The Effects of Hot-Pack Coating Materials on the Pack Rolling Process and Microstructural Characteristics during Ti-46Al-8Nb Sheet Fabrication

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

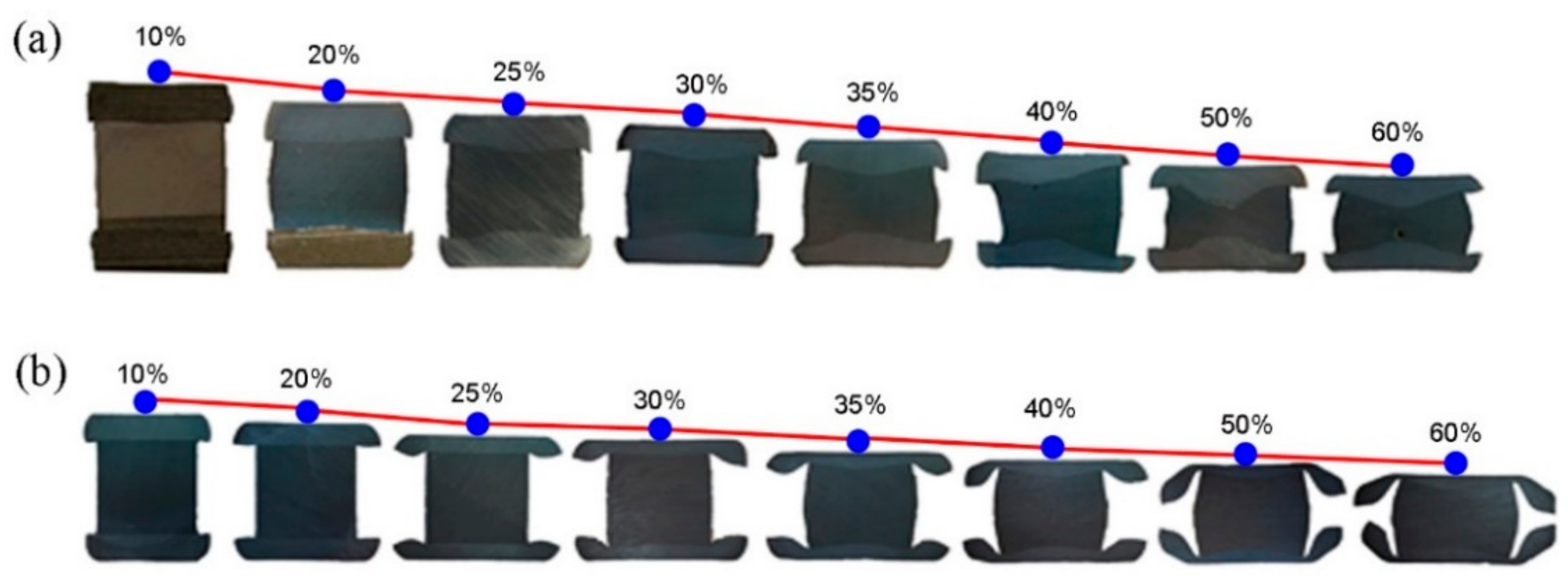

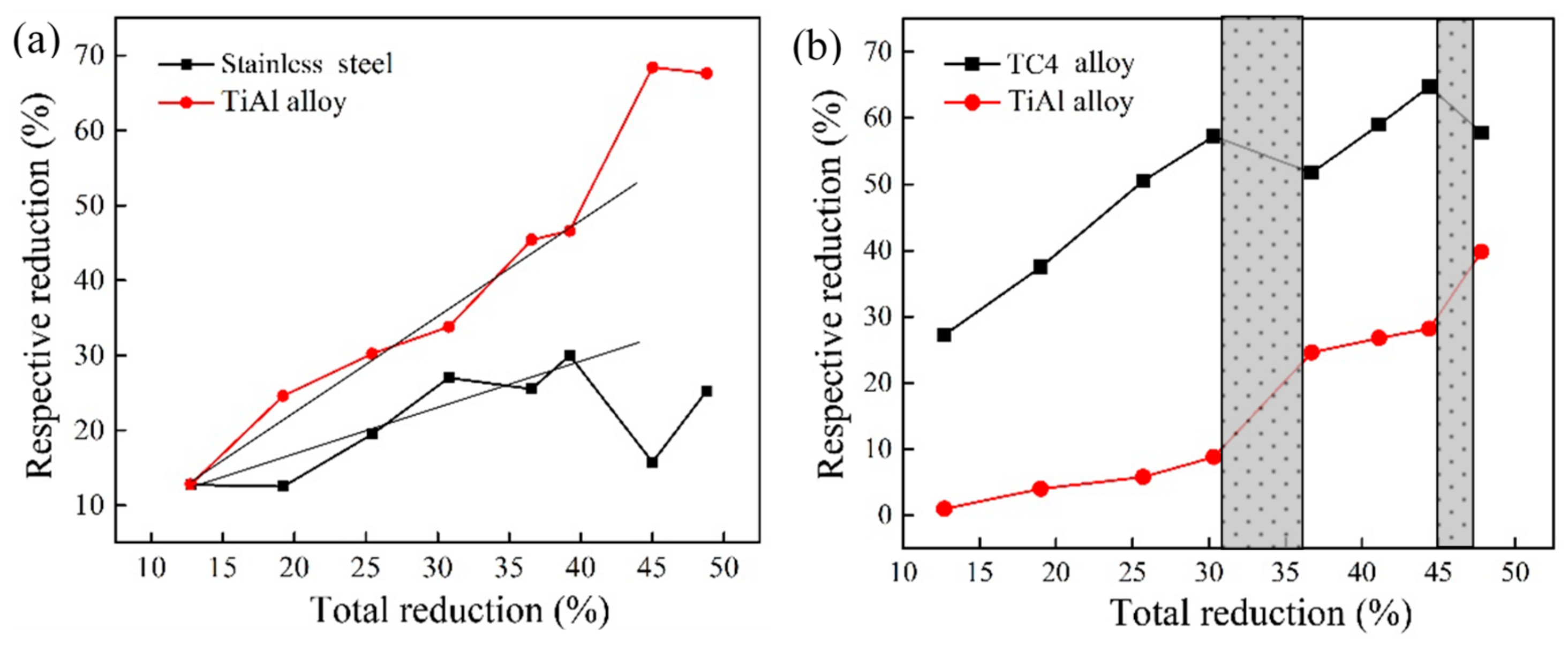

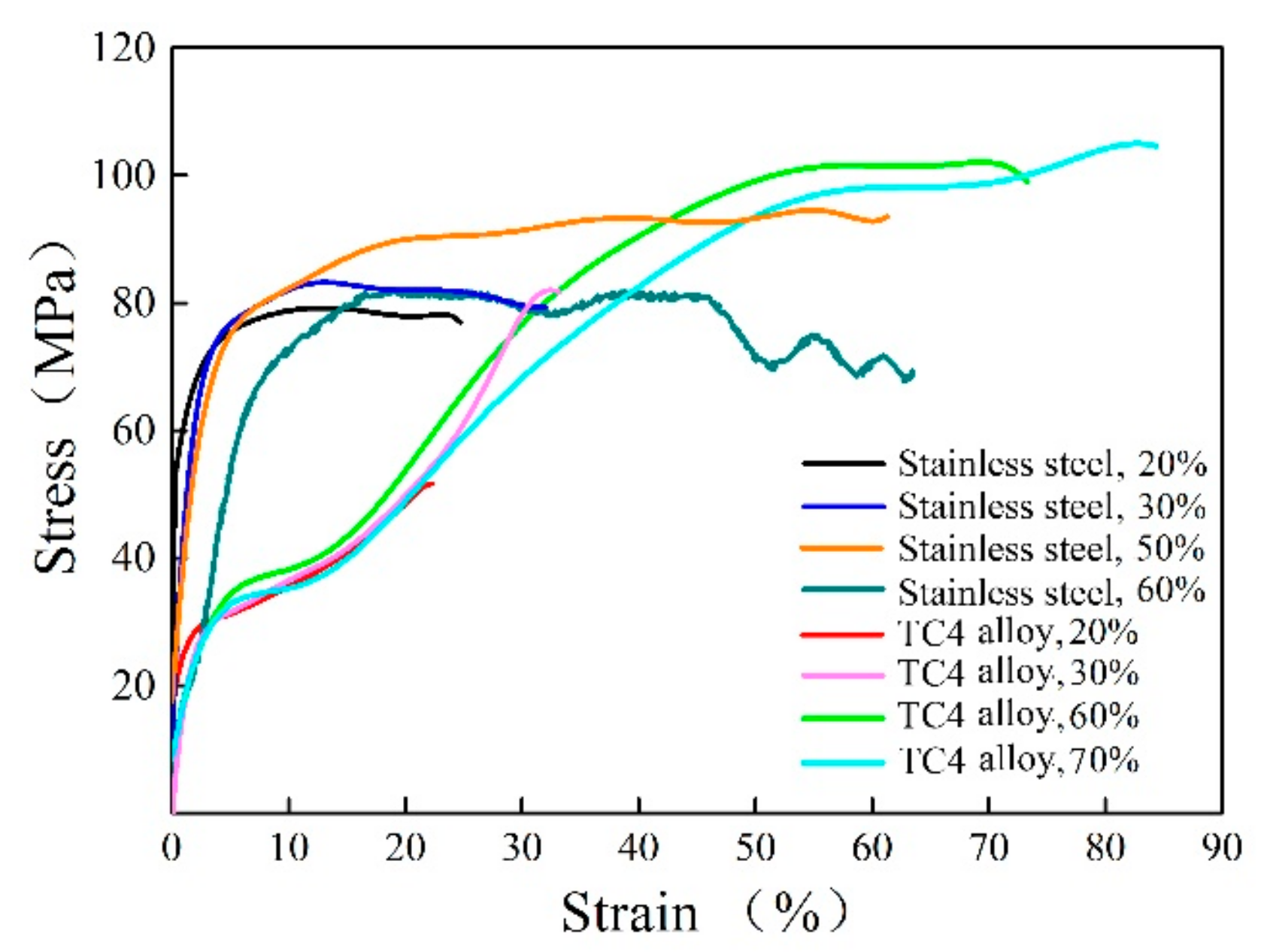

