Experimental and Numerical Characterization of High Damping Martensitic CuAlMn Sheets

Abstract

1. Introduction

2. Materials and Experiments

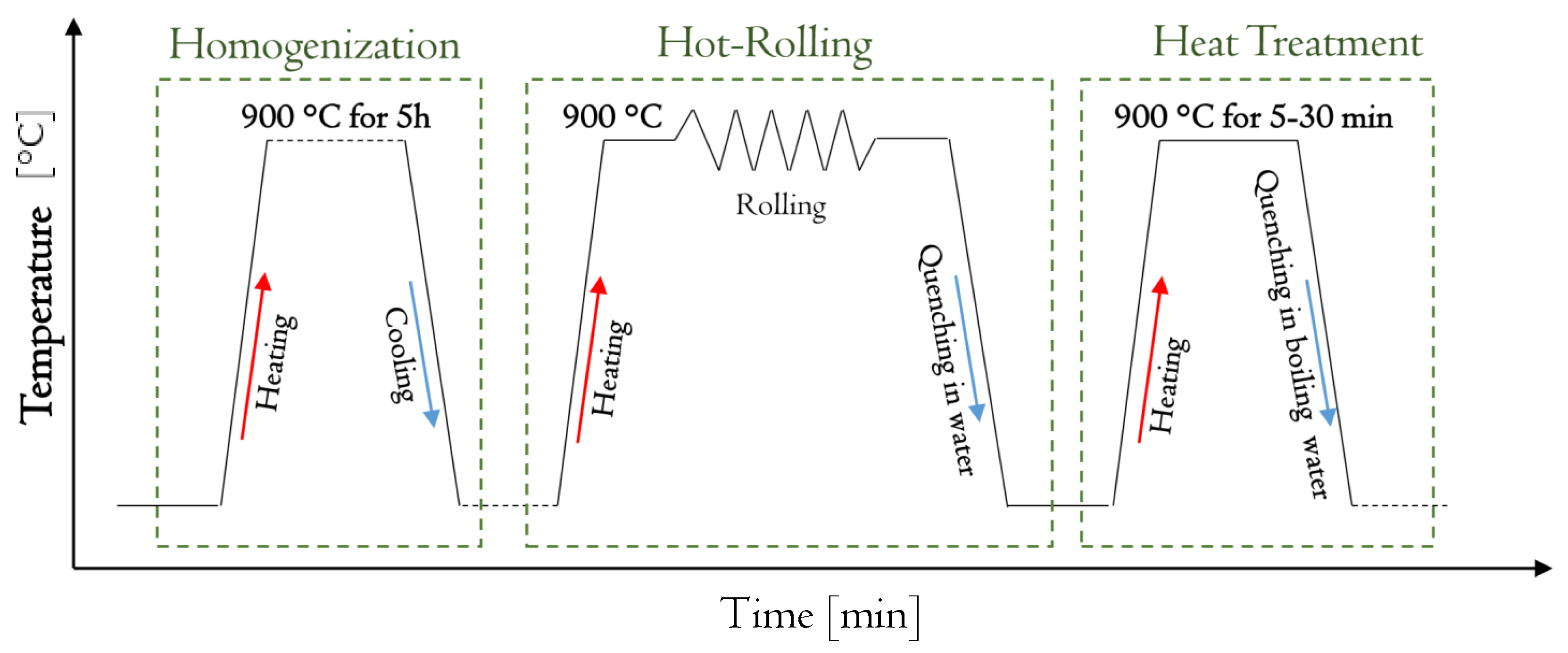

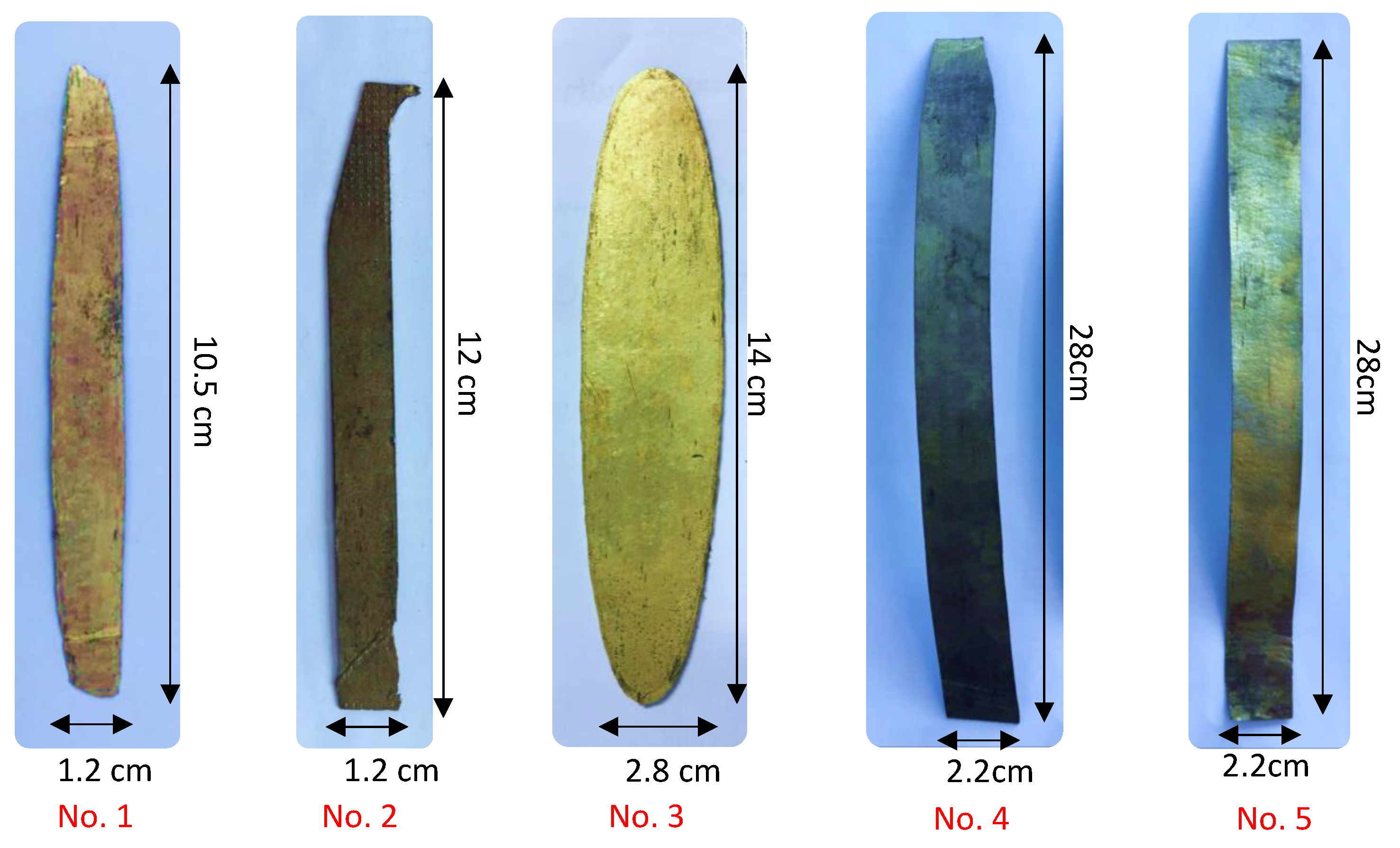

