Discrete Element Modelling of the Mechanical Behavior of Sand–Rubber Mixtures under True Triaxial Tests

Abstract

1. Introduction

2. Modelling Using the Discrete Element Method

2.1. Rolling Resistance Contact Model

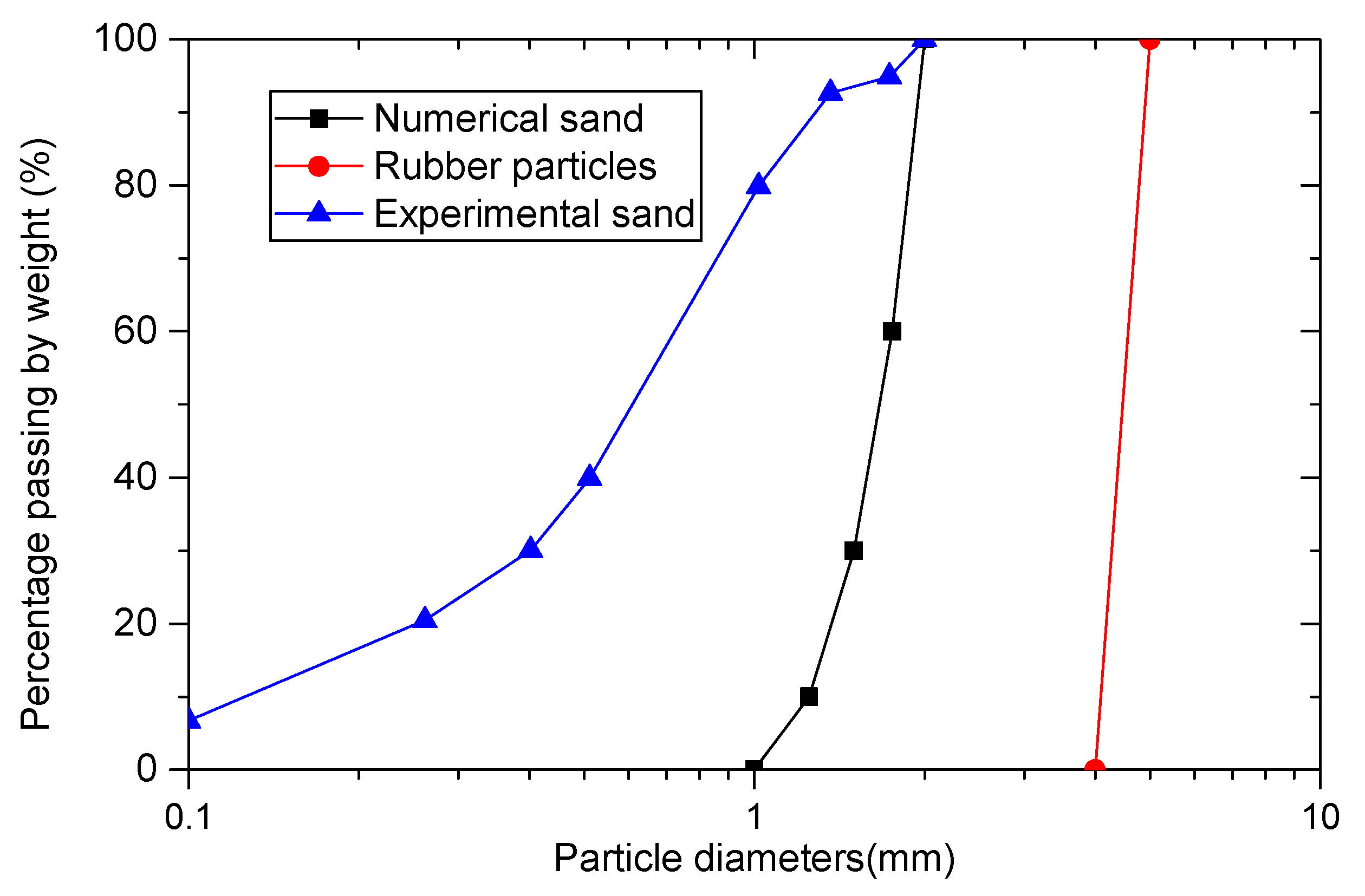

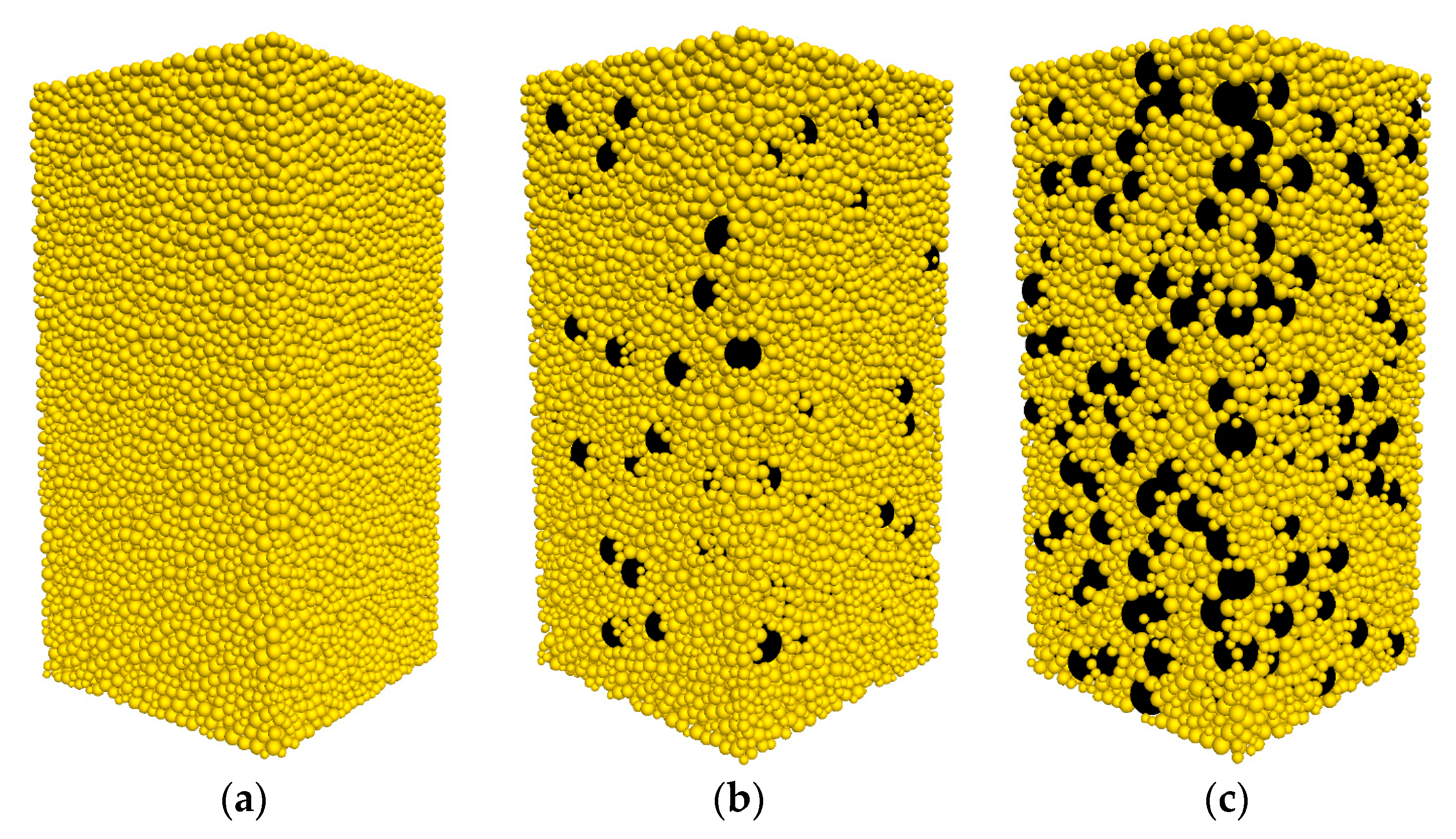

2.2. Model Generation and Loading Paths

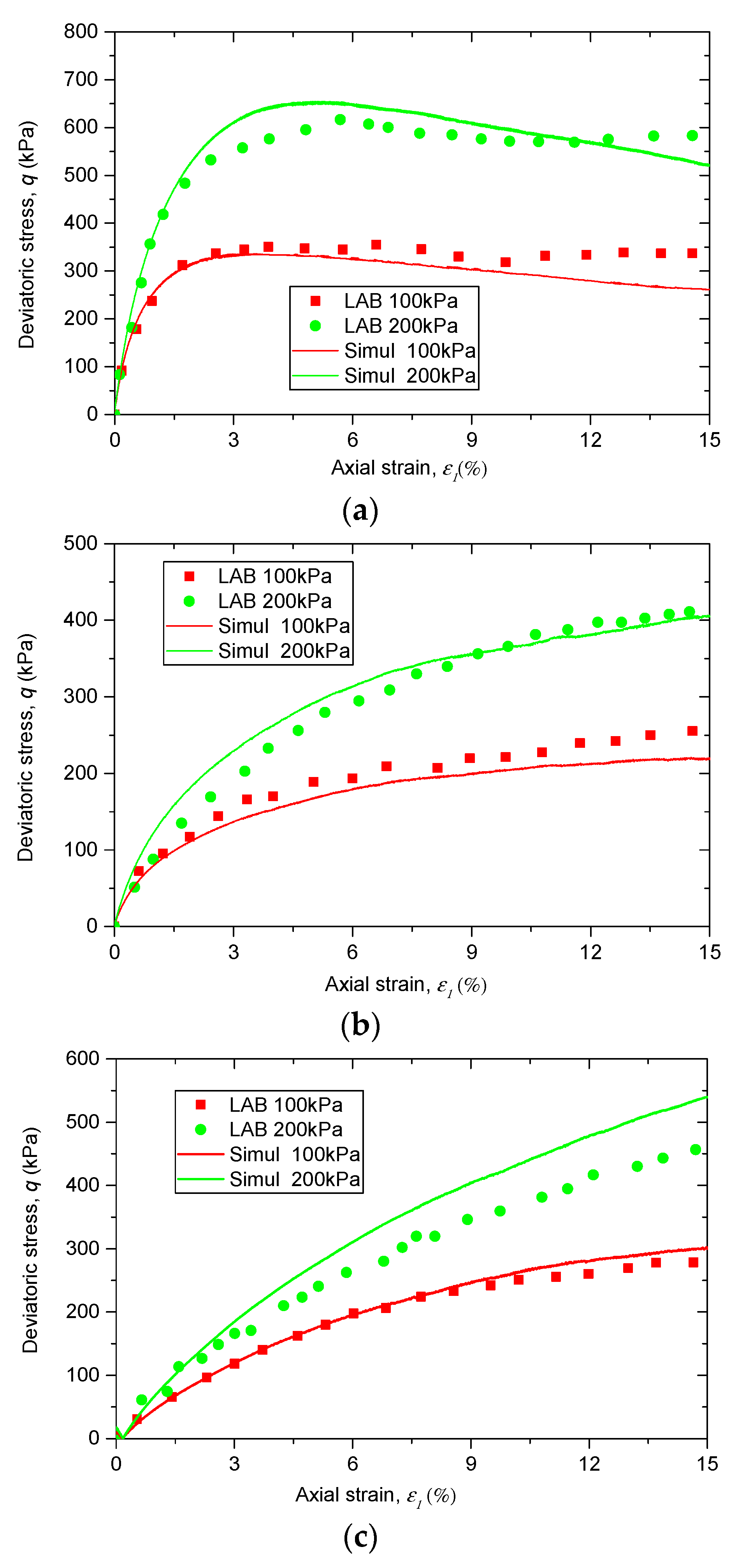

2.3. Calibration Procedure

3. Results

3.1. Macroscopic Behavior

3.1.1. Deviatoric Stress and Volumetric Strain Against the Axial Strain

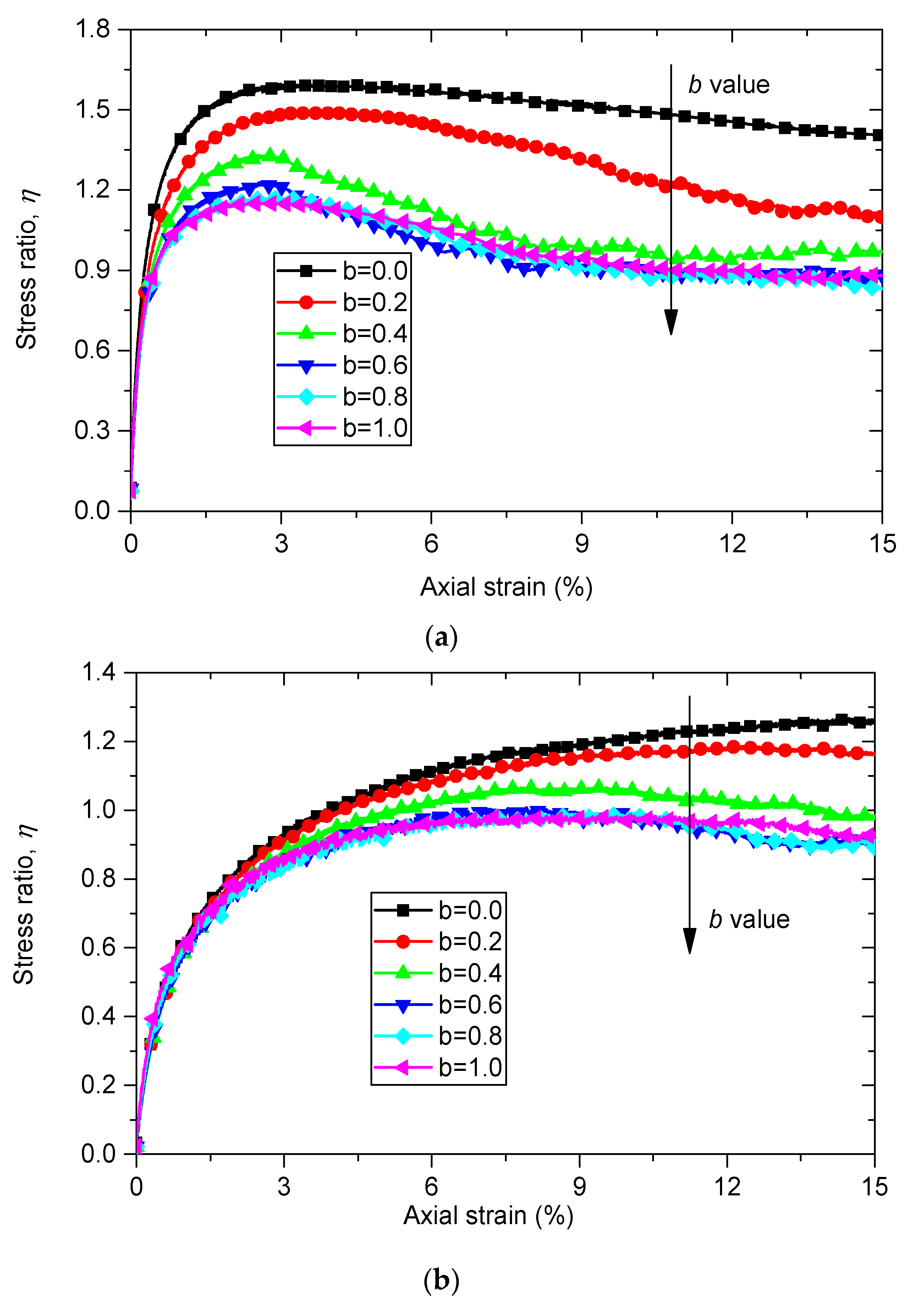

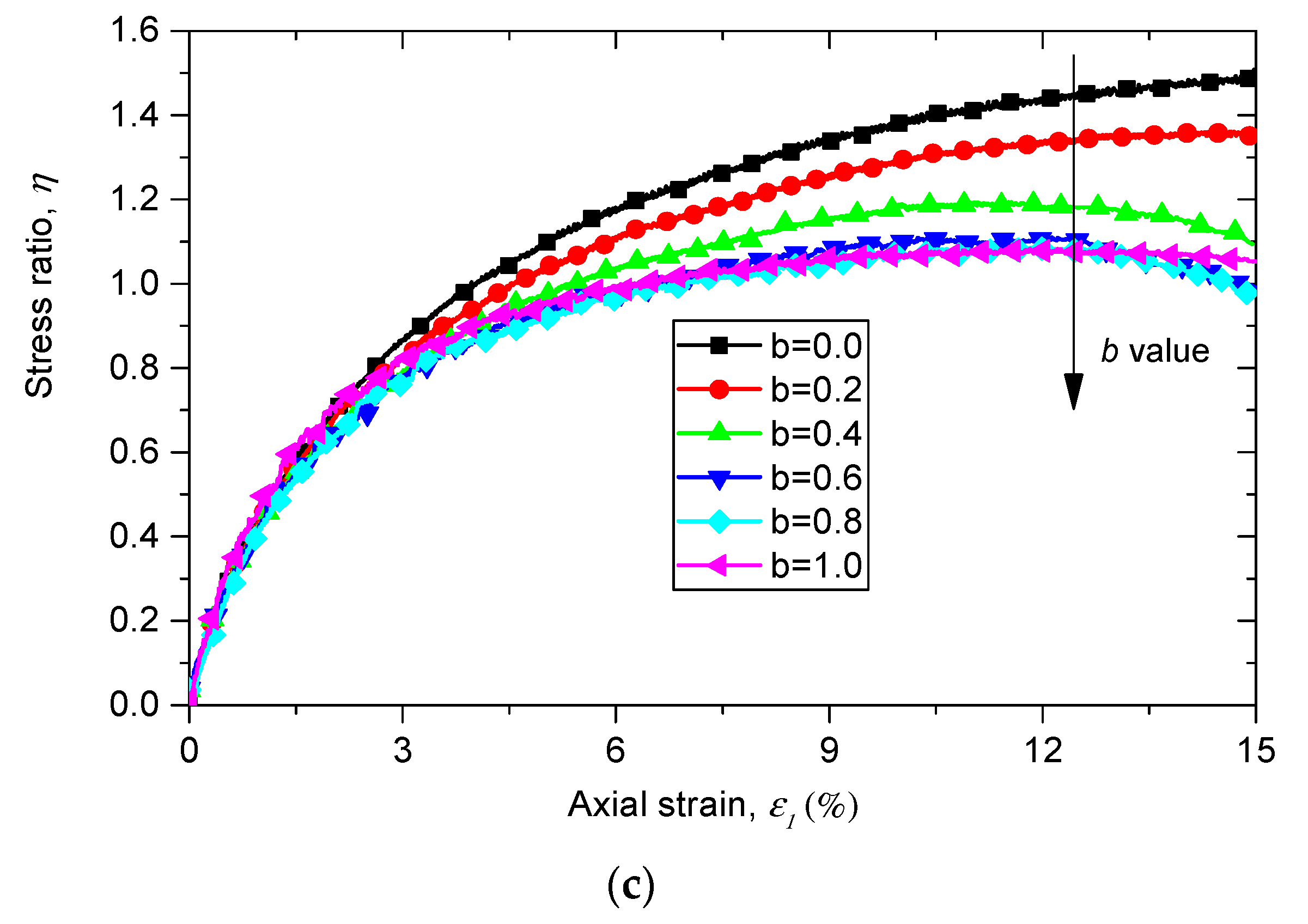

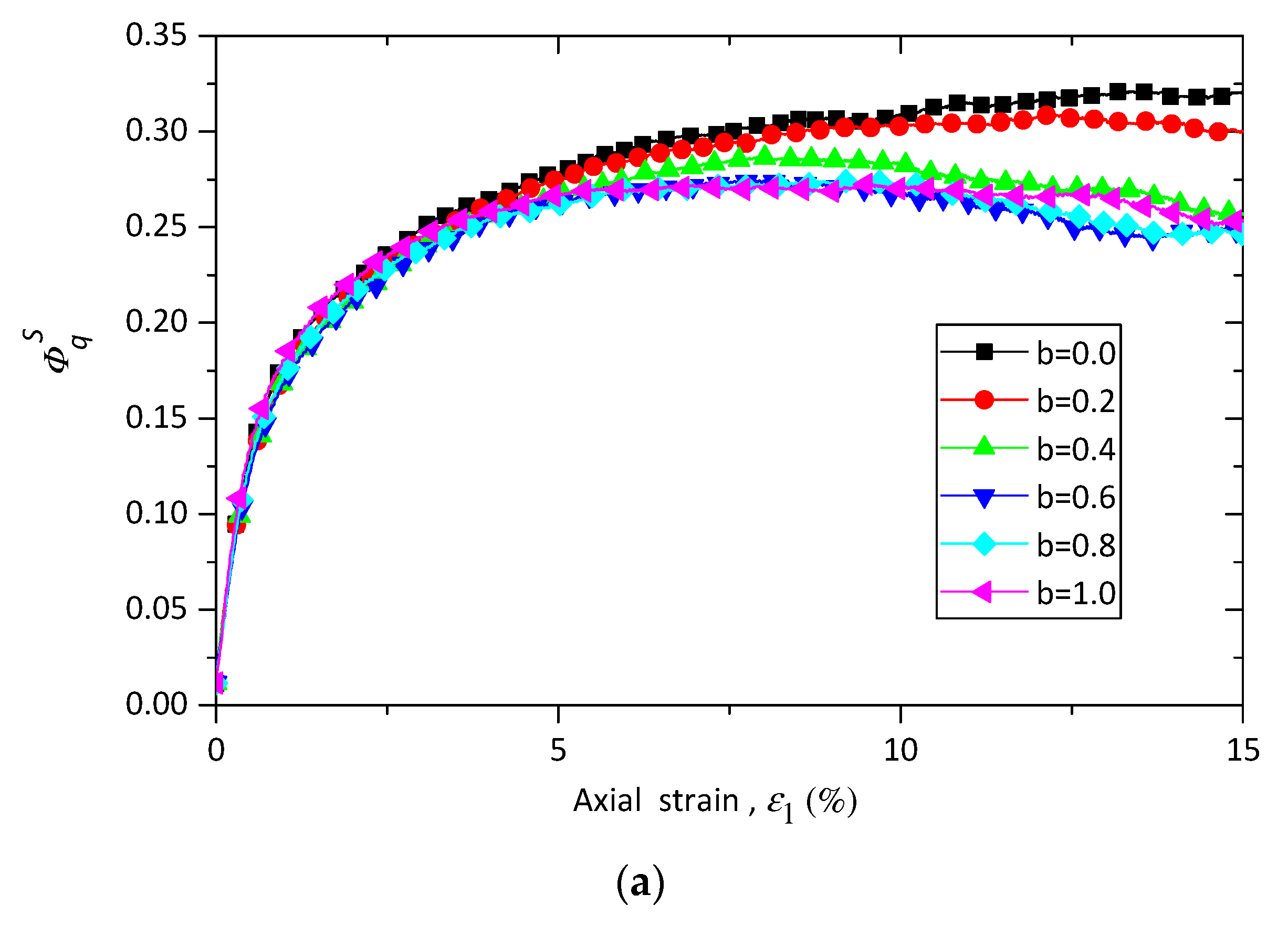

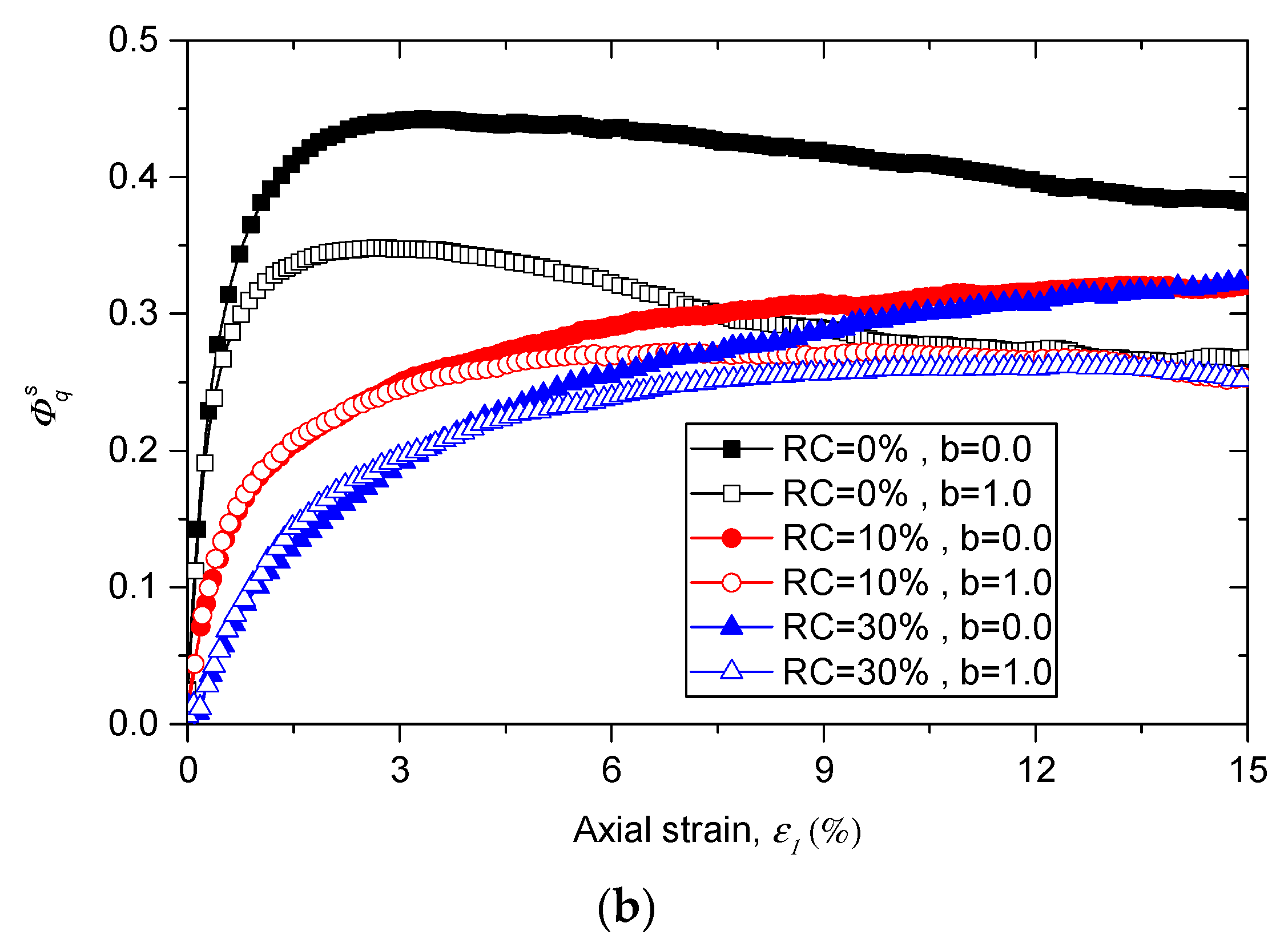

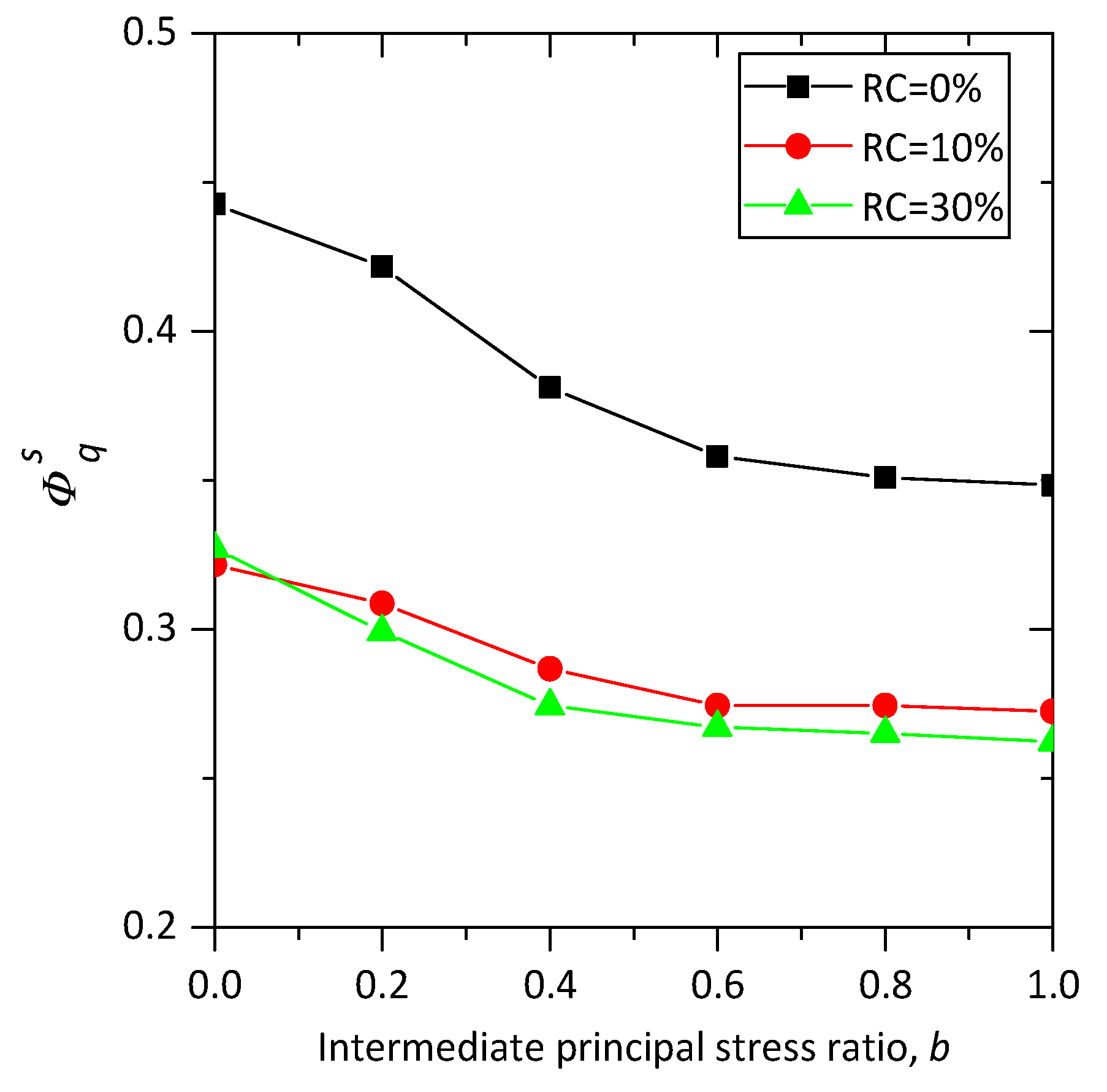

3.1.2. Effect of Rubber Content and Intermediate Principal Stress Ratio on the Stress Ratio in the Peak State

3.2. Micromechanical Response

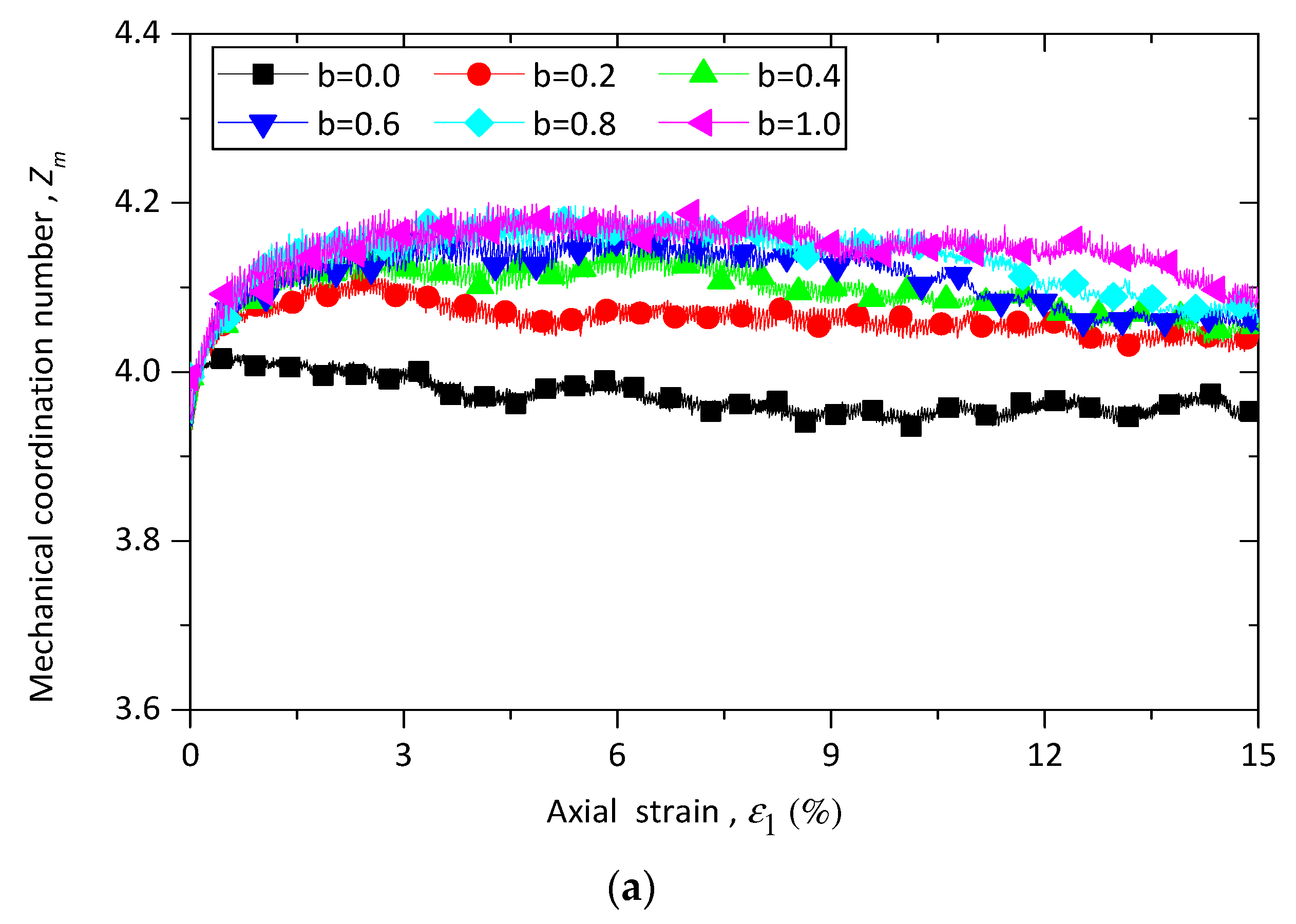

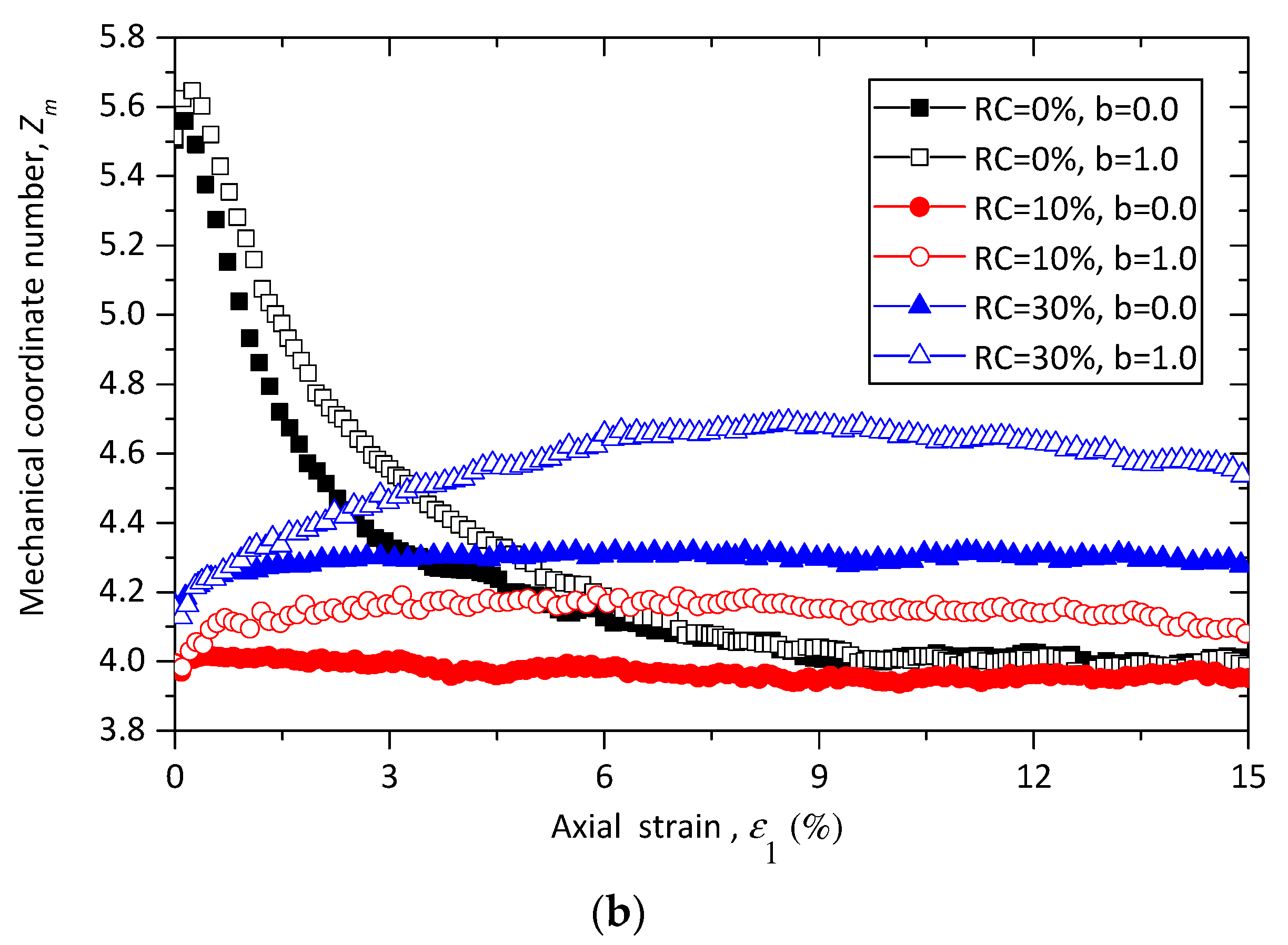

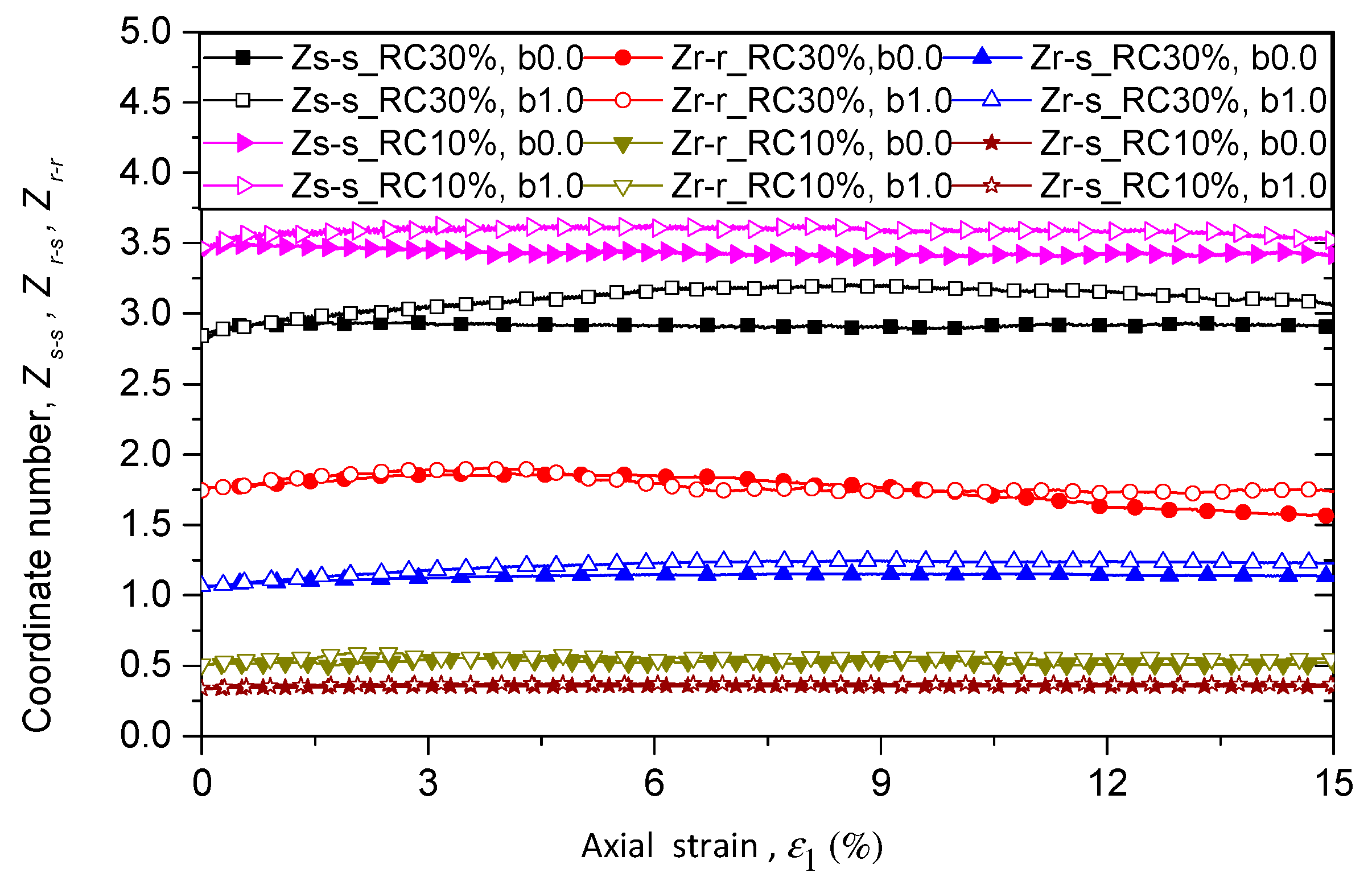

3.2.1. Coordination Number

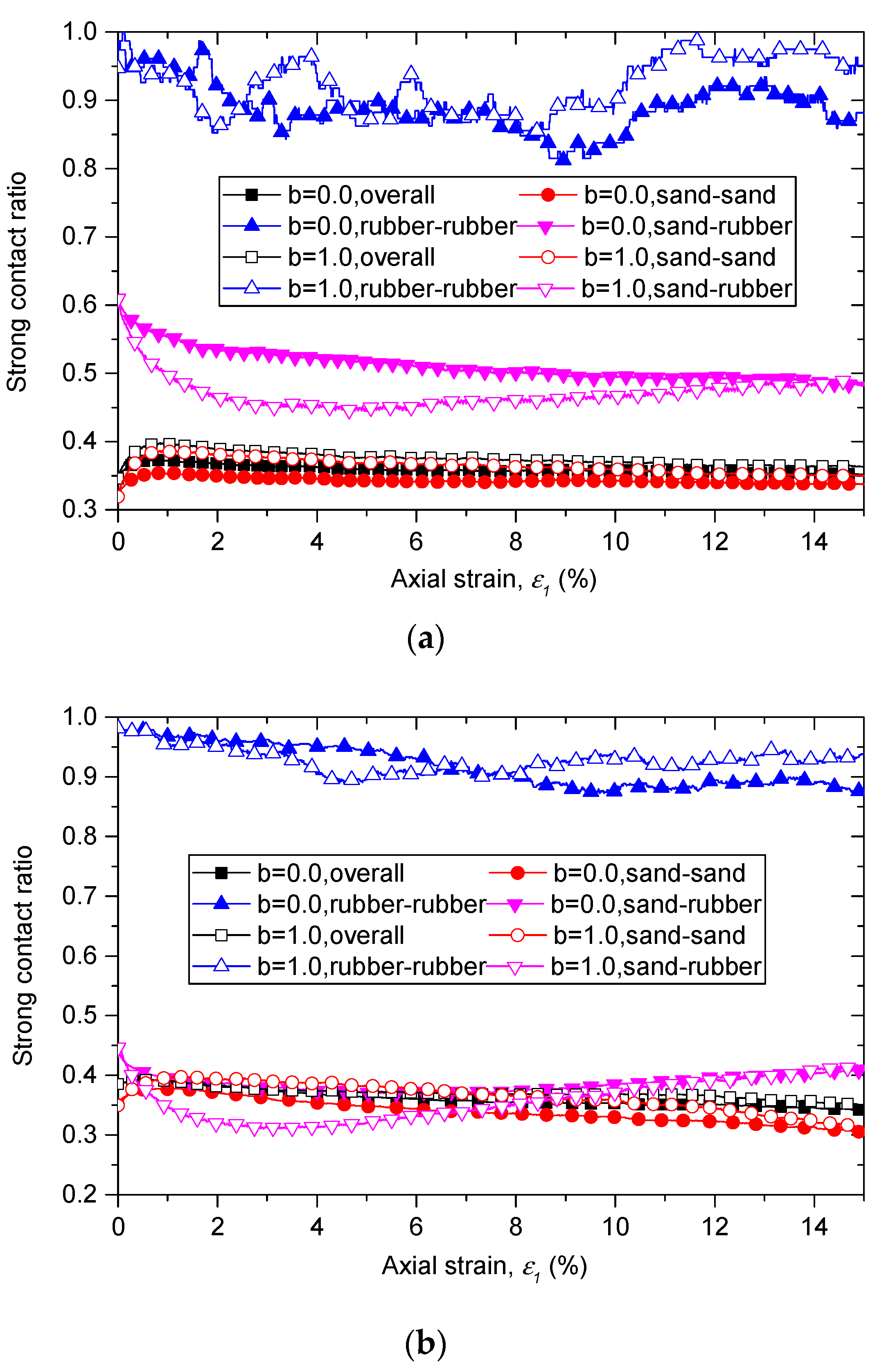

3.2.2. Proportion of Strong Contact in Different Types of Contacts