3.1. Deformation Conditions during the Pack Rolling Process

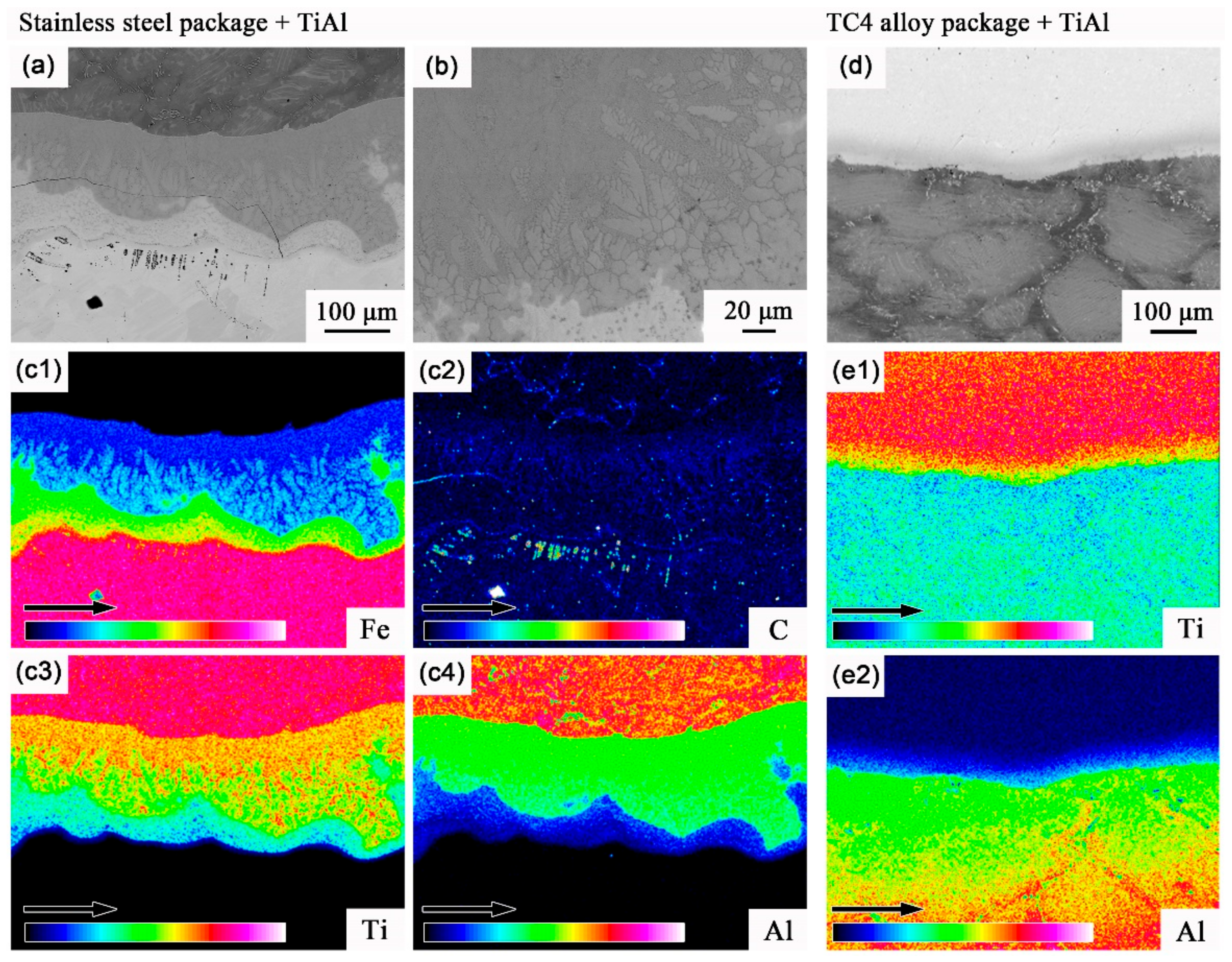

3.2. Pack-Rolling and the Microstructure of Ti-46Al-8Nb Alloy

4. Conclusions

- (1)

