Effect of Strain Rates on the Stress–Strain Behavior of FRP-Confined Pre-Damaged Concrete

Abstract

1. Introduction

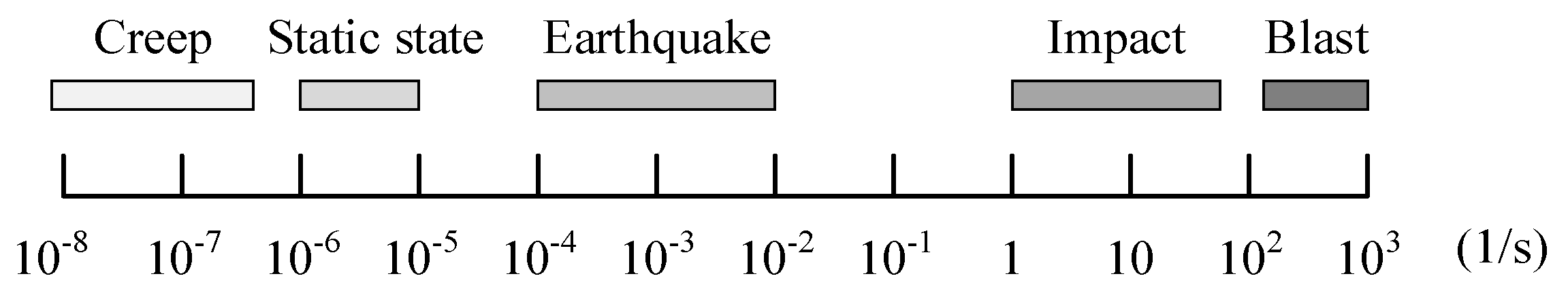

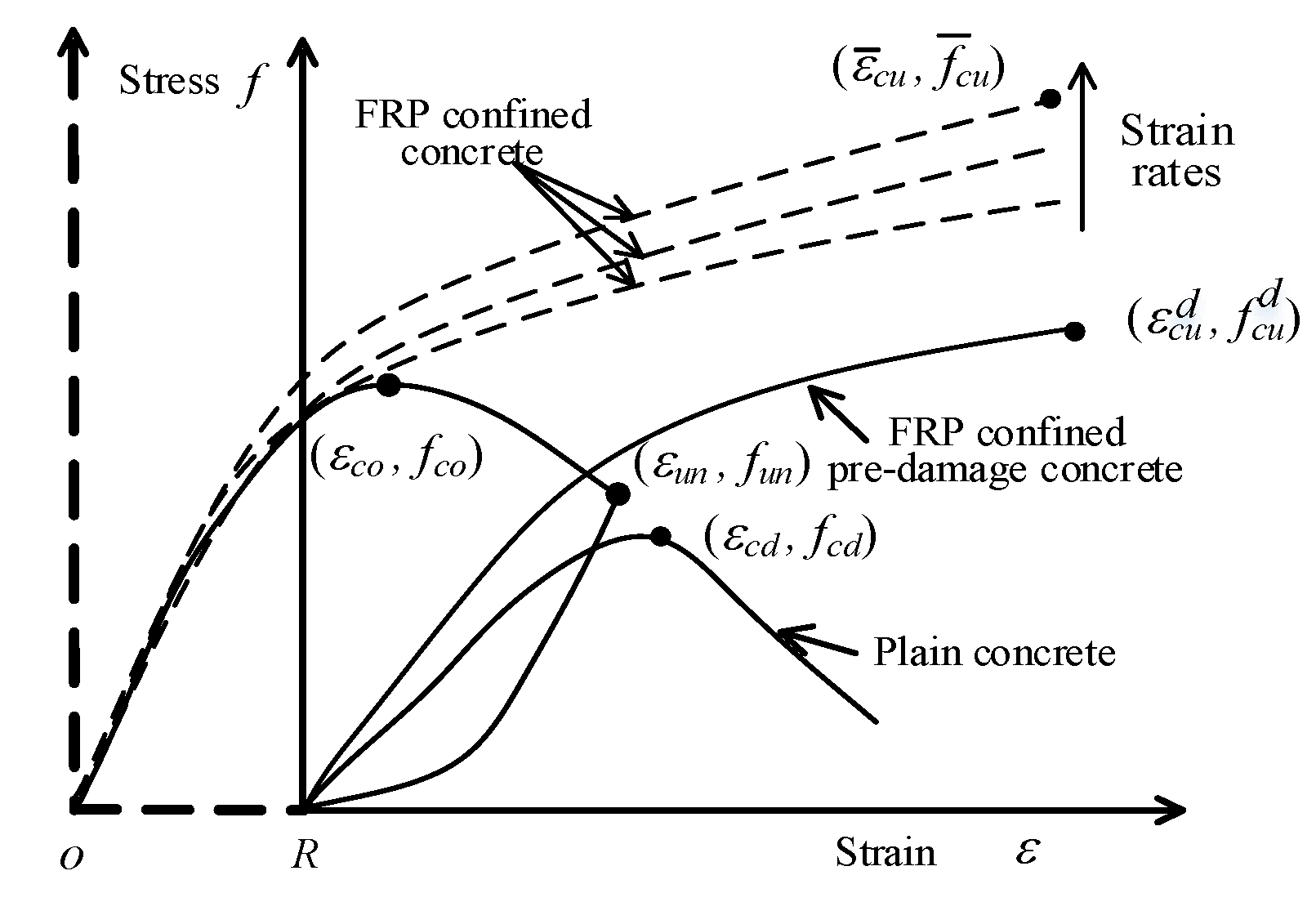

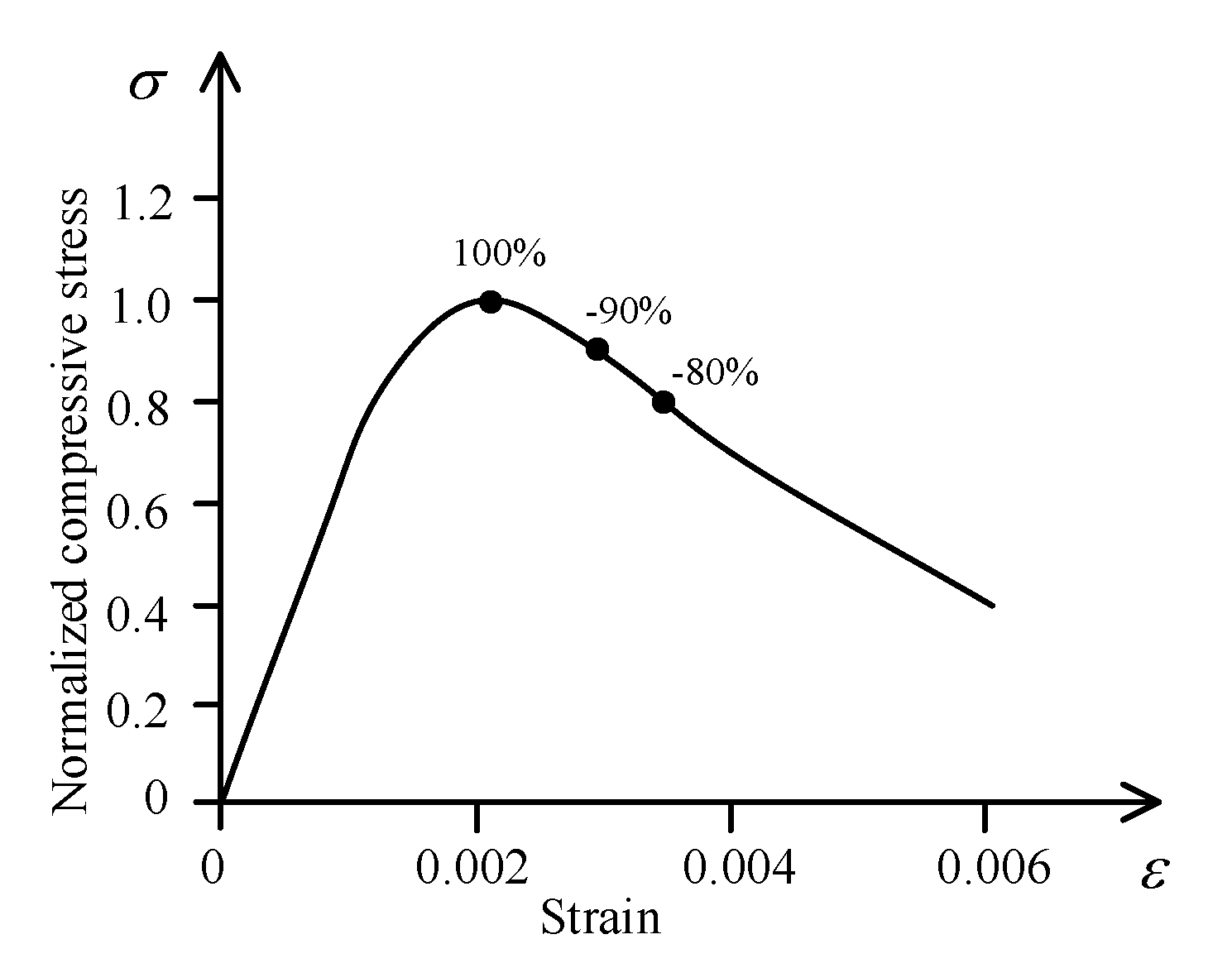

2. Strain Rate Effect and Definition of Concrete Damage

3. Experimental Program

3.1. Specimen Design

3.2. Material Properties

3.3. Specimen Preparation

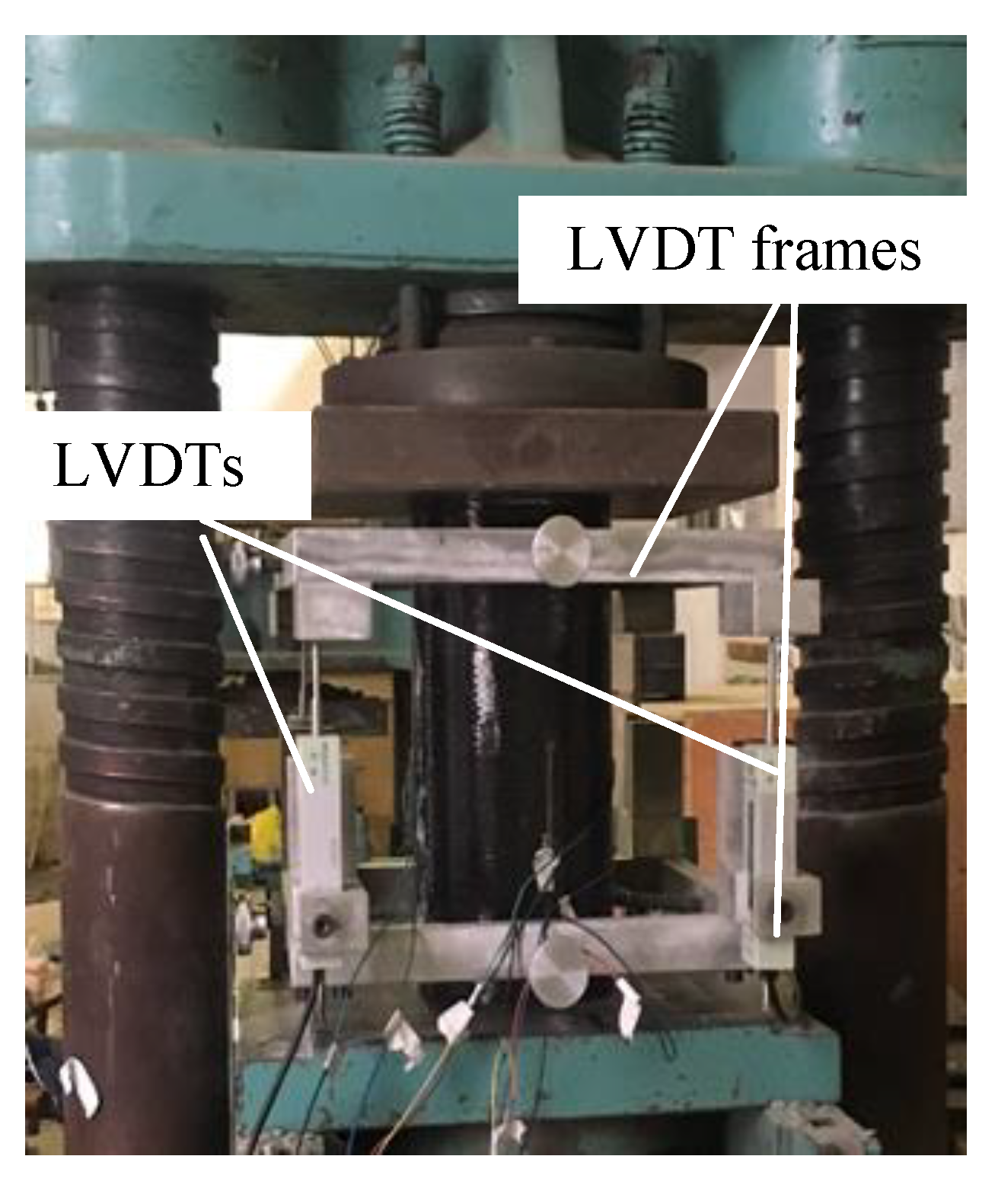

3.4. Testing Setup and Testing Program

4. Test Results and Analysis

4.1. Failure Modes

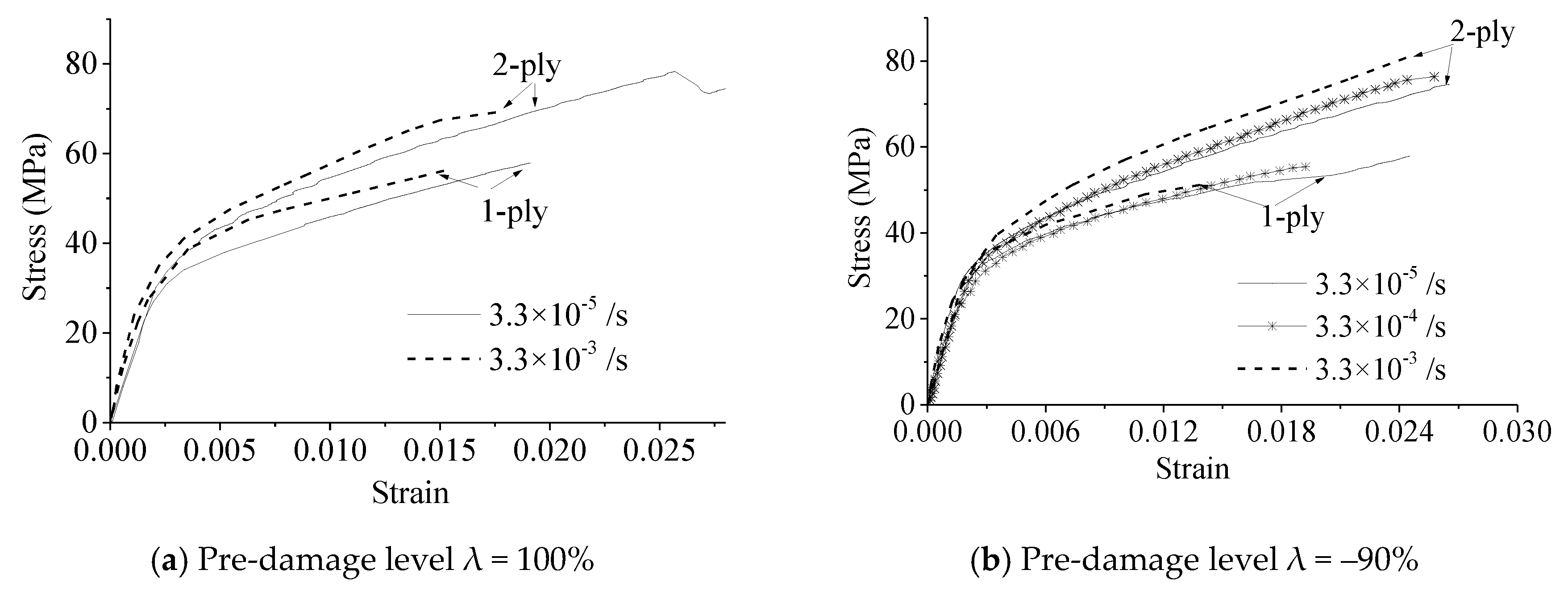

4.2. Stress–Strain Responses

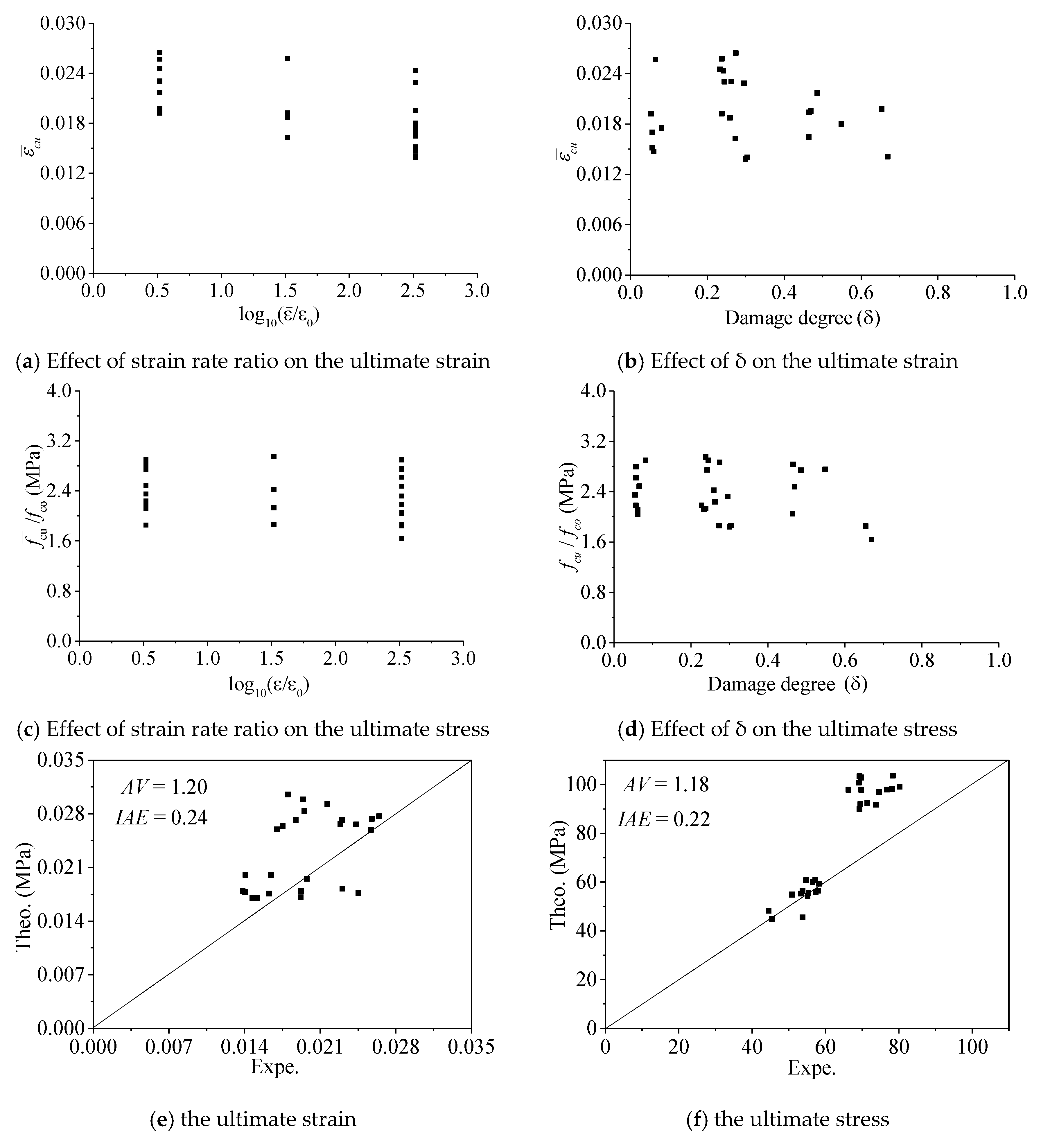

