Progress and Status of Hydrometallurgical and Direct Recycling of Li-Ion Batteries and Beyond

Abstract

1. Introduction

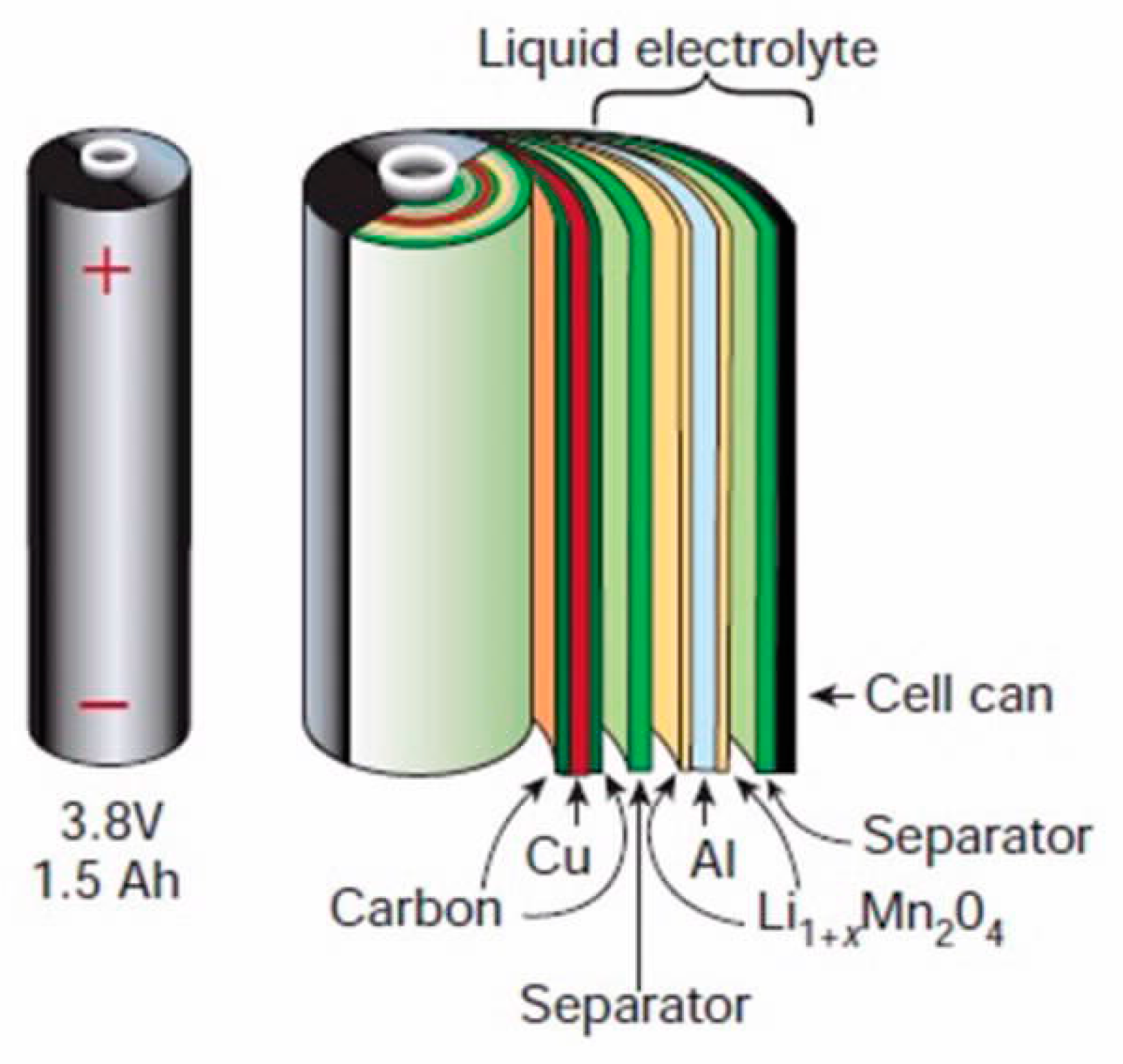

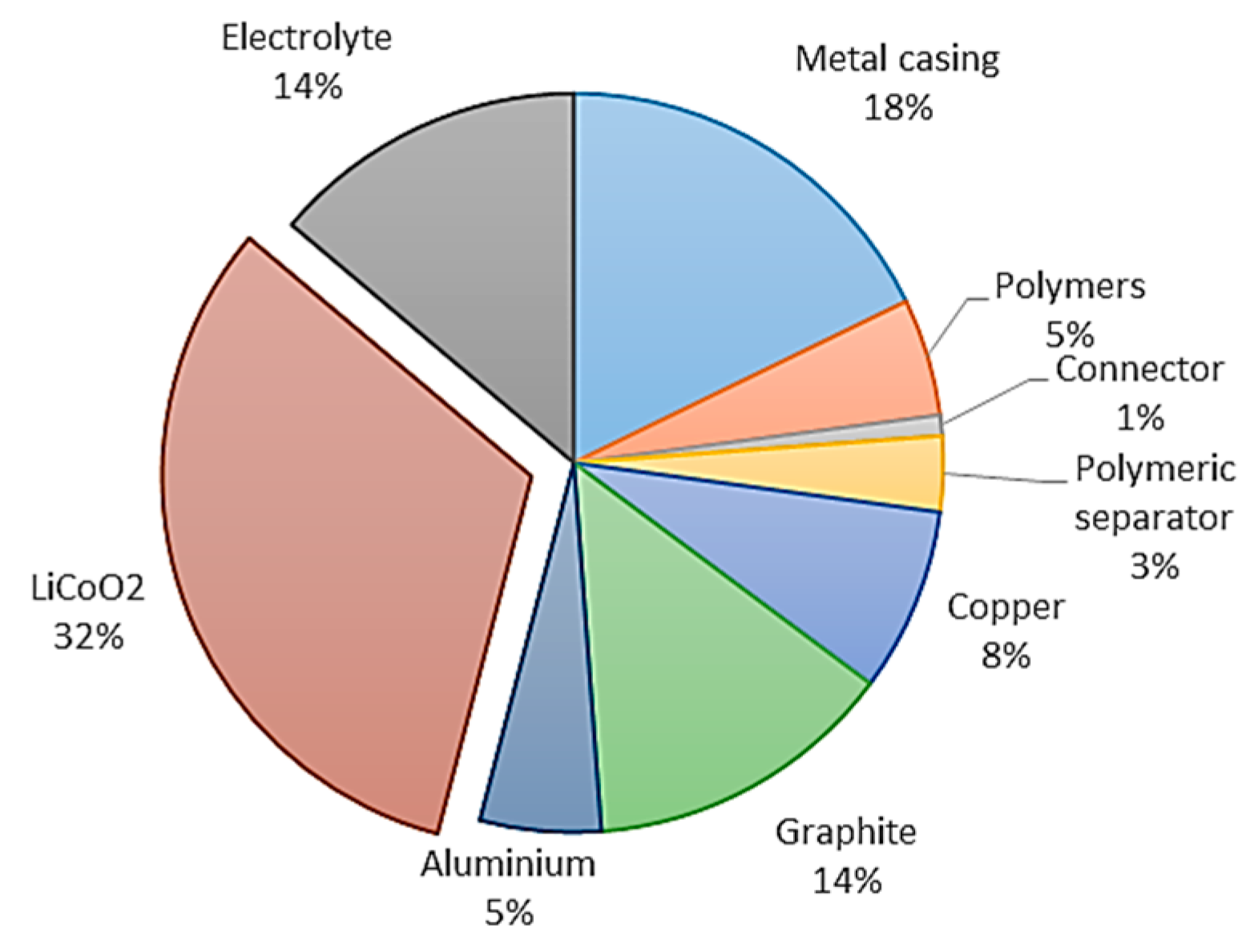

2. Description of LIBs

3. Recycling as Sustainable Solution for LIB Waste Management

4. Recycling Approaches

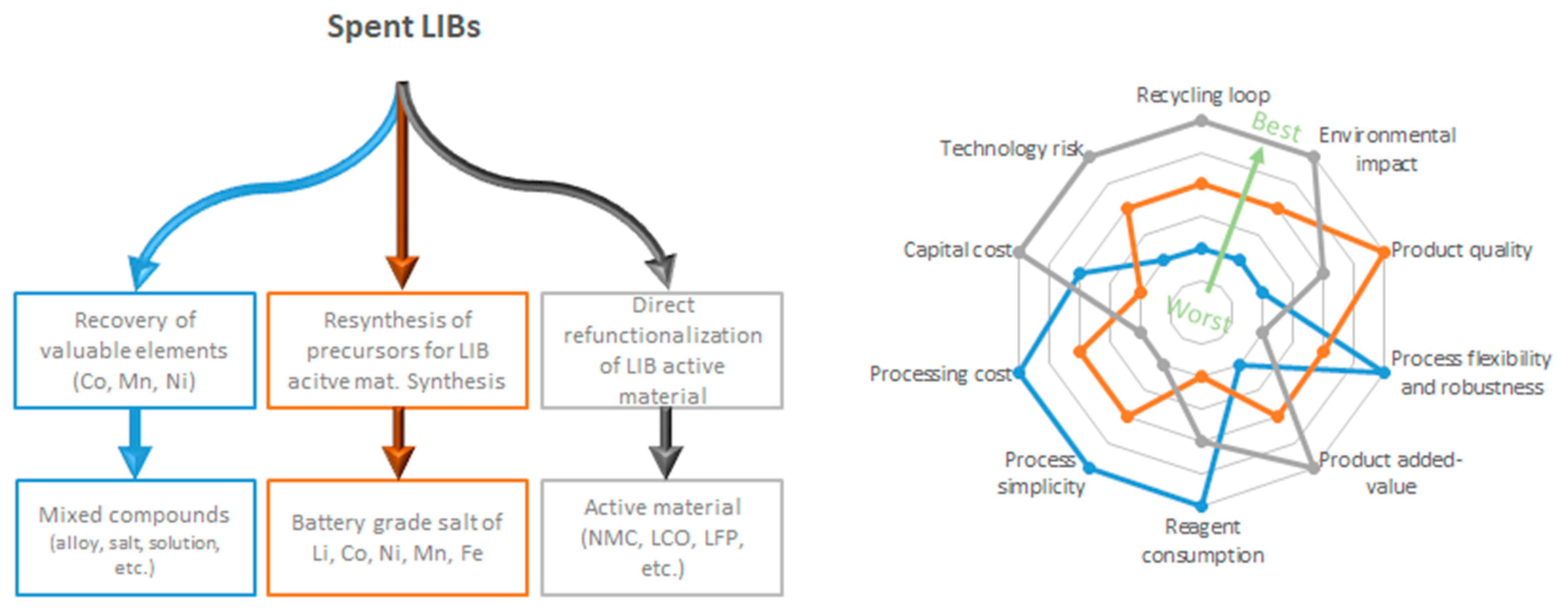

, “recycle”

, “recycle”  , and “down-cycle”

, and “down-cycle”  . Although the general objectives of recycling are to maximize the material recovery and economic value while minimizing the environmental impact, it also includes processes that focus on recovering only one target component from the whole battery system or degrade LIB components to different degrees of lower value products [48]. The term “downcycling” can be used to refer to this degradation process, whether deliberate or unintended, and is also designated as “open-loop” recycling in the literature [49]. The quality and inherent properties of a product that enters an open-loop recycling chain are undoubtedly altered. This arises from the cross-contamination with other type of materials, mixing various additive elements contained in similar materials, or the degradation of the physical and chemical properties of the recycled material. More specifically, downcycling is unintended when the qualities of a material have been degraded owing to its manipulation and processing. Conversely, downcycling is deliberate when the purpose of the process is to return the material to its more simple or elementary form. Thus, to reverse such decrease in quality, recycling should include additional costly purification steps. For example, Ni and Co alloys are recovered when Co- and Ni-based LIBs are processed together with ore concentrate in a smelter like Glencore’s Sudbury (Canada) facilities. The Co and Ni alloy requires additional hydrometallurgical treatment before it can be used for synthesis of fresh cathode compounds suitable for manufacturing new LIBs.

. Although the general objectives of recycling are to maximize the material recovery and economic value while minimizing the environmental impact, it also includes processes that focus on recovering only one target component from the whole battery system or degrade LIB components to different degrees of lower value products [48]. The term “downcycling” can be used to refer to this degradation process, whether deliberate or unintended, and is also designated as “open-loop” recycling in the literature [49]. The quality and inherent properties of a product that enters an open-loop recycling chain are undoubtedly altered. This arises from the cross-contamination with other type of materials, mixing various additive elements contained in similar materials, or the degradation of the physical and chemical properties of the recycled material. More specifically, downcycling is unintended when the qualities of a material have been degraded owing to its manipulation and processing. Conversely, downcycling is deliberate when the purpose of the process is to return the material to its more simple or elementary form. Thus, to reverse such decrease in quality, recycling should include additional costly purification steps. For example, Ni and Co alloys are recovered when Co- and Ni-based LIBs are processed together with ore concentrate in a smelter like Glencore’s Sudbury (Canada) facilities. The Co and Ni alloy requires additional hydrometallurgical treatment before it can be used for synthesis of fresh cathode compounds suitable for manufacturing new LIBs.4.1. Currently Used Recycling Processes

4.2. Pretreatment of Spent LIBs

- ▪

- Bulk shipment of small-size LIBs, including portable ones, small electronics, and E-bike modules;

- ▪

- Battery packs from used or crashed electric and hybrid vehicles or stationary devices.

- ▪

- Battery pack dismantling,

- ▪

- Sorting by chemistry,

- ▪

- Discharging,

- ▪

- Crushing and shredding,

- ▪

- Material separation,

- ▪

- Electrolyte recovery,

- ▪

- Binder separation,

- ▪

- Thermal treatment,

- ▪

- Washing.

- Combination of anode and cathode; the feed material comprises Cu and Al current collectors, graphite from the anode, carbon from the cathode, PVDF (or other plastic binder), and cathodic active material;

- Cathode only; the feed material includes Al, C, PVDF, and active material;

- Black mass; Al and Cu are removed mechanically or manually up-stream or dissolved in strong alkaline media, but PVDF and conductive carbon remain in the black mass. Generally, the anode is first separated from the cathode;

- Active material; either the binder material (mostly PVDF) is dissolved in solvent or is thermally degraded prior to leaching. In the latter case, the temperature of the thermal treatment determines the degree of degradation of PVDF and conductive carbon;

- Calcined black mass; active material has been subjected to high temperature in oxidizing environment, and consequently the binder and carbon burned, and the inorganic compounds were oxidized.

4.3. Battery Sorting

4.4. Size Reduction and Component Separation

4.5. Removal of Current Collector and Binder

4.6. Graphite Separation

5. Hydrometallurgical Approach

5.1. Sulfate System

- ▪

- The presence of a reducing agent is important for accelerating leaching kinetics;

- ▪

- Of all reducing agents, H2O2 appears to be the most efficient, followed by glucose and sulfites;

- ▪

- Metallic Cu (anode current collector) exhibited lower leaching efficiency followed by Li, Co, Ni, and Mn;

- ▪

- Roasting or chemical dissolution of PVDF is not a prerequisite for efficient leaching.

