Mechanical and Durability Performance Improvement of Natural Hydraulic Lime-Based Mortars by Lithium Silicate Solution

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation

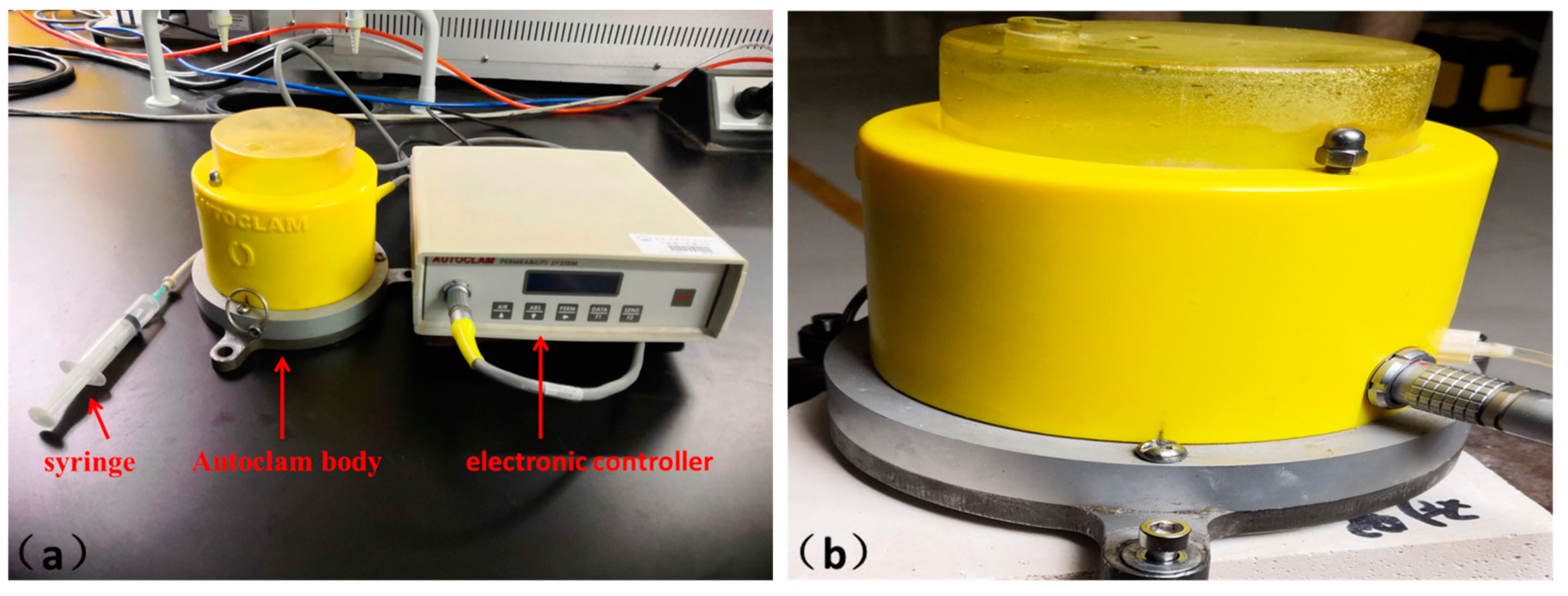

2.3. Test Methods

3. Results and Discussion

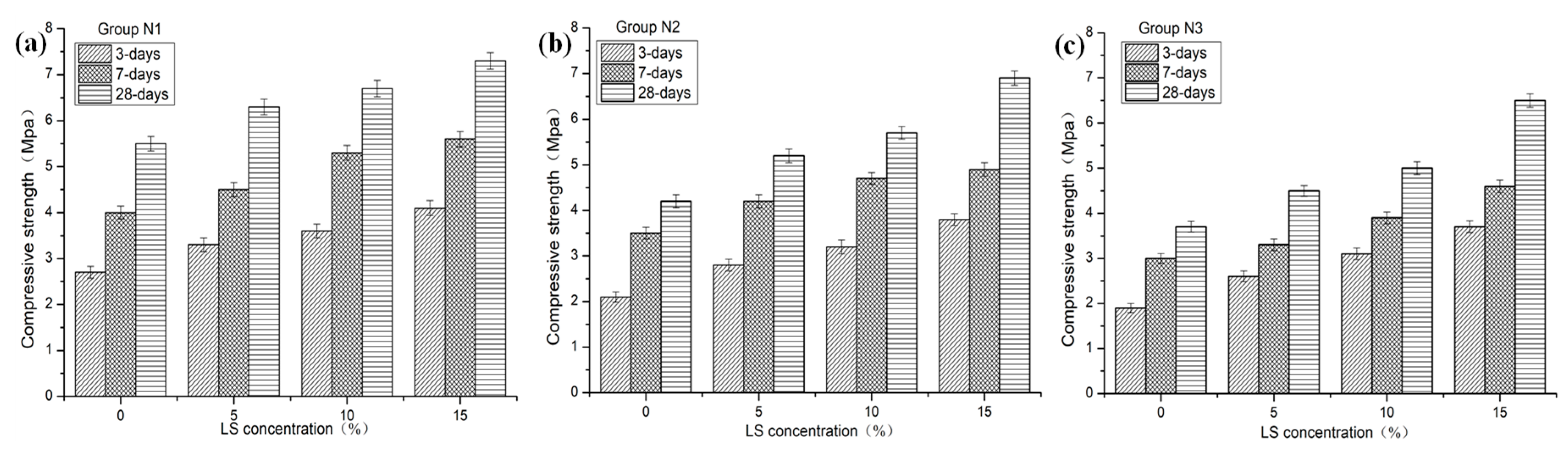

3.1. The Effect on Mechanical Properties

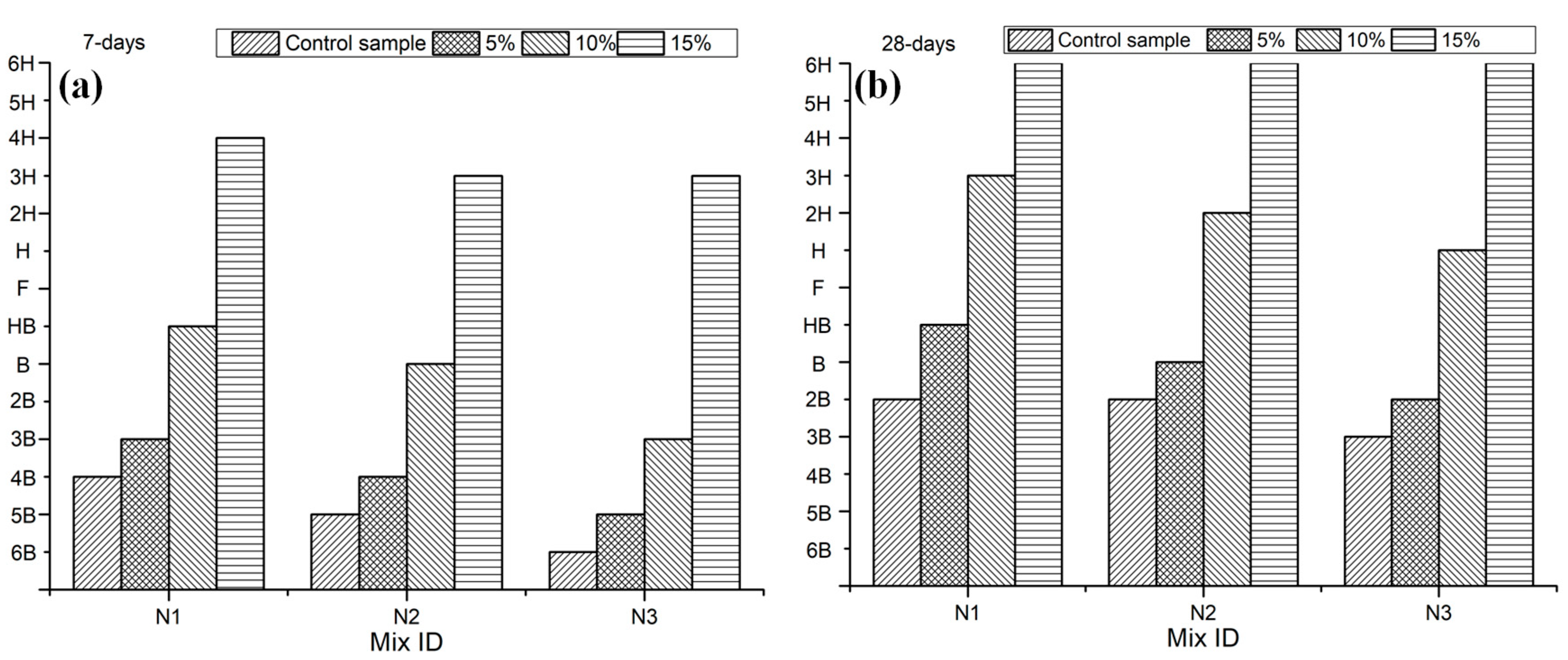

3.2. The Effect on Air Permeability

3.3. Effect of LS on Water Absorption of NHL-Based Mortar