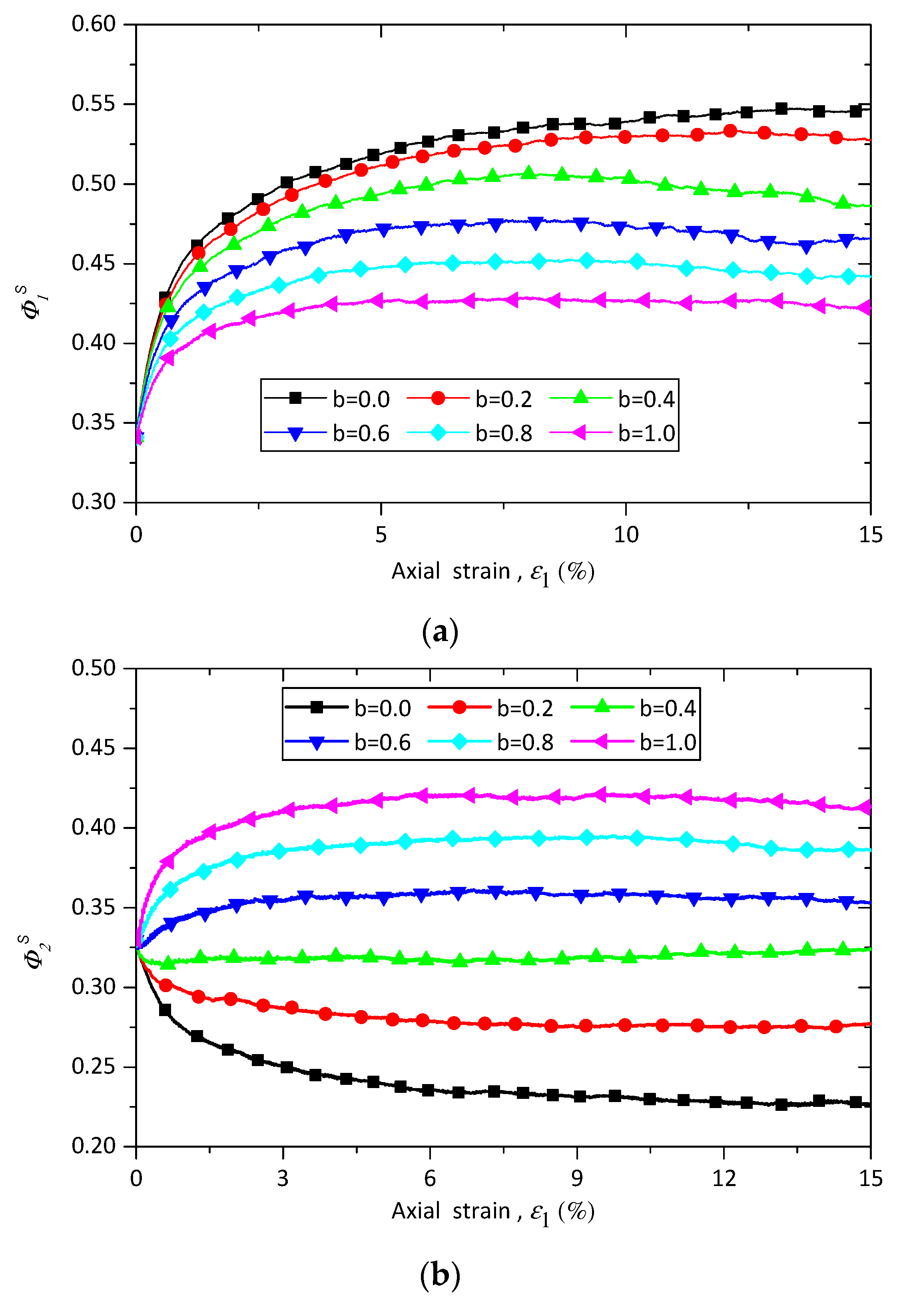

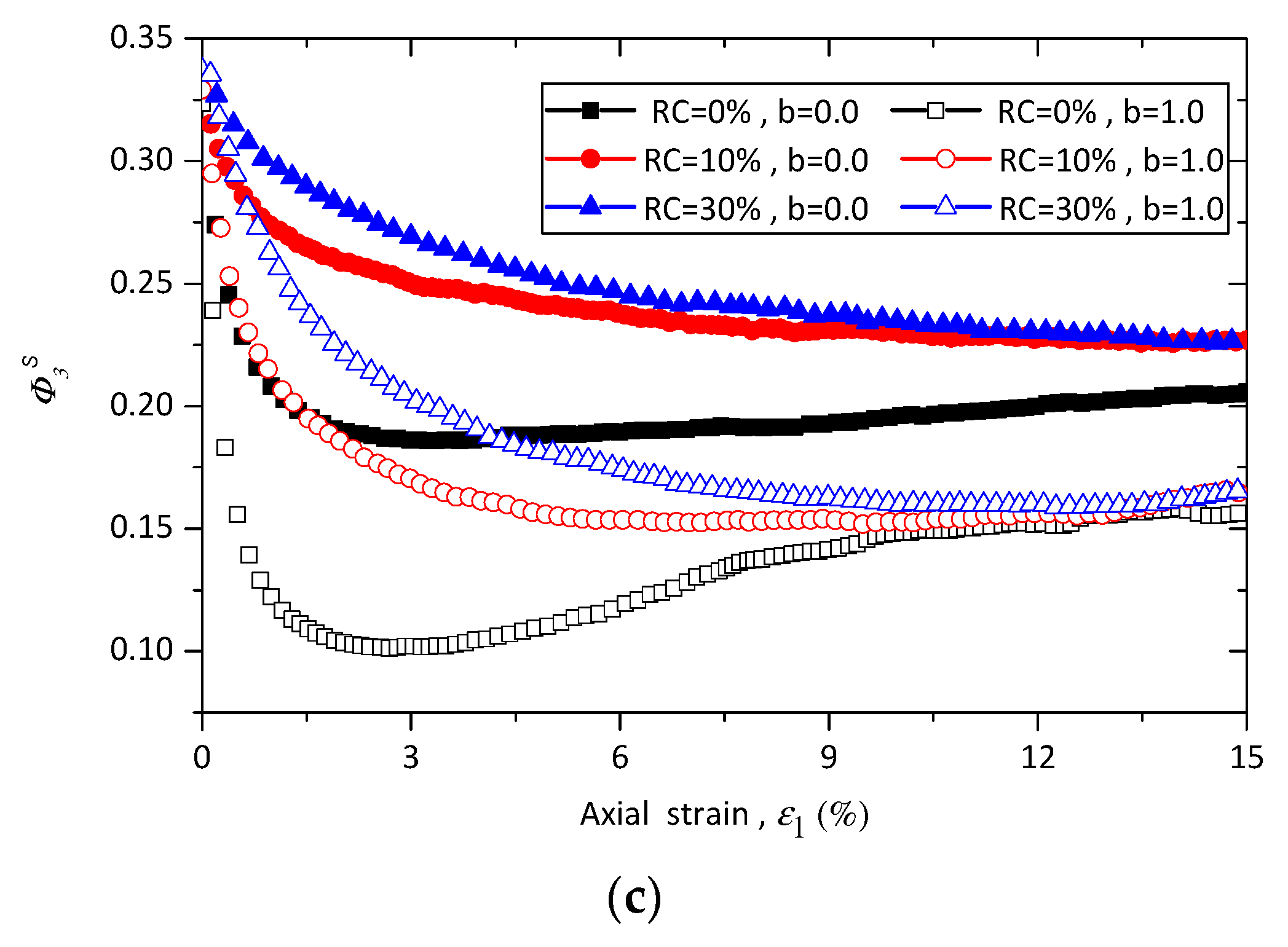

3.2.3. Fabric Tensor and Anisotropy

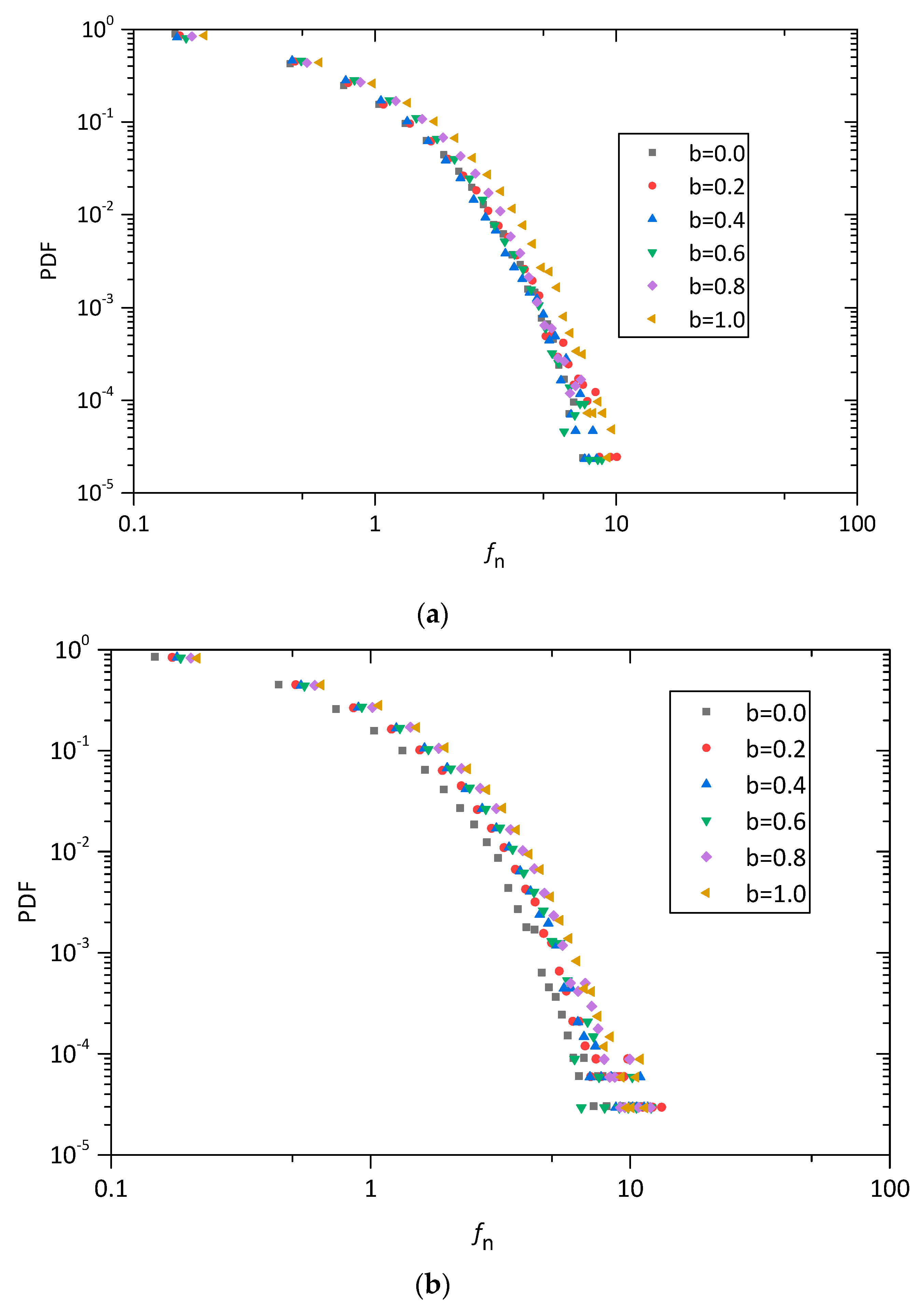

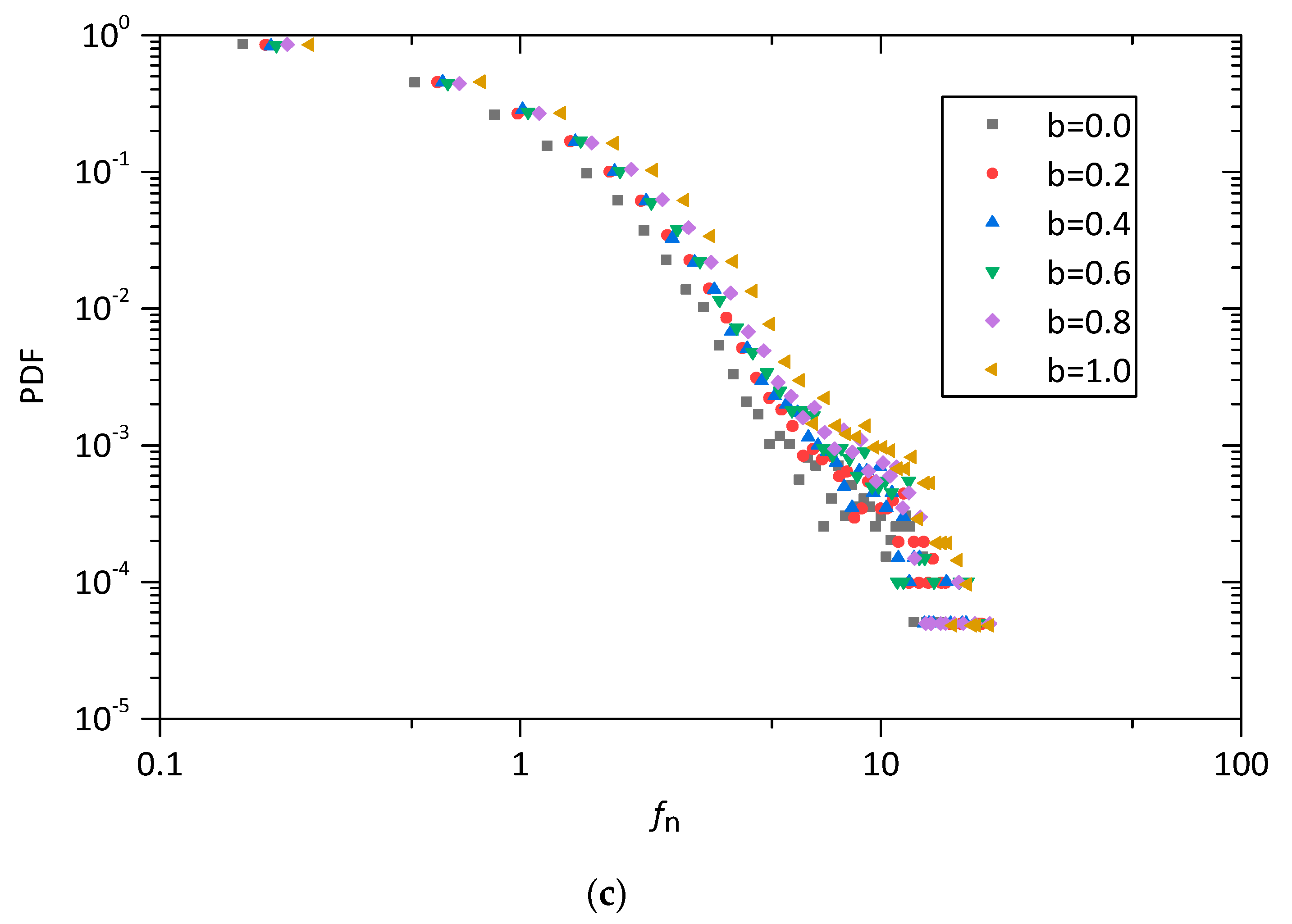

3.2.4. Normal Contact Force and the Probability Density Function of Normal Contact Force

4. Conclusions

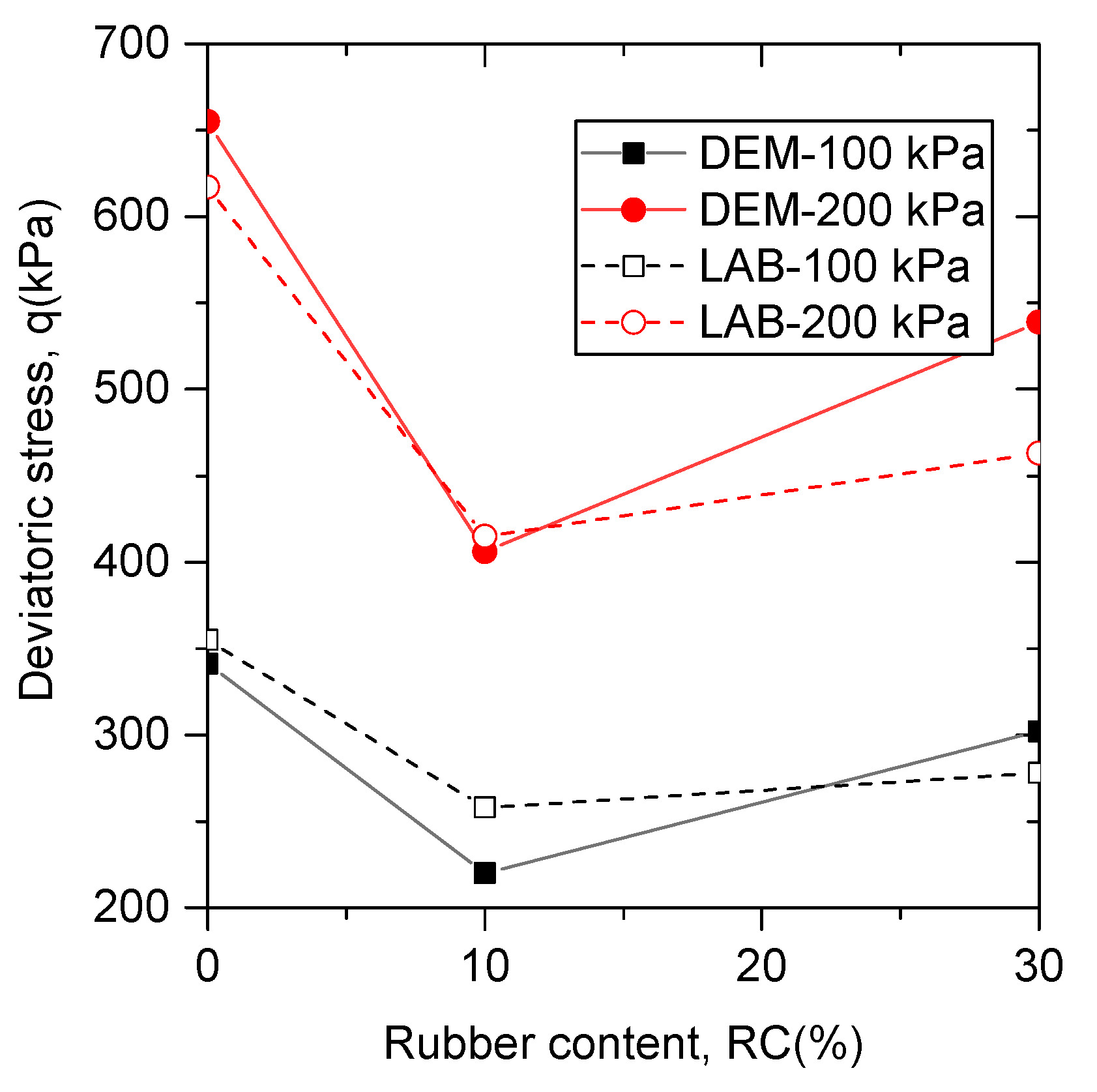

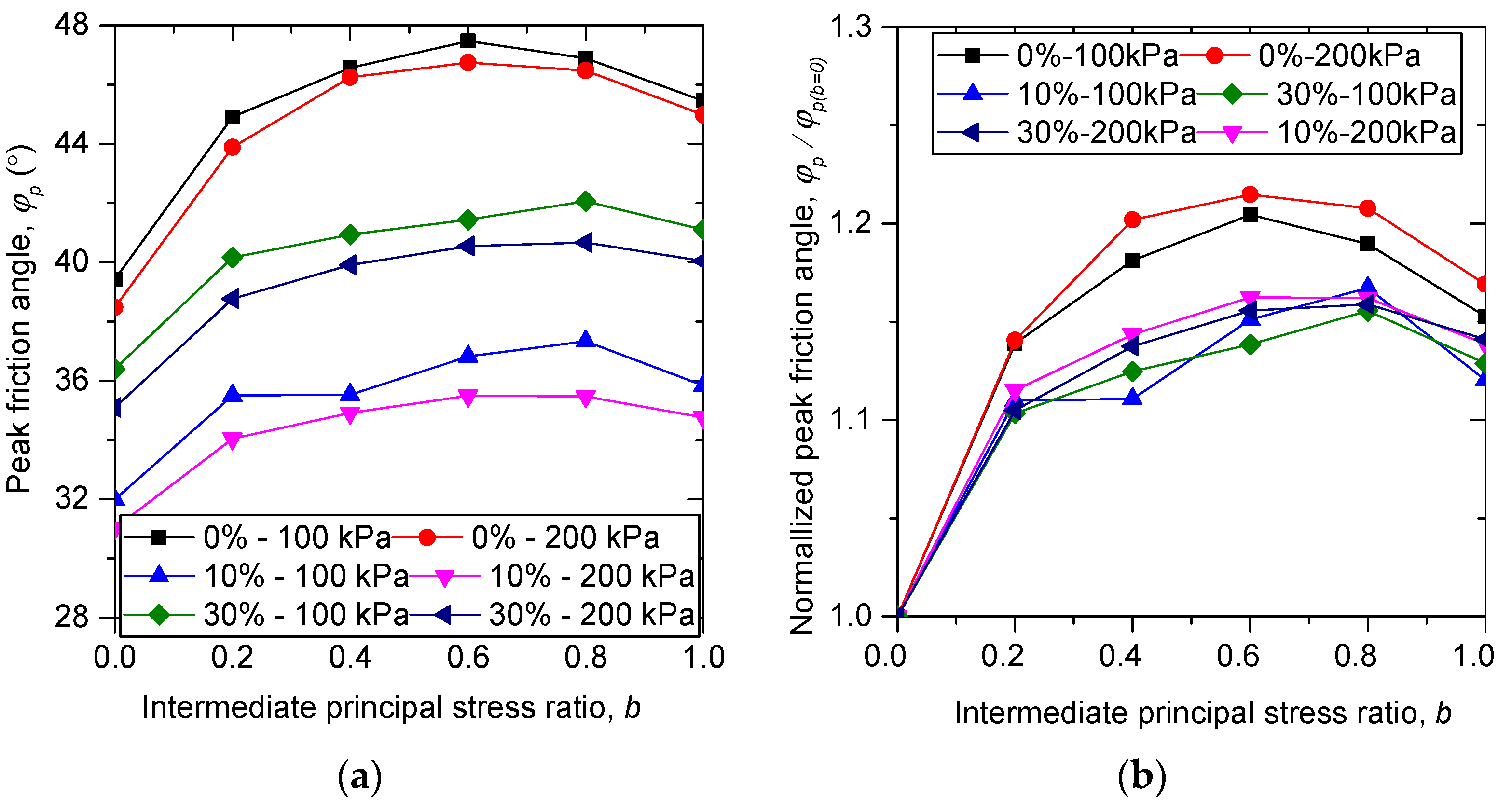

- The peak strengths of samples under conventional triaxial tests first decrease with 10% rubber particles added, and then increase when the proportion of rubber particles rises up to 30%, but the peak strengths sand–rubber mixtures with either 10% or 30% rubber particles are lower than those of pure sand. This trend is in agreement with previous experimental results and numerical simulations on sand–rubber mixtures with large rubber particles, which confirms the feasibility of the simulations conducted in this study. The same trend can also be observed in the peak friction angles for the samples at each intermediate principal stress ratio.

