Feasible Use of Cathode Ray Tube Glass (CRT) and Recycled Aggregates as Unbound and Cement-Treated Granular Materials for Road Sub-Bases

Abstract

1. Introduction

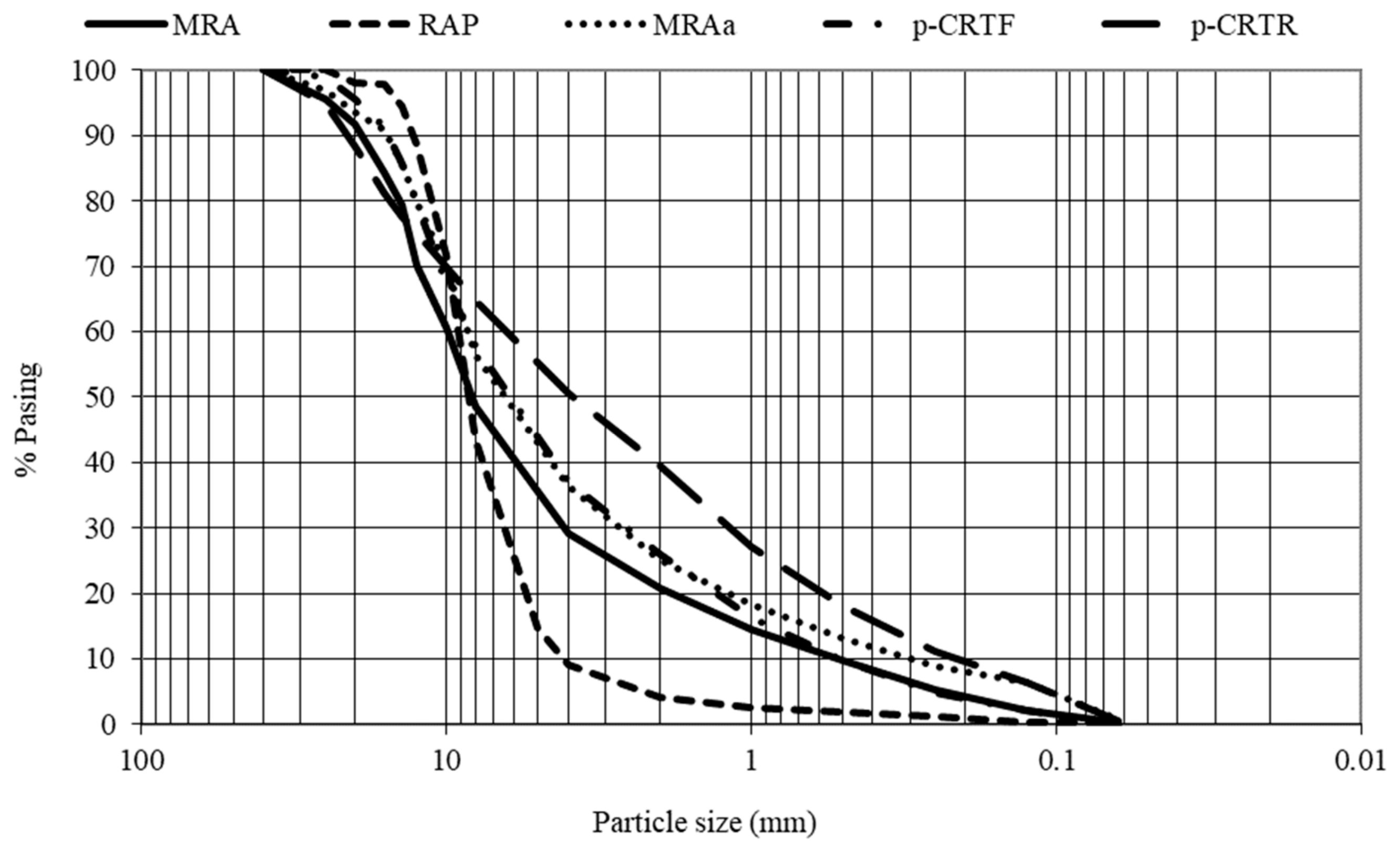

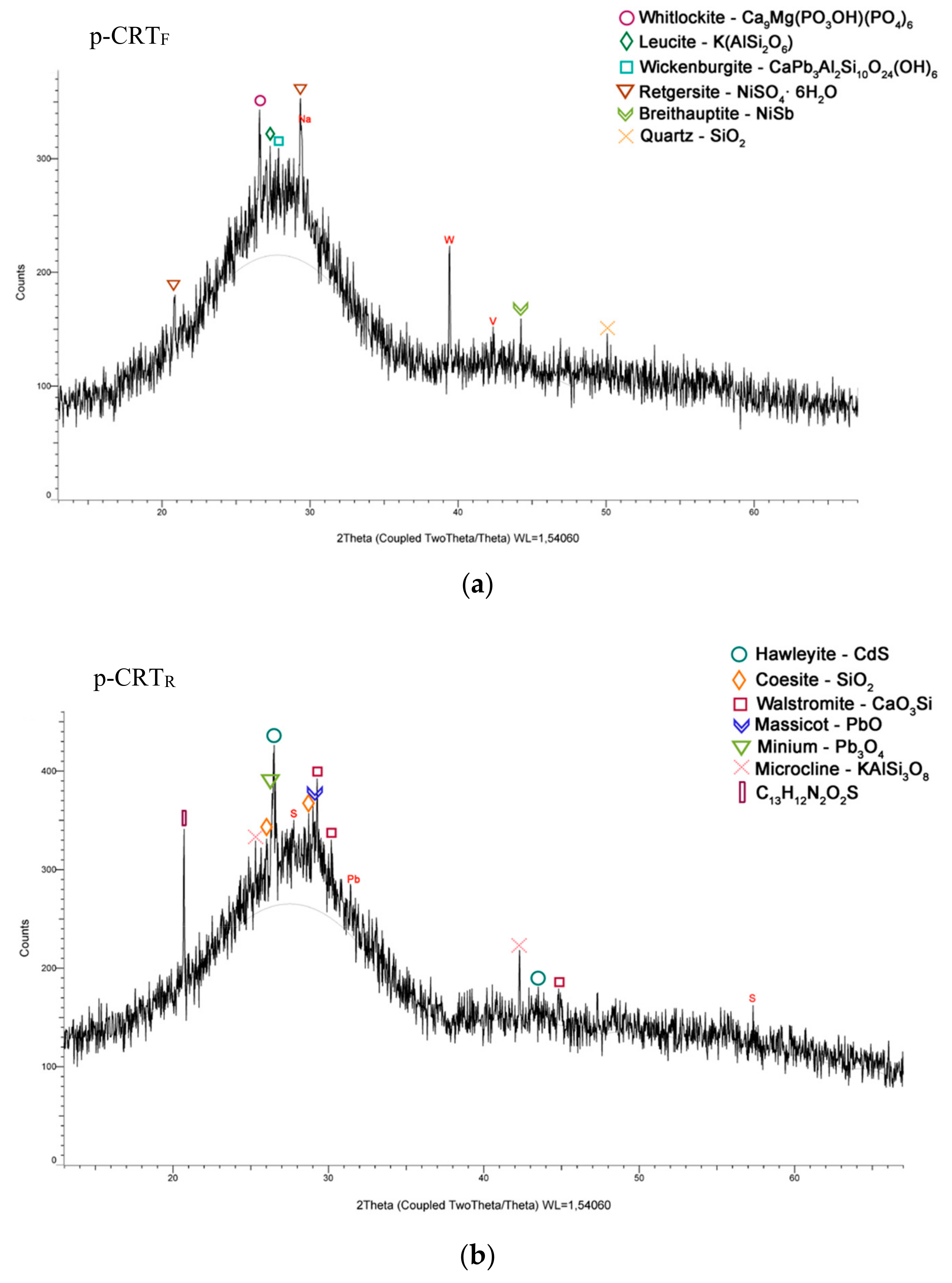

2. Materials

Mixtures of Recycled Materials and p-CRT Studied

3. Classification of Materials as a Function of their Pollutant Potential

3.1. Compliance Test UNE EN 12457-4:2004 [34]

3.2. Percolation Test CEN/TS 14405 [38]

4. Experimental Methods and Results

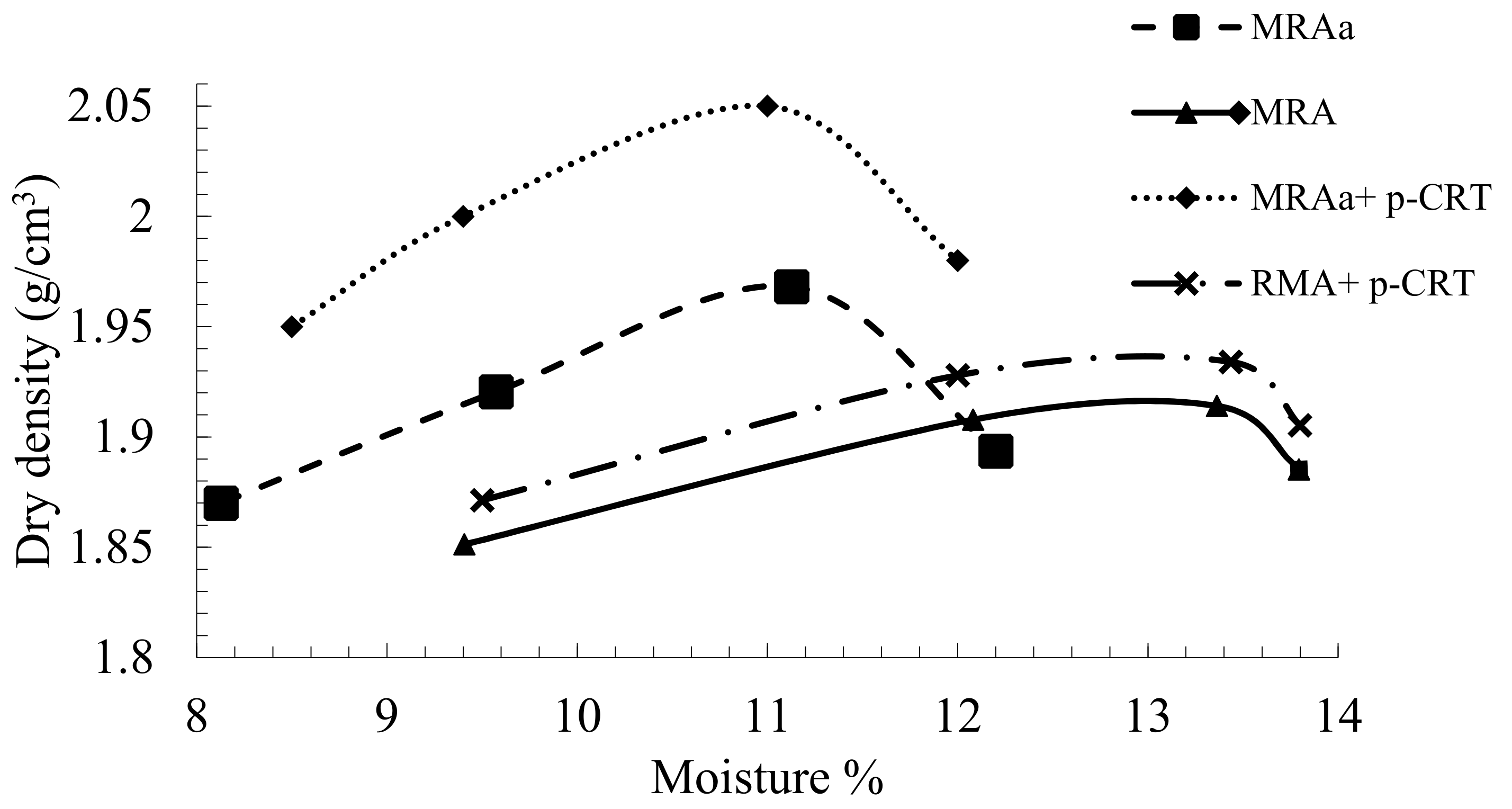

4.1. Modified Proctor (UNE 103501:1994) [40]

