Correlation between High Temperature Deformation and β Relaxation in LaCe-Based Metallic Glass

Abstract

1. Introduction

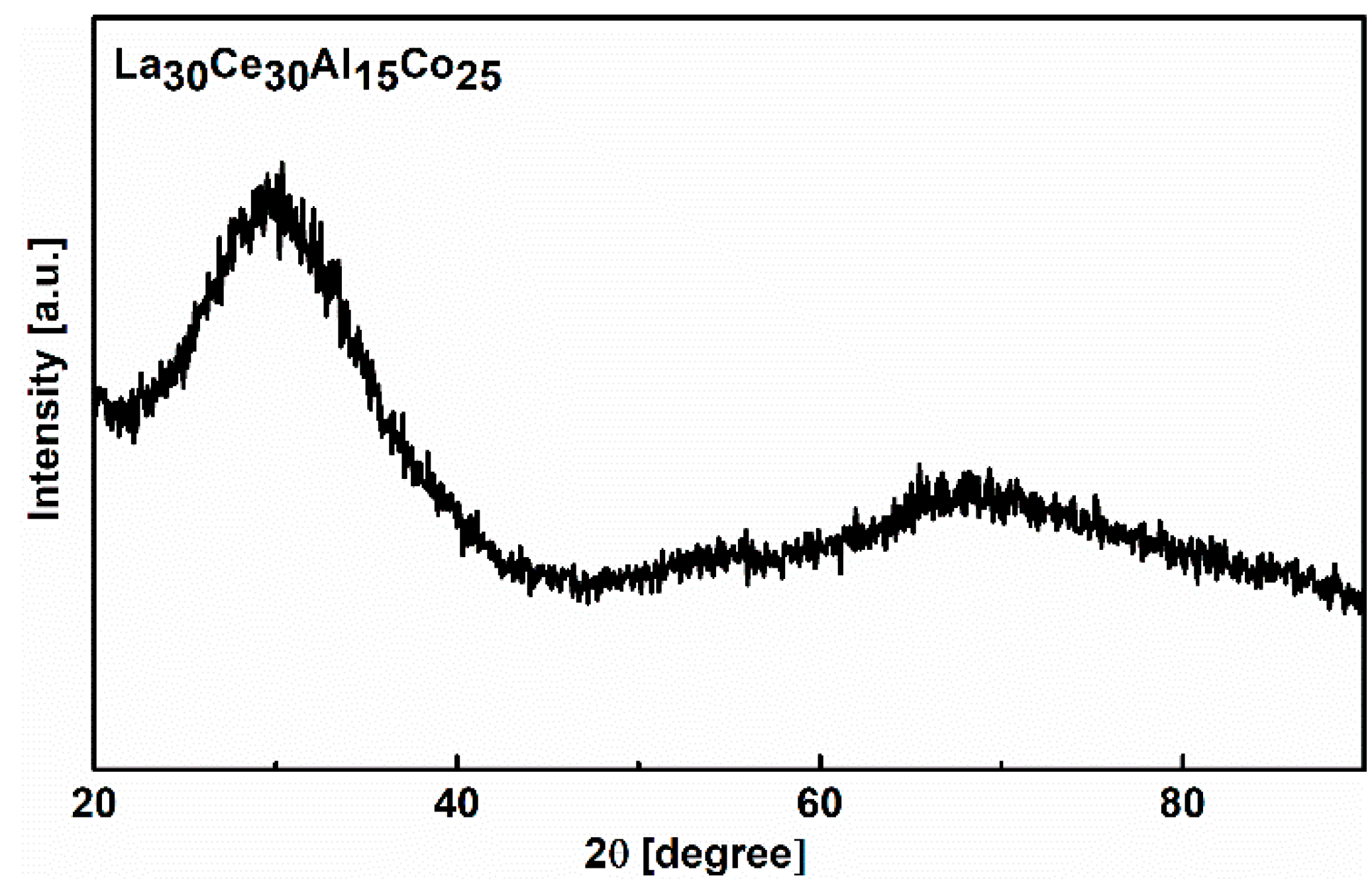

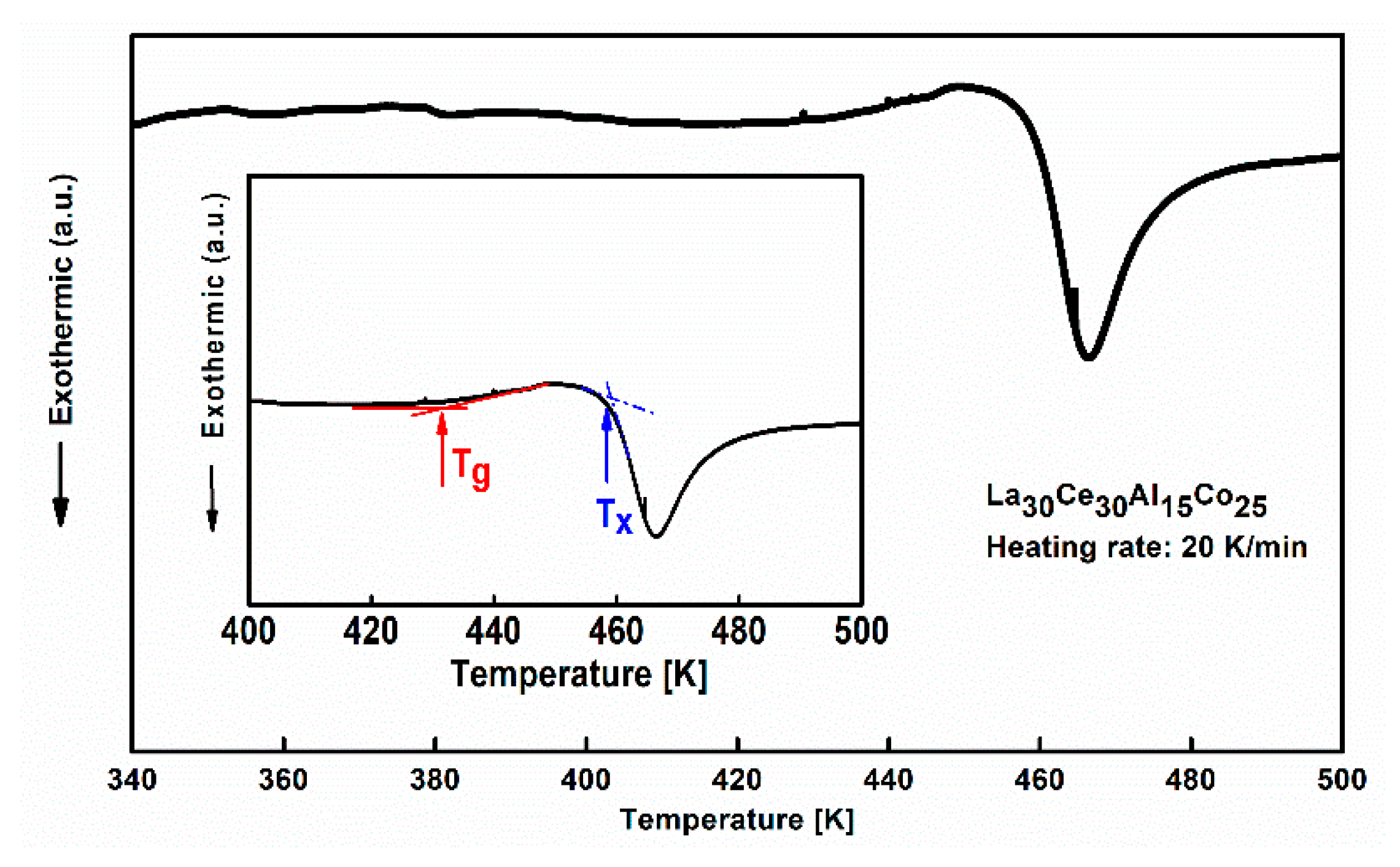

2. Experimental Procedure