Solution Purification and Metal Extraction

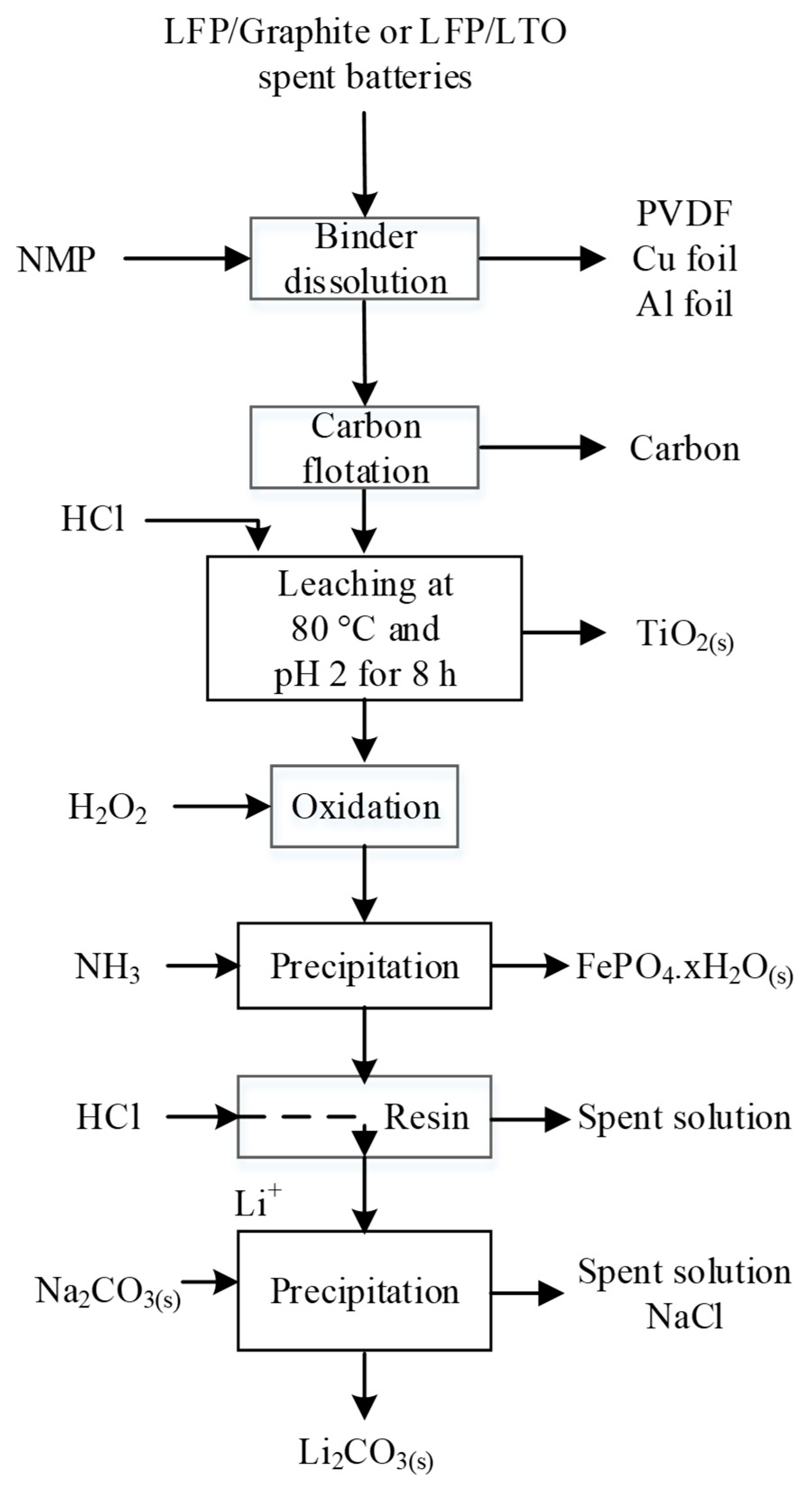

5.2. Chloride System

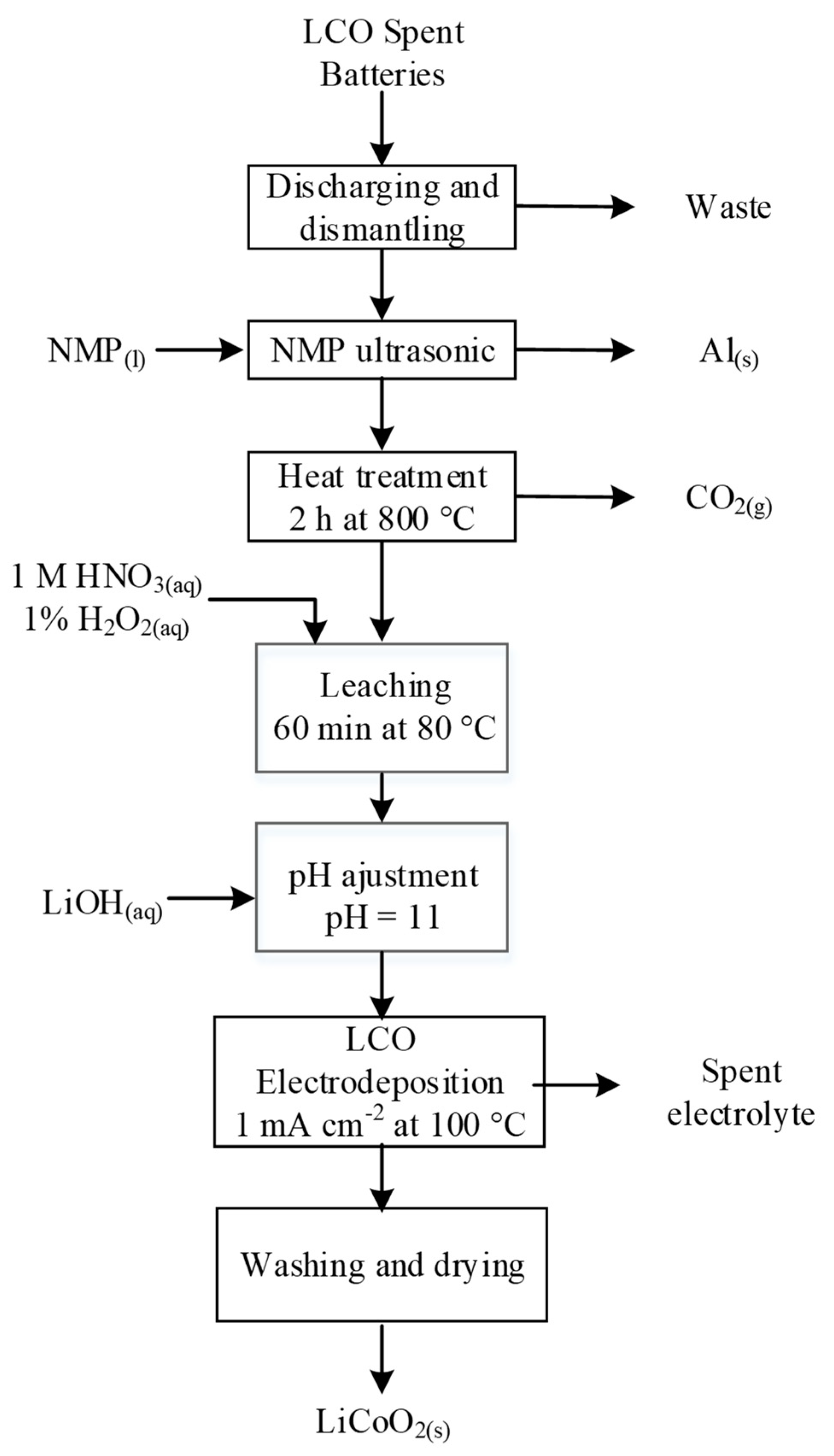

5.3. Nitrate System

5.4. Other Inorganic Acids or Alkaline Leaching Agents

5.5. Organic Acid Leaching

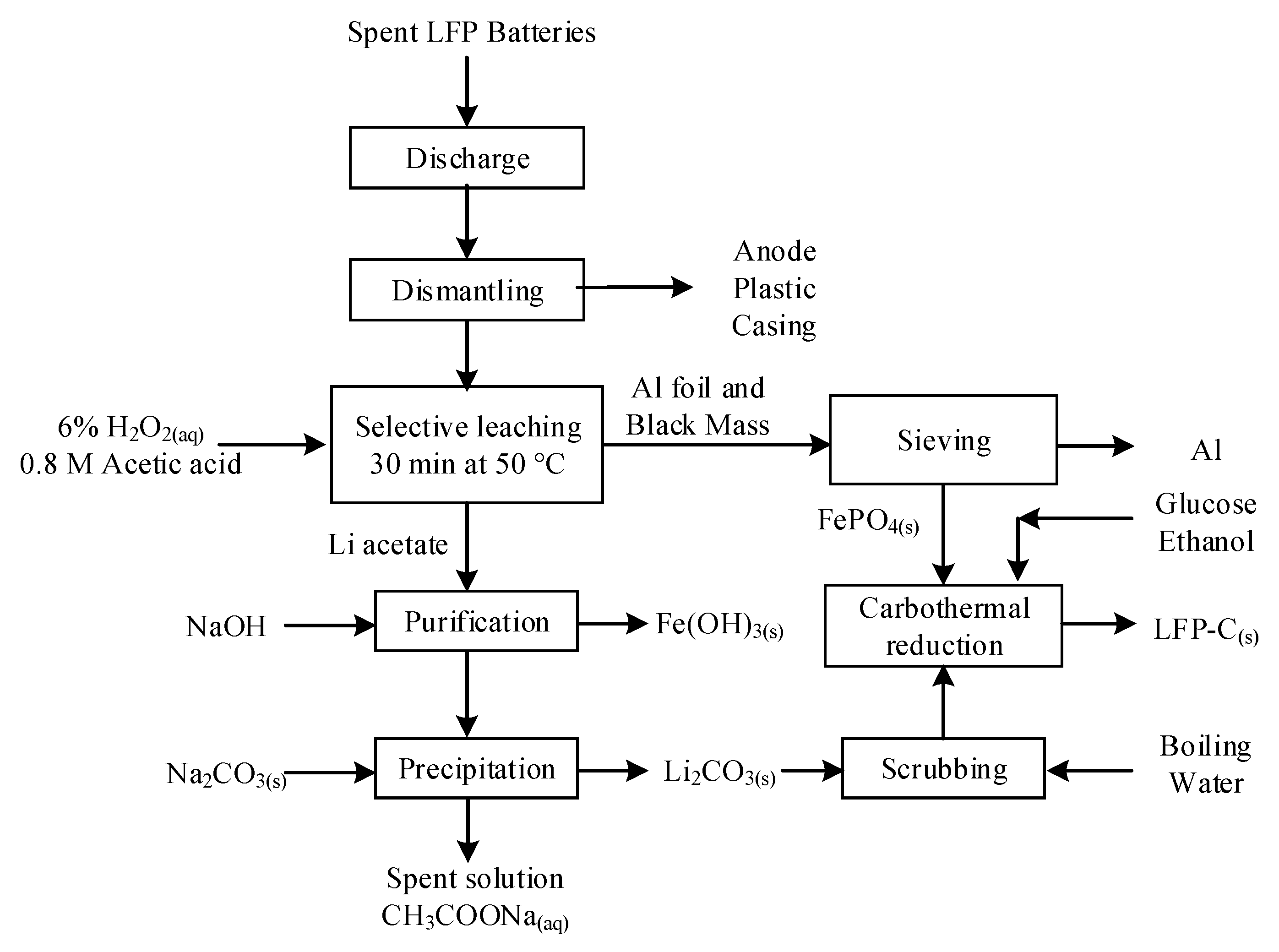

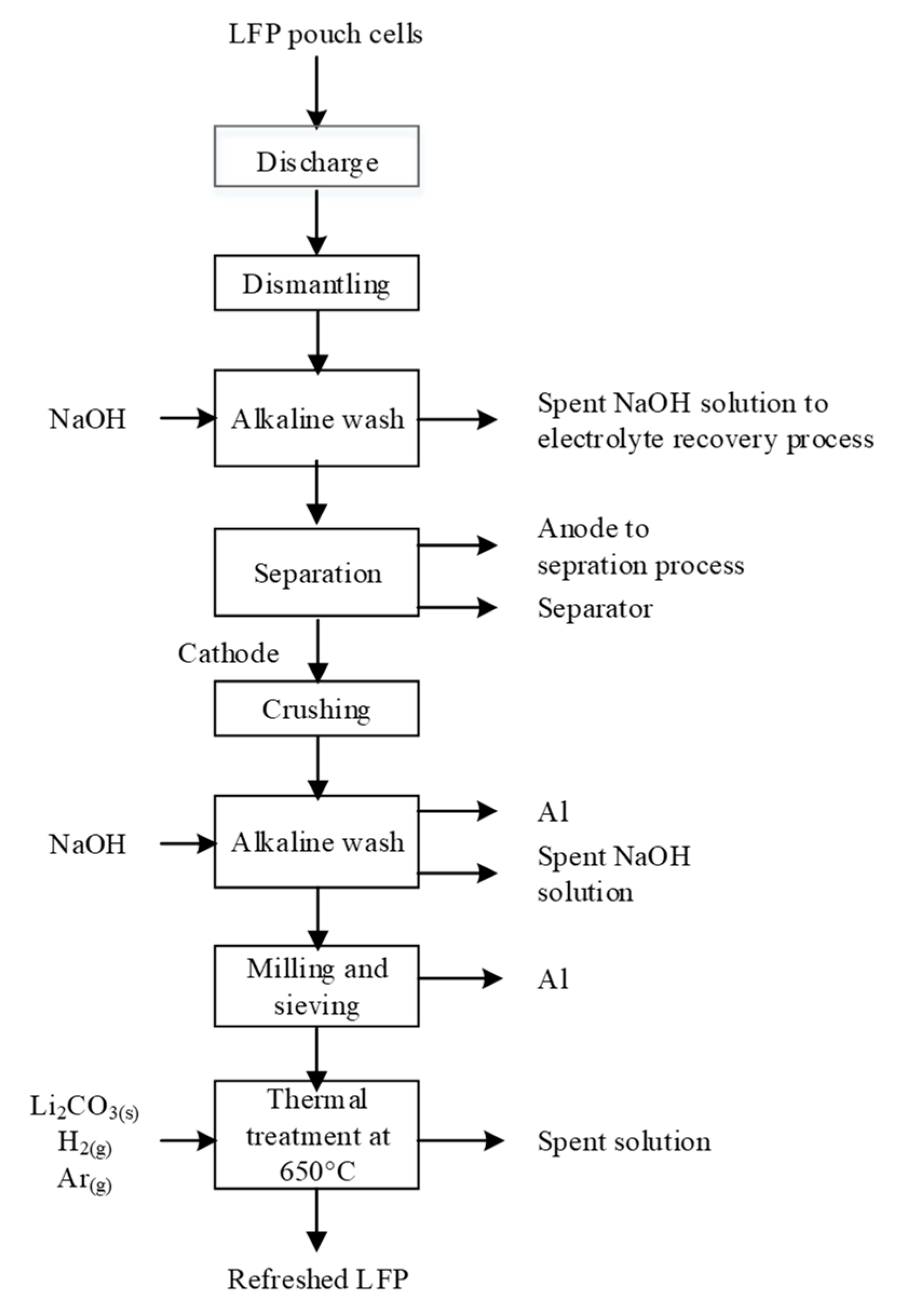

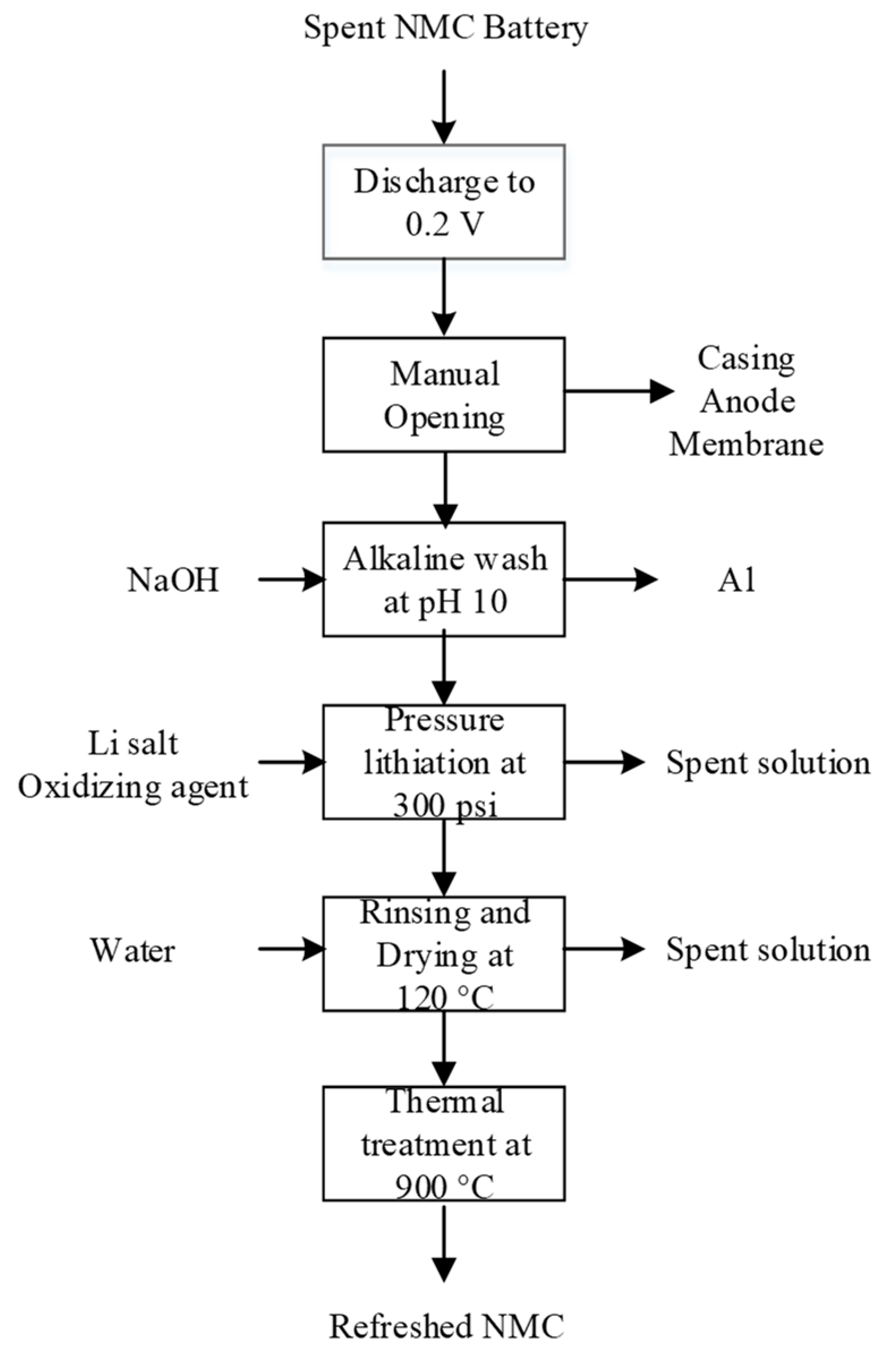

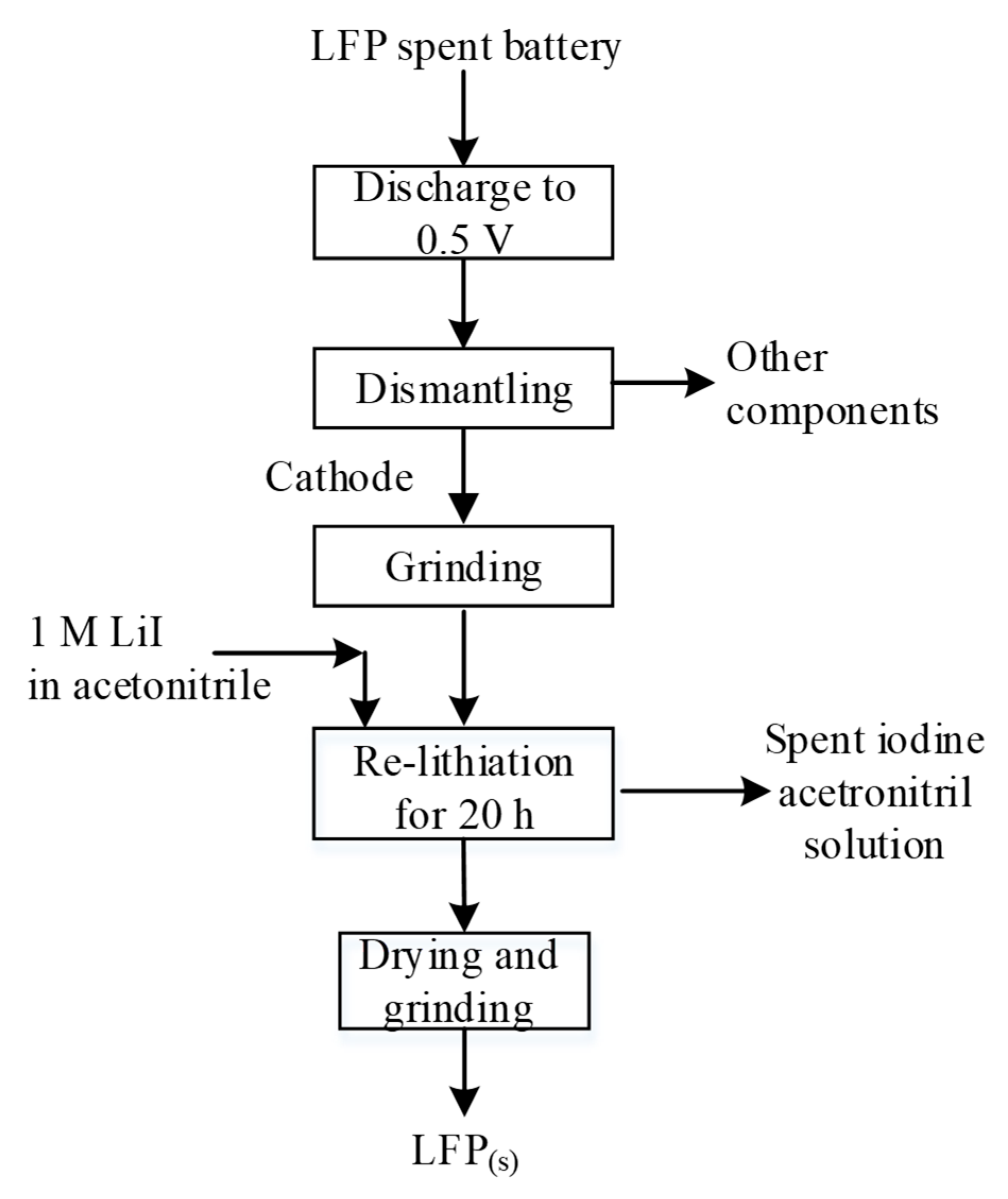

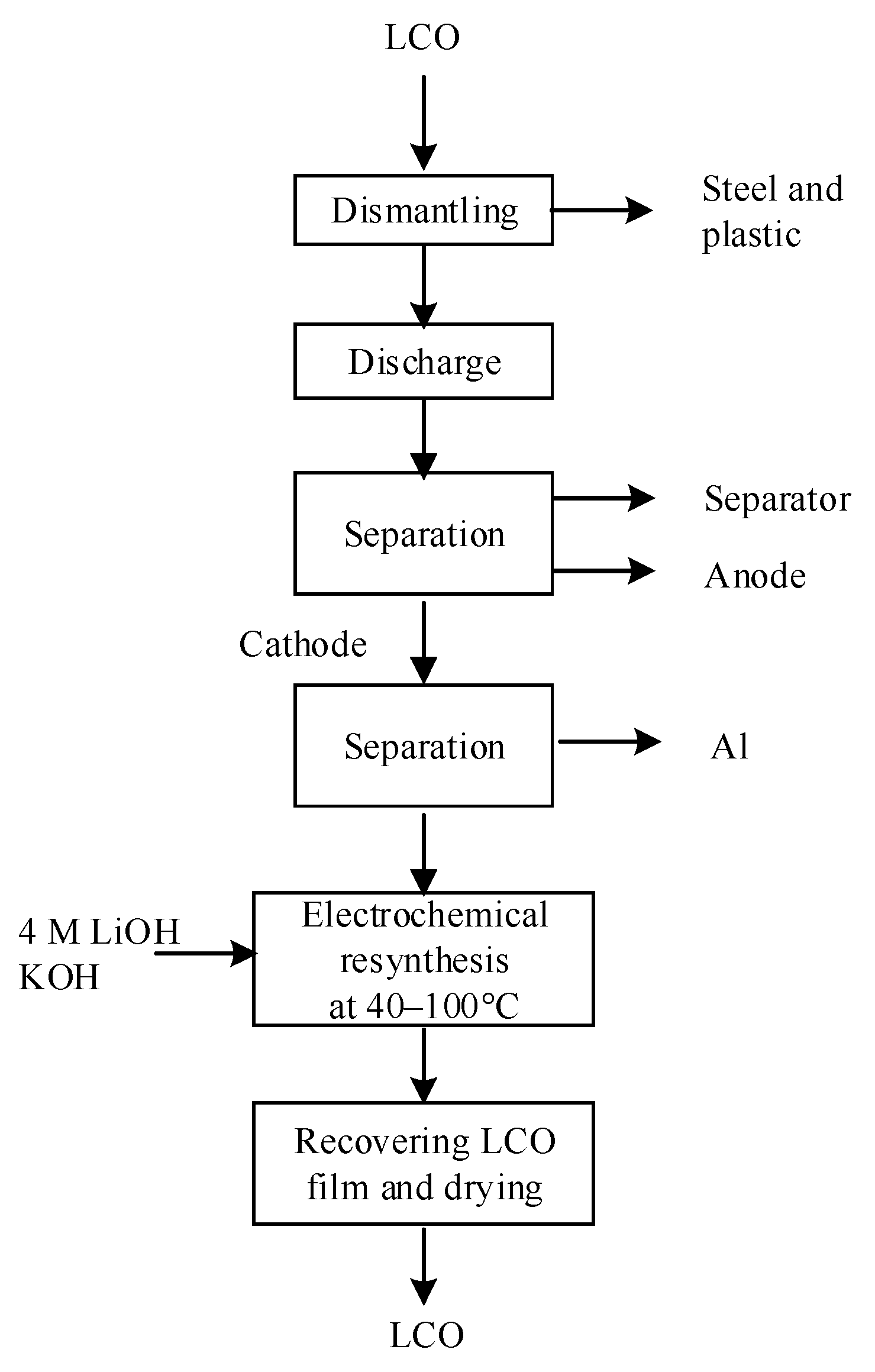

6. Direct Recycling Approach

7. Challenges and Trends for Recycling

- First, the collection of spent LIBs is costly and requires involvement of all members of the consumption chain, including producers, sellers, governments, waste managers, and consumers. For instance, in European Union, less than 20% of the spent LIBs were collected in 2016 according to Eucobat (European Compliance Organizations for Batteries) [16] despite well-established regulations and recycling industry. In North America, recovery estimation is around 5% [234]. Other than collection, shipment of spent LIBs, particularly large lithium-ion battery packs, is problematic. This critical aspect is one of the most discussed topics in conferences and workshops, as seen during NaatBat 2019 Battery Conference held in Buffalo. It is also studied by the United Nations Committee of Experts on the Transport of Dangerous Goods, and several sessions are dedicated to this subject.

- Secondly, the diversity in LIB materials and rapid evolution of technologies make it difficult to plan the variation of material inflow. Over the past decade, cathode composition has faced a deep evolution from early stage of LCO to new composition such as NMC, LFP, NCA, and LMO. In addition, some products having cathode additives such as yttrium are now available on the market, which will eventually end up in recycling process. Moreover, modification of the anode material is undergoing, shifting from graphite to LTO, and, in the near future, to silicon-based materials. Further, the segment of electrolyte additives in lithium-ion batteries is a dynamic sector; we noted 312 patents on various additives in 24 months. Lastly, the current research push towards all-solid-state Li batteries is imposing new challenges necessitating early consideration of the end-of-life fate of these new devices to simplify recycling. Considering these upcoming changes, management of the mass balance, mitigation of health and safety issues (One of the example is propane sultone, which is adopted in some composition and has a safety issue to manage with accuracy (see CAS number 1120-71-4)), and waste management will continue to be a challenge for battery recycling plants.

- Finally, strong competition between battery recyclers and the volatility of commodities market prices restrict profit margins for recyclers, which weaken the viability of the industry. This aspect must be addressed by reinforcement of producer responsibility to ensure the involvement of the producer of the waste in the recycling cost when recovered materials cannot compensate the processing cost, e.g., manufacturers of LFP and LMO systems. This concept is already largely accepted in Europe, where the recycling fee for alkaline batteries is shared by the manufacturer and importer.

8. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tsiropoulos, I.; Lebedeva, N. Li-ion Batteries for Mobility and Stationary Storage Applications. Report of the European Commission, Petten (NL). 2018. Available online: https://publications.europa.eu/en/publication-detail/-/publication/e65c072a-f389-11e8-9982-01aa75ed71a1/language-en/format-PDF/source-86566345 (accessed on 14 February 2019).