2.1. Alloy Preparation and Fabrication of Thin Sheets

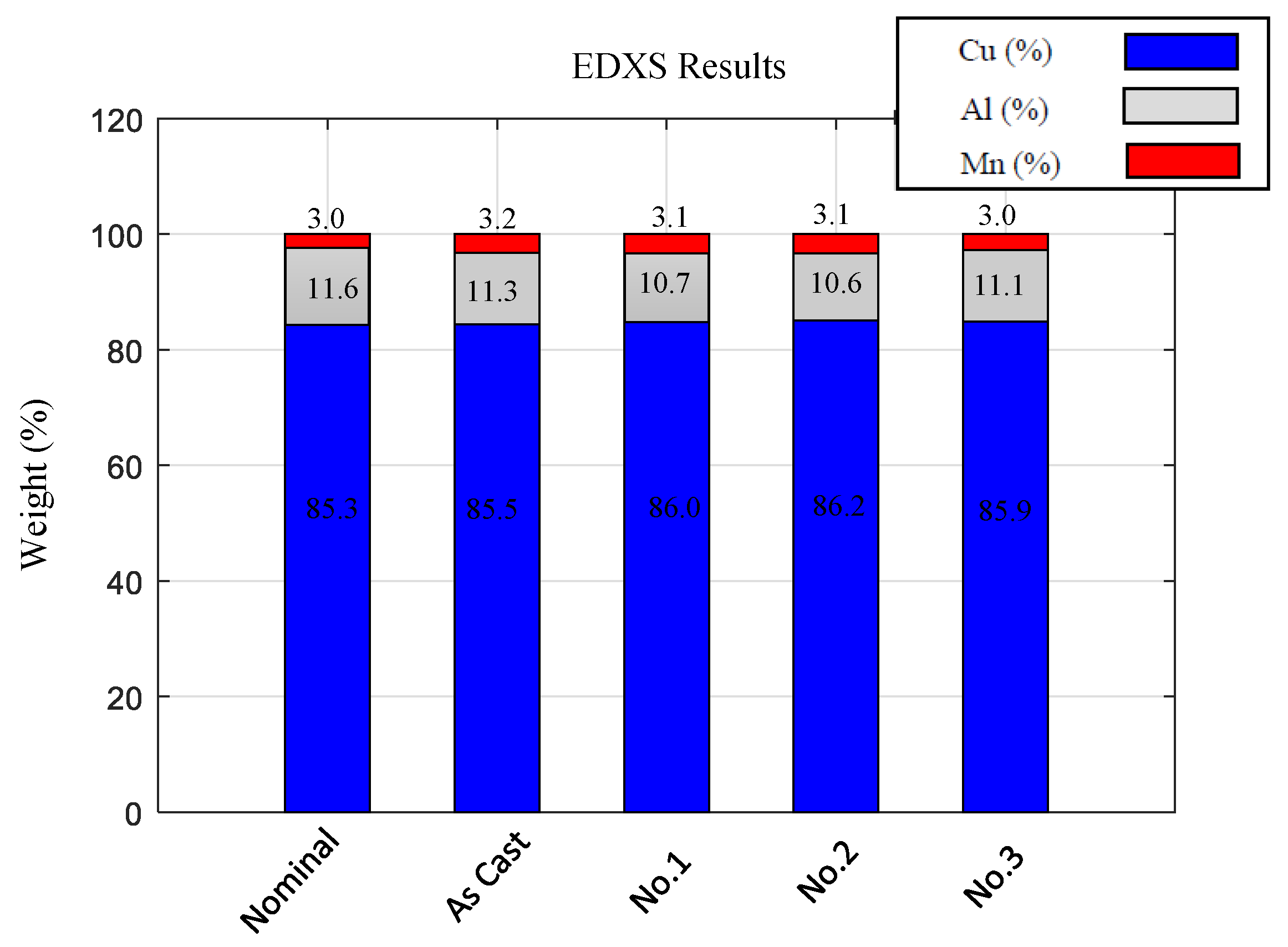

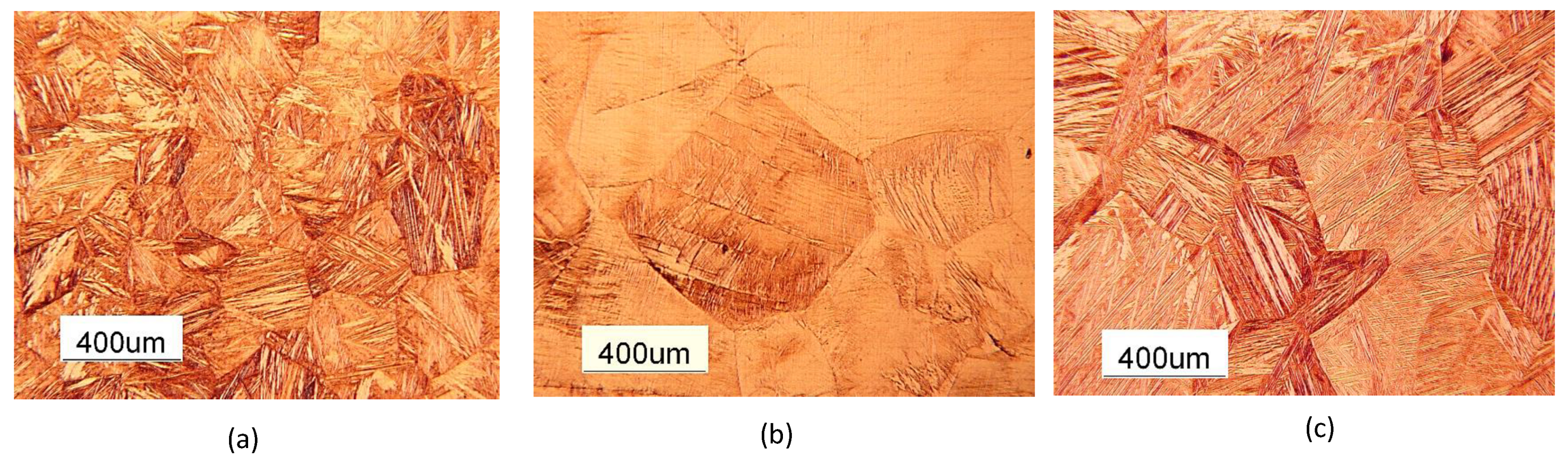

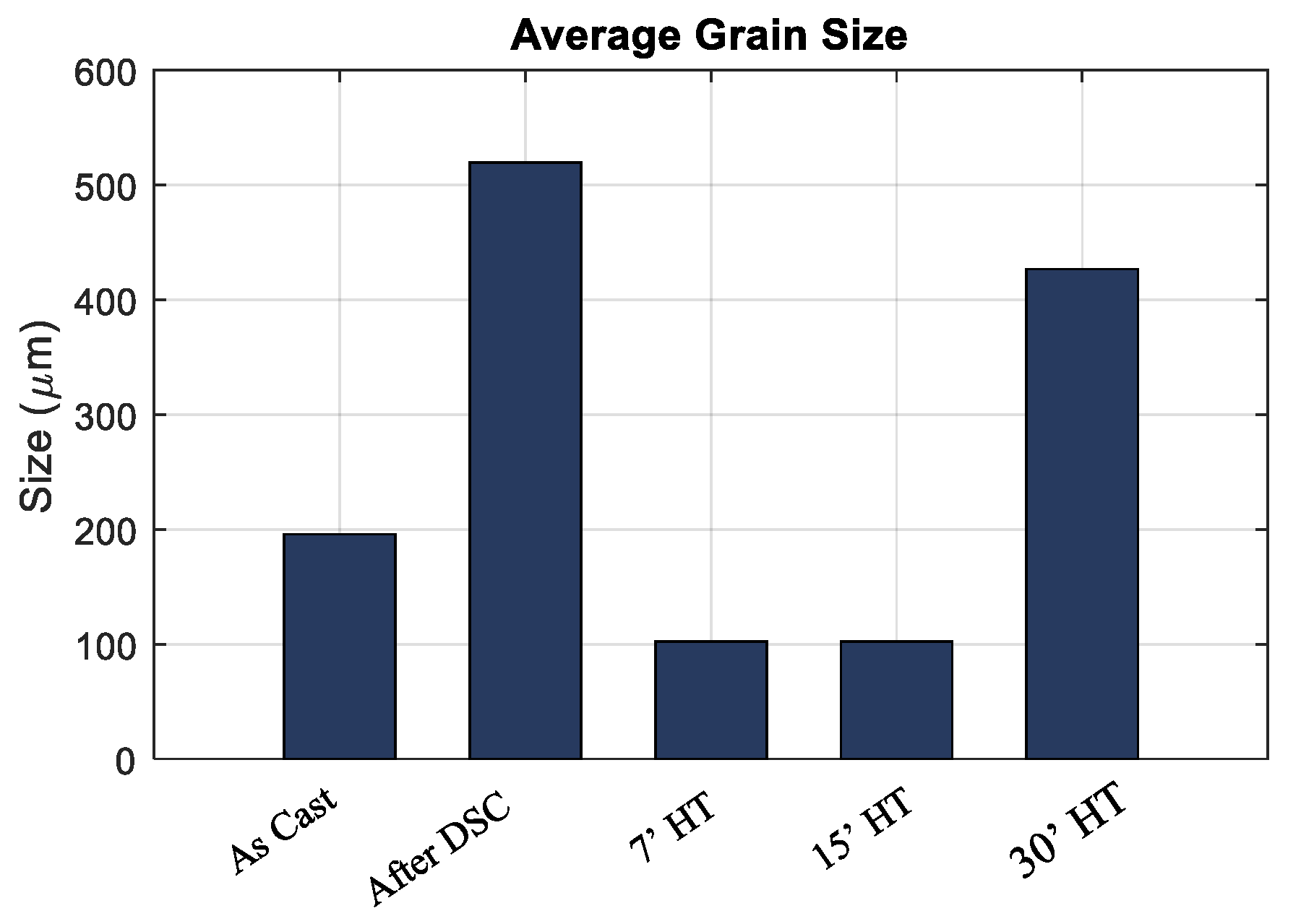