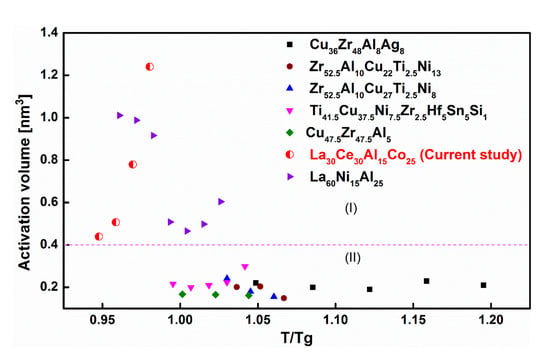

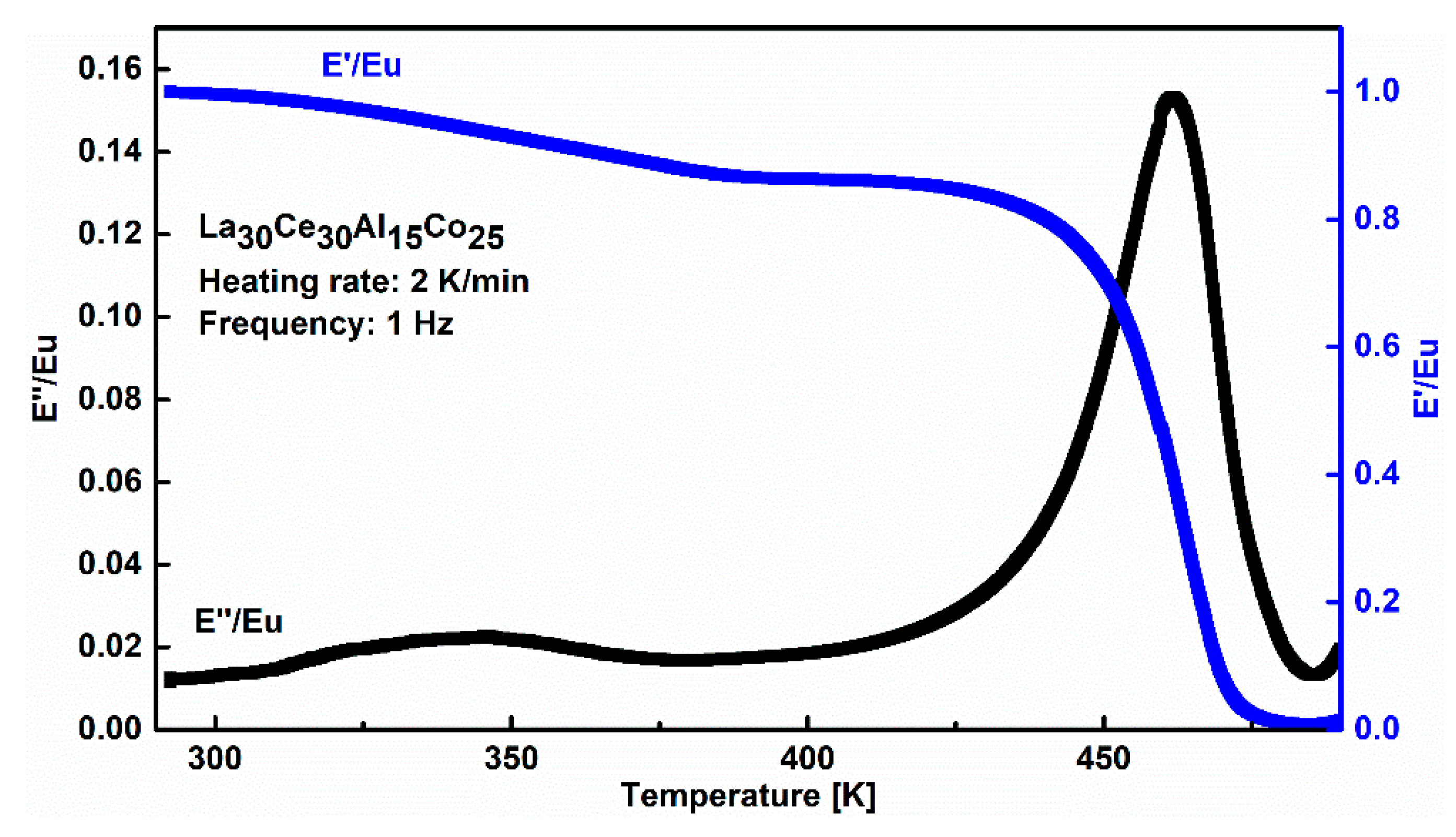

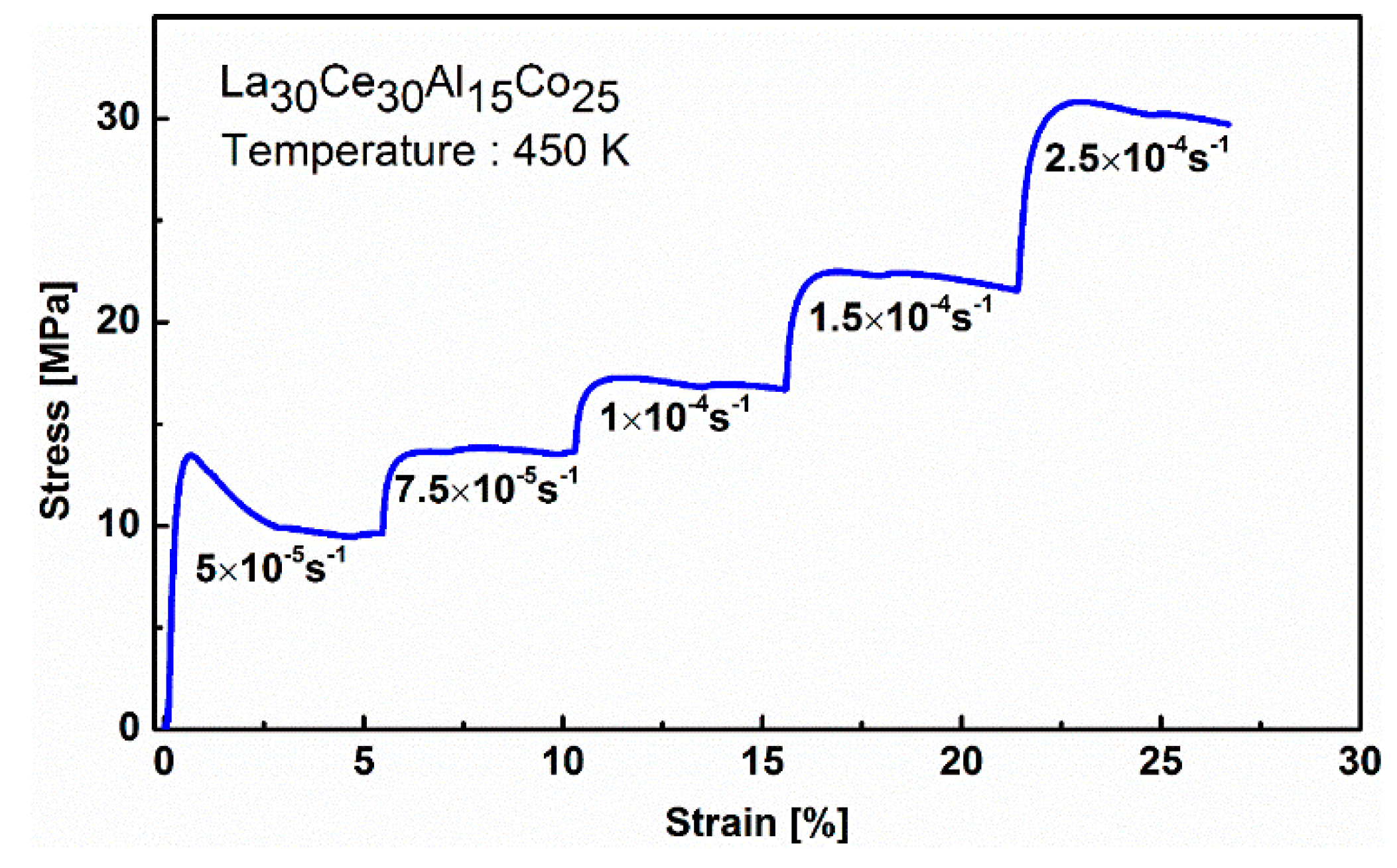

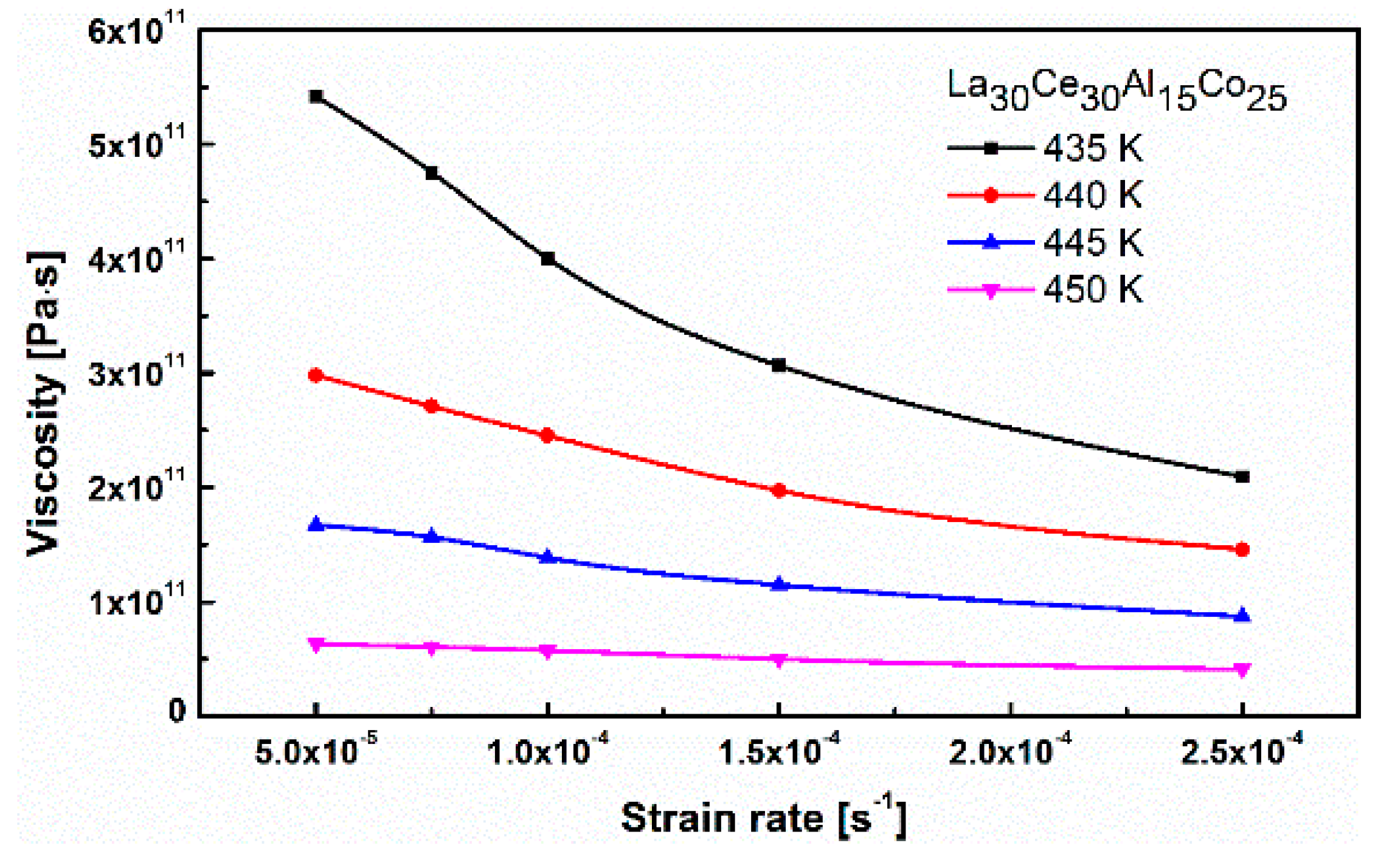

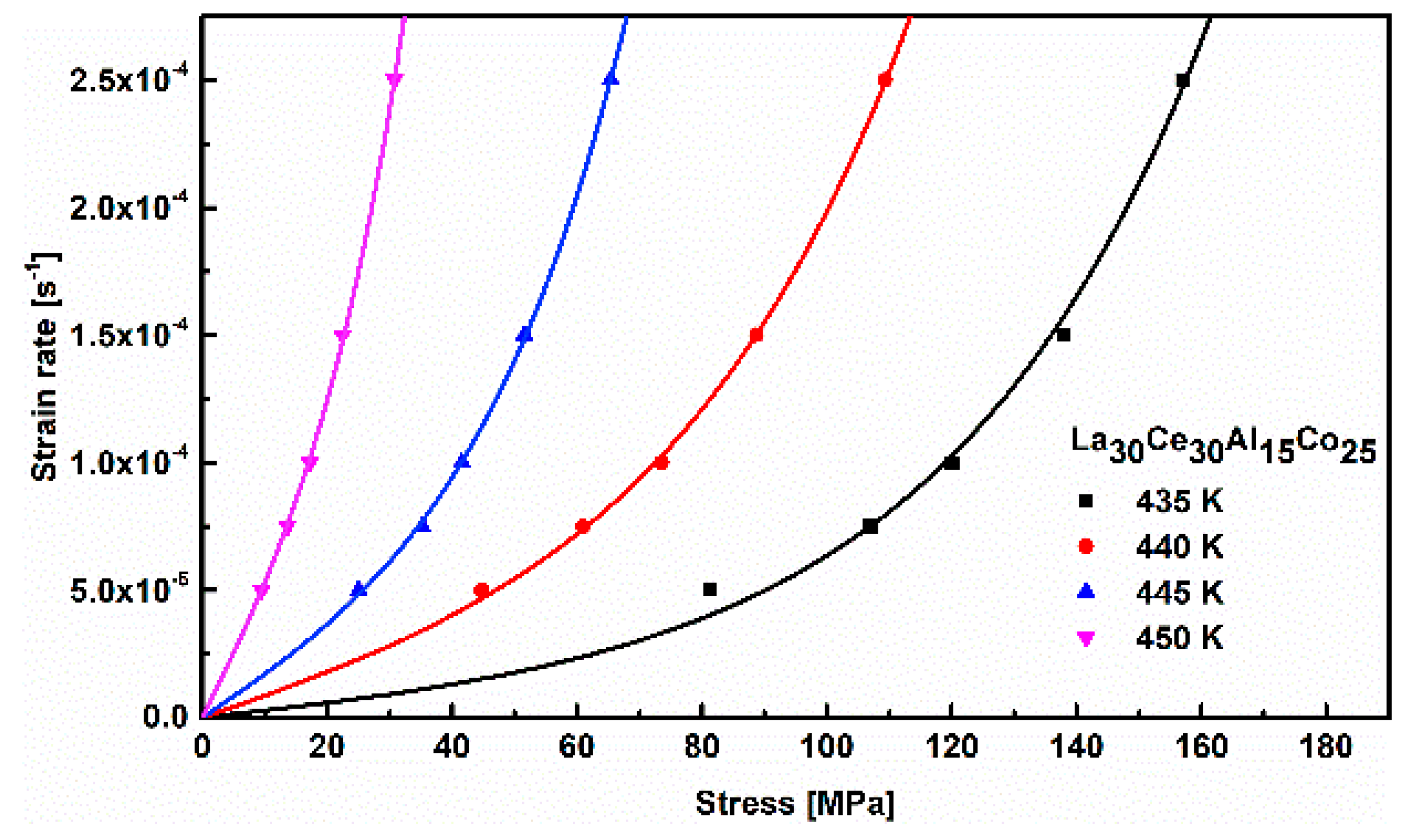

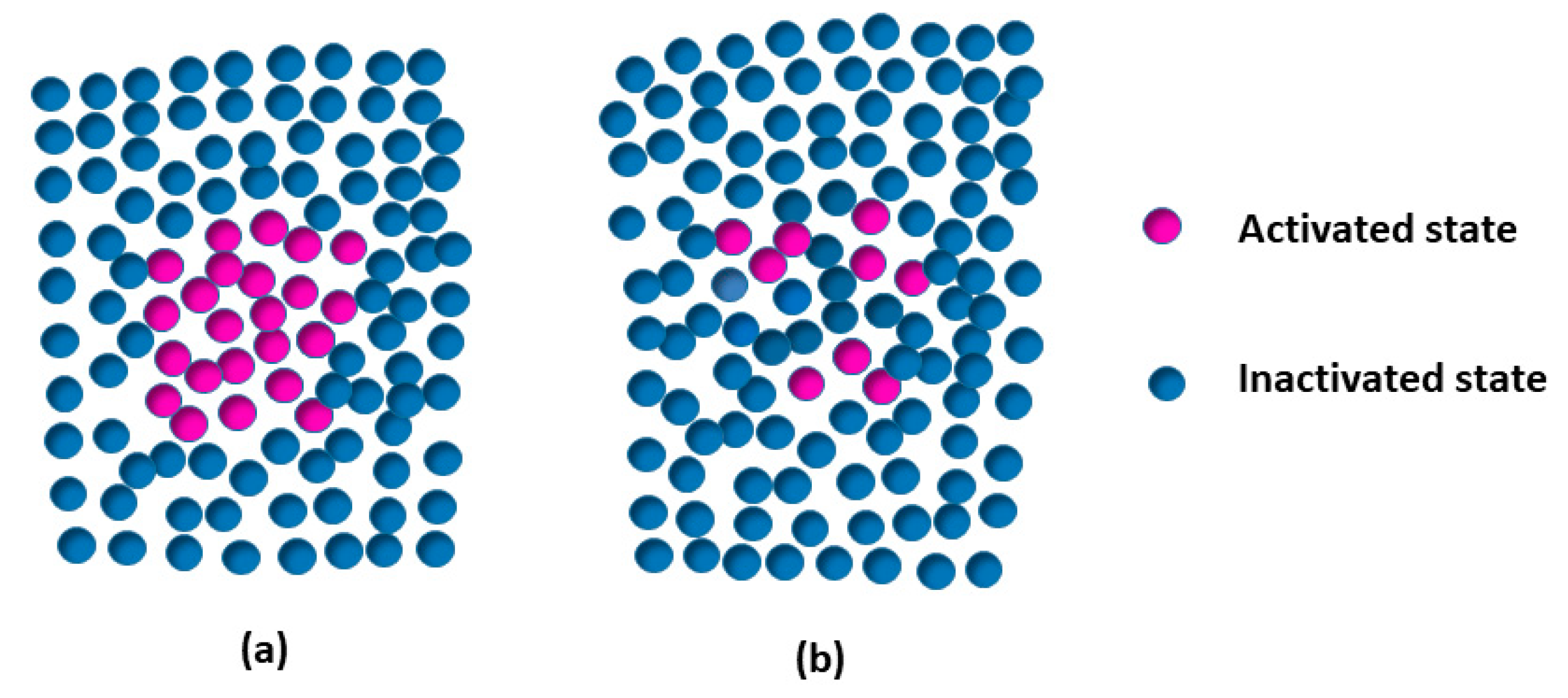