- (Statistics_Canada) Households Energy Consumption in Canada. Available online: https://www150.statcan.gc.ca/t1/tbl1/en/tv.action?pid=2510006001 (accessed on 10 August 2018).

- Winslow, K.M.; Laux, S.J.; Townsend, T.G. A review on the growing concern and potential management strategies of waste lithium-ion batteries. Resour. Conserv. Recycl. 2018, 129, 263–277. [Google Scholar] [CrossRef]

- Zheng, X.; Zhu, Z.; Lin, X.; Zhang, Y.; He, Y.; Cao, H.; Sun, Z. A Mini-Review on Metal Recycling from Spent Lithium Ion Batteries. Engineering 2018, 4, 361–370. [Google Scholar] [CrossRef]

- Nigl, T.; Schwarz, T.; Arnberger, A. Waste Li-Batteries – A Struggle to Safety in Waste Management Systems? In Proceedings of the 22nd ICBR - International Congress on Battery Recycling, Lisbon, Portugal, 20–22 September 2017. [Google Scholar]

- Huang, B.; Pan, Z.; Su, X.; An, L. Recycling of lithium-ion batteries: Recent advances and perspectives. J. Power Sources 2018, 399, 274–286. [Google Scholar] [CrossRef]

- Sonoc, A.; Jeswiet, J.; Soo, V.K. Opportunities to Improve Recycling of Automotive Lithium Ion Batteries. Procedia CIRP 2015, 29, 752–757. [Google Scholar] [CrossRef]

- Gies, E. Recycling: Lazarus batteries. Nature 2015, 526, S100–S101. [Google Scholar] [CrossRef]

- Golmohammadzadeh, R.; Faraji, F.; Rashchi, F. Recovery of lithium and cobalt from spent lithium ion batteries (LIBs) using organic acids as leaching reagents: A review. Resour. Conserv. Recycl. 2018, 136, 418–435. [Google Scholar] [CrossRef]

- Gaines, L.; Richa, K.; Spangenberger, J. Key issues for Li-ion battery recycling. MRS Energy Sustain. 2018, 5, E14. [Google Scholar] [CrossRef]

- Yun, L.; Linh, D.; Shui, L.; Peng, X.; Garg, A.; LE, M.L.P.; Asghari, S.; Sandoval, J. Metallurgical and mechanical methods for recycling of lithium-ion battery pack for electric vehicles. Resour. Conserv. Recycl. 2018, 136, 198–208. [Google Scholar] [CrossRef]

- Bauer, D.; Diamond, D.; Li, J.; Sandalow, D.; Telleen, P.; Wanner, B. Critical Materials Strategy; Report of the U.S. depart. of Energy; 2010. Available online: https://energy.gov/sites/prod/files/DOE_CMS2011_FINAL_Full.pdf (accessed on 14 March 2017).

- Emmanuel, H.; Marine, S.; Sokhna, S.G. Electrification du parc Automobile Mondial et Criticite du Lithium a L’horizon 2050. Report of ADEME, Angers (FR). 2018. Available online: www.ademe.fr/mediatheque (accessed on 14 November 2018).

- Wang, X.; Gaustad, G.; Babbitt, C.W.; Richa, K. Economies of scale for future lithium-ion battery recycling infrastructure. Resour. Conserv. Recycl. 2014, 83, 53–62. [Google Scholar] [CrossRef]

- Brinkman, B.; Gotterbarn, D.; Miller, K.; Wolf, M.J. 2016 Annual Report: Making a Positive Impact. Report from Call2Recycle Inc., Atlanta. 2016. Available online: https://www.call2recycle.ca/2016-annual-report/ (accessed on 28 November 2017).

- (Eucobat) Position Paper - Collection Target for Waste Batteries. Available online: http://www.eucobat.eu/downloads (accessed on 14 March 2017).

- Zeng, X.; Li, J.; Singh, N. Recycling of spent lithium-ion battery: A critical review. Crit. Rev. Environ. Sci. Technol. 2014, 44, 1129–1165. [Google Scholar] [CrossRef]

- Lebedeva, N.; Persio, F.D.; Boon-brett, L. Lithium Ion Battery Value Chain and Related Opportunities for EUROPE. Report of the European Commission, Petten (NL). 2016. Available online: https://ec.europa.eu/jrc/sites/jrcsh/files/jrc105010_161214_li-ion_battery_value_chain_jrc105010.pdf (accessed on 24 October 2017).

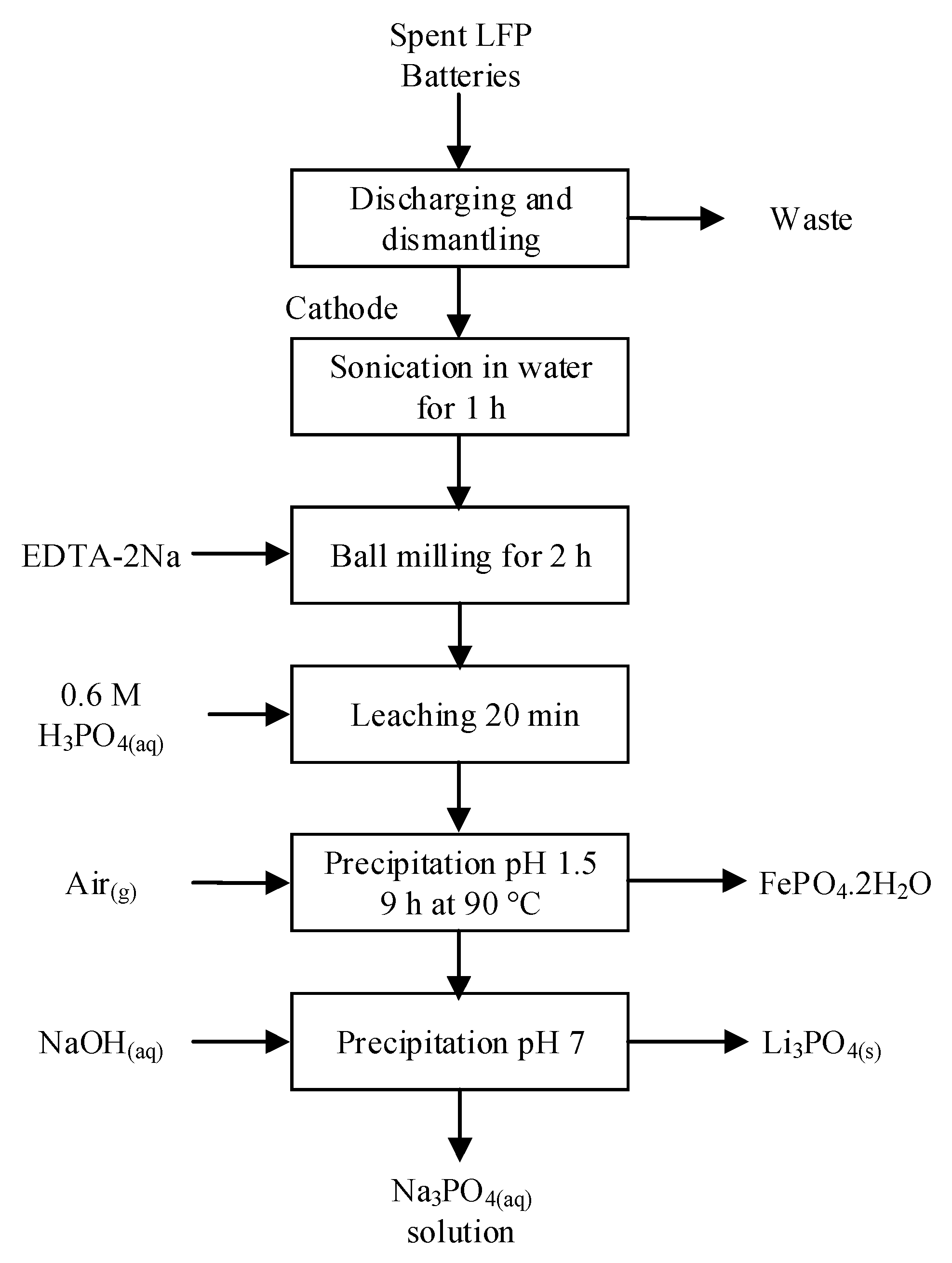

- Wang, X.; Wang, X.; Zhang, R.; Wang, Y.; Shu, H. Hydrothermal preparation and performance of LiFePO4 by using Li3PO4 recovered from spent cathode scraps as Li source. Waste Manag. 2018, 78, 208–216. [Google Scholar] [CrossRef]

