Rodlike YMn2O5 Powders Derived from Hydrothermal Process Using Oxygen as Oxidant

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Synthesis

2.2. Characterization

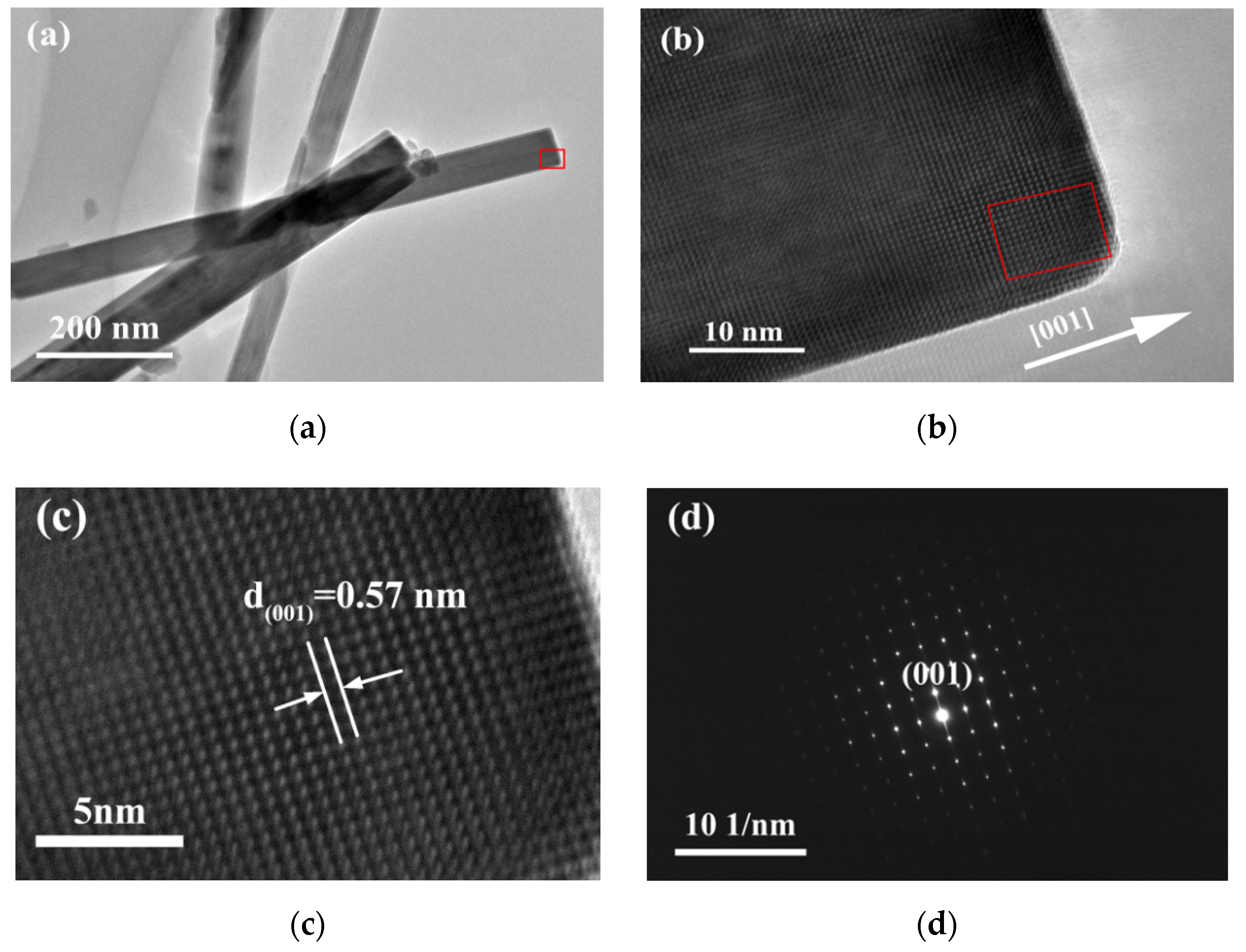

3. Results and Discussion

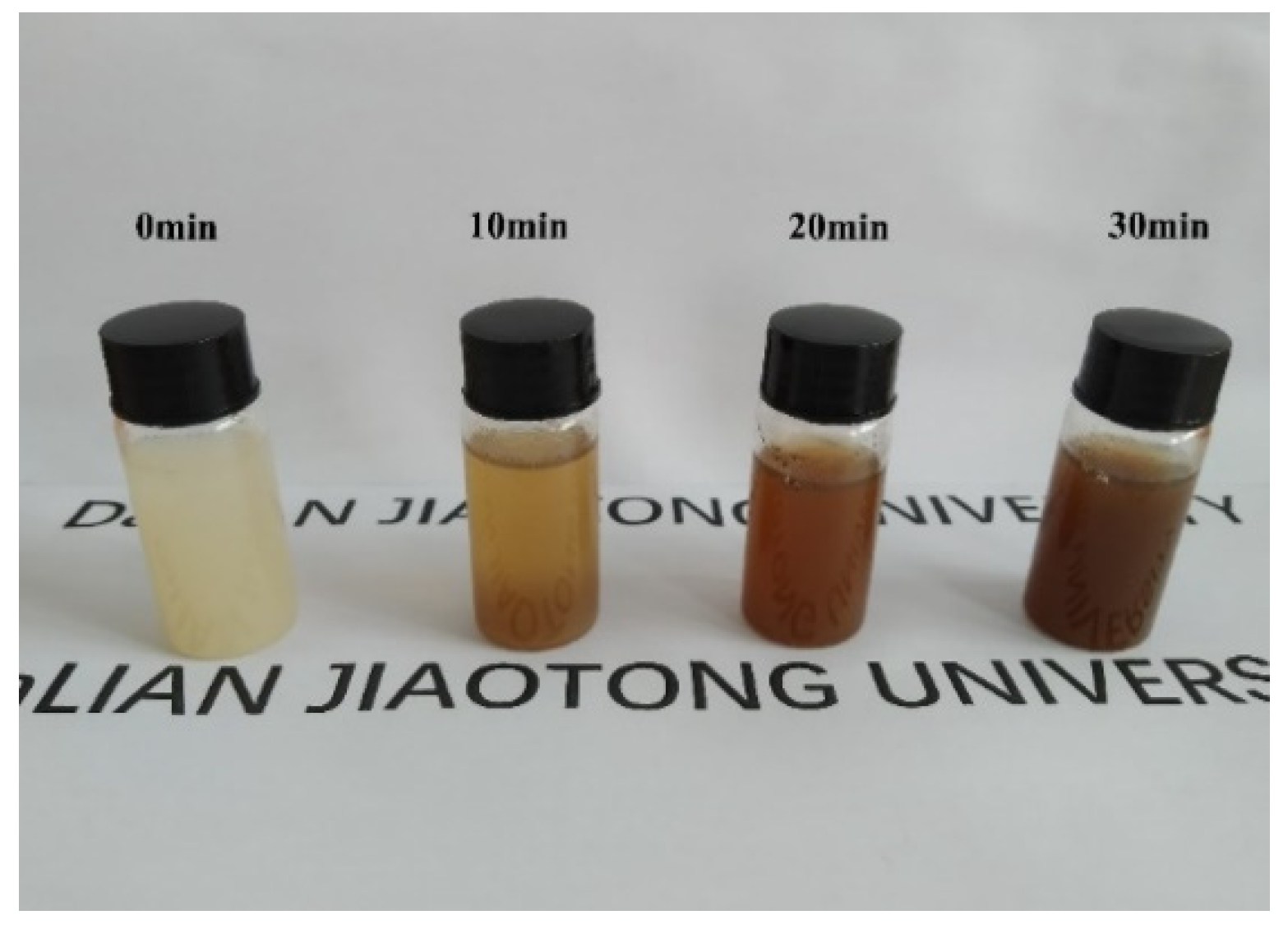

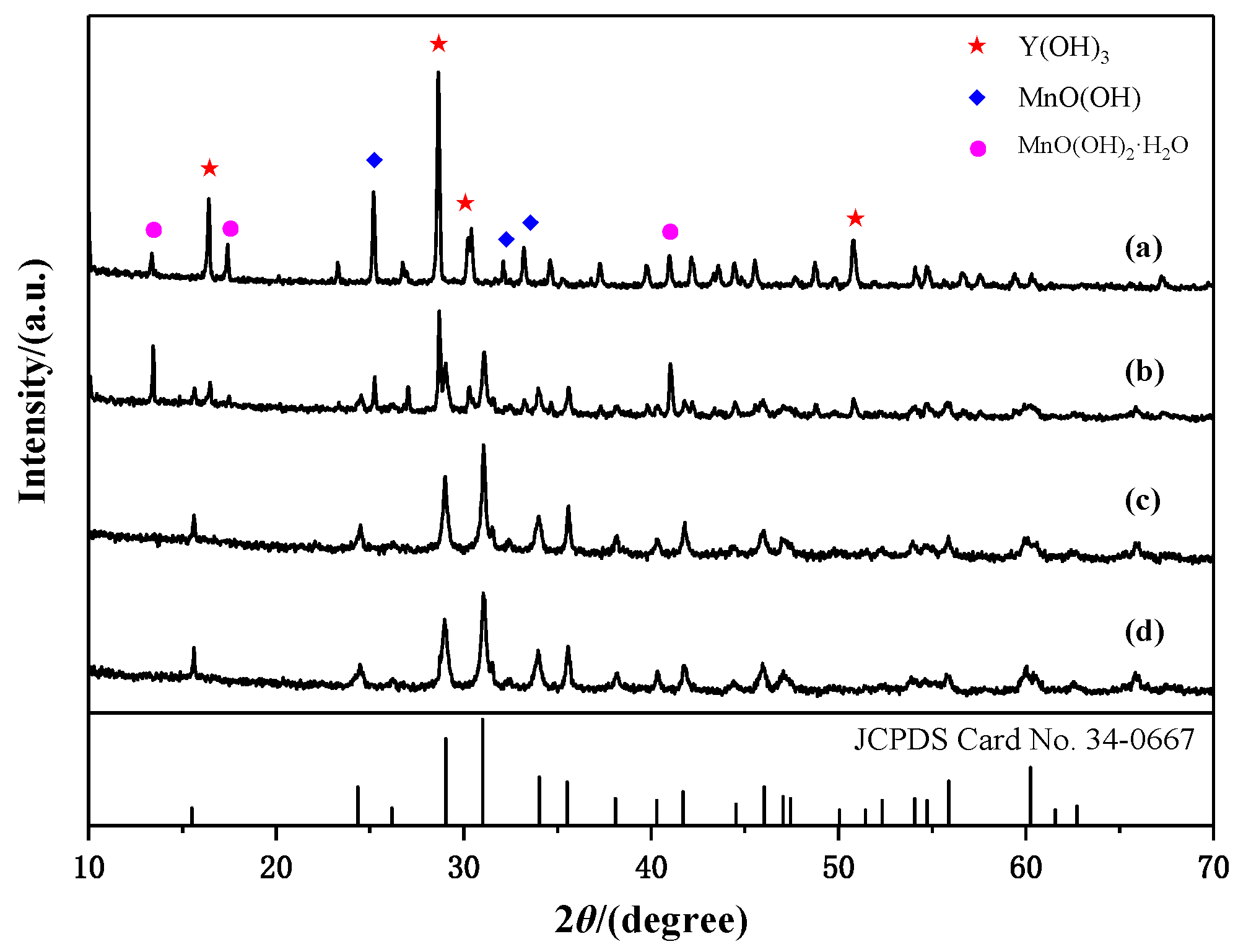

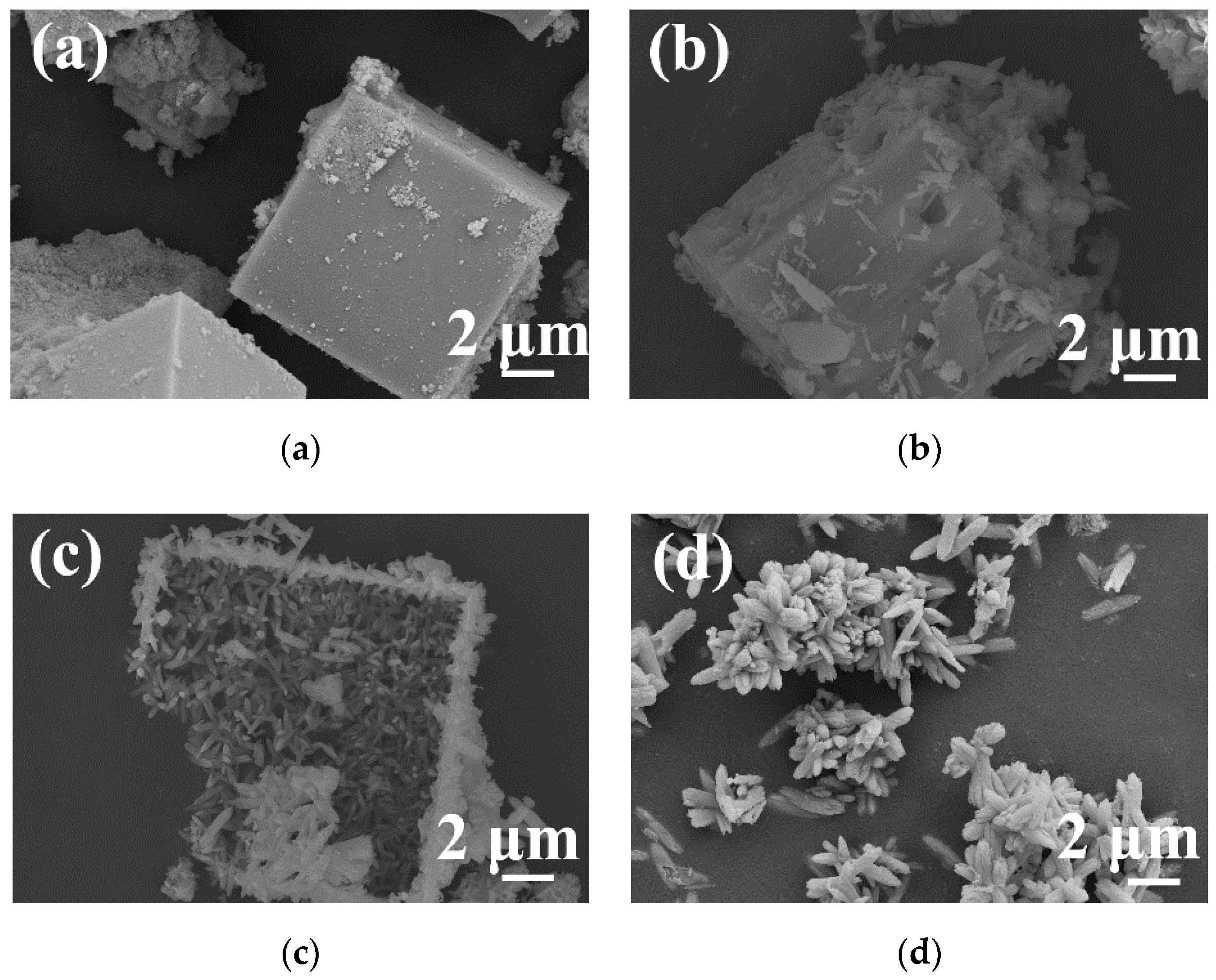

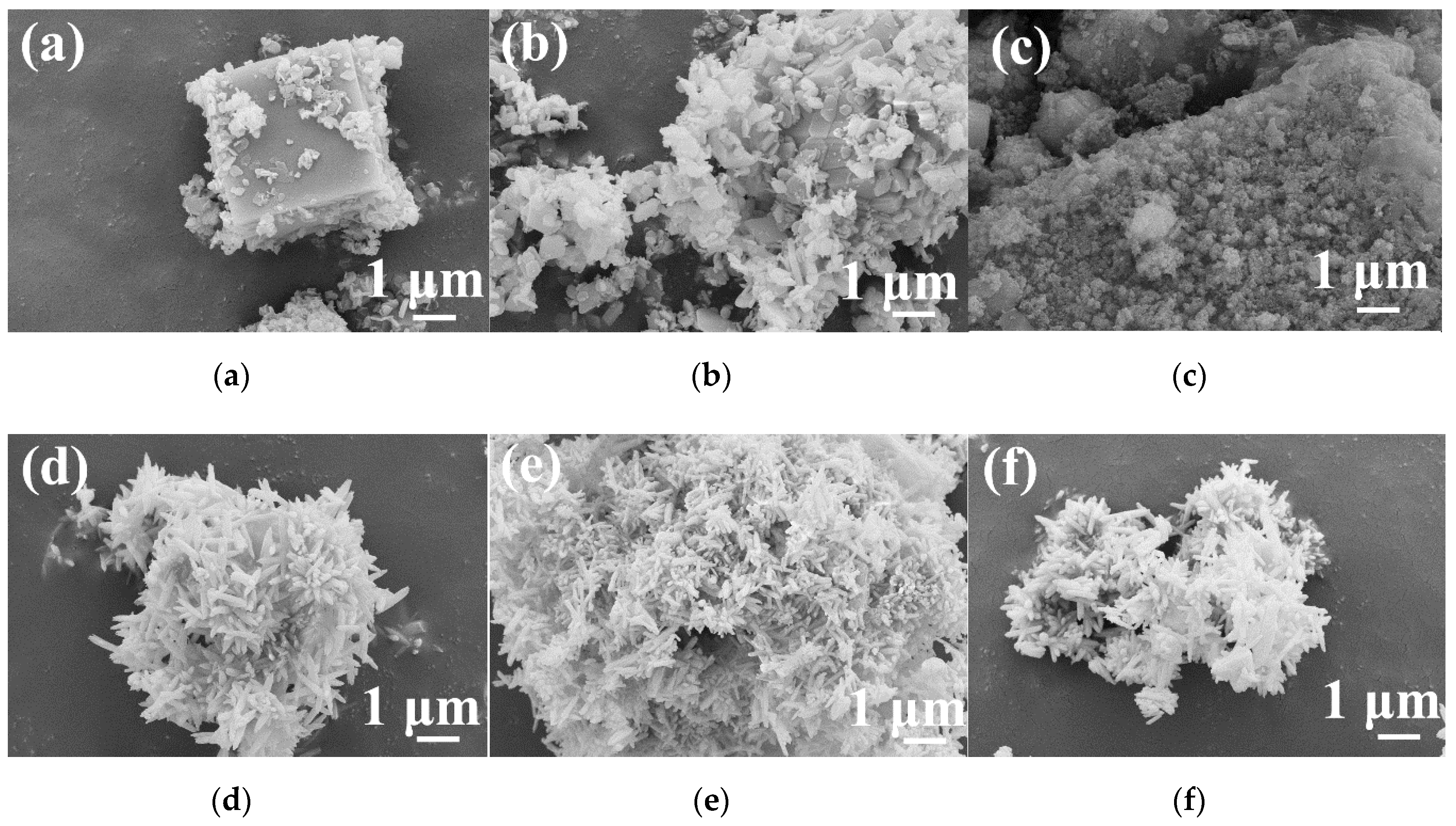

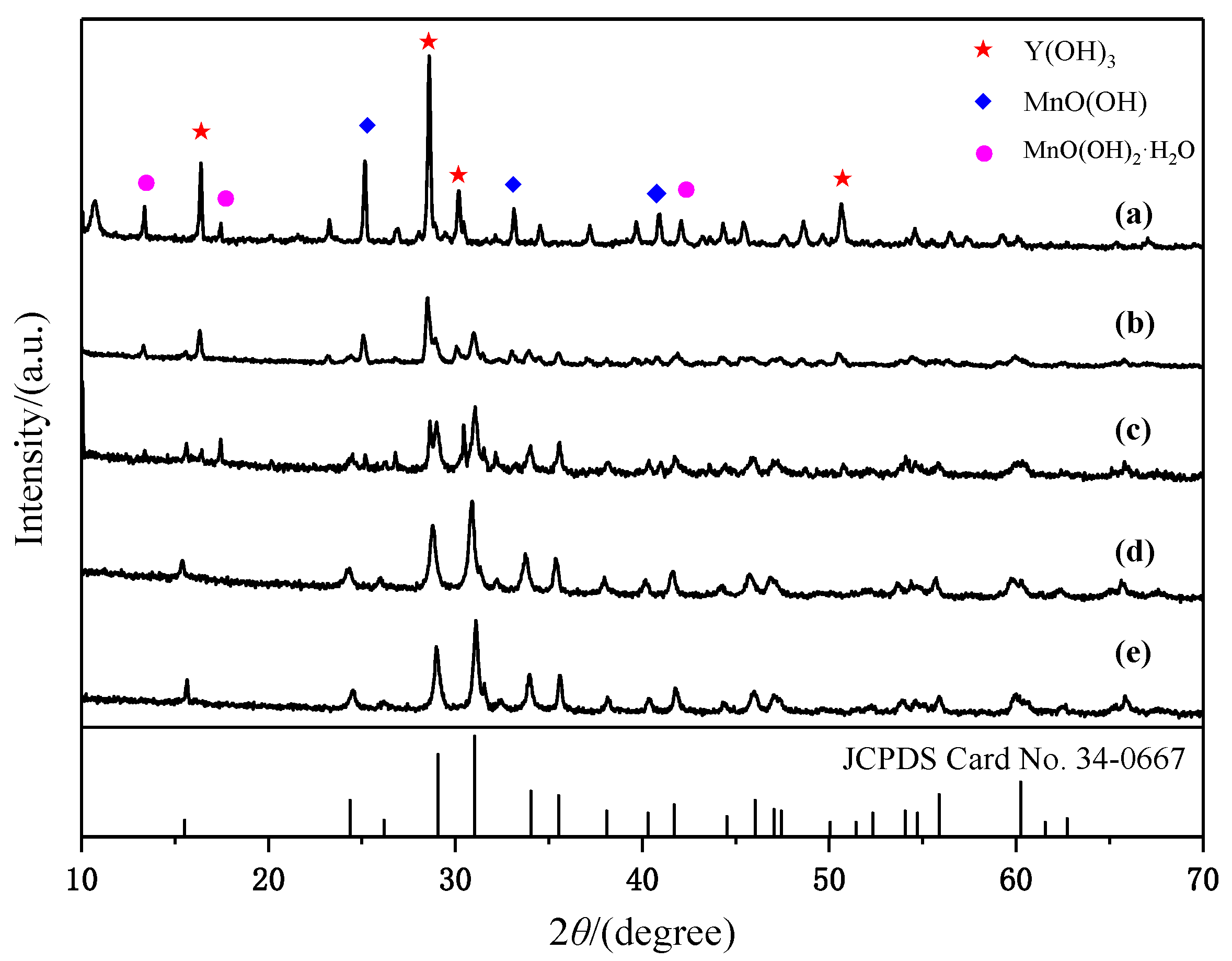

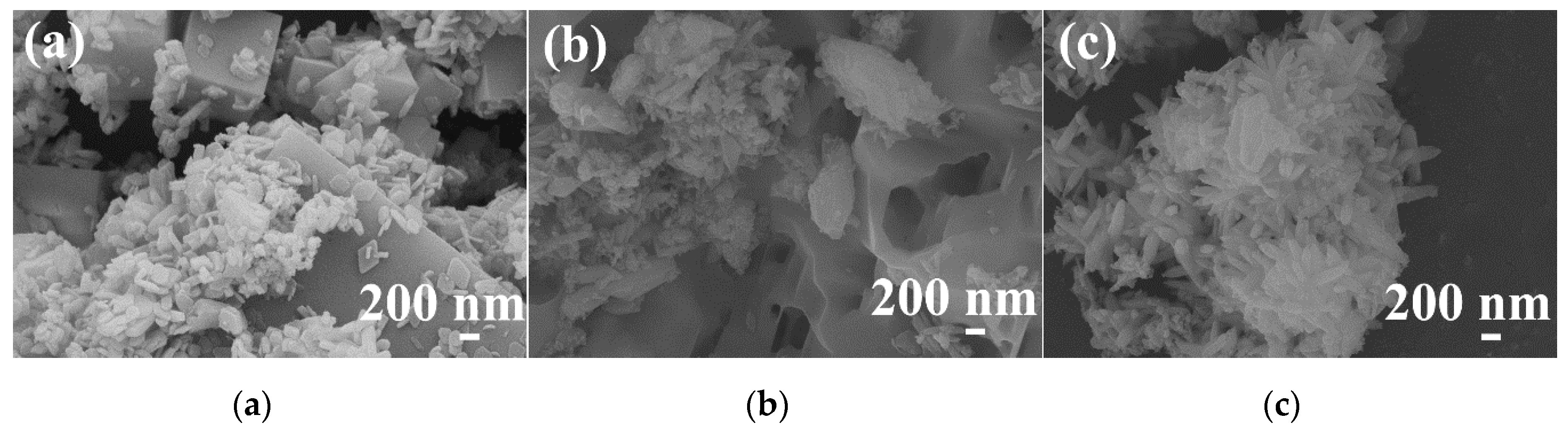

