Cellulose Modification for Improved Compatibility with the Polymer Matrix: Mechanical Characterization of the Composite Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Specimens

2.1.1. Materials

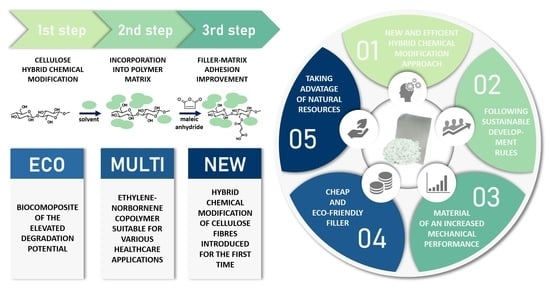

2.1.2. Cellulose Hybrid Chemical Modification

2.1.3. Polymer Composite Sample Preparation

2.2. Polymer Composite Sample Characterization

2.2.1. Static Mechanical Analysis

2.2.2. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

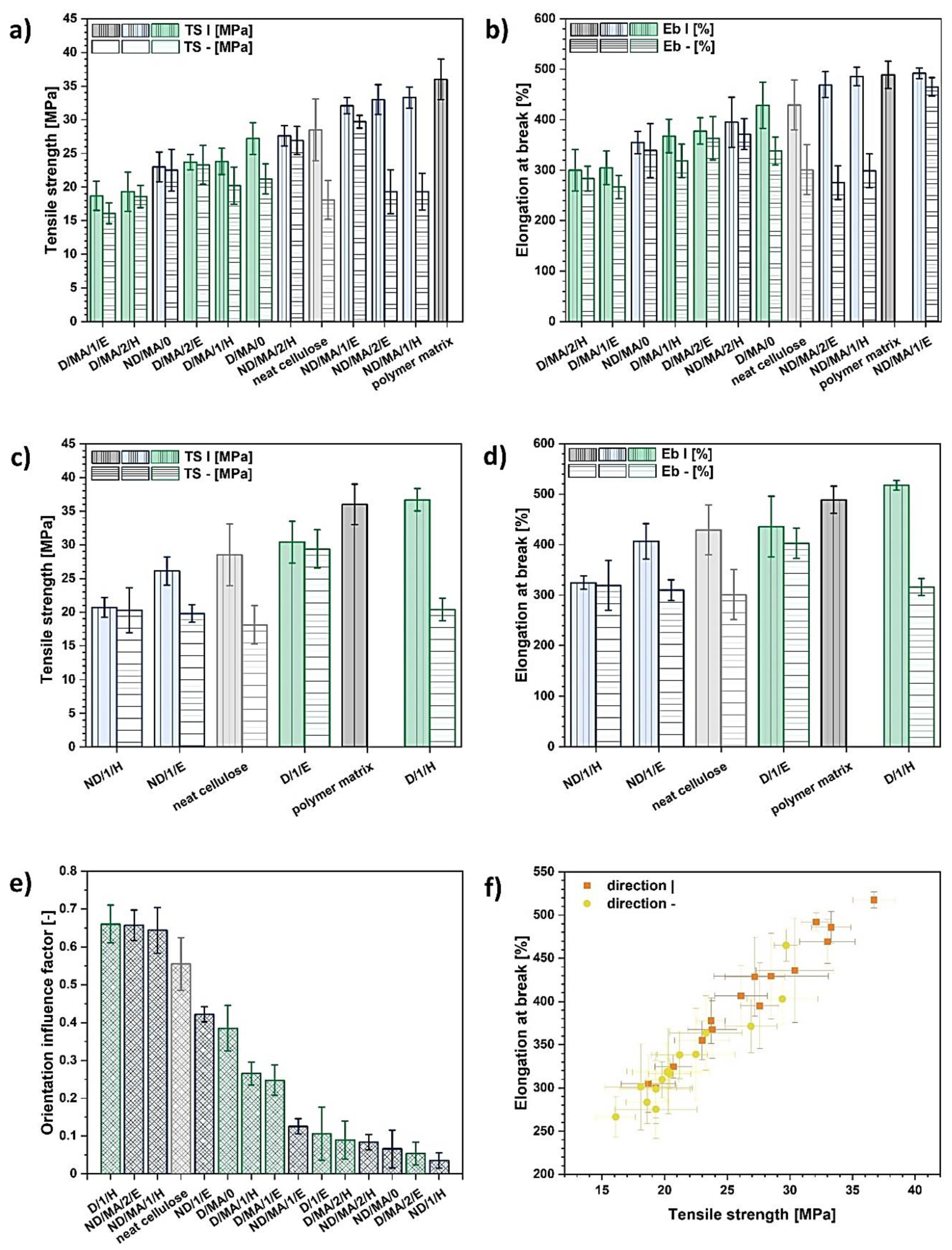

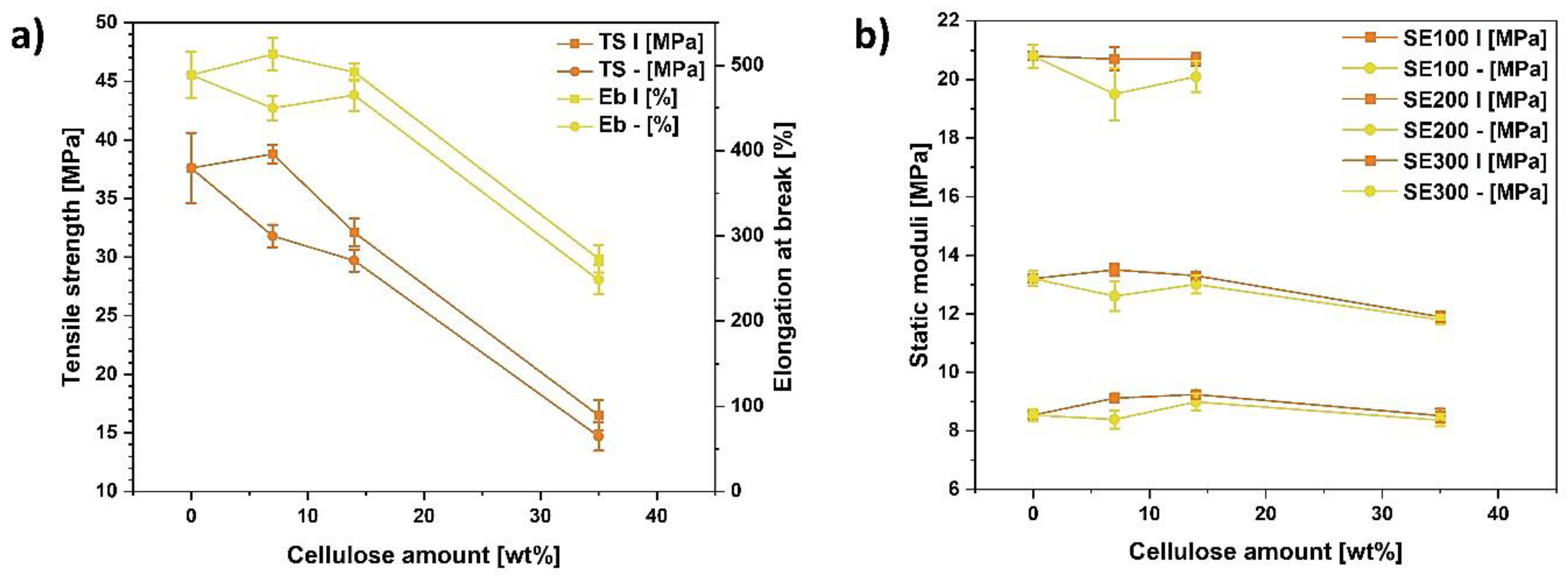

3.1. Static Mechanical Investigation

3.2. Dynamic Mechanical Analysis

3.3. Comparison of the Obtained Results with Literature

3.3.1. Tensile Properties

3.3.2. Dynamic Mechanical Analysis

4. Conclusions

- the highest performance was noticed in the case of the sample filled with ND/MA/1/E cellulose; here, undried cellulose was modified with MA after a solvent exchange with ethanol and the biopolymer was not dried before the carried out treatment;

- reinforcement of ethylene–norbornene copolymer with the employment of modified cellulose fibers has been successfully achieved—up to TS = (38.8 ± 0.8) MPa and Eb = (510 ± 20)%.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kemp, R.; Loorbach, D.; Rotmans, J. Transition management as a model for managing processes of co-evolution towards sustainable development. Int. J. Sustain. Dev. World Ecol. 2007, 14, 78–91. [Google Scholar] [CrossRef]