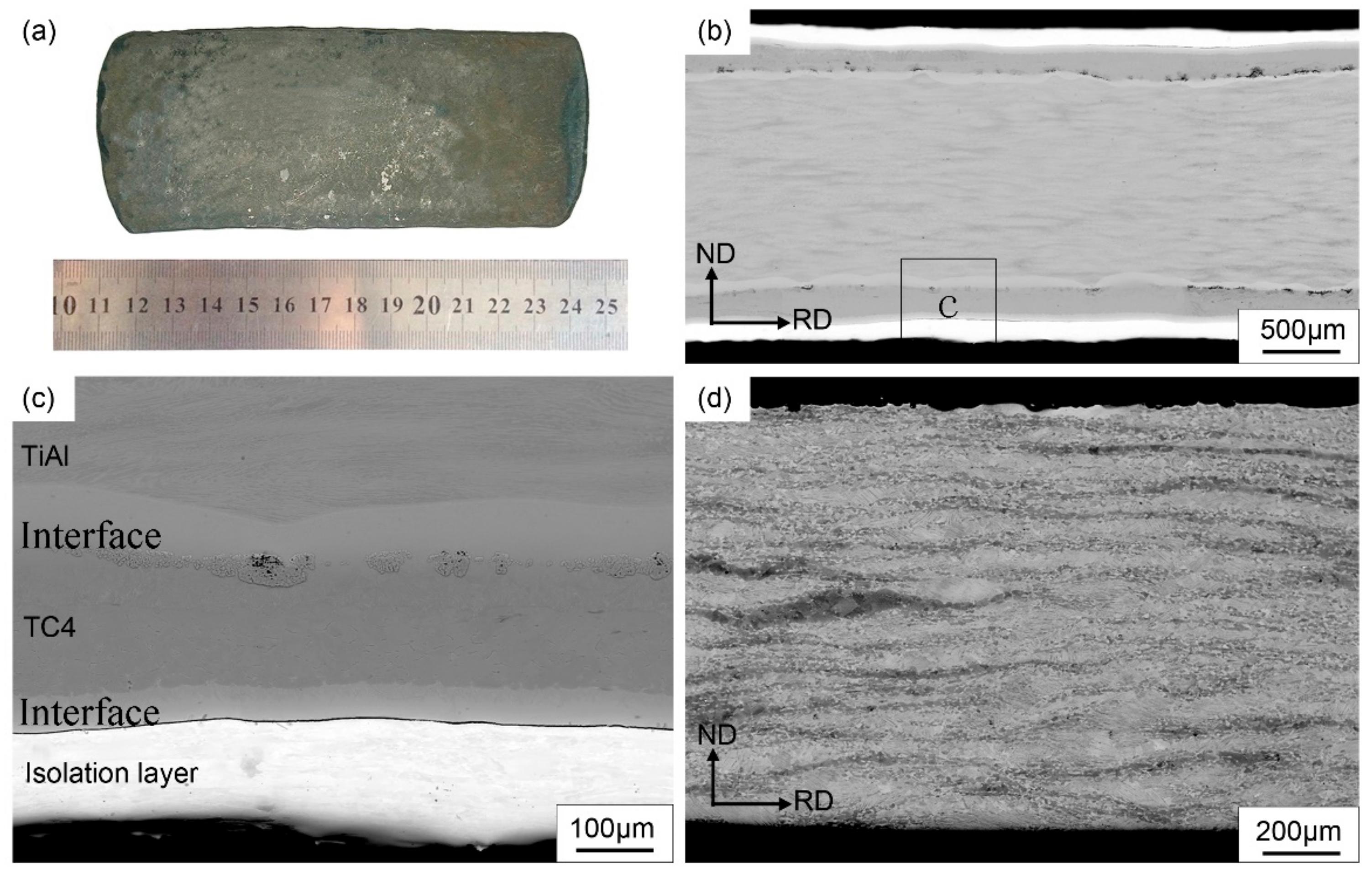

- The sandwich structure of stainless steel/TiAl matrix has good deformation compatibility due to the approximate high-temperature strength during the hot compression process, showing a less deformation-resistant and homogeneous deformation process, but a severe interfacial reaction is observed leading the aggravation of the contact interface. For the TC4/TiAl structure, the interfacial reaction can be neglected, but wavy reduction and high deformation resistance occur due to the low high-temperature strength of the titanium alloy package.

- (2)

- Considering the deformation compatibility and the interface protection, the pack-rolled Ti-46Al-8Nb alloy is complexly designed with an outer stainless steel/isolation layer; an inner TC4 alloy/coating structure for the sheet fabrication; and finally, the sound TiAl sheet with the intact interface. No crack defects can be observed with 85% reduction under the rolling conditions, showing the proper packing structure design and rolling conditions.

