Capabilities and Limitations of Fire-Shaping to Produce Glass Nozzles

Abstract

1. Introduction

2. Results

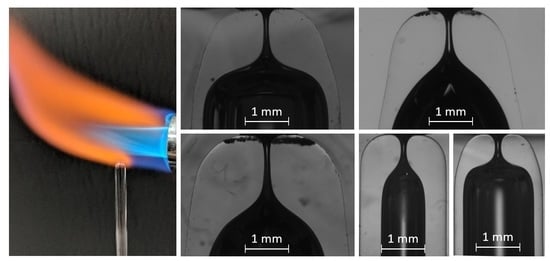

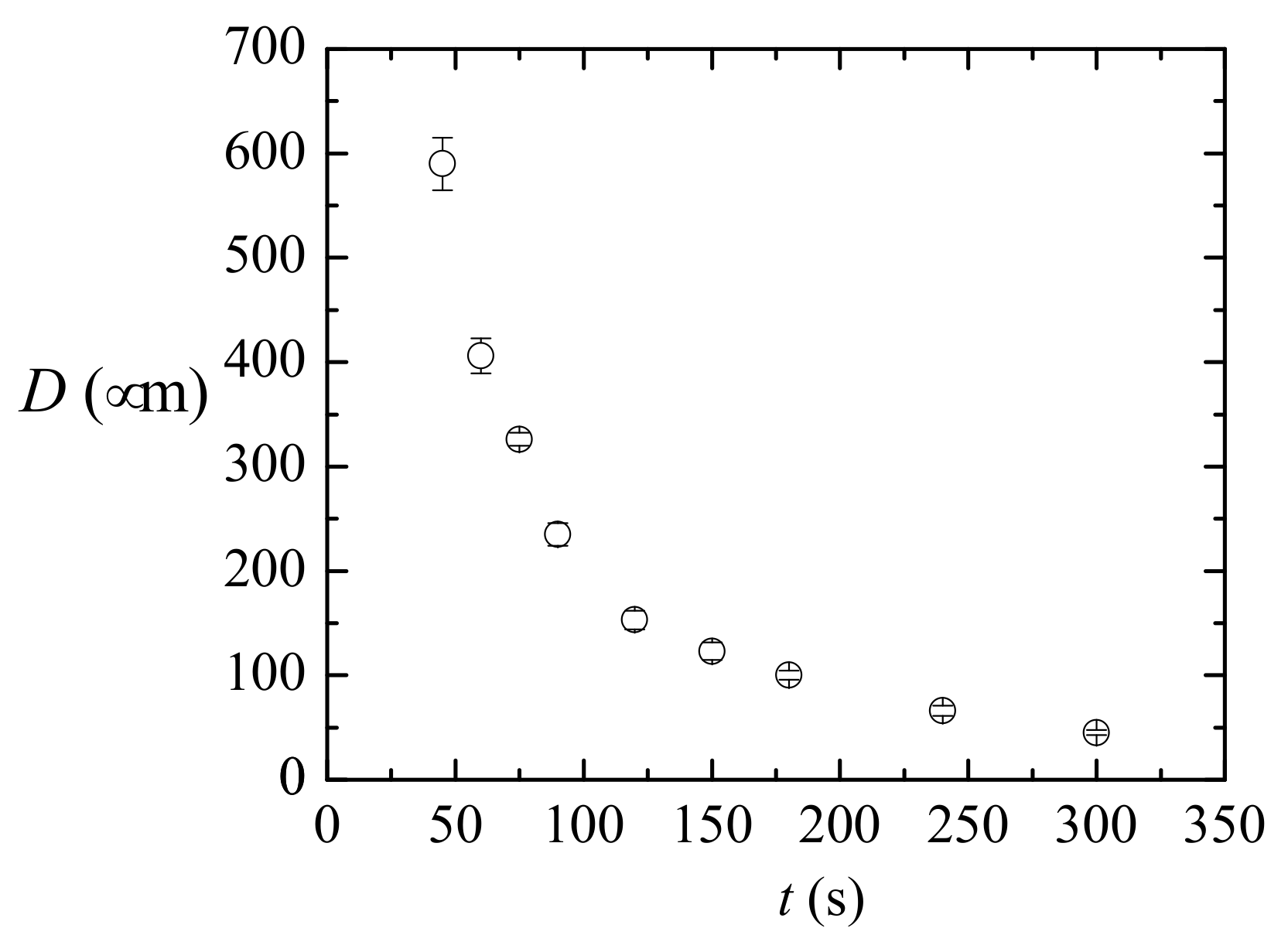

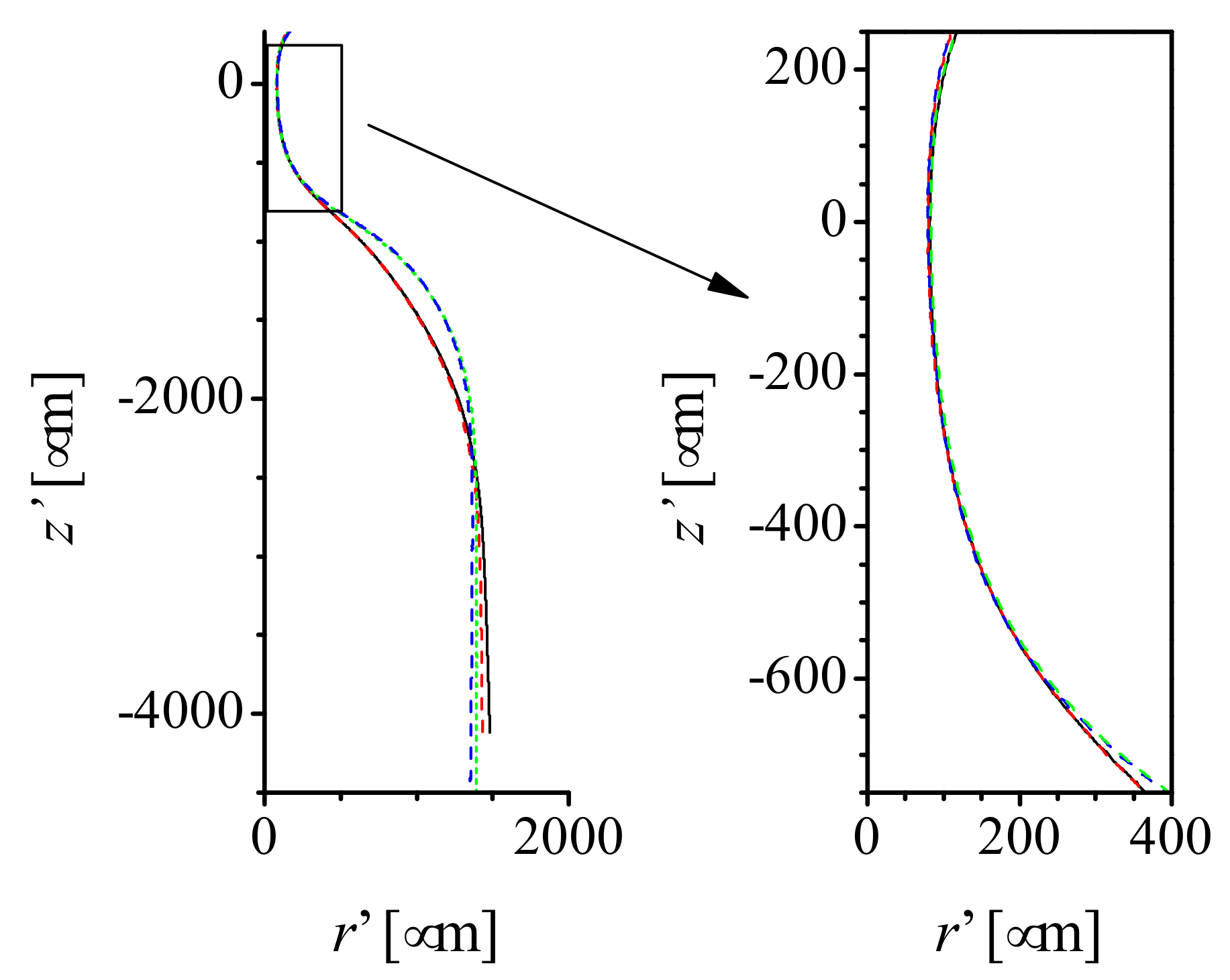

2.1. Effect of the Heating Time

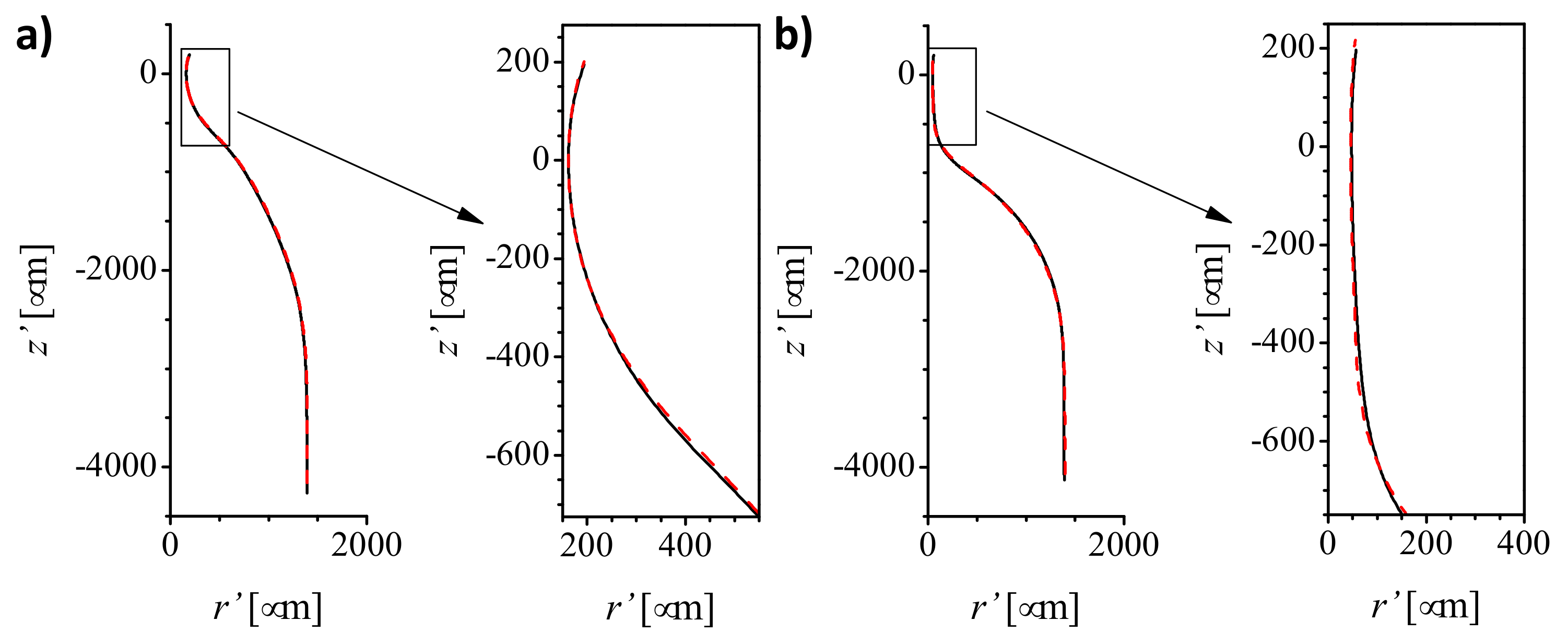

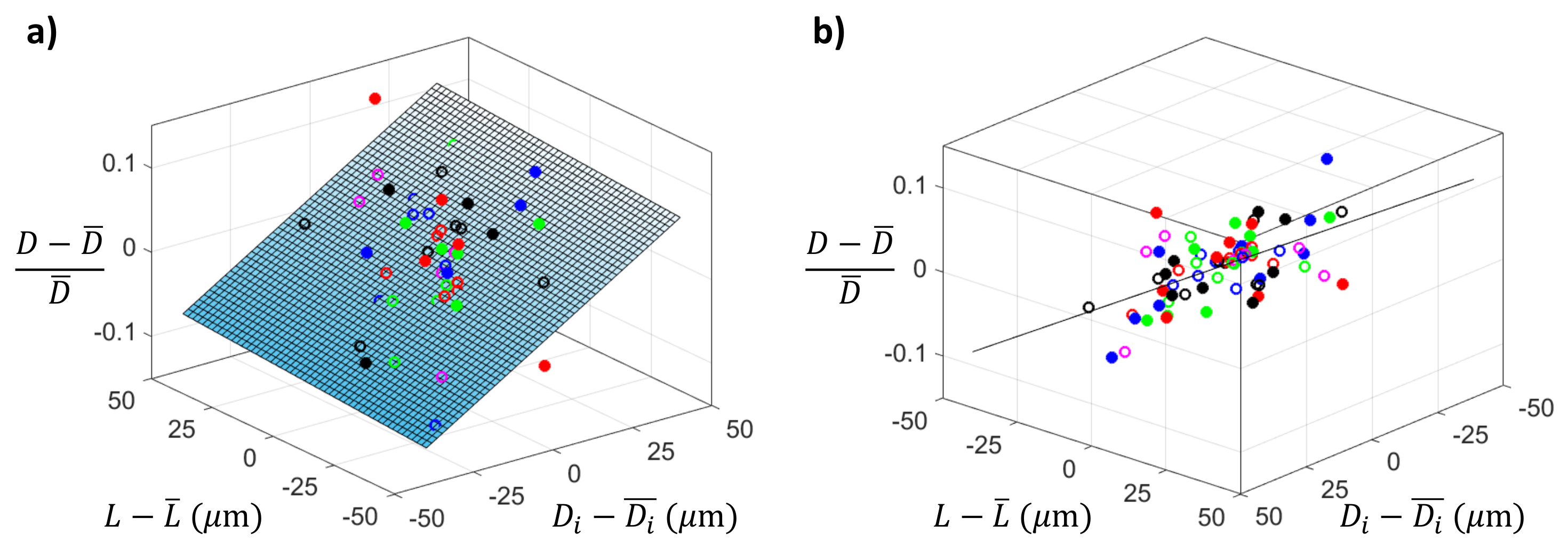

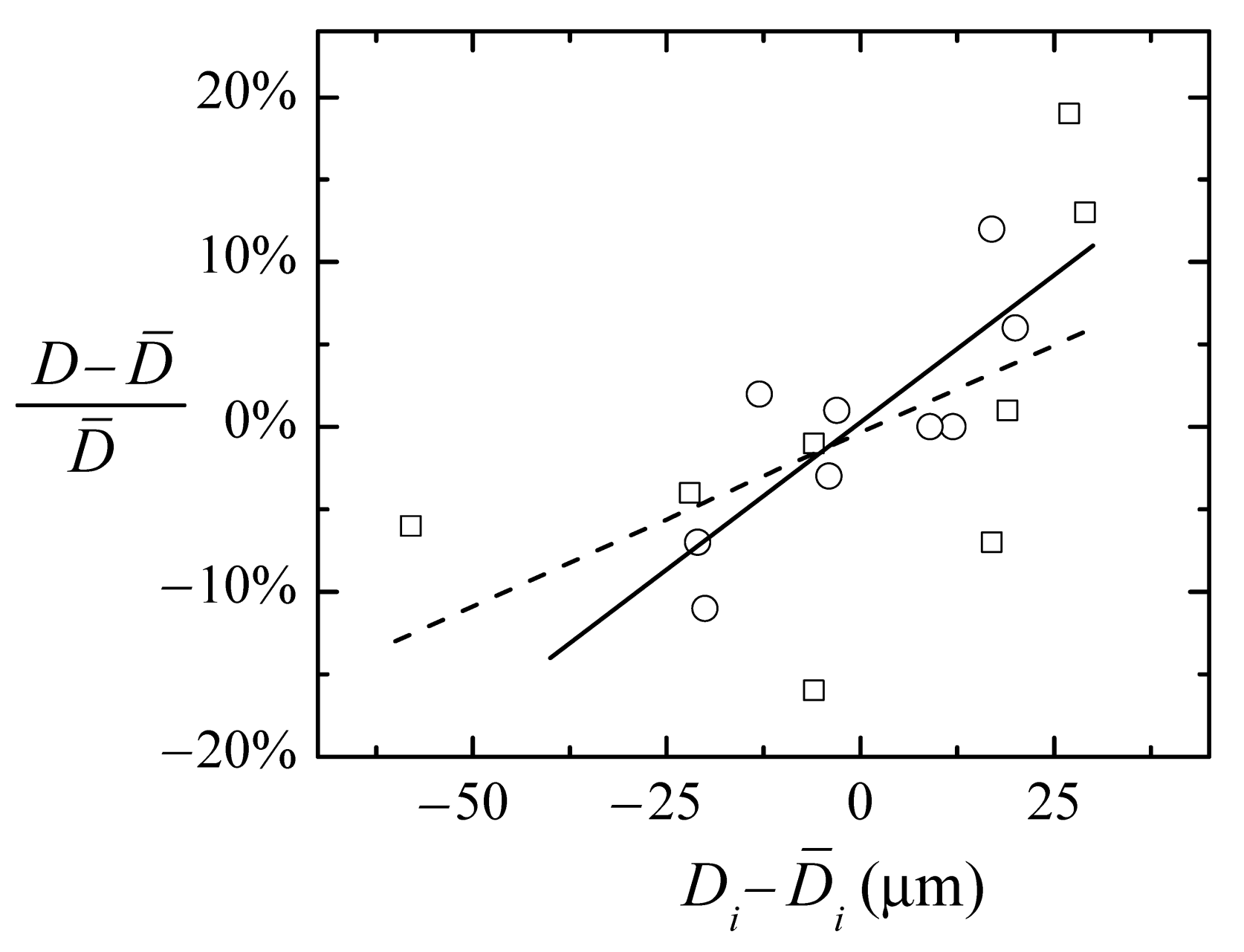

2.2. Effect of the Geometrical Tolerances of the Capillary

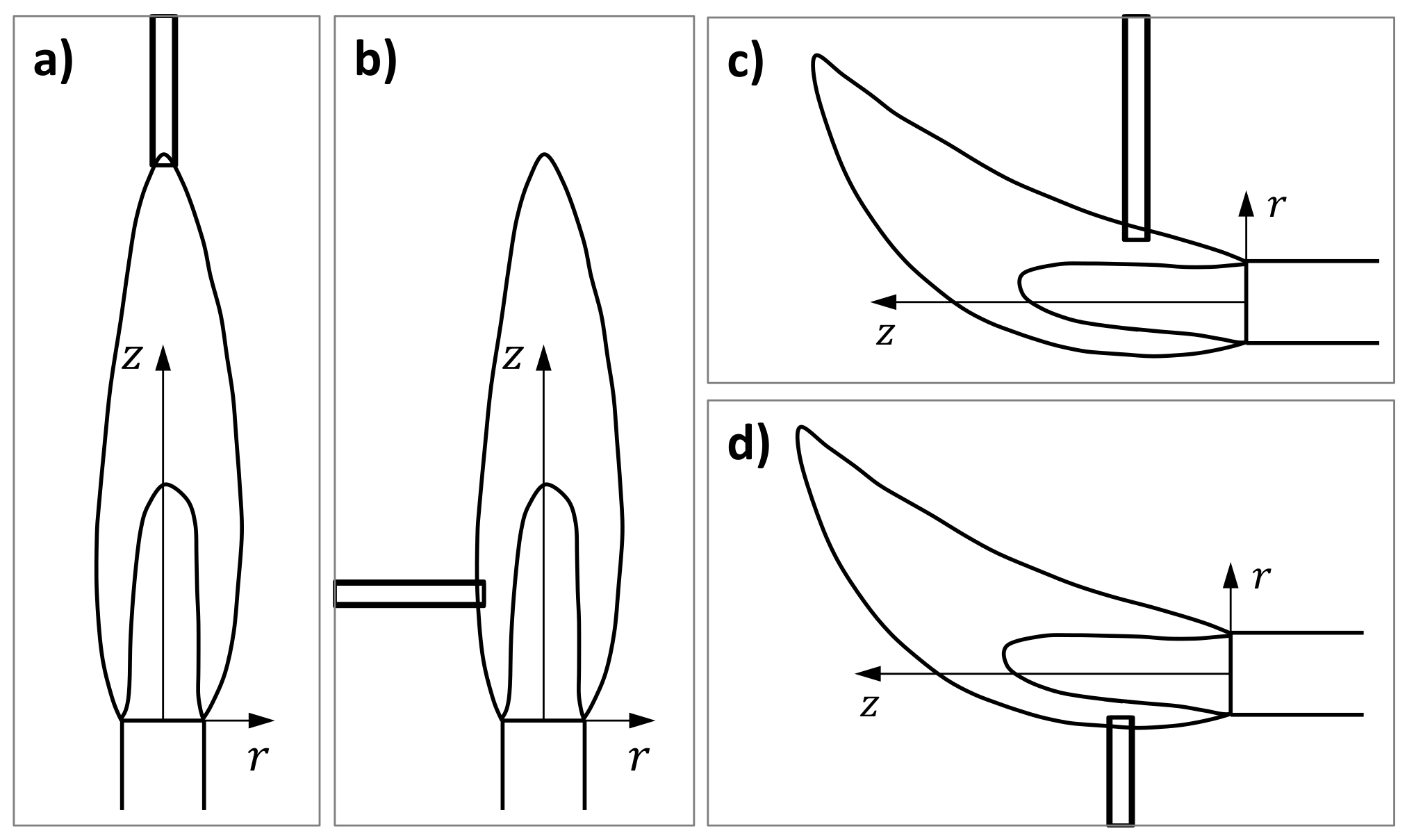

2.3. Effect of the Heating Position

2.4. Effect of the Capillary Geometry: Inner Diameter and Thickness

3. Discussion

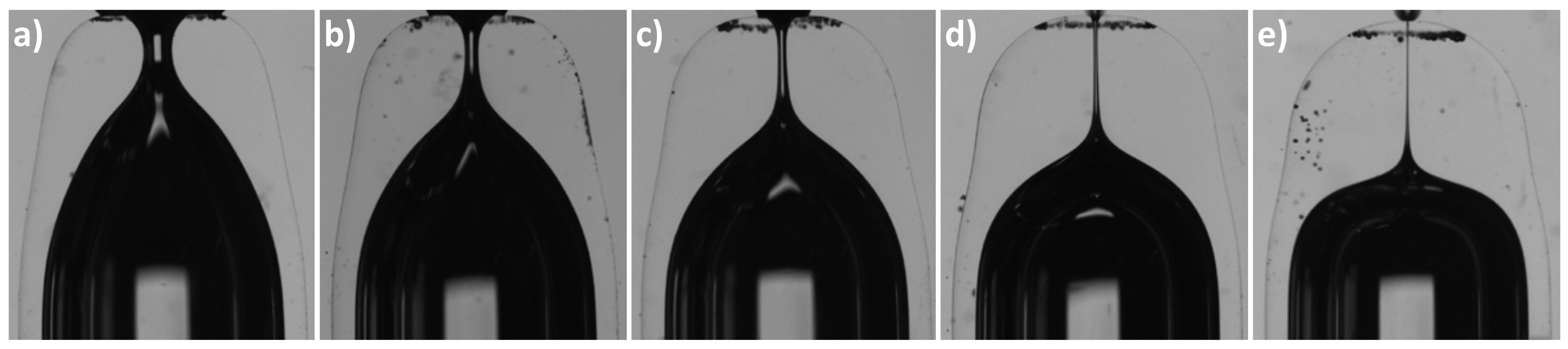

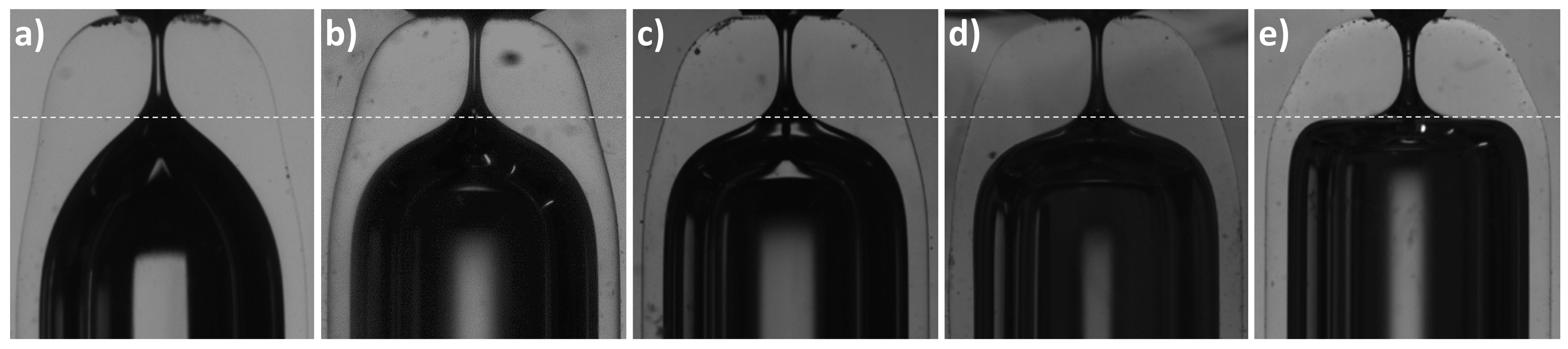

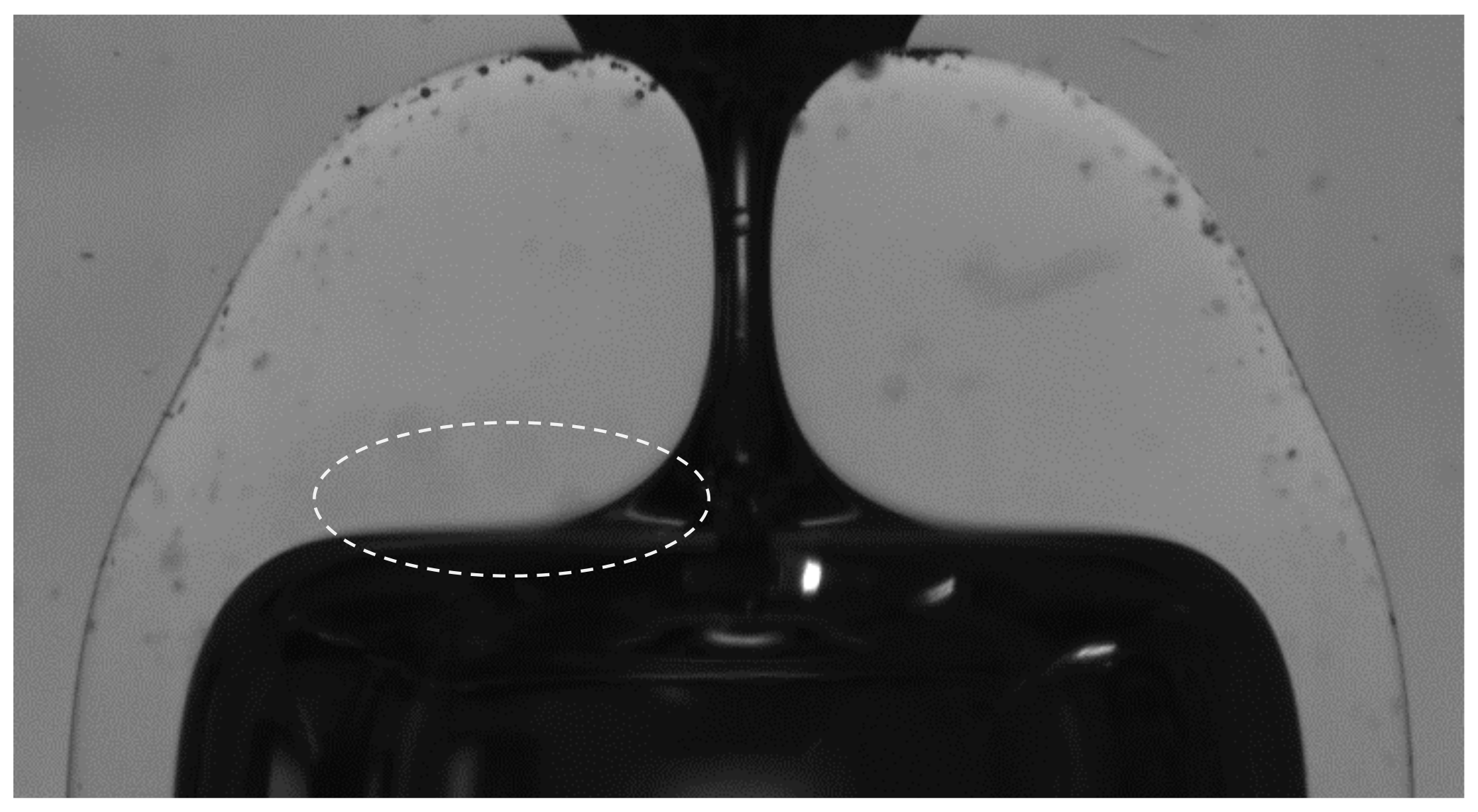