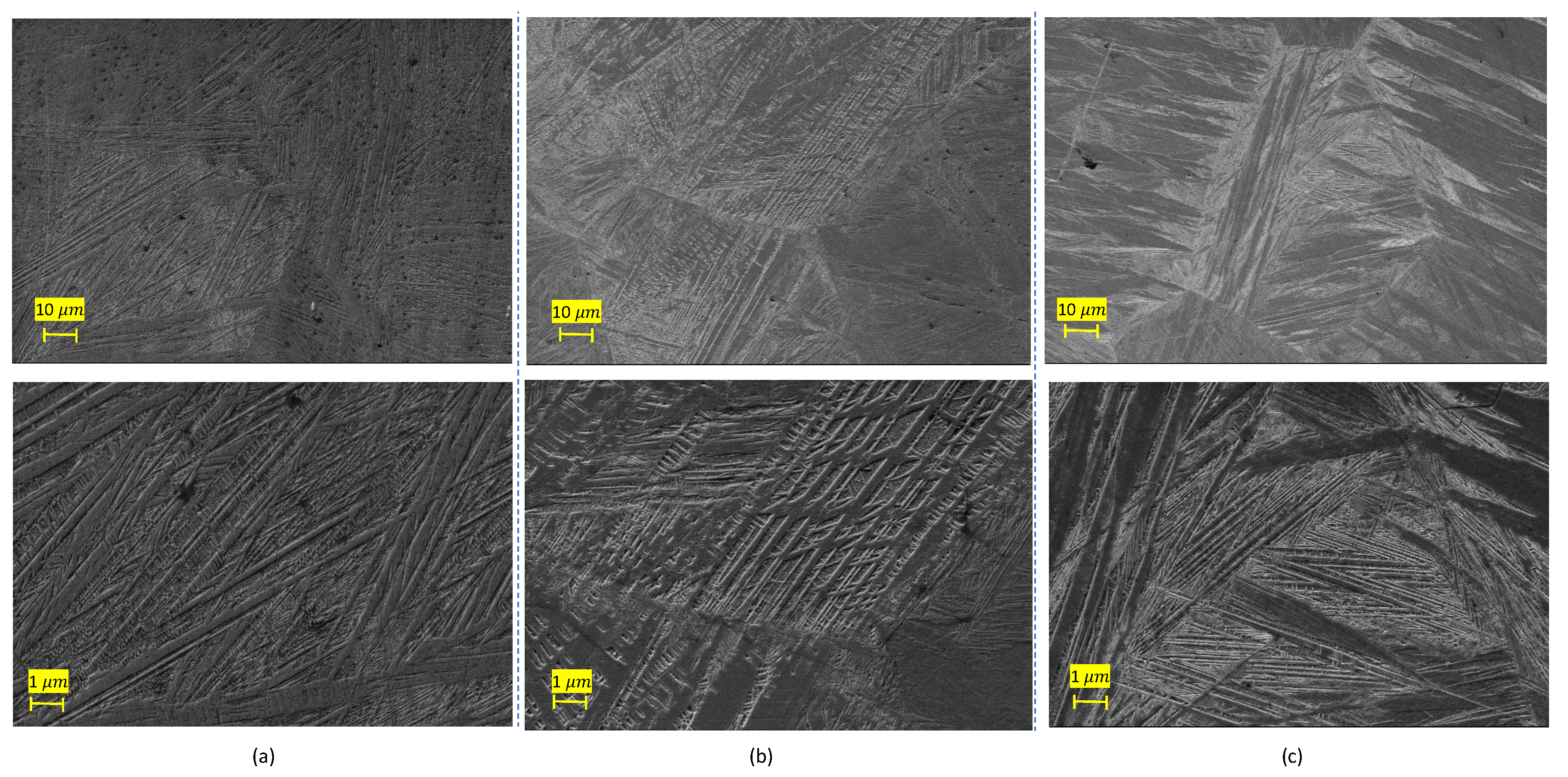

2.2. Microstructure and Composition Studies

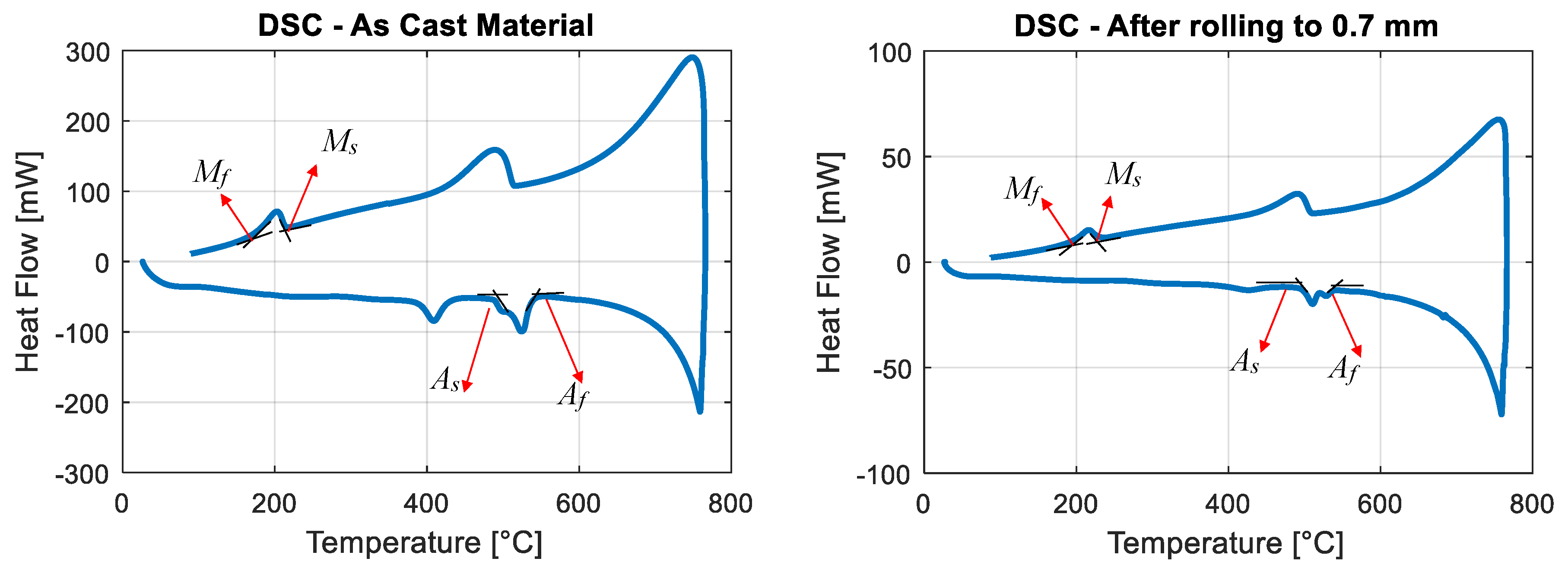

2.3. Transformation Temperatures

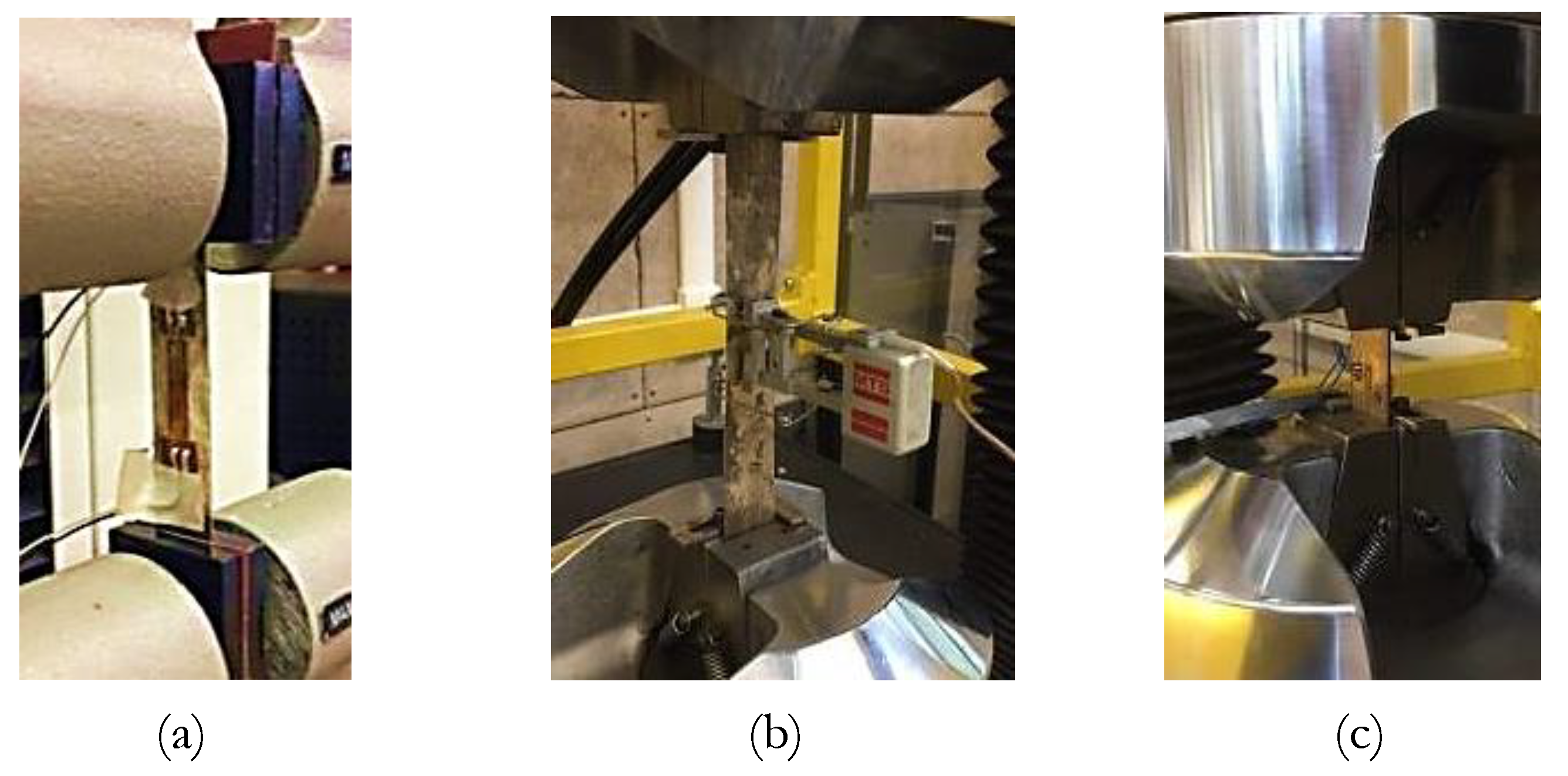

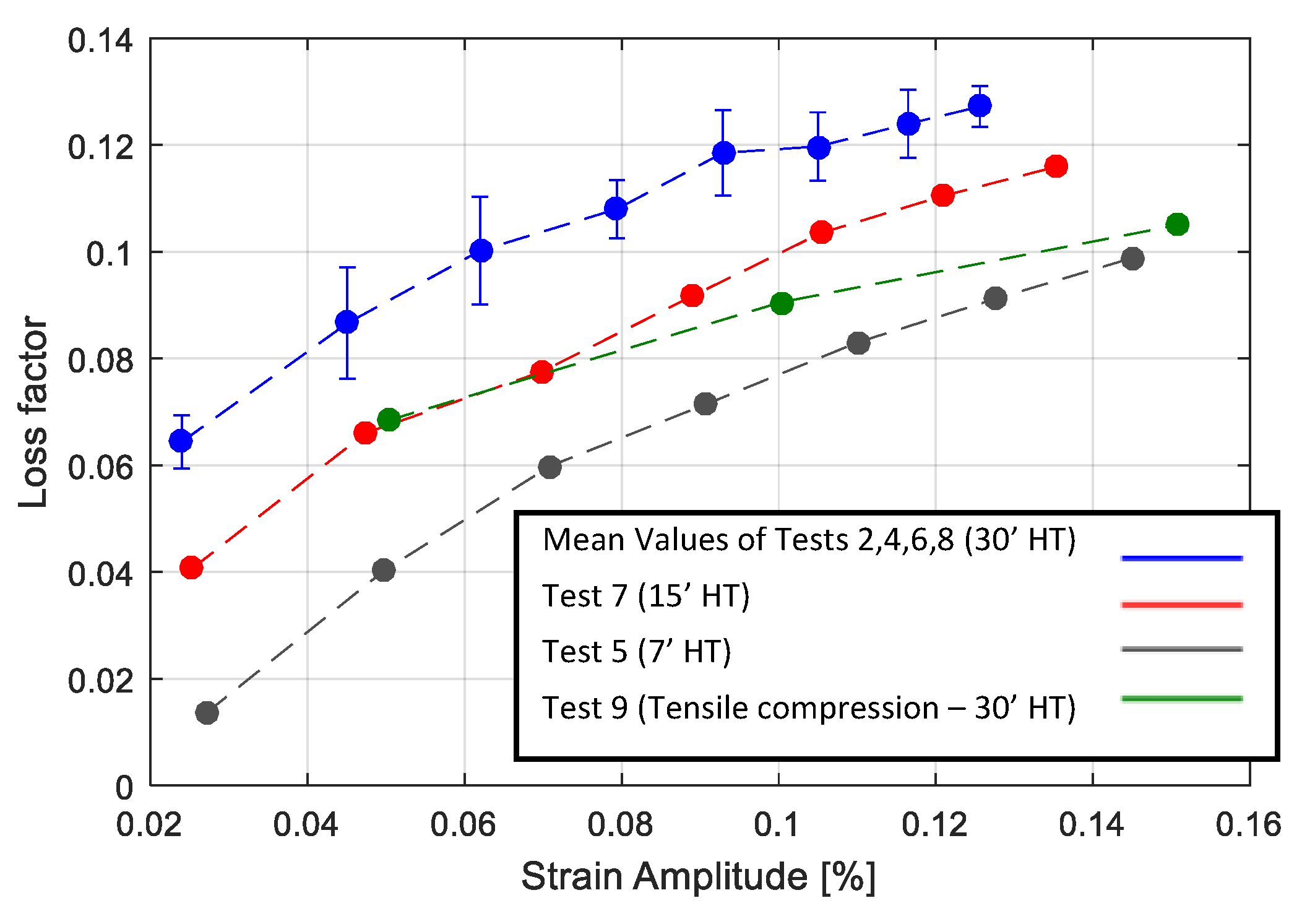

