Development and Optimization of Tin/Flux Mixture for Direct Tinning and Interfacial Bonding in Aluminum/Steel Bimetallic Compound Casting

Abstract

1. Introduction

2. Materials and Methods

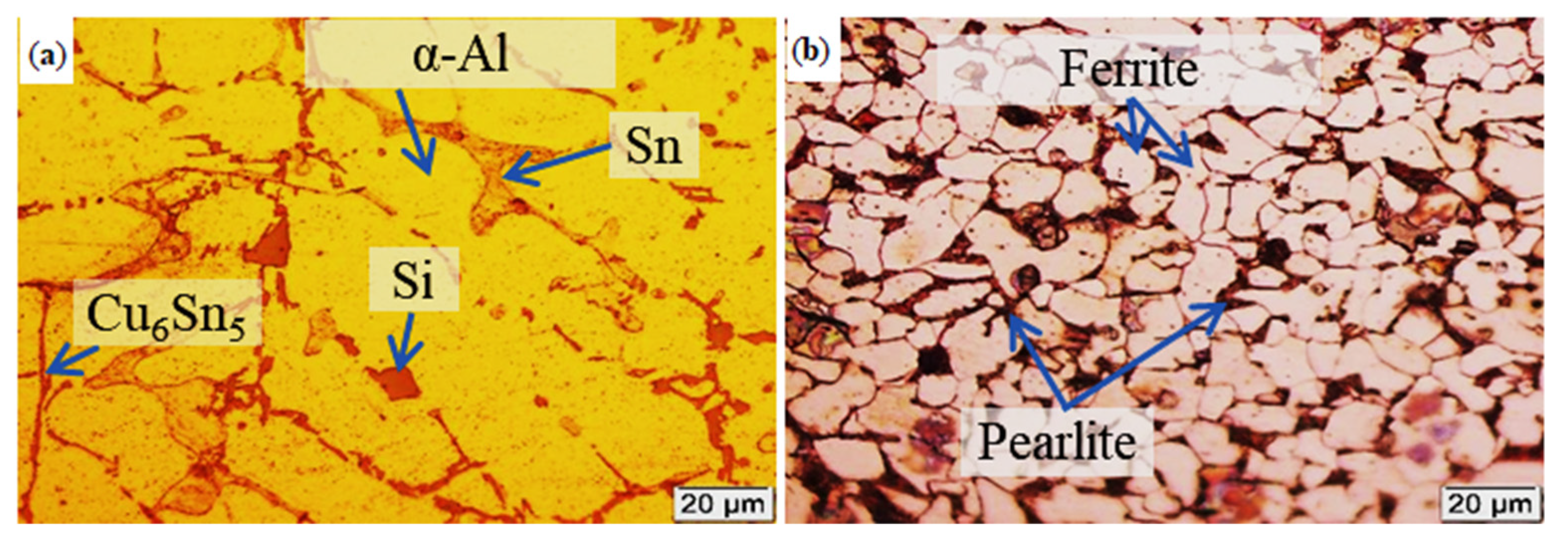

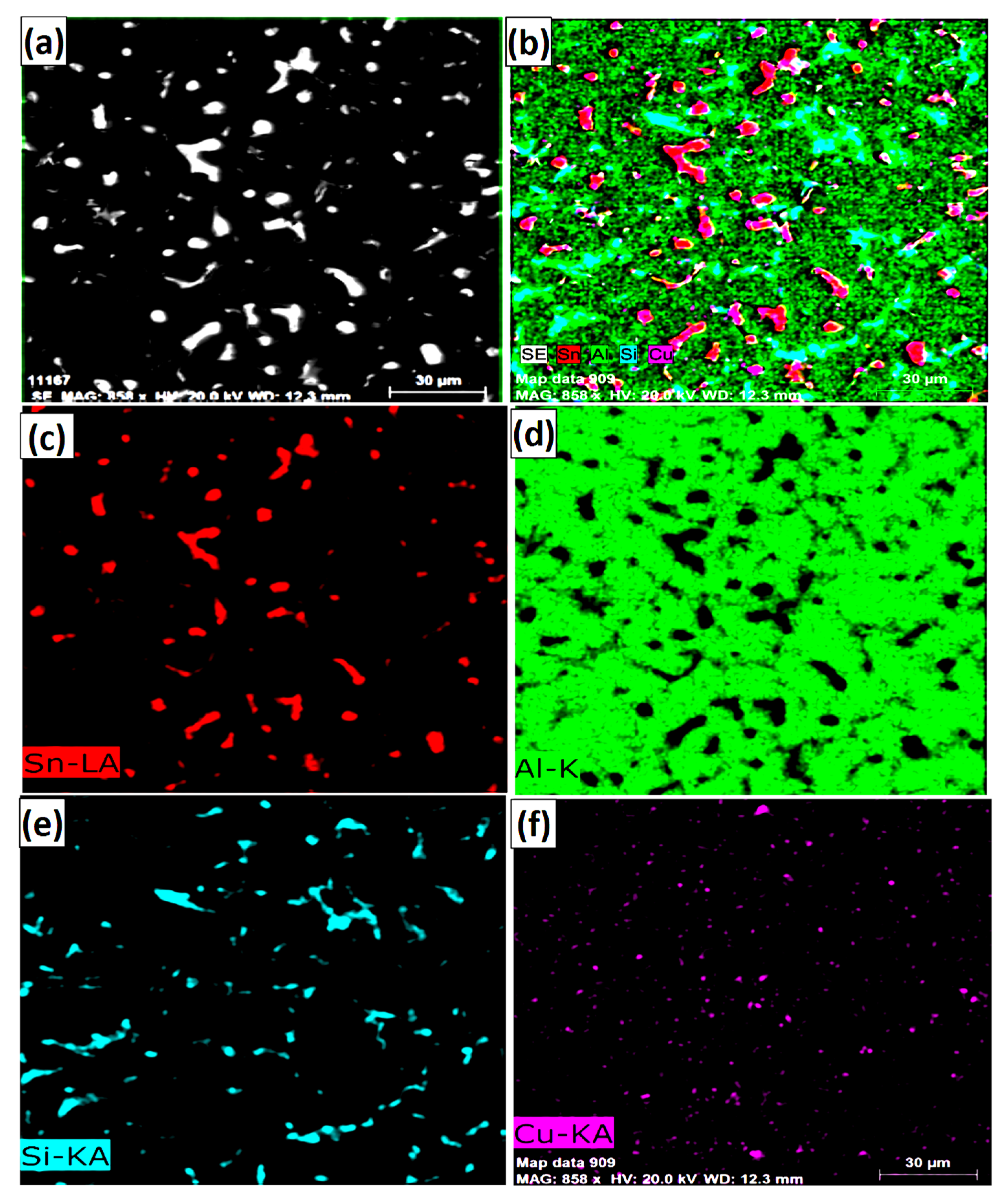

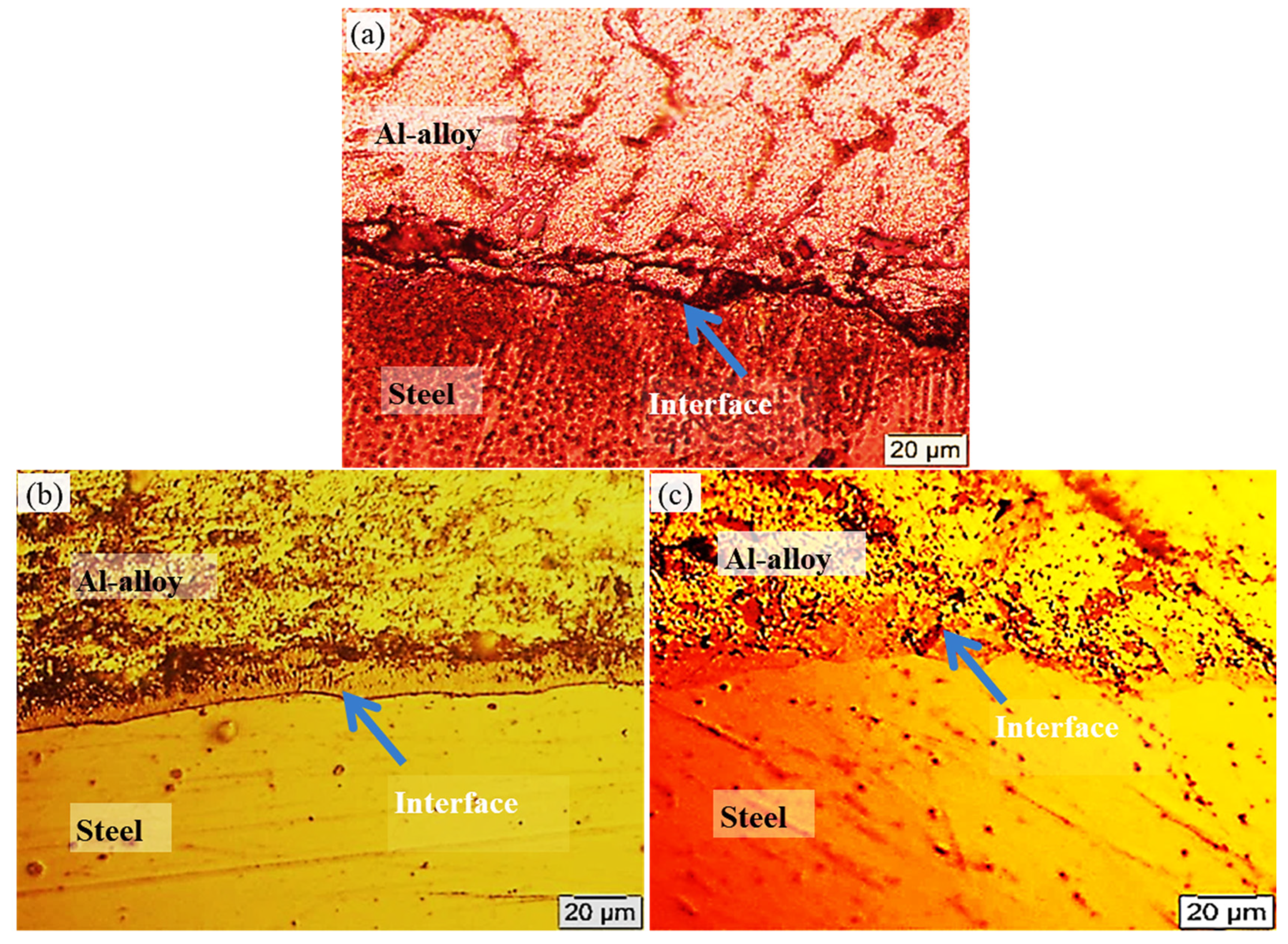

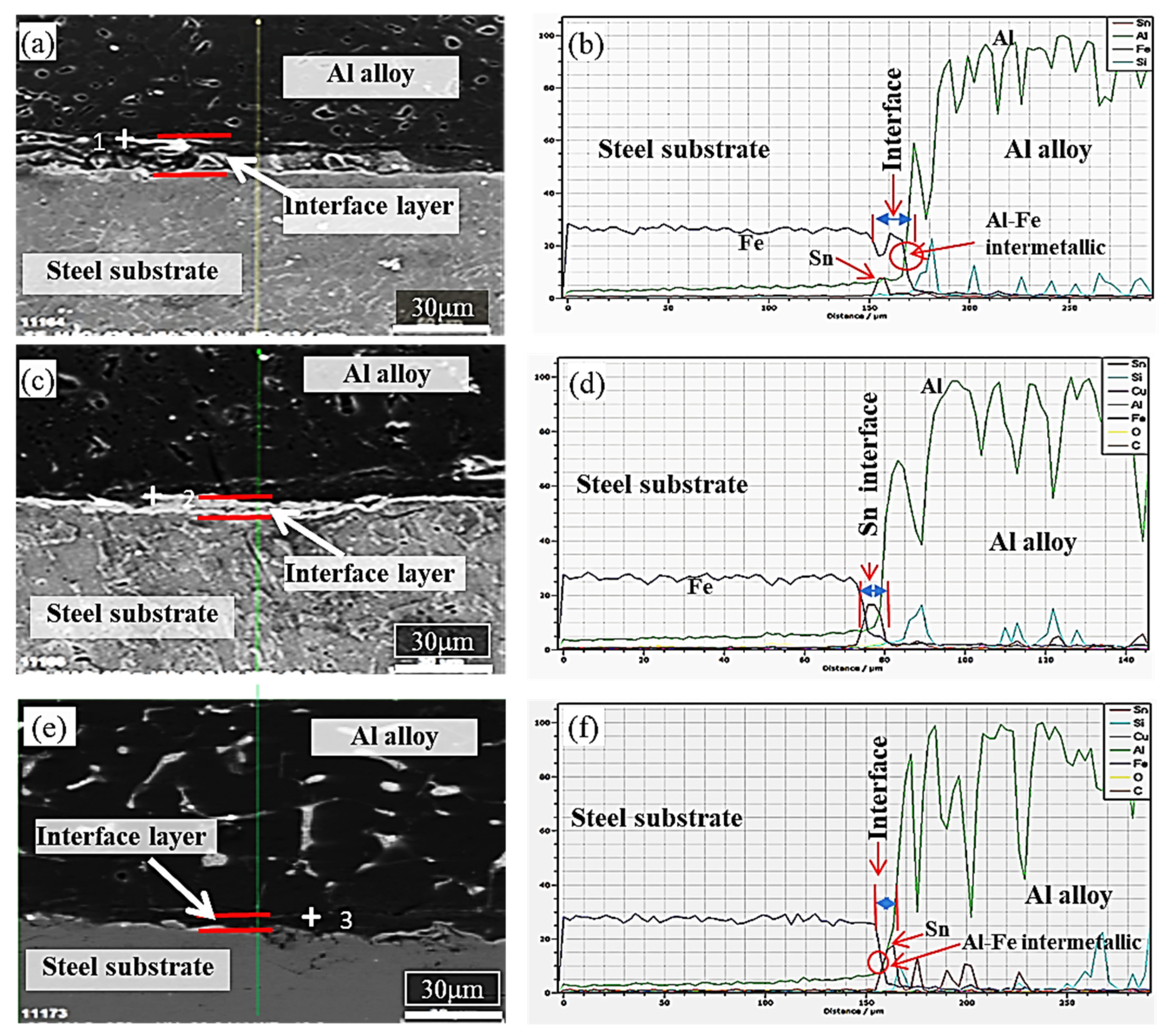

3. Results

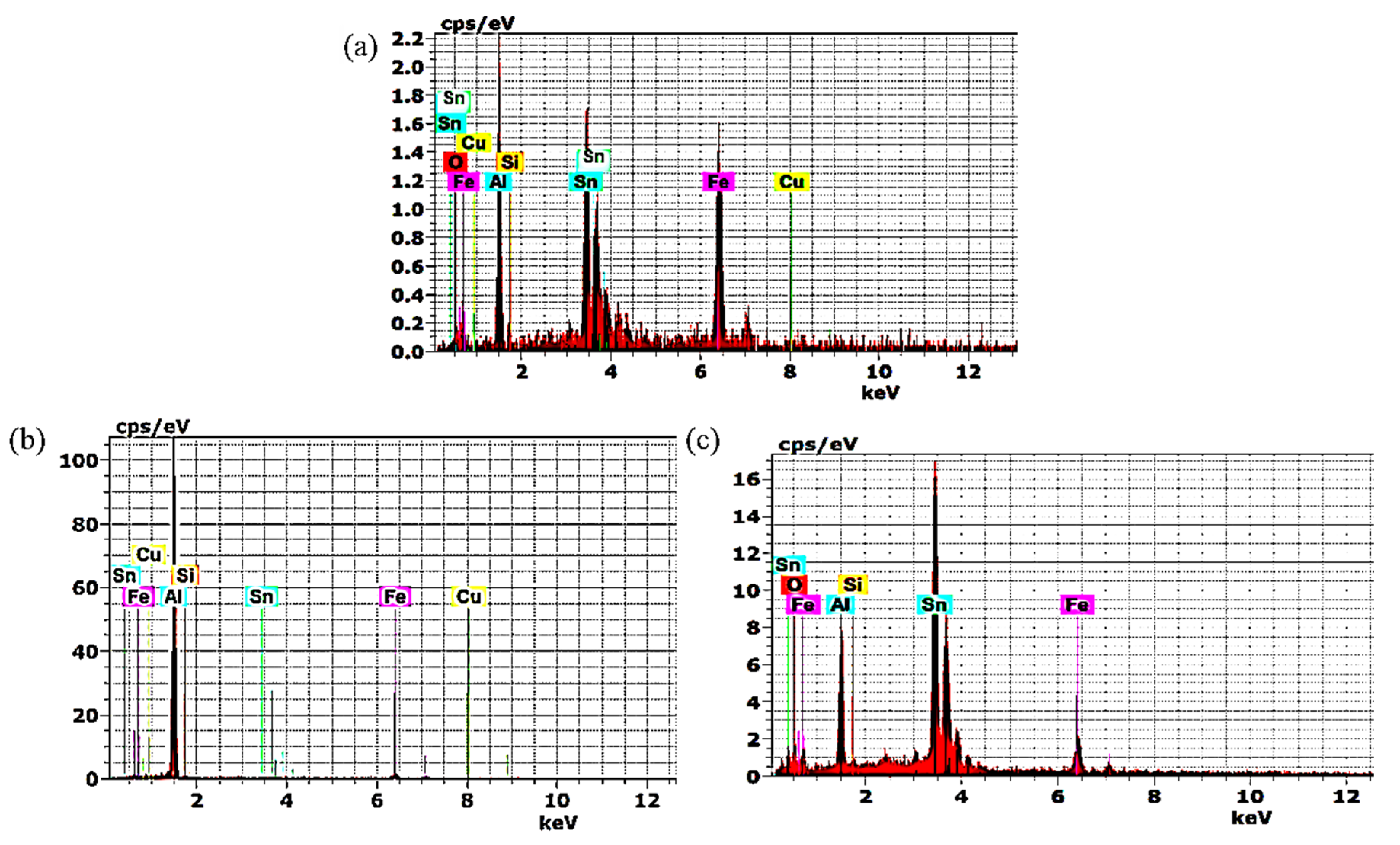

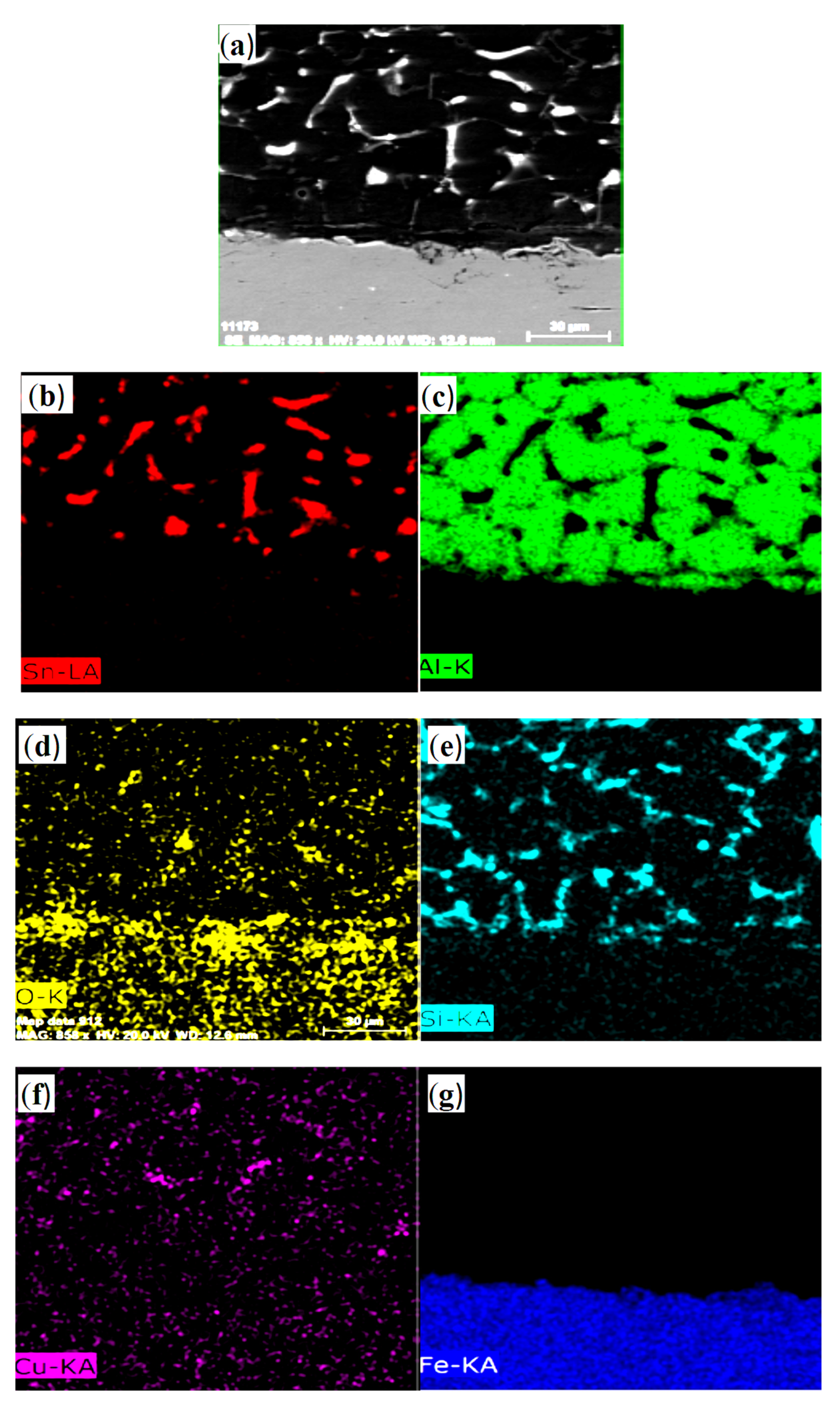

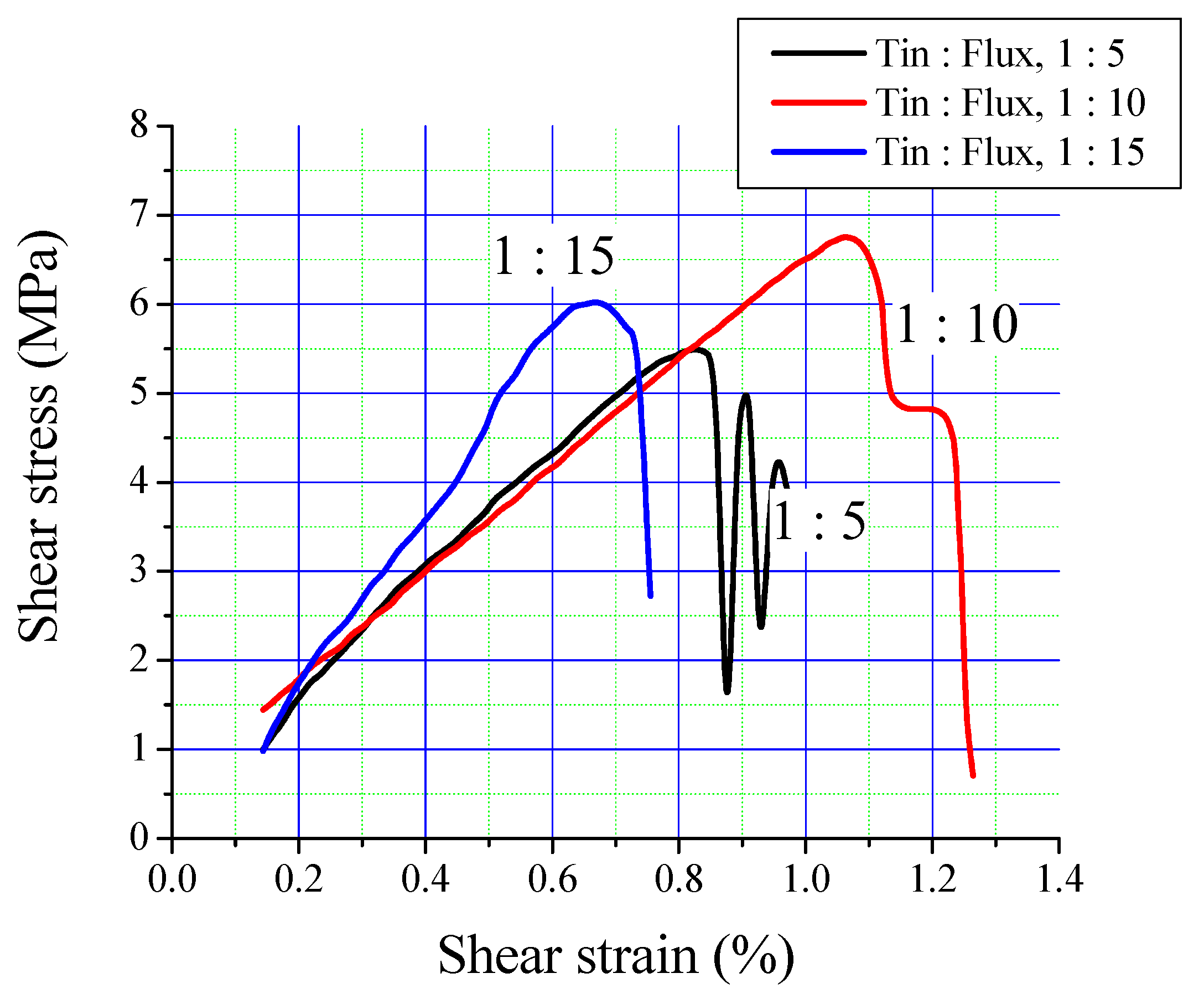

3.1. Effect of Sn-to-Flux Percentage on Structure and Properties of Bimetallic Interface

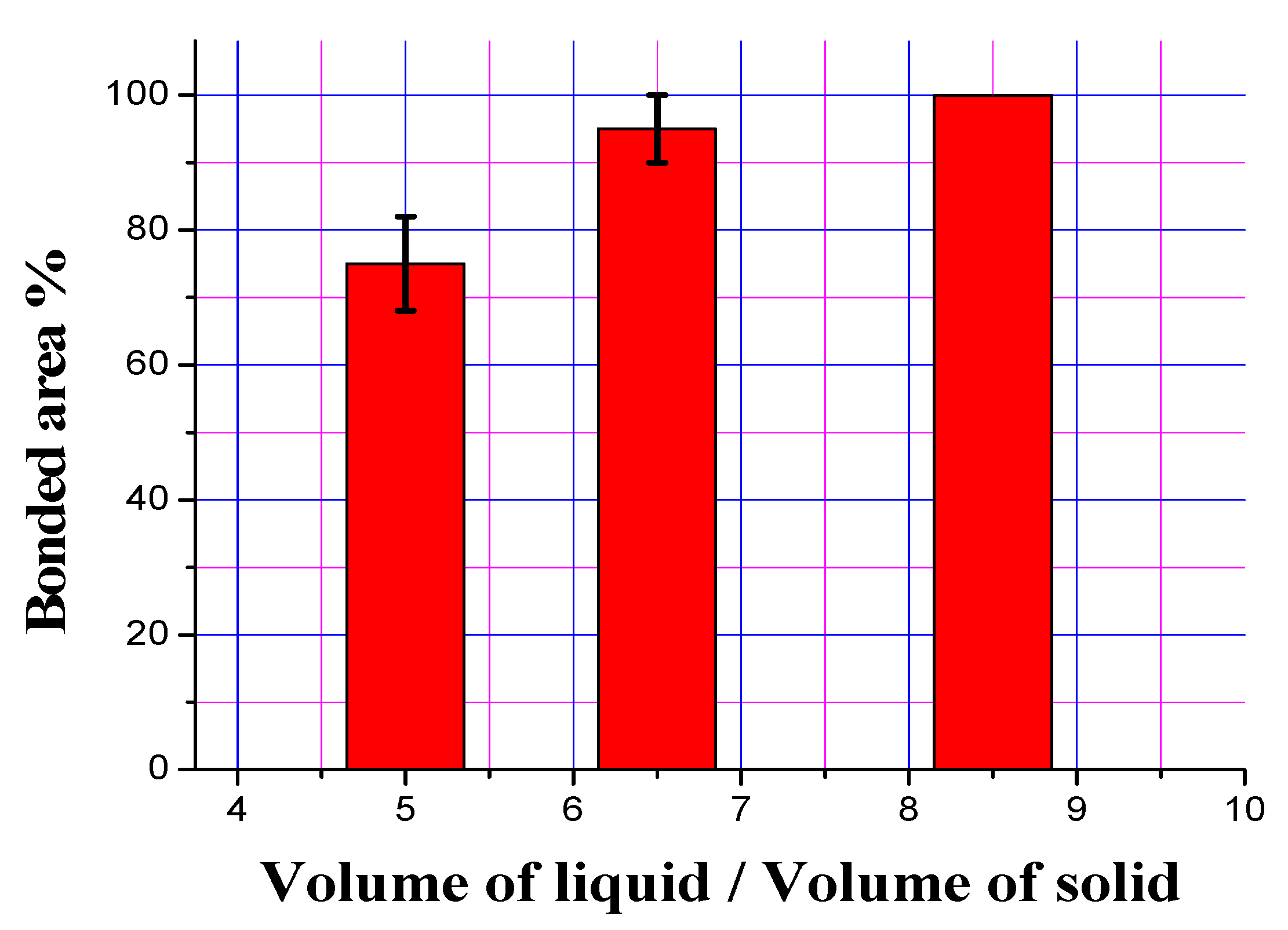

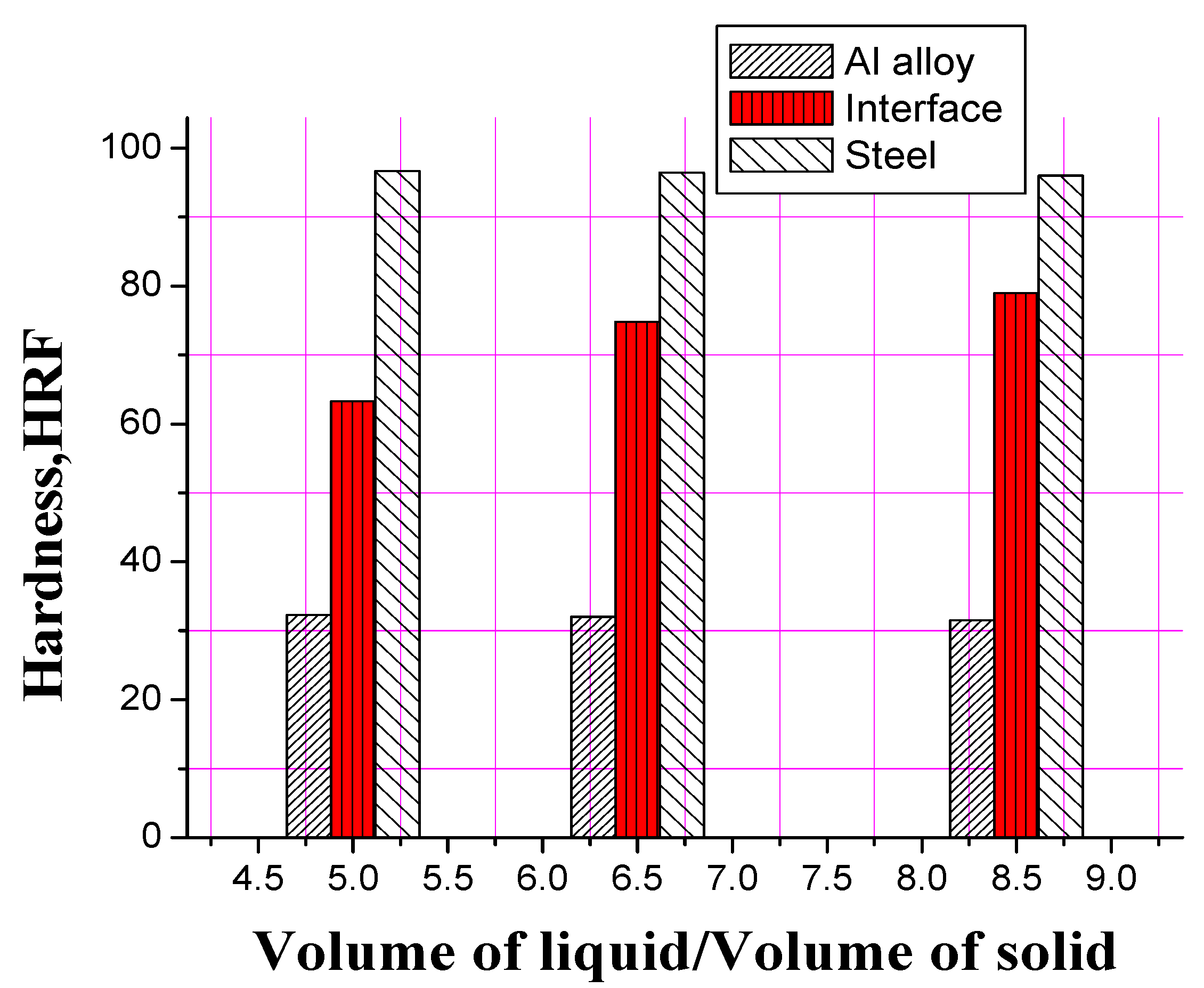