4.3. The Ultimate Condition

5. Proposed Stress–Strain Model

5.1. Analytical Stress–Strain Modeling

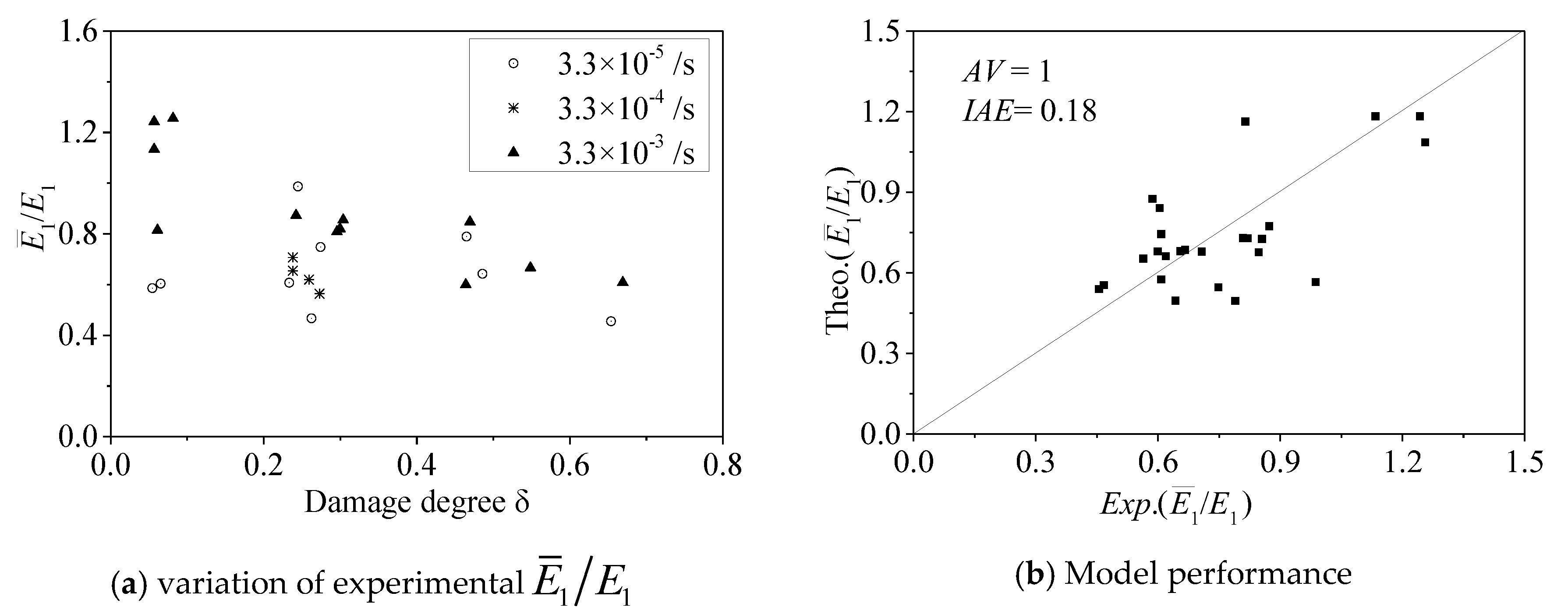

5.1.1. Initial Elastic Modulus

5.1.2. Transition Curve Parameter

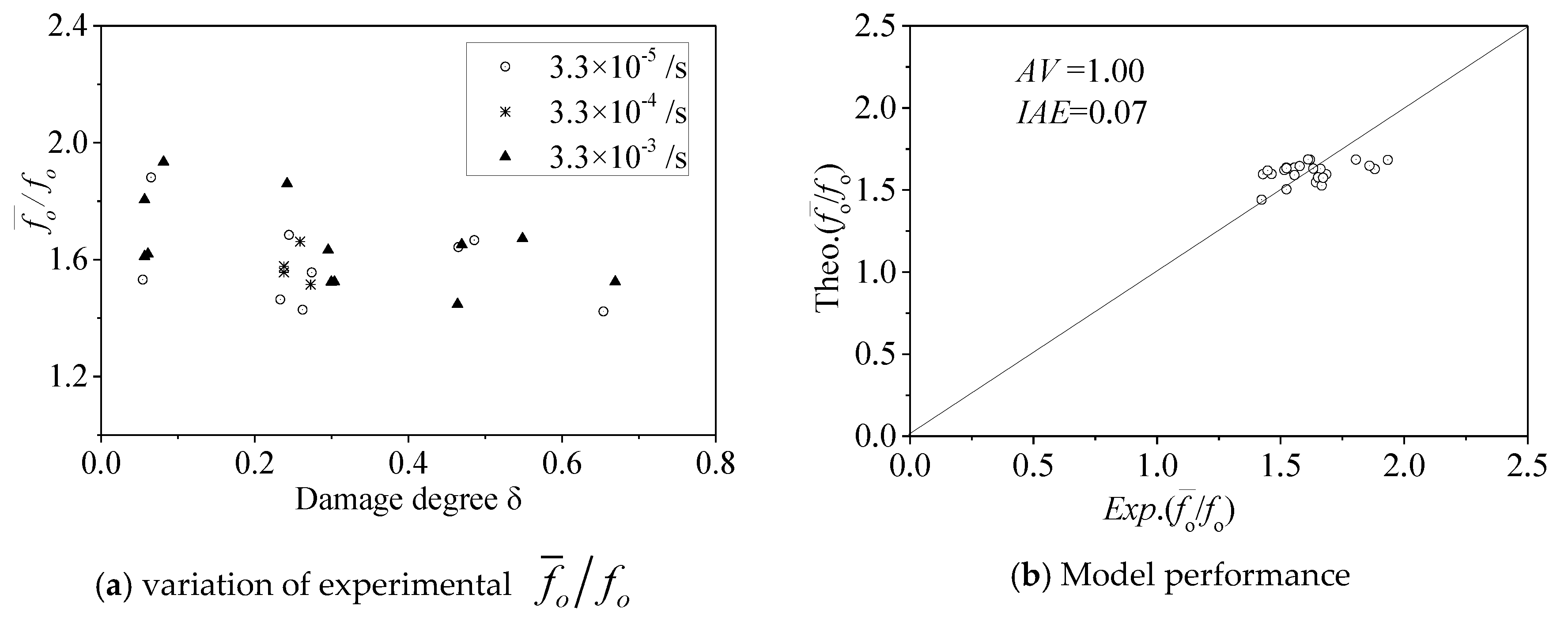

5.1.3. Elastic Limit stress

5.1.4. Hardening Modulus

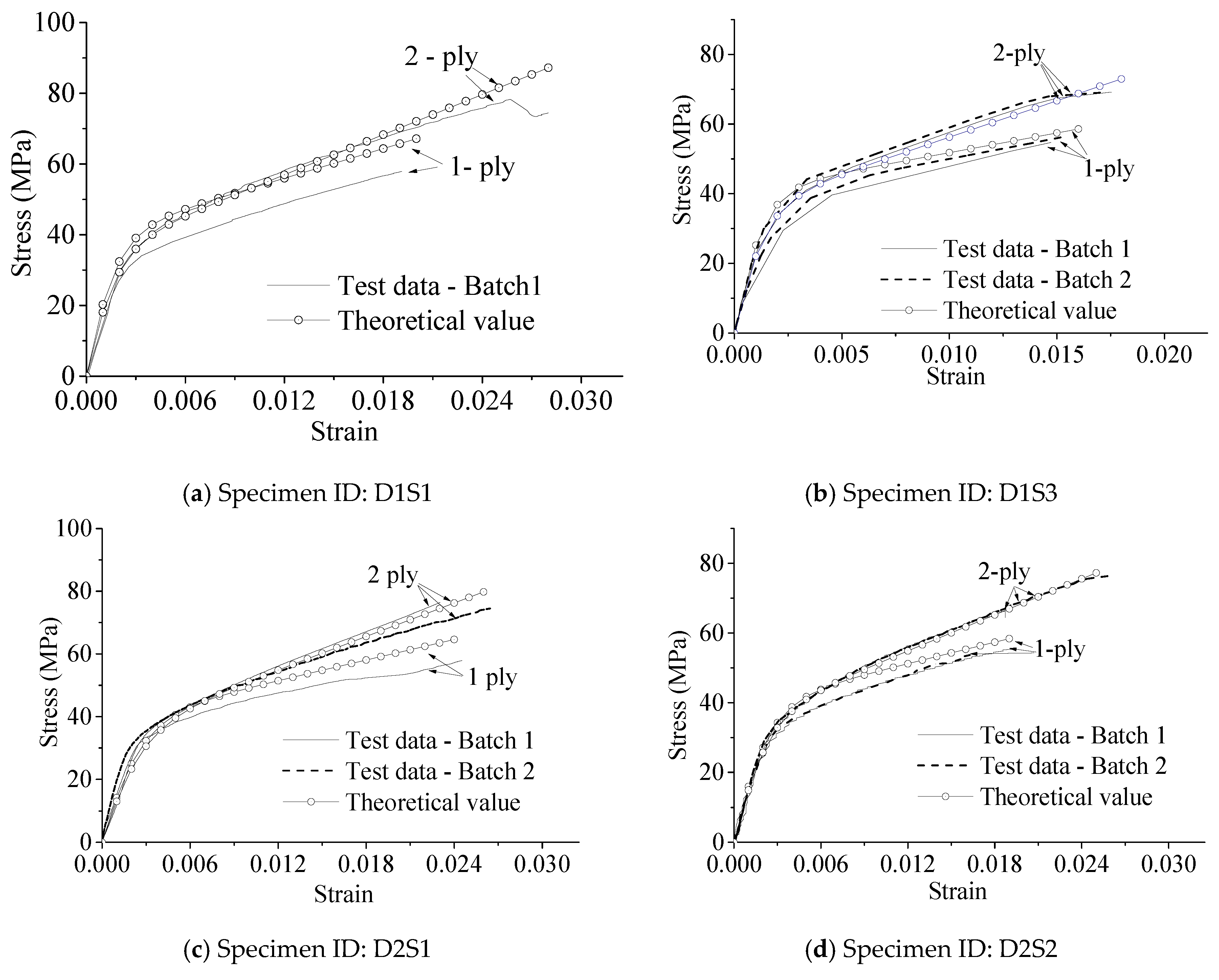

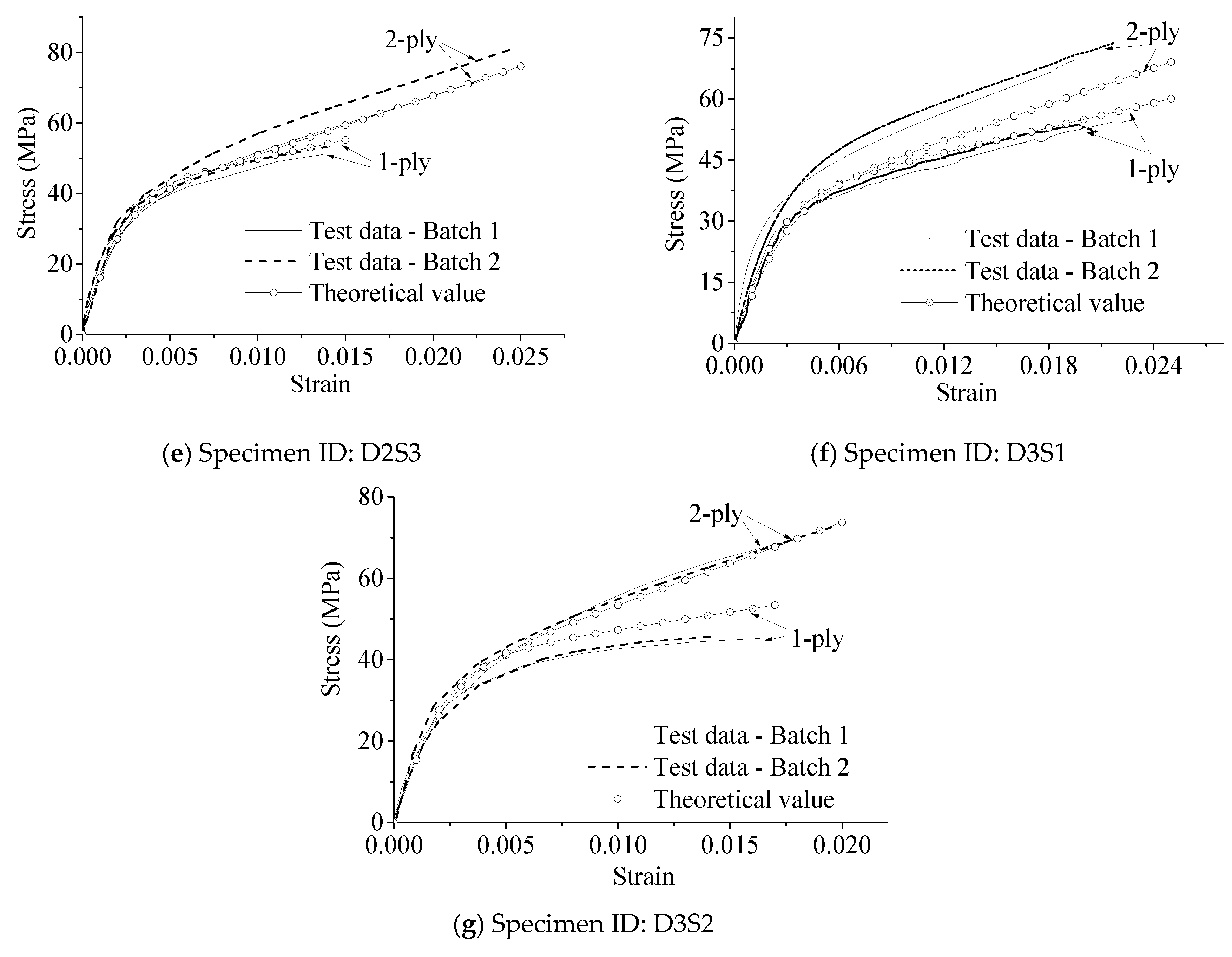

5.2. The Performance of the Proposed Model

6. Conclusions

- The experimental stress–strain curves of the FRP-confined damaged concrete under varying strain rates have a similar shape. Strain rates have significant effects on the