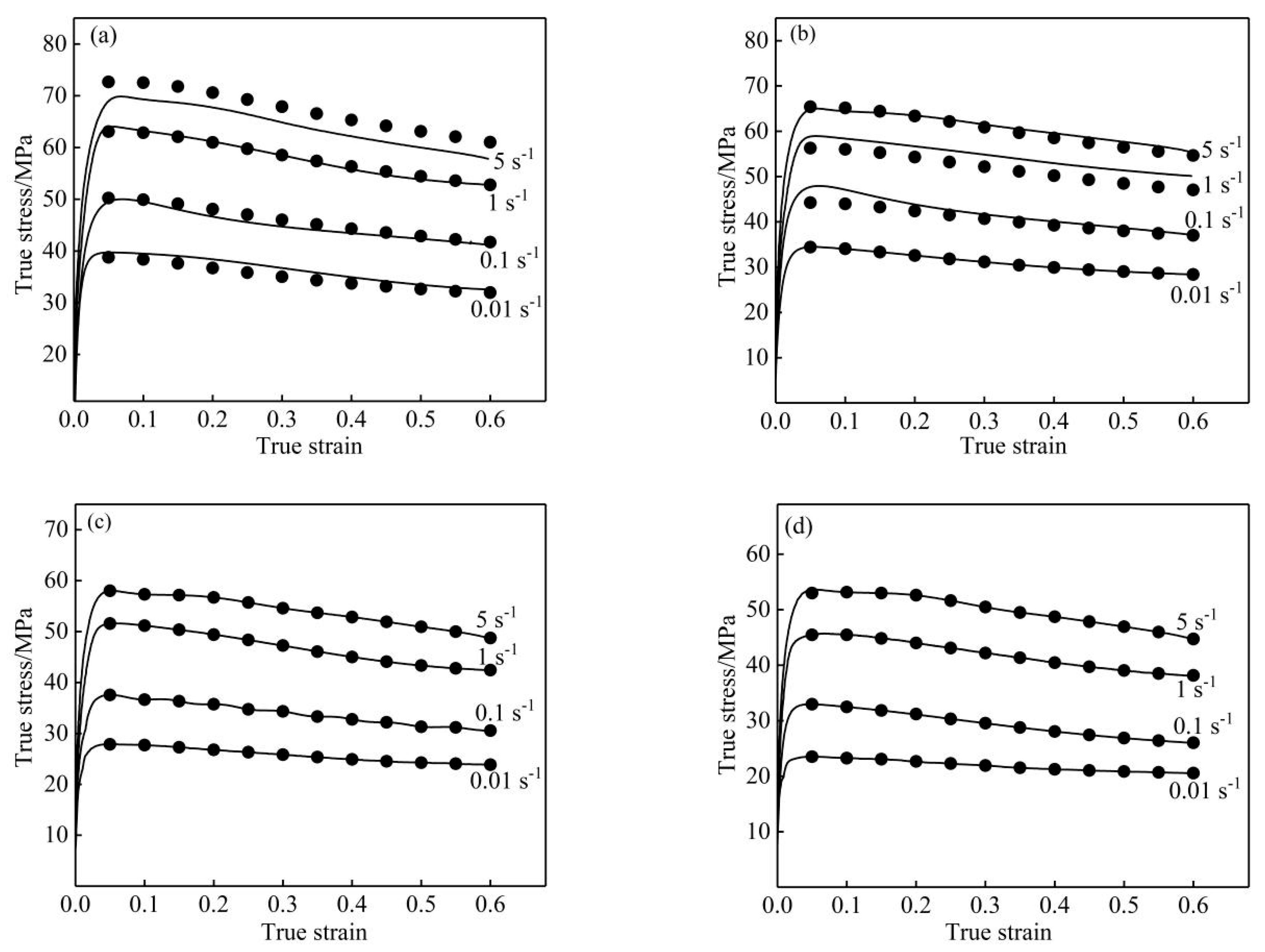

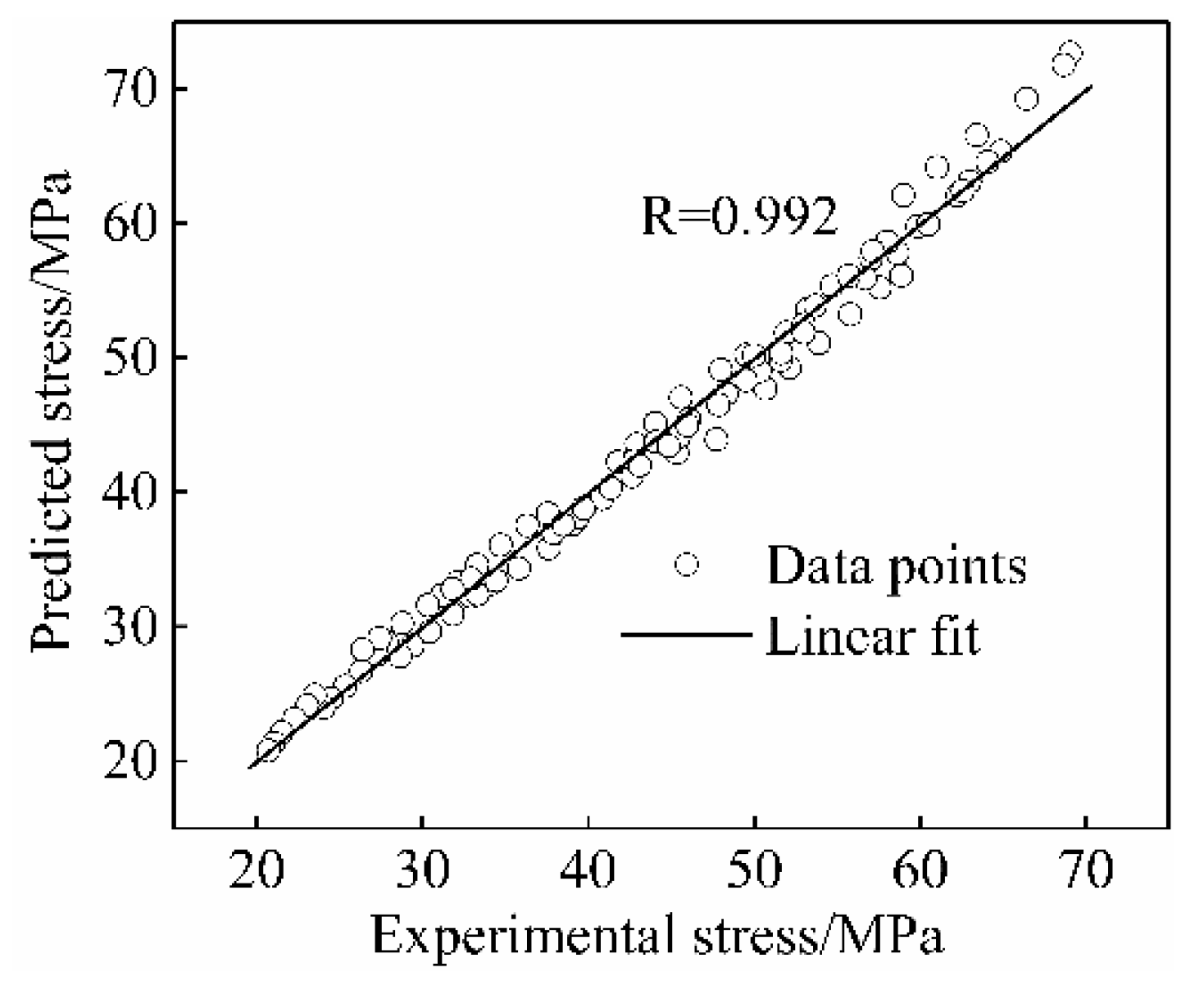

3.4. Strain Compensation Evaluation of Constitutive Equation

4. Conclusions

- (1)

- The flow curves of nano-SiCp/Al-Si composites showed a trend of peaking first and then decreasing gradually with the increase in strain variables, and the stress value was significantly affected by deformation temperature and strain rate.

- (2)

- The average activation energy for the nano-SiCp/Al-Si composites was 277 kJ/mol, which was larger than the activation energy for self-diffusion of pure aluminum.

- (3)

- A strain-compensation constitutive equation was proposed based on isothermal compression test data. The predicted values of the flow stress were consistent with those obtained from experience, indicating that the strain-compensated constitutive equation could predict the hot deformation behavior of nano-SiCp/Al-Si composites accurately.

