A Study of Low Young’s Modulus Ti–15Ta–15Nb Alloy Using TEM Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Young’s Modulus Analysis

2.3. Microstructural Analysis

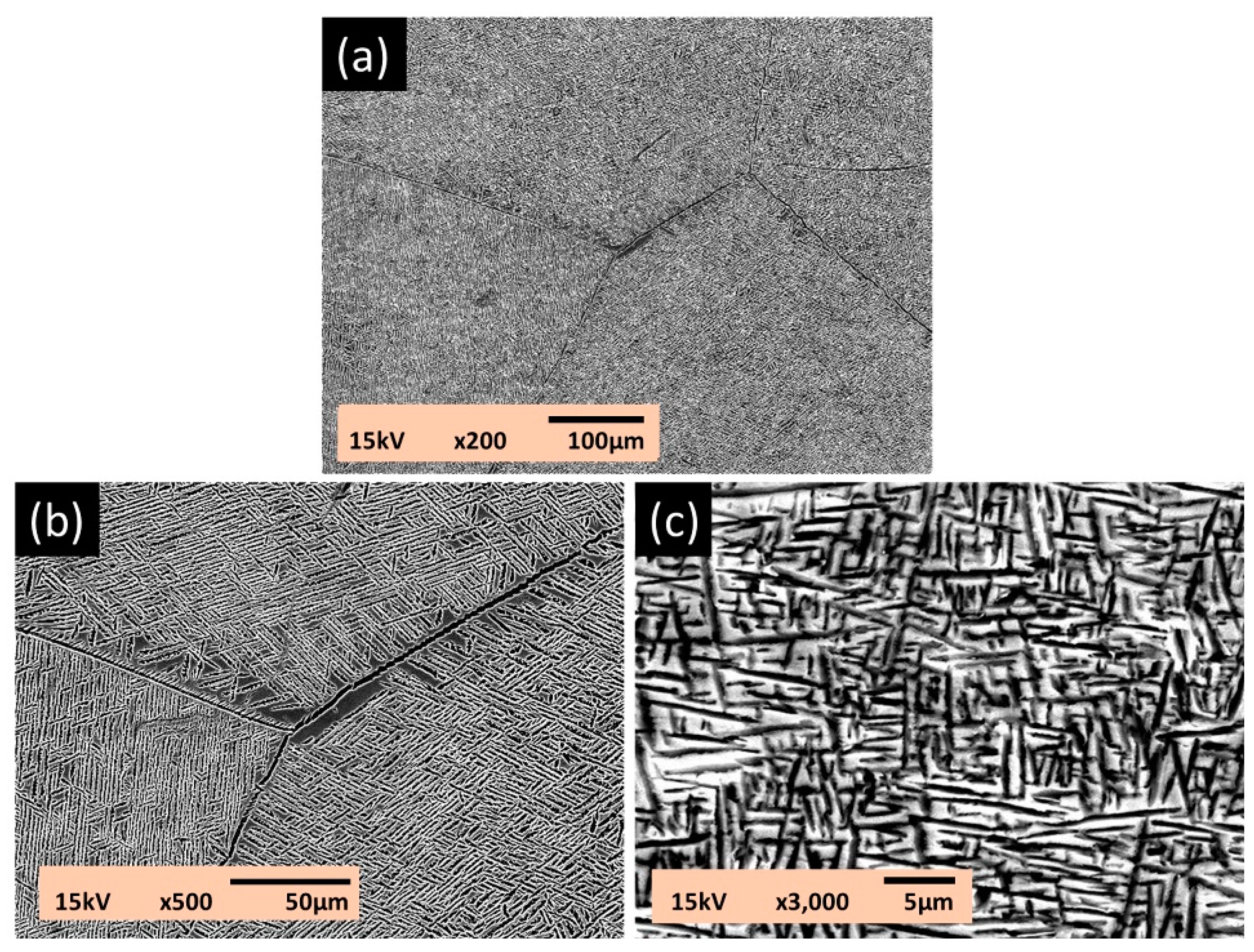

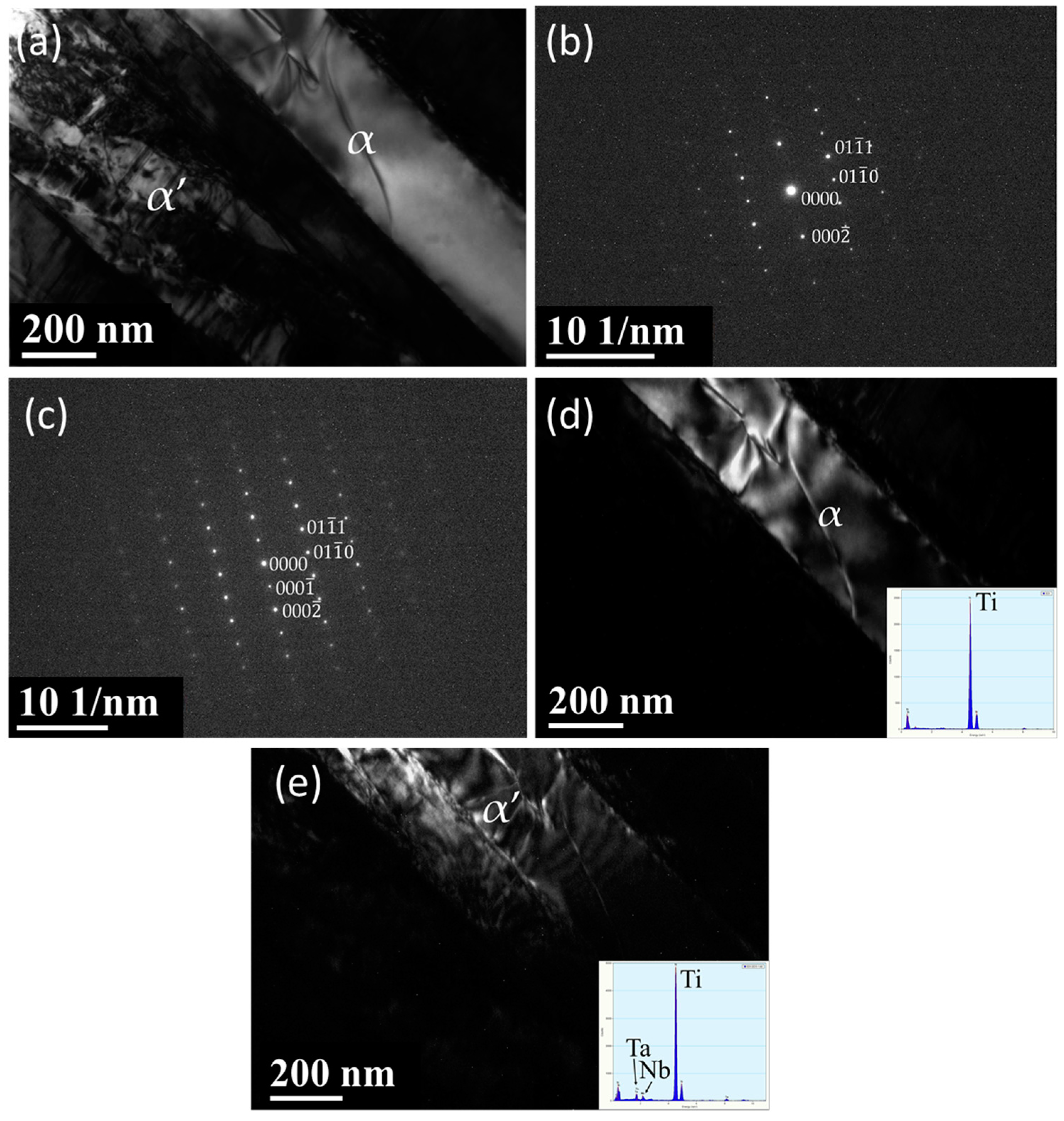

