2.1. Analytical Model

Due to the different ratio of volume under load and the number of fatigue cracking initiation and propagation points, the fatigue strength for rotary bending loading is higher than for axial loading (tension/compression). Fatigue tests for rotary bending are shorter and more cost-efficient.

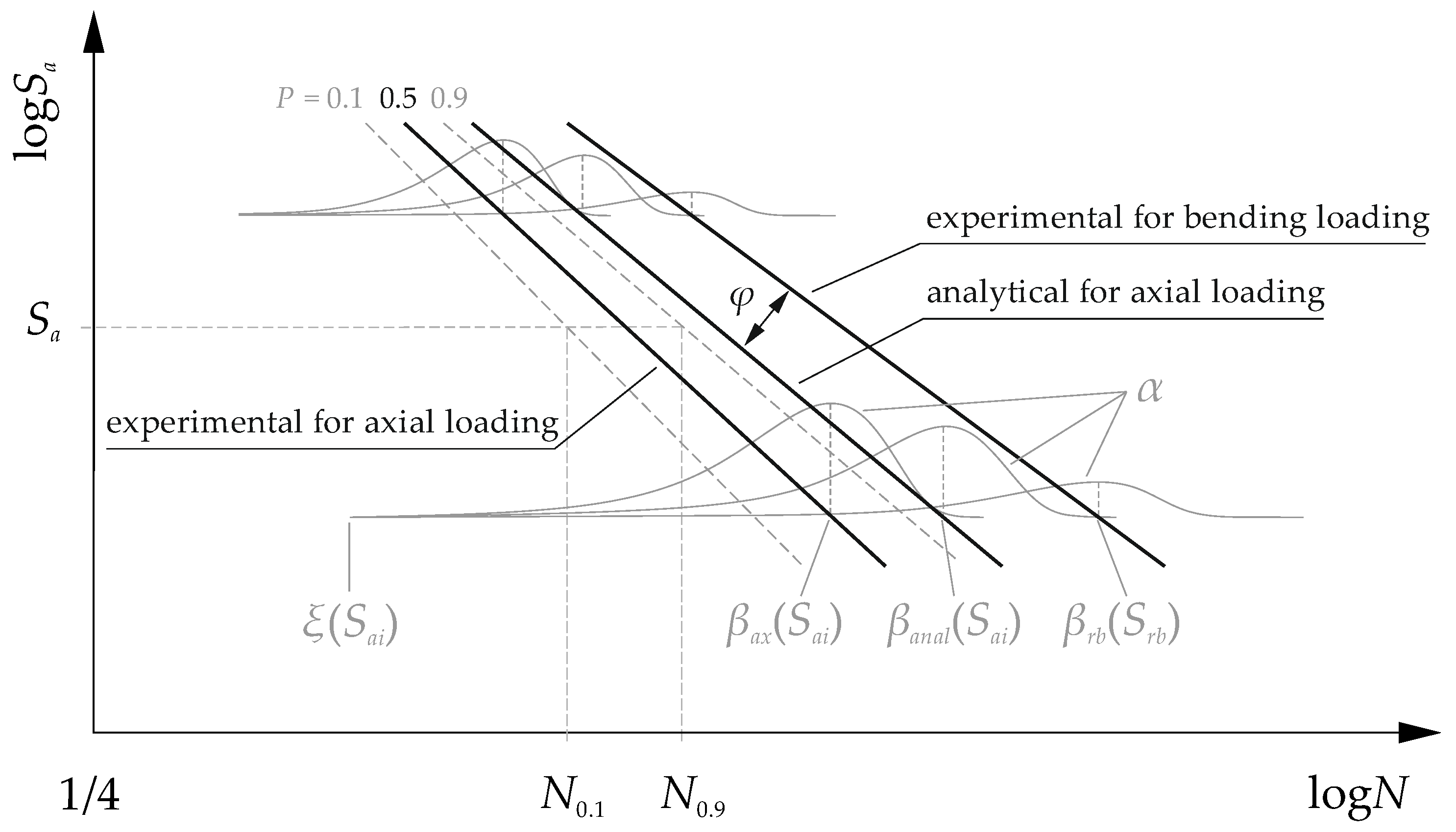

S-N characteristics for rotary bending were used as a basis for the analysis. The fatigue limit for axial loading was estimated on the basis of those results. The probability of failure for any stress level (

P = 0.1; 0.5; 0.9) was used to extend the relationship between the stress and the number of cycles. The spread of fatigue strength in the high cycle range decreased with increasing stress amplitude, which did not describe the Basquin model with normal distribution presented in the normative document [

19]. The Weibull distribution function was used to describe this spread. A graphic representation of the calculations and the Weibull distribution function parameters is pictured in

Figure 1. A correction coefficient

φ was used to evaluate the effects of the loading mode:

where

Sax is the fatigue strength for axial loading and

Srb is the fatigue strength for bending loading.

The weakest link theory presented by Weibull in [

11] assuming that stressed volume is divided in a finite number of infinitesimal links. The probability of failure in each link is the same. This probability of failure can be represented by the 3-parameters Weibull cumulative distribution function for general volume, and can be expressed by the following [

11]:

where

V0 is the reference volume,

V is the volume of material that is subjected to stress,

N is the fatigue life,

ξ is the location parameter,

σ is the scale coefficient, and

α is the shape parameter in the

S-N characteristic equation. Equations (3)–(8) kept the same description of the variables.