- For sand–rubber mixtures, the relationship between the peak friction angle and the intermediate principal stress ratio is quite different from that for pure sand, which means adding rubber particles can change the failure behavior of sand under complex loading conditions. A suggested explanation of this phenomenon is that the added large rubber particles mainly affect the inherent stability of the strong network. This study can provide a reference for the constitutive model development of sand–rubber mixtures.

- The investigation on the strong contact ratio of different types of contacts show that nearly all of the rubber–rubber contacts of sand–rubber mixtures are strong contacts, no matter what the rubber contents and the values of intermediate principal stress ratio are. While the strong contact ratio of rubber–sand contacts is higher than that of overall contacts for specimens with 10% of rubber particles, and becomes nearly equal to that of the overall contacts when rubber content rises up to 30%. It can be concluded that rubber content can significantly influence the micro structure and the force transmission in the contact network. This finding also confirms the explanation in the Conclusion 2.

- For samples with the same rubber content, the strong contact ratio of rubber–sand contacts decrease with the principal stress ratio b, while the coordinate number of rubber–sand contacts increase with b. It means that with an increase of b, the force transmitted through the rubber particles increases, and more rubber–sand contacts are needed to support the force chain.

- The analysis of the fabric anisotropy shows that the deviatoric fabric of strong contacts demonstrates a decline by adding large rubber particles, and the deviatoric fabric of strong contacts also decreases with b, which is in line with the previous numerical simulations.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| RSM | Sand–rubber mixtures |

| DEM | Discrete element method |

| PSD | Particle size distribution |

| RC | Rubber content |

| Probability density function | |

| The normal stiffness | |

| The shear stiffness | |

| The friction coefficient | |

| The rolling resistance moment | |

| The rolling resistance stiffness | |

| The rolling friction coefficient | |