- (3)

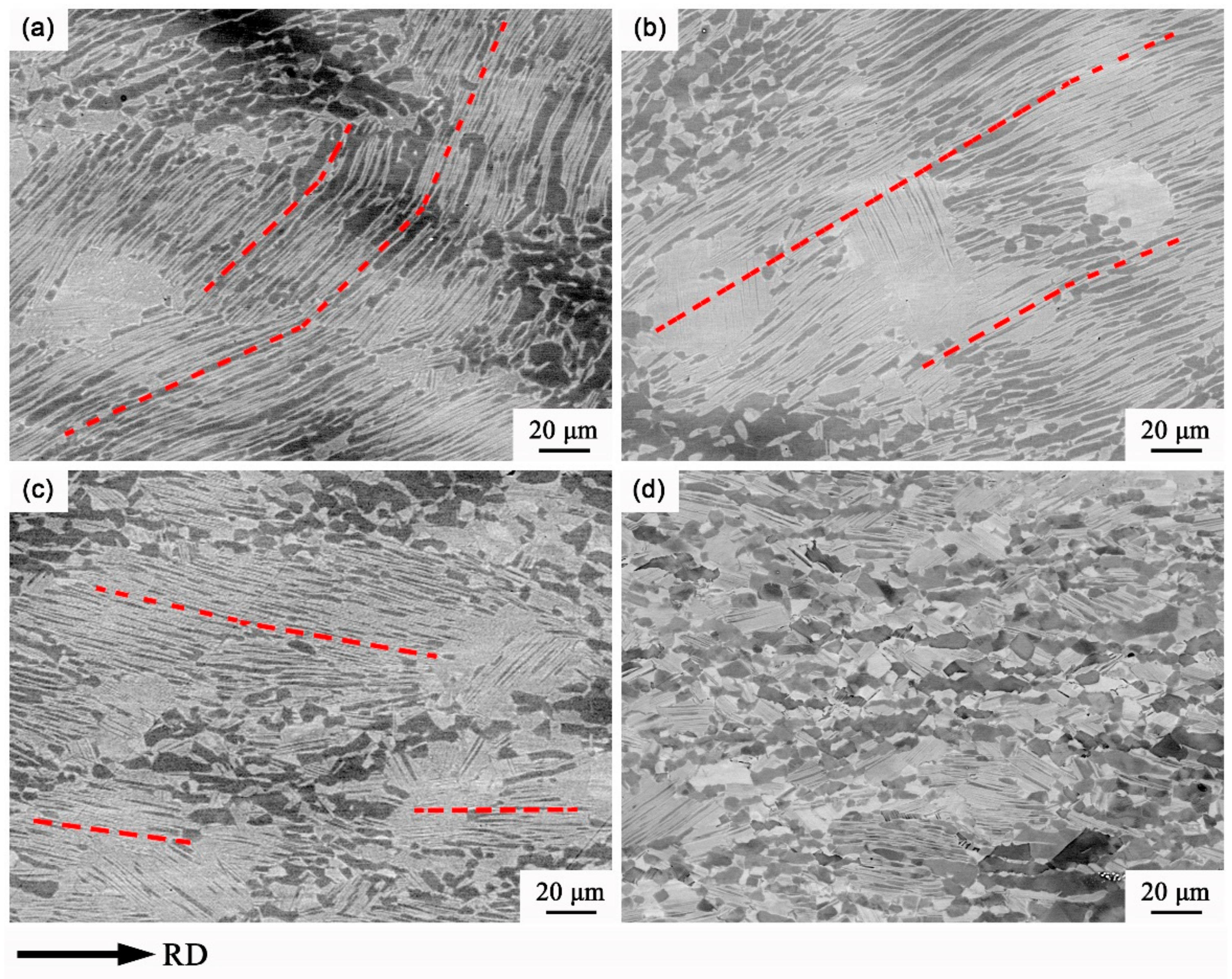

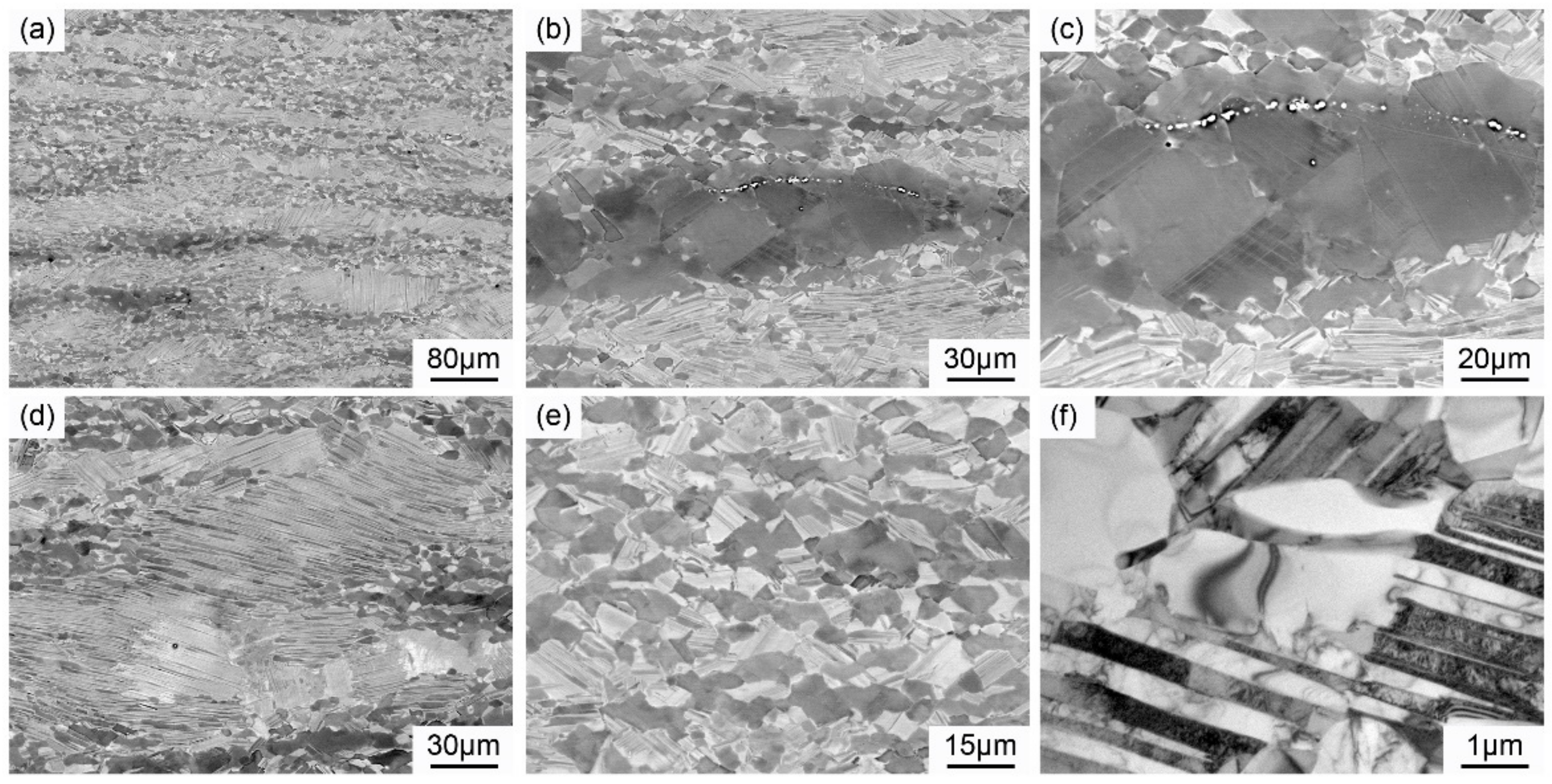

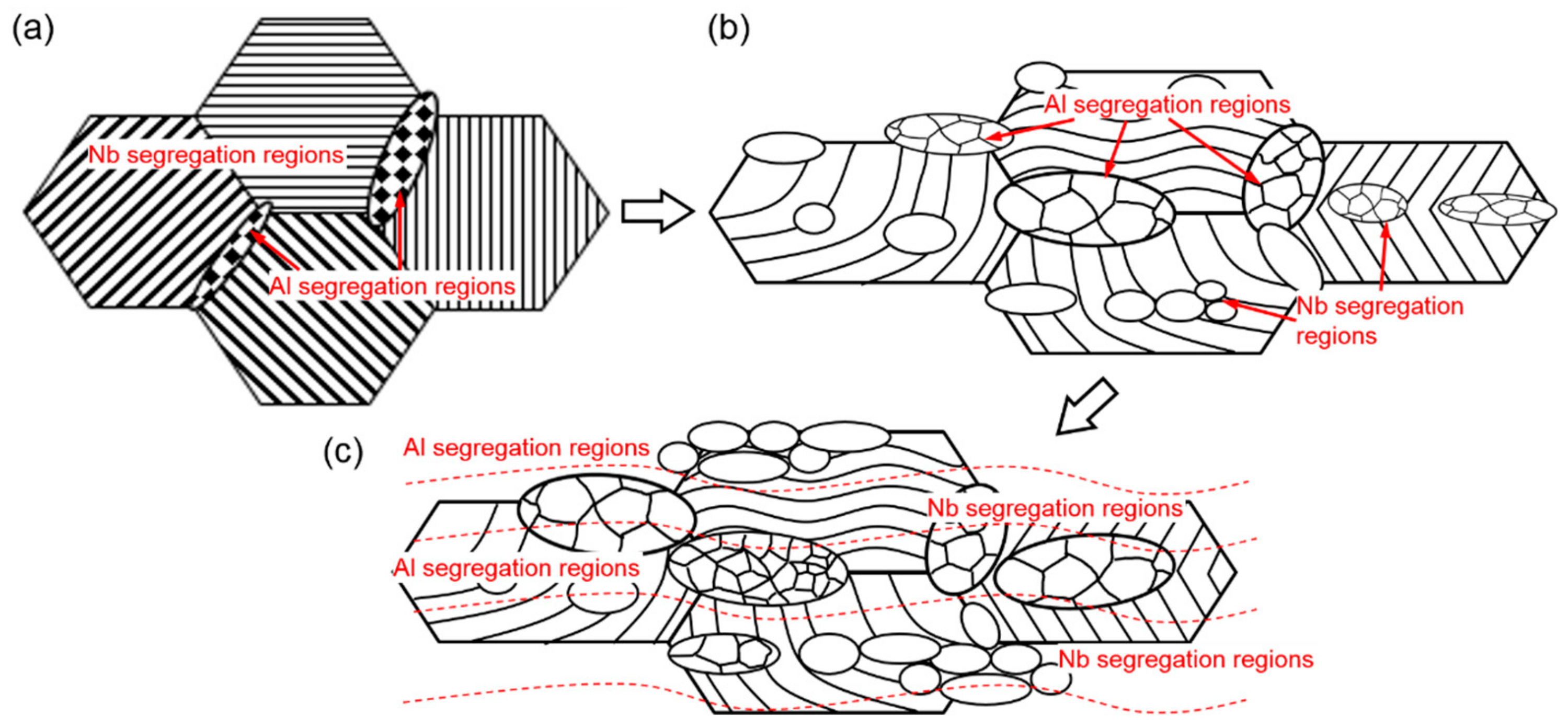

- The pack-rolled TiAl sheet takes on the alternate structure of the dark grain-boundary Al-enriched ribbons and the elongated lamellar colonies ribbons, in which the multistructure of the deformation ribbons’ structure, lumpy γ phase, and retained lamellar colony is obtained mainly from the local flow softening process due to the original microstructure and solute segregation in pack-rolled Ti-46Al-8Nb alloy.

Author Contributions

Funding

Conflicts of Interest

References

- Dimiduk, D.M. Gamma titanium aluminide alloys—An assessment within the competition ofaerospace structural materials. Mater. Sci. Eng. A 1999, 263, 281–288. [Google Scholar] [CrossRef]

- Loria, E.A. Gamma titanium aluminides as perspective structural materials. Intermetallics 2000, 8, 1339–1345. [Google Scholar] [CrossRef]

- Gupta, R.K.; Ramkumar, P. Titanium aluminides for metallic thermal protection system of reusable space transportation vehicle: A review. Front. Aerosp. Eng. 2015, 4, 14–19. [Google Scholar] [CrossRef]

- Gopal, D.; Kestler, H.; Clemens, H.; Bartolotta, P.A. Sheet gamma TiAl: Status and opportunities. J. Metal. 2004, 42–45. [Google Scholar] [CrossRef]

