Grain Growth Behavior of 0.95(Na0.5Bi0.5)TiO3–0.05BaTiO3 Controlled by Grain Shape and Second Phase

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, M.S.; Fisher, J.G.; Lee, H.Y.; Kang, S.-J.L. Diffusion-induced interface migration and mechanical property improvement in the lead magnesium niobate-lead titanate system. J. Am. Ceram. Soc. 2003, 86, 1988–1990. [Google Scholar] [CrossRef]

- Jung, Y.I.; Yoon, D.Y.; Kang, S.-J.L. Coarsening of polyhedral grains in a liquid matrix. J. Mater. Res. 2009, 24, 2949–2959. [Google Scholar] [CrossRef]

- Kang, S.-J.L.; Lee, M.G.; An, S.M. Microstructural evolution during sintering with control of the interface structure. J. Am. Ceram. Soc. 2009, 92, 1464–1471. [Google Scholar] [CrossRef]

- Kang, Y.-M.; Moon, K.-S. Magnetic properties of Ce–Mn substituted M-type Sr-hexaferrites. Ceram. Int. 2015, 41, 12828–12834. [Google Scholar] [CrossRef]

- Park, J.; Hong, Y.K.; Lee, W.; An, S.Y.; Seo, J.W.; Hur, K.H. Coercivity of SrFe12O19 hexaferrite platelets near single domain size. IEEE Magn. Lett. 2015, 6, 1–3. [Google Scholar] [CrossRef]

- Moon, K.-S.; Kang, Y.-M. Synthesis, structure, and magnetic properties of M-W hexaferrite composites. Ceram. Int. 2017, 43, 14309–14313. [Google Scholar] [CrossRef]

- Kinoshita, K.; Yamaji, A. Grain-size effects on dielectric properties in barium titanate ceramics. J. Appl. Phys. 1976, 47, 371–373. [Google Scholar] [CrossRef]

- Huo, S.; Yuan, S.; Tian, Z.; Wang, C.; Qiu, Y. Grain size effects on the ferroelectric and piezoelectric properties of Na0.5K0.5NbO3 ceramics prepared by pechini method. J. Am. Ceram. Soc. 2012, 95, 1383–1387. [Google Scholar] [CrossRef]

- Jung, Y.-I. Effect of Grain Boundary Structure on Grain Growth in BaTiO3 below the Eutectic Temperature. Ph.D. Thesis, Korea Advanced Institute of Science and Technology, Daejeon, Korea, 2006. [Google Scholar]

- Kim, M.S.; Fisher, J.G.; Kang, S.-J.L.; Lee, H.Y. Grain growth control and solid-state crystal growth by Li2O/PbO addition and dislocation introduction in the PMN-35PT system. J. Am. Ceram. Soc. 2006, 89, 1237–1243. [Google Scholar] [CrossRef]

- Fisher, J.G.; Choi, S.Y.; Kang, S.-J.L. Abnormal grain growth in barium titanate doped with alumina. J. Am. Ceram. Soc. 2006, 89, 2206–2212. [Google Scholar] [CrossRef]

- Jo, W.; Kim, D.Y.; Hwang, N.M. Effect of interface structure on the microstructural evolution of ceramics. J. Am. Ceram. Soc. 2006, 89, 2369–2380. [Google Scholar] [CrossRef]

- Choi, S.Y.; Kang, S.-J.L.; Chung, S.Y. Abnormal grain growth and intergranular amorphous film formation in BaTiO3. J. Am. Ceram. Soc. 2007, 90, 645–648. [Google Scholar] [CrossRef]

- Yoon, B.K.; Choi, S.Y.; Yamamoto, T.; Ikuhara, Y.; Kang, S.J.L. Grain boundary mobility and grain growth behavior in polycrystals with faceted wet and dry boundaries. Acta Mater. 2009, 57, 2128–2135. [Google Scholar] [CrossRef]