Author Contributions

Funding

Conflicts of Interest

References

- Cui, Y.; Jin, T.; Cao, L.; Liu, F. Aging behavior of high volume fraction SiCp/Al composites fabricated by pressureless infiltration. J. Alloys Compd. 2016, 681, 233–239. [Google Scholar] [CrossRef]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting–Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- Maurya, M.; Kumar, S.; Bajpai, V. Assessment of the mechanical properties of aluminium metal matrix composite: A review. J. Reinf. Plast. Compos. 2019, 38, 267–298. [Google Scholar] [CrossRef]

- Soltani, S.; Khosroshahi, R.A.; Mousavian, R.T.; Jiang, Z.Y.; Boostani, A.F.; Brabazon, D. Stir casting process for manufacture of Al–SiC composites. Rare Met. 2017, 36, 581–590. [Google Scholar] [CrossRef]

- Moazami-Goudarzi, M.; Akhlaghi, F. Wear behavior of Al 5252 alloy reinforced with micrometric and nanometric SiC particles. Tribol. Int. 2016, 102, 28–37. [Google Scholar] [CrossRef]

- Bembalge, O.B.; Panigrahi, S.K. Influence of SiC ceramic reinforcement size in establishing wear mechanisms and wear maps of ultrafine grained AA6063 composites. Ceram. Int. 2019, 45, 20091–20104. [Google Scholar] [CrossRef]

- Monazzah, A.H.; Pouraliakbar, H.; Bagheri, R.; Reihani, S.M.S. Al-Mg-Si/SiC laminated composites: Fabrication, architectural characteristics, toughness, damage tolerance, fracture mechanisms. Compos. Part B Eng. 2017, 125, 49–70. [Google Scholar] [CrossRef]

- Zhang, L.J.; Qiu, F.; Wang, J.G.; Jiang, Q.C. High strength and good ductility at elevated temperature of nano-SiCp/Al2014 composites fabricated by semi-solid stir casting combined with hot extrusion. Mater. Sci. Eng. A 2015, 626, 338–341. [Google Scholar] [CrossRef]

- Habibnejad-Korayem, M.; Mahmudi, R.; Poole, W.J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Qiu, F.; Gao, X.; Tang, J.; Gao, Y.Y.; Shu, S.L.; Han, X.; Jiang, Q.C. Microstructures and tensile properties of Al–Cu matrix composites reinforced with nano-sized SiCp fabricated by semisolid stirring process. Metals 2017, 7, 49. [Google Scholar] [CrossRef]

- Mousavian, R.T.; Behnamfard, S.; Khosroshahi, R.A.; Zavašnik, J.; Ghosh, P.; Krishnamurthy, S.; Brabazon, D. Strength-ductility trade-off via SiC nanoparticle dispersion in A356 aluminium matrix. Mater. Sci. Eng. A 2020, 771, 138639. [Google Scholar] [CrossRef]

- Chen, X.; Fu, D.; Teng, J.; Zhang, H. Hot deformation behavior and mechanism of hybrid aluminum-matrix composites reinforced with micro-SiC and nano-TiB2. J. Alloys Compd. 2018, 753, 566–575. [Google Scholar] [CrossRef]

- Yu, S.B.; Jeon, K.S.; Kim, M.S.; Lee, J.K.; Ryu, K.H. Microstructure and hot deformation behavior of A356/Al2O3 composite fabricated by infiltration method. Met. Mater. Int. 2017, 23, 639–647. [Google Scholar] [CrossRef]

- Ezatpour, H.R.; Sajjadi, S.A.; Sabzevar, M.H.; Chaichi, A.; Ebrahimi, G.R. Processing map and microstructure evaluation of AA6061/Al2O3 nanocomposite at different temperatures. Trans. Nonferr. Met. Soc. 2017, 27, 1248–1256. [Google Scholar] [CrossRef]

- Ji, H.; Liu, J.; Wang, B.; Tang, X.; Lin, J.; Huo, Y. Microstructure evolution and constitutive equations for the high-temperature deformation of 5Cr21Mn9Ni4N heat-resistant steel. J. Alloys Compd. 2017, 693, 674–687. [Google Scholar] [CrossRef]

- Gangolu, S.; Rao, A.G.; Sabirov, I.; Kashyap, B.P.; Prabhu, N.; Deshmukh, V.P. Development of constitutive relationship and processing map for Al-6.65Si-0.44Mg alloy and its composite with B4C particulates. Mater. Sci. Eng. A 2016, 655, 256–264. [Google Scholar] [CrossRef]

- Mousavian, R.T.; Khosroshahi, R.A.; Yazdani, S.; Brabazon, D.; Boostani, A.F. Fabrication of aluminum matrix composites reinforced with nano-to micrometer-sized SiC particles. Mater. Des. 2016, 89, 58–70. [Google Scholar] [CrossRef]