- Yang, R. Advances and challenges of TiAl base alloys. Acta Metall. Sin. 2015, 51, 129–147. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Norman, M.W. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V. Deformation and microstructure development during hot-pack rolling of a near-gamma titanium aluminide alloy. Metall. Mater. Trans. A 1995, 26A, 371–381. [Google Scholar] [CrossRef]

- Fujitsuna, N.; Ohyama, H.; Miyamoto, Y.; Ashida, Y. Isothermal Forging of TiAl-based Intermetallic Compounds. ISIJ Int. 1991, 31, 1147–1153. [Google Scholar] [CrossRef]

- Munetsugu, M.; Hanamura, T.; Kimura, M.; Masahashi, N.; Mizoguchi, T.; Miyazawa, K. Microstructural characterization of twin-roll cast gamma titanium aluminide sheets. ISIJ Int. 1991, 31, 289–297. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. Hot workability of titanium and titanium aluminide alloys—An overview. Mater. Sci. Eng. A 1998, 243, 1–24. [Google Scholar] [CrossRef]

- Fritz, A.; Jonathan, D.H.P.; Michael, O. Gamma Titanium Aluminide Alloys; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; pp. 662–666. [Google Scholar]

- Semiatin, S.L.; Seetharaman, V. Load-Signature analysis for pack rolling of near-gamma titanium aluminidealloys. Metall. Mater. Trans. A 1994, 25, 2539–2542. [Google Scholar] [CrossRef]

- Niu, H.Z.; Kong, F.T.; Xiao, S.L.; Chen, Y.Y.; Yang, F. Effect of pack rolling on microstructures and tensile properties of as-forged Ti-44Al-6V-3Nb-0.3Y alloy. Intermetallics 2012, 21, 97–104. [Google Scholar] [CrossRef]

- Liang, X.P.; Liu, Y.; Li, H.Z.; Gan, Z.Y.; Liu, B.; He, Y.H. An investigation on microstructural and mechanical properties of power metallurgical TiAl alloy during hot pack-rolling. Mater. Sci. Eng. A 2014, 619, 265–273. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Xiao, S.L.; Kong, F.T.; Zhang, C.J. High temperature deformation behaviors of Ti-45Al-2Nb-1.5V-1Mo-Y alloy. Intermetallics 2011, 19, 1767–1774. [Google Scholar] [CrossRef]

- Kim, H.Y.; Hong, S.H. Effect of microstructure on the high-temperature deformation behavior of Ti-48Al-2W intermetallic compounds. Mater. Sci. Eng. A 1999, 271, 382–389. [Google Scholar] [CrossRef]

- Liu, G.H.; Li, X.Z.; Su, Y.Q.; Liu, D.M.; Guo, J.J.; Fu, H.Z. Microstructure, microsegregation pattern and the formation of B2 phase in directionally solidified Ti-46Al-8Nb alloy. J. Alloys Compd. 2012, 541, 275–282. [Google Scholar] [CrossRef]