- Yazami, R.; Touzain, P.H. A reversible graphite-lithium electrochemical generators. J. Power Sources 1983, 9, 365–371. [Google Scholar] [CrossRef]

- Julien, C.; Mauger, A.; Vijh, A.; Zaghib, K. Lithium Batteries; Springer International Publishing: New York City, NY, USA, 2016; ISBN 978-3-319-19108-9. [Google Scholar]

- Doeff, M.M. Battery Cathodes. In Encyclopedia of Sustainability Science and Technology; Brod, R.J., Ed.; Springer: New York, NY, USA, 2013. [Google Scholar]

- Zhou, P.; Meng, H.; Zhang, Z.; Chen, C.; Lu, Y.; Cao, J.; Cheng, F.; Chen, J. Stable layered Ni-rich LiNi0.9Co0.07Al0.03O2 microspheres assembled with nanoparticles as high-performance cathode materials for lithium-ion batteries. J. Mater. Chem. A 2017, 5, 2724–2731. [Google Scholar] [CrossRef]

- Noh, H.J.; Youn, S.; Yoon, C.S.; Sun, Y.K. Comparison of the structural and electrochemical properties of layered Li[NixCoyMnz]O2 (x = 1/3, 0.5, 0.6, 0.7, 0.8 and 0.85) cathode material for lithium-ion batteries. J. Power Sources 2013, 233, 121–130. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, X.; Zhang, H. One-Pot Hydrothermal Synthesis of LiMn2O4 Cathode Material with Excellent High-Rate and Cycling Properties. J. Electron. Mater. 2016, 45, 4350–4356. [Google Scholar] [CrossRef]

- Tarascon, J.-M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef]

- Silveira, A.V.M.; Santana, M.P.; Tanabe, E.H.; Bertuol, D.A. Recovery of valuable materials from spent lithium ion batteries using electrostatic separation. Int. J. Miner. Process. 2017, 169, 91–98. [Google Scholar] [CrossRef]

- Birkl, C.R.; Roberts, M.R.; Mcturk, E.; Bruce, P.G.; Howey, D.A. Degradation diagnostics for lithium ion cells. J. Power Sources 2017, 341, 373–386. [Google Scholar] [CrossRef]

- Zhang, W.-J. Structure and performance of LiFePO4 cathode materials: A review. J. Power Sources 2010, 196, 2962–2970. [Google Scholar] [CrossRef]

- Perea, A.; Paolella, A.; Dubé, J.; Champagne, D.; Mauger, A.; Zaghib, K. State of charge influence on thermal reactions and abuse tests in commercial lithium-ion cells. J. Power Sources 2018, 399, 392–397. [Google Scholar] [CrossRef]

- Weise, E. Cell Phones Thrown in the Trash are Exploding, Causing 5-alarm Fires in Garbage Trucks. Available online: https://www.usatoday.com/story/tech/talkingtech/2018/05/18/cell-phones-lithium-ion-batteries-exploding-causing-trash-fires/619897002/ (accessed on 9 August 2018).

- Date, W. Waste Industry Looks to Tackle Lithium-Ion Battery Fires. Available online: https://www.letsrecycle.com/news/latest-news/waste-industry-looks-to-tackle-lithium-ion-battery-fires/ (accessed on 11 June 2019).

- Olapiriyakul, S.; Caudill, R.J. A framework for risk management and end-of-life (EOL) analysis for nanotechnology products: A case study in lithium-ion batteries. IEEE Int. Symp. Electron. Environ. 2008, 7102, 1–6. [Google Scholar]

- Yu, A.; Wei, Y.; Chen, W.; Peng, N.; Peng, L. Life cycle environmental impacts and carbon emissions: A case study of electric and gasoline vehicles in China. Transp. Res. Part D Transp. Environ. 2018, 65, 409–420. [Google Scholar] [CrossRef]

- Warburg, N.; Forell, A.; Guillon, L.; Teulon, H.; Canaguier, B. Elaboration Selon les Principes des ACV des Bilans Energetiques, des Emissions de gaz a Effet de Serre et des Autres Impacts Environnementaux Induits par L’ensemble des Filieres de Vehicules Electriques et de Vehicules Thermiques, VP de Segment B. Report of ADEME, Angers (FR). 2013, 25. Available online: https://www.ademe.fr/elaboration-selon-principes-acv-bilans-energetiques-emissions-gaz-a-effet-serre-autres-impacts-environnementaux (accessed on 25 January 2019).

- Majeau-Bettez, G.; Hawkins, T.R.; StrØmman, A.H. Life cycle environmental assessment of lithium-ion and nickel metal hydride batteries for plug-in hybrid and battery electric vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef]

- Oliveira, L.; Messagie, M.; Rangaraju, S.; Sanfelix, J.; Hernandez Rivas, M.; Van Mierlo, J. Key issues of lithium-ion batteries - From resource depletion to environmental performance indicators. J. Clean. Prod. 2015, 108, 354–362. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Kelly, J.C.; James, C.; Gallagher, K.G. The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy Environ. Sci. 2015, 8, 158–168. [Google Scholar] [CrossRef]

- Xie, J.; Gao, F.; Gong, X.; Wang, Z.; Liu, Y. Life Cycle Assessment of LFP Cathode Material Production for Power Lithium-Ion Batteries. In Proceedings of the Advances in Energy and Environmental Materials; Springer: Singapore, 2018; pp. 513–522. [Google Scholar]

- Xu, J.; Thomas, H.R.; Francis, R.W.; Lum, K.R.; Wang, J.; Liang, B. A review of processes and technologies for the recycling of lithium-ion secondary batteries. J. Power Sources 2008, 177, 512–527. [Google Scholar] [CrossRef]

- Liang, Y.; Su, J.; Xi, B.; Yu, Y.; Ji, D.; Sun, Y.; Cui, C.; Zhu, J. Life cycle assessment of lithium-ion batteries for greenhouse gas emissions. Resour. Conserv. Recycl. 2017, 117, 285–293. [Google Scholar] [CrossRef]

- Zhang, P.; Yokoyama, T.; Itabashi, O.; Suzuki, T.M.; Inoue, K. Hydrometallurgical process for recovery of metal values from spent lithium-ion secondary batteries. Hydrometallurgy 1998, 47, 259–271. [Google Scholar] [CrossRef]

- Zou, H.; Gratz, E.; Apelian, D.; Wang, Y. A novel method to recycle mixed cathode materials for lithium ion batteries. Green Chem. 2013, 15, 1183–1191. [Google Scholar] [CrossRef]

- Tedjar, F. Recycling Used Electric Cells by Hydrometallurgical Treatment. World Patent WO 2003021708 A2, 2003. [Google Scholar]

- Tedjar, F.; Foudraz, J.-C. Method for the Mixed Recycling of Lithium-based Aanode Batteries and Cells. World Patent WO 2005101564 A1, 2005. [Google Scholar]

- Tedjar, F.; Foudraz, J.-C. Method for the Mixed Recycling of Lithium-Based Anode Batteries and Cells. US. Patent 20070196725 A1, 2007. [Google Scholar]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Gaines, L.; Sullivan, J.; Burnham, A. Bel Life-Cycle Analysis for Lithium-Ion Battery Production and Recycling. Transp. Res. Board 90th Annu. Meet. 2011, 1–15. [Google Scholar]

- Ziemann, S.; Müller, D.B.; Schebek, L.; Weil, M. Modeling the potential impact of lithium recycling from EV batteries on lithium demand: A dynamic MFA approach. Resour. Conserv. Recycl. 2018, 133, 76–85. [Google Scholar] [CrossRef]

- (SNAM) [Sale of Alloys]. Available online: http://www.snam.com/activites/ventes-alliage-suite.php (accessed on 3 June 2019).

- (Umicore) Our Recycling Process. Available online: https://csm.umicore.com/en/recycling/battery-recycling/our-recycling-process/ (accessed on 3 June 2019).

- Zhang, X.; Li, L.; Fan, E.; Xue, Q.; Bian, Y.; Wu, F.; Chen, R. Toward sustainable and systematic recycling of spent rechargeable batteries. Chem. Soc. Rev. 2018, 47, 7239–7302. [Google Scholar] [CrossRef]

- Mayyas, A.; Steward, D.; Mann, M. The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries. Sustain. Mater. Technol. 2019, 19, e00087. [Google Scholar] [CrossRef]

- Pillot, C. The Rechargeable Battery Market and Main Trends 2014–2025. In Proceedings of the 22nd ICBR - International Congress on Battery Recycling, Lisbon, Portugal, 20–22 September 2017; 2017. [Google Scholar]

- Houde, S. Filière des batteries lithium-ion: Développer un secteur porteur d’avenir pour l’économie du Québec; Report of Propulsion Québec; Propulsion Québec: Montreal, QC, Canada, 2019. [Google Scholar]

- Tedjar, F.; Foudraz, J.-C. Procede de Recyclage en Melange de Piles et Batteries a Base d’anode en Lithium. French Patent 2868603 A1, 2004. [Google Scholar]

- Recycling of Primary and Secondary Lithium Batteries (VALIBAT). Available online: https://cordis.europa.eu/project/rcn/51959/factsheet/en (accessed on 12 August 2019).

- Sloop, S.E. Reintroduction of Lithium Into Recycled Battery Materials. U.S. Patent 9287552 B2, 2016. [Google Scholar]

- Sloop, S.E. Reintroduction of Lithium Into Recycled Battery Materials. U.S. Patent Application 20090214933, 2009. [Google Scholar]

- Novis Smith, W.; Swoffer, S. Recovery of Lithium Ion Batteries. U.S. Patent 861475 B1, 2013. [Google Scholar]

- Yinliang, Z.; Honghui, T.; Huan, C.; Qunying, T.; Du, W. A Method of Recycling Valuable Metal from Waste and Old Lithium ion Battery. Chinese Patent CN 108987841 A, 2018. [Google Scholar]

- Morin, D.; Gagne-Bourque, C.; Nadeau, E.; Couture, B. Lithium-ion Batteries Recycling Process. World Patent Application WO 2019060996 A1, 2019. [Google Scholar]

- Kim, S.; Yang, D.; Rhee, K.; Sohn, J. Recycling process of spent battery modules in used hybrid electric vehicles using physical/chemical treatments. Res. Chem. Intermed. 2014, 40, 2447–2456. [Google Scholar] [CrossRef]

- Hailey, P.; Kepler, K. Direct Recycling Technology for Plug-in Electric Vehicle Lithium-Ion Battery Packs; Farasis Energy Inc.: Hayward, CA, USA, 2015. [Google Scholar]

- Zhang, T.; He, Y.; Ge, L.; Fu, R.; Zhang, X.; Huang, Y. Characteristics of wet and dry crushing methods in the recycling process of spent lithium-ion batteries. J. Power Sources 2013, 240, 766–771. [Google Scholar] [CrossRef]

- Li, J.; Wang, G.; Xu, Z. Generation and detection of metal ions and volatile organic compounds (VOCs) emissions from the pretreatment processes for recycling spent lithium-ion batteries. Waste Manag. 2015, 52, 221–227. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, Y.; Lin, X.; Li, H.; Cao, H. An overview on the processes and technologies for recycling cathodic active materials from spent lithium-ion batteries. J. Mater. Cycles Waste Manag. 2013, 15, 420–430. [Google Scholar] [CrossRef]

- Dai, Q. The economics of lithium-ion battery recycling. In Proceedings of the NaatBatt Lithium-ion Battery Recycling Workshop, Buffalo, NY, USA, 9–10 July 2019. [Google Scholar]

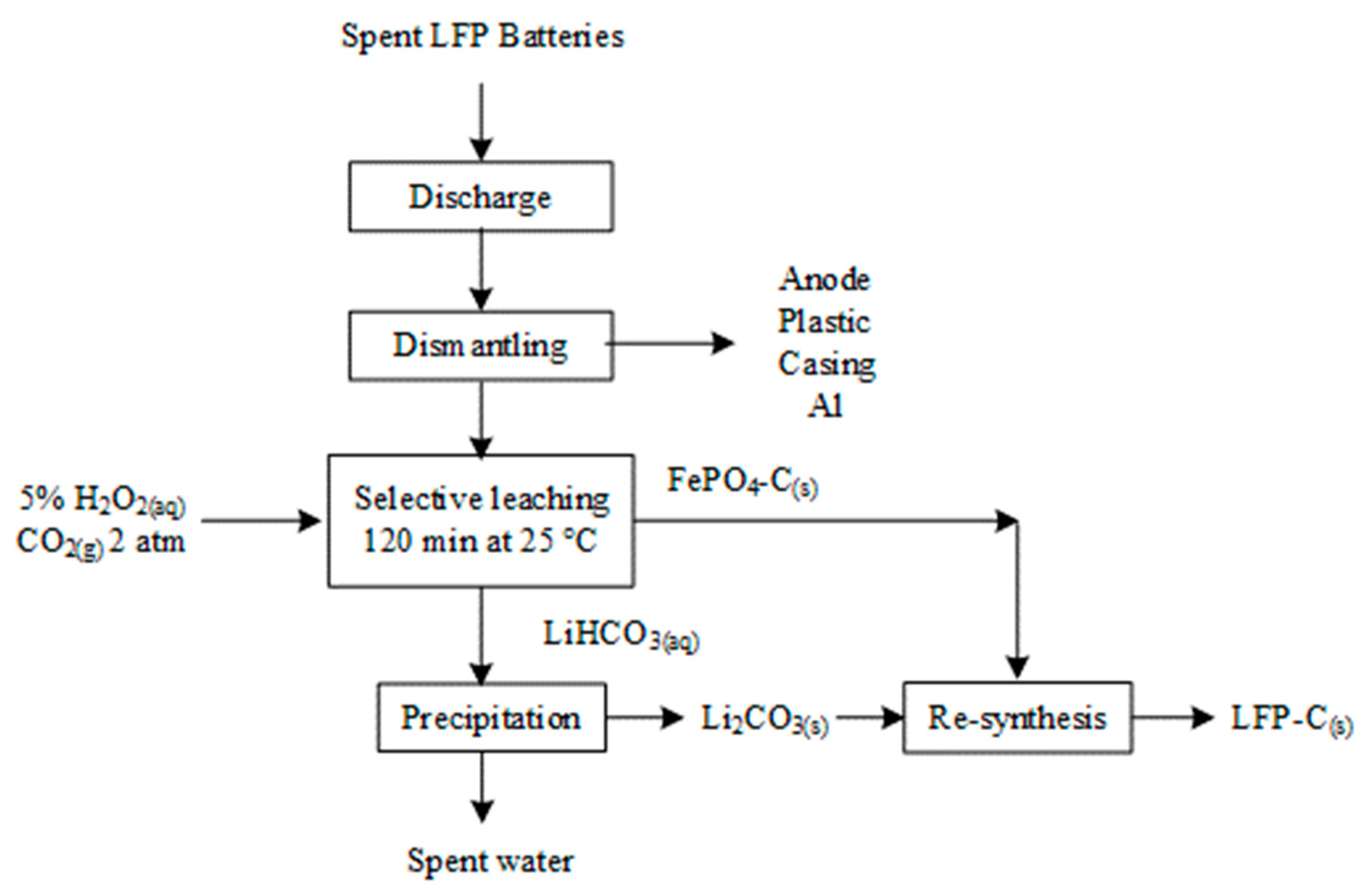

- Kim, H.S.; Shin, E.J. Re-synthesis and electrochemical characteristics of LiFePO4 cathode materials recycled from scrap electrodes. Bull. Korean Chem. Soc. 2013, 34, 851–855. [Google Scholar] [CrossRef]

- Larouche, F.; Demopoulos, G.P.; Amouzegar, K.; Bouchard, P.; Zaghib, K. Recycling of Li-Ion and Li-Solid State Batteries: The Role of Hydrometallurgy. In Extraction 2018; Davis, B., Ed.; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2018; pp. 2541–2553. [Google Scholar]