3.4. The Analysis of Morphology

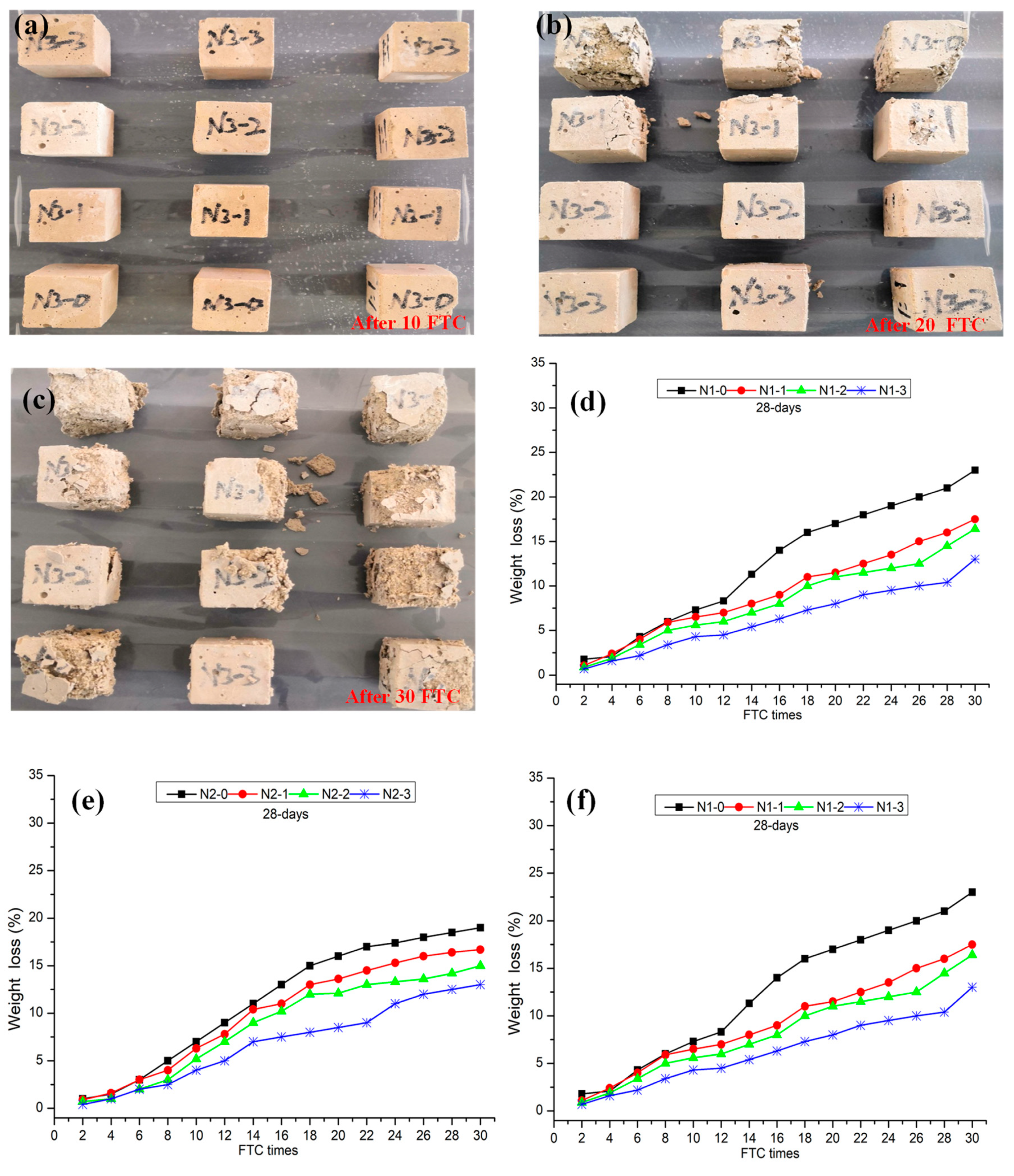

3.5. Effect of LS Pretreatment on FTC Resistance

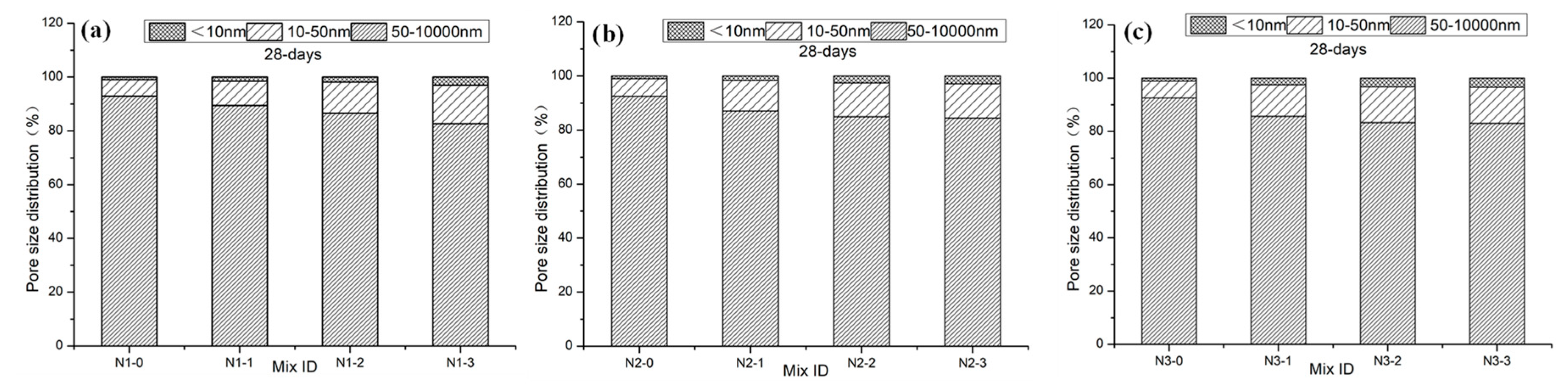

3.6. Pore Structures

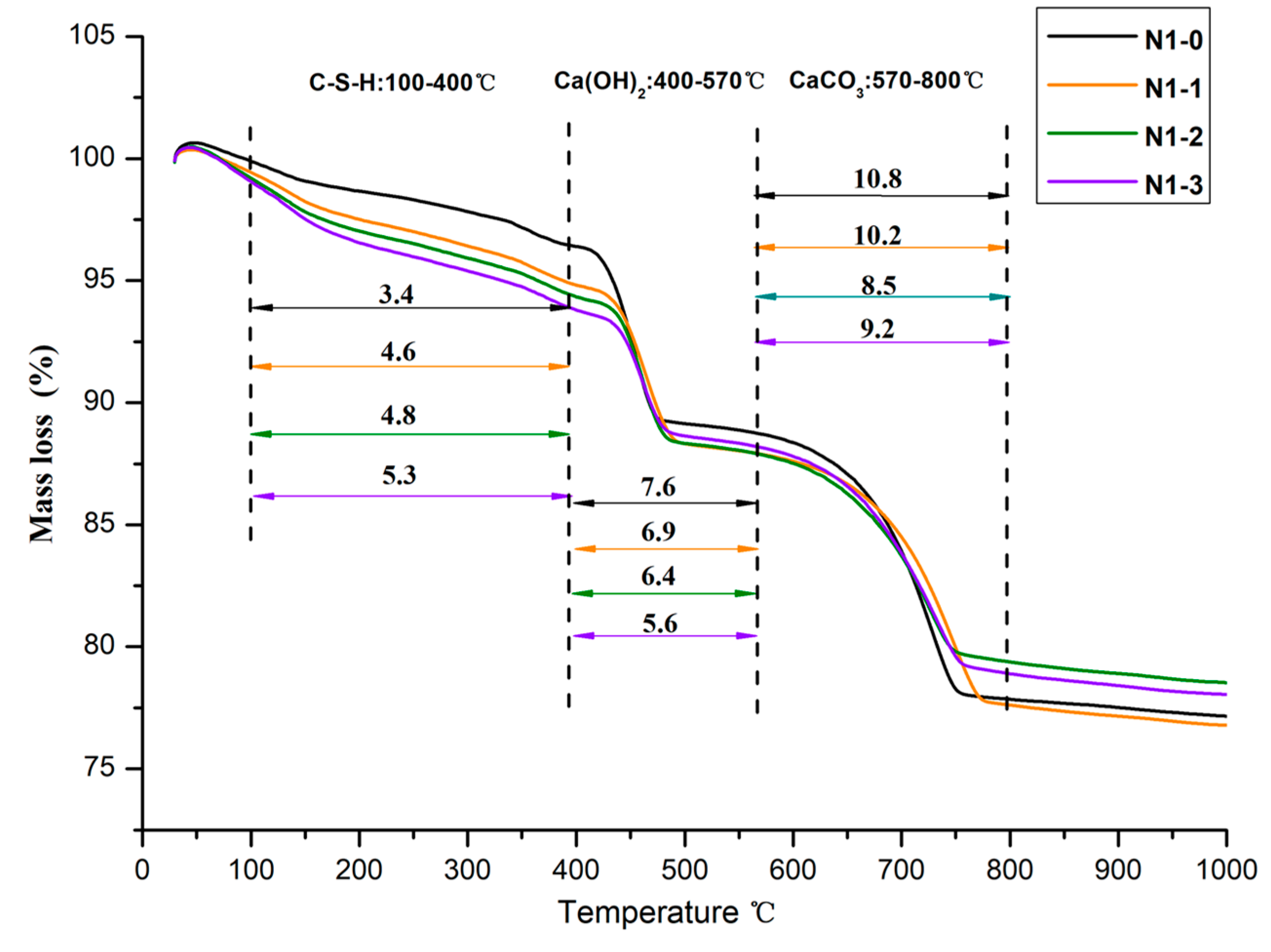

3.7. TG Analysis Results

4. Conclusions

- The NHL-based mortar’s compressive strength can be improved after being impregnated in LS solution for 8 h. The growth rate of compressive strength was maintained between 32.7% and 52.0%.

