1. Introduction

The effect of bimodularity of materials on the stress–strain state of beams, plates, and shells under the action of static and dynamic loads was studied in the works of Ambartsumyan and his colleagues [

1,

2,

3], as well as in the works of Jones, Bert [

4,

5,

6], and others. Although these models are often used, there are many unresolved issues related to material modeling. Several works developing classical methods are devoted to the bimodularity of the material in the study of stress–strain state (SSS) for various types of elements of engineering involving building structures (beams, plates, and shells) under the influence of static and dynamic loads. New materials used in engineering and construction also require new approaches for taking into account the heterogeneity of materials.

He et al., in [

7,

8,

9], analytically solved the problem of bending thin plates and beams with different tensile and compression modules based on the existing simplified model. Using the conditions of the continuity for the stress components in an unknown neutral layer, we can determine the location of the neutral layer and derive the fundamental differential equation for deflection, flexural rigidity, and internal forces in a thin plate. The results show that the use of various modules in structural calculations affects the bending stiffness of a flexible thin plate and allows for a more accurate determination of SSS.

A new method for calculating the position of the neutral surface of an orthotropic layered bimodular beam was proposed in [

10] by Kumar et al. Based on this original method, the bending analysis of a thick bimodular layered beam is considered, using the first-order shear strain theory for bimodular materials.

Shah et al. [

11] considered the determination of deformations of a simply supported, uniformly loaded bimodule beam and the decision of the location of the neutral axis. A theoretical model of bimodular and unimodular beams was developed to calculate the maximum deviation, taking into account the displacement of the neutral axis in the case of a bimodular beam. The finite element method was used for comparison, using the concept of the Ambardzumyan bimodular model for simply supported and cantilevered bimodular and unimodular beams with concentrated load, uniformly distributed weight, and gradually changing load. It was found that the maximum deflection for a bimodular beam exceeds the maximum deviation for a unimodular beam for all types of load, which is important in the analysis of deformations of long-span structures.

The method based on the Bernoulli principle was used to calculate reinforced concrete-reinforced beams [

12,

13,

14,

15] from bimodular material. The beam was considered as statically indeterminate. The obtained solutions make it possible to calculate beams of arbitrary shape for various types of statically applied loads reinforced with an arbitrary number of bars.

The consideration of bimodularity when calculating the strength of beams, plates, and shell elements under the action of dynamic loads is critical. The following dynamic problems are considered by Benveniste [

16,

17,

18]: (a) time-dependent harmonic, axial, and circumferential shear loading of a cylindrical cavity; (b) time-dependent normal loading of a spherical cavity. In both cases, the cavities are immersed in an infinite medium which is incompressible and has different behavior under tension and compression. Wave analytical solutions are obtained, the results of which are compared with the results of classical elastic solutions.

The flexural–vibrational behavior of bimodular layered composite cylindrical panels with various boundary conditions is considered in [

19,

20,

21]. The formulation is based on the theory of first-order shear deformation and Bert’s constitutive model. Governing equations are obtained by using the finite element method and the Lagrange equation of motion. An iterative approach to eigenvalues is used to obtain positive and negative frequencies of free oscillations of the half-period and the corresponding modes. A detailed parametric study of the influence of the thickness ratio, aspect ratio, lamination pattern, boundary conditions, and bimodularity coefficient on the free vibration characteristics of bimodular angular and transverse layered composite cylindrical panels was carried out. It is interesting to note that there is a significant difference between the frequencies of positive and negative half-cycles, depending on the panel parameters. The distribution of modal stresses in thickness for the positive half-cycle is significantly different from that for the negative half-period, in contrast to the unimodular case when the stresses at a certain place in the negative half-period would be of the same magnitude but of opposite sign corresponding to the positive half-period. Finally, for a typical case, the effect of bimodularity on the stationary characteristic is studied in comparison with the frequency ratio of forcing. Stresses under dynamic loading are different for the positive and negative half of the vibration cycle.

