Research on Bonding and Shrinkage Properties of SHCC-Repaired Concrete Beams

Abstract

1. Introduction

2. Experimental Program

2.1. Experimental Material

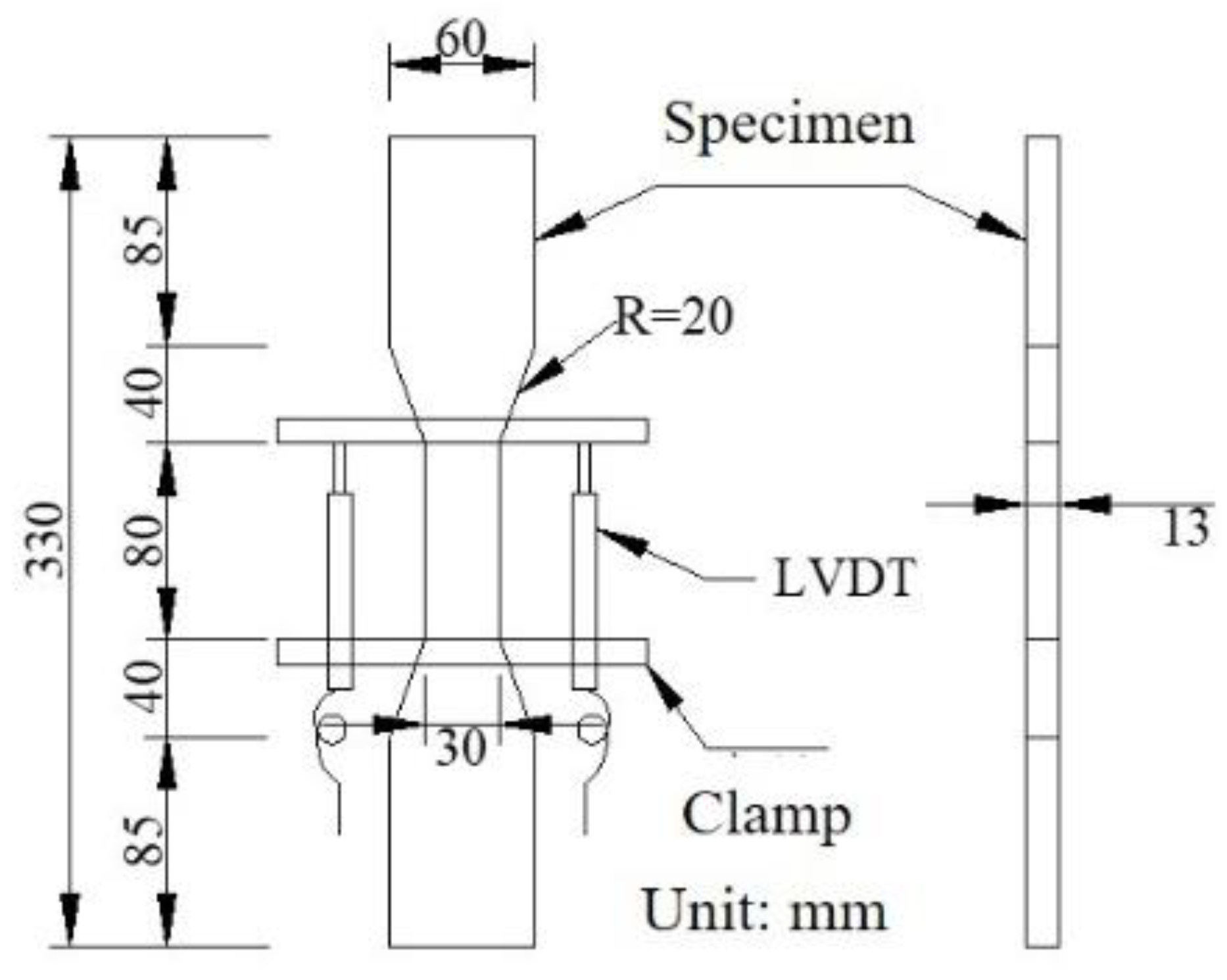

2.2. Uniaxial Tensile Test of SHCC

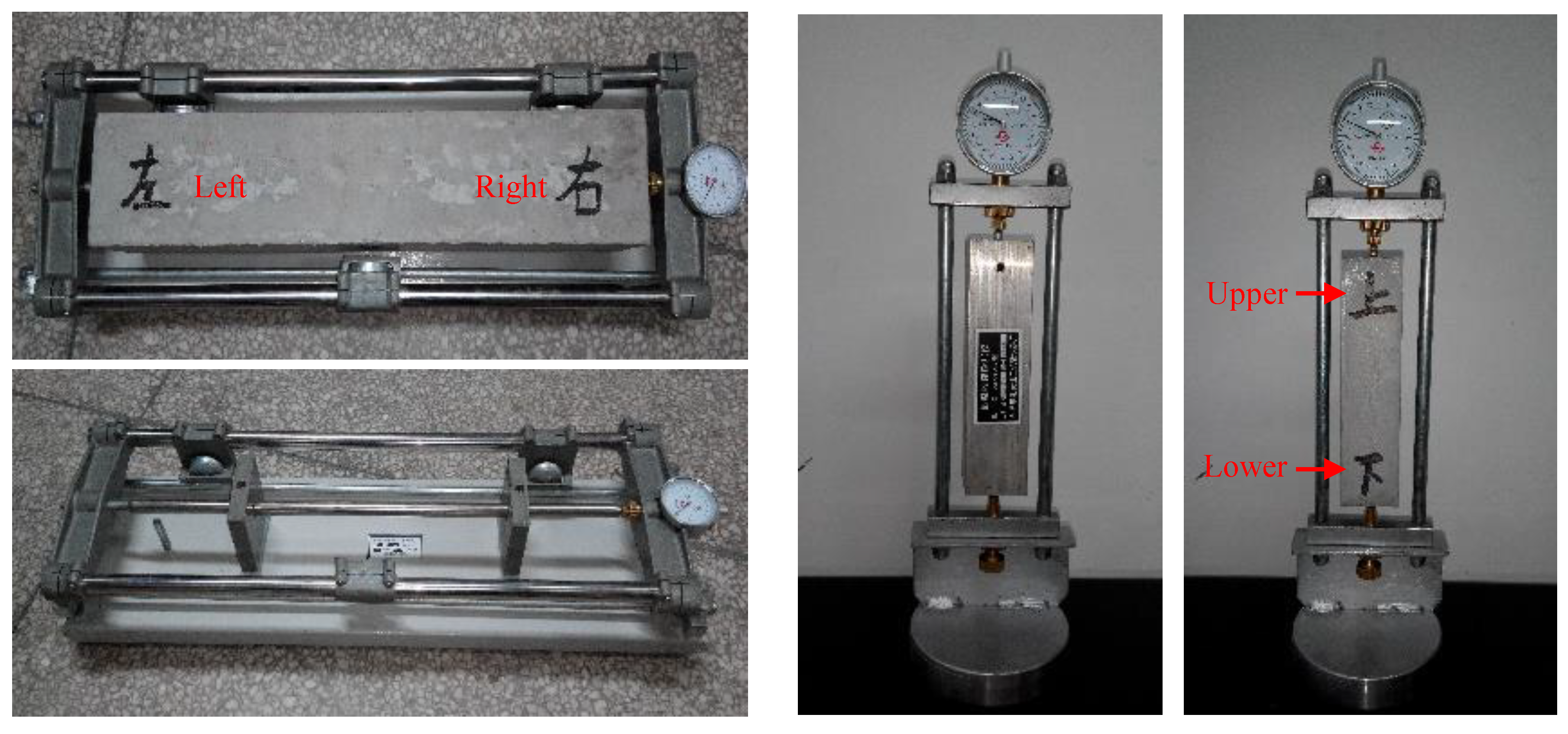

2.3. Free Shrinkage Test

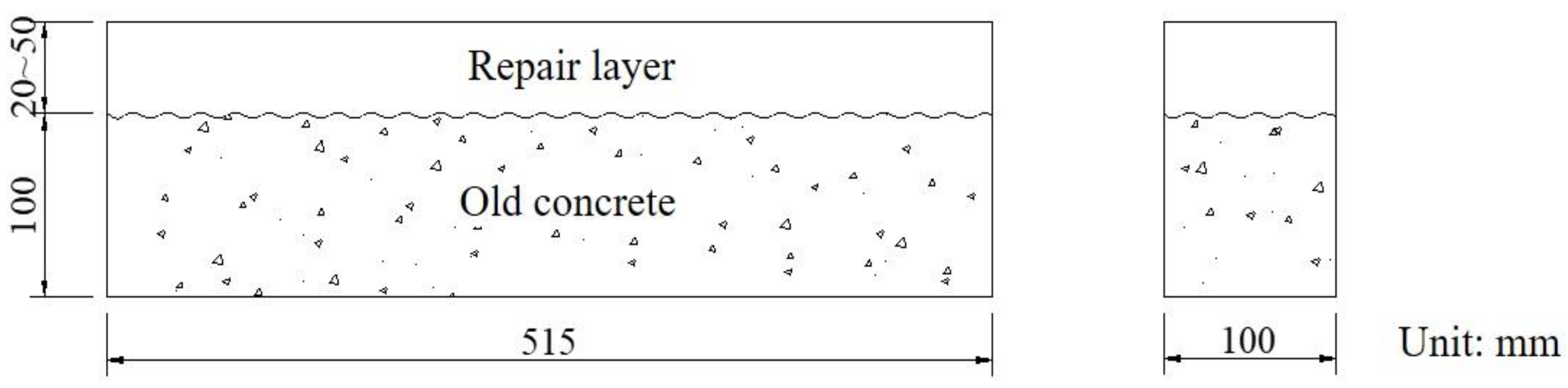

2.4. Interfacial Bonding and Shrinkage of SHCC-Repaired Concrete Beams