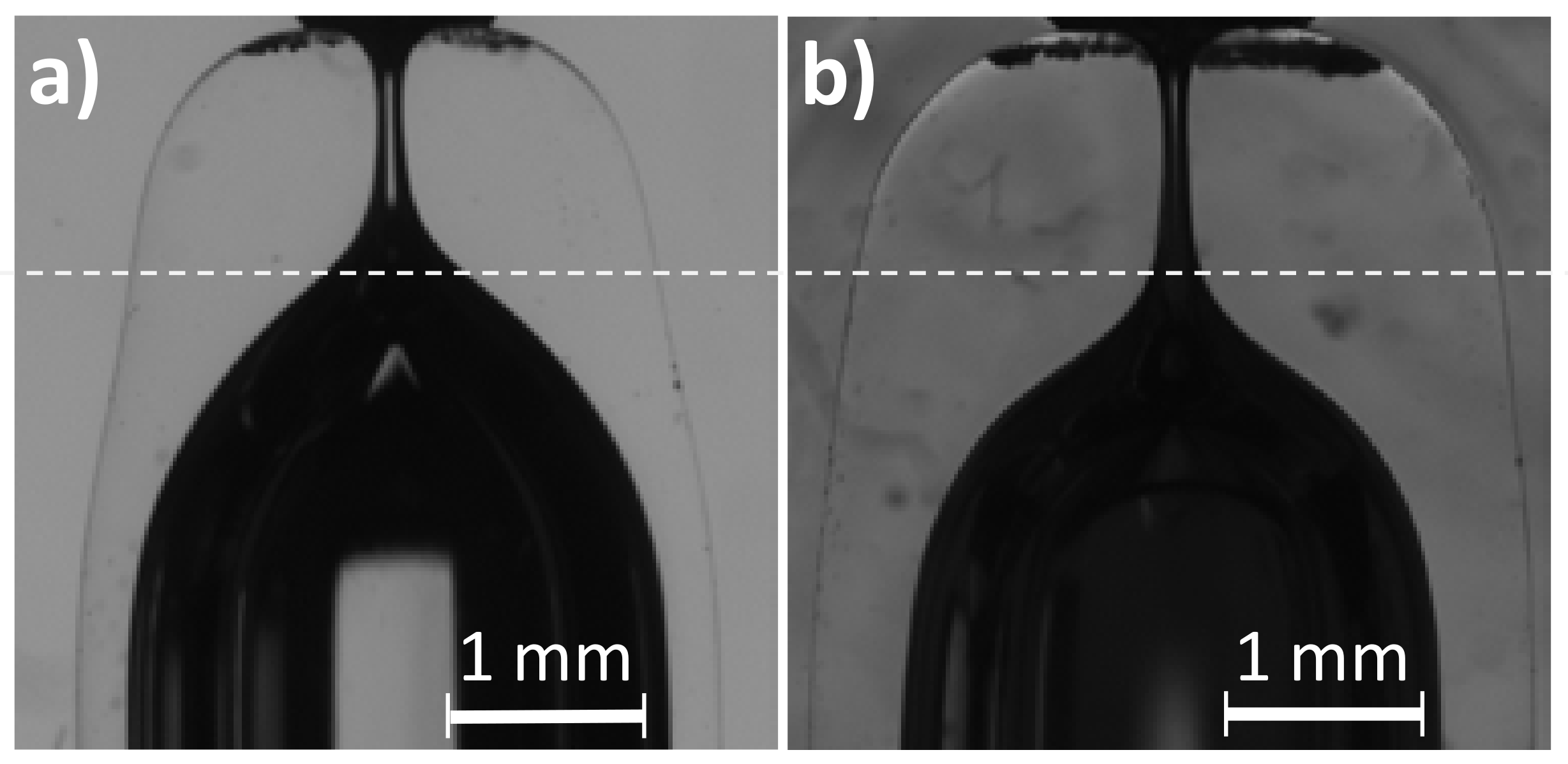

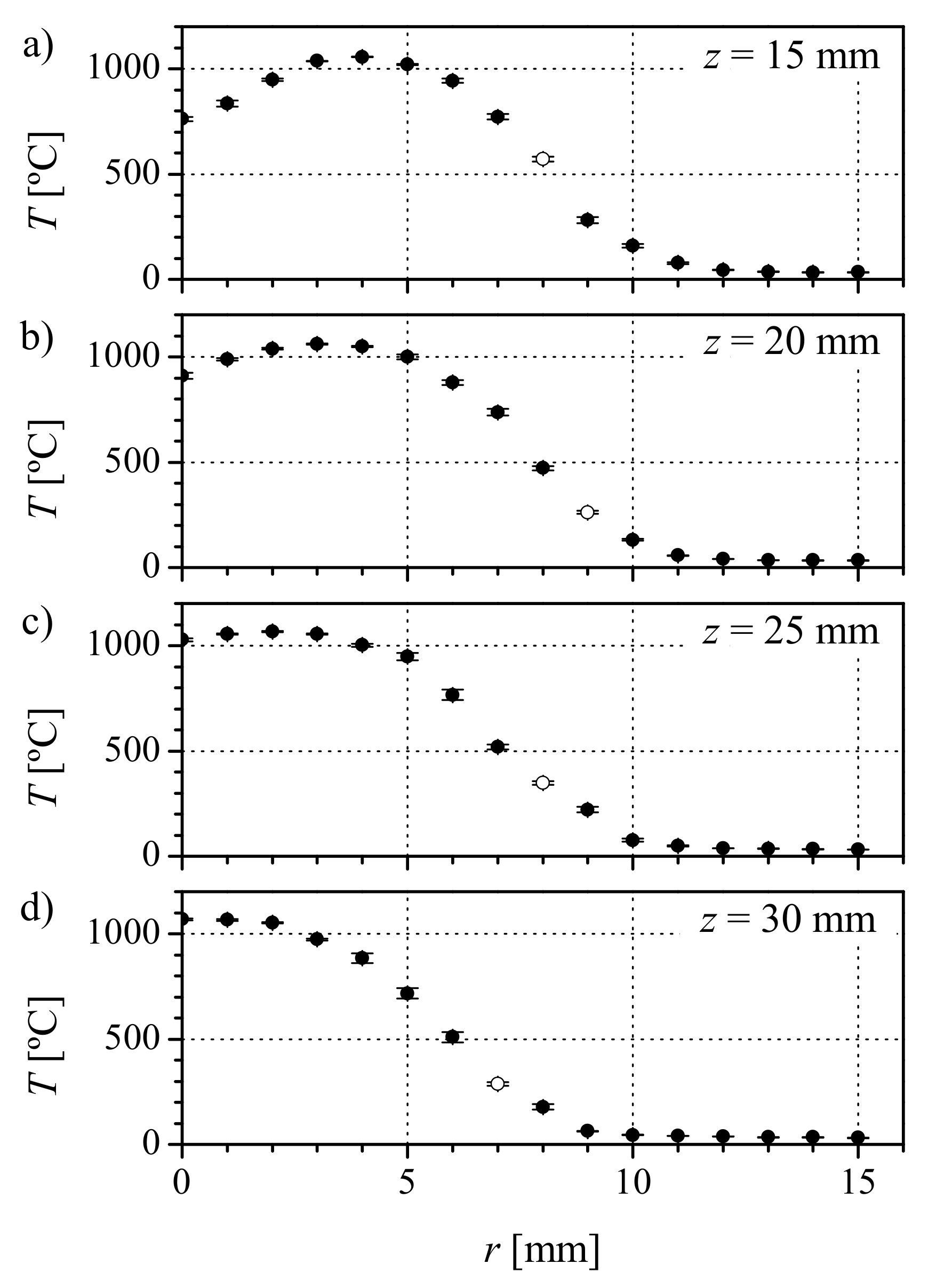

Application in Flow Focusing to Prevent Whipping

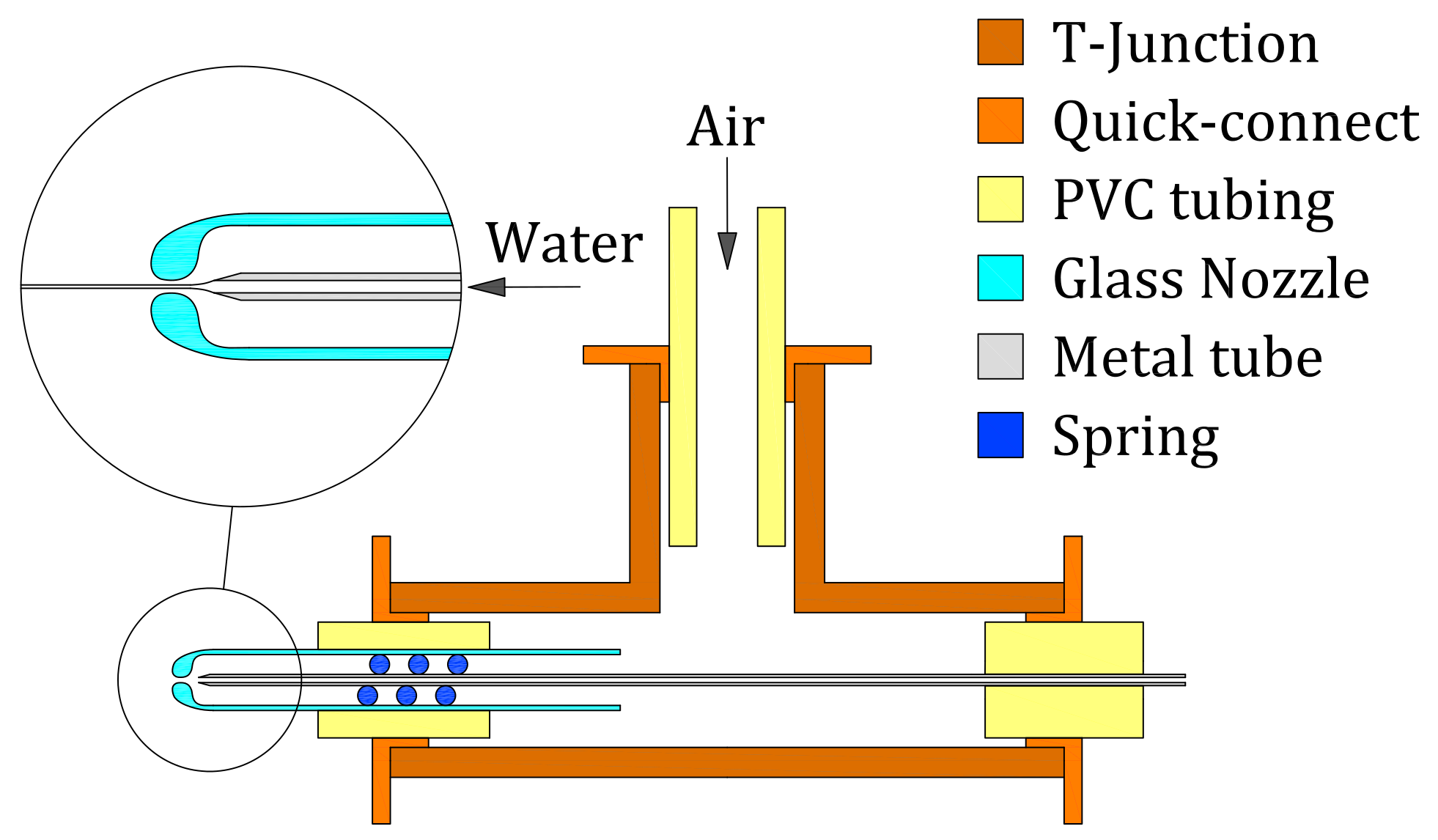

4. Materials and Methods

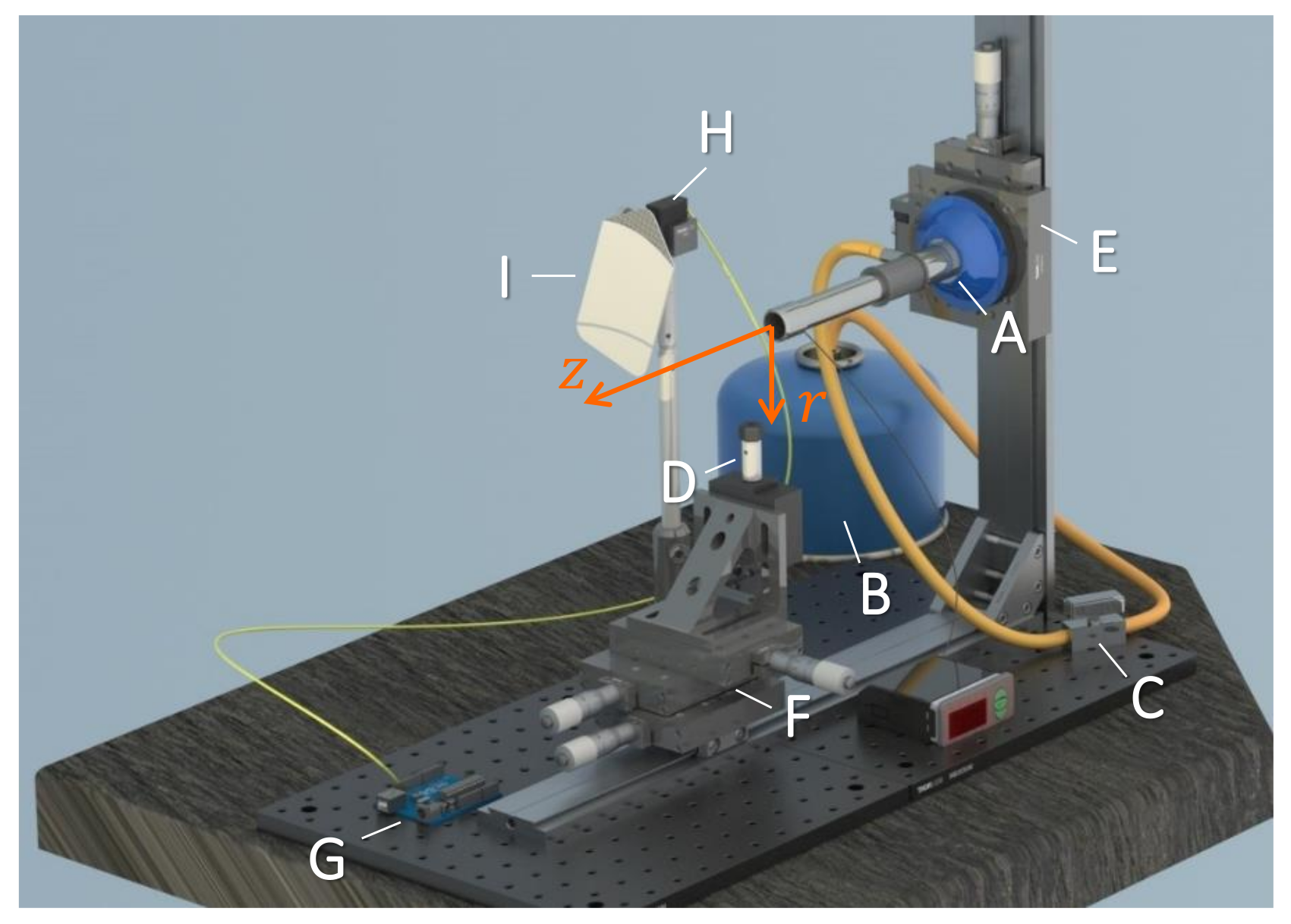

4.1. Fire-Shaping Setup

4.2. Capillaries and Nozzles Geometries

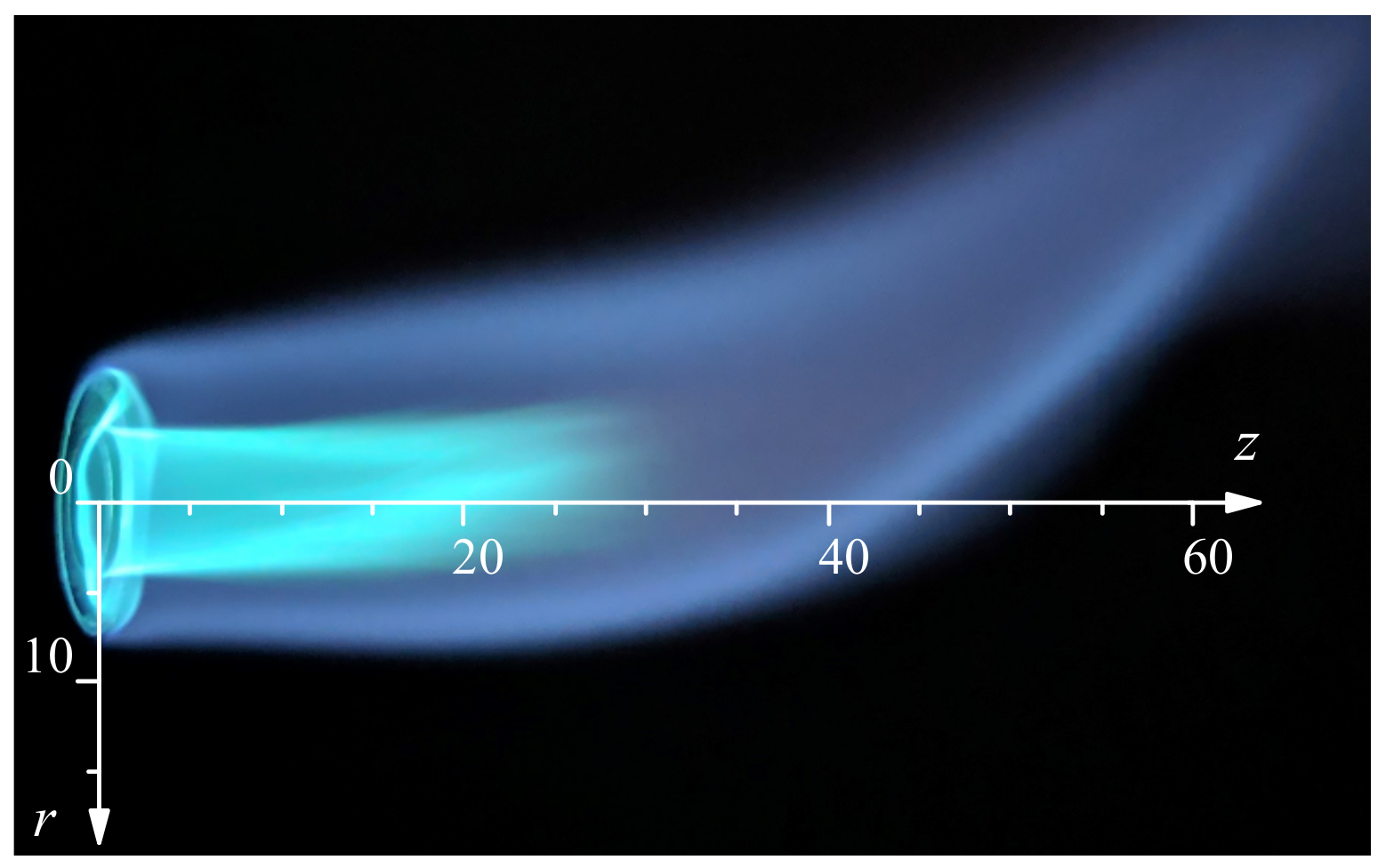

4.3. Gaseous Flow-Focusing

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sackmann, E.K.; Fulton, A.L.; Beebe, D.J. The present and future role of microfluidics in biomedical research. Nature 2014, 507, 181–189. [Google Scholar] [CrossRef]

- Shang, L.; Cheng, Y.; Zhao, Y. Emerging Droplet Microfluidics. Chem. Rev. 2017, 117, 7964–8040. [Google Scholar] [CrossRef]