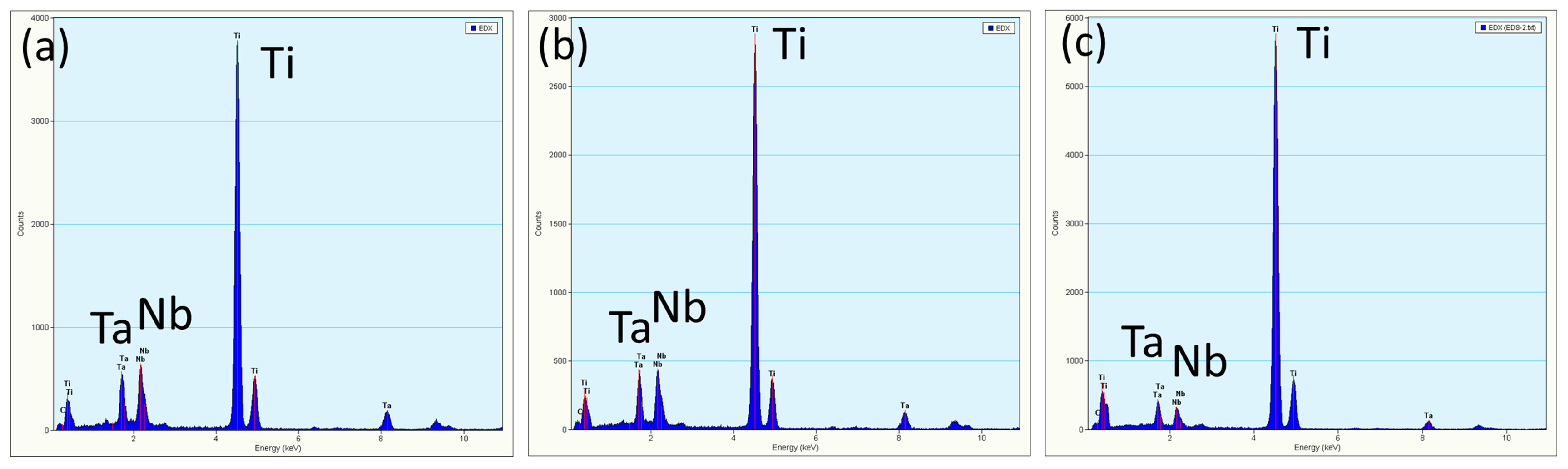

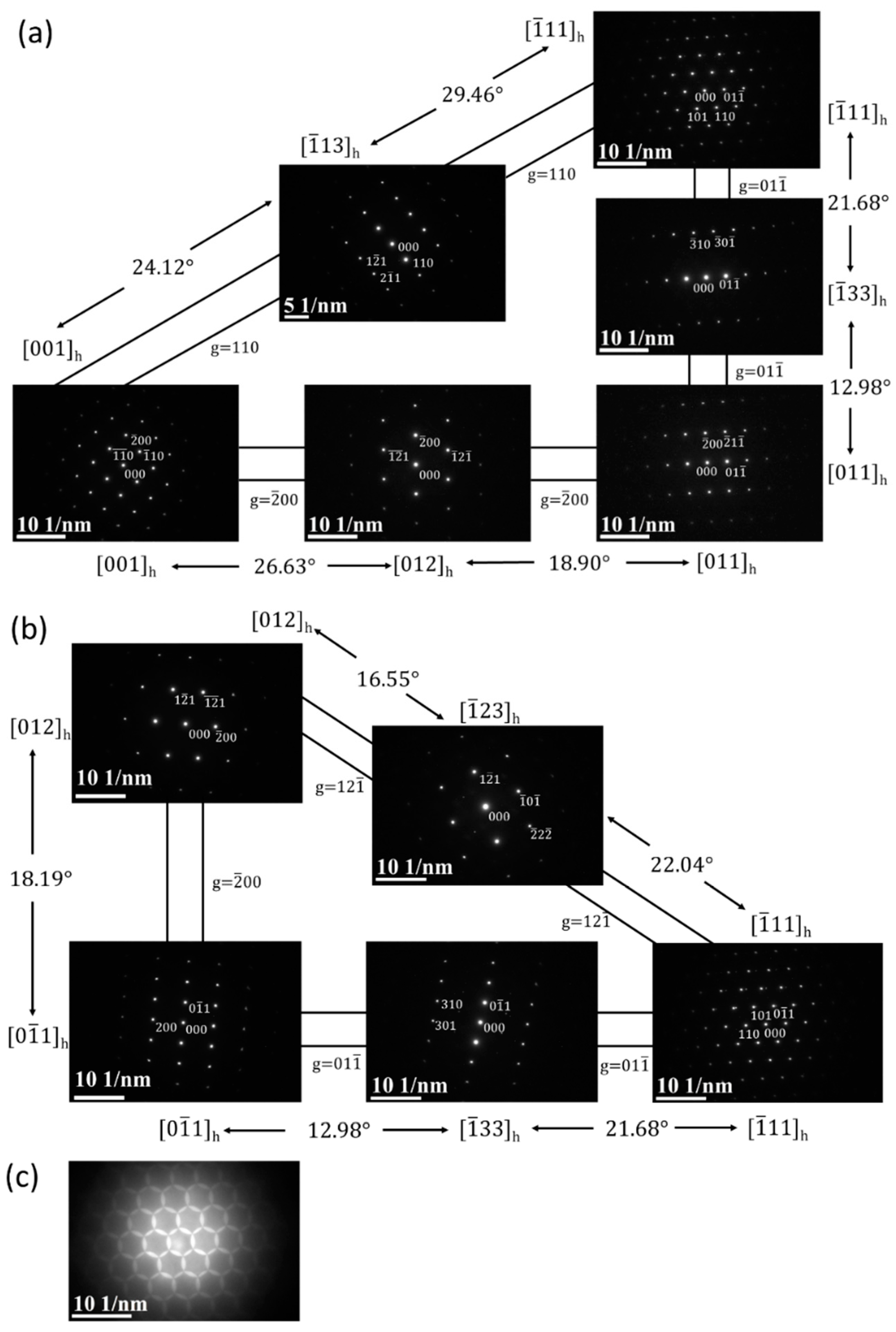

3. Results

4. Discussion

5. Conclusions

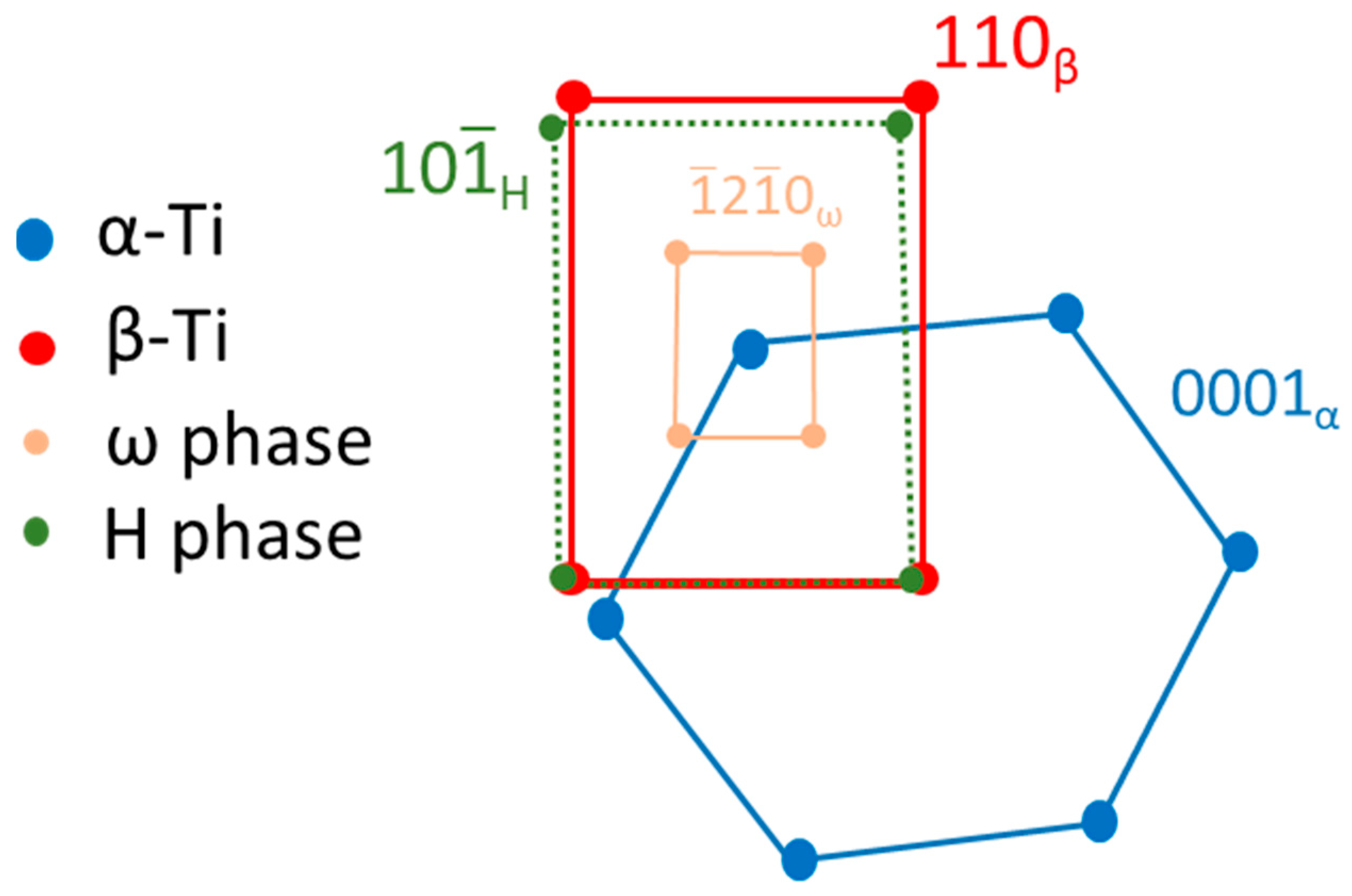

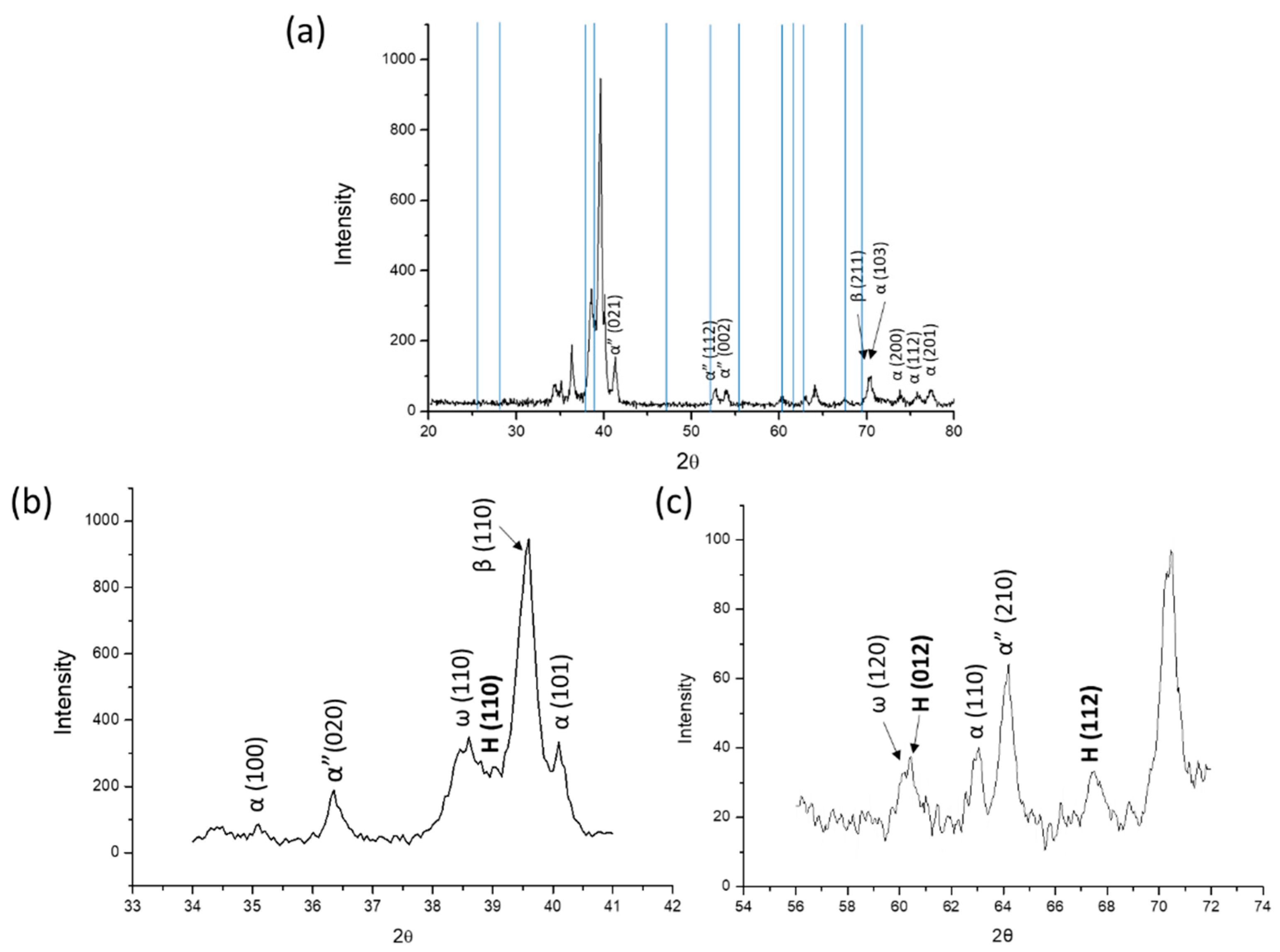

- On the basis the XRD and TEM examinations, the microstructure of the as-cast Ti–15Ta–15Nb alloy is a mixture (α + β + α′ + α″ + ω + H) phase;

- The α and α′ phases belong to the HCP structural class with the lattice parameters a = 0.294 nm and c = 0.471 nm and c/a = 1.602, which are slightly higher than 1.586. The observation of the BCC β phase, orthorhombic α″, and hexagonal ω phase is similar to the results obtained by other researchers;

- A new phase, denoted the H phase, was observed. The H phase belongs to the tetragonal structural class with the lattice parameters a = b = 0.328 nm and c = 0.343 nm;

- The orientation relationship between these phases of the as-cast Ti–15Ta–15Nb alloy is {0001}α//{110}β//{20}ω//{10}H and (010)α//(12)β//(010)ω//(121)H.