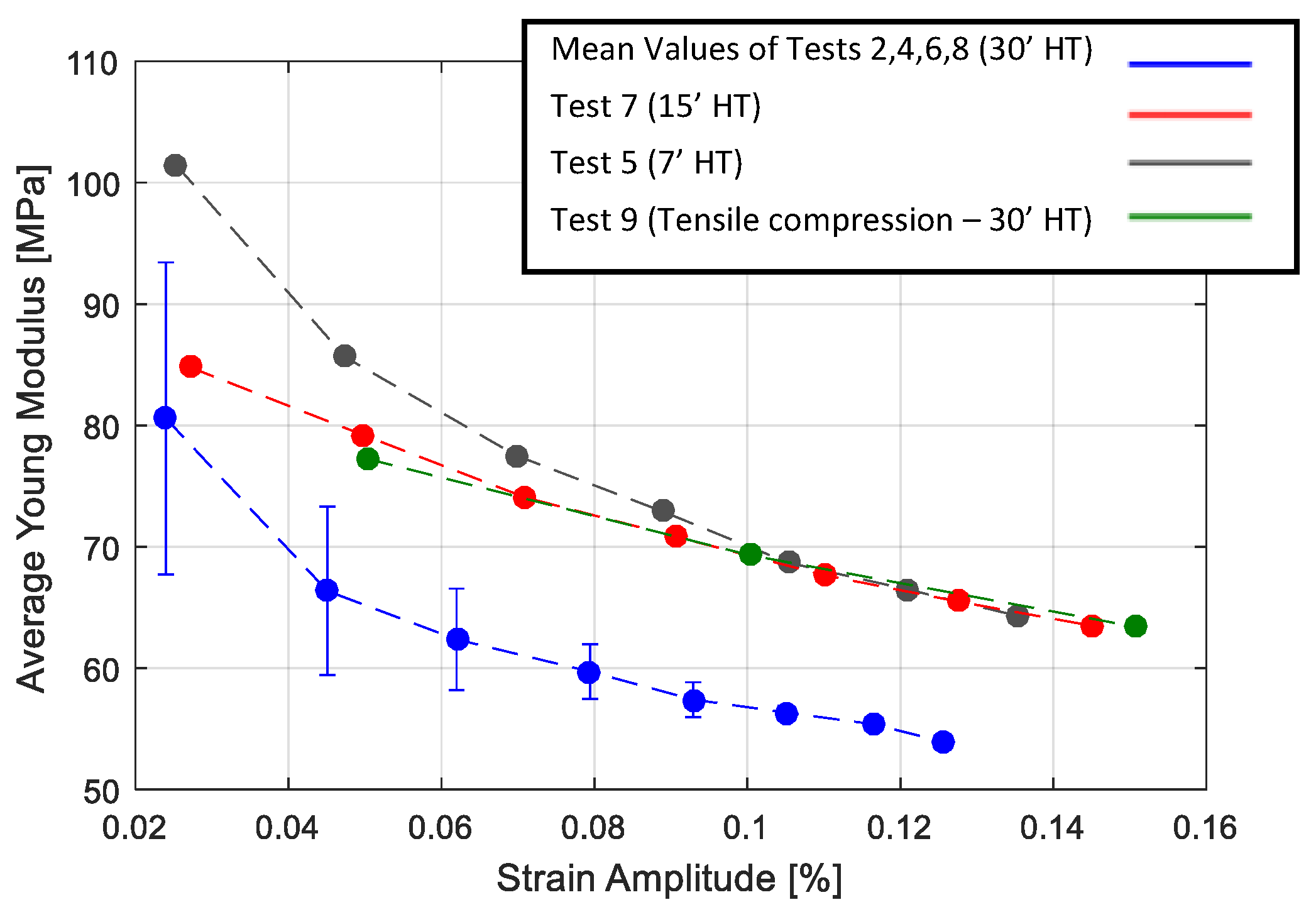

2.4. Internal Damping

3. Numerical Model of the Material’s Behavior

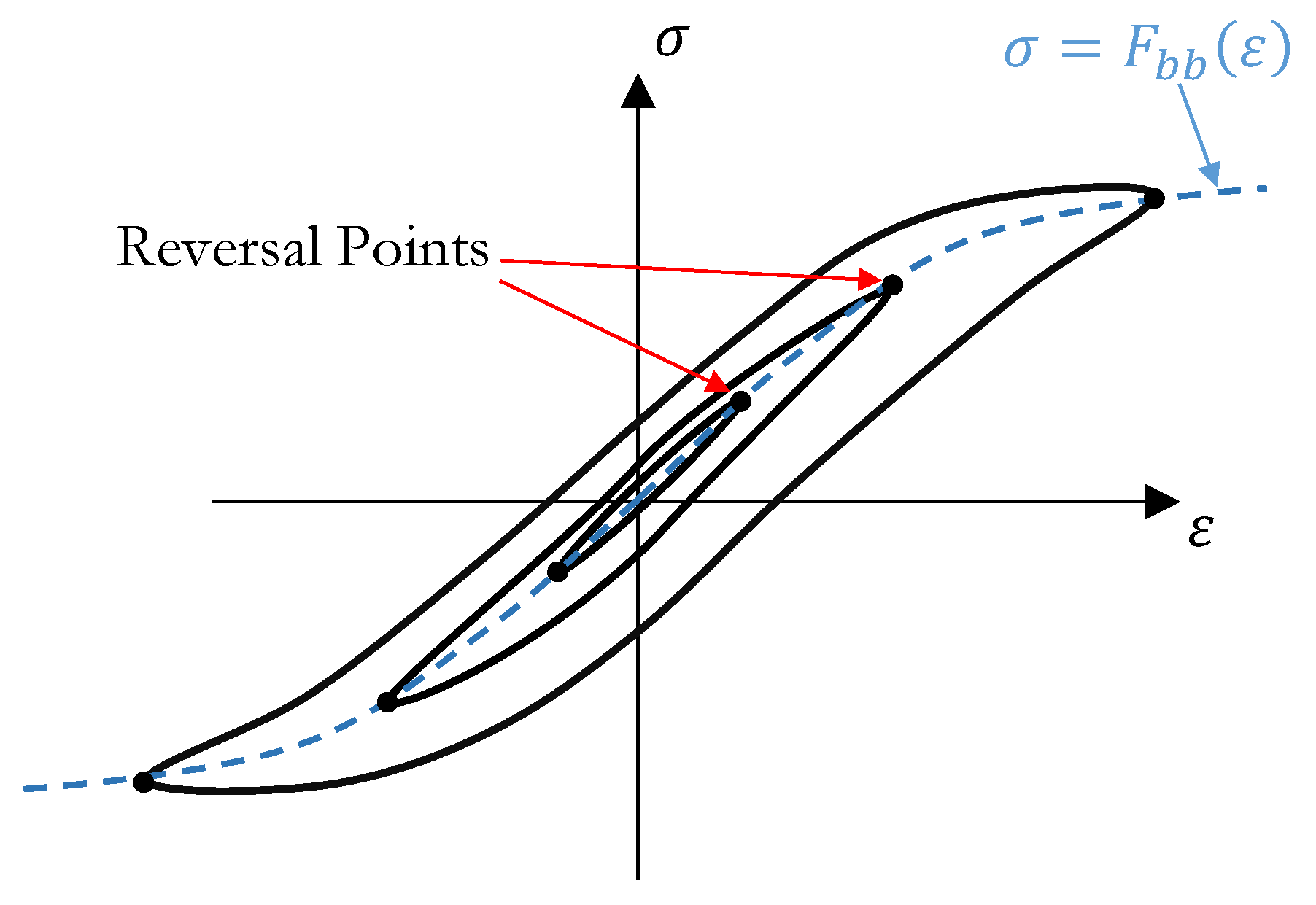

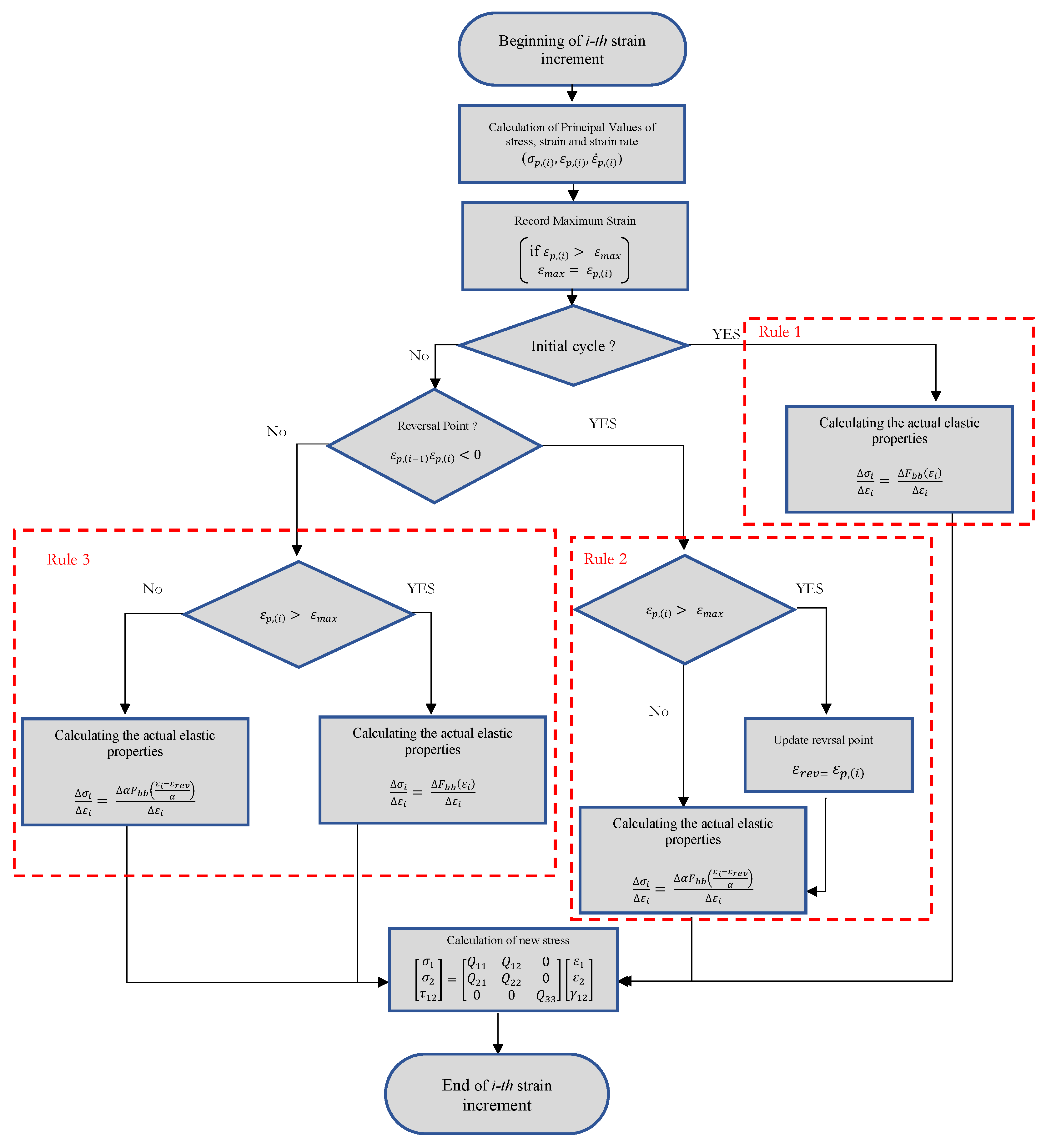