- Guerrero, J.; Chang, Y.; Fragkopoulos, A.A.; Fernández-Nieves, A. Capillary-Based Microfluidics-Coflow, Flow-Focusing, Electro-Coflow, Drops, Jets, and Instabilities. Small 2020, 16, 1904344. [Google Scholar] [CrossRef]

- Montanero, J.M.; Gañán-Calvo, A.M. Dripping, jetting and tip streaming. Rep. Prog. Phys. 2020, 83, 097001. [Google Scholar] [CrossRef]

- Nielsen, A.V.; Beauchamp, M.J.; Nordin, G.P.; Woolley, A.T. 3D Printed Microfluidics. Annu. Rev. Anal. Chem. 2020, 13, 45–65. [Google Scholar] [CrossRef]

- Utada, A.S.; Lorenceau, E.; Link, D.R.; Kaplan, P.D.; Stone, H.A.; Weitz, D.A. Monodisperse Double Emulsions Generated from a Microcapillary Device. Science 2005, 308, 537–541. [Google Scholar] [CrossRef] [PubMed]

- Comunian, T.A.; Ravanfar, R.; Alcaine, S.D.; Abbaspourrad, A. Water-in-oil-in-water emulsion obtained by glass microfluidic device for protection and heat-triggered release of natural pigments. Food Res. Int. 2018, 106, 945–951. [Google Scholar] [CrossRef] [PubMed]

- Benson, B.R.; Stone, H.A.; Prud’homme, R.K. An “off-the-shelf” capillary microfluidic device that enables tuning of the droplet breakup regime at constant flow rates. Lab Chip 2013, 13, 4507. [Google Scholar] [CrossRef] [PubMed]

- Bandulasena, M.V.; Vladisavljević, G.T.; Odunmbaku, O.G.; Benyahia, B. Continuous synthesis of PVP stabilized biocompatible gold nanoparticles with a controlled size using a 3D glass capillary microfluidic device. Chem. Eng. Sci. 2017, 171, 233–243. [Google Scholar] [CrossRef]