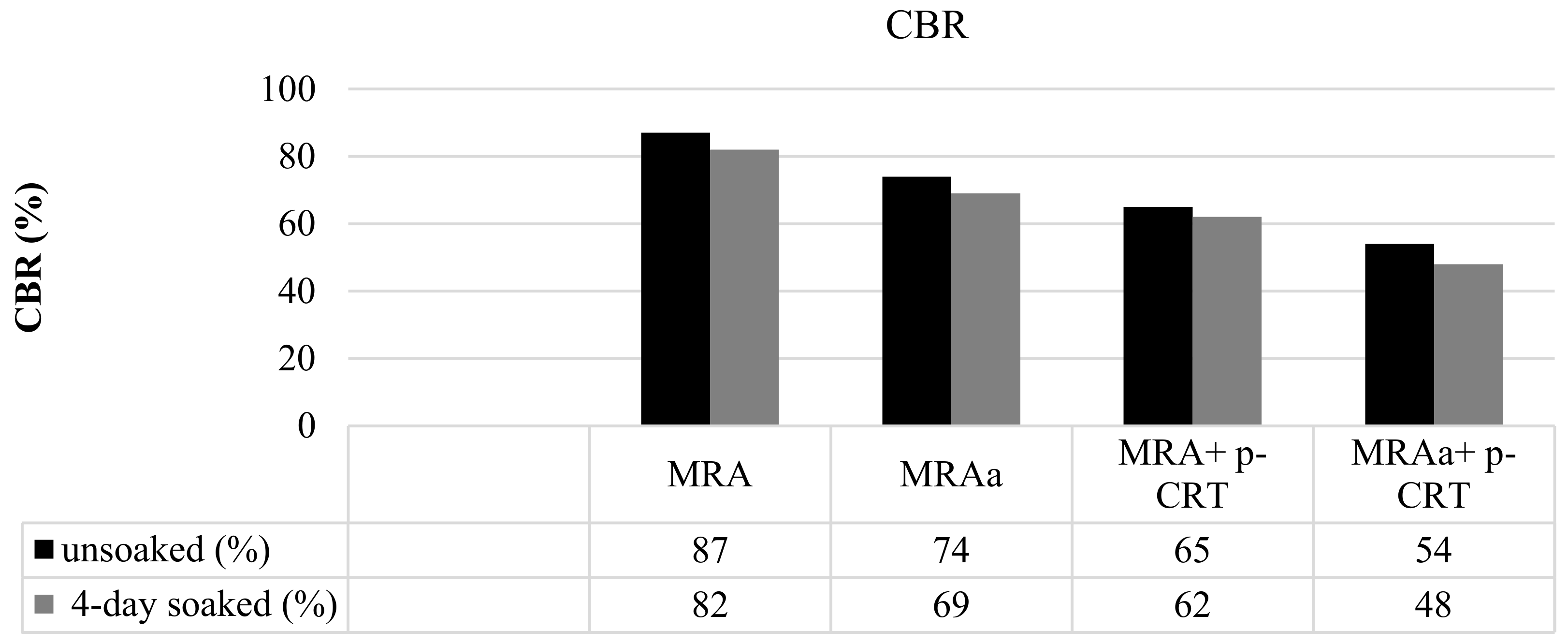

4.2. California Bearing Ratio (CBR)

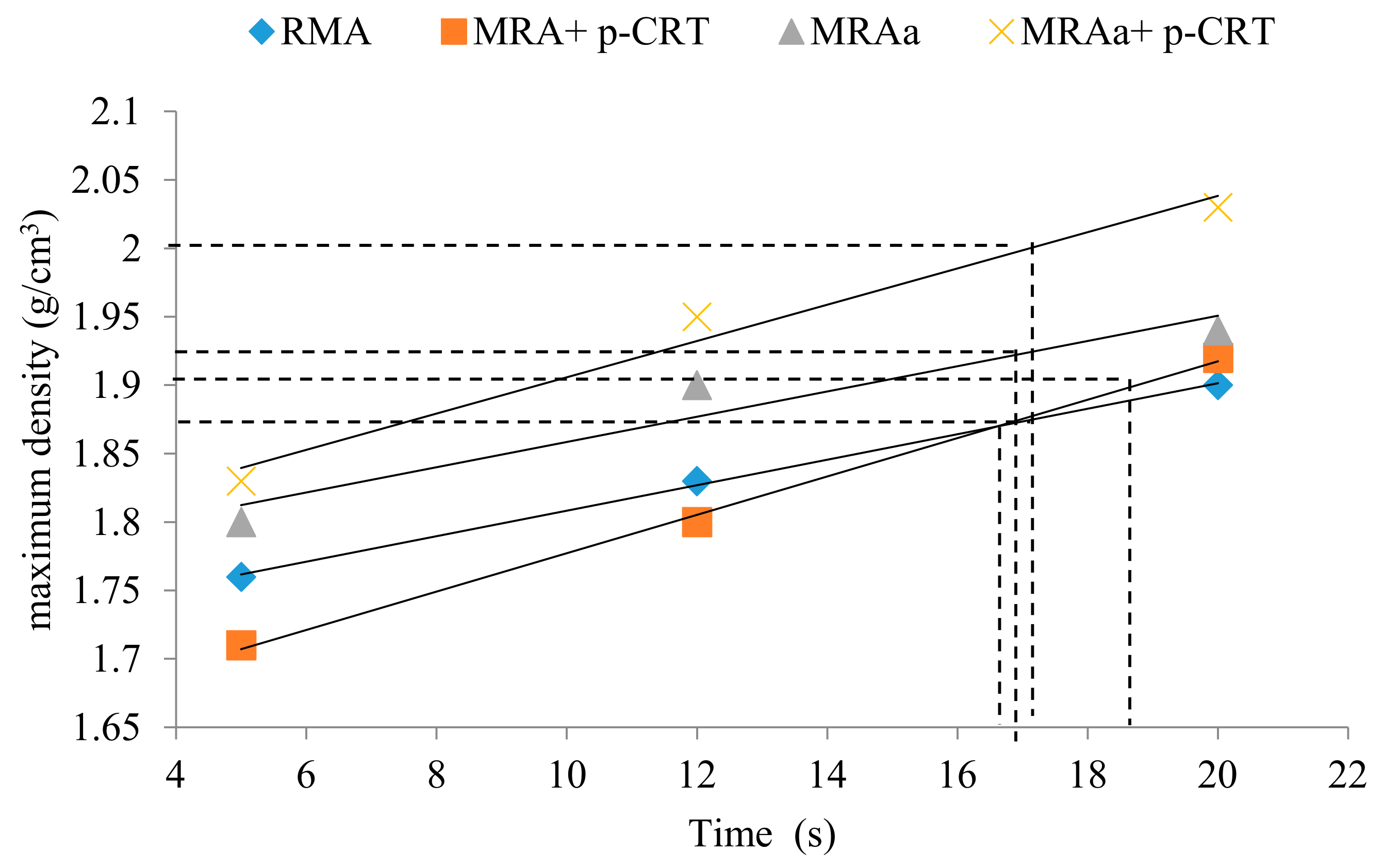

4.3. Vibrating Hammer Times

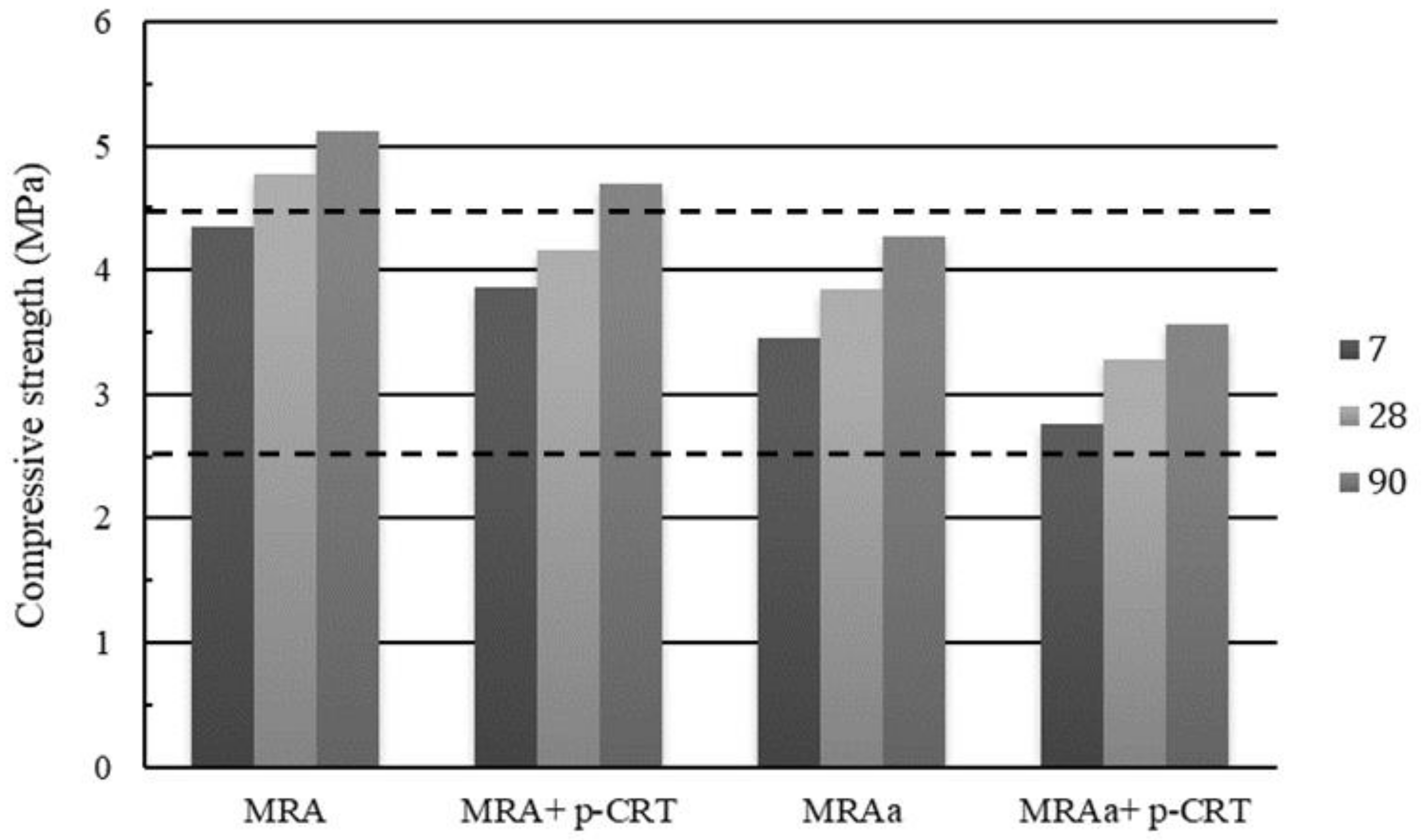

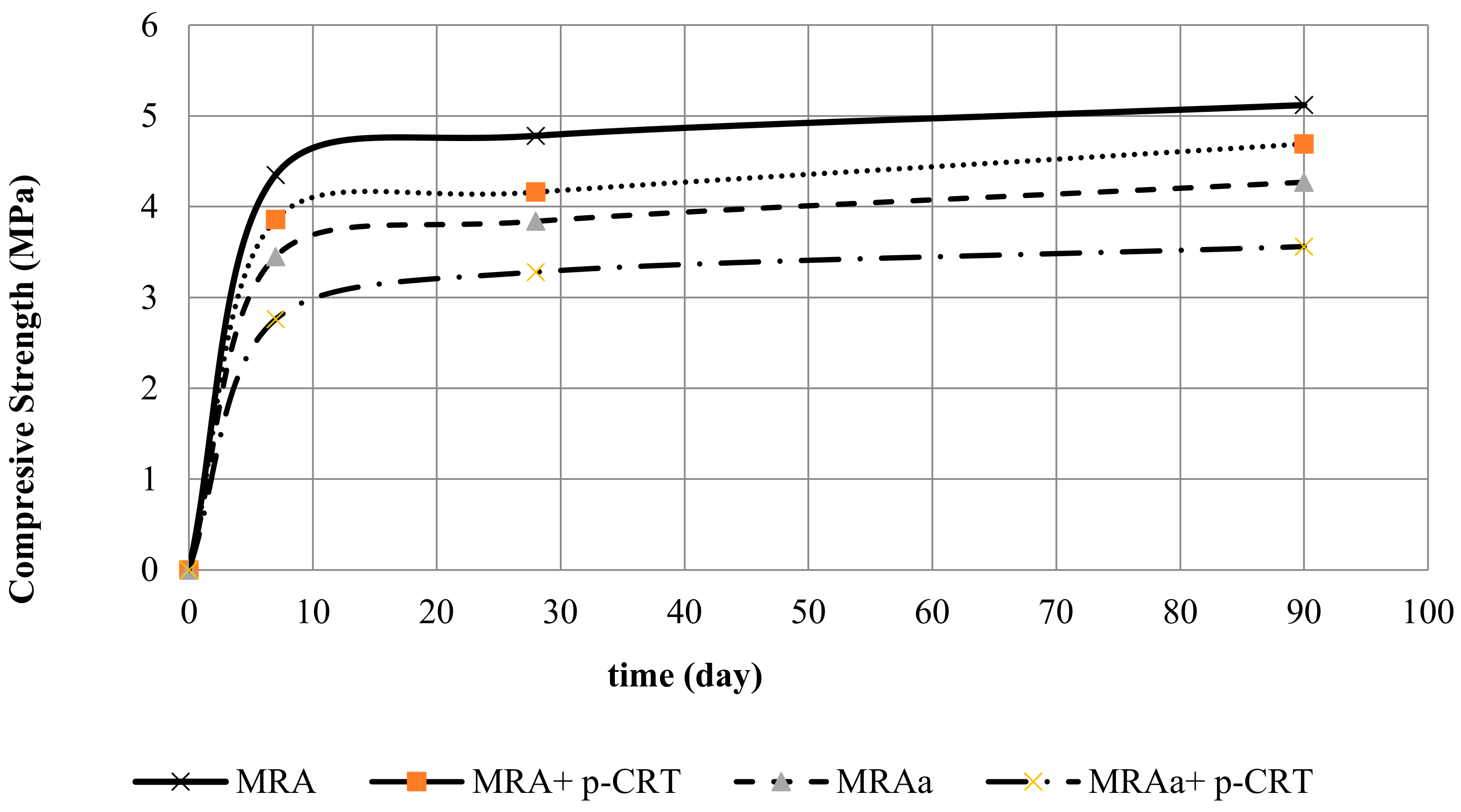

4.4. Compressive Strength

5. Conclusions

- Regarding the physical and chemical properties of the materials, the mixed recycled aggregates presented a lower density and greater absorption of water due to its content of ceramic particles (21.16% of ceramic particles). Los Angeles abrasion testing indicates a good quality of all aggregates in accordance with current regulations (>40).