3.1. Introducing the Model

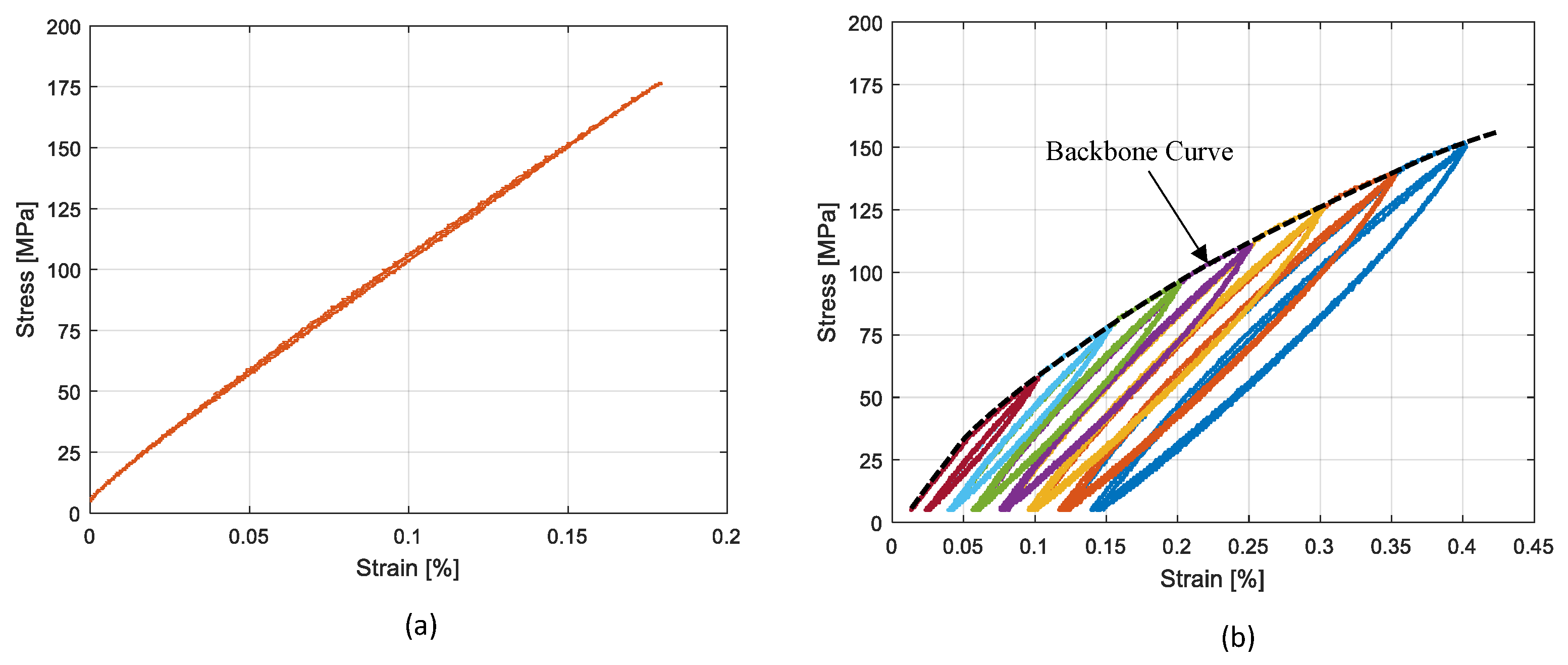

- 1. For initial loading, the stress strain curve follows the backbone curve (See Figure 16) which can be defined as:where is called backbone function.