3. Results and Discussion

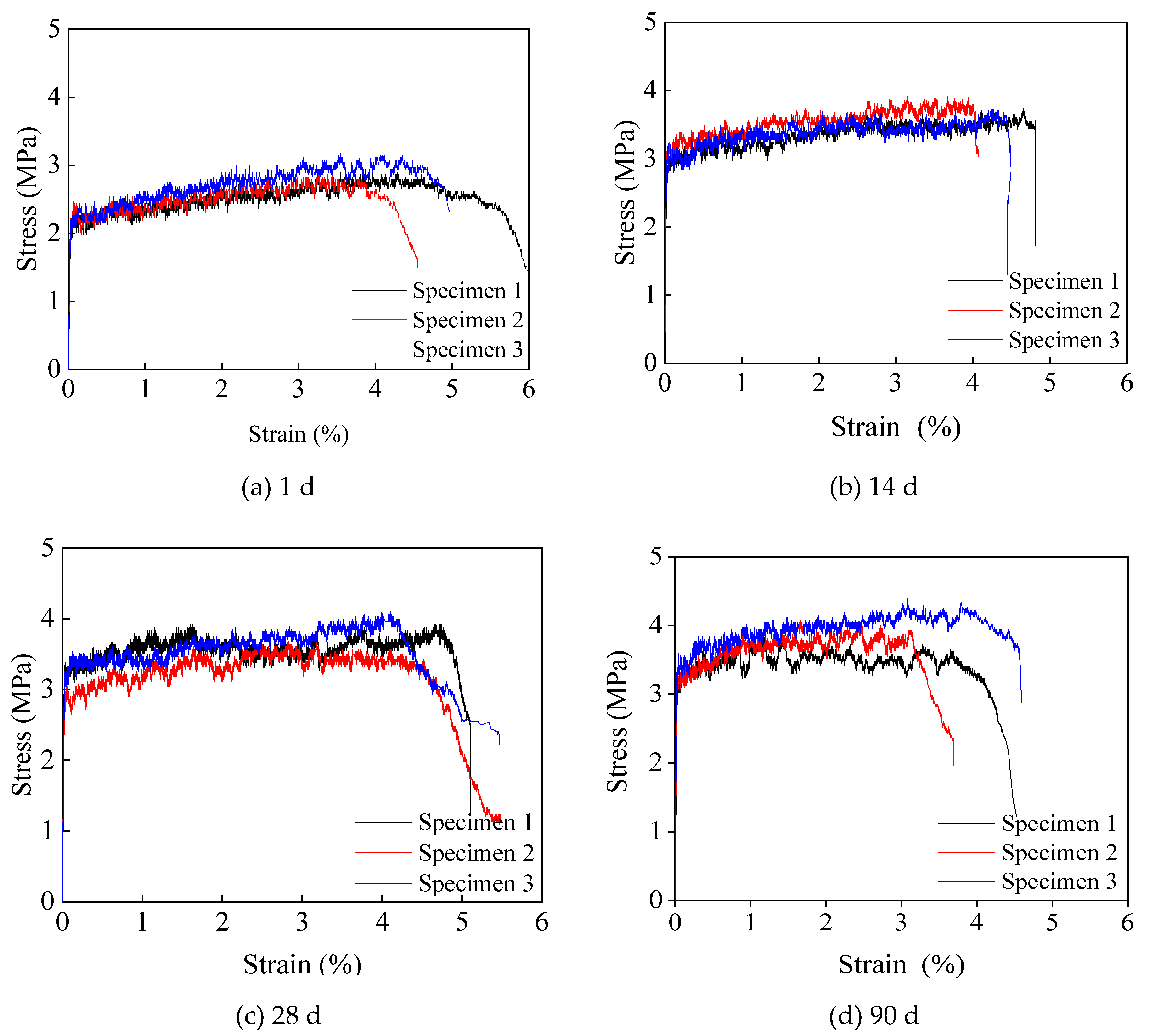

3.1. Uniaxial Tensile Properties of SHCC

3.1.1. Stress–Strain Curves of SHCC under Uniaxial Tension

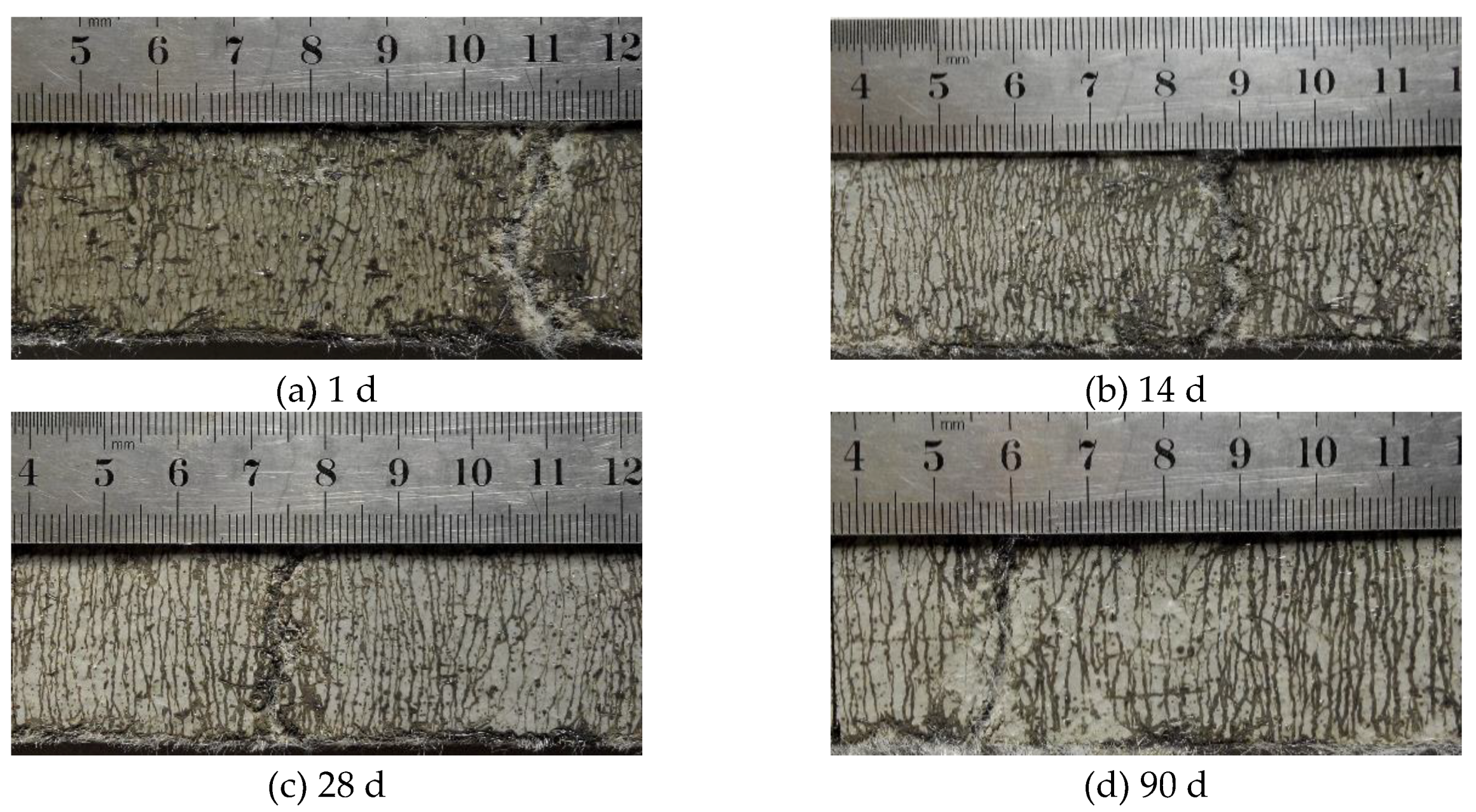

3.1.2. Crack Pattern of SHCC at Different Ages

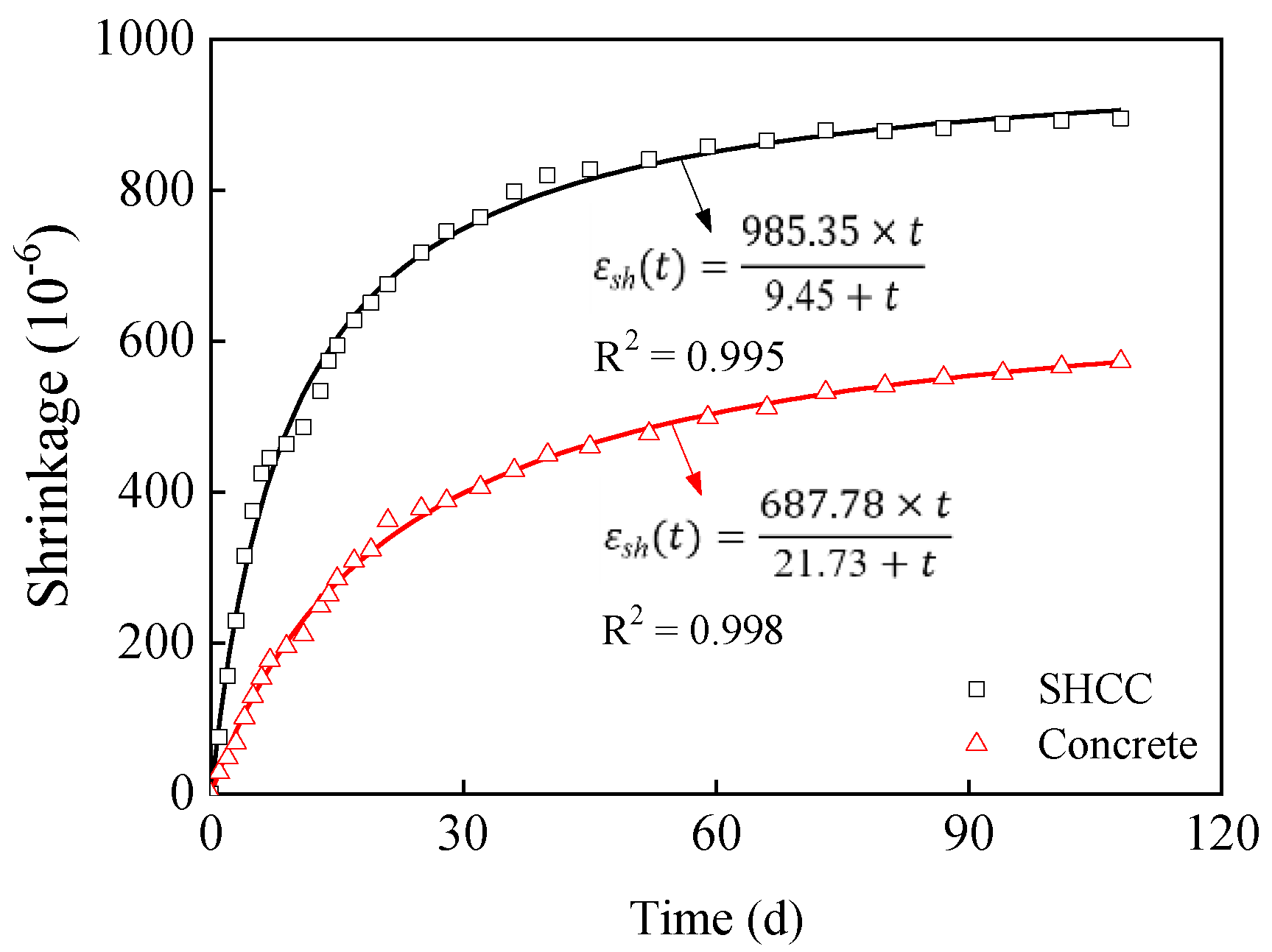

3.2. Free Shrinkage of SHCC and Concrete