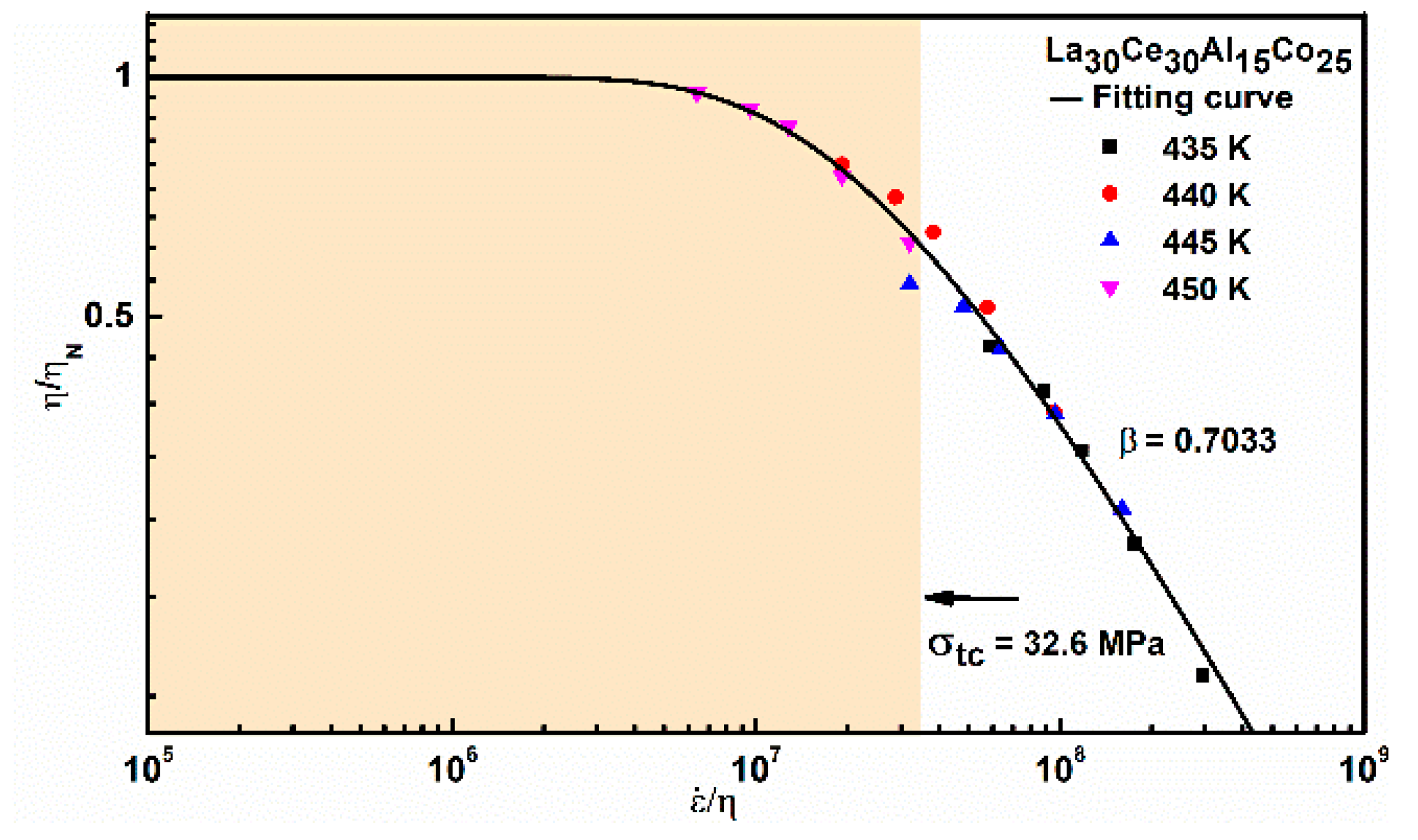

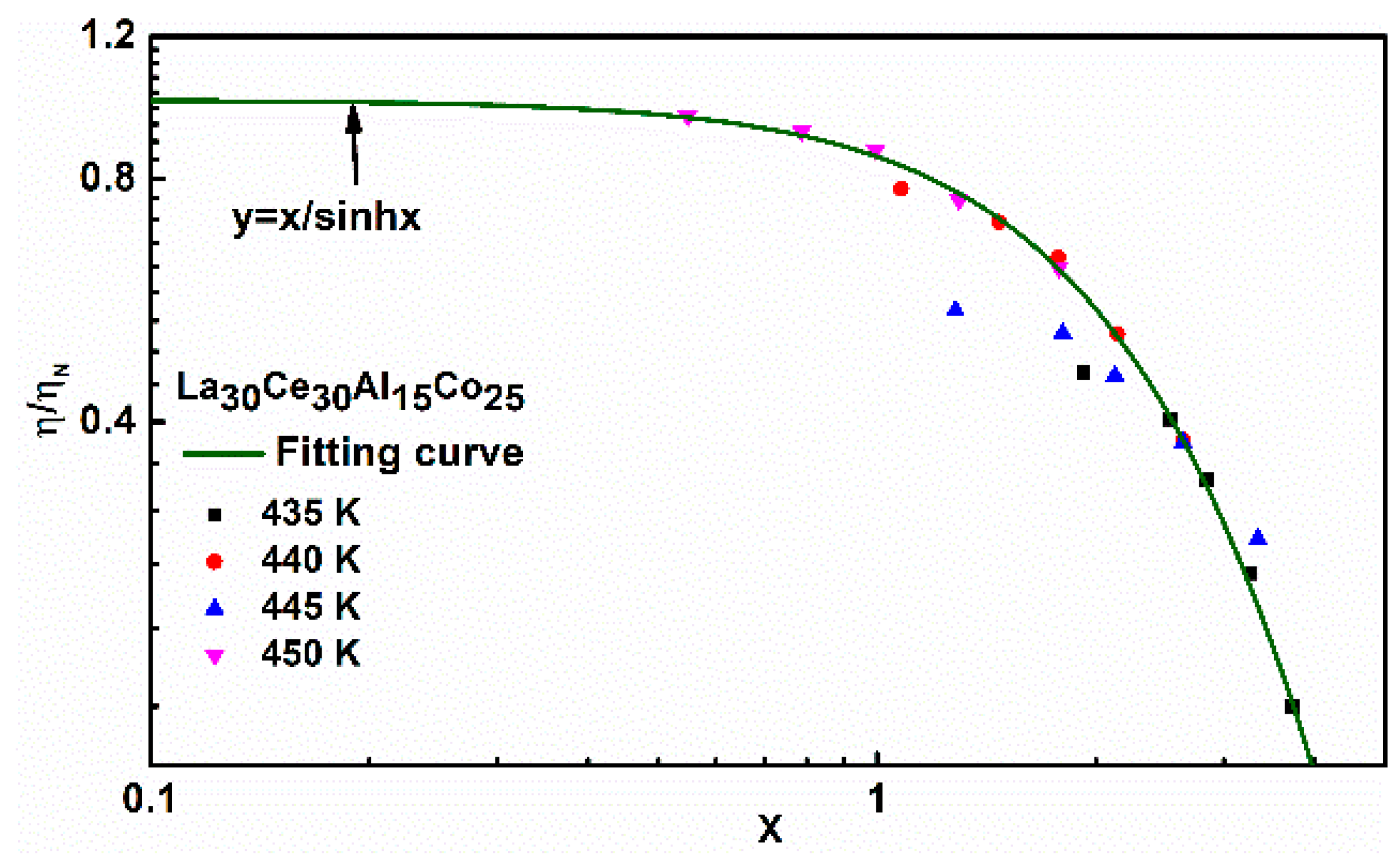

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qiao, J.C.; Pelletier, J.M. Dynamic Mechanical Relaxation in Bulk Metallic Glasses: A Review. J. Mater Sci. Technol. 2014, 30, 523–545. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Jia, Z.; Lyu, F.; Liang, S.-X.; Lu, J. A review of catalytic performance of metallic glasses in wastewater treatment: Recent progress and prospects. Prog. Mater. Sci. 2019, 105, 100576. [Google Scholar] [CrossRef]

- Wang, W.H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 2012, 57, 487–656. [Google Scholar] [CrossRef]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk Metallic Glasses. Mater. Sci. Eng. R 2008, 321, 502–503. [Google Scholar] [CrossRef]

- Sun, B.A.; Wang, W.H. The fracture of bulk metallic glasses. Prog. Mater. Sci. 2015, 74, 211–307. [Google Scholar] [CrossRef]