3.2. Effect of Volume Ratio of Liquid-to-Solid on the Interfacial Bonded Area and Hardness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Simsir, M.; Kumruoglu, L.C.; Ozer, A. An investigation into stainless-steel/structural-alloy-steel bimetal produced by shell mould casting. Mater. Des. 2009, 30, 264–270. [Google Scholar] [CrossRef]

- Paramsothy, M.; Srikanth, N.; Gupta, M. Solidification processed Mg/Al bimetal macrocomposite: Microstructure and mechanical properties. J. Alloy. Compd. 2008, 461, 200–208. [Google Scholar] [CrossRef]

- Kurt, B.; Calik, A. Interface structure of diffusion bonded duplex stainless steel and medium carbon steel couple. Mater. Charact. 2009, 60, 1035–1040. [Google Scholar] [CrossRef]

- Xiong, B.; Cai, C.; Lu, B. Effect of volume ratio of liquid to solid on the interfacial microstructure and mechanical properties of high chromium cast iron and medium carbon steel bimetal. J. Alloy. Compd. 2011, 509, 6700–6704. [Google Scholar] [CrossRef]

- Aleshin, N.P.; Kobernik, N.V.; Mikheev, R.S.; Vaganov, V.E.; Reshetnyak, V.V.; Aborkin, A.V. Plasma–Powder Application of Antifrictional Babbitt Coatings Modified by Carbon Nanotubes. Russ. Eng. Res. 2016, 36, 46–52. [Google Scholar] [CrossRef]