- Yang, D.-Y.; Kang, S.-J.L. Suppression of abnormal grain growth in WC-Co via pre-sintering treatment. Int. J. Refract. Met. Hard Mater. 2009, 27, 90–94. [Google Scholar] [CrossRef]

- Fisher, J.G.; Rout, D.; Moon, K.-S.; Kang, S.-J.L. Structural changes in potassium sodium niobate ceramics sintered in different atmospheres. J. Alloy. Compd. 2009, 479, 467–472. [Google Scholar] [CrossRef]

- Fisher, J.G.; Kang, S.-J.L. Microstructural changes in (K0.5Na0.5)NbO3 ceramics sintered in various atmospheres. J. Eur. Ceram. Soc. 2009, 29, 2581–2588. [Google Scholar] [CrossRef]

- Moon, K.-S.; Kang, S.-J.L. Coarsening behavior of round-edged cubic grains in the Na1/2Bi1/2TiO3-BaTiO3 system. J. Am. Ceram. Soc. 2008, 91, 3191–3196. [Google Scholar] [CrossRef]

- Moon, K.S.; Rout, D.; Lee, H.Y.; Kang, S.J.L. Effect of TiO2 addition on grain shape and grain coarsening behaviour in 95Na1/2Bi1/2O3-BaTiO3. J. Eur. Ceram. Soc. 2011, 31, 1915–1920. [Google Scholar] [CrossRef]

- Jung, S.H.; Kang, S.J.L. Repetitive grain growth behaviour with increasing temperature and grain boundary roughening in a model nickel system. Acta Mater. 2014, 69, 283–291. [Google Scholar] [CrossRef]

- Moon, K.-S.; Lim, E.-S.; Kang, Y.-M. Effect of Ca and La substitution on the structure and magnetic properties of M-type Sr-hexaferrites. J. Alloy. Compd. 2019, 771, 350–355. [Google Scholar] [CrossRef]

- Boutz, M.M.R.; Winnubst, A.J.A.; Burggraaf, A.J. Yttria-ceria stabilized tetragonal zirconia polycrystals: Sintering, grain growth and grain boundary segregation. J. Eur. Ceram. Soc. 1994, 13, 89–102. [Google Scholar] [CrossRef]

- Kang, S.J.L. Sintering: Densification, Grain Growth and Microstructure; Elsevier Butterworth-Heinemann: Oxford, UK, 2005. [Google Scholar]

- Park, Y.J.; Hwang, N.M.; Yoon, D.Y. Abnormal growth of faceted (WC) grains in a (Co) liqiud matrix. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 1996, 27, 2809–2819. [Google Scholar] [CrossRef]

- Kwon, S.K.; Hong, S.H.; Kim, D.Y.; Hwang, N.M. Coarsening behavior of tricalcium silicate (C3S) and dicalcium silicate (C2S) grains dispersed in a clinker melt. J. Am. Ceram. Soc. 2000, 83, 1247–1252. [Google Scholar] [CrossRef]

- Kang, C.H.; Yoon, D.N. Coarsening of cobalt grains dispersed in liquid copper matrix. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 1981, 12, 65–69. [Google Scholar] [CrossRef]

- Rohrer, G.S.; Rohrer, C.L.; Mullins, W.W. Coarsening of faceted crystals. J. Am. Ceram. Soc. 2002, 85, 675–682. [Google Scholar] [CrossRef]

- Choi, S.Y.; Kang, S.-J.L. Control of boundary structure and grain growth for microstructural design. Mater. Science Forum 2004, 475, 3891–3896. [Google Scholar]

- Chung, S.Y.; Kang, S.-J.L.; Dravid, V.P. Effect of sintering atmosphere on grain boundary segregation and grain growth in niobium-doped SrTiO3. J. Am. Ceram. Soc. 2002, 85, 2805–2810. [Google Scholar] [CrossRef]