Author Contributions

Funding

Conflicts of Interest

References

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef] [PubMed]

- Frutos, E.; Karlík, M.; Jiménez, J.A.; Langhansová, H.; Lieskovská, J.; Polcar, T. Development of new β/α″-Ti-Nb-Zr biocompatible coating with low Young’s modulus and high toughness for medical applications. Mater. Des. 2018, 142, 44–55. [Google Scholar] [CrossRef]

- Hussenbocus, S.; Kosuge, D.; Solomon, L.B.; Howie, D.W.; Oskouei, R.H. Head-neck taper corrosion in hip arthroplasty. BioMed Res. Int. 2015, 2015, 758123. [Google Scholar] [CrossRef] [PubMed]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Zhao, X.; Niinomi, M.; Nakai, M.; Hieda, J. Beta type Ti-Mo alloys with changeable Young’s modulus for spinal fixation applications. Acta Biomater. 2012, 8, 1990–1997. [Google Scholar] [CrossRef]

- Wei, T.Y.; Huang, J.C.; Chao, C.-Y.; Wei, L.L.; Tsai, M.T.; Chen, Y.H. Microstructure and elastic modulus evolution of TiTaNb alloys. J. Mech. Behav. Biomed. Mater. 2018, 86, 224–231. [Google Scholar] [CrossRef]

- Liu, H.; Niinomi, M.; Nakai, M.; Hieda, J.; Cho, K. Changeable Young’s modulus with large elongation-to-failure in β-type titanium alloys for spinal fixation applications. Scr. Mater. 2014, 82, 29–32. [Google Scholar] [CrossRef]

- Kopova, I.; Stráský, J.; Harcuba, P.; Landa, M.; Janeček, M.; Bačákova, L. Newly developed Ti–Nb–Zr–Ta–Si–Fe biomedical beta titanium alloys with increased strength and enhanced biocompatibility. Mater. Sci. Eng. C 2016, 60, 230–238. [Google Scholar] [CrossRef]

- Eisenbarth, E.; Velten, D.; Müller, M.; Thull, R.; Breme, J. Biocompatibility of β-stabilizing elements of titanium alloys. Biomaterials 2004, 25, 5705–5713. [Google Scholar] [CrossRef]

- Liu, H.; Niinomi, M.; Nakai, M.; Cho, K. β-Type titanium alloys for spinal fixation surgery with high Young’s modulus variability and good mechanical properties. Acta Biomater. 2015, 24, 361–369. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Xing, H.; Sun, J. Structural stability and generalized stacking fault energies in β Ti–Nb alloys: Relation to dislocation properties. Scr. Mater. 2012, 66, 682–685. [Google Scholar] [CrossRef]

- Hussein, A.H.; Gepreel, M.A.H.; Gouda, M.K.; Hefnawy, A.M.; Kandil, S.H. Biocompatibility of new Ti–Nb–Ta base alloys. Mater. Sci. Eng. C 2016, 61, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Mareci, D.; Chelariu, R.; Gordin, D.-M.; Ungureanu, G.; Gloriant, T. Comparative corrosion study of Ti–Ta alloys for dental applications. Acta Biomater. 2009, 5, 3625–3639. [Google Scholar] [CrossRef]

- de Almeida, L.H.; Bastos, I.N.; Santos, I.D.; Dutra, A.J.B.; Nunes, C.A.; Gabriel, S.B. Corrosion resistance of aged Ti–Mo–Nb alloys for biomedical applications. J. Alloys Compd. 2014, 615, S666–S669. [Google Scholar] [CrossRef]

- Raabe, D.; Sander, B.; Friák, M.; Ma, D.; Neugebauer, J. Theory-guided bottom-up design of β-titanium alloys as biomaterials based on first principles calculations: Theory and experiments. Acta Mater. 2007, 55, 4475–4487. [Google Scholar] [CrossRef]

- Aguilar, C.; Guzman, P.; Lascano, S.; Parra, C.; Bejar, L.; Medina, A.; Guzman, D. Solid solution and amorphous phase in Ti–Nb–Ta–Mn systems synthesized by mechanical alloying. J. Alloys Compd. 2016, 670, 346–355. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, J.; Cheng, X.; Zhao, X. A metastable β-type Ti–Nb binary alloy with low modulus and high strength. J. Alloys Compd. 2015, 644, 411–415. [Google Scholar] [CrossRef]

- Huang, H.-H.; Wu, C.-P.; Sun, Y.-S.; Lee, T.-H. Improvements in the corrosion resistance and biocompatibility of biomedical Ti–6Al–7Nb alloy using an electrochemical anodization treatment. Thin Solid Films 2013, 528, 157–162. [Google Scholar] [CrossRef]

- Chen, Y.; Han, P.; Dehghan-Manshadi, A.; Kent, D.; Ehtemam-Haghighi, S.; Jowers, C.; Bermingham, M.; Li, T.; Cooper-White, J.; Dargusch, M.S. Sintering and biocompatibility of blended elemental Ti-xNb alloys. J. Mech. Behav. Biomed. Mater. 2020, 104. [Google Scholar] [CrossRef]