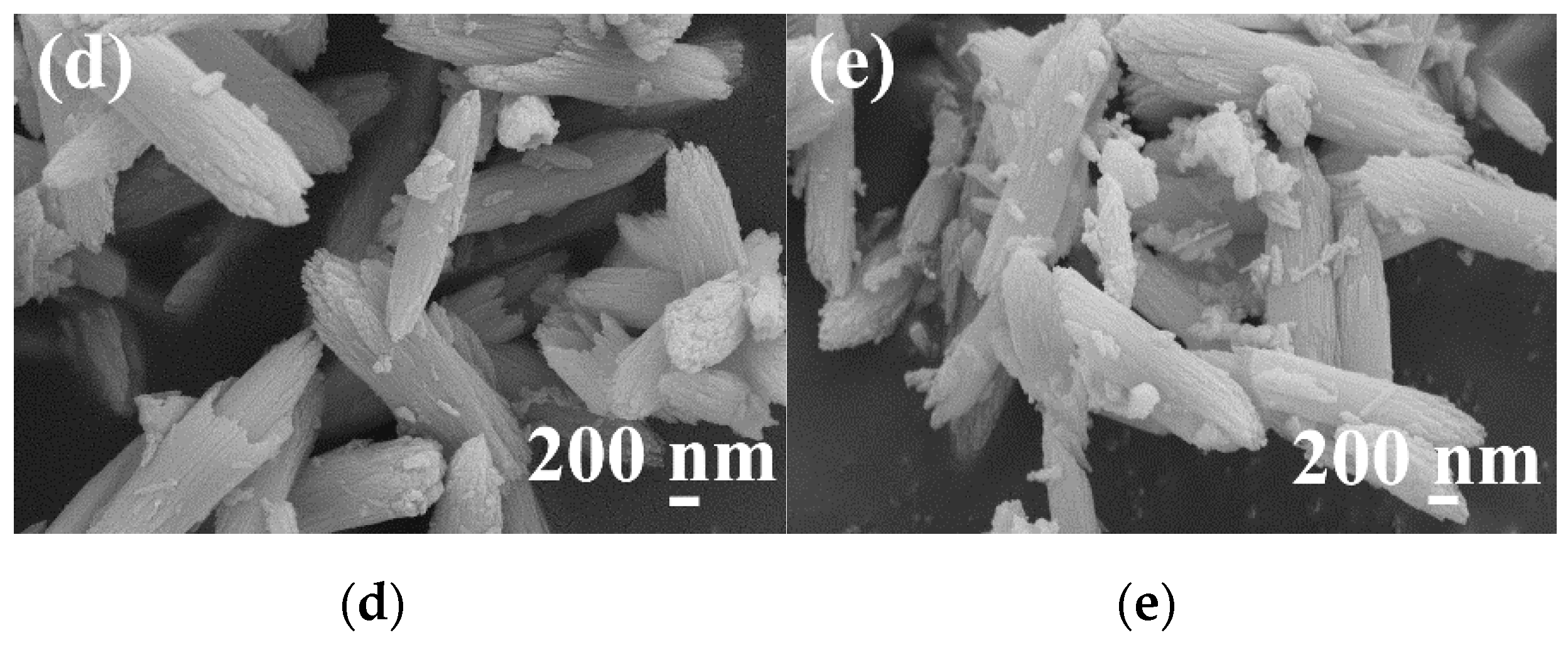

3.1. Effects of Oxidation Time

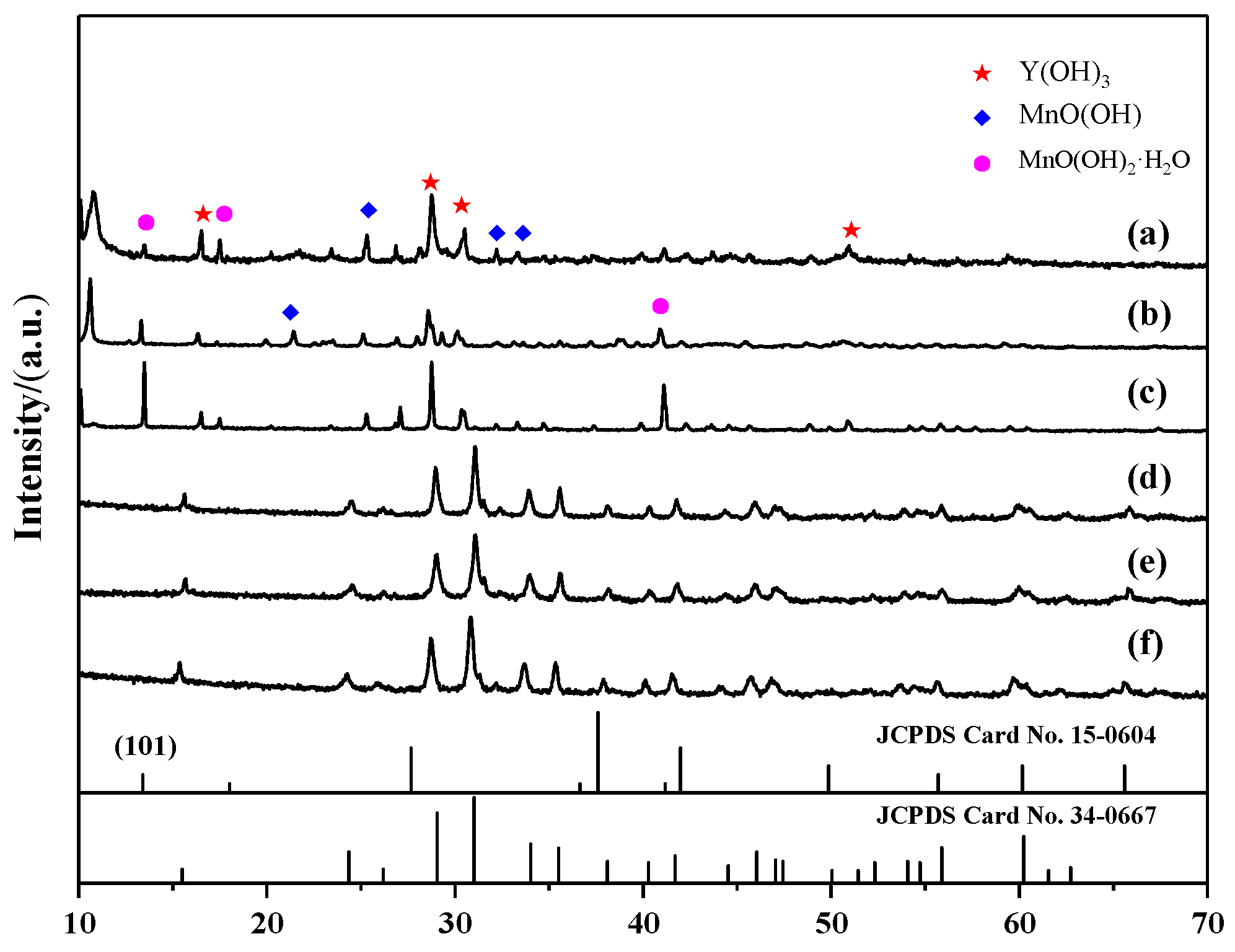

3.2. Effects of Hydrothermal Conditions

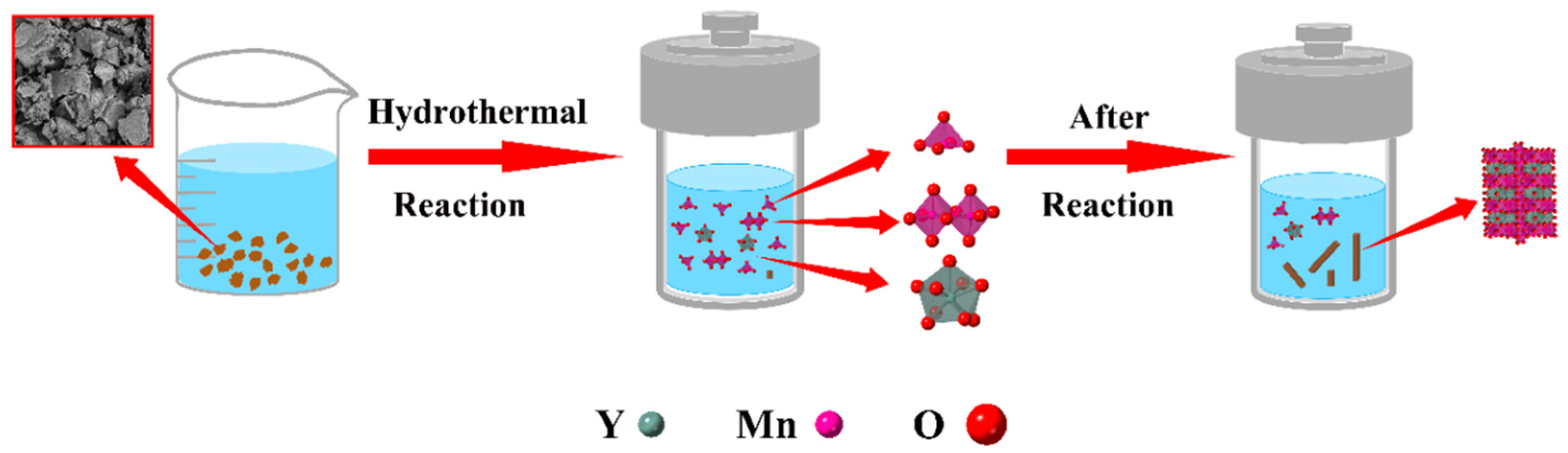

3.3. Mechanism Analysis

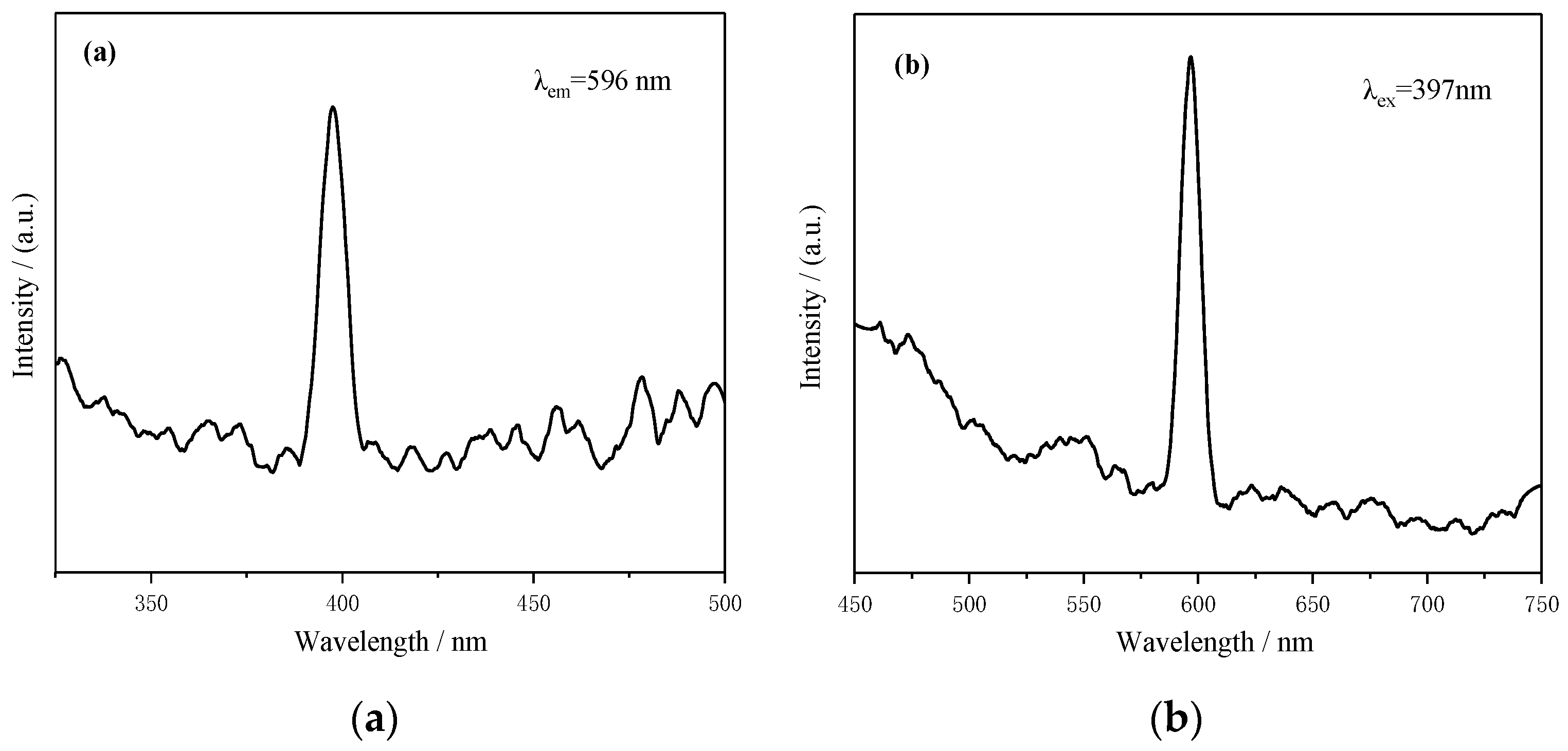

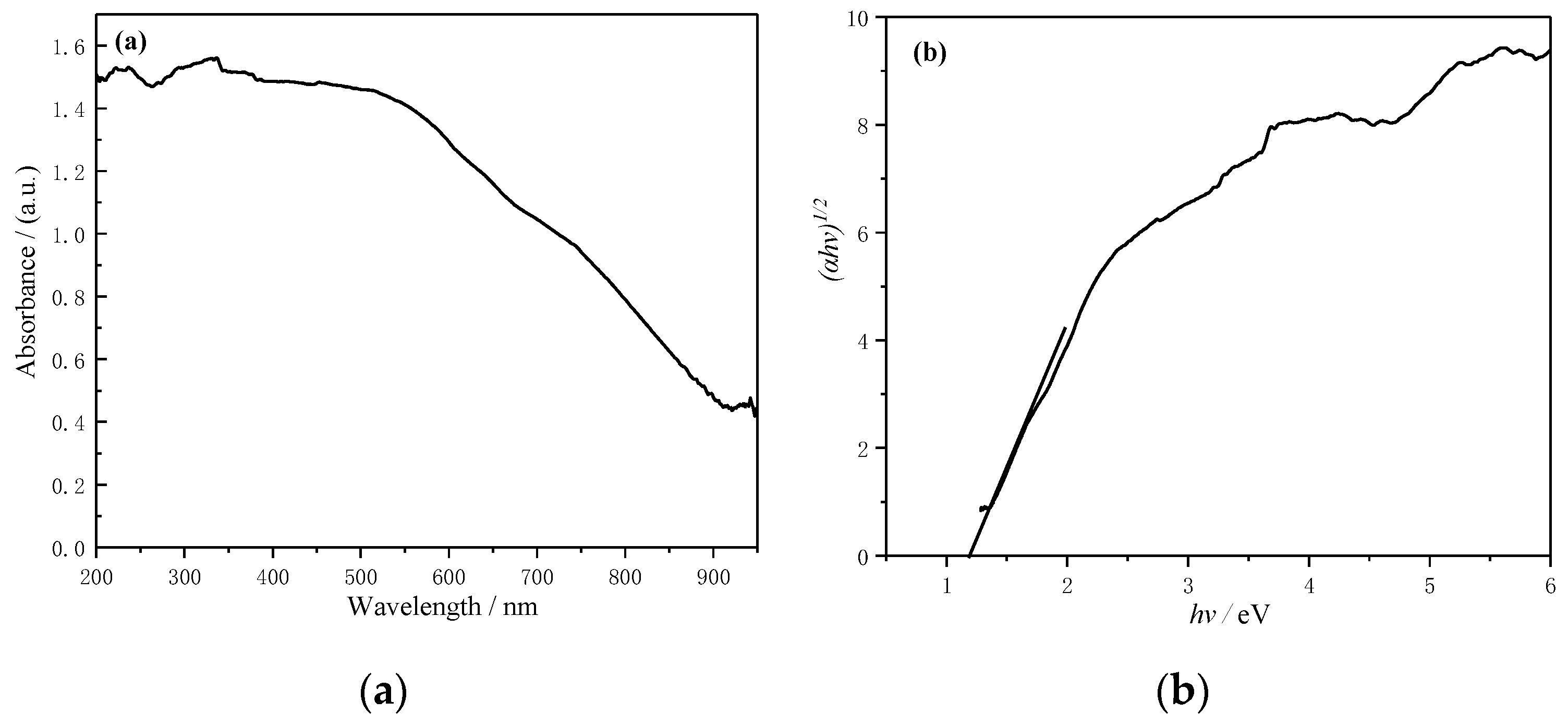

3.4. Luminescent Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schmid, H. Multi-ferroic magnetoelectrics. Ferroelectrics 1994, 162, 317–338. [Google Scholar] [CrossRef]