- Lee, B.K.; Chung, S.Y.; Kang, S.-J.L. Grain boundary faceting and abnormal grain growth in BaTiO3. Acta Mater. 2000, 48, 1575–1580. [Google Scholar] [CrossRef]

- Cho, Y.K.; Yoon, D.Y. Singular grain boundaries in BaTiO3 with excess TiO2. Mater. Trans. 2004, 45, 2083–2090. [Google Scholar] [CrossRef]

- Cho, Y.K.; Yoon, D.Y.; Kim, B.K. Surface roughening transition and coarsening of NbC grains in liquid cobalt-rich matrix. J. Am. Ceram. Soc. 2004, 87, 443–448. [Google Scholar] [CrossRef]

- Takenaka, T.; Maruyama, K.-I.; Sakata, K. (Bi0.5Na0.5)TiO3-BaTiO3 system for lead-free piezoelectric ceramics. Jpn. J. Appl. Phys. 1991, 30, 2236–2239. [Google Scholar] [CrossRef]

- Takenaka, T.; Nagata, H.; Hiruma, Y.; Yoshii, Y.; Matumoto, K. Lead-free piezoelectric ceramics based on perovskite structures. J. Electroceramics 2007, 19, 259–265. [Google Scholar] [CrossRef]

- Wang, X.X.; Choy, S.H.; Tang, X.G.; Chan, H.L.W. Dielectric behavior and microstructure of (Bi1/2Na1/2)TiO3-(Bi1/2K1/2)TiO3-BaTiO3 lead-free piezoelectric ceramics. J. Appl. Phys. 2005, 97, 1–4. [Google Scholar] [CrossRef]

- Mesrar, M.; Lamcharfi, T.; Echatoui, N.; Abdi, F.; Harrach, A.; Ahjyaje, F.Z. Hydrothermal synthesis, microstructure and electrical properties of (1-x)(Na0.5Bi0.5)TiO3-xBaTiO3 ceramics. Moroc. J. Quant. Qual. Res. 2019, 1, 14–24. [Google Scholar]

- Wei, Y.-F.; Chung, H.-H.; Yang, C.-F.; Chen, K.-H.; Diao, C.-C.; Kao, C.-H. The influence of different fabrication processes on characteristics of excess Bi2O3-doped 0.95 (Na0.5Bi0.5)TiO3–0.05 BaTiO3 ceramics. J. Phys. Chem. Solids 2008, 69, 934–940. [Google Scholar] [CrossRef]

- Ge, W.; Liu, H.; Zhao, X.; Pan, X.; He, T.; Lin, D.; Xu, H.; Luo, H. Growth and characterization of Na0.5Bi0.5TiO3-BaTiO3 lead-free piezoelectric crystal by the TSSG method. J. Alloy. Compd. 2008, 456, 503–507. [Google Scholar] [CrossRef]

- Zener, C. Grains, phase and interfaces: An interpretation of microstructures. Am. Inst. Min. Metall. Engrs. 1949, 175, 15–51. [Google Scholar]

- Choi, K.; Hwang, N.M.; Kim, D.Y. Effect of grain shape on abnormal grain growth in liquid-phase-sintered Nb1-xTixC-Co alloys. J. Am. Ceram. Soc. 2002, 85, 2313–2318. [Google Scholar] [CrossRef]

- Johnson, J.L.; Brezovsky, J.J.; German, R.M. Effect of liquid content on distortion and rearrangement densification of liquid-phase-sintered W-Cu. Metall. Mater. Trans. A: Phys. Metall. Mater. Sci. 2005, 36, 1557–1565. [Google Scholar] [CrossRef]

- Dong, W.M.; Jain, H.; Harmer, M.P. Liquid phase sintering of alumina, I. Microstructure evolution and densification. J. Am. Ceram. Soc. 2005, 88, 1702–1707. [Google Scholar] [CrossRef]