- Wu, C.; Sun, J.; Zhu, C.; Ge, Y.; Zhao, Y. Research on Overcharge and Overdischarge Effect on Lithium-Ion Batteries. In Proceedings of the Vehicle Power and Propulsion (VPPC), IEEE Conference, Montreal, QC, Canada, 19–22 October 2015; pp. 1–6. [Google Scholar]

- Chen, L.; Tang, X.; Zhang, Y.; Li, L.; Zeng, Z.; Zhang, Y. Process for the recovery of cobalt oxalate from spent lithium-ion batteries. Hydrometallurgy 2011, 108, 80–86. [Google Scholar] [CrossRef]

- Meshram, P.; Pandey, B.D.; Mankhand, T.R. Recovery of valuable metals from cathodic active material of spent lithium ion batteries: Leaching and kinetic aspects. Waste Manag. 2015, 45, 306–313. [Google Scholar] [CrossRef] [PubMed]

- Barik, S.P.; Prabaharan, G.; Kumar, L. Leaching and separation of Co and Mn from electrode materials of spent lithium-ion batteries using hydrochloric acid: Laboratory and pilot scale study. J. Clean. Prod. 2017, 147, 37–43. [Google Scholar] [CrossRef]

- Ebrahimzade, H.; Khayati, G.R.; Schaffie, M. Preparation and kinetic modeling of β-Co(OH)2 nanoplates thermal decomposition obtained from spent Li-ion batteries. Adv. Powder Technol. 2017, 28, 2779–2786. [Google Scholar] [CrossRef]

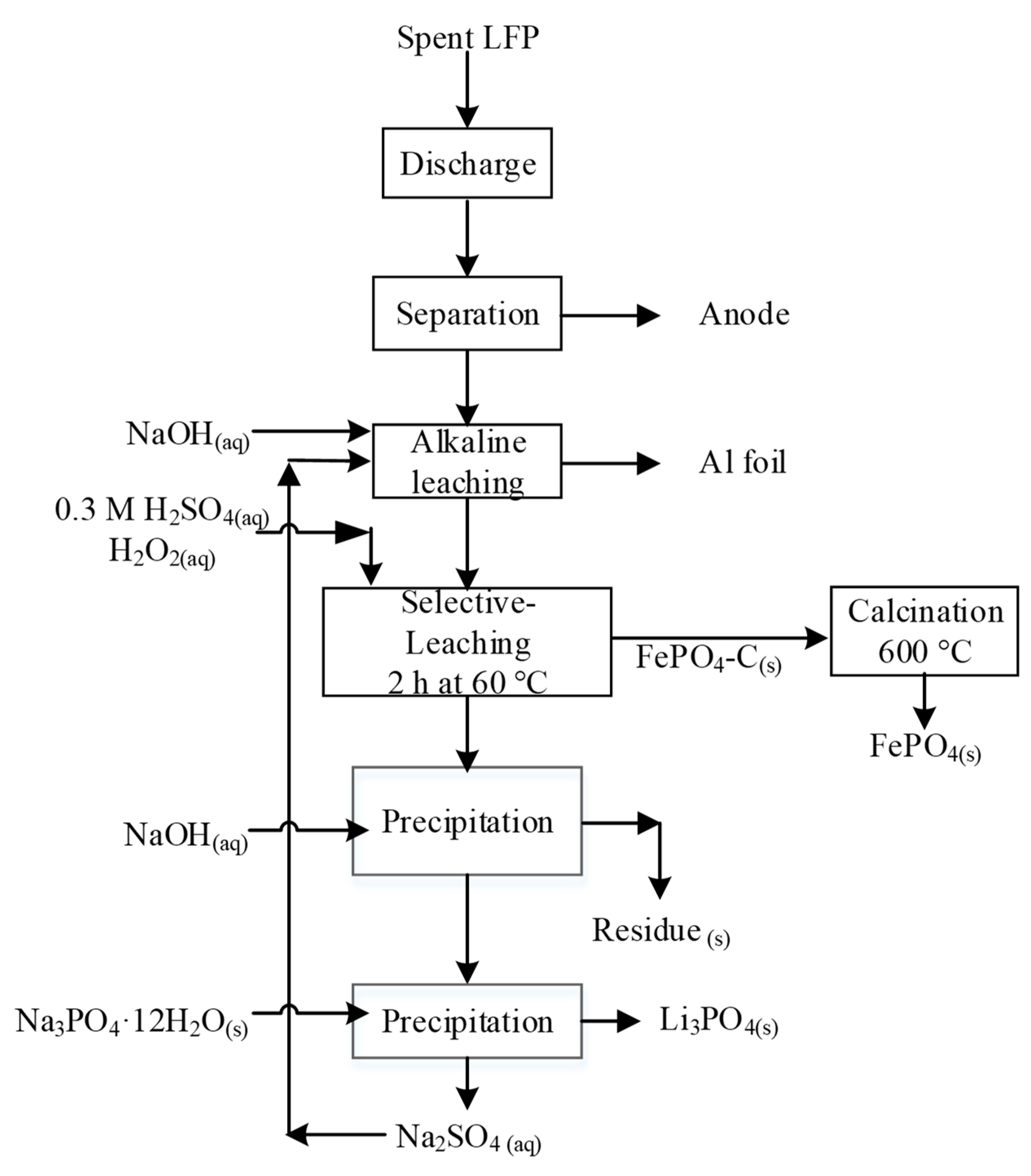

- Yang, Y.; Zheng, X.; Cao, H.; Zhao, C.; Lin, X.; Ning, P.; Zhang, Y.; Jin, W.; Sun, Z. A Closed-Loop Process for Selective Metal Recovery from Spent Lithium Iron Phosphate Batteries through Mechanochemical Activation. ACS Sustain. Chem. Eng. 2017, 5, 9972–9980. [Google Scholar] [CrossRef]

- Yang, Y.; Meng, X.; Cao, H.; Lin, X.; Liu, C.; Sun, Y.; Zhang, Y.; Sun, Z. Selective recovery of lithium from spent lithium iron phosphate batteries: a sustainable process. Green Chem. 2018, 20, 3121–3133. [Google Scholar] [CrossRef]

- Tanong, K.; Coudert, L.; Mercier, G.; Blais, J.-F.F. Recovery of metals from a mixture of various spent batteries by a hydrometallurgical process. J. Environ. Manag. 2016, 181. [Google Scholar] [CrossRef]

- Xi, G.; Xu, H.; Yao, L. Study on preparation of NiCo ferrite using spent lithium-ion and nickel-metal hydride batteries. Sep. Purif. Technol. 2015, 145, 50–55. [Google Scholar] [CrossRef]

- Fricke, J.; Kiehne, H.A. Collection and recycling of spent portable batteries-The actual situation in Europe. In Proceedings of the TELESCON 2000-Third International Telecommunications Energy Special Conference, Dresden, Germany, 10 May 2000. [Google Scholar]

- Coonen, P.; Allard, G. Sorting, a profession in its own. In Proceedings of the 22nd ICBR - International Congress on Battery Recycling, Lisbon, Portugal, 20–22 September 2017. [Google Scholar]

- (Bebat) Sorting. Available online: https://www.bebat.be/en/sorting (accessed on 2 August 2018).

- Bernardes, A.M.; Espinosa, D.C.R.; Tenório, J.A.S. Recycling of batteries: A review of current processes and technologies. J. Power Sources 2004, 130, 291–298. [Google Scholar] [CrossRef]

- Contestabile, M.; Panero, S.; Scrosati, B. A laboratory-scale lithium battery recycling process. J. Power Sources 1999, 83, 75–78. [Google Scholar] [CrossRef]

- Gratz, E.; Sa, Q.; Apelian, D.; Wang, Y. A closed loop process for recycling spent lithium ion batteries. J. Power Sources 2014, 262, 255–262. [Google Scholar] [CrossRef]

- Huang, Y.; Han, G.; Liu, J.; Chai, W.; Wang, W.; Yang, S.; Su, S. A stepwise recovery of metals from hybrid cathodes of spent Li-ion batteries with leaching-flotation-precipitation process. J. Power Sources 2016, 325, 555–564. [Google Scholar] [CrossRef]

- Al-Thyabat, S.; Nakamura, T.; Shibata, E.; Iizuka, A. Adaptation of minerals processing operations for lithium-ion (LiBs) and nickel metal hydride (NiMH) batteries recycling: Critical review. Miner. Eng. 2013, 45, 4–17. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, N.; Hu, F.; Ye, L.; Xi, Y.; Yang, S. Thermal treatment and ammoniacal leaching for the recovery of valuable metals from spent lithium-ion batteries. Waste Manag. 2018, 75, 469–476. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Zhao, S.; Ji, L.; Zhou, T.; Miao, Y.; Scott, K.; Li, D.; Yang, J.; Wu, X. Reuse of Ni-Co-Mn oxides from spent Li-ion batteries to prepare bifunctional air electrodes. Resour. Conserv. Recycl. 2018, 129, 135–142. [Google Scholar] [CrossRef]

- Li, L.; Lu, J.; Ren, Y.; Zhang, X.X.; Chen, R.J.; Wu, F.; Amine, K. Ascorbic-acid-assisted recovery of cobalt and lithium from spent Li-ion batteries. J. Power Sources 2012, 218, 21–27. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, G.; Xu, S.; He, Y.; Liu, X. Thermal treatment process for the recovery of valuable metals from spent lithium-ion batteries. Hydrometallurgy 2016, 165, 390–396. [Google Scholar] [CrossRef]

- Li, W.; Yang, S.; Liu, N.; Chen, Y.; Xi, Y.; Li, S.; Jie, Y.; Hu, F. Study on vacuum pyrolysis process of cathode sheets from spent lithium-ion batteries. In Minerals, Metals and Materials Series; Gaustad, G., Ed.; Springer: Cham, Switzerland, 2019; pp. 421–435. ISBN 9783030103866. [Google Scholar]

- Zheng, R.; Zhao, L.; Wang, W.; Liu, Y.; Ma, Q.; Mu, D.; Li, R.; Dai, C. Optimized Li and Fe recovery from spent lithium-ion batteries via a solution-precipitation method. RSC Adv. 2016, 6, 43613–43625. [Google Scholar] [CrossRef]

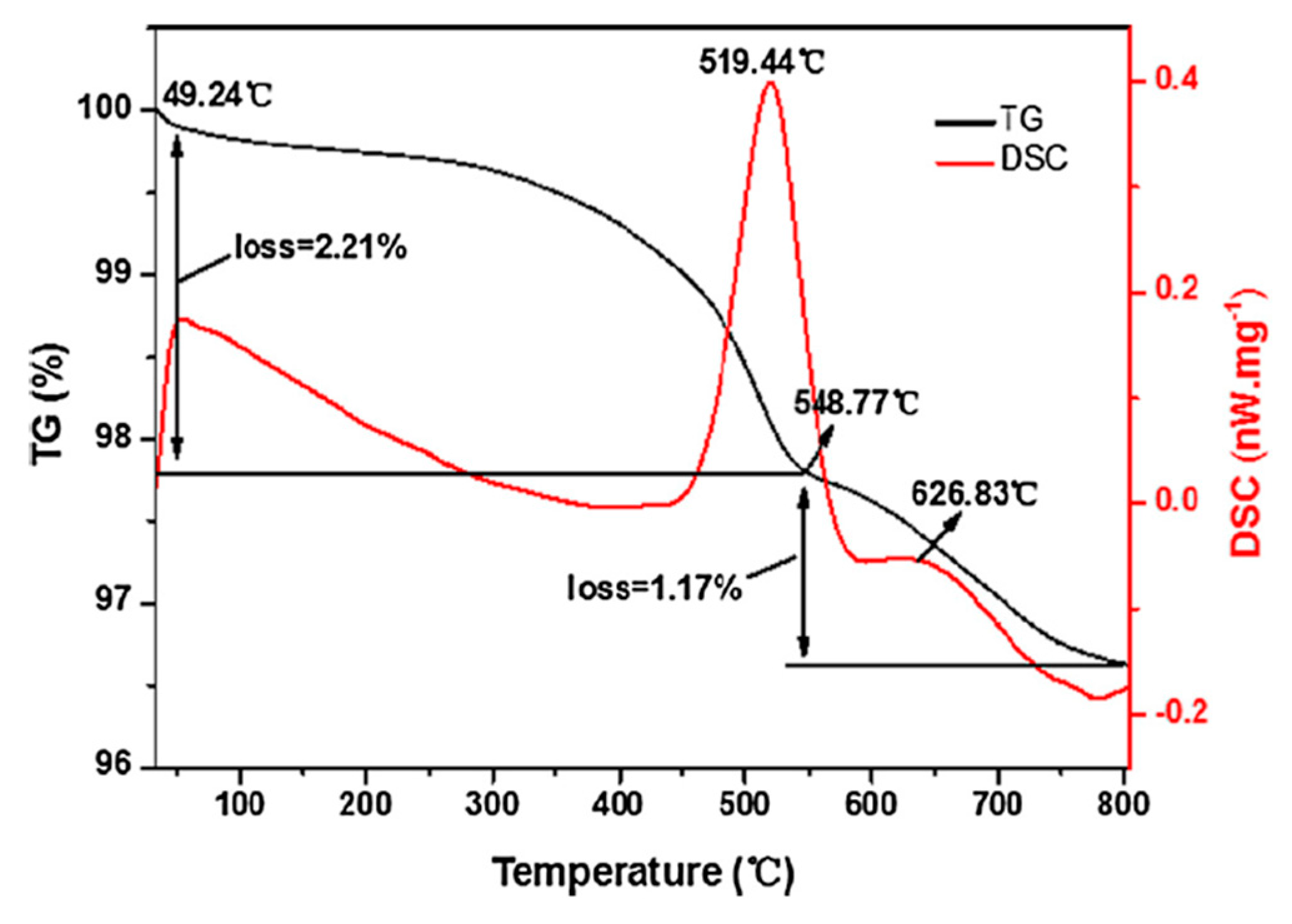

- Jie, Y.; Yang, S.; Chen, Y.; Liu, Z.; Hu, F. Research on Thermogravimetric-Differential Scanning Calorimeter of Spent Lithium Iron Phosphate Batteries Cathode Plate. In Proceedings of the REWAS 2019; Gaustad, G., Ed.; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2019; pp. 401–409. [Google Scholar]

- Gaabour, L.H. Thermal Spectroscopy and Kinetic Studies of PEO/PVDF Loaded by Carbon Nanotubes. J. Mater. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Zucolotto, V.; Avlyanov, J.; Gregorio, R.; Mattoso, L.H.C. Melt processing of composites of PVDF and carbon black modified with conducting polymers. J. Appl. Polym. Sci. 2004, 94, 553–557. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Song, D.; Song, J.; Zhang, L. Direct regeneration of recycled cathode material mixture from scrapped LiFePO4 batteries. J. Power Sources 2017, 345, 78–84. [Google Scholar] [CrossRef]

- Song, X.; Hu, T.; Liang, C.; Long, H.L.L.; Zhou, L.; Song, W.; You, L.; Wu, Z.S.; Liu, J.W. Direct regeneration of cathode materials from spent lithium iron phosphate batteries using a solid phase sintering method. RSC Adv. 2017, 7, 4783–4790. [Google Scholar] [CrossRef]

- Yang, L.; Xi, G.; Xi, Y. Recovery of Co, Mn, Ni, and Li from spent lithium ion batteries for the preparation of LiNixCoyMnzO2 cathode materials. Ceram. Int. 2015, 41, 11498–11503. [Google Scholar] [CrossRef]

- Nayaka, G.P.; Pai, K.V.; Manjanna, J.; Keny, S.J. Use of mild organic acid reagents to recover the Co and Li from spent Li-ion batteries. Waste Manag. 2016, 51, 234–238. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; Li, J. Innovative application of ionic liquid to separate Al and cathode materials from spent high-power lithium-ion batteries. J. Hazard. Mater. 2014, 271, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; He, W.Z.; Li, G.M.; Zhang, X.J.; Huang, J.W.; Zhu, S.G. Recycling of electrode materials from spent lithium-ion batteries. In Proceedings of the 2010 4th International Conference on Bioinformatics and Biomedical Engineering: iCBBE 2010, Chengdu, China, 18–20 June 2010; pp. 10–13. [Google Scholar]

- Li, J.; Shi, P.; Wang, Z.; Chen, Y.; Chang, C.-C. A combined recovery process of metals in spent lithium-ion batteries. Chemosp 2009, 77, 1132–1136. [Google Scholar] [CrossRef]

- Li, L.; Bian, Y.; Zhang, X.; Guan, Y.; Fan, E.; Wu, F.; Chen, R. Process for recycling mixed-cathode materials from spent lithium-ion batteries and kinetics of leaching. Waste Manag. 2018, 71, 362–371. [Google Scholar] [CrossRef]

- Nan, J.; Han, D.; Yang, M.; Cui, M.; Hou, X. Recovery of metal values from a mixture of spent lithium-ion batteries and nickel-metal hydride batteries. Hydrometallurgy 2006, 84, 75–80. [Google Scholar] [CrossRef]

- Ren, J.; Li, R.; Liu, Y.; Cheng, Y.; Mu, D.; Zheng, R.; Liu, J.; Dai, C. The impact of aluminum impurity on the regenerated lithium nickel cobalt manganese oxide cathode materials from spent LIBs. New J. Chem. 2017, 41, 10959–10965. [Google Scholar] [CrossRef]