- Potential contamination by leaching was studied by means of two different methods, compliance testing (UNE-12457-4) [34] and percolation testing (CEN/TS-14405) [38]. The compliance test data revealed a potential contaminant in the funnel (p-CRTR) of the analysed samples, due to the high content of Pb, confirming that they are an inappropriate material for the application as an isolated aggregate in any civil engineering application.

Author Contributions

Funding

Conflicts of Interest

References

- Agrela, F.; De Juan, M.S.; Ayuso, J.; Geraldes, V.; Jiménez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- Dhir, R.K.; Limbachiya, M.C.; Leelawat, T.; BS 5328; BS 882. Suitability of Recycled Concrete Aggregate for Use in Bs 5328 Designated Mixes. Proc. Inst. Civ. Eng. 1999, 134, 257–274. [Google Scholar] [CrossRef]

- Poon, C.; Kou, S.; Lam, L. Use of recycled aggregates in molded concrete bricks and blocks. Constr. Build. Mater. 2002, 16, 281–289. [Google Scholar] [CrossRef]

- Contrafatto, L.; Cosenza, R.; Barbagallo, R.; Ognibene, S. Use of recycled aggregates in road sub-base construction and concrete manufacturing. Ann. Geophys. 2018, 61, 223. [Google Scholar] [CrossRef]

- Jiménez, J.R.; Agrela, F.; Ayuso, J.; López, M. A comparative study of recycled aggregates from concrete and mixed debris as material for unbound road sub-base. Mater. Constr. 2011, 61, 289–302. [Google Scholar] [CrossRef]

- Molenaar, A.A.A.; Van Niekerk, A.A. Effects of Gradation, Composition, and Degree of Compaction on the Mechanical Characteristics of Recycled Unbound Materials. Transp. Res. Rec. 2002, 1787, 73–82. [Google Scholar] [CrossRef]

- Xuan, D.; Houben, L.J.M.; Molenaar, A.A.A.; Shui, Z. Cement treated recycled demolition waste as a road base material. J. Wuhan Univ. Technol. Sci. Ed. 2010, 25, 696–699. [Google Scholar] [CrossRef]