- German, R.M.; Suri, P.; Park, S.J. Review: Liquid phase sintering. J. Mater. Sci. 2009, 44, 1–39. [Google Scholar] [CrossRef]

- Chen, S.T.; Xu, Q.; Chen, W.; Zhou, J.; Li, Y.M.; Sun, H.J. Characterization of (Na1/2Bi1/2)TiO3 perovskite-type oxides synthesized by citrate method. Rare Met. Mater. Eng. 2005, 34, 50–53. [Google Scholar]

- Zhao, M.L.; Wang, C.L.; Zhong, W.L.; Wang, J.F.; Chen, H.C. Electrical properties of (Bi0.5Na0.5)TiO3 ceramic prepared by sol-gel method. Acta Phys. Sin. 2003, 52, 229–232. [Google Scholar]

- Cernea, M.; Vasile, B.S.; Capiani, C.; Ioncea, A.; Galassi, C. Dielectric and piezoelectric behaviors of NBT-BT0.05 processed by sol–gel method. J. Eur. Ceram. Soc. 2012, 32, 133–139. [Google Scholar] [CrossRef]

- Hiruma, Y.; Makiuchi, Y.; Aoyagi, R.; Nagata, H.; Takenaka, T. Lead-free piezoelectric ceramic based on (Bi1/2Na1/2)TiO3-(Bi1/2K1/2)TiO3-BaTiO3 solid solution. Ceram. Trans. 2006, 174, 139–146. [Google Scholar]

- Sasaki, A.; Chilba, T.; Mamiya, Y.; Otsuki, E. Dielectric and piezoelectric properties of (Bi1/2Na1/2)TiO3-(Bi0.5K0.5)TiO3 system. Jpn. J. Appl. Phys. 1999, 38, 5564–5567. [Google Scholar] [CrossRef]

- Li, H.D.; Feng, C.D.; Xiang, P.H. Dielectric behavior and piezoelectric properties of La3+-doping 0.94(Na1/2Bi1/2)TiO3-0.06BaTiO3 ceramics. J. Inorg. Mater. 2004, 19, 579–585. [Google Scholar] [CrossRef]