- Fathy, N.; Ramadan, M. Influence of volume ratio of liquid to solid and low pouring temperature on interface structure of cast Babbitt-steel bimetal composite. AIP Conf. Proc. 2018, 1966, 020028. [Google Scholar]

- Belov, N.A.; Akopyan, T.K.; Gershman, I.; Stolyarova, O.O.; Yakovleva, A.O. Effect of Si and Cu additions on the phase composition, microstructure and properties of Al-Sn alloys. J. Alloy. Compd. 2017, 695, 2730–2739. [Google Scholar] [CrossRef]

- Diouf, P.; Jones, A. Investigation of Bond Strength in Centrifugal Lining of Babbitt on Cast Iron. Metall. Mater. Trans. A 2010, 41, 603–609. [Google Scholar] [CrossRef]

- Ramadan, M.; Ayadi, B.; Rajhi, W.; Alghamdi, A.S. Influence of Tinning Material on Interfacial Microstructures and Mechanical Properties of Al12Sn4Si1Cu/Carbon Steel Bimetallic Castings for Bearing Applications. Key Eng. Mater. 2020, 835, 108–114. [Google Scholar] [CrossRef]

- Soderhjelm, C. Multi-Material Metal Casting: Metallurgically Bonding Aluminum to Ferrous Inserts. Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, April 2017. [Google Scholar]

- Mola, R.; Bucki, T.; Dzik, M.G. The Effect of a Zinc Interlayer on the Microstructure and mechanical Properties of a Magnesium Alloy (AZ31)–Aluminum Alloy (6060) Joint Produced by Liquid–Solid Compound Casting. JOM 2019, 71, 2078–2086. [Google Scholar] [CrossRef]