- Datta, J.; Kopczyńska, P. From polymer waste to potential main industrial products: Actual state of recycling and recovering. Crit. Rev. Environ. Sci. Technol. 2016, 46, 905–946. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, T.; Long, L.; Zhang, R.; Ding, S. Efficient enzymatic degradation of poly (ɛ-caprolactone) by an engineered bifunctional lipase-cutinase. Polym. Degrad. Stab. 2019, 160, 120–125. [Google Scholar] [CrossRef]

- Ivar Do Sul, J.A.; Costa, M.F. The present and future of microplastic pollution in the marine environment. Environ. Pollut. 2014, 185, 352–364. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Strakowska, A.; Strzelec, K.; Kairyte, A.; Kremensas, A. Bio-based polyurethane composite foams with improved mechanical, thermal, and antibacterial properties. Materials 2020, 13, 1108. [Google Scholar] [CrossRef]

- Platnieks, O.; Gaidukovs, S.; Barkane, A.; Sereda, A.; Gaidukova, G.; Grase, L.; Thakur, V.K.; Filipova, I.; Fridrihsone, V.; Skute, M.; et al. Bio-Based Poly(butylene succinate)/Microcrystalline Cellulose/Nanofibrillated Cellulose-Based Sustainable Polymer Composites: Thermo-Mechanical and Biodegradation Studies. Polymers 2020, 12, 1472. [Google Scholar] [CrossRef]

- Morrissey, A.J.; Browne, J. Waste management models and their application to sustainable waste management. Waste Manag. 2004, 24, 297–308. [Google Scholar] [CrossRef]