- After spraying LS on the sample’s surface (about 0.2 kg/m2), the surface hardness increased by up to 10 grades.

- The sample surface was densified by LS, and the FTC resistance was improved. In particular, compared with the control samples after 30 FTC tests, the weight loss of sample N1-3, N2-3, and N3-3 decreased by 43.0%, 31.6%, and 43.8%, respectively.

- LS can consume existing or newly generated CH to form C-S-H, which refines the NHL-based mortar’s pore structure, leading to a decrease in API value and water absorption.

Author Contributions

Funding

Conflicts of Interest

References

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Natural hydraulic lime versus cement for blended lime mortars for restoration works. Constr. Build. Mater. 2015, 94, 346–360. [Google Scholar]

- Arizzi, A.; Viles, H.; Cultrone, G. Experimental testing of the durability of lime-based mortars used for rendering historic buildings. Constr. Build. Mater. 2012, 28, 807–818. [Google Scholar]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Karatasios, I.; Kilikoglou, V. Hydraulic lime mortars for the restoration of historic masonry in Crete. Cem. Concr. Res. 2005, 35, 1577–1586. [Google Scholar]

- CEN. Building Lime. Definitions, Specifications and Conformity Criteria; Part 1; Cen: Brussels, Belgium, 2015. [Google Scholar]

- Lanas, J.; Pérez Bernal, J.L.; Bello, M.A.; Alvarez Galindo, J.I. Mechanical properties of natural hydraulic lime-based mortars. Cem. Concr. Res. 2004, 34, 2191–2201. [Google Scholar]