- 2. If a stress reversal (see Figure 16) occurs at a point defined by ( , ), the stress strain path will be given by:

- 3. If the loading curve intersects the backbone curve, it follows the backbone curve until the next stress reversal.

- 4. If an unloading or reloading curve crosses an unloading or reloading curve from the previous cycle, the stress strain curve follows that of the previous cycle.

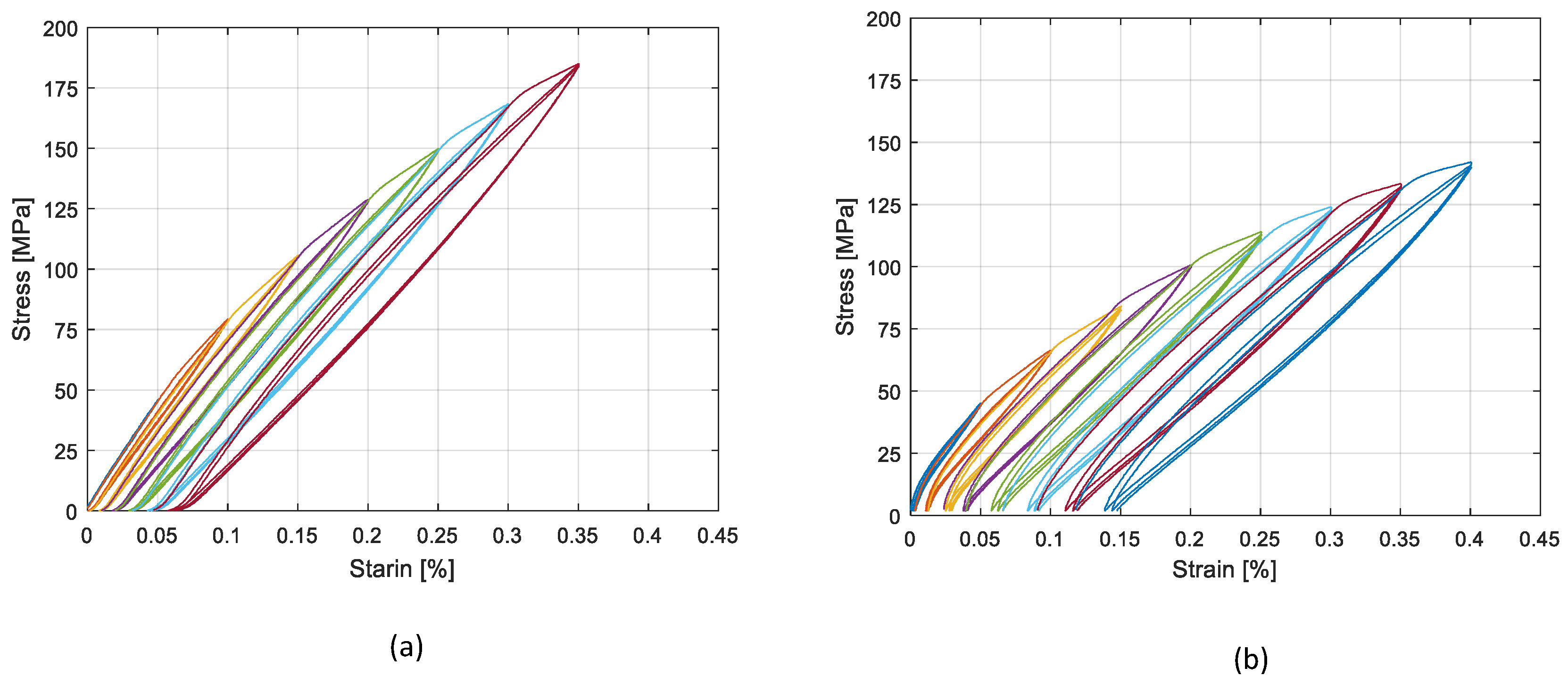

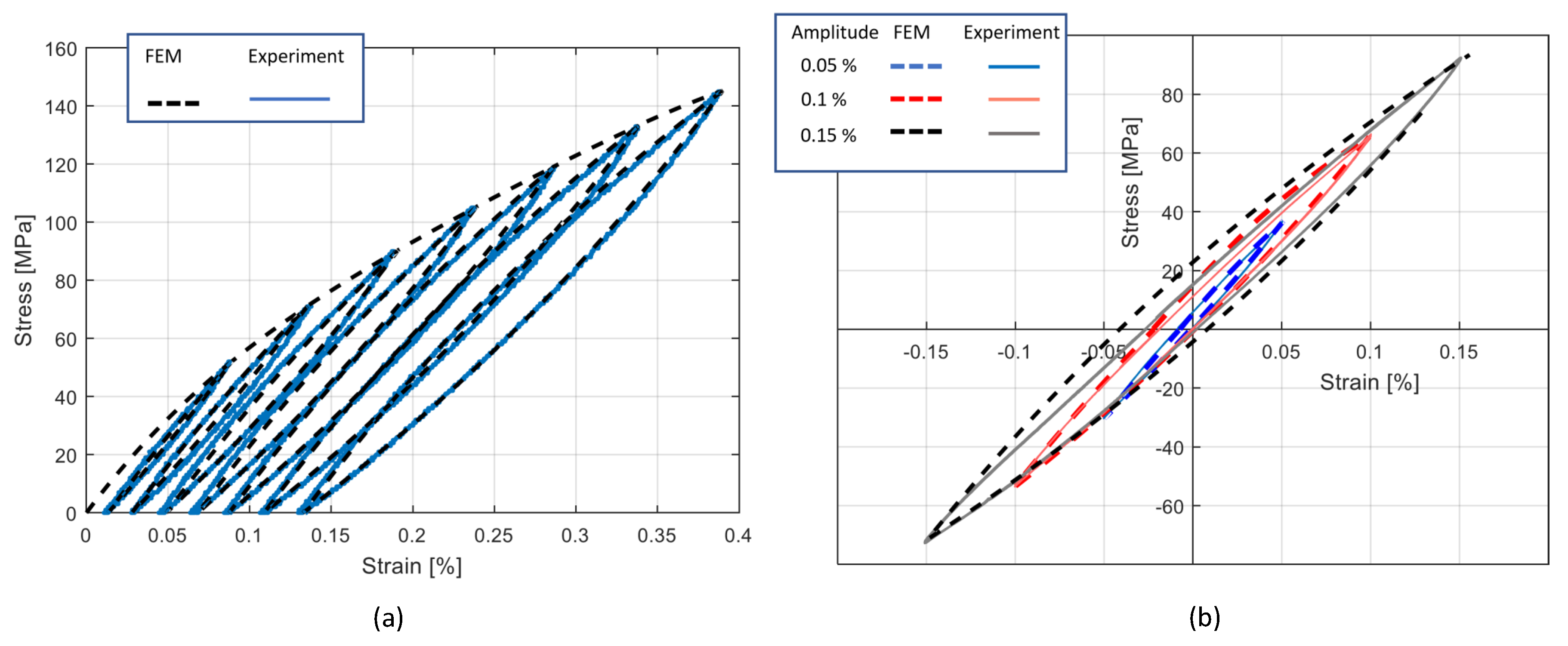

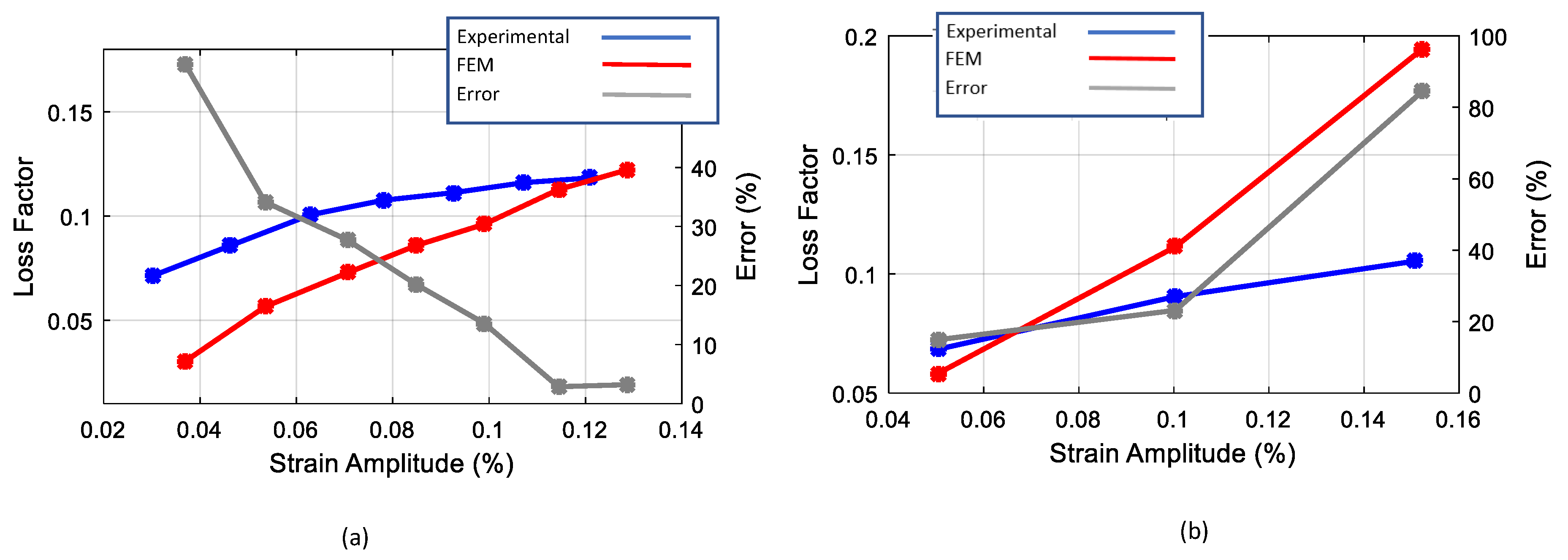

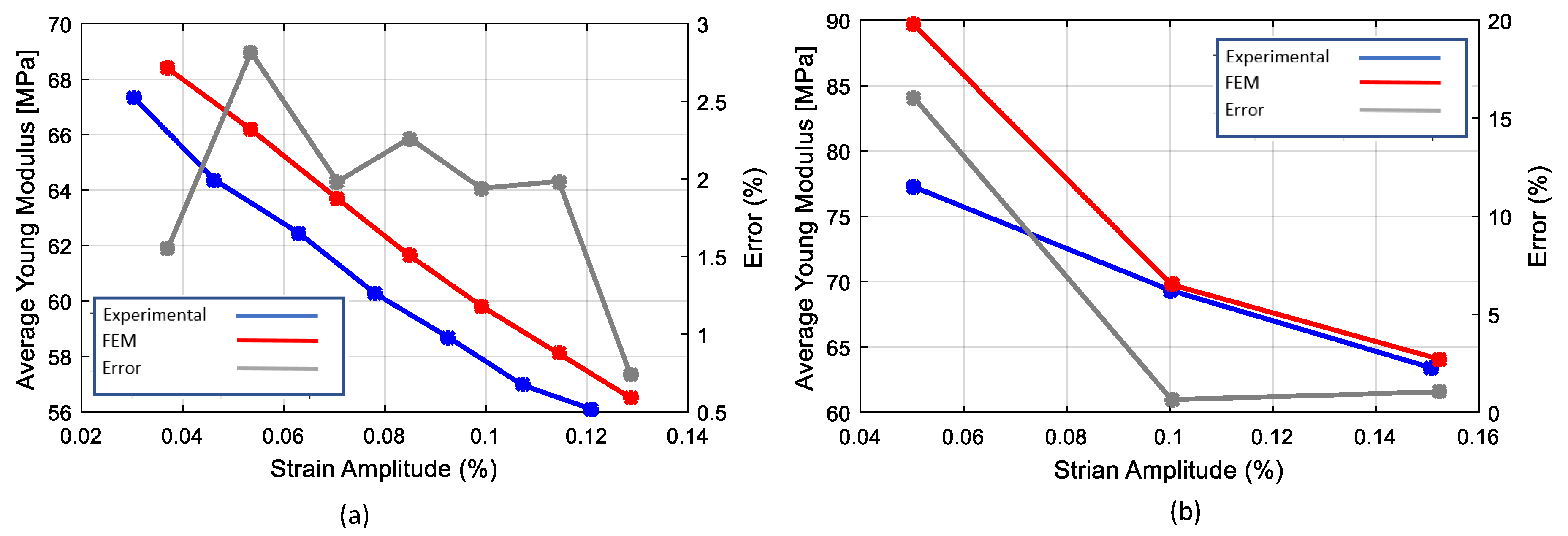

3.2. Characterizing and Validation of the Proposed Model

4. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lester, B.T.; Baxevanis, T.; Chemisky, Y.; Lagoudas, D.C. Review and perspectives: Shape memory alloy composite systems. Acta Mech. 2015, 226, 3907–3960. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Van Humbeeck, J.; Kustov, S. Active and passive damping of noise and vibrations through shape memory alloys: Applications and mechanisms. Smart Mater. Struct. 2005, 14, S171–S185. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Damping capacity of thermoelastic martensite in shape memory alloys. J. Alloys Compd. 2003, 355, 58–64. [Google Scholar] [CrossRef]

- Bassani, P.; Biffi, C.A.; Carnevale, M.; Lecis, N.; Previtali, B.; Lo Conte, A. Passive damping of slender and light structures. Mater. Des. 2013, 45, 88–95. [Google Scholar] [CrossRef]

- Haghdoust, P.; Cinquemani, S.; Lo Conte, A.; Lecis, N. Optimal design of damping layers in SMA/GFRP laminated hybrid composites. Smart Mater. Struct. 2017, 26, 105015. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Reconciling viability and cost-effective shape memory alloy options—A review of copper and iron based shape memory metallic systems. Eng. Sci. Technol. Int. J. Jestech 2016, 19, 1582–1592. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Kainuma, R.; Ishida, K. Ductile Cu-Al-Mn based shape memory alloys: General properties and applications. Mater. Sci. Technol. 2008, 24, 896–901. [Google Scholar] [CrossRef]

- Liu, J.L.; Chen, Z.H.; Huang, H.Y.; Xie, J.X. Microstructure and superelasticity control by rolling and heat treatment in columnar-grained Cu-Al-Mn shape memory alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2017, 696, 315–322. [Google Scholar] [CrossRef]

- Sutou, Y.; Kainuma, R.; Ishida, K. Effect of alloying elements on the shape memory properties of ductile Cu-Al-Mn alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 1999, 273, 375–379. [Google Scholar] [CrossRef]