| The major principal stress | |

| The intermediate principal stress | |

| The minor principal stress | |

| The major principle strain | |

| The deviatoric stress | |

| The mean stress | |

| The Intermediate principal stress ratio | |

| The peak friction angle | |

| The mobilized friction angle | |

| The mechanical coordination number | |

| The coordination number of sand–sand contacts | |

| The coordination number of rubber–sand contacts | |

| The coordination numbers of rubber–rubber contacts | |

| Major principal fabric of strong contacts | |

| Intermediate principal fabric of strong contacts | |

| Minor principal fabric of strong contacts | |

| Strong deviatoric fabric |

References

- Bernai, A.; Salgado, R.; Swan, R.H.; Lovell, C.W. Interaction between tire shreds, rubber-sand and geosynthetics. Geosynth. Int. 1997, 4, 623–643. [Google Scholar] [CrossRef]

- Bosscher, P.J.; Edil, T.B.; Kuraoka, S. Design of highway embankments using tire chips. J. Geotech. Eng. 1997, 123, 295–304. [Google Scholar] [CrossRef]

- Edeskar, T. Use of Tyre Shreds in Civil Engineering Applications: Technical and Environmental Properties. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2006; pp. 1402–1544. [Google Scholar]

- Reddy, S.B.; Krishna, A.M. Recycled Tire Chips Mixed with Sand as Lightweight Backfill Material in Retaining Wall Applications: An Experimental Investigation. Int. J. Geosynth. Ground Eng. 2015, 1, 31. [Google Scholar] [CrossRef]

- Tweedie, J.J.; Humphrey, D.N.; Sandford, T.C. Tire shreds as lightweight retaining wall backfill: Active conditions. J. Geotech. Geoenviron. Eng. 1998, 124, 1061–1070. [Google Scholar] [CrossRef]

- Djadouni, H.; Trouzine, H.; Gomes Correia, A.; da Miranda, T.F.S. 2D numerical analysis of a cantilever retaining wall backfilled with sand–tire chips mixtures. Eur. J. Environ. Civ. Eng. 2019, 1–17. [Google Scholar] [CrossRef]

- Pincus, H.; Edil, T.; Bosscher, P. Engineering Properties of Tire Chips and Soil Mixtures. Geotech. Test. J. 1994, 17, 453–464. [Google Scholar] [CrossRef]

- Fu, R.; Coop, M.R.; Li, X.Q. The mechanics of a compressive sand mixed with tyre rubber. Geotech. Lett. 2014, 4, 238–243. [Google Scholar] [CrossRef]