- Pang, S.J.; Zhang, T.; Asami, K.; Inoue, A. Synthesis of Fe-Cr-Mo-C-B-P bulk metallic glasses with high corrosion resistance. Acta Mater. 2002, 50, 489–497. [Google Scholar] [CrossRef]

- Hufnagel, T.C.; Schuh, C.A.; Falk, M.L. Deformation of metallic glasses: Recent developments in theory, simulations, and experiments. Acta Mater. 2016, 109, 375–393. [Google Scholar] [CrossRef]

- Qiao, J.C.; Wang, Q.; Pelletier, J.M.; Kato, H.; Casalini, R.; Crespo, D.; Pineda, E.; Yao, Y.; Yang, Y. Structural heterogeneities and mechanical behavior of amorphous alloys. Prog. Mater. Sci. 2019, 104, 250–329. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, Q.; Sun, L.; Wang, Q.; Zhang, L.C.; Wu, G.; Luan, J.H.; Jiao, Z.B.; Wang, A.; Liang, S.X. Attractive in Situ Self-Reconstructed Hierarchical Gradient Structure of Metallic Glass for High Efficiency and Remarkable Stability in Catalytic Performance. Adv. Funct. Mater. 2019, 29, 1807857. [Google Scholar] [CrossRef]

- Sha, Z.; She, C.; Xu, G.; Pei, Q.; Liu, Z.; Wang, T.; Gao, H. Metallic glass-based chiral nanolattice: Light weight, auxeticity, and superior mechanical properties. Mater. Today 2017, 20, 569–576. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A. Recent development and application products of bulk glassy alloys. Acta Mater. 2011, 59, 2243–2267. [Google Scholar] [CrossRef]

- Maass, R.; Derlet, P. Micro-plasticity and recent insights from intermittent and small-scale plasticity. Acta Mater. 2018, 143, 338–363. [Google Scholar] [CrossRef]

- Li, N.; Chen, Y.; Jiang, M.; Li, D.; He, J.; Wu, Y.; Liu, L. A thermoplastic forming map of a Zr-based bulk metallic glass. Acta Mater. 2013, 61, 1921–1931. [Google Scholar] [CrossRef]

- Lu, J.; Ravichandran, G.; Johnson, W.L. Deformation behavior of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass over a wide range of strain-rates and temperatures. Acta Mater. 2003, 51, 3429–3443. [Google Scholar] [CrossRef]

- Qiao, J.; Wang, Q.; Crespo, D.; Yang, Y.; Pelletier, J.M. Amorphous physics and materials: Secondary relaxation and dynamic heterogeneity in metallic glasses: A brief review. Chinese Phys. B 2017, 26, 016402. [Google Scholar] [CrossRef]

- Wang, W.H. Dynamic relaxations and relaxation-property relationships in metallic glasses. Prog. Mater. Sci. 2019, 106, 100561. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, J.; Ye, Y.; Liu, T.; Wang, S.; Liu, C.; Lu, J.; Yang, Y. Universal secondary relaxation and unusual brittle-to-ductile transition in metallic glasses. Mater. Today 2017, 20, 293–300. [Google Scholar] [CrossRef]

- Qiao, J.C.; Pelletier, J.M.; Casalini, R. Relaxation of bulk metallic glasses studied by mechanical spectroscopy. J. Phys. Chem. B. 2013, 117, 13658–13666. [Google Scholar] [CrossRef]

- Yu, H.B.; Wang, W.H.; Samwer, K. The β relaxation in metallic glasses: An overview. Mater. Today 2013, 16, 183–191. [Google Scholar] [CrossRef]

- Ge, Y.; Song, W.; Wang, X.; Luo, Z.; Li, W.; Lin, J. Temperature and strain rate dependence of deformation behavior of Zr65Al7.5Ni10Cu17.5. Mater. Chem. Phys. 2010, 124, 25–28. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, J.; Sun, Y.; Sun, J.; Chen, J.J.J. High temperature deformation behaviors of Ti40Zr25Ni3Cu12Be20 bulk metallic glass. J. Alloys Compd. 2010, 504, S82–S85. [Google Scholar] [CrossRef]

- Hiss, R.; Hobeika, S.; Lynn, C.; Strobl, G. Network stretching, slip processes, and fragmentation of crystallites during uniaxial drawing of polyethylene and related copolymers. A comparative study. Macromolecules 1999, 32, 4390–4403. [Google Scholar] [CrossRef]

- G’sell, C.; Hiver, J.; Dahoun, A. Experimental characterization of deformation damage in solid polymers under tension, and its interrelation with necking. Int. J. Solids Struct. 2002, 39, 3857–3872. [Google Scholar] [CrossRef]

- Greer, A.; Cheng, Y.; Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Tian, Y.B.; Lin, J.G.; Li, W.; Ma, M.; Luo, Z.C.; Jiang, W.J. Deformation behavior of a Cu-based amorphous alloy under different strain rates. J. Appl. Phys. 2011, 109, 083508. [Google Scholar] [CrossRef]

- Zhang, C.; Qiao, J.C.; Pelletier, J.M.; Yao, Y. Thermal activation in the Zr65Cu18Ni7 Al10 metallic glass by creep deformation and stress relaxation. Scr. Mater. 2016, 113, 180–184. [Google Scholar] [CrossRef]

- Spieckermann, F.; Wilhelm, H.; Polt, G.; Ahzi, S.; Zehetbauer, M. Rate Mechanism and Dislocation Generation in High Density Polyethylene and Other Semicrystalline Polymers. Polymer 2014, 55, 1217–1222. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Daridon, L.; Remond, Y. A Formulation of the Cooperative Model for the Yield Stress of Amorphous Polymers for a Wide Range of Strain Rates and Temperatures. Polymer 2005, 46, 6035–6043. [Google Scholar] [CrossRef]

- Zhang, C.; Qiao, J.; Pelletier, J.; Yao, Y. Arrhenius Activation of Zr65Cu18Ni7Al10 Bulk Metallic Glass in the Supercooled Liquid Region. Intermetallics 2017, 86, 88–93. [Google Scholar] [CrossRef]