- Mertens, G.; Madau, P.; Durinck, D.; Blanpain, B.; Elsen, J. Quantitative mineralogical analysis of hydraulic limes by X-ray diffraction. Cem. Concr. Res. 2007, 37, 1524–1530. [Google Scholar]

- Garijo, L.; Zhang, X.; Ruiz, G.; Ortega, J.J.; Wu, Z. The effects of dosage and production process on the mechanical and physical properties of natural hydraulic lime mortars. Constr. Build. Mater. 2018, 169, 325–334. [Google Scholar]

- Pozo-Antonio, J.S. Evolution of mechanical properties and drying shrinkage in lime-based and lime cement-based mortars with pure limestone aggregate. Constr. Build. Mater. 2015, 77, 472–478. [Google Scholar]

- Elert, K.; Rodriguez-Navarro, C.; Pardo, E.S.; Hansen, E.; Cazalla, O. Lime Mortars for the Conservation of Historic Buildings. Stud. Conserv. 2002, 47, 62–75. [Google Scholar]

- Jaafri, R.; Aboulayt, A.; Alam, S.Y.; Roziere, E.; Loukili, A. Natural hydraulic lime for blended cement mortars: Behavior from fresh to hardened states. Cem. Concr. Res. 2019, 120, 52–65. [Google Scholar]

- De Azeredo, A.F.N.; Struble, L.J.; Carneiro, A.M.P. Microstructural characteristics of lime-pozzolan pastes made from kaolin production wastes. Mater. Struct. 2014, 48, 2123–2132. [Google Scholar]

- Bras, A.; Henriques, F.M.A.; Cidade, M.T. Effect of environmental temperature and fly ash addition in hydraulic lime grout behaviour. Constr. Build. Mater. 2010, 24, 1511–1517. [Google Scholar]

- Pozo-Antonio, J.S.; Dionísio, A. Physical-mechanical properties of mortars with addition of TiO2 nanoparticles. Constr. Build. Mater. 2017, 148, 261–272. [Google Scholar]

- Grilo, J.; Faria, P.; Veiga, R.; Santos Silva, A.; Silva, V.; Velosa, A. New natural hydraulic lime mortars—Physical and microstructural properties in different curing conditions. Constr. Build. Mater. 2014, 54, 378–384. [Google Scholar]

- Vavričuk, A.; Bokan-Bosiljkov, V.; Kramar, S. The influence of metakaolin on the properties of natural hydraulic lime-based grouts for historic masonry repair. Constr. Build. Mater. 2018, 172, 706–716. [Google Scholar]

- Luso, E.; Lourenço, P.B. Experimental laboratory design of lime based grouts for masonry consolidation. Int. J. Archit. Herit. 2017, 1–10. [Google Scholar] [CrossRef]

- Grilo, J.; Santos Silva, A.; Faria, P.; Gameiro, A.; Veiga, R.; Velosa, A. Mechanical and mineralogical properties of natural hydraulic lime-metakaolin mortars in different curing conditions. Constr. Build. Mater. 2014, 51, 287–294. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A.; Jorne, F.; Cidade, M.T. Combined effect of superplasticizer, silica fume and temperature in the performance of natural hydraulic lime grouts. Constr. Build. Mater. 2014, 50, 584–597. [Google Scholar]

- Faria, P.; Duarte, P.; Barbosa, D.; Ferreira, I. New composite of natural hydraulic lime mortar with graphene oxide. Constr. Build. Mater. 2017, 156, 1150–1157. [Google Scholar]

- Tang, W.; Khavarian, M.; Yousefi, A.; Chan, R.W.K.; Cui, H. Influence of Surface Treatment of Recycled Aggregates on Mechanical Properties and Bond Strength of Self-Compacting Concrete. Sustainability 2019, 11, 1–18. [Google Scholar]

- Witzleben, S.T. Acceleration of Portland cement with lithium, sodium and potassium silicates and hydroxides. Mater. Chem. Phys. 2020, 243. [Google Scholar]