- Tsang, F.; Hailey, P. Method for Removing Copper and Aluminum From an Electrode Mateiral, And Process for Recycling Electrode Material From Waste Lithium-Ion Batteries. U.S. Patent Appl. 20160049700 A1, 2016. [Google Scholar]

- Poe, S.L.; Paradise, C.L.; Muollo, L.R.; Pal, R.; Warmer, J.C.; Korzenski, M.B. Method for the Recovery of Lithium Cobalt Oxide From Lithium Ion Batteries. U.S. Patent 9972830, 2018. [Google Scholar]

- Yu, J.; He, Y.; Ge, Z.; Li, H.; Xie, W.; Wang, S. A promising physical method for recovery of LiCoO2 and graphite from spent lithium-ion batteries: Grinding flotation. Sep. Purif. Technol. 2018, 190, 45–52. [Google Scholar] [CrossRef]

- He, Y.; Zhang, T.; Wang, F.; Zhang, G.; Zhang, W.; Wang, J. Recovery of LiCoO2 and graphite from spent lithium-ion batteries by Fenton reagent-assisted flotation. J. Clean. Prod. 2017, 143, 319–325. [Google Scholar] [CrossRef]

- Kepler, K.D.; Tsang, F.; Vermeulen, R.; Hailey, P. Process for Recycling Electrode Materials from Lithium-ion Batteries. U.S. Patent Appl. 20160072162 A1, 2016. [Google Scholar]

- Fuerstenau, M.C.; Han, K.N. Principles of Mineral Processing; Society for Mining, Metallurgy, and Exploration: Littleton, CO, USA, 2003; Chapter 12; ISBN 0873351673. [Google Scholar]

- Ordoñez, J.; Gago, E.J.; Girard, A. Processes and technologies for the recycling and recovery of spent lithium-ion batteries. Renew. Sustain. Energy Rev. 2016, 60, 195–205. [Google Scholar] [CrossRef]

- Meshram, P.; Pandey, B.D.; Mankhand, T.R. Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: A comprehensive review. Hydrometallurgy 2014, 150, 192–208. [Google Scholar] [CrossRef]

- Chagnes, A.; Pospiech, B. A brief review on hydrometallurgical technologies for recycling spent lithium-ion batteries. J. Chem. Technol. Biotechnol. 2013, 88, 1191–1199. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y. An overview of recycling and treatment of spent LiFePO4 batteries in China. Resour. Conserv. Recycl. 2017, 127, 233–243. [Google Scholar] [CrossRef]

- Espinosa, D.C.R.; Bernardes, A.M.; Tenório, J.A.S. An overview on the current processes for the recycling of batteries. J. Power Sources 2004, 135, 311–319. [Google Scholar] [CrossRef]

- Friedrich, B.; Peters, L. Status and Trends of industrialized Li-Ion battery recycling processes with qualitative comparison of economic and environmental impacts. In Proceedings of the 22nd ICBR - International Congress on Battery Recycling, Lisbon, Portugal, 20–22 September 2017. [Google Scholar]

- Gupta, N.; Prabaharan, G. Process for Recovery of Pure Cobalt Oxide From Spent Lithium Ion Batteries With High Manganese Content. World Patent WO2017145099, 2017. [Google Scholar]

- Joulié, M.; Billy, E.; Laucournet, R.; Meyer, D. Current collectors as reducing agent to dissolve active materials of positive electrodes from Li-ion battery wastes. Hydrometallurgy 2017, 169, 426–432. [Google Scholar] [CrossRef]

- Demopoulos, G.P. Aqueous precipitation and crystallization for the production of particulate solids with desired properties. Hydrometallurgy 2009, 96, 199–214. [Google Scholar] [CrossRef]

- Wu, Y.; Pei, F.; Jia, L.; Tian, X. Recovery of aluminum, iron and lithium from spent lithium iron phosphate batteries. Chinese J. Power Sources 2014, 38, 629–631. [Google Scholar]

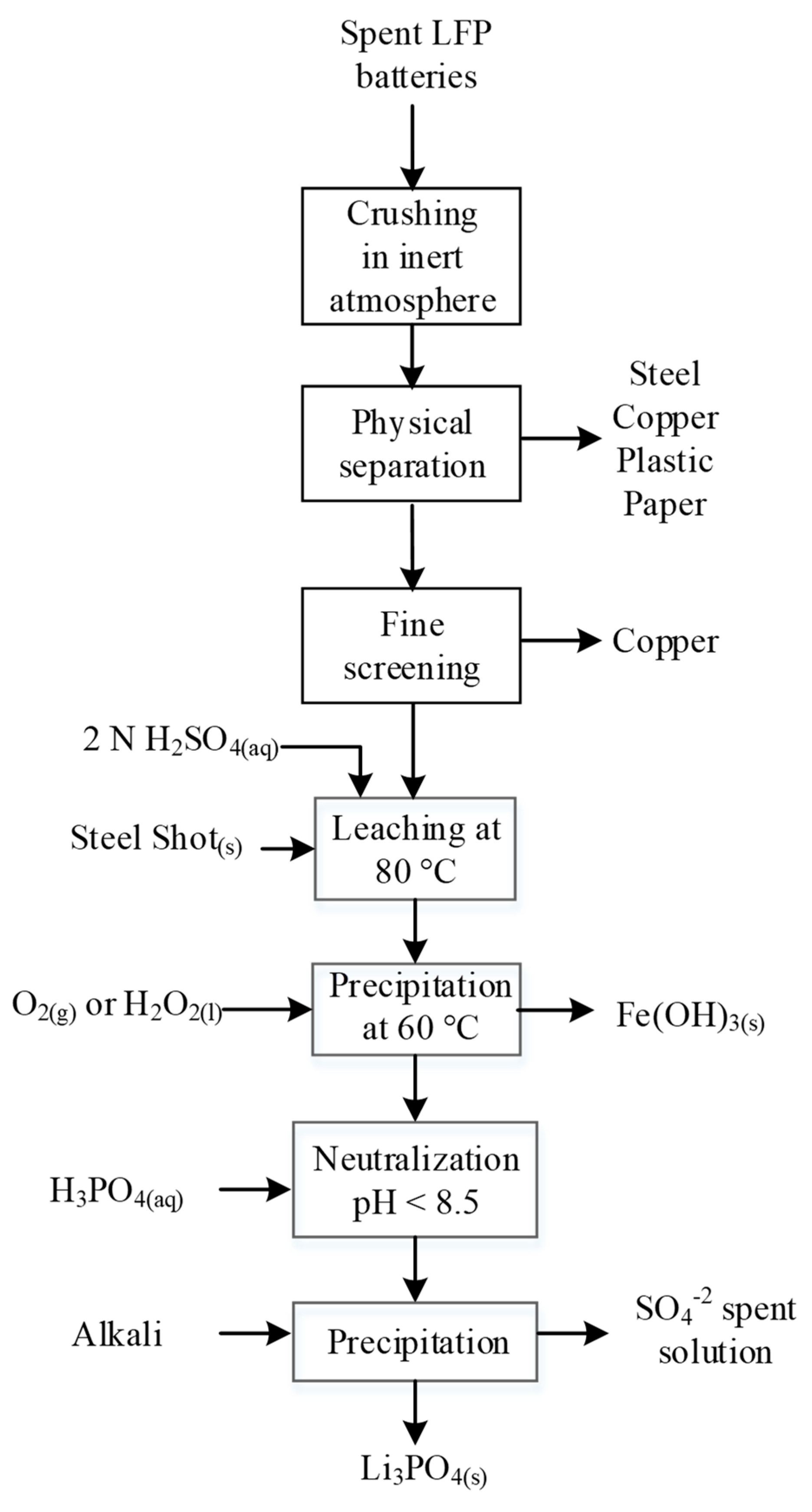

- Li, H.; Xing, S.; Liu, Y.; Li, F.; Guo, H.; Kuang, G. Recovery of Lithium, Iron, and Phosphorus from Spent LiFePO4 Batteries Using Stoichiometric Sulfuric Acid Leaching System. ACS Sustain. Chem. Eng. 2017. [Google Scholar] [CrossRef]

- Schurmans, M.; Thijs, B. Process for the Recovery of Lithium and Iron from LFP Batteries. World Patent WO 2012 072619 A1, 2012. [Google Scholar]

- Wohlgemuth, D.; Schneider, M.A.; Spielau, R.; Willems, J.; Steinbild, M. Method for the Hydrometallurgical Recovery of Lithium from the Fraction of Used Galvanic Cells Containing Lithium, Iron and Phosphate. World Patent WO 2014056608 A9, 2014. [Google Scholar]

- Zheng, Z.; Chen, M.; Wang, Q.; Zhang, Y.; Ma, X.; Shen, C.; Xu, D.; Liu, J.; Liu, Y.; Gionet, P.; et al. High Performance Cathode Recovery from Different Electric Vehicle Recycling Streams. ACS Sustain. Chem. Eng. 2018, 6, 13977–13982. [Google Scholar] [CrossRef]

- Granata, G.; Moscardini, E.; Pagnanelli, F.; Trabucco, F.; Toro, L. Product recovery from Li-ion battery wastes coming from an industrial pre-treatment plant: Lab scale tests and process simulations. J. Power Sources 2012, 206, 393–401. [Google Scholar] [CrossRef]

- Chen, X.; Guo, C.; Ma, H.; Li, J.; Zhou, T.; Cao, L.; Kang, D. Organic reductants based leaching: A sustainable process for the recovery of valuable metals from spent lithium ion batteries. Waste Manag. 2018, 75, 459–468. [Google Scholar] [CrossRef] [PubMed]

- Takacova, Z.; Havlik, T.; Kukurugya, F.; Orac, D. Cobalt and lithium recovery from active mass of spent Li-ion batteries: Theoretical and experimental approach. Hydrometallurgy 2016, 163, 9–17. [Google Scholar] [CrossRef]

- Prabaharan, G.; Barik, S.P.; Kumar, N.; Kumar, L. Electrochemical process for electrode material of spent lithium ion batteries. Waste Manag. 2017, 68, 527–533. [Google Scholar] [CrossRef]

- Dutta, D.; Kumari, A.; Panda, R.; Jha, S.; Gupta, D.; Goel, S. Separation and Puri fi cation Technology Close loop separation process for the recovery of Co, Cu, Mn, Fe and Li from spent lithium-ion batteries. Sep. Purif. Technol. 2018, 200, 327–334. [Google Scholar] [CrossRef]

- Zhu, S.G.; He, W.Z.; Li, G.M.; Zhou, X.; Zhang, X.J.; Huang, J.W. Recovery of Co and Li from spent lithium-ion batteries by combination method of acid leaching and chemical precipitation. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2012, 22, 2274–2281. [Google Scholar] [CrossRef]

- Jo, C.H.; Myung, S.T. Efficient recycling of valuable resources from discarded lithium-ion batteries. J. Power Sources 2019, 426, 259–265. [Google Scholar] [CrossRef]

- Higuchi, A.; Ankei, N.; Nishihama, S.; Yoshizuka, K. Selective Recovery of Lithium from Cathode Materials of Spent Lithium Ion Battery. JOM 2016, 68, 2624–2631. [Google Scholar] [CrossRef]

- Aaltonen, M.; Peng, C.; Wilson, B.; Lundström, M. Leaching of Metals from Spent Lithium-Ion Batteries. Recycling 2017, 2, 20. [Google Scholar] [CrossRef]

- Vieceli, N.; Nogueira, C.A.; Guimarães, C.; Pereira, M.F.C.; Durão, F.O.; Margarido, F. Hydrometallurgical recycling of lithium-ion batteries by reductive leaching with sodium metabisulphite. Waste Manag. 2018, 71, 350–361. [Google Scholar] [CrossRef]

- Chen, H.; Zhu, X.; Chang, Y.; Cai, J.; Zhao, R. 3D flower-like CoS hierarchitectures recycled from spent LiCoO2 batteries and its application in electrochemical capacitor. Mater. Lett. 2018, 218, 40–43. [Google Scholar] [CrossRef]

- Shin, S.M.; Kim, N.H.; Sohn, J.S.; Yang, D.H.; Kim, Y.H. Development of a metal recovery process from Li-ion battery wastes. Hydrometallurgy 2005, 79, 172–181. [Google Scholar] [CrossRef]

- Meshram, P.; Abhilash; Pandey, B.D.; Mankhand, T.R.; Deveci, H. Acid baking of spent lithium ion batteries for selective recovery of major metals: A two-step process. J. Ind. Eng. Chem. 2016, 43, 117–126. [Google Scholar] [CrossRef]

- Sun, L.; Qiu, K. Vacuum pyrolysis and hydrometallurgical process for the recovery of valuable metals from spent lithium-ion batteries. J. Hazard. Mater. 2011, 194, 378–384. [Google Scholar] [CrossRef] [PubMed]

- Sohn, J.S.; Shin, S.M.; Yang, D.H.; Kim, S.K.; Lee, C.K. Comparison of two acidic leaching processes for selecting the effective recycle process of spent lithium ion battery. Geosystem Eng. 2006, 9, 1–6. [Google Scholar] [CrossRef]

- Kang, J.; Sohn, J.; Chang, H.; Senanayake, G.; Shin, S.M. Preparation of cobalt oxide from concentrated cathode material of spent lithium ion batteries by hydrometallurgical method. Adv. Powder Technol. 2010, 21, 175–179. [Google Scholar] [CrossRef]

- Zhao, J.; Qu, X.; Qu, J.; Zhang, B.; Ning, Z.; Xie, H.; Zhou, X.; Song, Q.; Xing, P.; Yin, H. Extraction of Co and Li2CO3 from Cathode Materials of Spent Lithium-ion Batteries through a Combined Acid-leaching and Electro-deoxidation Approach. J. Hazard. Mater. 2019, 379, 120817. [Google Scholar] [CrossRef] [PubMed]

- Atia, T.A.; Elia, G.; Hahn, R.; Altimari, P.; Pagnanelli, F. Closed-loop hydrometallurgical treatment of end-of-life lithium ion batteries: Towards zero-waste process and metal recycling in advanced batteries. J. Energy Chem. 2019, 35, 220–227. [Google Scholar] [CrossRef]

- Wohlgemuth, D.; Schneider, M.A.; Spielau, R.; Willems, J.; Steinbild, M. Method for the Hydrometallurgical Recovery of Lithium, Nickel and Cobalt From the Lithium Transition Metal Oxide-Containing Fraction of Used Galvanic Cells. World Patent WO 2014056609, 2017. [Google Scholar]

- Chow, N.; Jung, J.C.-Y.; Nacu, A.M.; Warkentin, D.D. Processing of Cobaltous Sulphate/Dithionate Liquors Derived From Cobalt Resource. World Patent WO 2018089595, 2018. [Google Scholar]

- Hu, J.; Zhang, J.; Li, H.; Chen, Y.; Wang, C. A promising approach for the recovery of high value-added metals from spent lithium-ion batteries. J. Power Sources 2017, 351, 192–199. [Google Scholar] [CrossRef]

- Dorella, G.; Mansur, M.B. A study of the separation of cobalt from spent Li-ion battery residues. J. Power Sources 2007, 170, 210–215. [Google Scholar] [CrossRef]

- Weng, Y.; Xu, S.; Huang, G.; Jiang, C. Synthesis and performance of Li[(Ni1/3Co1/3Mn1/3)1-xMgx]O2 prepared from spent lithium ion batteries. J. Hazard. Mater. 2013, 246–247, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Xu, S.; He, Y. Lithium recycling and cathode material regeneration from acid leach liquor of spent lithium-ion battery via facile co-extraction and co-precipitation processes. Waste Manag. 2017, 64, 219–227. [Google Scholar] [CrossRef]

- Nan, J.; Han, D.; Zuo, X. Recovery of metal values from spent lithium-ion batteries with chemical deposition and solvent extraction. J. Power Sources 2005, 152, 278–284. [Google Scholar] [CrossRef]

- Sohn, J.S.; Yang, D.H.; Shin, S.M.; Kang, J.G. Recovery of cobalt in sulfuric acid leaching solution using oxalic acid. Geosystem Eng. 2006, 9, 81–86. [Google Scholar] [CrossRef]

- Lupi, C.; Pasquali, M.; Dell’Era, A. Nickel and cobalt recycling from lithium-ion batteries by electrochemical processes. Waste Manag. 2005, 25, 215–220. [Google Scholar] [CrossRef]

- Mantuano, D.P.; Dorella, G.; Elias, R.C.A.; Mansur, M.B. Analysis of a hydrometallurgical route to recover base metals from spent rechargeable batteries by liquid-liquid extraction with Cyanex 272. J. Power Sources 2006, 159, 1510–1518. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Lee, J.C.; Jeong, J.; Kim, B.S.; Pandey, B.D. Selective recovery of cobalt, nickel and lithium from sulfate leachate of cathode scrap of Li-ion batteries using liquid-liquid extraction. Met. Mater. Int. 2014, 20, 357–365. [Google Scholar] [CrossRef]

- Nguyen, T.; Lee, M. A Review on the Separation of Lithium Ion from Leach Liquors of Primary and Secondary Resources by Solvent Extraction with Commercial Extractants. Processes 2018, 6, 55. [Google Scholar] [CrossRef]

- Swain, B.; Jeong, J.; Yoo, K.; Lee, J. chun Synergistic separation of Co(II)/Li(I) for the recycling of LIB industry wastes by supported liquid membrane using Cyanex 272 and DR-8R. Hydrometallurgy 2010, 101, 20–27. [Google Scholar] [CrossRef]