Many graded materials have different tensile and compression moduli. One-dimensional and two-dimensional mechanical models of a functionally graded beam with a bimodular effect were established for the first time. A material that not only possesses a functionally graded characteristic, but also demonstrates various tensile and compression elastic moduli, is considered in [

22]. Analytical solutions of a bimodular functionally graded beam with pure bending and bending in the transverse direction were obtained, following the gradient function as an exponential expression. It was shown that, due to the introduction of a dual-module functional gradient effect of materials, maximum tensile and compressive bending stresses might not occur in the lower and upper parts of the beam.

A lot of materials demonstrate bimodularity, which is critical in electronics, medicine, engineering, and other industries. Pastor-Artigues et al. determined the mechanical properties of polylactic acid (PLA) under tensile, compressive, and bending stresses [

23]. The finite element model is used to verify differences in tensile and compression characteristics, including geometric non-linearity for realistic reproduction of conditions during physical tests. It is shown that the currently used test methods do not guarantee a consistent set of mechanical properties useful for numerical modeling, emphasizing the need to identify new characterization methods that are better adapted to PLA behavior. Experiments show that PLA has double asymmetry in the behavior of tension and compression, indicating the need to process this material by using a bimodular model of elasticity.

Thus, it can be seen that many materials, including metals, alloys, concrete, organic fabrics, and others, have different properties of stretching and compression. However, this is not taken into account in practical calculations. Moreover, this review shows that the bimodality of materials can have a critical impact on strength calculations, and therefore on the size and durability of structures. Dynamic effects and inertial forces, in combination with the bimodality, significantly change the SSS of structure. Thus, the purpose of this work is to develop a simplified engineering method for analyzing the stress–strain state of bimodular material structure elements under the action of shock loads.

2. Materials and Methods

Let us consider the behavior of metal beams under the action of static and dynamic loads, both with and without bimodularity. For metals, the tensile and compression moduli do not differ much. Therefore, for steel 40 (C 0.37%–0.45%, Si 0.17%–0.37%, Mn 0.5%–0.8%, Ni 0.25%, Cr 0.25%), the elastic modulus of compression

= 216,110 MPa, tensile strength

= 209,990 MPa, for silumin

= 74,920 MPa,

= 209,990 MPa [

24]. The data are presented by Ambardzumyan, according to the results of tests of various materials for uniaxial tension and compression.

The effect of the bimodularity of the material was confirmed by comparing the theoretical value of the maximum deflection () with the experimental ().

