Influence of Nominal Maximum Aggregate Size and Aggregate Gradation on Pore Characteristics of Porous Asphalt Concrete

Abstract

1. Introduction

2. Objectives

3. Materials and Methods

3.1. Materials and Sample Preparation

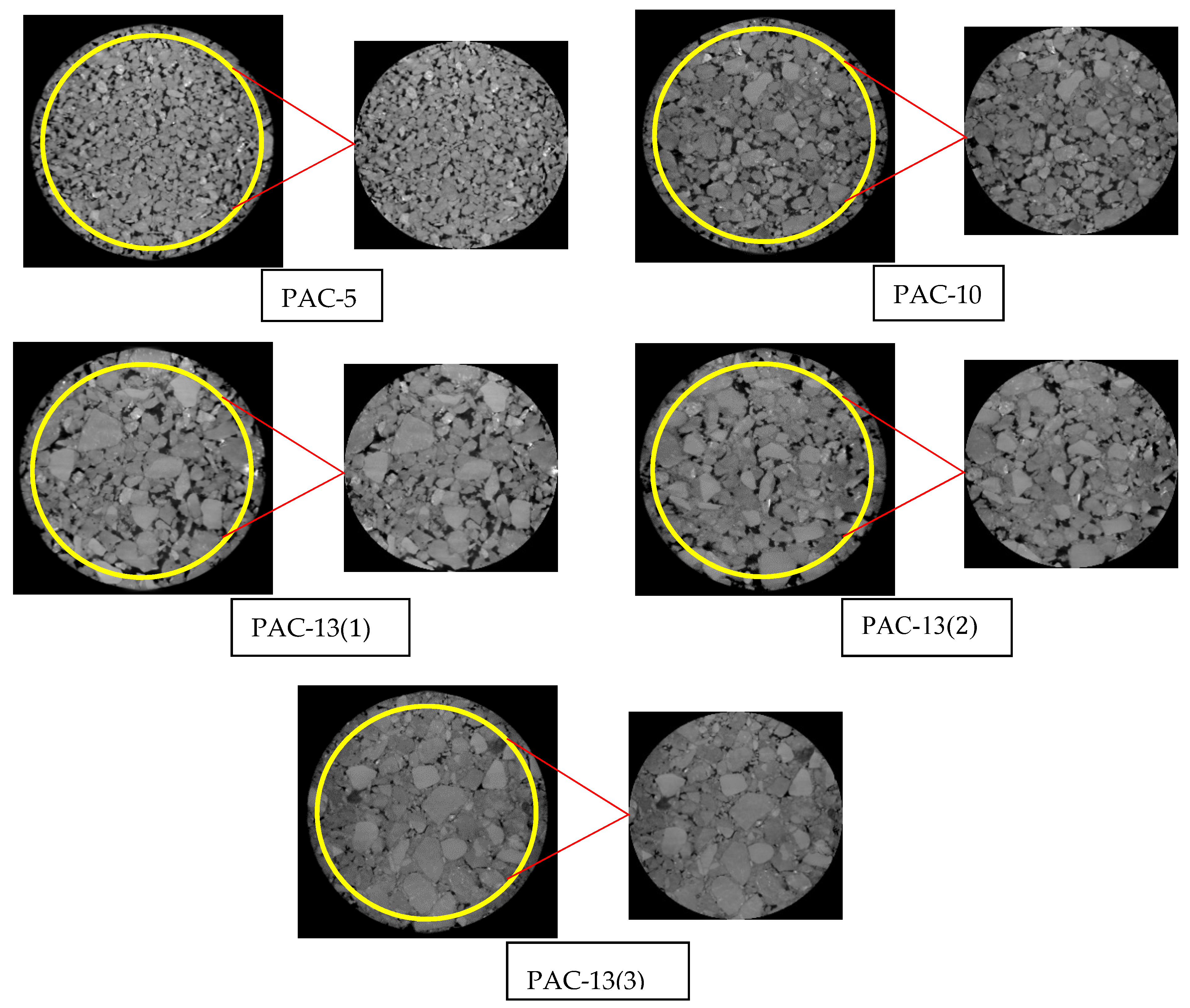

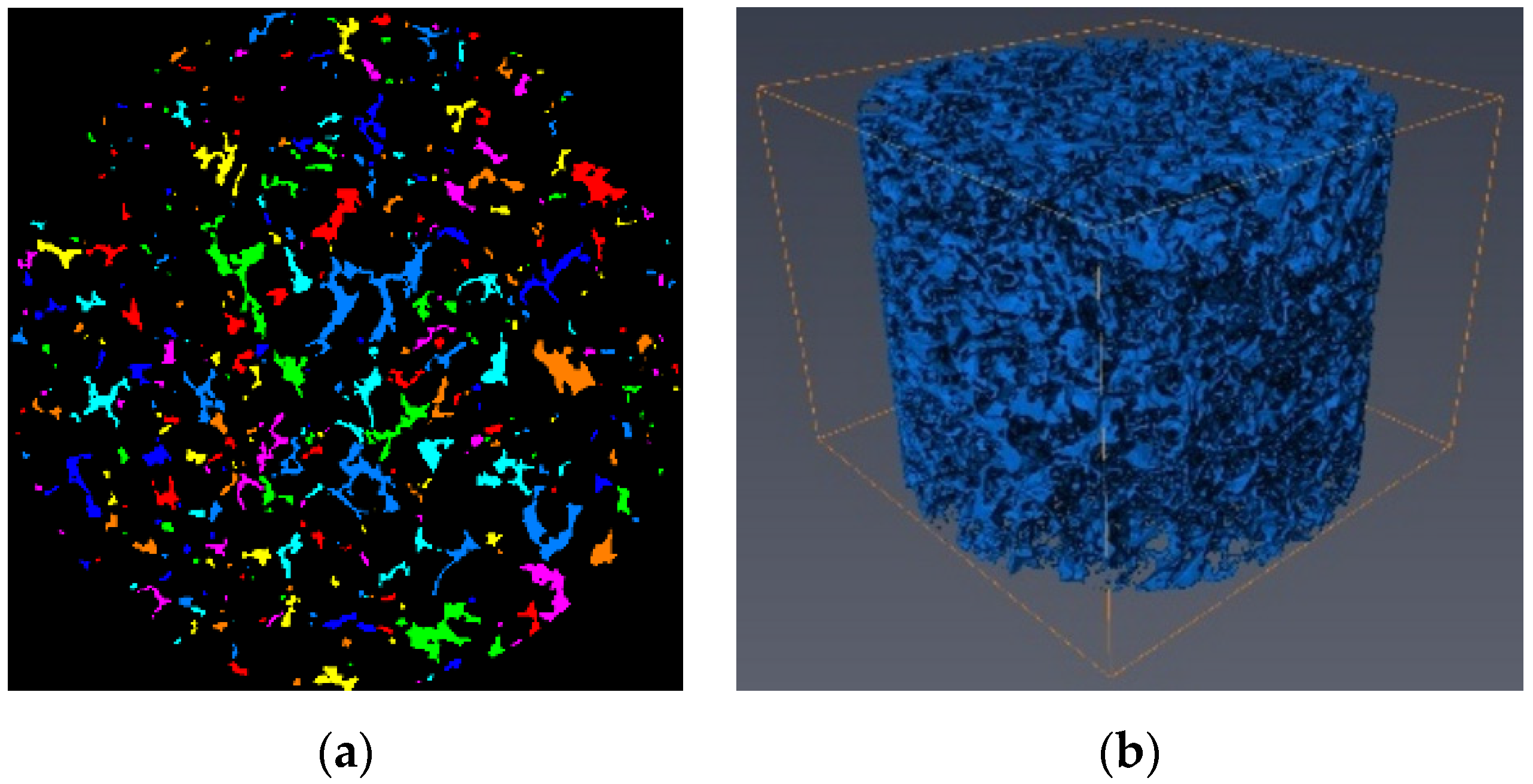

3.2. X-Ray Computer Tomography (CT) Scanning and Digital Image Segmentation

3.3. Characteristics of Air Void

3.3.1. Equivalent Void Diameter

3.3.2. Pore Circularity

4. Results and Discussion

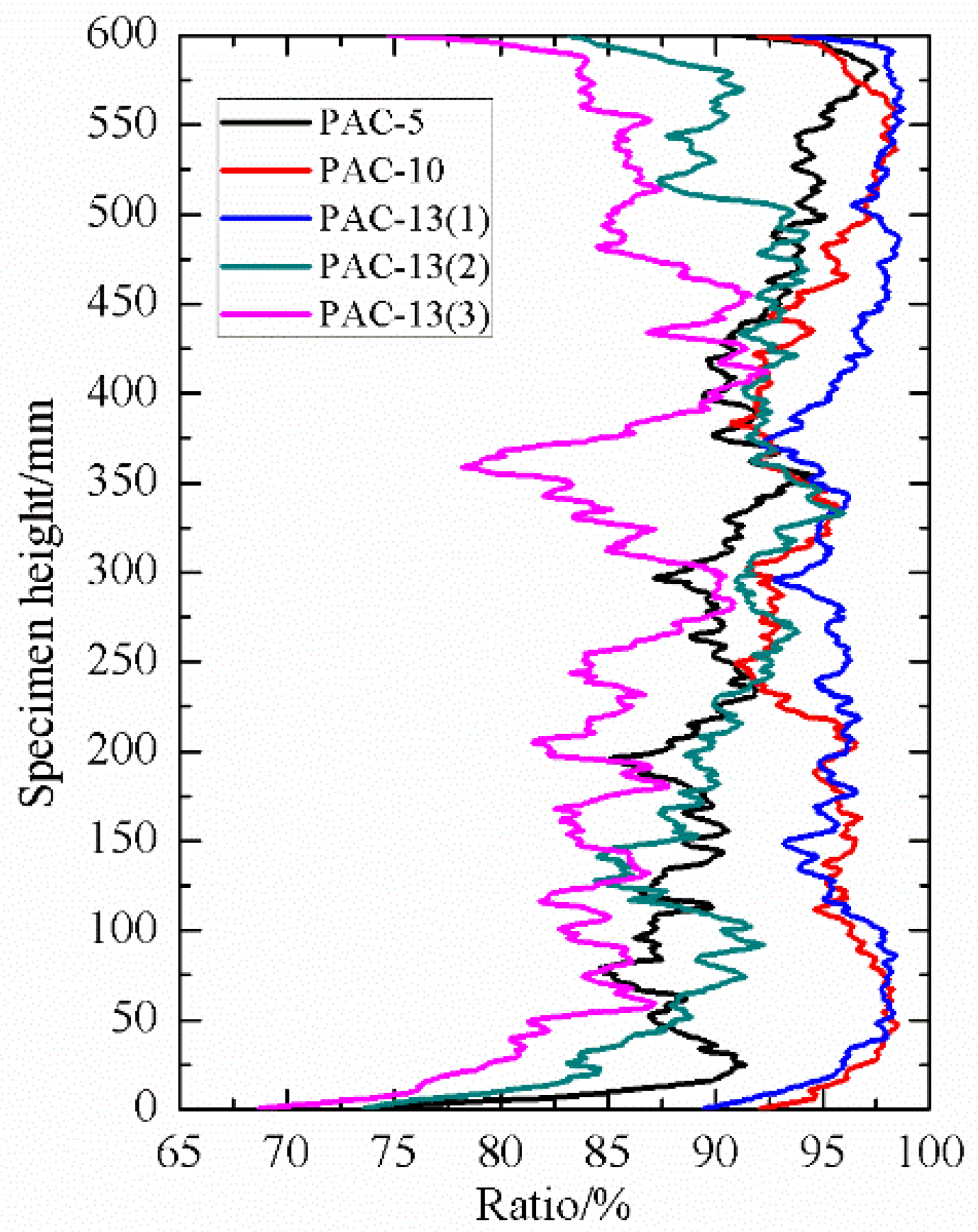

4.1. Pore Distribution

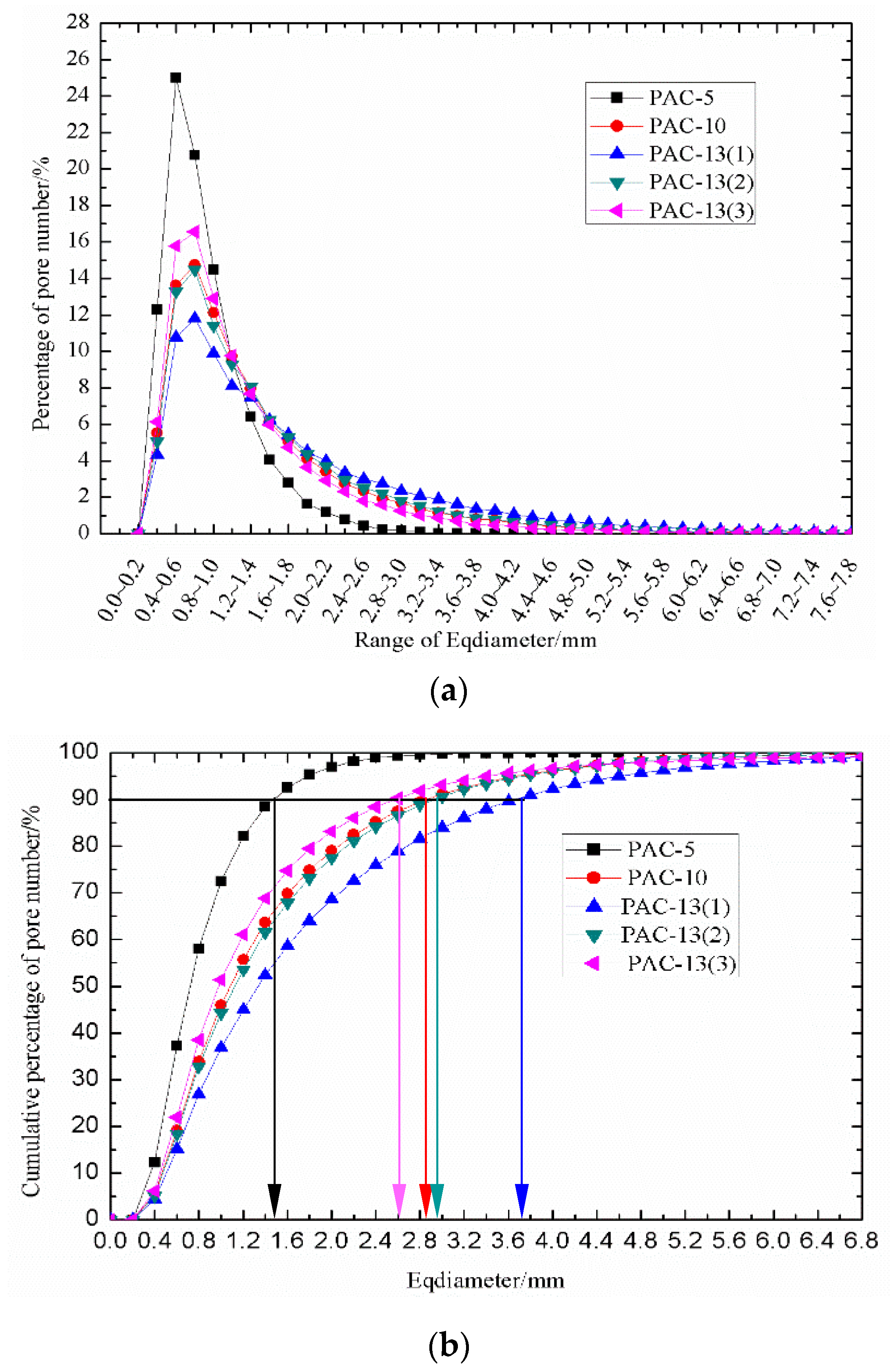

4.2. Void Dimensional Property

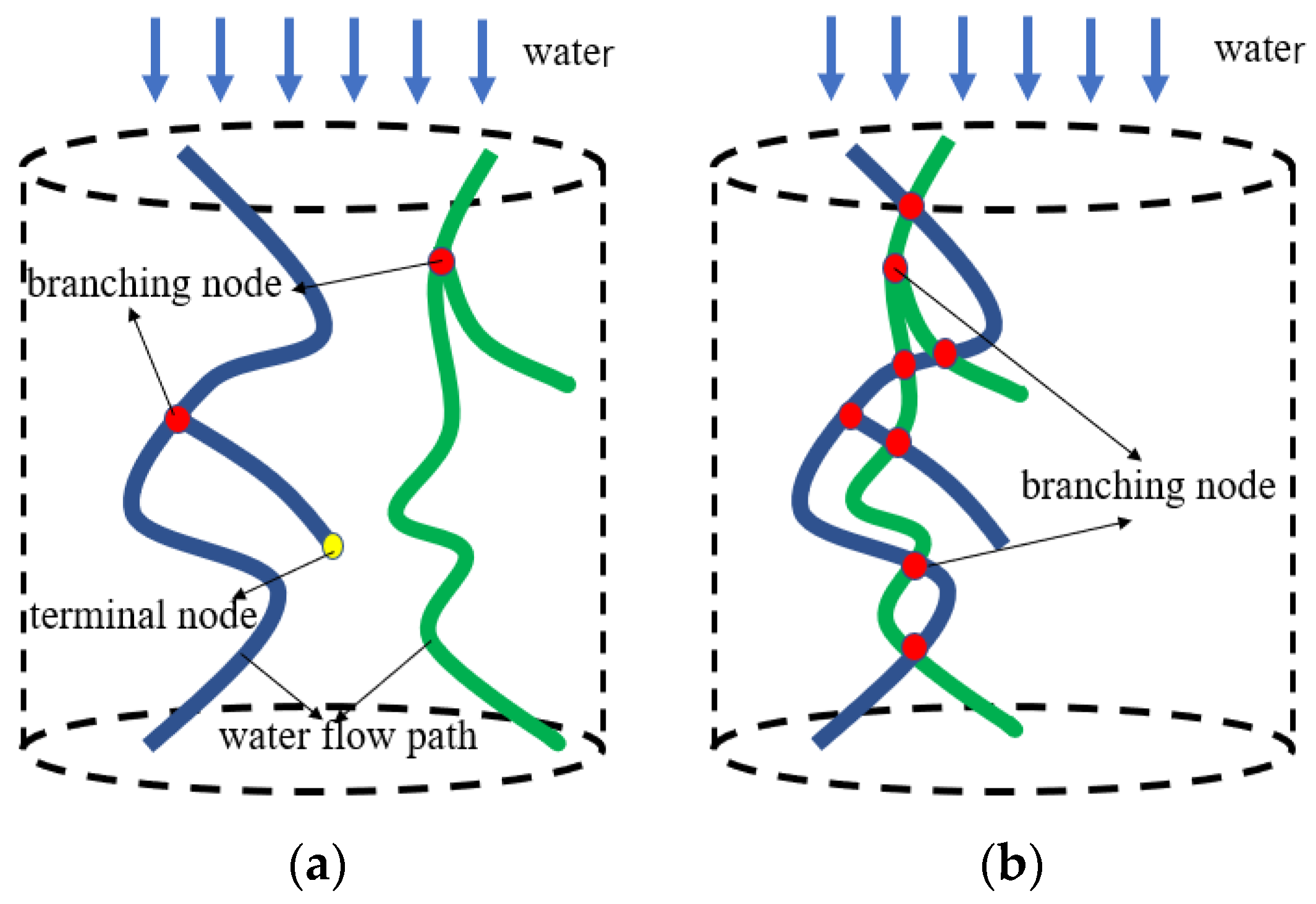

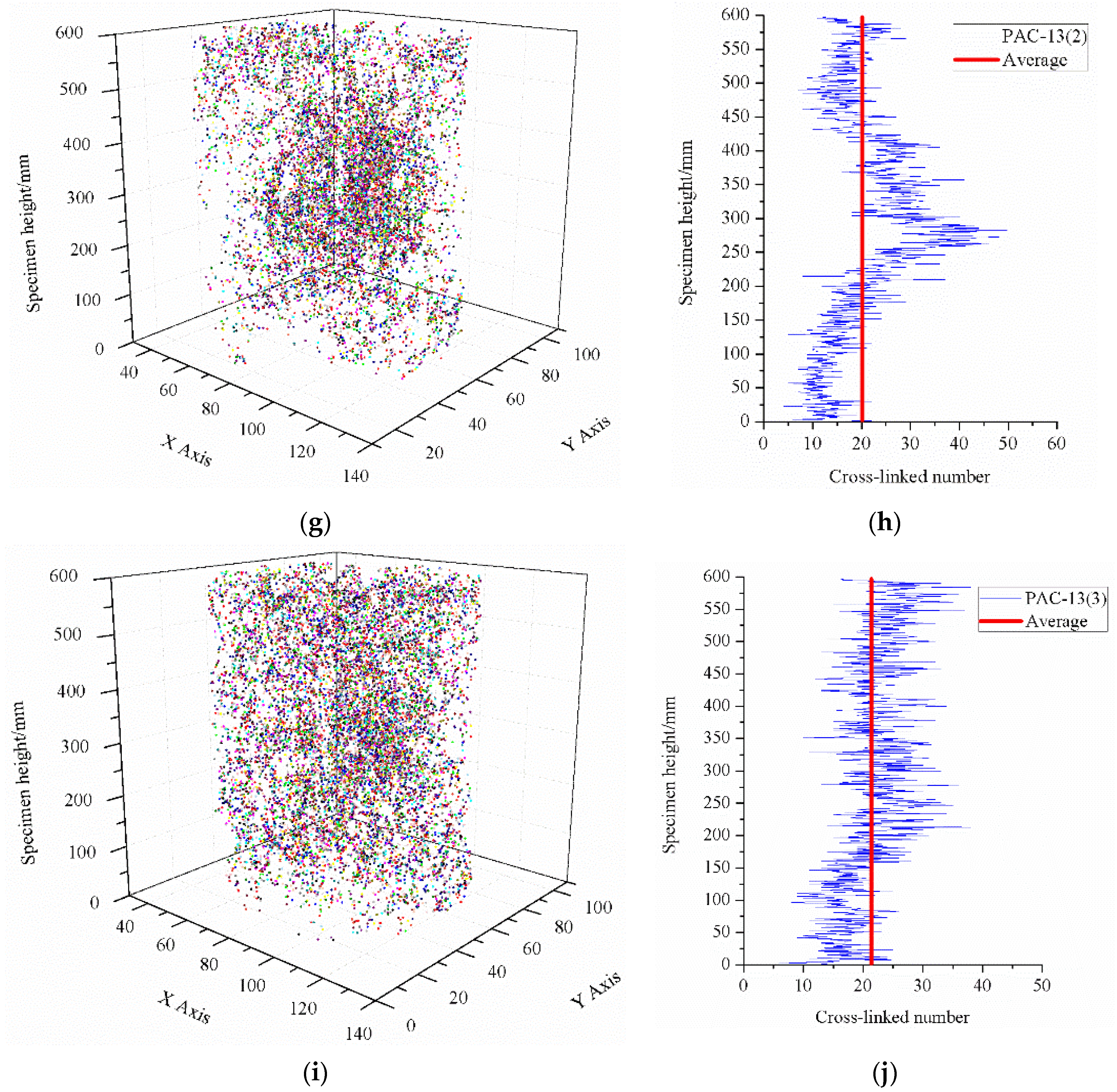

4.3. A New Proposed Void Connnectivity Index: Cross-Linked Number