- Huang, Z.J.; Cao, Y.; Sun, Y.Y.; Xue, Y.Y.; Chu, C.W. Coupling between the ferroelectric and antiferromagnetic orders in YMnO3. Phys. Rev. B 1997, 56, 2623–2626. [Google Scholar] [CrossRef]

- Fiebig, M.; Lottermoser, T.; Frohlich, D.; Goltsev, A.V.; Pisarev, R.V. Observation of coupled magnetic and electric domains. Nature 2002, 419, 818–820. [Google Scholar] [CrossRef] [PubMed]

- Lorenz, B.; Litvinchuk, A.P.; Gospodinov, M.M.; Chu, C.W. Field-induced reentrant novel phase and a ferroelectric-magnetic order coupling in HoMnO3. Phys. Rev. Lett. 2004, 92, 087204. [Google Scholar] [CrossRef] [PubMed]

- Hur, N.; Park, S.; Sharma, P.A.; Ahn, J.S.; Guha, S.; Cheong, S.W. Electric polarization reversal and memory in a multiferroic material induced by magnetic fields. Nature 2004, 429, 392–395. [Google Scholar] [CrossRef] [PubMed]

- Alonso, J.A.; Casais, M.T.; MartinezLope, M.J.; Rasines, I. High oxygen pressure preparation, structural