- Bing, X.; Bloemhof, J.M.; Ramos, T.R.P.; Barbosa-Povoa, A.P.; Wong, C.Y.; van der Vorst, J.G.A.J. Research challenges in municipal solid waste logistics management. Waste Manag. 2016, 48, 584–592. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Barczewski, M.; Sałasińska, K.; Szulc, J. Application of sunflower husk, hazelnut shell and walnut shell as waste agricultural fillers for epoxy-based composites: A study into mechanical behavior related to structural and rheological properties. Polym. Test. 2019, 75, 1–11. [Google Scholar] [CrossRef]

- Zhong, Z.; Qin, J.; Ma, J. Cellulose acetate/hydroxyapatite/chitosan coatings for improved corrosion resistance and bioactivity. Mater. Sci. Eng. C 2015, 49, 251–255. [Google Scholar] [CrossRef] [PubMed]

- Yunus Basha, R.; Sampath, S.K.; Doble, M. Design of biocomposite materials for bone tissue regeneration. Mater. Sci. Eng. C 2015, 57, 452–463. [Google Scholar] [CrossRef] [PubMed]

- Ates, B.; Koytepe, S.; Ulu, A.; Gurses, C.; Thakur, V.K. Chemistry, Structures, and Advanced Applications of Nanocomposites from Biorenewable Resources. Chem. Rev. 2020, 120, 9304–9362. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Strąkowska, A.; Kairytė, A. The impact of hemp shives impregnated with selected plant oils on mechanical, thermal, and insulating properties of polyurethane composite foams. Materials 2020, 13, 4709. [Google Scholar] [CrossRef]

- Bartos, A.; Anggono, J.; Farkas, Á.E.; Kun, D.; Soetaredjo, F.E.; Móczó, J.; Antoni; Purwaningsih, H.; Pukánszky, B. Alkali treatment of lignocellulosic fibers extracted from sugarcane bagasse: Composition, structure, properties. Polym. Test. 2020, 88, 106549. [Google Scholar] [CrossRef]

- Yang, Z.; Asoh, T.A.; Uyama, H. Cationic functionalization of cellulose monoliths using a urea-choline based deep eutectic solvent and their applications. Polym. Degrad. Stab. 2019, 160, 126–135. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A. Rigid Polyurethane Foams Based on Bio-Polyol and Additionally Reinforced with Silanized and Acetylated Walnut Shells for the Synthesis of Environmentally Friendly Insulating Materials. Materials 2020, 13, 3245. [Google Scholar] [CrossRef]

- Lisuzzo, L.; Cavallaro, G.; Milioto, S.; Lazzara, G. Layered composite based on halloysite and natural polymers: A carrier for the pH controlled release of drugs. New J. Chem. 2019, 43, 10887–10893. [Google Scholar] [CrossRef]

- Bertolino, V.; Cavallaro, G.; Milioto, S.; Lazzara, G. Polysaccharides/Halloysite nanotubes for smart bionanocomposite materials. Carbohydr. Polym. 2020, 245, 116502. [Google Scholar] [CrossRef]

- Kairyte, A.; Kremensas, A.; Vaitkus, S.; Członka, S.; Strakowska, A. Fire suppression and thermal behavior of biobased rigid polyurethane foam filled with biomass incinerationwaste ash. Polymers 2020, 12, 683. [Google Scholar] [CrossRef]

- Silva, R.M.; Pereira, F.V.; Mota, F.A.P.; Watanabe, E.; Soares, S.M.C.S.; Santos, M.H. Dental glass ionomer cement reinforced by cellulose microfibers and cellulose nanocrystals. Mater. Sci. Eng. C 2016, 58, 389–395. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Qiu, L.; Cui, J.; Wei, Q. Bacterial cellulose and bacterial cellulose-vaccarin membranes for wound healing. Mater. Sci. Eng. C 2016, 59, 303–309. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.L.; Jung, G.Y.; Yoon, J.H.; Han, J.S.; Park, Y.J.; Kim, D.G.; Zhang, M.; Kim, D.J. Preparation and characterization of nano-sized hydroxyapatite/alginate/chitosan composite scaffolds for bone tissue engineering. Mater. Sci. Eng. C 2015, 54, 20–25. [Google Scholar] [CrossRef] [PubMed]

- Nagy, S.; Fekete, E.; Móczó, J.; Koczka, K.; Csiszár, E. Heat-induced changes in cellulose nanocrystal/amino-aldehyde biocomposite systems. J. Therm. Anal. Calorim. 2020, 142, 2371–2383. [Google Scholar] [CrossRef]

- Thakur, M.K.; Gupta, R.K.; Thakur, V.K. Surface modification of cellulose using silane coupling agent. Carbohydr. Polym. 2014, 111, 849–855. [Google Scholar] [CrossRef]

- Roy, D.; Semsarilar, M.; Guthrie, J.T.; Perrier, S. Cellulose modification by polymer grafting: A review. Chem. Soc. Rev. 2009, 38, 2046–2064. [Google Scholar] [CrossRef]

- Pasquini, D.; de Morais Teixeira, E.; da Silva Curvelo, A.A.; Belgacem, M.N.; Dufresne, A. Surface esterification of cellulose fibres: Processing and characterisation of low-density polyethylene/cellulose fibres composites. Compos. Sci. Technol. 2008, 68, 193–201. [Google Scholar] [CrossRef]