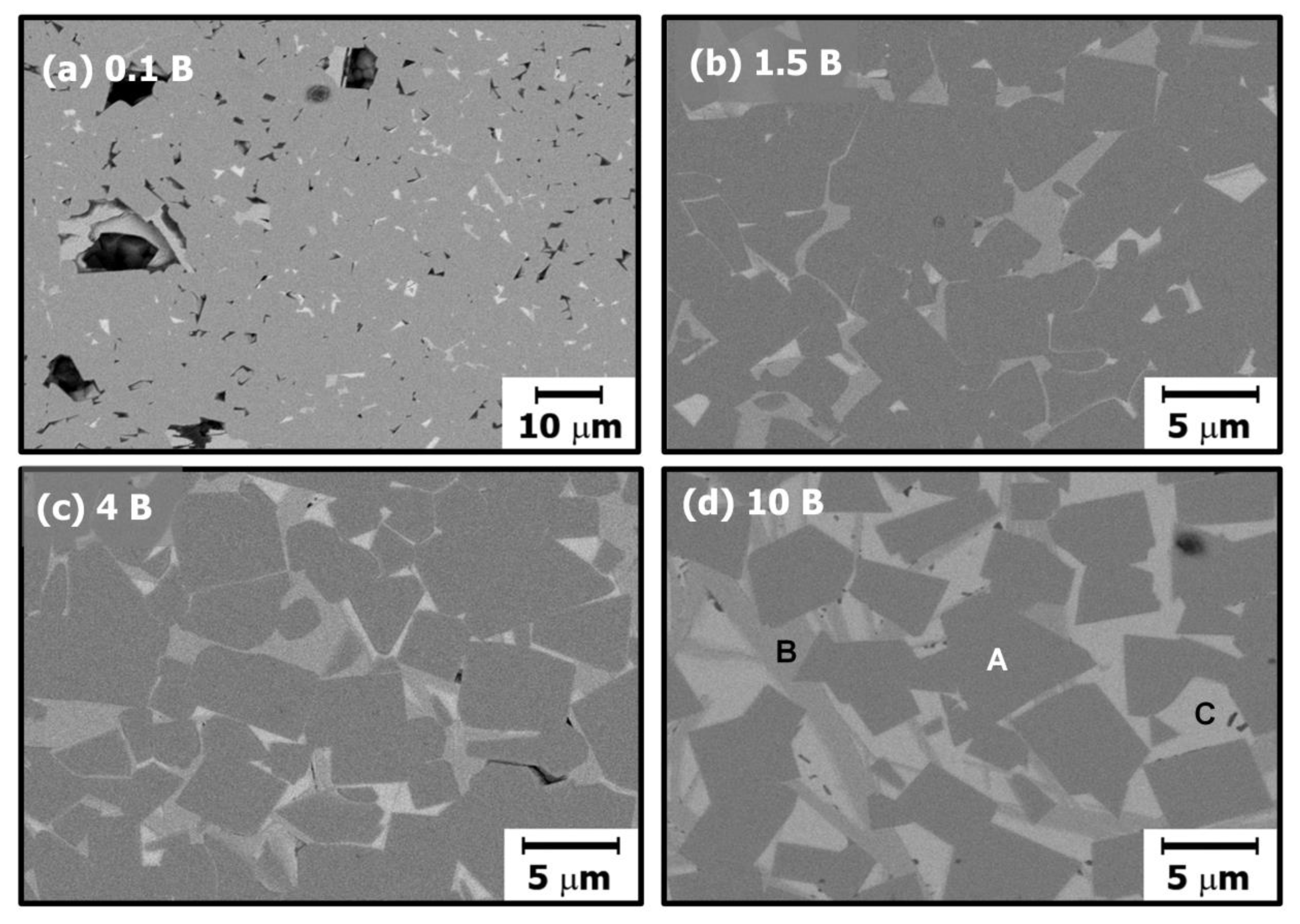

| Area | Na | Bi | Ti | O |

|---|---|---|---|---|

| Grain (A) | 11.94 at% | 11.17 at% | 26.52 at% | 50.38 at% |

| 2nd Phase (B) | – | 27.78 at% | 24.48 at% | 47.74 at% |

| Liquid (C) | – | 54.98 at% | 04.21 at% | 40.82 at% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, S.-C.; Fisher, J.G.; Kang, S.-J.L.; Moon, K.-S. Grain Growth Behavior of 0.95(Na0.5Bi0.5)TiO3–0.05BaTiO3 Controlled by Grain Shape and Second Phase. Materials 2020, 13, 1344. https://doi.org/10.3390/ma13061344

Jeon S-C, Fisher JG, Kang S-JL, Moon K-S. Grain Growth Behavior of 0.95(Na0.5Bi0.5)TiO3–0.05BaTiO3 Controlled by Grain Shape and Second Phase. Materials. 2020; 13(6):1344. https://doi.org/10.3390/ma13061344

Chicago/Turabian StyleJeon, Sang-Chae, John G. Fisher, Suk-Joong L. Kang, and Kyoung-Seok Moon. 2020. "Grain Growth Behavior of 0.95(Na0.5Bi0.5)TiO3–0.05BaTiO3 Controlled by Grain Shape and Second Phase" Materials 13, no. 6: 1344. https://doi.org/10.3390/ma13061344

APA StyleJeon, S.-C., Fisher, J. G., Kang, S.-J. L., & Moon, K.-S. (2020). Grain Growth Behavior of 0.95(Na0.5Bi0.5)TiO3–0.05BaTiO3 Controlled by Grain Shape and Second Phase. Materials, 13(6), 1344. https://doi.org/10.3390/ma13061344