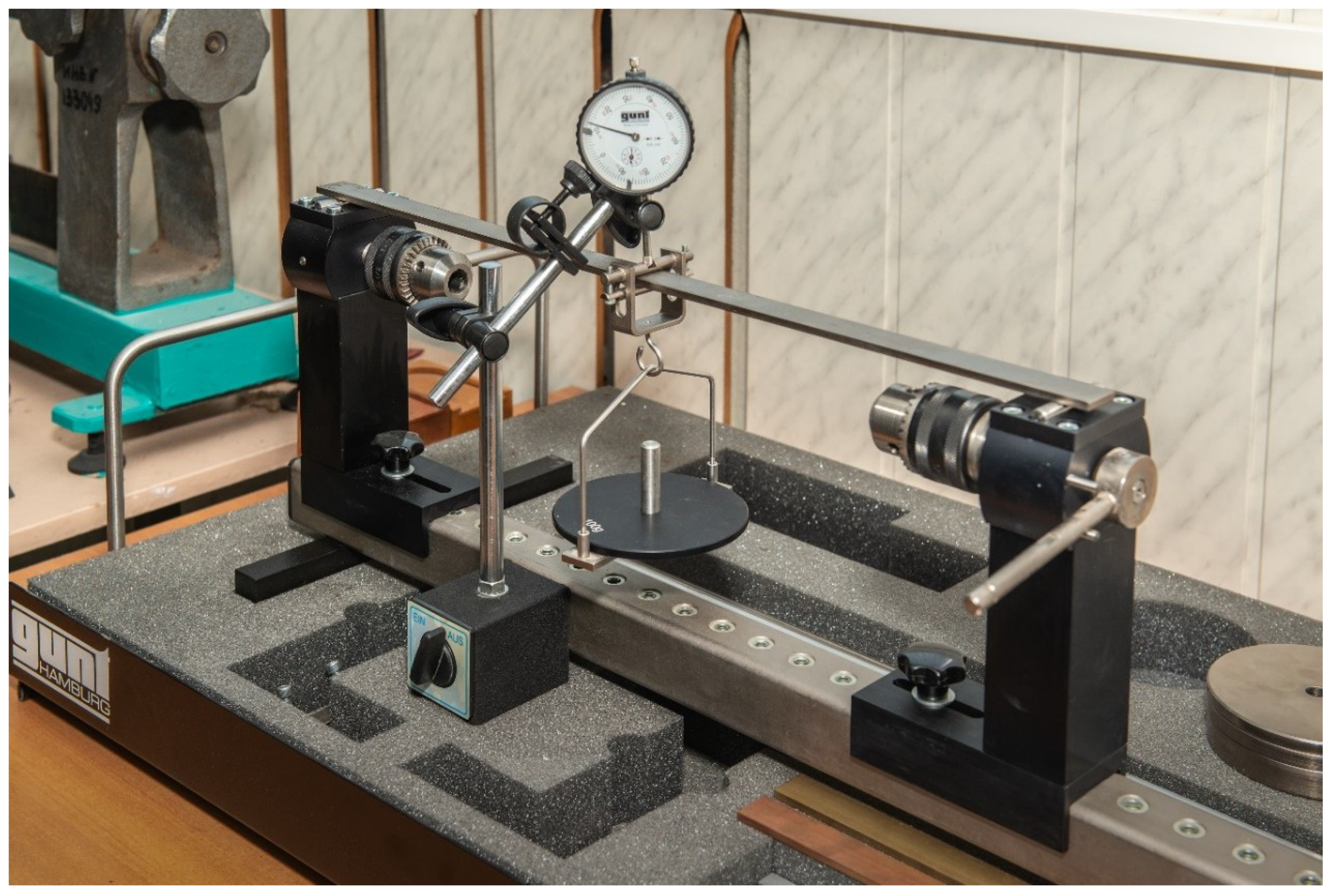

In this work, the values of the maximum deflection of a simply supported rectangular beam 4 × 20 mm are determined under the action of a concentrated force of 10 N, applied in the middle of the span. The experimental study of static deflection was carried out on the device shown in

Figure 1.

During the experiment, a three-point bend of a 4 × 20 mm beam was loaded, and the deflection was measured at the point of application of force (

Figure 1) hour-type indicator. The results are presented in

Table 1 and

Table 2.

We tested articulated beams of rectangular cross-section 4 × 20 mm, under the action of a statically applied concentrated force in the middle of the span. Beam materials were silumin and steel. The deflection in the middle of the beam span was determined. The conducted experiment on metal beams showed a good agreement of the deflection value of the experimental data and the calculated value with the bimodularity of the material. Taking into account the bimodularity allows you to more accurately determine the deflections that coincide with the experiment in statics. The static deflection value is included in the dynamic coefficient formula for determining the maximum normal stresses. A more precise determination of static deflection allows us to determine the dynamic maximum normal stresses more accurately.