initial Young’s modulus and hardening stiffness of stress–strain curves. With increasing strain rate, the initial elastic stiffness and hardening stiffness corresponding to the stress–strain curve also increase.

- Strain rate has a significant effect on the ultimate strain; its value decreases with increases in the strain rate. The degree of concrete damage also has an effect on the ultimate strain and stress. Ultimate strain and stress values decrease with increases in the damage degree δ.

- A stress–strain model of FRP-confined pre-damaged concrete under different strain rates is developed. After comparison with the test data, it is found that the proposed model can predict the characteristic points and the whole stress–strain curves.

Author Contributions

Funding

Conflicts of Interest

References

- Wu, Y.F.; Cao, Y. Energy balance method for modeling ultimate strain of confined concrete. ACI Struct. J. 2017, 114, 373–381. [Google Scholar] [CrossRef]

- Wu, Y.F.; Jiang, C. Quantification of bond-slip relationship for externally bonded FRP-to-concrete joints. J. Compos. Constr. 2013, 17, 673–686. [Google Scholar] [CrossRef]

- Wu, Y.F.; Wei, Y. General stress-strain model for steel-and FRP-confined concrete. J. Compos. Constr. 2014, 19, 04014069. [Google Scholar] [CrossRef]

- Hu, Y.J.; Jiang, C.; Liu, W.; Yu, Q.Q.; Zhou, Y.L. Degradation of the in-plane shear modulus of structural BFRP laminates due to high temperature. Sensors 2018, 18, 3361. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, Y.F. Compression behavior of concrete columns confined by high strength steel wire. Constr. Build. Mater. 2014, 54, 443–453. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.F.; Wu, G. Plastic hinge length of FRP-confined square RC columns. J. Compos. Constr. 2014, 18, 04014003. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y. Static bearing capacity of partially corrosion-damaged reinforced concrete structures strengthened with PET FRP composites. Constr. Build. Mater. 2019, 211, 33–43. [Google Scholar] [CrossRef]

- Naser, M.; Hawileh, R.; Abdalla, J. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Cao, Y.G.; Jiang, C.; Wu, Y.F. Cross-Sectional Unification on the Stress-Strain Model of Concrete Subjected to High Passive Confinement by Fiber-Reinforced Polymer. Polymers 2016, 8, 186. [Google Scholar] [CrossRef]

- Wu, Y.F.; Jiang, C. Effect of load eccentricity on the stress–strain relationship of FRP-confined concrete columns. Compos. Struct. 2013, 98, 228–241. [Google Scholar] [CrossRef]