3.3. Interfacial Bonding and Shrinkage Properties of SHCC-Repaired Concrete Beams

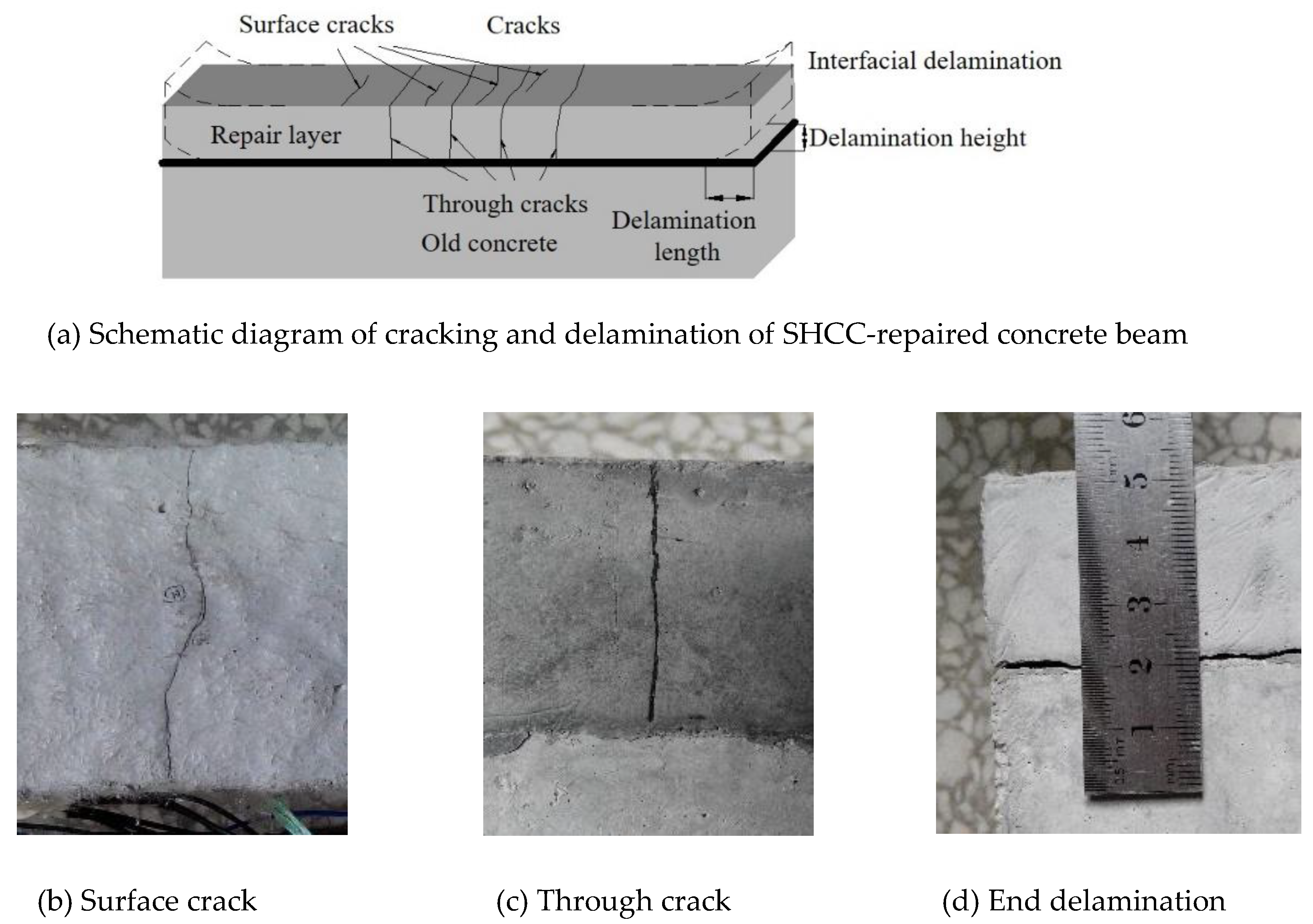

3.3.1. Restrained Shrinkage Stress and Failure Mode Analysis of SHCC-Repaired Concrete Beams

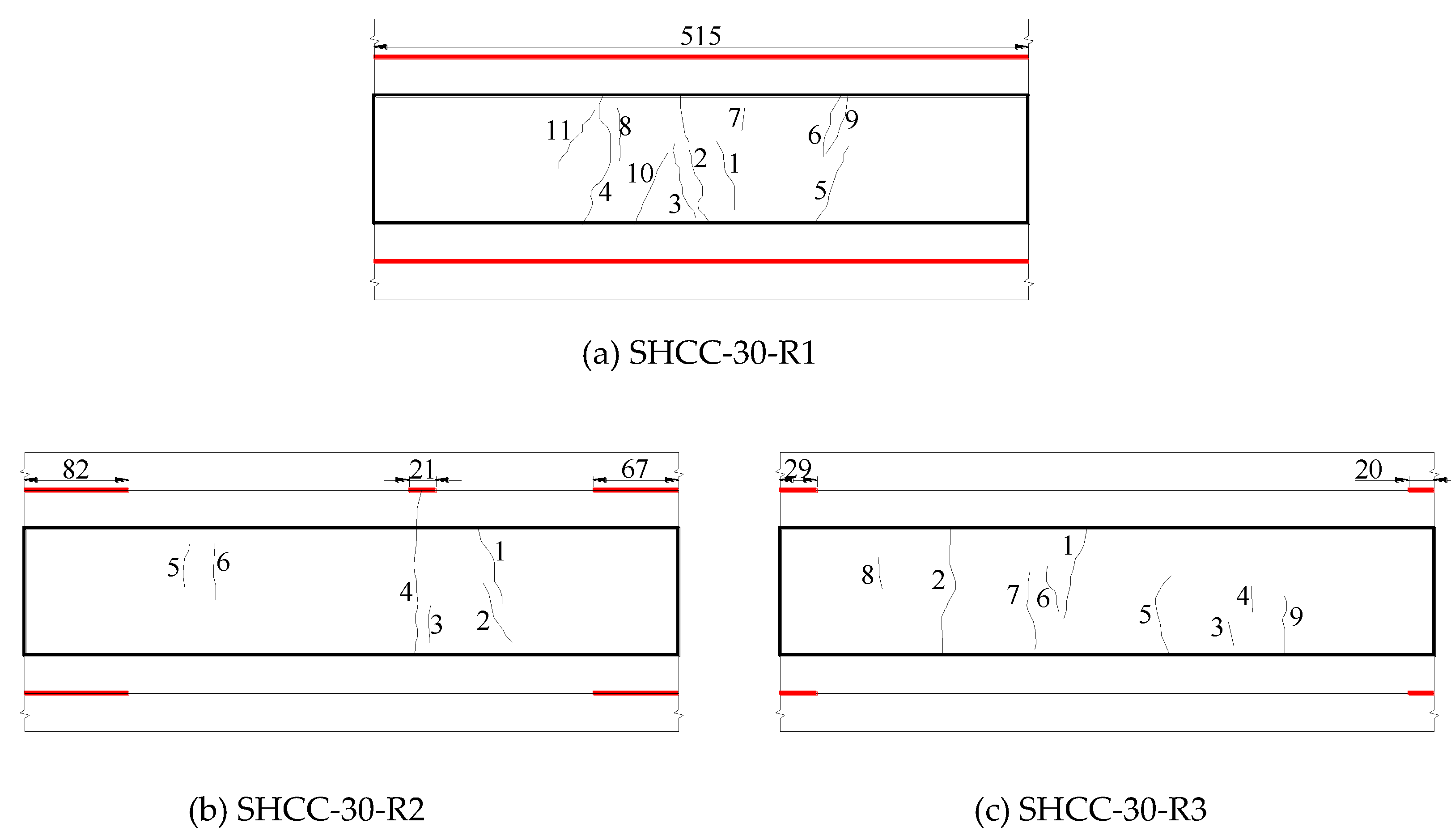

3.3.2. Influence of Interface Roughness on Cracking and Delamination Modes of SHCC-Repaired Concrete Beams

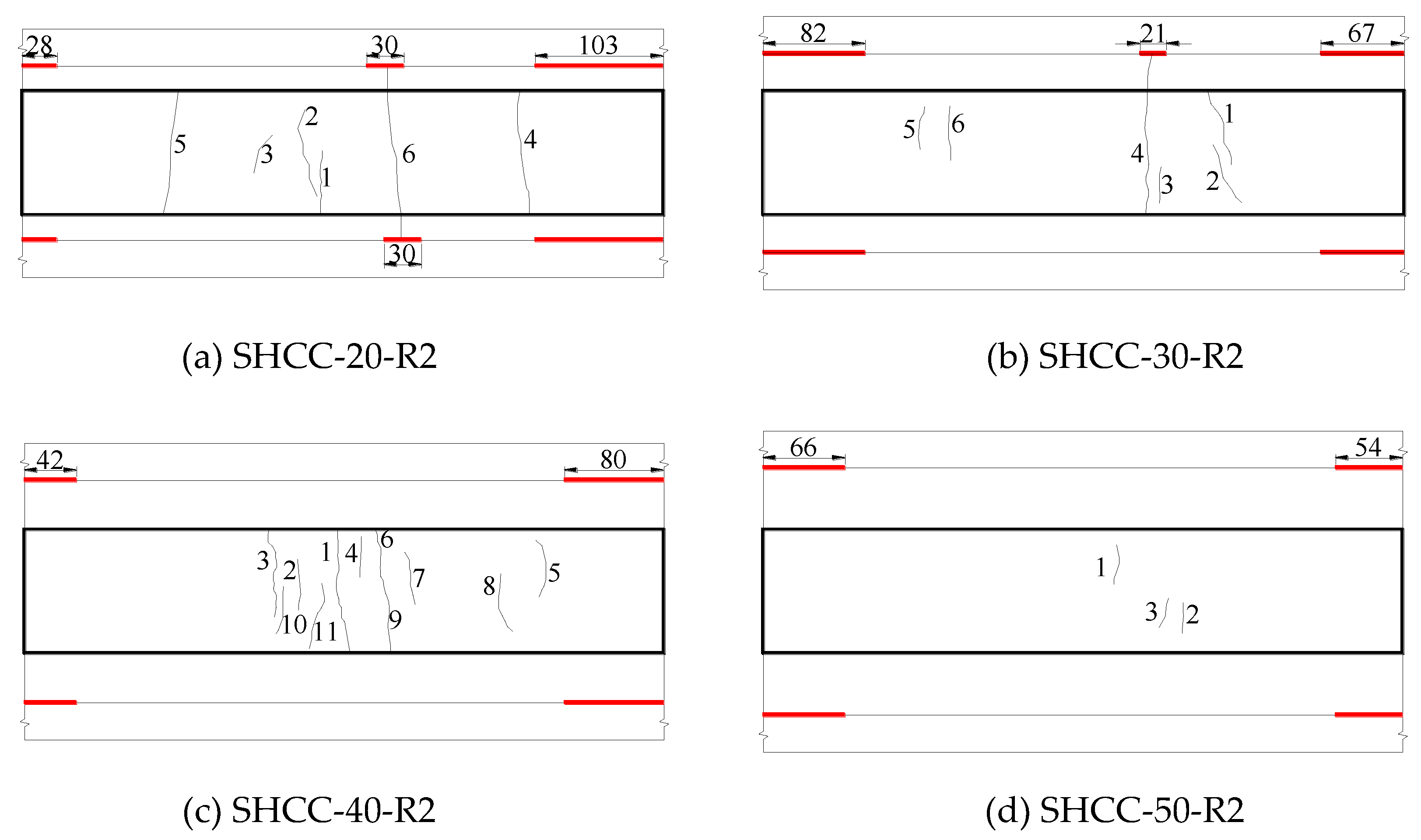