- Chung, K.Y.; Lee, H.Y.; Cho, B.-W. Recovery and Synthesis Method for Metaloxidic Cathodic Active Material for Lithium ion Secondary Battery. U.S. Patent 8835026 B2, 2014. [Google Scholar]

- He, L.P.; Sun, S.Y.; Yu, J.G. Performance of LiNi1/3Co1/3Mn1/3O2 prepared from spent lithium-ion batteries by a carbonate co-precipitation method. Ceram. Int. 2018, 44, 351–357. [Google Scholar] [CrossRef]

- Tedjar, F.; Foudraz, J.-C. Method for the Mixed Recycling of Lithium-Based Anode Batteries and Cells. U.S. Patent 7820317 B2, 2010. [Google Scholar]

- Shin, S.M.; Ju, S.-H. Method for Simultaneously Recovering Cobalt and Manganese from Lithium Based Battery. U.S. Patent Appl. 20170009358 A1, 2017. [Google Scholar]

- Freitas, M.B.J.G.; Garcia, E.M. Electrochemical recycling of cobalt from cathodes of spent lithium-ion batteries. J. Power Sources 2007, 171, 953–959. [Google Scholar] [CrossRef]

- Shuva, M.A.H.; Kurny, A.S.W. Dissolution Kinetics of Cathode of Spent Lithium Ion Battery in Hydrochloric Acid Solutions. J. Inst. Eng. Ser. D Metall. Mater. Min. Eng. 2013, 94, 13–16. [Google Scholar] [CrossRef]

- Laucournet, R.; Barthelemy, S.; Diaferia, N. Method for recycling lithium batteries and/or electrodes of such batteries. U.S. Patent 9312581 B2, 2016. [Google Scholar]

- Taniyama, K.; Haraguchi, K.; Shimoyama, K. Lithium-Ion Battery Capacity Recovery Method. World Patent WO 201212424 A1, 2012. [Google Scholar]

- Shin, E.J.; Kim, S.; Noh, J.-K.; Byun, D.; Chung, K.Y.; Kim, H.-S.; Cho, B.-W. A green recycling process designed for LiFePO4 cathode materials for Li-ion batteries. J. Mater. Chem. A 2015, 3, 11493–11502. [Google Scholar] [CrossRef]

- Kim, H.S.; Cho, B.-W.; Lee, H.Y.; Shin, E.J.; Kim, S.; Chung, K.Y. Recycling Method of Olivine-Based Cathode Material for Lithium Secondary Battery, Cathode Material Fabricated Therefrom, and Cathode and Lithium Secondary Battery Including the Same. U.S. Patent 9643846 B2, 2017. [Google Scholar]

- Kim, H.-S.; Cho, B.-W.; Lee, H.Y.; Kim, S.J.; Shin, E.J.; Chung, K.Y. Method of Fabricating LiFePO4 Cathode Electroactive Material by Recycling, and LiFePO4 Cathode electroactive Material, LiFePO4 Cathode, and Lithium Secondary Battery Fabricated Thereby. U.S. Patent 9199850 B2, 2015. [Google Scholar]

- Contestabile, M.; Panero, S.; Scrosati, B. Laboratory-scale lithium-ion battery recycling process. J. Power Sources 2001, 92, 65–69. [Google Scholar] [CrossRef]

- Boxall, N.J.; Adamek, N.; Cheng, K.Y.; Haque, N.; Bruckard, W.; Kaksonen, A.H. Multistage leaching of metals from spent lithium ion battery waste using electrochemically generated acidic lixiviant. Waste Manag. 2018, 74, 435–445. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.-C.; Lin, Y.-C.; Wu, S.-H. A novel recovery process of metal values from the cathode active materials of the lithium-ion secondary batteries. Hydrometallurgy 2009, 99, 194–201. [Google Scholar] [CrossRef]

- Porvali, A.; Aaltonen, M.; Ojanen, S.; Velazquez-Martinez, O.; Eronen, E.; Liu, F.; Wilson, B.P.; Serna-Guerrero, R.; Lundström, M. Mechanical and hydrometallurgical processes in HCl media for the recycling of valuable metals from Li-ion battery waste. Resour. Conserv. Recycl. 2019, 142, 257–266. [Google Scholar] [CrossRef]

- Castillo, S.; Ansart, F.; Laberty-Robert, C.; Portal, J. Advances in the recovering of spent lithium battery compounds. J. Power Sources 2002, 112, 247–254. [Google Scholar] [CrossRef]

- Guan, J.; Li, Y.; Guo, Y.; Su, R.; Gao, G.; Song, H.; Yuan, H.; Liang, B.; Guo, Z. Mechanochemical Process Enhanced Cobalt and Lithium Recycling from Wasted Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2017, 5, 1026–1032. [Google Scholar] [CrossRef]

- Lee, C.K.; Rhee, K.I. Reductive leaching of cathodic active materials from lithium ion battery wastes. Hydrometallurgy 2003, 68, 5–10. [Google Scholar] [CrossRef]

- Moura, M.N.; Barrada, R.V.; Almeida, J.R.; Moreira, T.F.M.; Schettino, M.A.; Freitas, J.C.C.; Ferreira, S.A.D.; Lelis, M.F.F.; Freitas, M.B.J.G. Synthesis, characterization and photocatalytic properties of nanostructured CoFe2O4 recycled from spent Li-ion batteries. Chemosphere 2017, 182, 339–347. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Guo, J.-Z.; Gu, Z.-Y.; Sun, Z.-H.; Hou, B.-H.; Yang, A.-B.; Ning, Q.-L.; Li, W.-H.; Wu, X.-L. Effective Recycling of the Whole Cathode in Spent Lithium Ion Batteries: From the Widely Used Oxides to High-Energy/Stable Phosphates. ACS Sustain. Chem. Eng. 2019, 7, 12014–12022. [Google Scholar] [CrossRef]

- Li, L.; Zhai, L.; Zhang, X.; Lu, J.; Chen, R.; Wu, F.; Amine, K. Recovery of valuable metals from spent lithium-ion batteries by ultrasonic-assisted leaching process. J. Power Sources 2014, 262, 380–385. [Google Scholar] [CrossRef]

- Myoung, J.; Jung, Y.; Lee, J.; Tak, Y. Cobalt oxide preparation from waste LiCoO2 by electrochemical-hydrothermal method. J. Power Sources 2002, 112, 639–642. [Google Scholar] [CrossRef]

- Li, L.; Chen, R.; Sun, F.; Wu, F.; Liu, J. Preparation of LiCoO2 films from spent lithium-ion batteries by a combined recycling process. Hydrometallurgy 2011, 108, 220–225. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, Y.; Dong, P. Use of glucose as reductant to recover Co from spent lithium ions batteries. Waste Manag. 2017, 64, 214–218. [Google Scholar] [CrossRef]

- Pinna, E.G.; Ruiz, M.C.; Ojeda, M.W.; Rodriguez, M.H. Cathodes of spent Li-ion batteries: Dissolution with phosphoric acid and recovery of lithium and cobalt from leach liquors. Hydrometallurgy 2017, 167, 66–71. [Google Scholar] [CrossRef]

- Bian, D.; Sun, Y.; Li, S.; Tian, Y.; Yang, Z.; Fan, X.; Zhang, W. A novel process to recycle spent LiFePO4 for synthesizing LiFePO4/C hierarchical microflowers. Electrochim. Acta 2016, 190, 134–140. [Google Scholar] [CrossRef]

- Suarez, D.S.; Pinna, E.G.; Rosales, G.D.; Rodriguez, M.H. Synthesis of Lithium Fluoride from Spent Lithium Ion Batteries. Minerals 2017, 7, 81. [Google Scholar] [CrossRef]

- Amouzegar, K.; Bouchard, P.; Turcotte, N.; Zaghib, K. Method for Recycling Electrode Materials of a Lithium Battery. World Patent WO 2017147528 A1, 2017. [Google Scholar]

- Chen, X.; Ma, H.; Luo, C.; Zhou, T. Recovery of valuable metals from waste cathode materials of spent lithium-ion batteries using mild phosphoric acid. J. Hazard. Mater. 2017, 326, 77–86. [Google Scholar] [CrossRef]

- Wu, C.; Li, B.; Yuan, C.; Ni, S.; Li, L. Recycling valuable metals from spent lithium-ion batteries by ammonium sulfite-reduction ammonia leaching. Waste Manag. 2019, 93, 153–161. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Hu, J.; Liu, Y.; Jing, Q.; Yang, C.; Chen, Y.; Wang, C. Sustainable and Facile Method for the Selective Recovery of Lithium from Cathode Scrap of Spent LiFePO4 Batteries. ACS Sustain. Chem. Eng. 2019, 7, 5626–5631. [Google Scholar] [CrossRef]

- Chen, X.; Luo, C.; Zhang, J.; Kong, J.; Zhou, T. Sustainable Recovery of Metals from Spent Lithium-Ion Batteries: A Green Process. ACS Sustain. Chem. Eng. 2015, 3, 3104–3113. [Google Scholar] [CrossRef]

- Golmohammadzadeh, R.; Rashchi, F.; Vahidi, E. Recovery of lithium and cobalt from spent lithium-ion batteries using organic acids: Process optimization and kinetic aspects. Waste Manag. 2017, 64, 244–254. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Song, W.; Mo, W.; Zhou, L.; Liu, J.-W. Lithium fluoride recovery from cathode material of spent lithium-ion battery. RSC Adv. 2018, 8, 8990–8998. [Google Scholar] [CrossRef]

- Rumble, J.R.; Lide, D.R.; Bruno, T.J.T.A.-T.T. CRC Handbook of Chemistry and Physics, 99th ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Gao, W.; Zhang, X.; Zheng, X.; Lin, X.; Cao, H.; Zhang, Y.; Sun, Z. Lithium Carbonate Recovery from Cathode Scrap of Spent Lithium-Ion Battery: A Closed-Loop Process. Environ. Sci. Technol. 2017, 51, 1662–1669. [Google Scholar] [CrossRef]

- Poling, B.E.; Thomson, G.H.; Friend, D.G.; Rowley, R.L.; Engineering, C.; Wilding, W.V. Physical and Chemical Data *. In Perry’s Chemical Engineers’ Handbook; Perry, R.H., Green, D.W., Eds.; McGramm-Hill Professional Publishing: New York City, NY, USA, 2008; ISBN 9780071593137. [Google Scholar]

- Gao, W.; Song, J.; Cao, H.; Lin, X.; Zhang, X.; Zheng, X.; Zhang, Y.; Sun, Z. Selective recovery of valuable metals from spent lithium-ion batteries – Process development and kinetics evaluation. J. Clean. Prod. 2018, 178, 833–845. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, F.S. Innovative leaching of cobalt and lithium from spent lithium-ion batteries and simultaneous dechlorination of polyvinyl chloride in subcritical water. J. Hazard. Mater. 2016, 316, 19–25. [Google Scholar] [CrossRef]

- Nayaka, G.P.; Pai, K.V.; Santhosh, G.; Manjanna, J. Recovery of cobalt as cobalt oxalate from spent lithium ion batteries by using glycine as leaching agent. J. Environ. Chem. Eng. 2016, 4, 2378–2383. [Google Scholar] [CrossRef]

- Li, L.; Ge, J.; Wu, F.; Chen, R.; Chen, S.; Wu, B. Recovery of cobalt and lithium from spent lithium ion batteries using organic citric acid as leachant. J. Hazard. Mater. 2010, 176, 288–293. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Chen, R.; Zhao, T.; Lu, J.; Wu, F.; Amine, K. Synthesis and electrochemical performance of cathode material Li1.2Co0.13Ni0.13Mn0.54O2 from spent lithium-ion batteries. J. Power Sources 2014, 249, 28–34. [Google Scholar] [CrossRef]

- Pant, D.; Dolker, T. Green and facile method for the recovery of spent Lithium Nickel Manganese Cobalt Oxide (NMC) based Lithium ion batteries. Waste Manag. 2017, 60, 689–695. [Google Scholar] [CrossRef] [PubMed]

- Yao, L.; Feng, Y.; Xi, G. A new method for the synthesis of LiNi1/3 Co1/3 Mn1/3 O2 from waste lithium ion batteries. RSC Adv. 2015, 5, 44107–44114. [Google Scholar] [CrossRef]

- Wang, M.M.; Zhang, C.C.; Zhang, F.S. An environmental benign process for cobalt and lithium recovery from spent lithium-ion batteries by mechanochemical approach. Waste Manag. 2016, 51, 239–244. [Google Scholar] [CrossRef]

- Nayaka, G.P.; Manjanna, J.; Pai, K.V.; Vadavi, R.; Keny, S.J.; Tripathi, V.S. Recovery of valuable metal ions from the spent lithium-ion battery using aqueous mixture of mild organic acids as alternative to mineral acids. Hydrometallurgy 2015, 151, 73–77. [Google Scholar] [CrossRef]

- Li, L.; Bian, Y.; Zhang, X.; Yao, Y.; Xue, Q.; Fan, E.; Wu, F.; Chen, R. A green and effective room-temperature recycling process of LiFePO4 cathode materials for lithium-ion batteries. Waste Manag. 2019, 85, 437–444. [Google Scholar] [CrossRef]

- Wang, B.; Lin, X.-Y.; Tang, Y.; Wang, Q.; Leung, M.K.H.; Lu, X.-Y. Recycling LiCoO2 with methanesulfonic acid for regeneration of lithium-ion battery electrode materials. J. Power Sources 2019, 436, 226828. [Google Scholar] [CrossRef]

- Zeng, X.; Li, J.; Shen, B. Novel approach to recover cobalt and lithium from spent lithium-ion battery using oxalic acid. J. Hazard. Mater. 2015, 295, 112–118. [Google Scholar] [CrossRef]

- Li, L.; Lu, J.; Zhai, L.; Zhang, X.; Curtiss, L.; Jin, Y.; Wu, F.; Chen, R.; Amine, K. A facile recovery process for cathodes from spent lithium iron phosphate batteries by using oxalic acid. CSEE J. Power Energy Syst. 2018, 4, 219–225. [Google Scholar] [CrossRef]

- He, L.P.; Sun, S.Y.; Mu, Y.Y.; Song, X.F.; Yu, J.G. Recovery of Lithium, Nickel, Cobalt, and Manganese from Spent Lithium-Ion Batteries Using L-Tartaric Acid as a Leachant. ACS Sustain. Chem. Eng. 2017, 5, 714–721. [Google Scholar] [CrossRef]

- Okayam, S.; Uchida, S. Degrade Performance Recovery Method for Lithium Ion Secondary Battery. U.S. Patent 9958508 B2, 2018. [Google Scholar]

- Petzl, M.; Danzer, M.A. Nondestructive detection, characterization, and quantification of lithium plating in commercial lithium-ion batteries. J. Power Sources 2014, 254, 80–87. [Google Scholar] [CrossRef]

- He, L.; Zhao, Z.; Liu, X.; Chen, A.; Si, X. Thermodynamics analysis of LiFePO4 precipitation from Li–Fe(II)–P–H2O system at 298 K. Trans. Nonferrous Met. Soc. China 2012, 22, 1766–1770. [Google Scholar] [CrossRef]

- Hamada, K.; Sugibuchi, Y.; Kashima, H. Treatment Process for a Positive Electrode Active Material for Lithium-Ion Secondary Battery. U.S. Patent 9755223 B2, 2017. [Google Scholar]

- Chen, J.; Li, Q.; Song, J.; Song, D.; Zhang, L.; Shi, X. Environmentally friendly recycling and effective repairing of cathode powders from spent LiFePO4 batteries. Green Chem. 2016, 18, 2500–2506. [Google Scholar] [CrossRef]

- Novis Smith, W.; Swoffer, S. Process for Recovering and Regenerating Lithium cathode Material From Lithium-Ion Batteries. U.S. Patent 8882007 B1, 2014. [Google Scholar]

- Sloop, S.E. Relithiation in Oxidizing Conditions. U.S. Patent Appl. 20170200989 A1, 2017. [Google Scholar]

- Shi, Y.; Chen, G.; Chen, Z. Effective regeneration of LiCoO2 from spent lithium-ion batteries: a direct approach towards high-performance active particles. Green Chem. 2018, 20, 851–862. [Google Scholar] [CrossRef]

- Ganter, M.J.; Landi, B.J.; Babbitt, C.W.; Anctil, A.; Gaustad, G. Cathode refunctionalization as a lithium ion battery recycling alternative. J. Power Sources 2014, 256, 274–280. [Google Scholar] [CrossRef]

- Sloop, S.E.; Trevey, J.; Gaines, L.; Lerner, M.M.; Xu, W. Advances in Direct Recycling of Lithium-Ion Electrode Materials. ECS Trans. 2018, 85, 397–403. [Google Scholar] [CrossRef]

- Ra, D.-I.; Han, K.-S. Used lithium ion rechargeable battery recycling using Etoile-Rebatt technology. J. Power Sources 2006, 163, 284–288. [Google Scholar] [CrossRef]

- Zhu, S.; Qin, Y.; Zhang, J. Renovation of lithium cobalt oxide from spent lithium ion batteries by an aqueous pulsed discharge plasma. Int. J. Electrochem. Sci. 2016, 11, 6403–6411. [Google Scholar] [CrossRef]