- Gawronski, J.; Szajnar, J.; Wróbel, P. Study on theoretical bases of receiving composite alloy layers on surface of cast steel castings. J. Mater. Process. Technol. 2004, 157, 679–682. [Google Scholar] [CrossRef]

- Cholewa, M.; Wróbel, T.; Tenerowicz, S. Bimetallic layer castings. J. Achiev. Mater. Manuf. Eng. 2010, 43, 385–391. [Google Scholar]

- Wrobel, T. Characterization of Bimetallic Castings with an Austenitic Working Surface Layer and an Unalloyed Cast Steel Base. J. Mater. Eng. Perform. 2014, 23, 1711–1717. [Google Scholar] [CrossRef]

- Liaw, P.K.; Gungor, M.N.; Logsdon, W.A.; Ijiri, Y.; Taszarek, B.J.; Fröhlich, S. Effect of Phase Morphologies on the Mechanical Properties of Babbitt-Bronze Composite Interfaces. Metall. Trans. A 1990, 21, 529–538. [Google Scholar] [CrossRef]

- Ramadan, M.; Alghamdi, A.S.; Subhani, T.; Halim, K.S.A. Fabrication and Characterization of Sn-Based Babbitt Alloy Nanocomposite Reinforced with Al2O3 Nanoparticles/Carbon Steel Bimetallic Material. Materials 2020, 13, 2759. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.; Kim, T.; Lim, K.; Cho, H.; Yang, D.; Jeong, C.; Yi, S. Effects of steel type and sandblasting pretreatment on the solid-liquid compound casting characteristics of zinc-coated steel/aluminum bimetals. J. Alloy. Compd. 2020, 778, 170–185. [Google Scholar] [CrossRef]