In this paper, we study the SSS of a beam made of structural fiber-reinforced concrete. Polyamide fibers are used as fibers. Fiber–concrete as structural or insulating foam concrete (GOST 25485-89) reinforced with fiber (GOST 14613–83) was made in accordance with Russian standards. The use of this material in construction makes it possible to several times lower the heat loss of buildings. For example, the walls of such products prevent significant heat leakage in the winter and protect the indoor climate from excessively high temperatures in the summer. To reduce shrinkage deformations and improve the uniformity of the structure of porous concrete, reinforcing fibers are added to the composition of the mixture for preparing the material. Such filling significantly improves the physical and mechanical properties of finished products. For example, with the addition of polypropylene fiber in an amount of 0.4% of the total cement volume, an increase in the compressive strength of the D400 foam concrete grade is increased to 26%.

The considered type of foam concrete by its functional purpose is divided into three independent groups:

Heat-insulating, density 400–500 kg/m3.

Structurally insulating, 600–1100 kg/m3.

Structural, density 1100–1200 kg/m3.

For a steel beam, the theoretically obtained deflection of the beam, taking into account bimodularity, is 4% more than the experimental one and excluding bimodularity by 5.3%. For a silumin beam, the theoretical deflection is 0.7% more than the experimental one, taking into account bimodularity, and 5.4% without, taking into account bimodularity. The results obtained confirm the need to take into account the bimodularity property when calculating the strength and stiffness of structural elements.

In the calculations of concrete structures, fiber-reinforced concrete with a tensile–compression modulus of 5000 MPa was used, if the material is considered as isotropic. Finding the heterogeneous properties of concrete, various elastic moduli under the tension of 5000 MPa and compression of 2550 MPa are accepted in the calculations.

3. A Heterogeneous (Bimodule) Model of a Beam

A heterogeneous (bimodule) model of a reinforced beam under the action of static loads is presented as a beam consisting of two layers: stretched, compressed, and reinforcement bars. Considering the beam as statically indeterminable, we obtain the equilibrium equation for a heterogeneous beam,

and condition for compatibility of deformations of a heterogeneous beam,

where

are the bending moment and curvature of the beam;

are the bending moment and curvature of the beam of the zone under tension;

are the bending moment and curvature of the beam of the zone under compression; and

are the bending moment and curvature of reinforced bars.

The equilibrium condition (1)

expressed in terms of normal stresses has the following form:

where

—normal stress and cross-sectional area of the beam of the stretched zone;

—normal stress and cross-sectional area of the beam in the compression zone; and

—normal stress and cross-sectional area of reinforcement bars.

By substituting normal stresses

into (3), we obtain the neutral line curvature formula for a beam of bimodular material:

For a beam, we have the general curvature formula:

where

D is the reduced stiffness of the beam of bimodular material;

is the modulus of elasticity of the material in the tensile zone;

is the modulus of elasticity of the material in the compression zone;

is the modulus of elasticity of the reinforcement;

is the moment of inertia of that part of the cross section that lies in the stretch zone relative to the neutral axis;

is the moment of inertia of that part of the cross-section, which lies in the compression zone, relative to the neutral axis;

is a moment of inertia of the cross section of the reinforcement, which lies in the tension zone, relative to its own central axis;

is the moment of inertia of the cross section of the reinforcement, which lies in the compression zone, relative to its own central axis;

is the number of reinforcement bars in the tension zone;

is the number of reinforcement bars in the compression zone;

is the cross-sectional area of the reinforcement in the tension zone,

is the cross-sectional area of the reinforcement in the compression zone;

is the distance from the reinforcement in the tension zone to the neutral axis; and

is the distance (coordinate) from bars in the compression zone to the neutral axis.

From Equations (4) and (5), we obtain the reduced-stiffness expression for reinforced beams of heterogeneous material

D:

To determine the position of the neutral line, we consider another static equation—the projection onto the axis of the bar,

:

By substituting

in Equation (7), we obtain the following:

where

is the static moment of that part of the cross-section that lies in the tension zone, relative to the neutral axis; and

is the static moment of that part of the cross-section that lies in the compression zone, relative to the neutral axis.