- McQueen, H.J.; Myshlyaev, M.; Konopleva, E.; Sakaris, A.P. High temperature mechanical and microstructural behavior of A356/15 vol% SiCp and A356 alloy. Can. Metall. Q. 1998, 37, 125–139. [Google Scholar] [CrossRef]

- Wu, B.; Li, M.Q.; Ma, D.W. The flow behavior and constitutive equations in isothermal compression of 7050 aluminum alloy. Mater. Sci. Eng. A 2012, 542, 79–87. [Google Scholar] [CrossRef]

- Xiao, B.L.; Huang, Z.Y.; Ma, K.; Zhang, X.X.; Ma, Z.Y. Research on hot deformation behaviors of discontinuously reinforced aluminum composites. Acta Metall. Sin. 2019, 55, 59–72. [Google Scholar]

- Li, J.; Li, F.; Cai, J. Constitutive Model Prediction and Flow Behavior Considering Strain Response in the Thermal Processing for the TA15 Titanium Alloy. Materials 2018, 11, 1985. [Google Scholar] [CrossRef] [PubMed]

- Ashtiani, H.R.; Parsa, M.H.; Bisadi, H. Constitutive equations for elevated temperature flow behavior of commercial purity aluminum. Mater. Sci. Eng. A 2012, 545, 61–67. [Google Scholar] [CrossRef]

- Mirzadeh, H. A simplified approach for developing constitutive equations for modeling and prediction of hot deformation flow stress. Metall. Mater. Trans. A 2015, 46, 4027–4037. [Google Scholar] [CrossRef]

- McQueen, H.J.; Ryan, N.D. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–63. [Google Scholar] [CrossRef]

- Shao, J.C.; Xiao, B.L.; Wang, Q.Z.; Ma, Z.Y.; Liu, Y.; Yang, K. Constitutive flow behavior and hot workability of powder metallurgy processed 20 vol.% SiCp/2024Al composite. Mater. Sci. Eng. A 2010, 527, 7865–7872. [Google Scholar] [CrossRef]

- Senthilkumar, V.; Balaji, A.; Narayanasamy, R. Analysis of hot deformation behavior of Al 5083–TiC nanocomposite using constitutive and dynamic material models. Mater. Des. 2012, 37, 102–110. [Google Scholar] [CrossRef]

- Saravanan, L.; Senthilvelan, T. Investigations on the hot workability characteristics and deformation mechanisms of aluminium alloy-Al2O3 nanocomposite. Mater. Des. 2015, 79, 6–14. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

| Si | Mg | Fe | Al |

|---|---|---|---|

| 7 | 0.3 | 0.1 | Bal. |

| Parameter | A0 | A1 | A2 | A3 | A4 | A5 |

|---|---|---|---|---|---|---|

| α | 0.0226 | −0.0008 | 0.0028 | 0.1299 | −0.336 | 0.2447 |

| n | 6.825 | −0.1867 | −17.22 | 85.90 | −156.3 | 100.83 |

| Q | 278.14 | 387.89 | −4464.85 | 17287.23 | −28326.98 | 16903.29 |

| lnA | 40.56 | 59.35 | −671.91 | 2591.48 | −4237.69 | 2524.44 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Wang, A.; Xie, J.; Liu, P. Hot Deformation Behavior and Strain-Compensated Constitutive Equation of Nano-Sized SiC Particle-Reinforced Al-Si Matrix Composites. Materials 2020, 13, 1812. https://doi.org/10.3390/ma13081812

Wang Z, Wang A, Xie J, Liu P. Hot Deformation Behavior and Strain-Compensated Constitutive Equation of Nano-Sized SiC Particle-Reinforced Al-Si Matrix Composites. Materials. 2020; 13(8):1812. https://doi.org/10.3390/ma13081812

Chicago/Turabian StyleWang, Zhen, Aiqin Wang, Jingpei Xie, and Pei Liu. 2020. "Hot Deformation Behavior and Strain-Compensated Constitutive Equation of Nano-Sized SiC Particle-Reinforced Al-Si Matrix Composites" Materials 13, no. 8: 1812. https://doi.org/10.3390/ma13081812

APA StyleWang, Z., Wang, A., Xie, J., & Liu, P. (2020). Hot Deformation Behavior and Strain-Compensated Constitutive Equation of Nano-Sized SiC Particle-Reinforced Al-Si Matrix Composites. Materials, 13(8), 1812. https://doi.org/10.3390/ma13081812