- Abou Sleiman, C.N.; Shi, X.; Zollinger, D.G. An Approach to Characterize the Wearability of Concrete Pavement Surface Treatments. Transport. Res. Rec. 2019, 2673, 230–239. [Google Scholar]

- Stepien, A.; Kostrzewa, P.; Dachowski, R. Influence of barium and lithium compounds on silica autoclaved materials properties and on the microstructure. J. Clean. Prod. 2019, 236, 117507. [Google Scholar]

- Forster, A.M.; Szadurski, E.M.; Banfill, P.F.G. Deterioration of natural hydraulic lime mortars, I: Effects of chemically accelerated leaching on physical and mechanical properties of uncarbonated materials. Constr. Build. Mater. 2014, 72, 199–207. [Google Scholar]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Influence of natural hydraulic lime content on the properties of aerial lime-based mortars. Constr. Build. Mater. 2014, 72, 208–218. [Google Scholar]

- Gulotta, D.; Goidanich, S.; Tedeschi, C.; Nijland, T.G.; Toniolo, L. Commercial NHL-containing mortars for the preservation of historical architecture. Part 1: Compositional and mechanical characterisation. Constr. Build. Mater. 2013, 38, 31–42. [Google Scholar]

- Gulotta, D.; Goidanich, S.; Tedeschi, C.; Toniolo, L. Commercial NHL-containing mortars for the preservation of historical architecture. Part 2: Durability to salt decay. Constr. Build. Mater. 2015, 96, 198–208. [Google Scholar]

- ASTM. Standard Test Method forFilm Hardness by Pencil Test; ASTM D3363-2005; ASTM: Philadelphia, PA, USA, 2005. [Google Scholar]

- Yang, K.; Basheer, P.A.M.; Magee, B.; Bai, Y. Investigation of moisture condition and Autoclam sensitivity on air permeability measurements for both normal concrete and high performance concrete. Constr. Build. Mater. 2013, 48, 306–314. [Google Scholar]

- Jia, L.; Shi, C.; Pan, X.; Zhang, J.; Wu, L. Effects of inorganic surface treatment on water permeability of cement-based materials. Cem. Concr. Compos. 2016, 67, 85–92. [Google Scholar]

- Pan, X.; Shi, C.; Zhang, J.; Jia, L.; Chong, L. Effect of inorganic surface treatment on surface hardness and carbonation of cement-based materials. Cem. Concr. Compos. 2018, 90, 218–224. [Google Scholar]

- Thompson, J.; Silsbee, M.; Gill, P.; Scheetz, B. Characterization of silicate sealers on concrete. Cem. Concr. Res. 1997, 27, 1561–1567. [Google Scholar]

- Basheer, P.A.M.; Montgomery, F.R.; Long, A.E. Clam’ Tests for Measuring in-Situ Permeation Properties of Concrete. Nondestruct. Test. Eval. 1995, 12, 53–73. [Google Scholar]

- Dai, J.-G.; Akira, Y.; Wittmann, F.; Yokota, H.; Zhang, P. Water repellent surface impregnation for extension of service life of reinforced concrete structures in marine environments: The role of cracks. Cem. Concr. Compos. 2010, 32, 101–109. [Google Scholar]

- Moon, H.Y.; Shin, D.G.; Choi, D.S. Evaluation of the durability of mortar and concrete applied with inorganic coating material and surface treatment system. Constr. Build. Mater. 2007, 21, 362–369. [Google Scholar]

- Levi, M.; Ferro, C.; Regazzoli, D.; Dotelli, G.; Presti, A.L. Comparative evaluation method of polymer surface treatments applied on high performance concrete. J. Mater. Sci. 2002, 4881–4888. [Google Scholar]

- Xu, S.; Ma, Q.; Wang, J. Combined effect of isobutyltriethoxysilane and silica fume on the performance of natural hydraulic lime-based mortars. Constr. Build. Mater. 2018, 162, 181–191. [Google Scholar]

- Luo, K.; Li, J.; Han, Q.; Lu, Z.; Deng, X.; Hou, L.; Niu, Y.; Jiang, J.; Xu, X.; Cai, P. Influence of nano-SiO2 and carbonation on the performance of natural hydraulic lime mortars. Constr. Build. Mater. 2020, 235, 117411. [Google Scholar]