Normal stress formulas taking into account Equations (4) and (5) have the following form:

For a rectangular cross-section, Equation (9) for the maximum normal tensile stress

and the maximum normal compressive stress

, taking into account the bimodularity of the material for reinforced beams during bending under static loads, has the following form [

11]:

where

h is the height of the beam;

b is the width of the beam;

is the bending moment relative to the neutral line in an arbitrary cross-section of the beam;

is the tensile modulus of reinforcement bars;

is the modulus of elasticity of concrete (aggregate) in tension;

is the axial moment of inertia of the cross-section of one reinforcement bar in the tensile zone;

is the modulus of elasticity of concrete (aggregate) in compression;

is the axial moment of inertia of the cross-section of one reinforcement bar in the compression zone;

is the number of bars in the compression zone;

is the number of bars in the tension zone; and

.

The stressed state of the beam was investigated under the action of concentrated force applied in the middle of the span of articulated metal and reinforced concrete beams. The impact is considered as an absolutely plastic impact of an absolutely rigid body on the elastic system, taking into account the hypothesis of proportionality of the dynamic and static characteristics of the stress–strain state of the body. The dynamic coefficient (

) [

25] is determined to take into account and without taking into account the bimodularity of the beam material.

The formulas determine the dynamic coefficient.

Considering the mass of the beam:

where

h is the height of the load;

is the static beam deflection under load, without taking into account the mass of the beam;

is the mass of the falling load;

is the reduced beam mass, according to Cox [

26].

For a simply supported beam, loaded in the middle of the span L, , where is the distributed mass of the beam, and L is the length of the beam.

As can be seen in

Table 3, the dynamic coefficient decreases with the increasing ratio

, and

= 2. Therefore, the initial data were taken in this study, ensuring the strength and rigidity of the beam and allowing us to study in enough detail the effect of various parameters on impact strength.

5. Conclusions

The method proposed in this work makes it possible to consider reinforced beam structural elements under the action of shock loads made of bimodular material. When comparing the experimental values of the deflections with the theoretical ones, it is evident (

Table 1 and

Table 2) that taking into account bimodularity gives a more accurate value of the deflection.

The value of the dynamic coefficient for metal beams is practically independent of bimodularity, since the elastic moduli under tension and compression differ little for metals. Taking into account the mass of the metal beam, the more the difference between the tensile and compression modules (

Table 4 and

Table 5), the more the dynamic coefficient and dynamic normal stresses decrease.

The obtained calculations (

Table 5 and

Table 6) show that taking into account the bimodularity of the material with given loads and mechanical characteristics of concrete affects the value of the dynamic coefficient by 45 times less than taking into account the mass of the beam compared to taking into account the bimodularity of the material.

The dynamic coefficient for the location of reinforcing bars in both the stretched and compressed zones is greater than the dynamic coefficient for the location of reinforcing bars only in the extended zone by 8%.