3.3.3. Influence of Repair Layer Thickness on Cracking and Delamination Modes of SHCC-Repaired Concrete Beams

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Trump, D. Legislative Outline for Rebuilding Infrastructure in America; White House: Washington, DC, USA, 2018.

- Hou, B.; Lu, D. Corrosion Cost and Preventive Strategies in China. Bull. Chin. Acad. Sci. 2018, 33, 601–609. [Google Scholar]

- Talbot, C.; Pigeon, M.; Beaupré, D.; Morgan, D.R. Influence of surface preparation on long-term bonding of concrete. ACI Mater. J. 1994, 91, 560–566. [Google Scholar]

- Li, S.; Frantz, G.C.; Stephens, J.E. Bond Performance of Rapid-Setting Repair Materials Subjected to Deicing Salt and Freezing-Thawing Cycles. ACI Mater. J. 1999, 96, 692–697. [Google Scholar]

- Li, G.Y. A new way to increase the long -term bond strength of new-to-old concrete by the use of fly ash. Cem. Concr. Res. 2003, 33, 799–806. [Google Scholar] [CrossRef]

- Momayez, A.; Ehsani, M.; Ramezanianpour, A.; Rajaie, H. Comparison of methods for evaluating bond strength between concrete substrate and repair materials. Cem. Concr. Res. 2005, 35, 748–757. [Google Scholar] [CrossRef]