- Colom, X.; Carrasco, F.; Pagès, P.; Canavate, J. Effects of different treatments on the interface of HDPE/lignocellulosic fiber composites. Compos. Sci. Technol. 2003, 63, 161–169. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Shi, J.; Lu, L.; Guo, W.; Sun, Y.; Cao, Y. An environment-friendly thermal insulation material from cellulose and plasma modification. J. Appl. Polym. Sci. 2013, 130, 3652–3658. [Google Scholar] [CrossRef]

- Sdrobiş, A.; Kylian, O.; Biederman, H.; Vasile, C. Modification of cellulose/chitin mix fibers under different cold plasma conditions. Cellulose 2013, 20, 509–524. [Google Scholar] [CrossRef]

- Ragoubi, M.; Bienaimé, D.; Molina, S.; George, B.; Merlin, A. Impact of corona treated hemp fibres onto mechanical properties of polypropylene composites made thereof. Ind. Crops Prod. 2010, 31, 344–349. [Google Scholar] [CrossRef]

- Jandura, P.; Riedl, B.; Kokta, B.V. Thermal degradation behavior of cellulose fibers partially esterified with some long chain organic acids. Polym. Degrad. Stab. 2000, 70, 387–394. [Google Scholar] [CrossRef]

- Ouajai, S.; Shanks, R.A. Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym. Degrad. Stab. 2005, 89, 327–335. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Hu, W.; Chen, S.; Xu, Q.; Wang, H. Solvent-free acetylation of bacterial cellulose under moderate conditions. Carbohydr. Polym. 2011, 83, 1575–1581. [Google Scholar] [CrossRef]

- Haig Zeronian, S.; Kawabata, H.; Alger, K.W. Factors Affecting the Tensile Properties of Nonmercerized and Mercerized Cotton Fibers. Text. Res. J. 1990, 60, 179–183. [Google Scholar] [CrossRef]

- Rueda, L.; Fernández d’Arlas, B.; Zhou, Q.; Berglund, L.A.; Corcuera, M.A.; Mondragon, I.; Eceiza, A. Isocyanate-rich cellulose nanocrystals and their selective insertion in elastomeric polyurethane. Compos. Sci. Technol. 2011, 71, 1953–1960. [Google Scholar] [CrossRef]

- Ma, K.; Xie, Z.; Jiang, Q.; Li, J.; Li, R.; Ren, X.; Huang, T.S.; Zhang, K.Q. Cytocompatible and regenerable antimicrobial cellulose modified by N-halamine triazine ring. J. Appl. Polym. Sci. 2014, 131, 2–7. [Google Scholar] [CrossRef]

- Achoundong, C.S.K.; Bhuwania, N.; Burgess, S.K.; Karvan, O.; Johnson, J.R.; Koros, W.J. Silane modification of cellulose acetate dense films as materials for acid gas removal. Macromolecules 2013, 46, 5584–5594. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Mathew, A.P.; Hussein, M.Z.B.; Oksman, K. Preparation of cellulose nanofibers with hydrophobic surface characteristics. Cellulose 2010, 17, 299–307. [Google Scholar] [CrossRef]

- Mandal, A.; Chakrabarty, D. Studies on the mechanical, thermal, morphological and barrier properties of nanocomposites based on poly(vinyl alcohol) and nanocellulose from sugarcane bagasse. J. Ind. Eng. Chem. 2014, 20, 462–473. [Google Scholar] [CrossRef]

- Carlmark, A.; Larsson, E.; Malmström, E. Grafting of cellulose by ring-opening polymerisation—A review. Eur. Polym. J. 2012, 48, 1646–1659. [Google Scholar] [CrossRef]

- Thakur, V.K.; Grewell, D.; Thunga, M.; Kessler, M.R. Novel composites from eco-friendly soy flour/SBS triblock copolymer. Macromol. Mater. Eng. 2014, 299, 953–958. [Google Scholar] [CrossRef]

- Zoppe, J.O.; Habibi, Y.; Rojas, O.J.; Venditti, R.A.; Johansson, L.S.; Efimenko, K.; Österberg, M.; Laine, J. Poly(N-isopropylacrylamide) brushes grafted from cellulose nanocrystals via surface-initiated single-electron transfer living radical polymerization. Biomacromolecules 2010, 11, 2683–2691. [Google Scholar] [CrossRef]

- Littunen, K.; Hippi, U.; Johansson, L.S.; Österberg, M.; Tammelin, T.; Laine, J.; Seppälä, J. Free radical graft copolymerization of nanofibrillated cellulose with acrylic monomers. Carbohydr. Polym. 2011, 84, 1039–1047. [Google Scholar] [CrossRef]

- Yeh, J.T.; Tsai, C.C.; Wang, C.K.; Shao, J.W.; Xiao, M.Z.; Chen, S.C. Ultradrawing novel ultra-high molecular weight polyethylene fibers filled with bacterial cellulose nanofibers. Carbohydr. Polym. 2014, 101, 1–10. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Gu, C.; Liu, J.; Liu, Y.; Li, M.; Lu, Y. Enhancement of the mechanical properties of basalt fiber-wood-plastic composites via maleic anhydride grafted high-density polyethylene (MAPE) addition. Materials 2013, 6, 2483–2496. [Google Scholar] [CrossRef]