- De Brito, J.; Silva, R.V.; Agrela, F. New Trends in Eco-Efficient and Recycled Concrete; Woodhead Publishing: Duxford, UK, 2018. [Google Scholar]

- Vegas, I.; Ibanez, J.; José, J.S.; Urzelai, A. Construction demolition wastes, Waelz slag and MSWI bottom ash: A comparative technical analysis as material for road construction. Waste Manag. 2008, 28, 565–574. [Google Scholar] [CrossRef]

- Herrador, R.; Pérez, P.; Garach, L.; Ordóñez, J. Use of recycled construction and demolition waste aggregate for road course surfacing. J. Transp. Eng. 2011, 138, 182–190. [Google Scholar] [CrossRef]

- Xuan, D.X.; Houben, L.J.M.; Molenaar, A.A.A.; Shui, Z.H. Mixture optimization of cement treated demolition waste with recycled masonry and concrete. Mater. Struct. 2012, 45, 143–151. [Google Scholar] [CrossRef]

- Agrela, F.; Barbudo, A.; Ramírez, A.; Ayuso, J.; Carvajal, M.D.; Jiménez, J.R. Construction of road sections using mixed recycled aggregates treated with cement in Malaga, Spain. Resour. Conserv. Recycl. 2011, 58, 98–106. [Google Scholar] [CrossRef]

- Agrela, F.; Cabrera, M.; Galvín, A.; Barbudo, A.; Ramirez, A. Influence of the sulphate content of recycled aggregates on the properties of cement-treated granular materials using Sulphate-Resistant Portland Cement. Constr. Build. Mater. 2014, 68, 127–134. [Google Scholar] [CrossRef]

- Pérez, P.; Agrela, F.; Herrador, R.; Ordoñez, J. Application of cement-treated recycled materials in the construction of a section of road in Malaga, Spain. Constr. Build. Mater. 2013, 44, 593–599. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Yuan, W.; Li, J.; Zhang, Q.; Saito, F. Innovated Application of Mechanical Activation to Separate Lead from Scrap Cathode Ray Tube Funnel Glass. Environ. Sci. Technol. 2012, 46, 4109–4114. [Google Scholar] [CrossRef]

- Tian, X.; Wu, Y. Recent development of recycling lead from scrap CRTs: A technological review. Waste Manag. 2016, 57, 176–186. [Google Scholar]

- Contrafatto, L. Recycled Etna volcanic ash for cement, mortar and concrete manufacturing. Constr. Build. Mater. 2017, 151, 704–713. [Google Scholar] [CrossRef]

- Hui, Z.; Sun, W. Study of properties of mortar containing cathode ray tubes (CRT) glass as replacement for river sand fine aggregate. Constr. Build. Mater. 2011, 25, 4059–4064. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S.; Lam, W.-S.; Chan, T.-P.; Fung, K.K.-L. Utilization of recycled cathode ray tubes glass in cement mortar for X-ray radiation-shielding applications. J. Hazard. Mater. 2012, 199, 321–327. [Google Scholar] [CrossRef]

- Romero, D.; James, J.; Mora, R.; Hays, C.D. Study on the mechanical and environmental properties of concrete containing cathode ray tube glass aggregate. Waste Manag. 2013, 33, 1659–1666. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M. Characteristics of concrete with waste glass as fine aggregate replacement. Int. J. of Eng. Tech. Res. 2014, 2, 11–17. [Google Scholar]

- Ling, T.-C.; Poon, C.-S. Utilization of recycled glass derived from cathode ray tube glass as fine aggregate in cement mortar. J. Hazard. Mater. 2011, 192, 451–456. [Google Scholar] [CrossRef] [PubMed]

- UNE-EN-13242:2003+A1:2008: Aggregates for Unbound and Hydraulically Bound Materials for Use in Civil Engineering Work and Road Construction; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2003.

- UNE-EN 933-11:2009: Tests for Geometrical Properties of Aggregates-Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2009.

- Barbudo, A.; Agrela, F.; Ayuso, J.; Jiménez, J.R.; Poon, C. Statistical analysis of recycled aggregates derived from different sources for sub-base applications. Constr. Build. Mater. 2012, 28, 129–138. [Google Scholar] [CrossRef]

- UNE-EN 1744-1:2010+A1:2013: Tests for Chemical Properties of Aggregates-Part 1: Chemical Analysis; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2003.

- UNE 103204:2019: Organic Matter Dontent of a Soil by the Potassium Permanganate Method; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2019.

- UNE-EN 196-2:2014: Method of Testing Cement-Part 2: Chemical Analysis of Cement; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2014.

- UNE-EN 1097-6:2014: Tests for Mechanical and Physical Properties of Aggregates-Part 6: Determination of Particle Density and Water Absorption; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2014.

- UNE-EN ISO 17892-12:2019: Geotechnical Investigation and Testing-Laboratory Testing of Soil-Part 12: Determination of Liquid and Plastic Limits; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2019.

- UNE-EN 1097-2:2010: Tests for Mechanical and Physical Properties of Aggregates-Part 2: Methods for the Determination of Resistance to Fragmentation; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2010.

- UNE 146404:2018: Determination of the Coefficient of Friability of the Sands; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2018.

- UNE-EN 12457-4:2004: Characterisation of Waste-Leaching-Compliance Test for Leaching of Granular Waste Materials and Sludges-Part 4: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size below 10 mm (Without or with Size Reduction); Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2004.