- Mashiri, M.S.; Vinod, J.S.; Sheikh, M.N.; Tsang, H.H. Shear strength and dilatancy behaviour of sand-tyre chip mixtures. Soils Found. 2015, 55, 517–528. [Google Scholar] [CrossRef]

- Mashiri, M.S.; Vinod, J.S.; Sheikh, M.N. Constitutive model for sand-tire chip mixture. Int. J. Geomech. 2016, 1, 1943–5622. [Google Scholar] [CrossRef]

- Fu, R.; Coop, M.R.; Li, X.Q. Influence of particle type on the mechanics of sand-rubber mixtures. J. Geotech. Geoenviron. Eng. 2017, 143, 1–15. [Google Scholar] [CrossRef]

- Youwai, S.; Bergado, D.T. Strength and deformation characteristics of shredded rubber tire-Sand mixtures. Can. Geotech. J. 2003, 40, 254–264. [Google Scholar] [CrossRef]

- Sheikh, M.N.; Mashiri, M.S.; Vinod, J.S.; Tsang, H.H. Shear and compressibility behavior of sand-tire crumb mixtures. J. Mater. Civ. Eng. 2013, 696, 1943–5533. [Google Scholar] [CrossRef]

- Li, W.; Kwok, C.Y.; Sandeep, C.S.; Senetakis, K. Sand type effect on the behaviour of sand-granulated rubber mixtures: Integrated study from micro- to macro-scales. Powder Technol. 2019, 342, 907–916. [Google Scholar] [CrossRef]