- Li, J.; Song, Z.; Li, D.; Shang, S.; Guo, Y. Cotton cellulose nanofiber-reinforced high density polyethylene composites prepared with two different pretreatment methods. Ind. Crops Prod. 2014, 59, 318–328. [Google Scholar] [CrossRef]

- Sato, A.; Kabusaki, D.; Okumura, H.; Nakatani, T.; Nakatsubo, F.; Yano, H. Surface modification of cellulose nanofibers with alkenyl succinic anhydride for high-density polyethylene reinforcement. Compos. Part A Appl. Sci. Manuf. 2016, 83, 72–79. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A.; Wolski, K.; Zaborski, M. Universal approach of cellulose fibres chemical modification result analysis via commonly used techniques. Polym. Bull. 2018. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A.; Wolski, K. Innovative cellulose fibres reinforced ethylene-norbornene copolymer composites of an increased degradation potential. Polym. Degrad. Stab. 2019, 159, 174–183. [Google Scholar] [CrossRef]

- Zhou, L.; He, H.; Li, M.C.; Huang, S.; Mei, C.; Wu, Q. Enhancing mechanical properties of poly(lactic acid) through its in-situ crosslinking with maleic anhydride-modified cellulose nanocrystals from cottonseed hulls. Ind. Crops Prod. 2018, 112, 449–459. [Google Scholar] [CrossRef]

- Stenstad, P.; Andresen, M.; Tanem, B.S.; Stenius, P. Chemical surface modifications of microfibrillated cellulose. Cellulose 2008, 15, 35–45. [Google Scholar] [CrossRef]

- Teacə, C.A.; Bodîrləu, R.; Spiridon, I. Maleic anhydride treatment of softwood—Effect on wood structure and properties. Cellul. Chem. Technol. 2014, 48, 863–868. [Google Scholar]

- Cichosz, S.; Masek, A. Cellulose structure and property changes indicated via wetting-drying cycles. Polym. Degrad. Stab. 2019, 167, 33–43. [Google Scholar] [CrossRef]

- Ishii, D.; Tatsumi, D.; Matsumoto, T. Effect of solvent exchange on the solid structure and dissolution behavior of cellulose. Biomacromolecules 2003, 4, 1238–1243. [Google Scholar] [CrossRef]

- Laine, J.; Lindstroem, T.; Brernberg, C.; Glad-Nordrnark, G. Studies on topochemical modification of cellulosic fibres. Part 4: Toposelectivity of carboxymethylation and its effects on the swelling of fibres. Nord. Pulp Pap. Res. J. 2003, 18, 316–324. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, X.; Zhu, P.; Jiang, Z. N-halamine Antibacterial Cellulose Fabrics Functionalized with Copoly(acrylamide-maleic anhydride). Fibers Polym. 2019, 20, 906–912. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. Drying of the Natural Fibers as A Solvent-Free Way to Improve the Cellulose-Filled Polymer Composite Performance. Polymers 2020, 12, 484. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. Cellulose Fibers Hydrophobization via a Hybrid Chemical Modification. Polymers 2019, 11, 1174. [Google Scholar] [CrossRef] [PubMed]

- Cichosz, S.; Masek, A. Thermal Behavior of Green Cellulose-Filled Thermoplastic Elastomer Polymer Blends. Molecules 2020, 25, 1279. [Google Scholar] [CrossRef] [PubMed]

- Merabia, S.; Sotta, P.; Long, D. A Microscopic Model for the Reinforcement and the Nonlinear Behavior of Filled Elastomers and Thermoplastic Elastomers (Payne and Mullins Effects). Macromolecules 2008, 41, 8252–8266. [Google Scholar] [CrossRef]

- Jyoti, J.; Singh, B.P.; Arya, A.K.; Dhakate, S.R. Dynamic mechanical properties of multiwall carbon nanotube reinforced ABS composites and their correlation with entanglement density, adhesion, reinforcement and C factor. RSC Adv. 2016, 6, 3997–4006. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres—A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef]

- Malkapuram, R.; Kumar, V.; Singh Negi, Y. Recent development in natural fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2009, 28, 1169–1189. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Aht-Ong, D.; Atong, D.; Pechyen, C. Surface and mechanical properties of cellulose micro-fiber reinforced recycle polyethylene film. Mater. Sci. Forum 2011, 695, 469–472. [Google Scholar] [CrossRef]

- Tang, L.; Huang, B.; Yang, N.; Li, T.; Lu, Q.; Lin, W.; Chen, X. Organic solvent-free and efficient manufacture of functionalized cellulose nanocrystals via one-pot tandem reactions. Green Chem. 2013, 15, 2369–2373. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-González, A. A study of the mechanical properties of short natural-fiber reinforced composites. Compos. Part B Eng. 2005, 36, 597–608. [Google Scholar] [CrossRef]