- Galvín, A.P.; Ayuso, J.; Barbudo, A.; Cabrera, M.; López-Uceda, A.; Rosales, J. Upscaling the pollutant emission from mixed recycled aggregates under compaction for civil applications. Environ. Sci. Pollut. Res. 2018, 25, 36014–36023. [Google Scholar] [CrossRef] [PubMed]

- Del Rey, I.; Ayuso, J.; Galvín, A.; Jiménez, J.R.; López, M.; García-Garrido, M. Analysis of chromium and sulphate origins in construction recycled materials based on leaching test results. Waste Manag. 2015, 46, 278–286. [Google Scholar] [CrossRef]

- Lee, C.-H.; Chang, C.-T.; Fan, K.-S.; Chang, T.-C. An overview of recycling and treatment of scrap computers. J. Hazard. Mater. 2004, 114, 93–100. [Google Scholar] [CrossRef]

- CEN-EN 14405: Characterization of Waste-Leaching Behaviour Test-Upflow Percolation Test (Under Specified Conditions); European Committee for Standardization (CEN): Brussels, Belgium, 2017.

- Roussat, N.; Méhu, J.; Abdelghafour, M.; Brula, P. Leaching behaviour of hazardous demolition waste. Waste Manag. 2008, 28, 2032–2040. [Google Scholar] [CrossRef]

- UNE 103501:1994: Geotechnic Compactation Test. Modified Proctor; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 2004.

- Arulrajah, A.; Rahman, M.A.; Piratheepan, J.; Bo, M.W.; Imteaz, M.A. Evaluation of interface shear strength properties of geogrid-reinforced construction and demolition materials using a modified large-scale direct shear testing apparatus. J. Mater. Civ. Eng. 2013, 26, 974–982. [Google Scholar] [CrossRef]

- UNE 103502:1995: Test Laboratory Nethod for Determining in a Soil the C.B.R. Index; Asociacion Española de Normalizacion (AENOR): Madrid, Spain, 1995.

- Das, B.M.; González, S.R.C. Fundamentos de Ingeniería Geotécnica; Thomson Learning: Madrid, Spain, 2001; pp. 445–494. [Google Scholar]

- Crespo, C. Mecánica de Suelos y Cimentaciones; Limusa: Mexico City, Mexico.

- Poon, C.S.; Chan, D. Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr. Build. Mater. 2006, 20, 578–585. [Google Scholar] [CrossRef]

- NLT 310/90: Vibrating Hammer Compaction of Granular Materials Treated; CEDEX: Madrid, Spain, 1990.

| Cement | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Loss on Ignition (975 °C) |

|---|---|---|---|---|---|---|---|---|

| CEM II (%) | 26.24 | 8.7 | 3.36 | 54.06 | 1.34 | 3.32 | 1.44 | 1.3 |

| Properties | MRA | RAP | MRAa | p-CRTR | p-CRTF | Test Method |

|---|---|---|---|---|---|---|

| Acid-soluble sulphate (%SO3) | 0.7 | 0.3 | 0.39 | 0.05 | 0.03 | UNE-EN 1744-1 [27] |

| Organic material (%) | 1.37 | 1.13 | 1.21 | - | - | UNE 103204 [28] |

| Oxide content (%) | - | - | - | - | - | - |

| SiO2 | 53.12 | - | 50.75 | 51.2 | 58.13 | UNE 196-2 [29] |

| Al2O3 | 13.15 | - | 10.6 | 4.15 | 2.71 | - |

| TiO2 | 1.74 | - | 0.98 | 0.1 | 0.5 | - |

| CaO | 10.12 | - | 16.56 | 3.56 | 2.4 | - |

| MgO | 5.15 | - | 2.28 | 2.45 | 0.80 | - |

| Na2O | 2.8 | - | 1.97 | 7.3 | 8.10 | - |

| K2O | 1.7 | - | 2.31 | 8.1 | 7.30 | - |

| Fe2O3 | 8.4 | - | 3.55 | - | 0.10 | - |

| BaO | - | - | - | - | 10.50 | - |

| SrO | - | - | - | - | 9.46 | - |

| PbO | - | - | - | 23.14 | - | - |

| Other | <4% | - | <11% | - | ||

| Density (kg/m3) | - | - | - | - | - | UNE-EN 1097-6 [30] |

| 0–4 mm | 2.01 | 2.42 | 2.24 | 2.2 | 2.25 | - |

| 4–31.5 mm | 2.08 | 2.26 | 2.12 | 2.49 | 2.51 | - |

| Water absorption (%) | - | - | - | - | - | UNE-EN 1097-6 [30] |

| 0–4 mm | 10.27 | 5.1 | 9.41 | 6.27 | 5.76 | - |

| 4–31.5 mm | 8.31 | 2.36 | 7.75 | 0.25 | 0.21 | - |

| Plasticity | Non-plastic | Non-plastic | Non-plastic | Non-plastic | Non-plastic | UNE-EN-ISO 17892-12 [31] |

| Los Angeles | 36 | 32 | 35 | - | - | UNE-EN 1097-2 [32] |

| Friability ratio | 27 | 21 | 24 | 31 | 33 | UNE 146404 [33] |

| Concrete (Rc) | Natural Aggregates (Rc) | Ceramic (Rb) | Bituminous (Ra) | Glass (Rg) | Other (X) | |

|---|---|---|---|---|---|---|

| MRA (%) | 27.68 | 37.28 | 21.16 | 13.67 | 0.04 | 0.17 |

| RAP (%) | - | - | - | 100 | - | - |

| MRAa (%) | 22.61 | 31.31 | 19.73 | 26.72 | 0.03 | 0.11 |

| p-CRT (%) | - | - | - | - | 100 | - |

| Mixtures | Materials (kg) | ||

|---|---|---|---|

| MRA | RAP | p-CRT | |

| MRA | 1000 | - | - |

| MRAa | 750 | 250 | - |

| MRA + p-CRT | 900 | - | 100 |

| MRAa + p-CRT | 675 | 225 | 100 |

| Element | MRA | MRA + p-CRT | p-CRTF | p-CRTR | p-CRT | MRAa + p-CRT | Limit Values (mg/kg) Inert | Non Hazardous |

|---|---|---|---|---|---|---|---|---|

| (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | |||

| Cr | 0.52496 | 0.43146 | 0.03208 | 0.00524 | 0.02291 | 0.470579 | <0.5 | 0.5–10 |