- Mwanza, M.C.; Joyce, M.R.; Lee, K.K.; Syngellakis, S.; Reed, P.A.S. Microstructural characterisation of fatigue crack initiation in Al-based plain bearing alloys. Int. J. Fatigue 2003, 25, 1135–1145. [Google Scholar] [CrossRef]

- Jiang, W.; Fana, Z.; Li, C. Improved steel/aluminum bonding in bimetallic castings by a compound casting process. J. Mater. Process. Technol. 2015, 226, 25–31. [Google Scholar] [CrossRef]

- Jiang, W.; Fan, Z.; Li, G.; Liu, X.; Liu, F. Effects of hot dipping galvanizing and aluminizing on interfacial microstructures and mechanical properties of aluminum/iron bimetallic composites. J. Alloy. Compd. 2016, 25, 742–751. [Google Scholar] [CrossRef]

- Raja, V.; Kavitha, M.; Chokkalingam, B.; Ashraya, T.S. Effect of Interlayers on Mechanical Properties of Aluminium Casting over Stainless Steel Pipe for Heat Exchanger Applications. Trans. Indian Inst. Met. 2020, 73, 1555–1560. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, M.; Bian, X.; Liu, M.; Li, J. An Al–7Si alloy/cast iron bimetallic composite with super-high shear strength. J. Mater. Res. Technol. 2019, 8, 3126–3136. [Google Scholar] [CrossRef]

- Afolalu, S.A.; Akinlabi, S.A.; Ongbali, S.O.; Abioye, A.A. Investigation of morphology characterization andmechanical properties of nano-flux (MnO) powder for TIG welding. Int. J. Mech. Prod. Eng. Res. Dev. 2019, 9, 887–898. [Google Scholar]

- Laurent, S.; Forge, D.; Port, M.; Roch, A.; Obic, C.; Vander, E.L. Magnetic iron oxide nanoparticles: Synthesis, stabilization, vectorization, physicochemical characterizations, andbiological applications. Chem. Rev. 2010, 108, 2064–2110. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.; Yu, J.; Kang, S.K.; Shih, D.-Y. Oxidation Study of Pure Tin and Its Alloys via Electrochemical Reduction Analysis. J. Electron. Mater. 2005, 34, 635–642. [Google Scholar] [CrossRef]

- Liu, Y.H.; Liu, H.F.; Yu, S.R.; Guo, G.C. Special Cast. Nonferr. Alloys 2001, 2, 17–19. (In Chinese) [Google Scholar]

| C | Si | Mn | Cu | Sn | Cr | Ni | Fe | Al | |

|---|---|---|---|---|---|---|---|---|---|

| Al-based bearing alloy | - | 4 | - | 1 | 12 | - | - | - | Bal. |

| Steel substrate | 0.14 | 0.30 | 0.48 | 0.20 | - | 0.14 | 0.09 | Bal. | - |

| (Equivalent standard of steel substrate, Japanese Industrial Standards, JIS, G4051) | 0.130.18 | 0.15 0.35 | 0.30 0.60 | ≤0.3 | - | ≤0.2 | ≤0.2 | Bal. | - |

| Number | Element Compositions (at.%) | Inference Adjacent to Al Bearing Alloy, Al, Fe-Al (IMC) | |||||

|---|---|---|---|---|---|---|---|

| Al | Fe | Sn | Si | O | Cu | ||

| 1 | 49.6 | 22.94 | 14.71 | 1.16 | 10.68 | 0.91 | Fe2Al5 |

| 2 | 94.56 | 3.71 | 0.29 | 1.31 | 0 | 0.13 | Al |

| 3 | 30.32 | 10.44 | 33.02 | 0.92 | 25.31 | 0 | FeAl3 |

| Interlayer Material | Shear Stress, MPa | ||

|---|---|---|---|

| Deposition Process | |||

| Hot Dipping | Electroplating | Direct Tinning | |

| Brass | - | 17.5 [21] | - |

| Al-7.2 wt.% Si | 8.5 [22] | - | - |

| Pure Zn | 16.0 [22] | 20.0 [17] | - |

| Pure Sn | - | - | 6.75 [This work] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadan, M.; Alghamdi, A.S.; Hafez, K.M.; Subhani, T.; Abdel Halim, K.S. Development and Optimization of Tin/Flux Mixture for Direct Tinning and Interfacial Bonding in Aluminum/Steel Bimetallic Compound Casting. Materials 2020, 13, 5642. https://doi.org/10.3390/ma13245642

Ramadan M, Alghamdi AS, Hafez KM, Subhani T, Abdel Halim KS. Development and Optimization of Tin/Flux Mixture for Direct Tinning and Interfacial Bonding in Aluminum/Steel Bimetallic Compound Casting. Materials. 2020; 13(24):5642. https://doi.org/10.3390/ma13245642

Chicago/Turabian StyleRamadan, Mohamed, Abdulaziz S. Alghamdi, K. M. Hafez, Tayyab Subhani, and K. S. Abdel Halim. 2020. "Development and Optimization of Tin/Flux Mixture for Direct Tinning and Interfacial Bonding in Aluminum/Steel Bimetallic Compound Casting" Materials 13, no. 24: 5642. https://doi.org/10.3390/ma13245642

APA StyleRamadan, M., Alghamdi, A. S., Hafez, K. M., Subhani, T., & Abdel Halim, K. S. (2020). Development and Optimization of Tin/Flux Mixture for Direct Tinning and Interfacial Bonding in Aluminum/Steel Bimetallic Compound Casting. Materials, 13(24), 5642. https://doi.org/10.3390/ma13245642