- Judge, A.I.; Cheriton, L.W.; Lambe, R.W. Bonding Systems for Concrete Repair—An Assessment of Commonly Used Materials. In Adhesion between Polymers and Concrete; Springer: Berlin/Heidelberg, Germany, 1986. [Google Scholar]

- Sasse, H.R.; Fiebrich, M. Bonding of polymer materials to concrete. Mater. Struct. 1983, 16, 293–301. [Google Scholar] [CrossRef]

- Frigione, M.; Aiello, M.A.; Naddeo, C. Water effects on the bond strength of concrete/concrete adhesive joints. Constr. Build. Mater. 2006, 20, 957–970. [Google Scholar] [CrossRef]

- Zhang, J.; Ju, X. Effect of cracks in concrete on chloride penetration. J. Harbin Eng. Univ. 2010, 31, 720–724. [Google Scholar]

- Maes, M.; Snoeck, D.; De Belie, N. Chloride penetration in cracked mortar and the influence of autogenous crack healing. Constr. Build. Mater. 2016, 115, 114–124. [Google Scholar] [CrossRef]

- Zacchei, E.; Nogueira, C.G. Chloride diffusion assessment in RC structures considering the stress–strain state effects and crack width influences. Constr. Build. Mater. 2019, 201, 100–109. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y.; Zhao, T.; Wang, H.; Zhang, Z. Water absorption and chloride diffusivity of concrete under the coupling effect of uniaxial compressive load and freeze–thaw cycles. Constr. Build. Mater. 2019, 209, 566–576. [Google Scholar] [CrossRef]

- Zhang, P.; Penggang, W.; Hou, D.; Liu, Z.; Haist, M.; Zhao, T. Application of neutron radiography in observing and quantifying the time-dependent moisture distributions in multi-cracked cement-based composites. Cem. Concr. Compos. 2017, 78, 13–20. [Google Scholar] [CrossRef]

- Hu, Y. Compatibility of Repair Materials with the Existing Substrate in Concrete Structure Repair. Ph.D. Thesis, Hunan University, Changsha, China, 2014. [Google Scholar]

- Deng, H.; Qian, S. Utilization of Local Ingredients for the Production of High-Early-Strength Engineered Cementitious Composites. Adv. Mater. Sci. Eng. 2018, 2018, 1–15. [Google Scholar] [CrossRef]

- Szeląg, M. Development of cracking patterns in modified cement matrix with microsilica. Materials 2018, 11, 1928–1947. [Google Scholar] [CrossRef] [PubMed]

- Nili, M.; Afroughsabet, V. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Fischer, G.; Li, V.C. Effect of matrix ductility on deformation behavior of steel-reinforced ECC flexural members under reversed cyclic loading conditions. Struct. J. 2002, 99, 781–790. [Google Scholar]

- Li, M.; Li, V.C. Cracking and Healing of Engineered Cementitious Composites under Chloride Environment. ACI Mater. J. 2011, 108, 333–340. [Google Scholar]

- Şahmaran, M.; Li, V.C. Durability of mechanically loaded engineered cementitious composites under highly alkaline environments. Cem. Concr. Compos. 2008, 30, 72–81. [Google Scholar] [CrossRef]

- Arain, M.F.; Wang, M.; Chen, J.; Zhang, H. Study on PVA fiber surface modification for strain-hardening cementitious composites (PVA-SHCC). Constr. Build. Mater. 2019, 197, 107–116. [Google Scholar] [CrossRef]

- Jin, C.; Wu, C.; Feng, C.; Zhang, Q.; Shangguan, Z.; Pan, Z.; Meng, S. Mechanical Properties of High-Volume Fly Ash Strain Hardening Cementitious Composite (HVFA-SHCC) for Structural Application. Materials 2019, 12, 2607–2625. [Google Scholar] [CrossRef]

- Han, J. Study on Fracture Performance and Engineering Application of Adherence of New and Old Concrete. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 4 June 2002. [Google Scholar]

- Li, V.C.; Horii, H.; Kabele, P.; Kanda, T.; Lim, Y.M. Repair and retrofit with engineered cementitious composites. Eng. Fract. Mech. 2000, 65, 317–334. [Google Scholar] [CrossRef]

- Zhang, J.; Gong, C.; Ju, X. Characteristics of high ductility and low shrinkage engineered cementitious composite and its applications. J. Hydraul. Eng. ASCE 2011, 42, 1452–1461. [Google Scholar]

- Şahmaran, M.; Lachemi, M.; Hossain, K.M.; Li, V.C. Internal curing of engineered cementitious composites for prevention of early age autogenous shrinkage cracking. Cem. Concr. Res. 2009, 39, 893–901. [Google Scholar] [CrossRef]

- Almudaiheem, J.A.; Hansen, W. Prediction of concrete drying shrinkage from short-term measurements. Mater. J. 1989, 86, 401–408. [Google Scholar]

- Xian, Y. Influence of Integral Water Repellent Treatment on the Property of Concrete. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 4 June 2006. [Google Scholar]

- Wang, L. Research on Performance of Drying Shrinkage of Cement-Based Materials Based on Inverse Analysis. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 14 December 2010. [Google Scholar]

- Huang, G.; Hui, R.; Wang, X. Creep and Shrinkage of Concrete; China Electric Power Press: Beijing, China, 2012. [Google Scholar]

- Habel, K.; Brühwiler, E. Structural Behaviour of Elements Combining Ultra-High Performance Fibre Reinforced Concretes (UHPFRC) and Reinforced Concrete; EPFL: Lausanne, Switzerland, 2004. [Google Scholar]

- Zhou, J.; Ye, G.; Schlangen, E.; Klaas, V.B. Modelling of stresses and strains in bonded concrete overlays subjected to differential volume changes. Theor. Appl. Fract. Mech. 2008, 49, 199–205. [Google Scholar] [CrossRef]