- Nishino, T.; Hirao, K.; Kotera, M.; Nakamae, K.; Inagaki, H. Kenaf reinforced biodegradable composite. Compos. Sci. Technol. 2003, 63, 1281–1286. [Google Scholar] [CrossRef]

- Frone, A.N.; Berlioz, S.; Chailan, J.F.; Panaitescu, D.M.; Donescu, D. Cellulose fiber-reinforced polylactic acid. Polym. Compos. 2011, 32, 976–985. [Google Scholar] [CrossRef]

- Arrakhiz, F.Z.; El Achaby, M.; Kakou, A.C.; Vaudreuil, S.; Benmoussa, K.; Bouhfid, R.; Fassi-Fehri, O.; Qaiss, A. Mechanical properties of high density polyethylene reinforced with chemically modified coir fibers: Impact of chemical treatments. Mater. Des. 2012, 37, 379–383. [Google Scholar] [CrossRef]

- Vuoti, S.; Talja, R.; Johansson, L.S.; Heikkinen, H.; Tammelin, T. Solvent impact on esterification and film formation ability of nanofibrillated cellulose. Cellulose 2013, 20, 2359–2370. [Google Scholar] [CrossRef]

- Östlund, Å.; Idström, A.; Olsson, C.; Larsson, P.T.; Nordstierna, L. Modification of crystallinity and pore size distribution in coagulated cellulose films. Cellulose 2013, 20, 1657–1667. [Google Scholar] [CrossRef]

- Kontturi, E.; Vuorinen, T. Indirect evidence of supramolecular changes within cellulose microfibrils of chemical pulp fibers upon drying. Cellulose 2009, 16, 65–74. [Google Scholar] [CrossRef]

- Ruffini, G. Improvement in bonding of wood pulps by the presence of acidic groups. Sven. Papprstidn. 1966, 69, 72–76. [Google Scholar]

- Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement based composite systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Minor, J.L. Hornification—Its origin and meaning. Prog. Pap. Recycl. 1994, 3, 93–95. [Google Scholar]

- Amash, A.; Zugenmaier, P. Morphology and properties of isotropic and oriented samples of cellulose fibre-polypropylene composites. Polymer 2000, 41, 1589–1596. [Google Scholar] [CrossRef]

- Haoqun, H.; Tao, L.; Hui, H.; Demin, J.; Haiyan, Z. Effect of Interfacial Modifiers on Physical Properties and Flammability Properties of PE/Wood Composites. Polym. Polym. Compos. 2011, 19, 639–646. [Google Scholar] [CrossRef]

- Meesorn, W.; Shirole, A.; Vanhecke, D.; De Espinosa, L.M.; Weder, C. A Simple and Versatile Strategy to Improve the Mechanical Properties of Polymer Nanocomposites with Cellulose Nanocrystals. Macromolecules 2017, 50, 2364–2374. [Google Scholar] [CrossRef]

- Essabir, H.; Elkhaoulani, A.; Benmoussa, K.; Bouhfid, R.; Arrakhiz, F.Z.; Qaiss, A. Dynamic mechanical thermal behavior analysis of doum fibers reinforced polypropylene composites. Mater. Des. 2013, 51, 780–788. [Google Scholar] [CrossRef]

- Essabir, H.; Nekhlaoui, S.; Malha, M.; Bensalah, M.O.; Arrakhiz, F.Z.; Qaiss, A.; Bouhfid, R. Bio-composites based on polypropylene reinforced with Almond Shells particles: Mechanical and thermal properties. Mater. Des. 2013, 51, 225–230. [Google Scholar] [CrossRef]

- Saba, N.; Safwan, A.; Sanyang, M.L.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.Y.; Sain, M. Thermal and dynamic mechanical properties of cellulose nanofibers reinforced epoxy composites. Int. J. Biol. Macromol. 2017, 102, 822–828. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Szulc, J.; Kloziński, A. Poly(lactic acid) green composites filled with linseed cake as an agricultural waste filler. Influence of oil content within the filler on the rheological behavior. J. Appl. Polym. Sci. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Lion, A.; Kardelky, C.; Haupt, P. On the Frequency and Amplitude Dependence of the Payne Effect: Theory and Experiments. Rubber Chem. Technol. 2011, 76, 533–547. [Google Scholar] [CrossRef]

- Scagliusi, S.R.; Cardoso, E.C.L.; Parra, D.F.; Lima, L.F.C.P.; Lugão, A.B. Evaluation of “Payne effect” in radiation-induced modification of chlorobutyl rubber. Radiat. Phys. Chem. 2013, 84, 42–46. [Google Scholar] [CrossRef]

- Essabir, H.; Achaby, M.E.I.; Hilali, E.M.; Bouhfid, R.; Qaiss, A. Morphological, Structural, Thermal and Tensile Properties of High Density Polyethylene Composites Reinforced with Treated Argan Nut Shell Particles. J. Bionic Eng. 2015, 12, 129–141. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Kloziński, A. Complex modification effect of linseed cake as an agricultural waste filler used in high density polyethylene composites. Iran. Polym. J. (Engl. Ed.) 2018, 27, 677–688. [Google Scholar] [CrossRef]