refinement, and thermal behavior of RMn2O5 (R = La, Pr, Nd, Sm, Eu). J. Solid State Chem. 1997, 129, 105–112. [Google Scholar] [CrossRef]

- Chapon, L.C.; Blake, G.R.; Gutmann, M.J.; Park, S.; Hur, N.; Radaelli, P.G.; Cheong, S.W. Structural anomalies and multiferroic behavior in magnetically frustrated TbMn2O5. Phys. Rev. Lett. 2004, 93, 177402. [Google Scholar] [CrossRef]

- Inomata, A.; Kohn, K. Pyroelectric effect and possible ferroelectric transition of helimagnetic GdMn2O5, TbMn2O5 and YMn2O5. J. Phys.: Condens. Matter 1996, 8, 2673–2678. [Google Scholar] [CrossRef]

- Kobayashi, S.; Osawa, T.; Kimura, H.; Noda, Y.; Kagomiya, I.; Kohn, K. Reinvestigation of simultaneous magnetic and ferroelectric phase transitions in YMn2O5. J. Phys. Soc. Jpn. 2004, 73, 1593–1596. [Google Scholar] [CrossRef]

- Noda, Y.; Kimura, H.; Fukunaga, M.; Kobayashi, S.; Kagomiya, I.; Kohn, K. Magnetic and ferroelectric properties of multiferroic RMn2O5. J. Phys. Condens. Matter 2008, 20, 434206. [Google Scholar] [CrossRef]

- Kagomiya, I.; Kakimoto, K.; Ohsato, H. Precursor phenomenon on ferroelectric transition in multiferroic YMn2O5. J. Eur. Ceram. Soc. 2010, 30, 255–258. [Google Scholar] [CrossRef]

- Ma, C.; Yan, J.Q.; Dennis, K.W.; McCallum, R.W.; Tan, X. Size-dependent magnetic properties of high oxygen content YMn2O5+/-δ multiferroic nanoparticles. J. Appl. Phys. 2009, 105, 033908. [Google Scholar] [CrossRef]