- Wittmann, F.H.; Martinola, G. Decisive properties of durable cement-based coatings for reinforced concrete structures. Int. J. Restor. Build. Monum. 2003, 9, 235–264. [Google Scholar]

- Xu, S.; Cai, X. Experimental study on mechanical properties of ultra-high toughness fiber reinforced cementitious composite. J. Hydraul. Eng. ASCE 2009, 40, 1055–1063. [Google Scholar]

| No. | Cement | Sand | Aggregate | Water |

|---|---|---|---|---|

| Concrete | 317 | 757 | 1136 | 190 |

| No. | Cement | Fly Ash | Sand | Water | SP | PVA Fiber |

|---|---|---|---|---|---|---|

| SHCC | 555 | 680 | 490 | 420 | 27.8 | 26 |

| Material | CaO | SiO2 | Al2O3 | MgO | SO3 | Fe2O3 | K2O | TiO2 | MnO | Na2O | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 57.27 | 20.60 | 7.17 | 4.70 | 4.43 | 3.85 | 0.77 | 0.40 | 0.35 | 0.17 | 0.13 |

| Fly ash | 1.83 | 58.10 | 31.79 | - | 0.51 | 3.76 | 1.51 | 1.57 | 0.02 | 0.36 | 0.20 |

| Length (mm) | Diameter (μm) | Young’s Modulus (GPa) | Elongation (%) | Tensile Strength (MPa) | Density, (g/cm3) |

|---|---|---|---|---|---|

| 8 | 39 | 42 | 7 | 1600 | 1.3 |

| Influencing Factors | No. | Interface Type/Average Depth of Sand Filling (mm) | Repair Layer Thickness (mm) |

|---|---|---|---|

| Interface roughness | SHCC-30-R1 | Natural smooth/0 | 30 |

| SHCC-30-R2 | Artificial chiseling/2.64 | 30 | |

| SHCC-30-R3 | Groove/3.5 | 30 | |

| Repair layer thickness | SHCC-20-R2 | Artificial chiseling/2.50 | 20 |

| SHCC-30-R2 | Artificial chiseling/2.64 | 30 | |

| SHCC-40-R2 | Artificial chiseling/2.27 | 40 | |

| SHCC-50-R2 | Artificial chiseling/2.59 | 50 |

| Age (day) | Ft (MPa) | εt (%) | Et (GPa) | ftu, (MPa) | εtu (%) |

|---|---|---|---|---|---|

| 1 | 2.050 ± 0.028 | 0.0237 ± 0.00024 | 8.645 ± 0.064 | 2.945 ± 0.143 | 4.247 ± 0.370 |

| 14 | 2.893 ± 0.125 | 0.0242 ± 0.00076 | 11.945 ± 0.489 | 3.750 ± 0.057 | 4.336 ± 2.956 |

| 28 | 2.950 ± 0.166 | 0.0237 ± 0.00055 | 12.421 ± 0.956 | 3.824 ± 0.219 | 4.331 ± 0.306 |

| 90 | 3.073 ± 0.018 | 0.0223 ± 0.00106 | 13.795 ± 0.586 | 3.950 ± 0.291 | 3.545 ± 0.287 |

| Influencing Factors | No. | Cracks of Repair Layer | Interfacial Delamination | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Time of the First Crack (d) | Number of Cracks | Crack Width | Delamination Position | Delamination Time (d) | Delamination Length (mm) | Delamination Height (mm) | ||||

| Number of Surface Cracks | Number of through Cracks | Average Crack Width (mm) | Maximum Crack Width (mm) | |||||||

| Interface roughness | SHCC-30-R1 | 8 | 11 | 0 | <0.04 | 0.04 | Left Right | 3 4 | 515 515 | 2.71 0.45 |

| SHCC-30-R2 | 9 | 5 | 1 | <0.04 | 0.05 | Left Right | 25 28 | 82 67 | 0.07 0.07 | |

| SHCC-30-R3 | 9 | 9 | 0 | <0.04 | 0.04 | Left Right | 28 28 | 29 20 | 0.08 0.07 | |

| Repair layer thickness | SHCC-20-R2 | 7 | 5 | 1 | <0.04 | 0.05 | Left Right | 19 21 | 28 103 | 0.05 0.08 |

| SHCC-30-R2 | 9 | 5 | 1 | <0.04 | 0.05 | Left Right | 25 28 | 82 67 | 0.07 0.07 | |

| SHCC-40-R2 | 10 | 10 | 0 | <0.04 | 0.04 | Left Right | 25 32 | 42 80 | 0.05 0.08 | |

| SHCC-50-R2 | 13 | 3 | 0 | <0.04 | 0.04 | Left Right | 32 25 | 66 54 | 0.05 0.07 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Jiao, M.; Hu, C.; Tian, L.; Zhao, T.; Lei, D.; Fu, H. Research on Bonding and Shrinkage Properties of SHCC-Repaired Concrete Beams. Materials 2020, 13, 1757. https://doi.org/10.3390/ma13071757

Wang P, Jiao M, Hu C, Tian L, Zhao T, Lei D, Fu H. Research on Bonding and Shrinkage Properties of SHCC-Repaired Concrete Beams. Materials. 2020; 13(7):1757. https://doi.org/10.3390/ma13071757

Chicago/Turabian StyleWang, Penggang, Maopeng Jiao, Chunhong Hu, Li Tian, Tiejun Zhao, Dongyi Lei, and Hua Fu. 2020. "Research on Bonding and Shrinkage Properties of SHCC-Repaired Concrete Beams" Materials 13, no. 7: 1757. https://doi.org/10.3390/ma13071757

APA StyleWang, P., Jiao, M., Hu, C., Tian, L., Zhao, T., Lei, D., & Fu, H. (2020). Research on Bonding and Shrinkage Properties of SHCC-Repaired Concrete Beams. Materials, 13(7), 1757. https://doi.org/10.3390/ma13071757