- Chen, G.L.; Xu, X.J.; Teng, Z.K.; Wang, Y.L.; Lin, J.P. Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale. Intermetallics 2007, 15, 625–631. [Google Scholar] [CrossRef]

- Xu, Z.F.; Xu, X.J.; Lin, J.P.; Zhang, Y.; Wang, Y.L.; Lin, Z.; Chen, G.L. Elimination of β Phase Segregation in As-cast High Nb Containing TiAl Alloy by Heat Treatment. J. Mater. Eng. 2007, 9, 42–46. [Google Scholar]

- Li, H.Z.; Li, Z.; Zhang, W.; Wang, Y.; Liu, Y.; Wang, H.J. High temperature deformability and microstructural evolution of Ti-47Al-2Cr-0.2Mo alloy. J. Alloys Compd. 2010, 2, 359–363. [Google Scholar] [CrossRef]

- Huang, Z.H. Workability and microstructure evolution of Ti-47Al-2Cr-1Nb alloy during isothermal deformation. Intermetallics 2005, 3, 245–250. [Google Scholar] [CrossRef]

- Cheng, T.T. Effects of thermal exposure on the microstructure and properties of a γ-TiAl based alloy containing 44Al-4Nb-4Zr-0.2Si-0.3B. Intermetallics 1999, 9, 995–999. [Google Scholar] [CrossRef]

- Li, T.R.; Liu, G.H.; Xu, M.; Fu, T.L.; Tian, Y.; Misra, R.D.K.; Wang, Z.D. Hot deformation behavior and microstructure characteristics of Ti-46Al-8Nb alloy. Acta Metall. Sin. 2018, 31, 933–944. [Google Scholar] [CrossRef]

- Rees, D.W.A. Plane strain compression of aluminium alloy sheets. Mater. Des. 2012, 39, 495–503. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Ma, X. Non-Schmidt behavior during secondary twinning in a polycrystalline magnesium alloy. Acta Mater. 2007, 56, 5–15. [Google Scholar] [CrossRef]

- Li, T.R.; Liu, G.H.; Xu, M.; Wang, B.X.; Fu, T.L.; Wang, Z.D.; Misra, R.D.K. Flow stress prediction and hot deformation mechanisms in Ti-44Al-5Nb-(Mo, V, B) alloy. Materials 2018, 11, 2044. [Google Scholar] [CrossRef]

- Liu, G.H.; Zhong, L.X.; Qing, S.Y.; Chen, R.R.; Guo, J.J.; Zhi, F.H. Microstructure and microsegregation in directionally solidified Ti–46Al–8Nb alloy. Trans. Nonferr. Met. Soc. China 2012, 22, 275–282. [Google Scholar] [CrossRef]

- Inui, H.; Kishid, K.; Misaki, M.; Kobayashi, M.; Shirai, Y.; Yamaguchi, M. Temperature dependence of yield stress, tensile elongation and deformation structures in polysymthetically twinned crystals of Ti-Al. Philos. Mag. A 1995, 7, 1609–1631. [Google Scholar] [CrossRef]

- Chen, G.L.; Zhang, L.C. Deformation mechanism at large strains in a high-Nb-containing TiAl at room temperature. Mater. Sci. Eng. A 2002, 329, 163–170. [Google Scholar] [CrossRef]

- Li, M.G.; Xiao, S.L.; Xu, L.J.; Chen, Y.Y.; Tian, J.; Zhang, B.Y. Mechanical properties, deformation behavior and microstructure evolution of Ti-43Al-6Nb-1Mo-1Cr alloys. Mater. Charact. 2018, 136, 69–83. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.; Liao, M.; Yu, Q.; Liu, G.; Wang, Z. The Effects of Hot-Pack Coating Materials on the Pack Rolling Process and Microstructural Characteristics during Ti-46Al-8Nb Sheet Fabrication. Materials 2020, 13, 762. https://doi.org/10.3390/ma13030762

Huang H, Liao M, Yu Q, Liu G, Wang Z. The Effects of Hot-Pack Coating Materials on the Pack Rolling Process and Microstructural Characteristics during Ti-46Al-8Nb Sheet Fabrication. Materials. 2020; 13(3):762. https://doi.org/10.3390/ma13030762

Chicago/Turabian StyleHuang, Haohong, Minle Liao, Qikai Yu, Guohuai Liu, and Zhaodong Wang. 2020. "The Effects of Hot-Pack Coating Materials on the Pack Rolling Process and Microstructural Characteristics during Ti-46Al-8Nb Sheet Fabrication" Materials 13, no. 3: 762. https://doi.org/10.3390/ma13030762

APA StyleHuang, H., Liao, M., Yu, Q., Liu, G., & Wang, Z. (2020). The Effects of Hot-Pack Coating Materials on the Pack Rolling Process and Microstructural Characteristics during Ti-46Al-8Nb Sheet Fabrication. Materials, 13(3), 762. https://doi.org/10.3390/ma13030762