5. Conclusions

- 1)

- PAC specimens with a high maximum aggregate size tend to have a slightly higher connectivity. However, the mean percentages of connected pores to total pores for porous asphalt concrete with the same target air void content were all above 90%, which means that the maximum aggregate size will not have a significant effect on the percentage of connected pores to total pores for porous asphalt concrete. Furthermore, the percentage of connected pores is related to the air void content, but for PAC-13 with a 20% target air void content or above, the connectivity does not seem to have a sharp increase.

- 2)

- Porous asphalt concrete with a smaller nominal particle size or lower target air void content seems to generate a more concentrated distribution of Eqdiameter. Furthermore, pore circularities for porous asphalt concrete with a maximum aggregate size of 10 mm or above are independent of maximum aggregate sizes, and air void contents ranging from 16% to 21% do not have a significant effect on the voids’ circularity.

- 3)

- The branching nodes in porous asphalt concrete with a smaller nominal maximum aggregate size or lower target air void content seem to have a more uniform spatial distribution. However, the percentage of cross-linked number to total node rises as the nominal maximum aggregate size or target air void content increases. This finding indicates that porous asphalt concrete with larger nominal maximum aggregate sizes or target air void content seems to have a greater inter-connectivity.

6. Further Research

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, B.; Chen, J.; Li, M.; Cao, D.; Ping, S.; Zhang, Y.; Wang, W. Experimental investigation of preventive maintenance materials of porous asphalt mixture based on high viscosity modified bitumen. Constr. Build. Mater. 2016, 124, 681–689. [Google Scholar] [CrossRef]

- Wang, X.; Gu, X.; Dong, Q.; Wu, J.; Jiang, J. Evaluation of permanent deformation of multilayer porous asphalt courses using an advanced multiply-repeated load test. Constr. Build. Mater. 2018, 160, 19–29. [Google Scholar] [CrossRef]

- Garcia, A.; Aboufoul, M.; Asamoah, F.; Jing, D. Study the influence of the air void topology on porous asphalt clogging. Constr. Build. Mater. 2019, 227, 116791. [Google Scholar] [CrossRef]