- Robertson, C.G.; Wang, X. Isoenergetic jamming transition in particle-filled systems. Phys. Rev. Lett. 2005, 95, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Hong, K.H.; Liu, N.; Sun, G. UV-induced graft polymerization of acrylamide on cellulose by using immobilized benzophenone as a photo-initiator. Eur. Polym. J. 2009, 45, 2443–2449. [Google Scholar] [CrossRef]

- Jordan, J.; Jacob, K.I.; Tannenbaum, R.; Sharaf, M.A.; Jasiuk, I. Experimental trends in polymer nanocomposites—A review. Mater. Sci. Eng. A 2005, 393, 1–11. [Google Scholar] [CrossRef]

- Gurovich, D.; Macosko, C.W.; Tirrell, M. The Influence of Filler-Filler and Filler-Polymer Interactions on the Physical Properties of Silica-Filled Liquid Polyisoprene. Rubber Chem. Technol. 2011, 77, 1–12. [Google Scholar] [CrossRef]

- Bras, J.; Hassan, M.L.; Bruzesse, C.; Hassan, E.A.; El-Wakil, N.A.; Dufresne, A. Mechanical, barrier, and biodegradability properties of bagasse cellulose whiskers reinforced natural rubber nanocomposites. Ind. Crops Prod. 2010, 32, 627–633. [Google Scholar] [CrossRef]

- Scrivani, T.; Benavente, R.; Pérez, E.; Pereña, J.M. Stress-strain behaviour, microhardness, and dynamic mechanical properties of a series of ethylene-norbornene copolymers. Macromol. Chem. Phys. 2001, 202, 2547–2553. [Google Scholar] [CrossRef]

- Abdulkhani, A.; Hosseinzadeh, J.; Ashori, A.; Dadashi, S.; Takzare, Z. Preparation and characterization of modified cellulose nanofibers reinforced polylactic acid nanocomposite. Polym. Test. 2014, 35, 73–79. [Google Scholar] [CrossRef]

- Nachtigall, S.M.B.; Cerveira, G.S.; Rosa, S.M.L. New polymeric-coupling agent for polypropylene/wood-flour composites. Polym. Test. 2007, 26, 619–628. [Google Scholar] [CrossRef]

- Mastalygina, E.E.; Popov, A.A. Mechanical properties and stress-strain behaviour of binary and ternary composites based on polyolefins and vegetable fillers. Solid State Phenom. 2017, 265 SSP, 221–226. [Google Scholar] [CrossRef]

- Chee, P.E.; Talib, R.A.; Yusof, Y.A.; Chin, N.L.; Ratnam, C.T.; Khalid, M.; Chuah, T.G. Mechanical and Physical Properties of Oil Palm Derived Cellulose-Ldpe Biocomposites As Packaging Material. Int. J. Eng. Technol. 2010, 7, 26–32. [Google Scholar]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Salleh, F.M.; Hassan, A.; Yahya, R.; Azzahari, A.D. Effects of extrusion temperature on the rheological, dynamic mechanical and tensile properties of kenaf fiber/HDPE composites. Compos. Part B Eng. 2014, 58, 259–266. [Google Scholar] [CrossRef]

- Shumigin, D.; Tarasova, E.; Krumme, A.; Meier, P. Rheological and Mechanical Properties of Poly (lactic) Acid/Cellulose and LDPE/Cellulose Composites. Mater. Sci. 2011, 17, 32–37. [Google Scholar] [CrossRef]

- Etaati, A.; Pather, S.; Fang, Z.; Wang, H. The study of fibre/matrix bond strength in short hemp polypropylene composites from dynamic mechanical analysis. Compos. Part B Eng. 2014, 62, 19–28. [Google Scholar] [CrossRef]

- Tajvidi, M.; Motie, N.; Rassam, G.; Falk, R.H.; Felton, C. Mechanical performance of hemp fiber polypropylene composites at different operating temperatures. J. Reinf. Plast. Compos. 2010, 29, 664–674. [Google Scholar] [CrossRef]

- Lu, N.; Oza, S. Thermal stability and thermo-mechanical properties of hemp-high density polyethylene composites: Effect of two different chemical modifications. Compos. Part B Eng. 2013, 44, 484–490. [Google Scholar] [CrossRef]

- Nagalakshmaiah, M.; Pignon, F.; El Kissi, N.; Dufresne, A. Surface adsorption of triblock copolymer (PEO-PPO-PEO) on cellulose nanocrystals and their melt extrusion with polyethylene. RSC Adv. 2016, 6, 66224–66232. [Google Scholar] [CrossRef]

- Reixach, R.; Puig, J.; Méndez, J.A.; Gironès, J.; Espinach, F.X.; Arbat, G.; Mutjé, P. Orange wood fiber reinforced polypropylene composites: Thermal properties. BioResources 2015, 10, 2156–2166. [Google Scholar] [CrossRef]