- Mallik, U.S.; Sampath, V. Influence of aluminum and manganese concentration on the shape memory characteristics of Cu-Al-Mn shape memory alloys. J. Alloys Compd. 2008, 459, 142–147. [Google Scholar] [CrossRef]

- Mallik, U.S.; Sampath, V. Effect of composition and ageing on damping characteristics of Cu-Al-Mn shape memory alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2008, 478, 48–55. [Google Scholar] [CrossRef]

- Mallik, U.S.; Sampath, V. Effect of alloying on microstructure and shape memory characteristics of Cu-Al-Mn shape memory alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2008, 481, 680–683. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Koeda, N.; Kainuma, R.; Ishida, K. Effects of grain size and texture on damping properties of Cu-Al-Mn-based shape memory alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2006, 438, 743–746. [Google Scholar] [CrossRef]

- Biffi, C.A.; Bassani, P.; Tuissi, A.; Carnevale, M.; Lecis, N.; Lo Conte, A.; Previtali, B. Flexural Vibration Suppression of Glass Fiber/cuznal SMA Composite. Funct. Mater. Lett. 2012, 5. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Q.Z.; Yin, F.X.; Cui, C.X.; Ji, P.G.; Li, B. Effects of grain refinement on the structure and properties of a CuAlMn shape memory alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2016, 664, 215–220. [Google Scholar] [CrossRef]

- Velmurugan, C.; Senthilkumar, V.; Dinesh, S.; Arulkirubakaran, D. Review on phase transformation behavior of NiTi shape memory alloys. Mater. Today Proc. 2018, 5, 14597–14606. [Google Scholar] [CrossRef]

- Balasubramanian, P.; Ferrari, G.; Amabili, M. Identification of the viscoelastic response and nonlinear damping of a rubber plate in nonlinear vibration regime. Mech. Syst. Signal Process. 2018, 111, 376–398. [Google Scholar] [CrossRef]

- Gottlieb, O.; Habib, G. Non-linear model-based estimation of quadratic and cubic damping mechanisms governing the dynamics of a chaotic spherical pendulum. J. Vib. Control 2012, 18, 536–547. [Google Scholar] [CrossRef]

- Masing, G. Eigenspannungen und Verfestigung beim Messing. In Proceedings of the 2nd International Congress on Applied Mechanics, Zürich, Switzerland, 12–17 September 1926; pp. 332–335. [Google Scholar]

- Kramer, S. Damping of Materials and Members in Structural Mechanics; Prentice-Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Muravskii, G. On description of hysteretic behaviour of materials. Int. J. Solids Struct. 2005, 42, 2625–2644. [Google Scholar] [CrossRef]