- Luo, K.; Li, J.; Lu, Z.; Jiang, J.; Niu, Y. Effect of nano-SiO2 on early hydration of natural hydraulic lime. Constr. Build. Mater. 2019, 216, 119–127. [Google Scholar]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar]

- Xu, S.; Wang, J.; Sun, Y. Effect of water binder ratio on the early hydration of natural hydraulic lime. Mater. Struct. 2014, 48, 3431–3441. [Google Scholar]

- Tsivilis, S.; Kakali, G.; Chaniotakis, E. A Study on the Hydration of Portland Limestone Cement by Means of TG. J. Therm. Anal. Calorim. 1998, 52, 863–870. [Google Scholar]

| Chemical Composition | SiO2 | CaO | Fe2O3 | MgO | Al2O3 |

|---|---|---|---|---|---|

| NHL2 | 9.48 | 78.66 | 1.98 | 4.51 | 3.12 |

| Samples | Composition of Mixture (kg/m3) | LS Concentration (%) | ||||

|---|---|---|---|---|---|---|

| Sand/NHL2 | Water/NHL2 | NHL2 | Sand | Water | ||

| N1-0 | 1:1 | 0.5 | 450 | 450 | 225 | 0 |

| N1-1 | 5 | |||||

| N1-2 | 10 | |||||

| N1-3 | 15 | |||||

| N2-0 | 2:1 | 0.5 | 450 | 900 | 225 | 0 |

| N2-1 | 5 | |||||

| N2-2 | 10 | |||||

| N2-3 | 15 | |||||

| N3-0 | 3:1 | 0.5 | 450 | 1350 | 225 | 0 |

| N3-1 | 5 | |||||

| N3-2 | 10 | |||||

| N3-3 | 15 | |||||

| Concentration of LS | Group N1 | Group N2 | Group N3 |

|---|---|---|---|

| 0% | 25.58 | 29.84 | 37.71 |

| 5.0% | 23.58 | 29.20 | 36.72 |

| 10.0% | 23.11 | 28.38 | 34.72 |

| 15.0% | 20.12 | 26.38 | 31.83 |

| Group | Samples | Water Bound to C-S-H | CH | CC |

|---|---|---|---|---|

| N1 | N1-0 | 3.4 | 31.4 | 24.5 |

| N1-1 | 4.6 | 28.3 | 23.3 | |

| N1-2 | 4.8 | 26.5 | 19.2 | |

| N1-3 | 5.3 | 23.1 | 21.0 | |

| N2 | N2-0 | 3.5 | 32.4 | 24.6 |

| N2-1 | 4.3 | 29.2 | 23.7 | |

| N2-2 | 4.5 | 27.3 | 19.8 | |

| N2-3 | 5.2 | 23.8 | 18.0 | |

| N3 | N2-0 | 3.3 | 32.3 | 24.0 |

| N2-1 | 4.7 | 29.3 | 23.0 | |

| N2-2 | 4.6 | 27.4 | 19.1 | |

| N2-3 | 5.3 | 24.1 | 18.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Z.; Lu, Z.; Lai, Z. Mechanical and Durability Performance Improvement of Natural Hydraulic Lime-Based Mortars by Lithium Silicate Solution. Materials 2020, 13, 5292. https://doi.org/10.3390/ma13225292

Song Z, Lu Z, Lai Z. Mechanical and Durability Performance Improvement of Natural Hydraulic Lime-Based Mortars by Lithium Silicate Solution. Materials. 2020; 13(22):5292. https://doi.org/10.3390/ma13225292

Chicago/Turabian StyleSong, Zijian, Zhongyuan Lu, and Zhenyu Lai. 2020. "Mechanical and Durability Performance Improvement of Natural Hydraulic Lime-Based Mortars by Lithium Silicate Solution" Materials 13, no. 22: 5292. https://doi.org/10.3390/ma13225292

APA StyleSong, Z., Lu, Z., & Lai, Z. (2020). Mechanical and Durability Performance Improvement of Natural Hydraulic Lime-Based Mortars by Lithium Silicate Solution. Materials, 13(22), 5292. https://doi.org/10.3390/ma13225292