For uniform stress distribution (subscript 0) (equation axial loading for a round specimen):

For nonuniform stress distribution (subscript 1), it can be written [

20,

21]:

Assuming that shape and location parameters are in common and only differ in the scale parameter for two stress distributions, which is the variable allowing the following to be written:

To satisfy the assumption that the probability of failure is the same for two different stress distributions, we have:

From Equation (6), the scale parameter for nonuniform stress distribution and uniform stress distribution at the same probability of failure satisfy:

It is assumed that the fatigue life is the same (

N1 =

N0), because the fatigue strength changes for the different types of loading. Then, Equation (6) takes the following form:

Assuming that the Weibull distribution presented above describes an

S-N characteristic, the location parameter and the scale parameter by regression line can be defined. Finally, the equation for

S-N characteristics is defined by the following formula:

where

α is the shape parameter,

Ni is the number of cycles,

ξ(

Sai) is the location parameter (

ξ(

Sai) = 10

n⋅log(Sai)+d),

β(

Sai) is the scale parameter (

β(

Sai) = 10

m⋅log(Sai)+b),

d and

b are the constant term in the

S-N characteristics equation,

m and

n is the slope coefficient in the

S-N characteristics equation, subscript

i is the stress level ordinal number. Equations (10)–(13), (15)–(17) kept the same description of the variables. Substituting the scale parameter to Equation (8) gives:

In Equation (10), it is assumed that the scale coefficient in the

S-N characteristic for different type loading is the same, which is proven in the following part of this article. The final form of Equation (10) is:

The weakest link theory model was used to estimate the fatigue strength for axial load. The equation is presented in [

21,

22] for axial loading (subscript

ax):

For bending loading (subscript

rb):

Implementation of the Weibull weakest link theory assumes comparison of a highly-stressed volume or a highly-stressed surface area. The surface area was analytically calculated using the following formula:

where

d corresponds to

Sg = 0.95

Smax (

Figure 2).

The constant term

bax in the

S-N characteristics equation for axial loading depends on the type of load. For an area, it is defined by the following formula:

The highly-stressed volume was numerically calculated using the finite element method (

Section 2.2) for rotary bending (

Vrb V) and pure bending (

Vrb S). The constant term

bax for rotary bending takes the form:

and for pure bending:

2.3. Experimental Tests

The analytical models were verified on the basis of experimental data for AW 6063 T6 aluminum alloy, S355J2+C structural steel, and 1.4301 acid-resistant steel. The mechanical properties were determined on the basis of monotonic tensile tests according to PN-EN ISO 6892-1:2016 [

24].

Table 1 presents the average values.

High-cycle fatigue tests were conducted on a specimen made from a 10 mm drawn bar. The minimum diameter of the working section of the round specimen with a cross-section was 5 mm (

Figure 4).

Experimental tests were carried out at axial load on an Instron 8874 hydraulic testing machine and at rotary bending load on the test stand. A symmetric sinusoidal cycle (

R = −1) was used for the axial load. The tests were carried out in accordance with international standards [

19,

25,

26]. The purpose was to determine the

S-N characteristic for a load-controlled test. The end of the test criterion was a micro-fracture of the specimen. Figure 7 show a graphic representation of the results. The maximum likelihood method was used to estimate the parameters for a 3-parameters Weibull distribution and was described in [

27,

28]. Linear regression equation parameters for both loading modes are included in

Table 2. A statistical parallelism test was conducted for the characteristics in accordance with [

29]. It can be assumed that the characteristics for AW 6063 aluminum alloy are parallel. At this stage, the assumption for the analytical model to estimate the fatigue strength should allow for the parallelism of the characteristics, depending on the material.

Correction coefficient

φ values were determined on the basis of the obtained data.

Table 3 presents the experimental test results. The calculations were conducted for the extreme values of the fatigue strength for a specific range of tests. Structural steel is more sensitive to changes in loading mode.

The analysis of coefficient

a of the regression line equation involved comparison of the experimental values of gamma distribution. The distributions were determined on the basis of the analysis of the experimental data for the

S-N characteristics. The static distribution equation was expressed as follows [

30,

31]:

where

λ,

k are the gamma distribution parameters (size, shape), and

Γ() is the Euler function.

Table 4 shows the gamma distribution parameters for coefficient

a. The fifth and sixth columns indicate the results of the statistical test

χ2 in accordance with the following formula [

31]:

where

r is the number of classes,

ni is the empirical numbers of subsequent classes,

pi is the theoretical frequencies of the class and

n is the sample size.

The gamma distribution values were similar for the distribution of coefficient

a in the tensile and bending tests, which may indicate a similar distribution. To verify the null hypothesis on the uniform distribution in both loading cases, a conformity test for two populations was conducted, the Mann–Whitney U test [

29]. Value of

W amounted to 1011.5, and the

p-value amounted to 0.8646 (it was assumed that the null hypothesis can be rejected if the

p-value is lower than 0.05). This fact means that there is no basis to reject the null hypothesis.

Figure 5 shows the distribution of coefficient

a, taking into account the values obtained experimentally for the steel materials.