- Wu, Y.F.; Yun, Y.; Wei, Y.; Zhou, Y. Effect of Predamage on the Stress-Strain Relationship of Confined Concrete under Monotonic Loading. J. Struct. Eng. 2014, 140, 04014093. [Google Scholar] [CrossRef]

- Li, P.; Sui, L.; Xing, F.; Li, M.; Zhou, Y.; Wu, Y.F. Stress–Strain Relation of FRP-Confined Predamaged Concrete Prisms with Square Sections of Different Corner Radii Subjected to Monotonic Axial Compression. J. Compos. Constr. 2019, 23, 04019001. [Google Scholar] [CrossRef]

- Dalgic, K.D.; Ispir, M.; Ilki, A. Cyclic and monotonic compression behavior of CFRP-jacketed damaged noncircular concrete prisms. J. Compos. Constr. 2015, 20, 04015040. [Google Scholar] [CrossRef]

- Ilki, A.; Peker, O.; Karamuk, E.; Demir, C.; Kumbasar, N. FRP retrofit of low and medium strength circular and rectangular reinforced concrete columns. J. Mater. Civil. Eng. 2008, 20, 169–188. [Google Scholar] [CrossRef]

- Ma, G.; Li, H.; Yan, L.; Huang, L. Testing and analysis of basalt FRP-confined damaged concrete cylinders under axial compression loading. Constr. Build. Mater. 2018, 169, 762–774. [Google Scholar] [CrossRef]

- Guo, Y.; Xie, J.; Xie, Z.; Zhong, J. Experimental study on compressive behavior of damaged normal- and high-strength concrete confined with CFRP laminates. Constr. Build. Mater. 2016, 107, 411–425. [Google Scholar] [CrossRef]

- Liu, H.K.; Liao, W.C.; Liang, T.; Lee, W.H.; Sawada, Y. Compression strength of pre-damaged concrete cylinders reinforced by non-adhesive filament wound composites. Compos. Part A Appl. Sci. Manufact. 2004, 35, 281–292. [Google Scholar] [CrossRef]

- Peng, G.; Jian, W.; Li, Z.; Li, H.; Wang, Z. Effects of predamage on the compression performance of CFRP-confined rectangular steel reinforced concrete columns. Eng. Struct. 2018, 162, 109–120. [Google Scholar]

- Grote, D.; Park, S.; Zhou, M. Dynamic behavior of concrete at high strain rates and pressures: I. experimental characterization. Int. J. Impact Eng. 2001, 25, 869–886. [Google Scholar] [CrossRef]

- Li, Q.; Meng, H. About the dynamic strength enhancement of concrete-like materials in a split Hopkinson pressure bar test. Int. J. Solids Struct. 2003, 40, 343–360. [Google Scholar] [CrossRef]

- Demir, C.; Kolcu, K.; Ilki, A. Effects of loading rate and duration on axial behavior of concrete confined by fiber-reinforced polymer sheets. J. Compos. Constr. 2010, 14, 146–151. [Google Scholar] [CrossRef]

- Demir, C.; Kucukkapili, A.; Doyrangol, D.; Ilki, A. The effects of loading rate and duration on the axial behavior of low-strength and medium-strength noncircular concrete members confined by fiber-reinforced polymer sheets. Polymers 2014, 6, 1685–1704. [Google Scholar] [CrossRef]

- Zhang, B.; Pan, J. Stress-strain relation of FRP confined concrete subjected to fast load. Cumbust. Explo. Shock Waves 2003, 23, 466–471. [Google Scholar]

- Zhang, B.; Pan, J.; Jiang, H. Computation of strength for FRP confined concrete under fast loading. J. Harbin Inst. Technol. 2003, 35, 958–961. [Google Scholar]

- Zhang, Y. Experimental Study of the Mechanical Properties of Concrete under Different Strain Rates. Ph.D. Thesis, Beijing University of Technology, Beijing, China, 2012. [Google Scholar]

- Moustafa, A.; Elgawady, M.A. Strain Rate Effect on Properties of Rubberized Concrete Confined with Glass Fiber–Reinforced Polymers. J. Compos. Constr. 2016, 20, 04016014. [Google Scholar] [CrossRef]

- Jin, X.R. Experimental Studies on Behavior of FRP Confined Concrete Columns under Rapid Loading. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2007. [Google Scholar]

- Bischoff, P.; Perry, S. Compressive behaviour of concrete at high strain rates. Mater. Struct. 1991, 24, 425–450. [Google Scholar] [CrossRef]

- Hu, B.; Wang, J. Unified model for calculating stress-strain relationship of circular and rectangular concrete columns confined with FRP. J. Xi’an Univ. Arch Technol. 2010, 42, 394–400. [Google Scholar]

- Hui, Y.; Heng, W. Dynamic Compressive Behavior of FRP-Confined Concrete under Impact and a New Design-Oriented Strength Model. Polym. Polym. Compos. 2016, 24, 127–131. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, X.; Wu, G.; Zhou, Y. Behaviour of concrete confined by both steel spirals and fiber-reinforced polymer under axial load. Compos. Struct. 2018, 192, 577–591. [Google Scholar] [CrossRef]

- Cao, Y.G.; Wu, Y.F.; Li, X.Q. Unified model for evaluating ultimate strain of FRP confined concrete based on energy method. Constr. Build. Mater. 2016, 103, 23–35. [Google Scholar] [CrossRef]

- Jiang, J.; Xiao, P.; Li, B. True-triaxial compressive behaviour of concrete under passive confinement. Constr. Build. Mater. 2017, 156, 584–598. [Google Scholar] [CrossRef]

- Zhou, Y.W.; Wu, Y.F. General Model for constitutive relationships of concrete and its composite structures. Compos. Struct. 2012, 94, 580–592. [Google Scholar] [CrossRef]