- Muravskii, G.B. On frequency independent damping. J. Sound Vib. 2004, 274, 653–668. [Google Scholar] [CrossRef]

| Specimen Number | Initial Thickness (mm) | Final Thickness (mm) | Heat Treatment |

|---|---|---|---|

| 1 | 3.14 | 0.35 | 30 at 900 C + WQ |

| 2 | 4.12 | 0.35 | 30 at 900 C + WQ |

| 3 | 6.28 | 1.11 | 30 at 900 C + WQ |

| 7 at 900 C + WQ | |||

| 4 | 7.25 | 0.42 | 15 at 900 C + WQ |

| 30 at 900 C + WQ | |||

| 5 | 7.30 | 0.45 | 15 at 900 C + WQ |

| 30 at 900 C + WQ |

| Sample Description | (C) | (C) | (C) | (C) |

|---|---|---|---|---|

| As Cast | 472 | 546 | 215 | 169 |

| As hot-rolled to 0.7 mm | 481 | 538 | 229 | 198 |

| hot rolled and heat treated for 30 at 900 C | 484 | 568 | 357 | 163 |

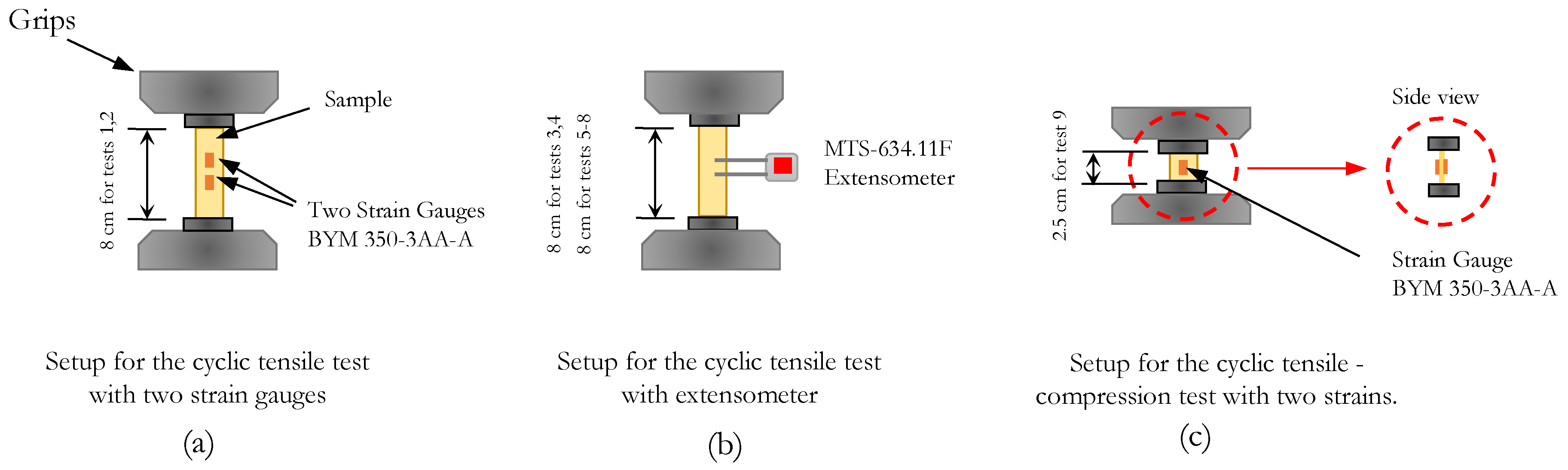

| Test | Sample | Heat Treatment | Loading Condition | Strain Measurement |

|---|---|---|---|---|

| 1 | No. 1 | No Heat treatment | Tensile | Strain gauges |

| 2 | No. 1 | 30 at 900 C | Tensile | Strain gauges |

| 3 | No. 2 | No Heat treatment | Tensile | Extensometer |

| 4 | No. 2 | 30 at 900 C | Tensile | Extensometer |

| 5 | No. 4 | 7 at 900 C | Tensile | Extensometer |

| 6 | No. 4 | 30 at 900 C | Tensile | Extensometer |

| 7 | No. 5 | 15 at 900 C | Tensile | Extensometer |

| 8 | No. 5 | 30 at 900 C | Tensile | Extensometer |

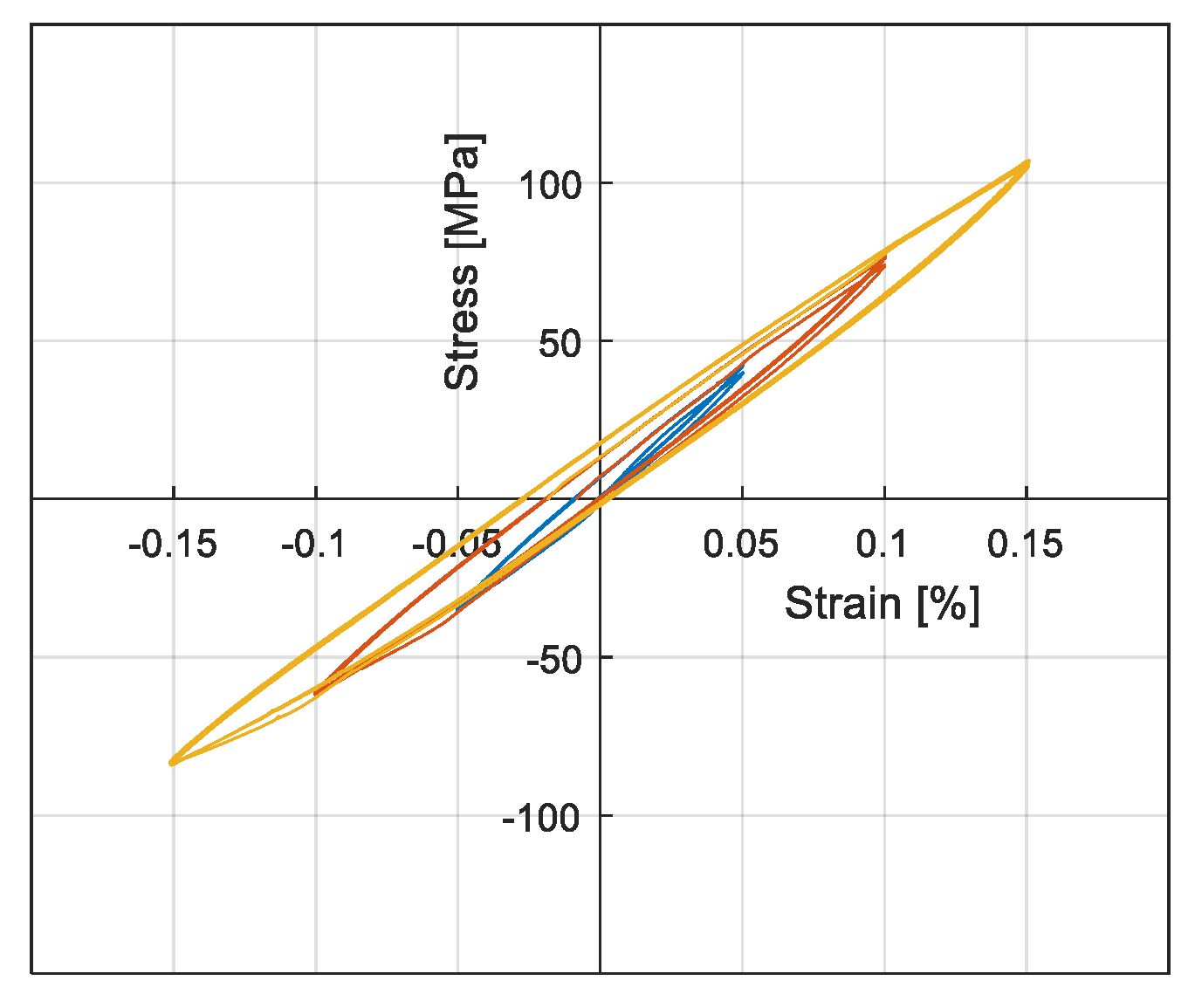

| 9 | No. 3 | 30 at 900 C | Tensile-Compression | Strain gauges |

| Hysteresis Function | Backbone Curve Fitting Line | ||||

|---|---|---|---|---|---|

| a | b | c | d | e | |

| 2.5 | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haghdoust, P.; Conte, A.L.; Cinquemani, S.; Lecis, N. Experimental and Numerical Characterization of High Damping Martensitic CuAlMn Sheets. Materials 2020, 13, 529. https://doi.org/10.3390/ma13030529

Haghdoust P, Conte AL, Cinquemani S, Lecis N. Experimental and Numerical Characterization of High Damping Martensitic CuAlMn Sheets. Materials. 2020; 13(3):529. https://doi.org/10.3390/ma13030529

Chicago/Turabian StyleHaghdoust, Pouya, Antonietta Lo Conte, Simone Cinquemani, and Nora Lecis. 2020. "Experimental and Numerical Characterization of High Damping Martensitic CuAlMn Sheets" Materials 13, no. 3: 529. https://doi.org/10.3390/ma13030529

APA StyleHaghdoust, P., Conte, A. L., Cinquemani, S., & Lecis, N. (2020). Experimental and Numerical Characterization of High Damping Martensitic CuAlMn Sheets. Materials, 13(3), 529. https://doi.org/10.3390/ma13030529