- Anastasiadis, A.; Senetakis, K.; Pitilakis, K. Small-Strain Shear Modulus and Damping Ratio of Sand-Rubber and Gravel-Rubber Mixtures. Geotech. Geol. Eng. 2012, 30, 363–382. [Google Scholar] [CrossRef]

- Lopera Perez, J.C.; Kwok, C.Y.; Senetakis, K. Investigation of the micro-mechanics of sand–rubber mixtures at very small strains. Geosynth. Int. 2017, 24, 30–44. [Google Scholar] [CrossRef]

- Lee, J.S.; Dodds, J.; Santamarina, J.C. Behavior of rigid-soft particle mixtures. J. Mater. Civ. Eng. 2007, 19, 179–184. [Google Scholar] [CrossRef]

- Lopera Perez, J.C.; Kwok, C.Y.; Senetakis, K. Micromechanical analyses of the effect of rubber size and content on sand-rubber mixtures at the critical state. Geotext. Geomembr. 2017, 45, 81–97. [Google Scholar] [CrossRef]

- Indraratna, B.; Ionescu, D.; Christie, H.D. Shear behavior of railway ballast based on large-scale triaxial tests. J. Geotech. Geoenviron. Eng. 1998, 124, 439–449. [Google Scholar] [CrossRef]

- Lade, P.V.; Wang, Q. Analysis of shear banding in true triaxial tests on sand. J. Eng. Mech. 2001, 127, 762–768. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Zhu, J.; Shi, W. Dilatancy equation of rockfill material under the true triaxial stress condition. Sci. China Technol. Sci. 2011, 54, 175–184. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Chen, Y.; Chu, J. Influence of intermediate principal stress on the strength and dilatancy behavior of rockfill material. J. Geotech. Geoenviron. Eng. 2014, 140, 04014064. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Liu, H.; Chen, Y.; Zhang, W. Strength and dilatancy behaviors of dense modeled rockfill material in general stress space. Int. J. Geomech. 2016, 16, 04016015. [Google Scholar] [CrossRef]

- Mahmud Sazzad, M.D.; Suzuki, K.A. Modaressi-Farahmand-Razavi, Macro-Micro Responses of Granular Materials under Different b Values Using DEM. Int. J. Geomech. 2012, 12, 220–228. [Google Scholar] [CrossRef]

- Sazzad, M.M.; Suzuki, K. Density dependent macro-micro behavior of granular materials in general triaxial loading for varying intermediate principal stress using DEM. Granul. Matter 2013, 15, 583–593. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Mao, H. DEM investigation of the effect of intermediate principle stress on particle breakage of granular materials. Comput. Geotech. 2017, 84, 58–67. [Google Scholar] [CrossRef]

- Xie, Y.H.; Yang, Z.X.; Barreto, D.; Jiang, M.D. The influence of particle geometry and the intermediate stress ratio on the shear behavior of granular materials. Granul. Matter 2017, 19, 35. [Google Scholar] [CrossRef]

- Zhou, W.; Yang, L.; Ma, G.; Chang, X.; Cheng, Y.; Li, D. Macro–micro responses of crushable granular materials in simulated true triaxial tests. Granul. Matter 2015, 17, 497–509. [Google Scholar] [CrossRef]

- Lü, X.; Huang, M.; Qian, J. Influences of loading direction and intermediate principal stress ratio on the initiation of strain localization in cross-anisotropic sand. Acta Geotech. 2018, 13, 619–633. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Gong, L.; Nie, L.; Xu, Y.; Wang, H.; Zhang, T.; Du, C.; Wang, Y. Discrete element modelling of the mechanical behaviour of a sand-rubber mixture containing large rubber particles. Constr. Build. Mater. 2019, 205, 574–585. [Google Scholar] [CrossRef]

- Itasca, PFC Documentation. Release 5.0; Itasca Consulting Group Inc.: Minneapolis, MN, USA, 2014. [Google Scholar]

- Bardet, J.P. Observations on the effects of particle rotations on the failure of idealized granular materials. Mech. Mater. 1994, 18, 159–182. [Google Scholar] [CrossRef]

- Iwashita, K.; Oda, M. Rolling resistance at contacts in simulation of shear band development by DEM. J. Eng. Mech. 1998, 124, 285–292. [Google Scholar] [CrossRef]

- Ai, J.; Chen, J.F.; Rotter, J.M.; Ooi, J.Y. Assessment of rolling resistance models in discrete element simulations. Powder Technol. 2011, 206, 269–282. [Google Scholar] [CrossRef]

- Wensrich, C.M.; Katterfeld, A. Rolling friction as a technique for modelling particle shape in DEM. Powder Technol. 2012, 217, 409–417. [Google Scholar] [CrossRef]

- Jiang, M.; Shen, Z.; Wang, J. A novel three-dimensional contact model for granulates incorporating rolling and twisting resistances. Comput. Geotech. 2015, 65, 147–163. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Mao, H. The influence of rolling resistance on the stress-dilatancy and fabric anisotropy of granular materials. Granul. Matter 2018, 20, 12. [Google Scholar] [CrossRef]

- Deng, A.; Feng, J.R. Experimental study on sand-shredded tire lightweight fills. J. Build. Mater. 2010, 13, 116–120. [Google Scholar] [CrossRef]

- Evans, T.M.; Valdes, J.R. The microstructure of particulate mixtures in one-dimensional compression: Numerical studies. Granul. Matter 2011, 13, 657–669. [Google Scholar] [CrossRef]

- Thornton, C. Numerical simulations of deviatoric shear deformation of granular media. Geotechnique 2000, 50, 43–53. [Google Scholar] [CrossRef]

- Cui, L.; O’Sullivan, C. Exploring the macro-and micro-scale response of an idealised granular material in the direct shear apparatus. Geotechnique 2006, 56, 455–468. [Google Scholar] [CrossRef]

- El Shamy, U.; Zeghal, M. Coupled continuum-discrete model for saturated granular soils. J. Eng. Mech. 2005, 131, 413–426. [Google Scholar] [CrossRef]

- Jiang, M.; Yu, H.S.; Leroueil, S. A simple and efficient approach to capturing bonding effect in naturally microstructured sands by discrete element method. Int. J. Numer. Methods Eng. 2007, 69, 1158–1193. [Google Scholar] [CrossRef]

- Jacobson, D.E.; Valdes, J.R.; Evans, T.M. A numerical view into direct shear specimen size effects. Geotech. Test. J. 2007, 30, 512–516. [Google Scholar] [CrossRef]

- Feng, K.; Montoya, B.M.; Evans, T.M. Discrete element method simulations of bio-cemented sands. Comput. Geotech. 2017, 85, 139–150. [Google Scholar] [CrossRef]

- Valdes, J.R.; Evans, T.M. Sand-rubber mixtures: Experiments and numerical simulations. Can. Geotech. J. 2008, 45, 588–595. [Google Scholar] [CrossRef]

- Wang, C.; Deng, A.; Taheri, A. Three-dimensional discrete element modeling of direct shear test for granular rubber−sand. Comput. Geotech. 2018, 97, 204–216. [Google Scholar] [CrossRef]

- Lopera Perez, J.C.; Kwok, C.Y.; Senetakis, K. Effect of rubber size on the behaviour of sand-rubber mixtures: A numerical investigation. Comput. Geotech. 2016, 80, 199–214. [Google Scholar] [CrossRef]

- Minh, N.H.; Cheng, Y.P. A DEM investigation of the effect of particle-size distribution on one-dimensional compression. Geotechnique 2013, 63, 44–53. [Google Scholar] [CrossRef]

- Radjai, F.; Wolf, D.E.; Jean, M.; Moreau, J.J. Bimodal character of stress transmission in granular packings. Phys. Rev. Lett. 1998, 80, 61–64. [Google Scholar] [CrossRef]

- Shi, J.; Guo, P. Fabric evolution of granular materials along imposed stress paths. Acta Geotech. 2018, 13, 116–120. [Google Scholar] [CrossRef]

- Oda, M. Co-Ordination Number and Its Relation To Shear Strength of Granular Material. Soils Found. 1977, 17, 29–42. [Google Scholar] [CrossRef]

- Satake, M. Fabric tensor in granular materials. Deform. Fail. Granul. Mater. IUTAM Symp. Delft. 1982, 1, 63–68. [Google Scholar]

| Set Test ID | b Values | Rubber Content (%) | Sand Particles | Rubber Particles |

|---|---|---|---|---|

| CS-100-b | 0.0, 0.2, 0.4, 0.6, 0.8, 1.0 | 0 | 43,693 | 0 |

| CS-200-b | 0.0, 0.2, 0.4, 0.6, 0.8, 1.0 | 0 | 43,693 | 0 |

| RS-10-100-b | 0.0, 0.2, 0.4, 0.6, 0.8, 1.0 | 10 | 34,909 | 299 |

| RS-10-200-b | 0.0, 0.2, 0.4, 0.6, 0.8, 1.0 | 10 | 34,909 | 299 |

| RS-30-100-b | 0.0, 0.2, 0.4, 0.6, 0.8, 1.0 | 30 | 18,995 | 631 |

| RS-30-200-b | 0.0, 0.2, 0.4, 0.6, 0.8, 1.0 | 30 | 18,995 | 631 |

| Parameters | Values | |||

|---|---|---|---|---|

| Rubber–Rubber Contact | Sand–Sand Contact | Rubber–Sand Contact | Wall-Particle Contact | |

| Effective modules | 3.5 × 104 | 1.0 × 108 | 8.0 × 106 | 1.0 × 108 |

| Normal to shear stiffness ratio | 1.0 | 1.0 | 1.0 | 1.0 |

| Inter-particle friction coefficient | 1.5 | 0.335 | 0.5 | 0.0 |

| Rolling friction coefficient | 1.0 | 0.35 | 0.5 | N/A |

| Damping coefficient | 0.7 | 0.7 | 0.7 | N/A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liao, X.; Li, L.; Mao, H. Discrete Element Modelling of the Mechanical Behavior of Sand–Rubber Mixtures under True Triaxial Tests. Materials 2020, 13, 5716. https://doi.org/10.3390/ma13245716

Liu Y, Liao X, Li L, Mao H. Discrete Element Modelling of the Mechanical Behavior of Sand–Rubber Mixtures under True Triaxial Tests. Materials. 2020; 13(24):5716. https://doi.org/10.3390/ma13245716

Chicago/Turabian StyleLiu, Yiming, Xinchao Liao, Lihua Li, and Haijun Mao. 2020. "Discrete Element Modelling of the Mechanical Behavior of Sand–Rubber Mixtures under True Triaxial Tests" Materials 13, no. 24: 5716. https://doi.org/10.3390/ma13245716

APA StyleLiu, Y., Liao, X., Li, L., & Mao, H. (2020). Discrete Element Modelling of the Mechanical Behavior of Sand–Rubber Mixtures under True Triaxial Tests. Materials, 13(24), 5716. https://doi.org/10.3390/ma13245716