- Kepler, D.K.; Tsang, F.; Vermeulen, R.; Hailey, P. Process for Preparing and Recycling Cathode Active Materials for Lithium-ion Batteries. U.S. Patent Appl. 20160049701 A1, 2016. [Google Scholar]

- Yang, Z.; Zhang, J.; Wu, Q.; Zhi, L.; Zhang, W. Electrochemical Regeneration of LiFePO4/C CathodeMaterials fromSpent Lithium Ion Batteries. J. Chinese Ceram. Soc. 2013, 41, 1051–1056. [Google Scholar]

- Wang, Q.; Liu, Y.; Yanhong, C.; Jinping, W.; Liangliang, L.; Yanhua, L. Method for Treating Lithium Iron Phosphate Cathode Material of Waste and Old Power Lithium Battery of Automobile. Chinese Patent CN 102956936 A, 2011. [Google Scholar]

- Xie, Y.; Yu, H.; Ou, Y.; Li, C. Recovery and preparation of LiFePO4 from used traction battery. Chinese J. Power Sources 2014, 38, 2239–2241. [Google Scholar]

- Wang, L.; Li, J.; Zhou, H.; Huang, Z.; Tao, S.; Zhai, B.; Liu, L.; Hu, L. Regeneration cathode material mixture from spent lithium iron phosphate batteries. J. Mater. Sci. Mater. Electron. 2018, 29, 9283–9290. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, M.; Meng, Y.S.; Chen, Z. Ambient-Pressure Relithiation of Degraded LixNi0.5Co0.2Mn0.3O2 (0 < x <1) via Eutectic Solutions for Direct Regeneration of Lithium-Ion Battery Cathodes. Adv. Energy Mater. 2019, 2, 1–9. [Google Scholar]

- Zhong, X.; Liu, W.; Han, J.; Jiao, F.; Qin, W.; Liu, T.; Zhao, C. Pyrolysis and physical separation for the recovery of spent LiFePO4 batteries. Waste Manag. 2019, 89, 83–93. [Google Scholar] [CrossRef]

- Bi, H.; Zhu, H.; Zu, L.; He, S.; Gao, Y.; Gao, S. Pneumatic separation and recycling of anode and cathode materials from spent lithium iron phosphate batteries. Waste Manag. Res. 2019, 37, 374–385. [Google Scholar] [CrossRef]

- Baumann, M.; Peters, J.F.; Weil, M.; Grunwald, A. CO2 Footprint and Life-Cycle Costs of Electrochemical Energy Storage for Stationary Grid Applications. Energy Technol. 2017, 5, 1071–1083. [Google Scholar] [CrossRef]

- Vandepaer, L.; Cloutier, J.; Bauer, C.; Amor, B. Integrating Batteries in the Future Swiss Electricity Supply System: A Consequential Environmental Assessment. J. Ind. Ecol. 2018. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Hawkins, T.R.; Strømman, A.H. Life Cycle Environmental Assessment of Li-ion and Nickel Metal Hydride Batteries for Plug-in Hybrid and Battery Electric Vehicles. Supporting Information. Zhurnal Eksp. i Teor. Fiz. 2011, 1–51. [Google Scholar]

- Tedjar, F. Sustainability of battery segment with recycling of strategic metals. In Proceedings of the Circular Economy Batteries Conference, Gothenburg, Sweden, 24–26 September 2018. Keynote speech page 2. [Google Scholar]

- Tedjar, F. Circular economy around EV Batteries. In Proceedings of the E-Mobility & Circular Economy Conference, Tokyo, Japan, 1–3 July 2019. Invited Speaker page 3. [Google Scholar]

- Kincaide, J. Where Are Batteries Ending Up Now? In Proceedings of the NaatBatt Lithium-ion Battery Recycling Workshop, Buffalo, NY, USA, 9–10 July 2019. [Google Scholar]

| Cathode Material | LCO | NCO | NCA | NMC | LMO | LFP-C |

|---|---|---|---|---|---|---|

| References | [21] | [21] | [22,23] | [21,24] | [21,25] | [21] |

| Average potential (V vs. Li0) | 3.7–3.9 | 3.8 | 3.8 | 3.3 | 3.8 | 3.3 |

| First cycle discharge capacity (mAh/g at 0.1 C) | 140 | 180 | 180–200 | 170 | 120 | 155–160 |

| Specific energy (Wh/kg) | 520 | 675 | 680–760 | 560 | 455 | 560 |

| Capacity retention after 100 cycles (% of initial capacity) | 97–98 | N/A | 93 | 95 | 89–93 | >99 |

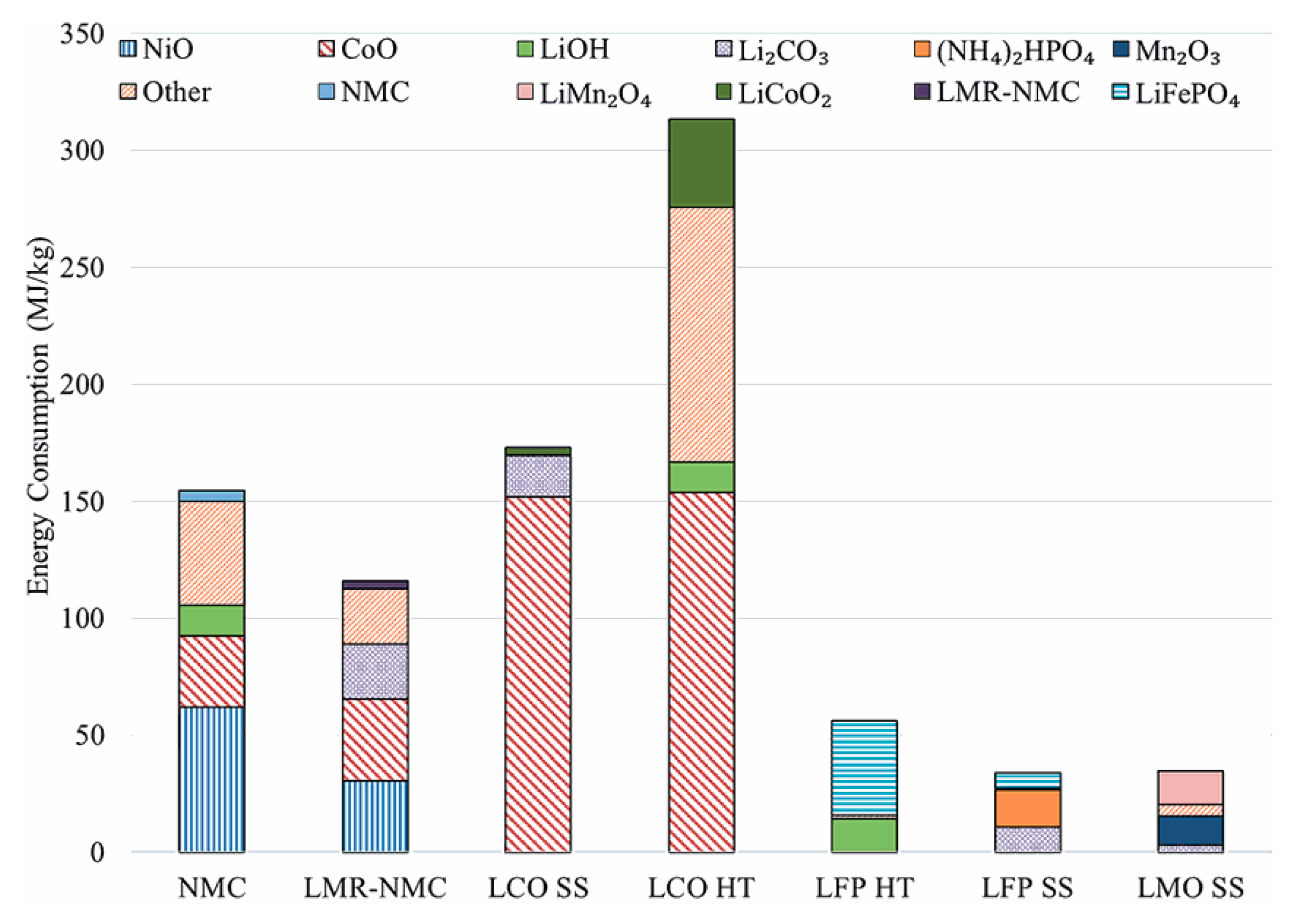

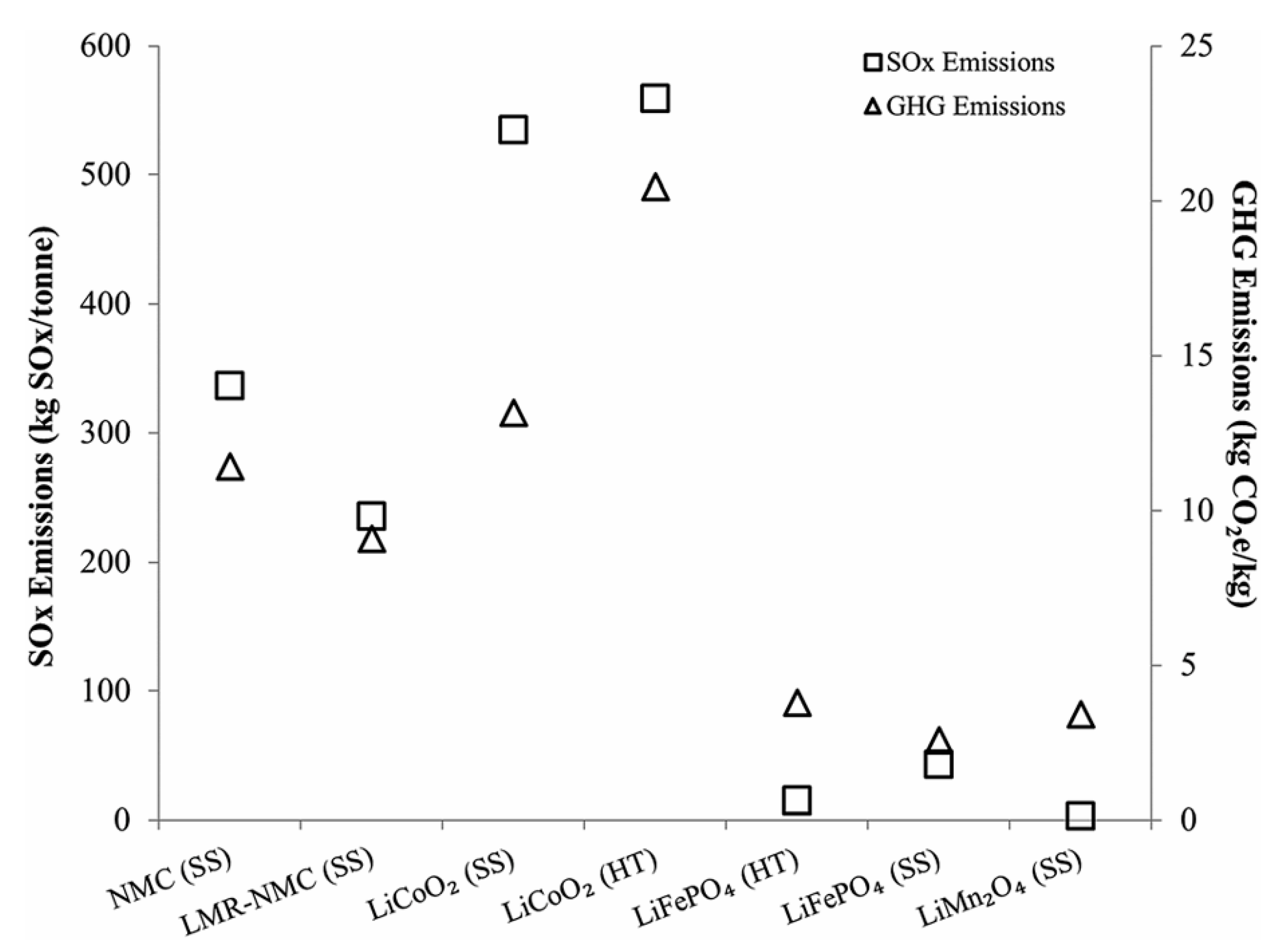

| Synthesis Method | SS | SS | HT | HT | SS |

|---|---|---|---|---|---|

| References | [41] | [39] | [37] | [38] | [38] |

| GWP (kg CO2 equivalent) | 4.2 | 2.0 | 5.3 | 4.5 | 3.0 |

| Energy consumption (MJ) | N.S. | 19 | N.S. | 56 | 34 |

| Company (Location) | Process Type | Recovered Elements |

|---|---|---|

| Retriev (Canada) | Cryo-hydrometallurgy | Li |

| Umicore (Belgium) | Pyro-hydrometallurgy | Co, Ni, and Mn |

| Sumimoto (Japan) | Pyro-hydrometallurgy | Cu, and Ni |

| Recupyl (France) | Hydrometallurgy | Li, Co, Ni, Mn, Cu, and Al |

| Snam (France) | Pyrometallurgy | Cd, Ni, Co, and Fe |

| Accurec (Germany) | Pyrometallurgy | Al, Cu, Co, Ni, and Fe |

| Glencore (Canada) | Pyro-hydrometallurgy | Ni, and Co |

| Batrec (Switzerland) | Pyro-hydrometallurgy | Zn, Co, Ni, Mn, and Hg |

| AkkuSer Oy (Finland) | Mechanical | LIB active materials |

| OnTo Technology (USA) | Direct Recycling | LIB active materials |

| Dowa (Japan) | Pyrometallurgy | Co, Ni, and Mn |

| Nickelhütte Aue Gmbh (Germany) | Pyrometallurgy | Co, Ni, and Mn |

| Brunp (China) | Pyro- and hydrometallurgy | Li, Co, Ni, Mn, Cu, and Al |

| Company | Start Date | Method Used to Access the Active Materials | Method Used to Recover the Valuable Components | References |

|---|---|---|---|---|

| Recupyl (France) | February 1996 | Dry mechanical treatment under inert atmosphere | H2SO4 leaching | [56,57] |

| H2O2 reduction | ||||

| Selective precipitation | ||||

| OnTo Technology (USA) | November 2005 | Supercritical CO2 | Heating at 400–900 °C, LiOH alkaline solution | [58,59] |

| June 2010 | Disassembly/cutting | |||

| November 2016 | - | |||

| Retriev (Canada) | December 2013 | Wet mechanical treatment | Flotation and alkaline treatment | [60] |

| Brunp (China) | August 2018 | Pyrolysis/hydrometallurgy | H2SO4 leaching | [61] |

| H2O2, Na2S, or NaHS reduction | ||||

| No indication of metal recovery in reports |

| Description | Co | Li | Al | Cu | Fe | Mn | Ni | P | References |

|---|---|---|---|---|---|---|---|---|---|

| LCO—anode and cathode: Black mass with current collector contamination | 26.77 | 3.34 | 5.95 | 1.24 | 3.76 | 1.1 | 0.34 | N.S. | [72] |

| LCO, NMC, and LNO—cathode black mass: manually detached from current collectors | 35.8 | 6.5 | 0.58 | 0.005 | 0.06 | 11.6 | 10.06 | N.S. | [73] |

| Mixed LIBs—roasted black mass: Mechanically shredded and separated from current collectors | 11.73 | 1.95 | 0.58 | 0.004 | N.S. | 8.48 | 0.26 | N.S. | [74] |

| Mixed LIBs—cathode black mass: Manually detached from current collectors | 34.66 | 5.92 | 0.68 | N.S. | N.S. | 11.26 | 0.68 | N.S. | [75] |

| LFP—cathode black mass: Manually separated | N.S. | 4.08 | 0.16 | N.S. | 31.25 | N.S. | N.S. | 18.94 | [76] |

| LFP—entire cathode: Manually separated | N.S. | 3.46 | 16.85 | N.S. | 26.45 | N.S. | N.S. | 15.88 | [77] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Larouche, F.; Tedjar, F.; Amouzegar, K.; Houlachi, G.; Bouchard, P.; Demopoulos, G.P.; Zaghib, K. Progress and Status of Hydrometallurgical and Direct Recycling of Li-Ion Batteries and Beyond. Materials 2020, 13, 801. https://doi.org/10.3390/ma13030801

Larouche F, Tedjar F, Amouzegar K, Houlachi G, Bouchard P, Demopoulos GP, Zaghib K. Progress and Status of Hydrometallurgical and Direct Recycling of Li-Ion Batteries and Beyond. Materials. 2020; 13(3):801. https://doi.org/10.3390/ma13030801

Chicago/Turabian StyleLarouche, François, Farouk Tedjar, Kamyab Amouzegar, Georges Houlachi, Patrick Bouchard, George P. Demopoulos, and Karim Zaghib. 2020. "Progress and Status of Hydrometallurgical and Direct Recycling of Li-Ion Batteries and Beyond" Materials 13, no. 3: 801. https://doi.org/10.3390/ma13030801

APA StyleLarouche, F., Tedjar, F., Amouzegar, K., Houlachi, G., Bouchard, P., Demopoulos, G. P., & Zaghib, K. (2020). Progress and Status of Hydrometallurgical and Direct Recycling of Li-Ion Batteries and Beyond. Materials, 13(3), 801. https://doi.org/10.3390/ma13030801