- Yang, B.; Li, H.; Zhang, H.; Xie, N.; Zhou, H. Laboratorial investigation on effects of microscopic void characteristics on properties of porous asphalt mixture. Constr. Build. Mater. 2019, 213, 434–446. [Google Scholar] [CrossRef]

- Cui, P.; Wu, S.; Xiao, Y.; Niu, Y.; Yuan, G.; Lin, J. 3D reconstruction of moisture damage resulted volumetric changes in porous asphalt mixture. Constr. Build. Mater. 2019, 228, 116658. [Google Scholar] [CrossRef]

- Aboufoul, M.; Chiarelli, A.; Triguero, I.; Garcia, A. Virtual porous materials to predict the air void topology and hydraulic conductivity of asphalt roads. Powder Technol. 2019, 352, 294–304. [Google Scholar] [CrossRef]

- Kutay, M.E. Modeling Moisture Transport in Asphalt Pavements; University of Maryland: Baltimore, MD, USA, 2005. [Google Scholar]

- Suresha, S.N.; George, V.; Shankar, A.U.R. Laboratory and theoretical evaluation of clogging behavior of porous friction course mixes. Int. J. Pavement Eng. 2010, 11, 61–70. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Hasan, M.R.M.; Ven, M. Permeability loss in porous asphalt due to binder creep. Constr. Build. Mater. 2012, 30, 10–15. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Zhu, H. Investigation of permeability of open graded asphalt mixture considering effects of anisotropy and two-dimensional flow. Constr. Build. Mater. 2017, 145, 318–325. [Google Scholar] [CrossRef]

- Plessis, A.; Boshoff, W.P. A review of X-ray computed tomography of concrete and asphalt construction materials. Constr. Build. Mater. 2019, 199, 637–651. [Google Scholar] [CrossRef]