- Wu, Y.F.; Cao, Y.G. Effect of Load Path on Behavior of FRP-Confined Concrete. J. Compos. Constr. 2017, 21, 04017014. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, Y.F.; Jiang, C. Stress-strain relationship of FRP confined concrete columns under combined axial load and bending moment. Compos. B Eng. 2018, 134, 207–217. [Google Scholar] [CrossRef]

| Specimen ID | fco (MPa) | fun (MPa) | fcd (MPa) | δ | fcu (MPa) | εcu | E1 (GPa) | n | fo (MPa) | E2 (GPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| * D0L1S1 | 27 | 0 | 27 | 0 | - | - | 22.3 | 0.7 | 21 | 2.8 |

| * D0L2S1 | 27 | 0 | 27 | 0 | - | - | 19.8 | 0.7 | 21 | 4.1 |

| D1L1S1-1 | 25 | 25 | 23.4 | 0.05 | 58 | 0.019 | 16.6 | 0.6 | 32.2 | 1.4 |

| # D1L1S1-2 | 27 | 27 | 25.4 | 0.06 | 57 | - | - | - | - | - |

| D1L1S3-1 | 27 | 27 | 25.2 | 0.06 | 55 | 0.015 | 35.3 | 0.6 | 33.8 | 2.5 |

| D1L1S3-2 | 26 | 26 | 24.4 | 0.06 | 56 | 0.015 | 23.1 | 0.7 | 34 | 1.5 |

| D1L2S1-1 | 28 | 28 | 26 | 0.07 | 69 | 0.026 | 14.7 | 0.6 | 39.5 | 1.5 |

| # D1L2S1-2 | 28 | 28 | 26.4 | 0.06 | 78 | - | - | - | - | - |

| D1L2S3-1 | 24 | 24 | 21.9 | 0.08 | 69 | 0.018 | 27.6 | 0.8 | 37.9 | 1.9 |

| D1L2S3-2 | 27 | 27 | 25.1 | 0.06 | 70 | 0.017 | 30.6 | 0.8 | 40.6 | 1.8 |

| # D2L1S1-1 | 26 | 24 | 20.3 | 0.23 | 57 | - | - | - | - | - |

| D2L1S1-2 | 27 | 25 | 21 | 0.23 | 58 | 0.025 | 17.2 | 0.7 | 30.7 | 1.3 |

| D2L1S2-1 | 26 | 24 | 19.8 | 0.24 | 55 | 0.019 | 18.6 | 0.8 | 32.7 | 1.3 |

| D2L1S2-2 | 29 | 26 | 21 | 0.27 | 54 | 0.016 | 16 | 0.6 | 31.8 | 1.4 |

| D2L1S3-1 | 28 | 24 | 19.3 | 0.3 | 51 | 0.014 | 23.3 | 0.6 | 32 | 1.5 |

| D2L1S3-2 | 29 | 25 | 19.9 | 0.3 | 53 | 0.014 | 24.3 | 0.7 | 32 | 1.8 |

| D2L2S1-1 | 27 | 25 | 20.4 | 0.24 | 78 | 0.023 | 18.2 | 0.8 | 32.7 | 1.9 |

| D2L2S1-2 | 26 | 23 | 18.9 | 0.27 | 75 | 0.026 | 24.1 | 0.8 | 35.4 | 1.5 |

| D2L2S2-1 | 27 | 25 | 20.3 | 0.26 | 66 | 0.019 | 17.2 | 0.8 | 33.1 | 1.9 |

| D2L2S2-2 | 26 | 23 | 18.5 | 0.24 | 77 | 0.026 | 15.1 | 0.6 | 34.9 | 1.7 |

| D2L2S3-1 | 29 | 27 | 22.1 | 0.24 | 80 | 0.024 | 21.3 | 0.8 | 39.1 | 1.7 |

| D2L2S3-2 | 30 | 27 | 21.2 | 0.3 | 70 | 0.023 | 19.7 | 0.8 | 34.3 | 1.7 |

| D3L1S1-1 | 25 | 22 | 18.2 | 0.26 | 55 | 0.023 | 13.3 | 0.6 | 30 | 1.1 |

| D3L1S1-2 | 29 | 21 | 10 | 0.65 | 54 | 0.020 | 12.9 | 0.6 | 29.9 | 1.2 |

| D3L1S3-1 | 22 | 17 | 11.6 | 0.46 | 44 | 0.016 | 17.3 | 0.7 | 32 | 1.3 |

| D3L1S3-2 | 28 | 20 | 9.2 | 0.67 | 45 | 0.014 | 17 | 0.6 | 30.4 | 1.4 |

| D3L2S1-1 | 25 | 20 | 13.1 | 0.47 | 70 | 0.019 | 19.2 | 0.8 | 34.5 | 1.8 |

| D3L2S1-2 | 27 | 21 | 13.8 | 0.49 | 74 | 0.022 | 15.7 | 0.8 | 35 | 1.9 |

| D3L2S3-1 | 29 | 23 | 15.3 | 0.47 | 71 | 0.020 | 20.6 | 0.7 | 34.7 | 2 |

| D3L2S3-2 | 25 | 19 | 11.3 | 0.55 | 69 | 0.018 | 16.2 | 0.8 | 35.1 | 2 |

| Strain Rate (strain/s) | Tensile Strength (MPa) | Rupture Strain | Elastic Modulus (GPa) | |||

|---|---|---|---|---|---|---|

| Test | Mean | Test | Mean | Test | Mean | |

| 3.3 × 10−3 | 4594 | 4566 | 0.0147 | 0.015 | 314 | 304 |

| 3.3 × 10−4 | 4662 | 0.0157 | 299 | |||

| 3.3 × 10−5 | 4444 | 0.0147 | 299 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Liu, M.; Zhang, Y.; Hu, J.; Yang, S. Effect of Strain Rates on the Stress–Strain Behavior of FRP-Confined Pre-Damaged Concrete. Materials 2020, 13, 1078. https://doi.org/10.3390/ma13051078

Cao Y, Liu M, Zhang Y, Hu J, Yang S. Effect of Strain Rates on the Stress–Strain Behavior of FRP-Confined Pre-Damaged Concrete. Materials. 2020; 13(5):1078. https://doi.org/10.3390/ma13051078

Chicago/Turabian StyleCao, Yugui, Muyu Liu, Yang Zhang, Jun Hu, and Shengchun Yang. 2020. "Effect of Strain Rates on the Stress–Strain Behavior of FRP-Confined Pre-Damaged Concrete" Materials 13, no. 5: 1078. https://doi.org/10.3390/ma13051078

APA StyleCao, Y., Liu, M., Zhang, Y., Hu, J., & Yang, S. (2020). Effect of Strain Rates on the Stress–Strain Behavior of FRP-Confined Pre-Damaged Concrete. Materials, 13(5), 1078. https://doi.org/10.3390/ma13051078