- Bandulasena, M.V.; Vladisavljević, G.T.; Benyahia, B. Versatile reconfigurable glass capillary microfluidic devices with Lego® inspired blocks for drop generation and micromixing. J. Colloid Interface Sci. 2019, 542, 23–32. [Google Scholar] [CrossRef]

- DePonte, D.P.; Weierstall, U.; Schmidt, K.; Warner, J.; Starodub, D.; Spence, J.C.H.; Doak, R.B. Gas dynamic virtual nozzle for generation of microscopic droplet streams. J. Phys. D Appl. Phys. 2008, 41, 195505. [Google Scholar] [CrossRef]

- Gañán-Calvo, A.M. Generation of Steady Liquid Microthreads and Micron-Sized Monodisperse Sprays in Gas Streams. Phys. Rev. Lett. 1998, 80, 285–288. [Google Scholar] [CrossRef]

- Bayram, A.; Serhatlioglu, M.; Ortac, B.; Demic, S.; Elbuken, C.; Sen, M.; Solmaz, M.E. Integration of glass micropipettes with a 3D printed aligner for microfluidic flow cytometer. Sens. Actuator A Phys. 2018, 269, 382–387. [Google Scholar] [CrossRef]

- Weierstall, U.; Spence, J.C.H.; Doak, R.B. Injector for scattering measurements on fully solvated biospecies. Rev. Sci. Instrum. 2012, 83, 035108. [Google Scholar] [CrossRef] [PubMed]

- Beyerlein, K.R.; Adriano, L.; Heymann, M.; Kirian, R.; Knoska, J.; Wilde, F.; Chapman, H.N.; Bajt, S. Ceramic micro-injection molded nozzles for serial femtosecond crystallography sample delivery. Rev. Sci. Instrum. 2015, 86, 125104. [Google Scholar] [CrossRef]

- Piotter, V.; Klein, A.; Plewa, K.; Beyerlein, K.R.; Chapman, H.N.; Bajt, S. Development of a ceramic injection molding process for liquid jet nozzles to be applied for X-ray free-electron lasers. Microsyst. Technol. 2018, 24, 12471252. [Google Scholar] [CrossRef]

- Nelson, G.; Kirian, R.A.; Weierstall, U.; Zatsepin, N.A.; Faragó, T.; Baumbach, T.; Wilde, F.; Niesler, F.B.P.; Zimmer, B.; Ishigami, I.; et al. Three-dimensional-printed gas dynamic virtual nozzles for X-ray laser sample delivery. Opt. Express 2016, 24, 1515–1530. [Google Scholar] [CrossRef]

- Knoška, J.; Adriano, L.; Awel, S.; Beyerlein, K.R.; Yefanov, O.; Oberthuer, D.; Peña Murillo, E.; Roth, N.; Sarrou, I.; Villanueva-Perez, P.; et al. Ultracompact 3D microfluidics for time-resolved structural biology. Nat. Commun. 2020, 11, 657. [Google Scholar] [CrossRef]