- Chen, G.; Yin, J.; Zhao, S.; Tang, H.; Qu, X. Microstructure and tensile properties of a Ti-28Ta alloy studied by transmission electron microscopy and digital image correlation. Int. J. Refract. Met. Hard. Mater. 2019, 81, 71–77. [Google Scholar] [CrossRef]

- Liu, Q.; Meng, Q.; Guo, S.; Zhao, X. α′ Type Ti–Nb–Zr alloys with ultra-low Young’s modulus and high strength. Prog. Nat. Sci. 2013, 23, 562–565. [Google Scholar] [CrossRef]

- Meng, Q.; Guo, S.; Liu, Q.; Hu, L.; Zhao, X. A β-type TiNbZr alloy with low modulus and high strength for biomedical applications. Prog. Nat. Sci. 2014, 24, 157–162. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, Q.; Wen, D.; Xu, F.; Chen, G.; Dong, C.; Sun, L.; Liaw, P.K. Effects of Nb and Zr on structural stabilities of Ti-Mo-Sn-based alloys with low modulus. Mater. Sci. Eng. C 2017, 687, 1–7. [Google Scholar] [CrossRef]

- Guo, S.; Meng, Q.; Zhao, X.; Wei, Q.; Xu, H. Design and fabrication of a metastable β-type titanium alloy with ultralow elastic modulus and high strength. Sci. Rep. 2015, 5, 14688. [Google Scholar] [CrossRef] [PubMed]

- Qiu, D.; Zhang, M.X.; Kelly, P.M.; Furuhara, T. Non-classical {334}β type of twinned α′ martensite in a Ti–5.26wt.% Cr alloy. Acta Mater. 2014, 67, 373–382. [Google Scholar] [CrossRef]

- Akanuma, T.; Matsumoto, H.; Sato, S.; Chiba, A.; Inagaki, I.; Shirai, Y.; Maeda, T. Enhancement of athermal α″ martensitic transformation in Ti–10V–2Fe–3Al alloy due to high-speed hot deformation. Scr. Mater. 2012, 67, 21–24. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Raducanu, D.; Gloriant, T.; Gordin, D.; Cinca, I. Effects of cold-rolling deformation on texture evolution and mechanical properties of Ti–29Nb–9Ta–10Zr alloy. Mater. Sci. Eng. A 2013, 586, 1–10. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Yi, D.; Wang, B.; Jiang, Y.; Hu, T.; Xiao, Y.; Yang, Q.; Wang, J.; Gao, Q. Stress-induced α″ phase in a beta Ti–19Nb–1.5Mo–4Zr–8Sn alloy. Mater. Charact. 2018, 140, 247–258. [Google Scholar] [CrossRef]

- Knowles, K.M.; Smith, D.A. The nature of the parent-martensite interface in titanium-manganese. Acta Metall. 1981, 29, 1445–1466. [Google Scholar] [CrossRef]

- Duerig, T.W.; Albrecht, J.; Richter, D.; Fischer, P. Formation and reversion of stress induced martensite in Ti-10V-2Fe-3Al. Acta Metall. 1982, 30, 2161–2172. [Google Scholar] [CrossRef]

- Qin, D.; Lu, Y.; Zhang, K.; Liu, Q.; Zhou, L. X-ray photoelectron spectroscopy characterization of the ω phase in water quenched Ti-5553 alloy. Mater. Charact. 2012, 73, 77–80. [Google Scholar] [CrossRef]

- Liu, H.; Niinomi, M.; Nakai, M.; Cho, K. Athermal and deformation-induced ω-phase transformations in biomedical beta-type alloy Ti–9Cr–0.2O. Acta Mater. 2016, 106, 162–170. [Google Scholar] [CrossRef]

- Min, X.H.; Emura, S.; Zhang, L.; Tsuzaki, K. Effect of Fe and Zr additions on ω phase formation in β-type Ti–Mo alloys. Mater. Sci. Eng. A Struct. Mater. 2008, 497, 74–78. [Google Scholar] [CrossRef]

- Ali, T.; Wang, L.; Cheng, X.; Liu, A.; Xu, X. Omega phase formation and deformation mechanism in heat treated Ti-5553 alloy under high strain rate compression. Mater. Lett. 2019, 236, 163–166. [Google Scholar] [CrossRef]

- He, B.; Cheng, X.; Li, J.; Li, G.-C.; Wang, H.-M. ω-assisted α phase and hardness of Ti-5Al-5Mo-5V-1Cr-1Fe during low temperature isothermal heat treatment after laser surface remelting. J. Alloys Compd. 2017, 708, 1054–1062. [Google Scholar] [CrossRef]