- De la Calle, C.; Alonso, J.A.; Martinez-Lope, M.J.; Garcia-Hernandez, M.; Andre, G. Synthesis under high-oxygen pressure, magnetic and structural characterization from neutron powder diffraction data of YGa1-xMn1+xO5 (x = 0.23): A comparison with YMn2O5. Mater. Res. Bull. 2008, 43, 197–206. [Google Scholar] [CrossRef]

- Yang, H.; Wang, S.F.; Xian, T.; Wei, Z.Q.; Feng, W.J. Fabrication and photocatalytic activity of YMn2O5 nanoparticles. Mater. Lett. 2011, 65, 884–886. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, C.; Sun, G.; Chen, B.; Xiang, X.; Ding, Q.; Zu, X. Chelating agents role on phase formation and surface morphology of single orthorhombic YMn2O5 nanorods via modified polyacrylamide gel route. Sci. China Chem. 2014, 57, 402–408. [Google Scholar] [CrossRef]

- Li, S.H.; Lei, G.P.; Peng, H. Synthesized and magnetic and ferroelectric phase transitions of single phase multiferroic YMn2O5 nanoparticles through microwave assisted polyacrylamide gel method. Ferroelectrics 2017, 520, 135–143. [Google Scholar] [CrossRef]

- Wang, S.F.; Yang, H.; Xian, T.; Wei, Z.Q.; Ma, J.Y.; Feng, W.J. Nano YMn2O5 Visible-light-driven Semiconductor Photocatalyst. J. Inorg. Mater. 2011, 26, 1164–1168. [Google Scholar] [CrossRef]

- Gao, Y.; Wu, Y.J.; Chen, X.M.; Cheng, J.P.; Lin, Y.Q.; Ma, Y. Dense YMn2O5 Ceramics Prepared by Spark Plasma Sintering. J. Am. Ceram. Soc. 2008, 91, 3728–3730. [Google Scholar] [CrossRef]

- Zhang, T.; Li, H.; Yang, Z.; Cao, F.R.; Li, L.; Chen, H.J.; Liu, H.; Xiong, K.; Wu, J.; Hong, Z.L.; et al. Electrospun YMn2O5 nanofibers: A highly catalytic activity for NO oxidation. Appl. Catal. B 2019, 247, 133–141. [Google Scholar] [CrossRef]

- Li, L.L.; Wu, S.Y.; Chen, X.M. Multiferroic YMn2O5 fine powders derived from hydrothermal process. J. Mater. Sci. Mater. Electron. 2009, 20, 1159–1163. [Google Scholar] [CrossRef]

- Mei, Y.X.; Wu, S.P. Morphology control of YMn2O5 nanocrystals by hydrothermal synthesis and their magnetic properties. RSC Adv. 2013, 3, 11888–11894. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, N.; Xia, M.; Yokoyama, M.; Hintzen, H.T. Research progress and application prospects of transition metal Mn4+-activated luminescent materials. J. Mater. Chem. C 2016, 4, 9143–9161. [Google Scholar] [CrossRef]

- Hu, C.C.; Wu, Y.T.; Chang, K.H. Low-temperature hydrothermal synthesis of Mn3O4 and MnOOH single crystals: Determinant influence of oxidants. Chem. Mater. 2008, 20, 2890–2894. [Google Scholar] [CrossRef]

- Zheng, W.J.; Pang, W.Q.; Meng, G.Y.; Peng, D.K. Hydrothermal synthesis and characterization of LaCrO3. J. Mater. Chem. 1999, 9, 2833–2836. [Google Scholar] [CrossRef]

- Jana, S.; Basu, S.; Pande, S.; Ghosh, S.K.; Pal, T. Shape-selective synthesis, magnetic properties, and catalytic activity of single crystalline β-MnO2 nanoparticles. J. Phys. Chem. C 2007, 111, 16272–16277. [Google Scholar] [CrossRef]

- Li, F.; Wu, J.; Qin, Q.; Li, Z.; Huang, X. Facile synthesis of γ-MnOOH micro/nanorods and their conversion to β-MnO2, Mn3O4. J. Alloys Compd. 2010, 492, 339–346. [Google Scholar] [CrossRef]

- Cha, D.K.; Park, S.M. Electrochemical oxidation of Mn(OH)2 in alkaline media. J. Electrochem. Soc. 1997, 144, 2573–2580. [Google Scholar] [CrossRef]

- Vedmid, L.B.; Yankin, A.M.; Fedorova, O.M.; Balakirev, V.F. Evolution of phase equilibrium states in the Y-Mn-O system in the thermal dissociation of the compound YMn2O5. Russ. J. Inorg. Chem. 2014, 59, 519–523. [Google Scholar] [CrossRef]

- Wu, Y.H. An Introduction to Nanomaterials; Chemical Industry Press: Beijing, China, 2009. [Google Scholar]

- Jun, Y.W.; Choi, J.S.; Cheon, J. Shape control of semiconductor and metal oxide nanocrystals through nonhydrolytic colloidal routes. Angew. Chem. Int. Ed. 2006, 45, 3414–3439. [Google Scholar] [CrossRef]

- Shang, M.M.; Li, C.X.; Lin, J. How to produce white light in a single-phase host? Chem. Soc. Rev. 2014, 43, 1372–1386. [Google Scholar] [CrossRef]

- Yang, L.; Kruse, B. Revised Kubelka-Munk theory. I. Theory and application. J. Opt. Soc. Am. A 2004, 21, 1933–1941. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Wang, J.; He, H.; Lu, Y.; Shi, Z. Rodlike YMn2O5 Powders Derived from Hydrothermal Process Using Oxygen as Oxidant. Materials 2020, 13, 805. https://doi.org/10.3390/ma13030805

Shi J, Wang J, He H, Lu Y, Shi Z. Rodlike YMn2O5 Powders Derived from Hydrothermal Process Using Oxygen as Oxidant. Materials. 2020; 13(3):805. https://doi.org/10.3390/ma13030805

Chicago/Turabian StyleShi, Jun, Jing Wang, Huifen He, Yang Lu, and Zhongxiang Shi. 2020. "Rodlike YMn2O5 Powders Derived from Hydrothermal Process Using Oxygen as Oxidant" Materials 13, no. 3: 805. https://doi.org/10.3390/ma13030805

APA StyleShi, J., Wang, J., He, H., Lu, Y., & Shi, Z. (2020). Rodlike YMn2O5 Powders Derived from Hydrothermal Process Using Oxygen as Oxidant. Materials, 13(3), 805. https://doi.org/10.3390/ma13030805