- Jerjen, I.; Poulikakos, L.D.; Plamondon, M.; Schuetz, P.; Flisch, A. Drying of Porous Asphalt Concrete Investigated by X-Ray Computed Tomography. Phys. Procedia 2015, 69, 451–456. [Google Scholar] [CrossRef]

- Zhang, Y.; Verwaal, W.; van de Ven, M.F.C.; Molenaar, A.A.A.; Wu, S.P. Using high-resolution industrial CT scan to detect the distribution of rejuvenation products in porous asphalt concrete. Constr. Build. Mater. 2015, 100, 1–10. [Google Scholar] [CrossRef]

- Alber, S.; Ressel, W.; Liu, P.; Hu, J.; Wang, D.; Oeser, M.; Uribe, D.; Steeb, H. Investigation of microstructure characteristics of porous asphalt with relevance to acoustic pavement performance. Int. J. Transp. Sci. Technol. 2018, 7, 199–207. [Google Scholar] [CrossRef]

- Alber, S.; Ressel, W.; Liu, P.; Wang, D.; Oeser, M. Influence of soiling phenomena on air-void microstructure and acoustic performance of porous asphalt pavement. Constr. Build. Mater. 2018, 158, 938–948. [Google Scholar] [CrossRef]

- Mahmud, M.Z.H.; Hassan, N.A.; Hainin, M.R.; Ismail, C.R. Microstructural investigation on air void properties of porous asphalt using virtual cut section. Constr. Build. Mater. 2017, 155, 485–494. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, X.; Jiang, J.; Zhou, L. Characterization of interconnectivity, size distribution and uniformity of air voids in porous asphalt concrete using X-ray CT scanning images. Constr. Build. Mater. 2019, 213, 182–193. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Hu, M.; Wang, J. Study on the pores characteristics and permeability simulation of pervious concrete based on 2D/3D CT images. Constr. Build. Mater. 2019, 200, 687–702. [Google Scholar] [CrossRef]

- Ćosić, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of aggregate type and size on properties of pervious concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Wang, J.; Hu, M. Influence of aggregate size on compressive strength of pervious concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Linking pore system characteristics to the compressive behavior of pervious concrete, Cement. Cem. Concr. Compos. 2016, 70, 130–138. [Google Scholar] [CrossRef]

- Suresa, S.N.; Varghese, G.; Shankar, R. Effect of aggregate gradations on properties of porous friction course mixes. Mater. Struct. 2010, 43, 789–801. [Google Scholar] [CrossRef]

- Mansour, T.N.; Putman, B.J. Influence of aggregate gradation on the performance properties of porous asphalt mixtures. J. Mater. Civ. Eng. 2013, 25, 281–288. [Google Scholar] [CrossRef]

- Martin, W.D.; Putman, B.J.; Andrew, I. Influence of aggregate gradation on clogging characteristics of porous asphalt mixtures. J. Mater. Civ. Eng. 2014, 26, 14–26. [Google Scholar] [CrossRef]

- Chen, J.; Li, H.; Huang, X.; Wu, J. Permeability loss of open-graded friction course mixtures due to deformation-related and particle-related clogging: Understanding from a laboratory investigation. J. Mater. Civ. Eng. 2015, 27, 15–23. [Google Scholar] [CrossRef]

- Katuwal, S.; Moldrup, P.; Lamandé, M.; Tuller, M.; de Jonge, L.W. Effects of CT number derived matrix density on preferential flow and transport in amacroporous agricultural soil. Vadose Zone J. 2015, 14, 7. [Google Scholar] [CrossRef]

- Li, Z.; Liu, D.; Cai, Y.; Ranjith, P.G.; Yao, Y. Multi-scale quantitative characterization of 3-D pore-fracture networks in bituminous and anthracite coals using FIB-SEM tomography and X-ray μ-CT. Fuel 2017, 209, 43–53. [Google Scholar] [CrossRef]

- Tang, B.; Gao, S.; Wang, Y.; Liu, X.; Zhang, N. Pore structure analysis of electrolytic manganese residue based permeable brick by using industrial CT. Constr. Build. Mater. 2019, 208, 697–709. [Google Scholar] [CrossRef]

- Zhou, H.; Li, H.; Abdelhady, A.; Liang, X.; Wang, H.; Yang, B. Experimental investigation on the effect of pore characteristics on clogging risk of pervious concrete based on CT scanning. Constr. Build. Mater. 2019, 212, 130–139. [Google Scholar] [CrossRef]

- Aboufoul, M.; Garcia, A. Factors affecting hydraulic conductivity of asphalt mixture. Mater. Struct. 2017, 50, 116. [Google Scholar] [CrossRef]