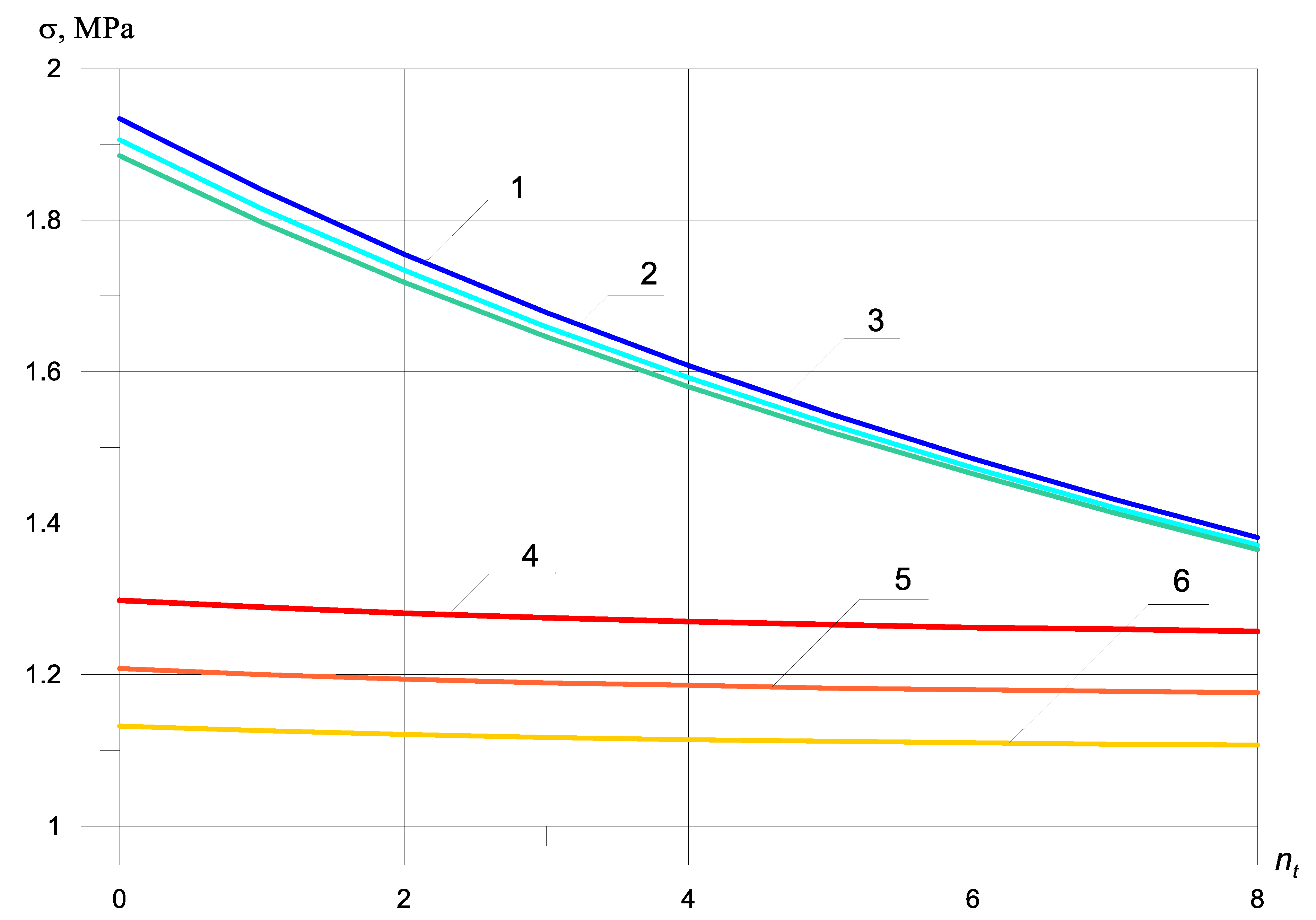

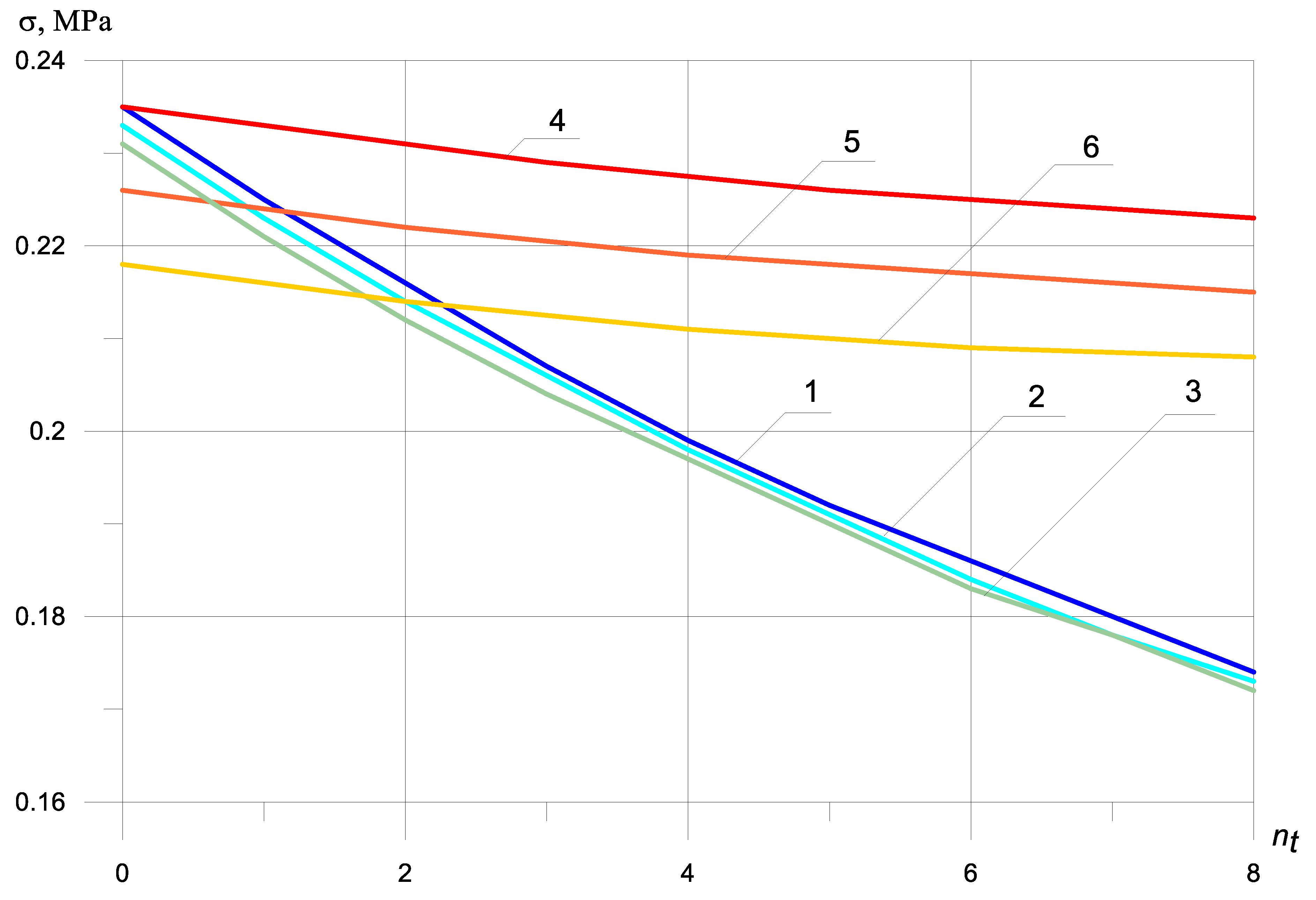

The dependence of the maximum tensile and normal compressive stresses on the number of reinforcing bars located in the compressed and elongated ones showed a qualitative and quantitative difference between the graphs shown in

Figure 2 and

Figure 3, with and without taking into account the bimodularity of the beam material. When taking into account the mass of the beam (

Figure 4 and

Figure 5), dynamic stresses decrease on average by 700%.

The study conducted in this work shows that, for reinforced bimodular beams’ calculation under impact load, the stress state depends on many factors:

The ratio of the mass of the beam and the mass of impact load;

The ratio of the height with which the load falls and the magnitude of the static deflection under the load;

The ratio of tensile and compression moduli;

The location of reinforcing bars in a compressed and stretched zone.

The method proposed in this work makes it possible to analyze in detail the influence of all the above factors for arbitrarily supported beams, with a cross-section of various rectangular shapes, with different mechanical characteristics of the material, and with different locations of the reinforcing bars of the beams under impact loads.