- Wei, C.Y.; Yu, C.Z.; Wu, J.J.; Li, J.W.; Li, S.S.; Dai, S.J.; Li, T.J. Easy-to-operate fabrication of tapered glass capillaries for microdroplet generation. J. Micromech. Microeng. 2019, 29, 037001. [Google Scholar] [CrossRef]

- Switzer, G.L. A versatile system for stable generation of uniform droplets. Rev. Sci. Instrum. 1991, 62, 2765–2771. [Google Scholar] [CrossRef]

- Levenstein, M.; Bawazer, L.; Nally, C.M.; Marchant, W.; Gong, X.; Meldrum, F.; Kapur, N. A reproducible approach to the assembly of microcapillaries for double emulsion production. Microfluid. Nanofluid. 2016, 20, 143. [Google Scholar] [CrossRef]

- Chapman, H.N.; Fromme, P.; Barty, A.; White, T.A.; Kirian, R.A.; Aquila, A.; Hunter, M.S.; Schulz, J.; DePonte, D.P.; Weierstall, U.; et al. Femtosecond X-ray protein nanocrystallography. Nature 2011, 470, 73–79. [Google Scholar] [CrossRef] [PubMed]

- Cabezas, M.G.; Rubio, M.; Rebollo-Muñoz, N.; Herrada, M.A.; Montanero, J.M. Global stability analysis of axisymmetric liquid-liquid flow focusing. J. Fluid Mech. 2021, in press. [Google Scholar]

- Ponce-Torres, A.; Ortega, E.; Rubio, M.; Rubio, A.; Vega, E.J.; Montanero, J.M. Gaseous flow focusing for spinning micro and nanofibers. Polymer 2019, 178, 121623. [Google Scholar] [CrossRef]

- Muñoz-Sánchez, B.N.; Cabezas, M.G. Borosilicate nozzles manufactured by reproducible fire shaping. J. Mater. Process. Tech. 2018, 261, 173–183. [Google Scholar] [CrossRef]

- Muñoz-Sánchez, B.N.; Gañán-Calvo, A.M.; Cabezas, M.G. A new fire shaping approach to produce highly axisymmetric and reproducible nozzles. J. Mater. Process. Tech. 2019, 270, 241–253. [Google Scholar] [CrossRef]

- Doshi, P.; Cohen, I.; Zhang, W.W.; Siegel, M.; Howel, P.; Basaran, O.A.; Nagel, S.R. Persistence of memory in drop breakup: The breakdown of universality. Science 2003, 302, 1185–1188. [Google Scholar] [CrossRef]

- Acero, A.J.; Ferrera, C.; Montanero, J.M.; Gañán-Calvo, A.M. Focusing liquid microjets with nozzles. J. Micromech. Microeng. 2012, 22, 065011. [Google Scholar] [CrossRef]

- Wiedorn, M.O.; Awel, S.; Morgan, A.J.; Ayyer, K.; Gevorkov, Y.; Fleckenstein, H.; Roth, N.; Adriano, L.; Bean, R.; Beyerlein, K.R.; et al. Rapid sample delivery for megahertz serial crystallography at X-ray FELs. IUCRJ 2018, 5, 574–584. [Google Scholar] [CrossRef]

- Vakili, M.; Vasireddi, R.; Gwozdz, P.V.; Monteiro, D.C.F.; Heymann, M.; Blick, R.H.; Trebbin, M. Microfluidic polyimide gas dynamic virtual nozzles for serial crystallography. Rev. Sci. Instrum. 2020, 91, 085108. [Google Scholar] [CrossRef]

- Blanco-Trejo, S.; Herrada, M.A.; Gañán-Calvo, A.M.; Rubio, A.; Cabezas, M.G.; Montanero, J.M. Whipping in gaseous flow focusing. Int. J. Multiphase Flow 2020, 130, 103367. [Google Scholar] [CrossRef]

| t (s) | (m) | (%) | (mm) | |

|---|---|---|---|---|

| 45 | 590 | 4 | 1.08 | 0.47 |

| 60 | 406 | 4 | 1.21 | 0.62 |

| 75 | 326 | 2 | 1.26 | 0.78 |

| 90 | 235 | 4 | 1.36 | 1.04 |

| 120 | 153 | 6 | 1.48 | 1.78 |

| 150 | 123 | 7 | 1.50 | 2.55 |

| 180 | 100 | 4 | 1.57 | 3.65 |

| 240 | 66 | 7 | 1.65 | 7.13 |

| 300 | 45 | 5 | 1.72 | 10.1 |

| r (mm) | t (s) | (m) | (%) | (mm) | |

|---|---|---|---|---|---|

| 3.5 | 150 | 123 | 7 | 1.50 | 2.55 |

| 4.0 | 250 | 135 | 5 | 1.39 | 2.46 |

| 4.5 | 325 | 140 | 4 | 1.29 | 1.81 |

| 5.0 | 600 | 140 | 3 | 1.20 | 1.73 |

| Type | r (mm) | t (s) | (m) | (%) | (mm) | |

|---|---|---|---|---|---|---|

| 1 | 3.5 | 150 | 123 | 7 | 1.50 | 2.5 |

| 2 | 3.5 | 520 | 115 | 12 | 1.28 | 3.6 |

| Type | r (mm) | t (s) | (m) | (%) | (mm) | |

|---|---|---|---|---|---|---|

| 3 | 5.5 | 70 | 70 | 19 | 0.25 | 4.2 |

| 3 | 6 | 70 | 239 | 12 | 0.12 | 1.0 |

| 3 | 6.6 | 480 | 221 | 36 | 0.08 | 1.2 |

| 4 | 5.5 | 70 | 55 | 14 | 0.77 | 4.6 |

| 4 | 6 | 70 | 95 | 18 | 0.65 | 2.6 |

| 4 | 6.6 | 480 | 122 | 29 | 0.54 | 1.8 |

| Type | (mm) | (mm) | T (mm) | L (mm) |

|---|---|---|---|---|

| 1 | 3.3 ± 0.1 | 2.773 ± 0.1 | 0.264 | 100 ± 0.5 |

| 2 | 3.7 ± 0.1 | 2.775 ± 0.1 | 0.462 | 100 ± 0.5 |

| 3 | 2.0 ± 0.1 | 1.0 ± 0.1 | 0.5 | 100 ± 0.5 |

| 4 | 2.0 ± 0.1 | 1.6 ± 0.1 | 0.2 | 100 ± 0.5 |

| Noozle | r (mm) | z (mm) | t (s) | D (m) | |

|---|---|---|---|---|---|

| A | 3.5 | 15 | 90 | 224 ± 2 | 1.07 |

| B | 5 | 15 | 700 | 218 ± 3 | 0.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rubio, A.; Rodríguez, S.; Cabezas, M.G. Capabilities and Limitations of Fire-Shaping to Produce Glass Nozzles. Materials 2020, 13, 5477. https://doi.org/10.3390/ma13235477

Rubio A, Rodríguez S, Cabezas MG. Capabilities and Limitations of Fire-Shaping to Produce Glass Nozzles. Materials. 2020; 13(23):5477. https://doi.org/10.3390/ma13235477

Chicago/Turabian StyleRubio, Alejandro, Sergio Rodríguez, and Maria G. Cabezas. 2020. "Capabilities and Limitations of Fire-Shaping to Produce Glass Nozzles" Materials 13, no. 23: 5477. https://doi.org/10.3390/ma13235477

APA StyleRubio, A., Rodríguez, S., & Cabezas, M. G. (2020). Capabilities and Limitations of Fire-Shaping to Produce Glass Nozzles. Materials, 13(23), 5477. https://doi.org/10.3390/ma13235477