- Aboufoul, M.; Garcia, A. Influence of air voids characteristics on the hydraulic conductivity of asphalt mixture. Road Mater. Pavement Des. 2017, 18, 39–49. [Google Scholar] [CrossRef]

- Luo, L.; Lin, H.; Li, S. Quantification of 3-D soil macropore networks in different soil types and land uses using computed tomography. J. Hydrol. 2010, 393, 53–64. [Google Scholar] [CrossRef]

| Sieve Size (mm) | Percentage Passing (%) | ||||

|---|---|---|---|---|---|

| PAC-5 | PAC-10 | PAC-13(1) | PAC-13(2) | PAC-13(3) | |

| 16 | – | – | 100.0 | 100.0 | 100.0 |

| 13.2 | – | 100.0 | 87.0 | 87.0 | 87.0 |

| 9.5 | 100.0 | 84.7 | 63.7 | 63.7 | 63.7 |

| 4.75 | 90.0 | 22.8 | 22.0 | 22.0 | 28.3 |

| 2.36 | 21.1 | 15.6 | 16.5 | 19.3 | 22.1 |

| 1.18 | 20.0 | 12.6 | 14.0 | 14.0 | 14.0 |

| 0.6 | 15.5 | 9.4 | 9.2 | 10.2 | 10.2 |

| 0.3 | 11.9 | 6.5 | 6.3 | 7.2 | 7.2 |

| 0.15 | 9.1 | 5.1 | 4.5 | 5.2 | 5.2 |

| 0.075 | 7.0 | 4.6 | 4.0 | 4.7 | 4.7 |

| Asphalt binder (%) | 6.3 | 5.7 | 5.67 | 5.8 | 5.9 |

| Target air void content (%) | 20 | 20 | 20 | 18 | 16 |

| Materials | Physical Properties | Unit | Test Results | Test Method |

|---|---|---|---|---|

| Coarse Aggregate | Relative Apparent Density | – | 2.601 | T0304 |

| Water Absorption | % | 0.93 | T0304 | |

| Aggregate Crushed Value | % | 18.25 | T0316 | |

| Fine Aggregate | Relative Apparent Density | – | 2.653 | T0328 |

| Clay Content | % | 1.2 | T0333 | |

| Sand Equivalent | % | 75 | T0334 | |

| Mineral Filler | Relative Apparent Density | – | 2.606 | T0352 |

| Moisture Content | % | 0.8 | T0332 | |

| High-viscosity Modified Asphalt | Softening Point | °C | 81.8 | T0606 |

| Penetration at 25 °C | 0.1 mm | 43.1 | T0604 | |

| Viscosity at 135 °C | Pa.s | 4.72 | T0619 |

| Aggregate Gradation | PAC-5 | PAC-10 | PAC-13(1) | PAC-13(2) | PAC-13(3) |

|---|---|---|---|---|---|

| Target air void content/% | 20 | 20 | 20 | 18 | 16 |

| Mean percentage of connected pore to total pore /% | 90.6 | 94.1 | 96.2 | 90.1 | 85.2 |

| Aggregate gradation | PAC-5 | PAC-10 | PAC-13(1) | PAC-13(2) | PAC-13(3) |

| Mean pore circularity | 0.74 | 0.59 | 0.62 | 0.62 | 0.59 |

| Aggregate gradation | PAC-5 | PAC-10 | PAC-13(1) | PAC-13(2) | PAC-13(3) |

| Percentage of cross-linked number to total Node/% | 66.1 | 77.0 | 79.0 | 71.5 | 69.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.; Cai, X.; Li, X.; Cui, W.; Wu, K. Influence of Nominal Maximum Aggregate Size and Aggregate Gradation on Pore Characteristics of Porous Asphalt Concrete. Materials 2020, 13, 1355. https://doi.org/10.3390/ma13061355

Huang W, Cai X, Li X, Cui W, Wu K. Influence of Nominal Maximum Aggregate Size and Aggregate Gradation on Pore Characteristics of Porous Asphalt Concrete. Materials. 2020; 13(6):1355. https://doi.org/10.3390/ma13061355

Chicago/Turabian StyleHuang, Wenke, Xu Cai, Xiang Li, Wentian Cui, and Kuanghuai Wu. 2020. "Influence of Nominal Maximum Aggregate Size and Aggregate Gradation on Pore Characteristics of Porous Asphalt Concrete" Materials 13, no. 6: 1355. https://doi.org/10.3390/ma13061355

APA StyleHuang, W., Cai, X., Li, X., Cui, W., & Wu, K. (2020). Influence of Nominal Maximum Aggregate Size and Aggregate Gradation on Pore Characteristics of Porous Asphalt Concrete. Materials, 13(6), 1355. https://doi.org/10.3390/ma13061355