- Argon, A.S. Plastic deformation in metallic glasses. Acta Metall. 1979, 27, 7–58. [Google Scholar] [CrossRef]

- Spaepen, F. A Microscopic Mechanism for Steady State Inhomogeneous Flow in Metallic Glasses. Acta Metall. 1976, 25, 407–415. [Google Scholar] [CrossRef]

- Qiao, J.C.; Chen, Y.H.; Casalini, R.; Pelletier, J.M.; Yao, Y. Main α relaxation and slow β relaxation processes in a La30Ce30Al15Co25 metallic glass. J. Mater Sci. Technol. 2019, 35, 982–986. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Yuan, Z.Z.; Feng, X.L.; Cui, L.Z.; Li, D.X. Homogeneous viscous flow behavior of a Cu–Zr based bulk metallic glass composites. Mater. Sci. Eng. A 2015, 620, 352–358. [Google Scholar] [CrossRef]

- Chan, K.C.; Chen, Q.; Liu, L. Deformation behavior of Zr55.9Cu18.6Ta8Al7.5Ni10 bulk metallic glass matrix composite in the supercooled liquid region. Intermetallics 2007, 15, 500–505. [Google Scholar] [CrossRef]

- Lee, K.S.; Chang, Y.W. Deformation behavior of Zr-based bulk metallic glass in an undercooled liquid state under compressive loading. Met. Mater. Int. 2005, 11, 53. [Google Scholar] [CrossRef]

- Liu, Y.; Blandin, J.J.; Kapelski, G.; Suéry, M. High temperature deformation of a Cu40Zr44Ag8Al8 bulk metallic glass. Mater. Sci. Eng. A 2011, 528, 3748–3753. [Google Scholar] [CrossRef]

- Mei, J.N.; Soubeyroux, J.L.; Blandin, J.J.; Li, J.S.; Kou, H.C.; Fu, H.Z.; Zhou, L. Homogeneous deformation of Ti41.5Cu37.5Ni7.5Zr2.5Hf5Sn5Si1 bulk metallic glass in the supercooled liquid region. Intermetallics 2011, 19, 48–53. [Google Scholar] [CrossRef]

- Qiao, J.C.; Pelletier, J.M.; Blandin, J.J.; Gravier, S. High temperature deformation in a lanthanum based bulk metallic glass showing a pronounced secondary relaxation. Mater. Sci. Eng. A 2013, 586, 57–61. [Google Scholar] [CrossRef]

- Yao, Z.F.; Qiao, J.C.; Pelletier, J.M.; Yao, Y. High temperature deformation behaviors of the Zr63.36Cu14.52Ni10.12Al12 bulk metallic glass. J. Mater. Sci. 2016, 51, 4079–4087. [Google Scholar] [CrossRef]

- Yu, H.B.; Samwer, K.; Wu, Y.; Wang, W.H. Correlation between beta relaxation and self-diffusion of the smallest constituting atoms in metallic glasses. Phys. Rev. Lett. 2012, 109, 095508. [Google Scholar] [CrossRef]

- Yu, H.B.; Shen, X.; Wang, Z.; Gu, L.; Wang, W.H.; Bai, H.Y. Tensile plasticity in metallic glasses with pronounced β relaxations. Phys. Rev. Lett. 2012, 108, 015504. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.H. Correlation between relaxations and plastic deformation, and elastic model of flow in metallic glasses and glass-forming liquids. J. Appl. Phys. 2011, 110, 053521. [Google Scholar]

- Wang, Z.; Sun, B.A.; Bai, H.Y.; Wang, W.H. Evolution of hidden localized flow during glass-to-liquid transition in metallic glass. Nat. Commun. 2014, 5, 5823. [Google Scholar] [CrossRef]

- Perez, J. Defect diffusion model for volume and enthalpy recovery in amorphous polymers. Polymer 1988, 29, 483–489. [Google Scholar] [CrossRef]

- Lee, K.S.; Lee, Y.-S. High-temperature deformation and crystallization behavior of a Cu36Zr48Al8Ag8 bulk metallic glass. J. Mater. Sci. 2012, 47, 2472–2478. [Google Scholar] [CrossRef]

- Wang, Q.; Pelletier, J.M.; Blandin, J.J.; Suéry, M. Mechanical properties over the glass transition of Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass. J. Non-Cryst. Solids 2005, 351, 2224–2231. [Google Scholar] [CrossRef]

- Aken, B.v.; Hey, P.d.; Sietsma, J. Structural relaxation and plastic flow in amorphous La50Al25Ni25. Mater. Sci. Eng. A 2000, 278, 247–254. [Google Scholar] [CrossRef]

- Bletry, M.; Guyot, P.; Blandin, J.J.; Soubeyroux, J.L. Free volume model: High-temperature deformation of a Zr-based bulk metallic glass. Acta Mater. 2006, 54, 1257–1263. [Google Scholar] [CrossRef]

| Temperature (K) | Activation Volume (nm3) | Frequency Factor (S−1) |

|---|---|---|

| 435 | 0.439 | 1.20 × 10−5 |

| 440 | 0.507 | 3.59 × 10−5 |

| 445 | 0.779 | 4.59 × 10−5 |

| 450 | 1.240 | 8.70 × 10−5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Qiao, J. Correlation between High Temperature Deformation and β Relaxation in LaCe-Based Metallic Glass. Materials 2020, 13, 833. https://doi.org/10.3390/ma13040833

Chen Y, Qiao J. Correlation between High Temperature Deformation and β Relaxation in LaCe-Based Metallic Glass. Materials. 2020; 13(4):833. https://doi.org/10.3390/ma13040833

Chicago/Turabian StyleChen, Yinghong, and Jichao Qiao. 2020. "Correlation between High Temperature Deformation and β Relaxation in LaCe-Based Metallic Glass" Materials 13, no. 4: 833. https://doi.org/10.3390/ma13040833

APA StyleChen, Y., & Qiao, J. (2020). Correlation between High Temperature Deformation and β Relaxation in LaCe-Based Metallic Glass. Materials, 13(4), 833. https://doi.org/10.3390/ma13040833