| Ni | 0.00817 | 0.010147 | 0.00635 | 0.02166 | 0.01133 | 0.016748 | <0.4 | 0.4–10 |

| Cu | 0.06137 | 0.036868 | 0.01116 | 0.09846 | 0.04015 | 0.036969 | <2 | 2–50 |

| Zn | 0.04186 | 0.053005 | 0.16044 | 0.40719 | 0.24241 | 0.031649 | <4 | 4–50 |

| As | 0.01705 | 0.019116 | 0.00822 | 0.00518 | 0.00074 | 0.020214 | <0.5 | 0.5–2 |

| Se | 0.00143 | 0.01233 | 0.00275 | 0.00491 | 0.00394 | 0.010007 | <0.1 | 0.1–0.5 |

| Mo | 0.07182 | 0.032939 | 0.02103 | 0.00604 | 0.01519 | 0.036853 | <0.5 | 0.5–10 |

| Cd | 0.00016 | 0.00001 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | <0.04 | 0.04–1 |

| Sb | 0.04046 | 0.041975 | 0.28803 | 0.24131 | 0.26973 | 0.042393 | <0.06 | 0.06–0.7 |

| Ba | 0.16046 | 0.288945 | 16.4451 | 8.26438 | 13.6741 | 0.281764 | <20 | 20–100 |

| Hg | 0.00018 | 0.000921 | 0.00001 | 0.00000 | 0.00000 | 0.001562 | <0.01 | 0.01–0.2 |

| Pb | 0.00048 | 0.00374 | 0.48885 | 2.47351 | 1.5493 | 0.00001 | <0.5 | 0.5–10 |

| Cl− | 21.5 | 50 | 300 | 40 | 197 | 18.5 | 800 | 15000 |

| F− | <2 | <2 | <2 | <2 | <2 | <2 | 10 | 150 |

| SO4− | 1150 | 1280 | 127 | 138 | 129 | 1240 | 1500 | 20000 |

| Element | RMA | RMA | p-CRTF | p-CRTR | p-CRT | RMAa | Limit Values Directive 2003/33/EC (mg/L) | |

|---|---|---|---|---|---|---|---|---|

| + | + | |||||||

| p-CRT | p-CRT | |||||||

| (mg/L) | (mg/L) | (mg/L) | (mg/L) | (mg/L) | (mg/L) | Inert | Non Hazardous | |

| Cr | 0.0052 | 0.0412 | 0.0087 | 0.0023 | 0.0065 | 0.0513 | <0.1 | 0.1–2.5 |

| Ni | 0.0006 | 0.0052 | 0.0043 | 0.0020 | 0.0035 | 0.0057 | <0.12 | 0.12–3 |

| Cu | 0.0010 | 0.0144 | 0.0219 | 0.0047 | 0.0160 | 0.0176 | <0.6 | 0.6–30 |

| Zn | 0.0016 | 0.0079 | 0.0142 | 0.0160 | 0.0146 | 0.0097 | <1.2 | 1.2–15 |

| As | 0.0006 | 0.0043 | 0.0030 | 0.0027 | 0.0028 | 0.0072 | <0.06 | 0.06–0.3 |

| Se | 0.0016 | 0.0057 | 0.0011 | 0.0014 | 0.0012 | 0.0090 | <0.04 | 0.04–0.2 |

| Mo | 0.0210 | 0.0811 | 0.0044 | 0.0038 | 0.0042 | 0.0820 | <0.2 | 0.2–3.5 |

| Cd | 0.0001 | 0.0001 | 0.0000 | 0.0000 | 0.0000 | 0.0001 | <0.02 | 0.02–0.3 |

| Sb | 0.0016 | 0.0077 | 0.0116 | 0.040 | 0.0208 | 0.0047 | <0.1 | 0.1–0.15 |

| Ba | 0.0557 | 0.0615 | 0.2327 | 0.7725 | 0.4085 | 0.0972 | <4 | 4–20 |

| Hg | <0.0001 | <0.0001 | 0.0001 | 0.0000 | 0.0001 | 0.0000 | <0.002 | 0.002–0.03 |

| Pb | 0.0004 | 0.0018 | 0.0908 | 0.1608 | 0.1130 | 0.0028 | <0.15 | 0.15–3 |

| MRA | MRA + p-CRT | MRAa | MRAa + p-CRT | |

|---|---|---|---|---|

| Dry density (g/cm3) | 1.92 | 1.94 | 1.97 | 2.05 |

| Moisture (%) | 13.29 | 13.19 | 11.1 | 11.01 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabrera, M.; Pérez, P.; Rosales, J.; Agrela, F. Feasible Use of Cathode Ray Tube Glass (CRT) and Recycled Aggregates as Unbound and Cement-Treated Granular Materials for Road Sub-Bases. Materials 2020, 13, 748. https://doi.org/10.3390/ma13030748

Cabrera M, Pérez P, Rosales J, Agrela F. Feasible Use of Cathode Ray Tube Glass (CRT) and Recycled Aggregates as Unbound and Cement-Treated Granular Materials for Road Sub-Bases. Materials. 2020; 13(3):748. https://doi.org/10.3390/ma13030748

Chicago/Turabian StyleCabrera, M., P. Pérez, J. Rosales, and F. Agrela. 2020. "Feasible Use of Cathode Ray Tube Glass (CRT) and Recycled Aggregates as Unbound and Cement-Treated Granular Materials for Road Sub-Bases" Materials 13, no. 3: 748. https://doi.org/10.3390/ma13030748

APA StyleCabrera, M., Pérez, P., Rosales, J., & Agrela, F. (2020). Feasible Use of Cathode Ray Tube Glass (CRT) and Recycled Aggregates as Unbound and Cement-Treated Granular Materials for Road Sub-Bases. Materials, 13(3), 748. https://doi.org/10.3390/ma13030748