- Haghighi, S.; Lu, H.B.; Jian, G.Y.; Cao, G.H.; Habibi, D.; Zhang, L. Effect of α″ martensite on the microstructure and mechanical properties of beta-type Ti–Fe–Ta alloys. Mater. Des. 2015, 76, 47–54. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, W.; Sun, J. Formation of {332}〈113〉β twins from parent {130}〈310〉α″ plastic twins in a full α″ Ti-Nb alloy by annealing. Mater. Charact. 2018, 145, 724–729. [Google Scholar] [CrossRef]

- Kirkland, E.J. Advanced Computing in Electron Microscopy; Kluwer Academic Publisher: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Edington, J.W. The Operation and Calibration of the Electron Microscope; MacMillan: New York, NY, USA, 1985; Volume 2. [Google Scholar]

- Prima, F.; Vermaut, P.; Texier, G.; Ansel, D.; Gloriant, T. Evidence of α-nanophase heterogeneous nucleation from ω particles in a β-metastable Ti-based alloy by high-resolution electron microscopy. Scr. Mater. 2006, 54, 645–648. [Google Scholar] [CrossRef]

- Bertrand, E.; Castany, P.; Yang, Y.; Menou, E.; Gloriant, T. Deformation twinning in the full-α″ martensitic Ti–25Ta–20Nb shape memory alloy. Acta Mater. 2016, 105, 94–103. [Google Scholar] [CrossRef]

- Behera, M.; Mythili, R.; Raju, S.; Saroja, S. Effect of cooling rate on mechanism of β→α phase transformation on continuous cooling in Ti–5Ta–1.8Nb alloy. J. Alloys Compd. 2013, 553, 59–68. [Google Scholar] [CrossRef]

- Matsumoto, H.; Chiba, A.; Hanada, S. Anisotropy of Young’s modulus and tensile properties in cold rolled α′ martensite Ti–V–Sn alloys. Mater. Sci. Eng. A Struct. Mater. 2008, 486, 503–510. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

| Number | Observed D-Spacing * | Calculated D-Spacing ** | Indexed Plane |

|---|---|---|---|

| 1 | 0.3284 | 0.3284 | 100 |

| 2 | 0.3284 | 0.3284 | 010 |

| 3 | 0.2372 | 0.2372 | 011 |

| 4 | 0.2362 | 0.2372 | 01 |

| 5 | 0.2372 | 0.2372 | 101 |

| 6 | 0.2321 | 0.2322 | 110 |

| 7 | 0.1922 | 0.1922 | 11 |

| 8 | 0.1924 | 0.1922 | 11 |

| 9 | 0.1352 | 0.1350 | 211 |

| 10 | 0.1350 | 0.1350 | 2. 1 |

| 11 | 0.1348 | 0.1350 | 1 |

| 0.1352 | 0.1350 | 11 | |

| 13 | 0.1350 | 0.1350 | 21 |

| 14 | 0.1040 | 0.1038 | 10 |

| 15 | 0.1038 | 0.1038 | 0 |

| 16 | 0.1042 | 0.1042 | 0 |

| 17 | 0.1044 | 0.1042 | 1 |

| 18 | 0.0980 | 0.0960 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-E.; Wu, J.-H.; Chao, C.-Y.; Chang, Y.-H.; Du, J.-K.; Chen, K.-K.; Chen, H.-M. A Study of Low Young’s Modulus Ti–15Ta–15Nb Alloy Using TEM Analysis. Materials 2020, 13, 5694. https://doi.org/10.3390/ma13245694

Lee H-E, Wu J-H, Chao C-Y, Chang Y-H, Du J-K, Chen K-K, Chen H-M. A Study of Low Young’s Modulus Ti–15Ta–15Nb Alloy Using TEM Analysis. Materials. 2020; 13(24):5694. https://doi.org/10.3390/ma13245694

Chicago/Turabian StyleLee, Huey-Er, Ju-Hui Wu, Chih-Yeh Chao, Yen-Hao Chang, Je-Kang Du, Ker-Kong Chen, and Huey-Ming Chen. 2020. "A Study of Low Young’s Modulus Ti–15Ta–15Nb Alloy Using TEM Analysis" Materials 13, no. 24: 5694. https://doi.org/10.3390/ma13245694

APA StyleLee, H.-E., Wu, J.-H., Chao, C.-Y., Chang, Y.-H., Du, J.-K., Chen, K.-K., & Chen, H.-M. (2020). A Study of Low Young’s Modulus Ti–15Ta–15Nb Alloy Using TEM Analysis. Materials, 13(24), 5694. https://doi.org/10.3390/ma13245694