- Khoshkava, V.; Kamal, M.R. Effect of cellulose nanocrystals (CNC) particle morphology on dispersion and rheological and mechanical properties of polypropylene/CNC nanocomposites. ACS Appl. Mater. Interfaces 2014, 6, 8146–8157. [Google Scholar] [CrossRef]

| Property | Acetone | Ethanol (99.9%) | Hexane |

|---|---|---|---|

| boiling point (°C) | 55–57 | 78 | 68 |

| solubility in water (g/cm3) | yes | yes | 0.1 |

| solubility in organic solvents | yes | yes | yes |

| Sample | Dried before Modification (D) | Not Dried before Modification (ND) | Solvent Exchange | MA Treated | |||

|---|---|---|---|---|---|---|---|

| Before MA Treatment | After MA Treatment | ||||||

| H | E | H | E | ||||

| ND/MA/0 | - | ✔ | - | - | - | - | ✔ |

| ND/MA/1/H | - | ✔ | ✔ | - | - | - | ✔ |

| ND/MA/1/E | - | ✔ | - | ✔ | - | - | ✔ |

| ND/MA/2/H | - | ✔ | - | - | ✔ | - | ✔ |

| ND/MA/2/E | - | ✔ | - | - | - | ✔ | ✔ |

| ND/1/H | - | ✔ | ✔ | - | - | - | - |

| ND/1/E | - | ✔ | - | ✔ | - | - | - |

| D/MA/0 | ✔ | - | - | - | - | - | ✔ |

| D/MA/1/H | ✔ | - | ✔ | - | - | - | ✔ |

| D/MA/1/E | ✔ | - | - | ✔ | - | - | ✔ |

| D/MA/2/H | ✔ | - | - | - | ✔ | - | ✔ |

| D/MA/2/E | ✔ | - | - | - | - | ✔ | ✔ |

| D/1/H | ✔ | - | ✔ | - | - | - | - |

| D/1/E | ✔ | - | - | ✔ | - | - | - |

| Filler | Modifying Agent/Treatment | Polymer Matrix | Neat Polymer Matrix | Polymer Matrix Filled with Unmodified Bio-Filler | Polymer Matrix Filled with Modified Bio-Filler | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|

| TS (MPa) | Eb (%) | TS (MPa) | Eb (%) | TS (MPa) | Eb (%) | ||||

| wood flour | ternary-graft copolymers (PE solid phase grafting: graft degree of 10.5%) | recycled PE | 20 ± 2 | - | - | - | 36 ± 2 | - | [81] |

| cotton fabric waste microfibers | chlorination (2 M HCl, 80 °C, 4 h) and further NaOH treatment (60 °C, 4 h) | recycled PE + PE-g-MA | 5 ± 1 | - | 25 ± 4 | - | 25 ± 3 | - | [68] |

| nanocellulose | alkenyl succinic anhydride (1 h, 70–80 °C in the presence of: K2CO3, NMP) | HDPE | ~21 | >10 | ~5 | >10 | ~43 | 4 | [50] |

| powdered cellulose | - | LDPE | ~7 | >20 | 12 | >20 | - | - | [99] |

| clean oil palm empty fruit bunch fibers (holocellulose) | Chlorination (NaCl and CH3COOH, 70 °C, 6 h), mercerization (17.5% NaOH, 20 °C, 2 h) | LDPE | ~11 | ~600 | - | - | ~13 | <50 | [100] |

| nanocellulose | PVA (solution casting from DMSO; PVA solution added to EO/EPI/CNC mixture at 70 °C, further sonification) | EO-co-EPI | - | - | 0.50 ± 0.07 | 39.9 ± 0.9 | 1.98 ± 0.08 | 17.1 ± 1.4 | [82] |

| THIS RESEARCH STUDY | |||||||||

| cellulose (8–14 μm) | maleic anhydride | TOPAS | 36 ± 3 | 490 ± 20 | 29 ± 5 | 430 ± 50 | 38.8 ± 0.8 | 510 ± 20 | - |

| Polymer Matrix | Filler | Ref. |

|---|---|---|

| high density polyethylene (HDPE) | hemp fibers | [106] |

| kenaf bast fiber | [102] | |

| cotton nanocellulose fiber | [49] | |

| linear low density polyethylene (LLDPE) | cellulose nanocrystal (CNC) | [107] |

| polypropylene (PP) | orange wood fibers | [108] |

| hemp fibers | [104] | |

| cellulose nanocrystals | [109] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cichosz, S.; Masek, A.; Rylski, A. Cellulose Modification for Improved Compatibility with the Polymer Matrix: Mechanical Characterization of the Composite Material. Materials 2020, 13, 5519. https://doi.org/10.3390/ma13235519

Cichosz S, Masek A, Rylski A. Cellulose Modification for Improved Compatibility with the Polymer Matrix: Mechanical Characterization of the Composite Material. Materials. 2020; 13(23):5519. https://doi.org/10.3390/ma13235519

Chicago/Turabian StyleCichosz, Stefan, Anna Masek, and Adam Rylski. 2020. "Cellulose Modification for Improved Compatibility with the Polymer Matrix: Mechanical Characterization of the Composite Material" Materials 13, no. 23: 5519. https://doi.org/10.3390/ma13235519

APA StyleCichosz, S., Masek, A., & Rylski, A. (2020). Cellulose Modification for Improved Compatibility with the Polymer Matrix: Mechanical Characterization of the Composite Material. Materials, 13(23), 5519. https://doi.org/10.3390/ma13235519