Sorption of Heavy Metal Ions of Chromium, Manganese, Selenium, Nickel, Cobalt, Iron from Aqueous Acidic Solutions in Batch and Dynamic Conditions on Natural and Synthetic Aluminosilicate Sorbents

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Standards

2.2. Sorbents Descriptions

2.3. Batch Studies

2.4. Dynamic Operation Condition

2.5. XRF, XRD and SEM

2.6. Surface Area Measurements

2.7. AAS

2.8. Adsorption Isotherm Model

3. Results and Discussion

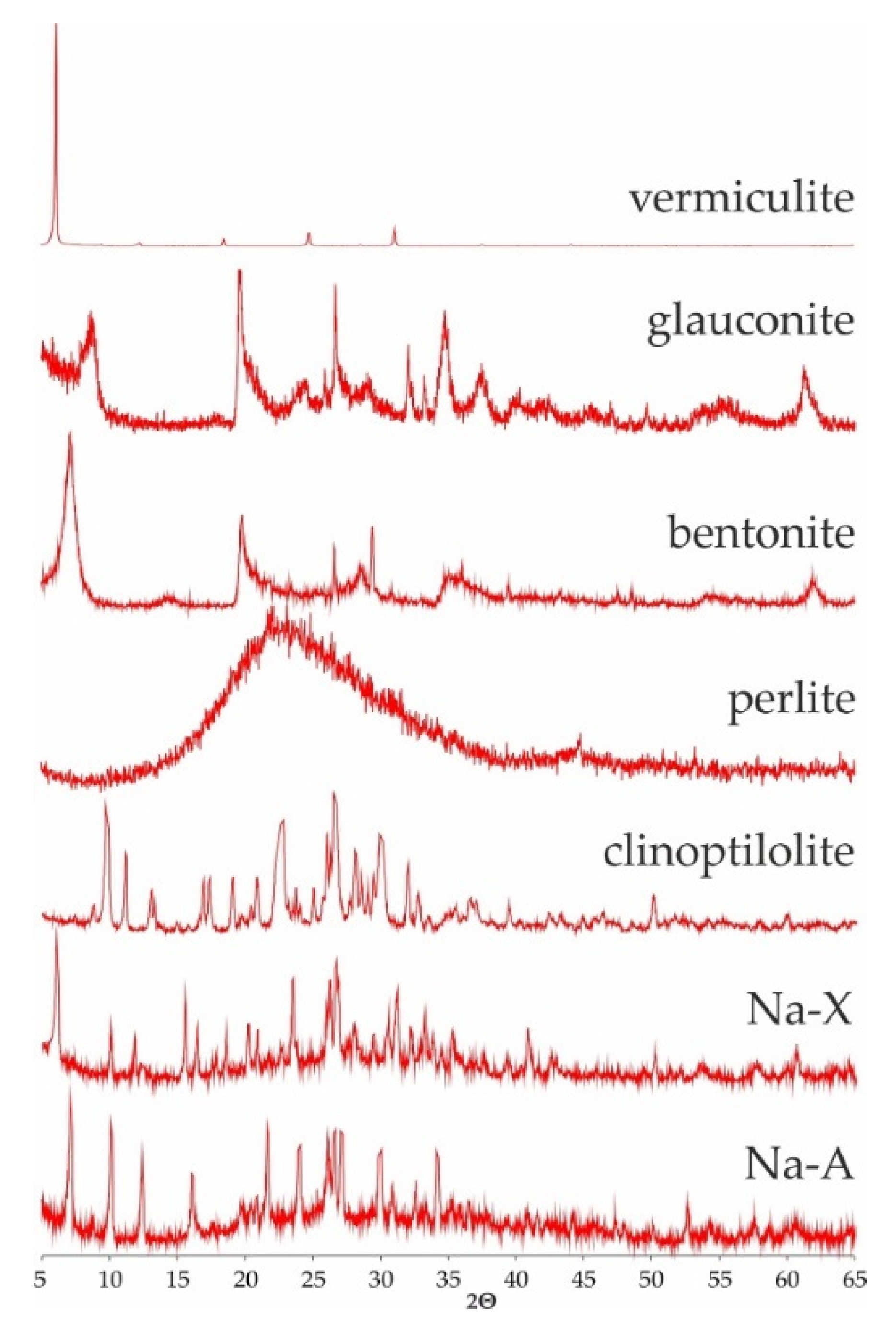

3.1. Sorbent Characteristics

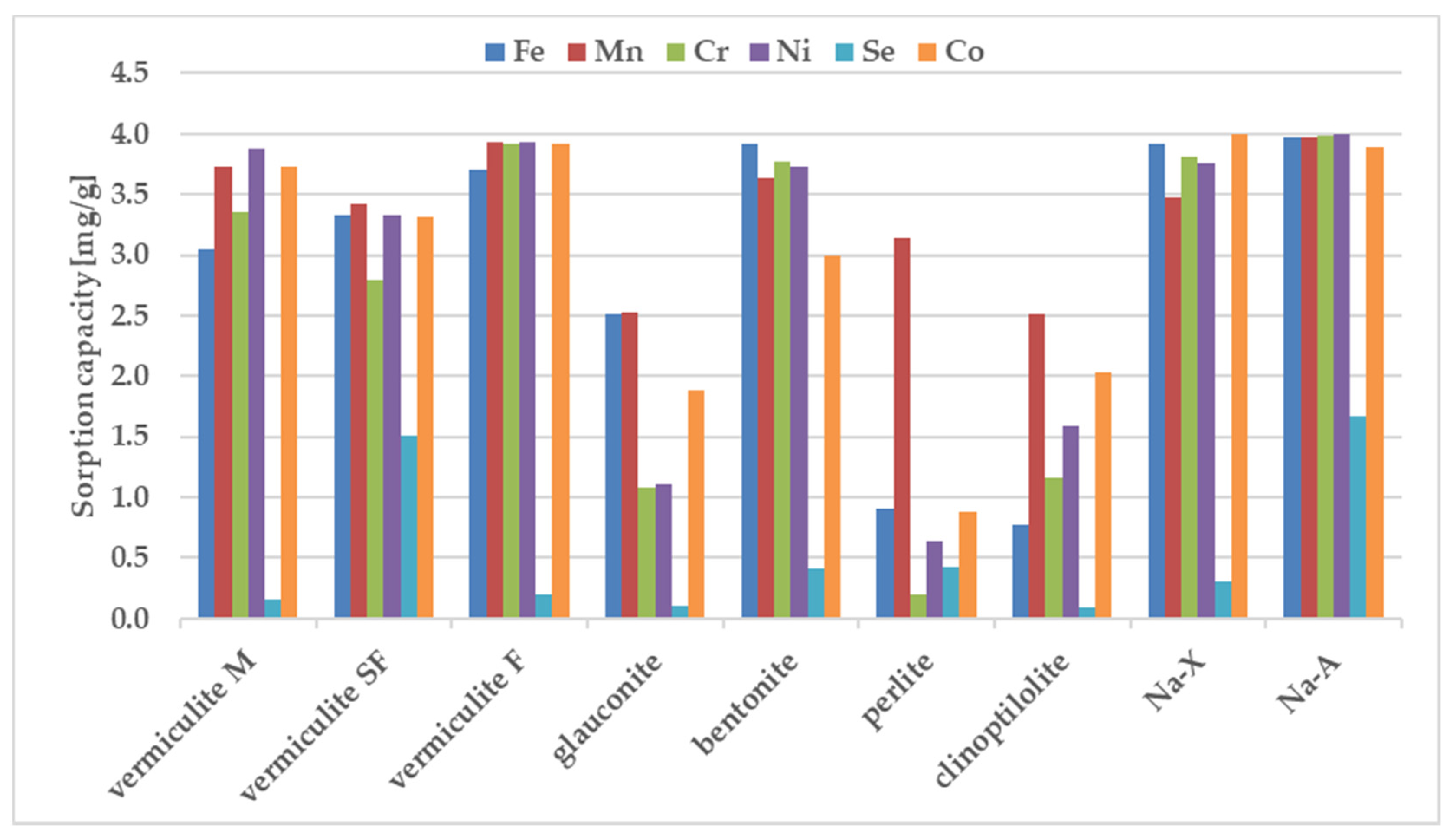

3.2. Sorption Properties at Batch Conditions

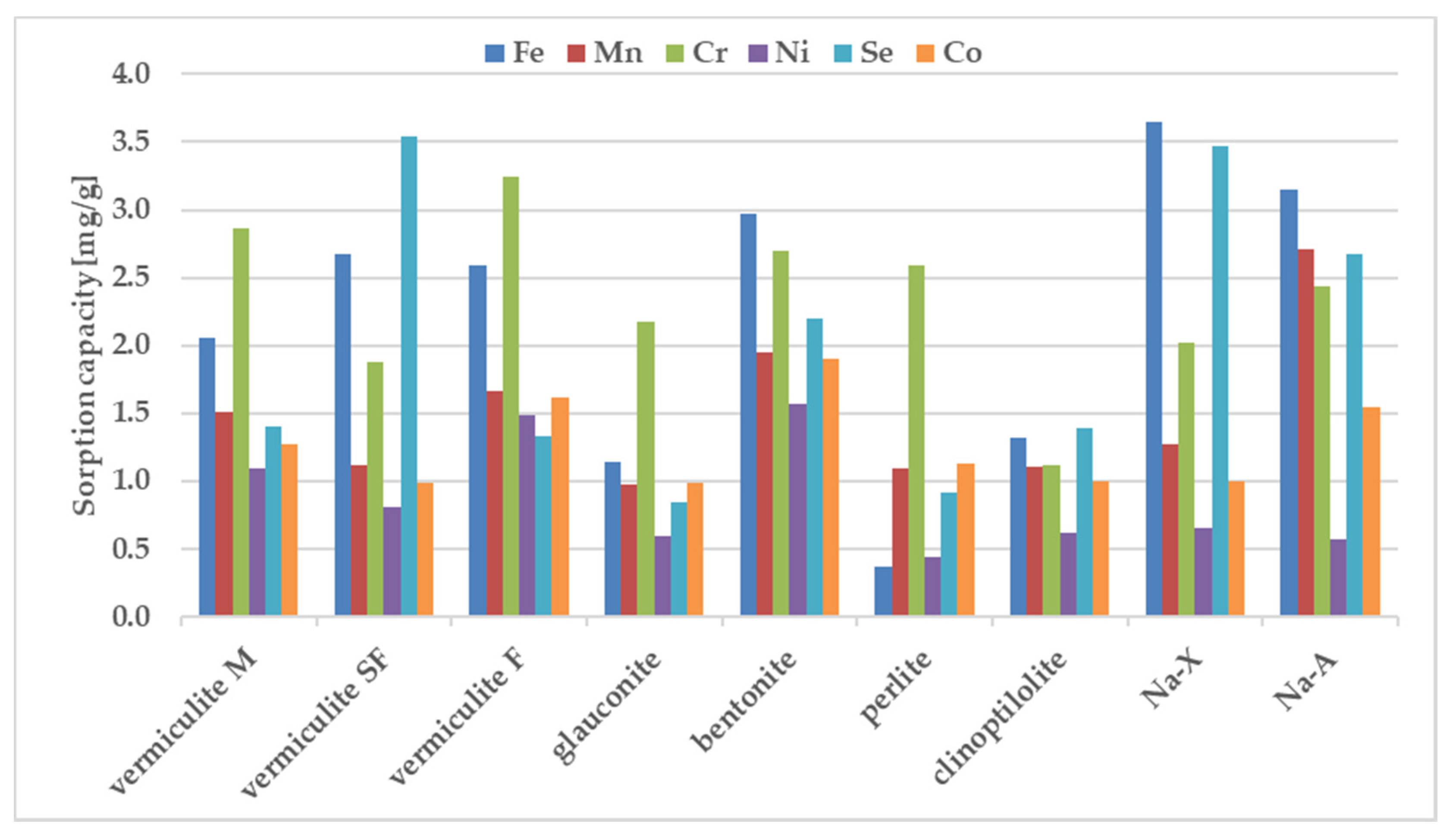

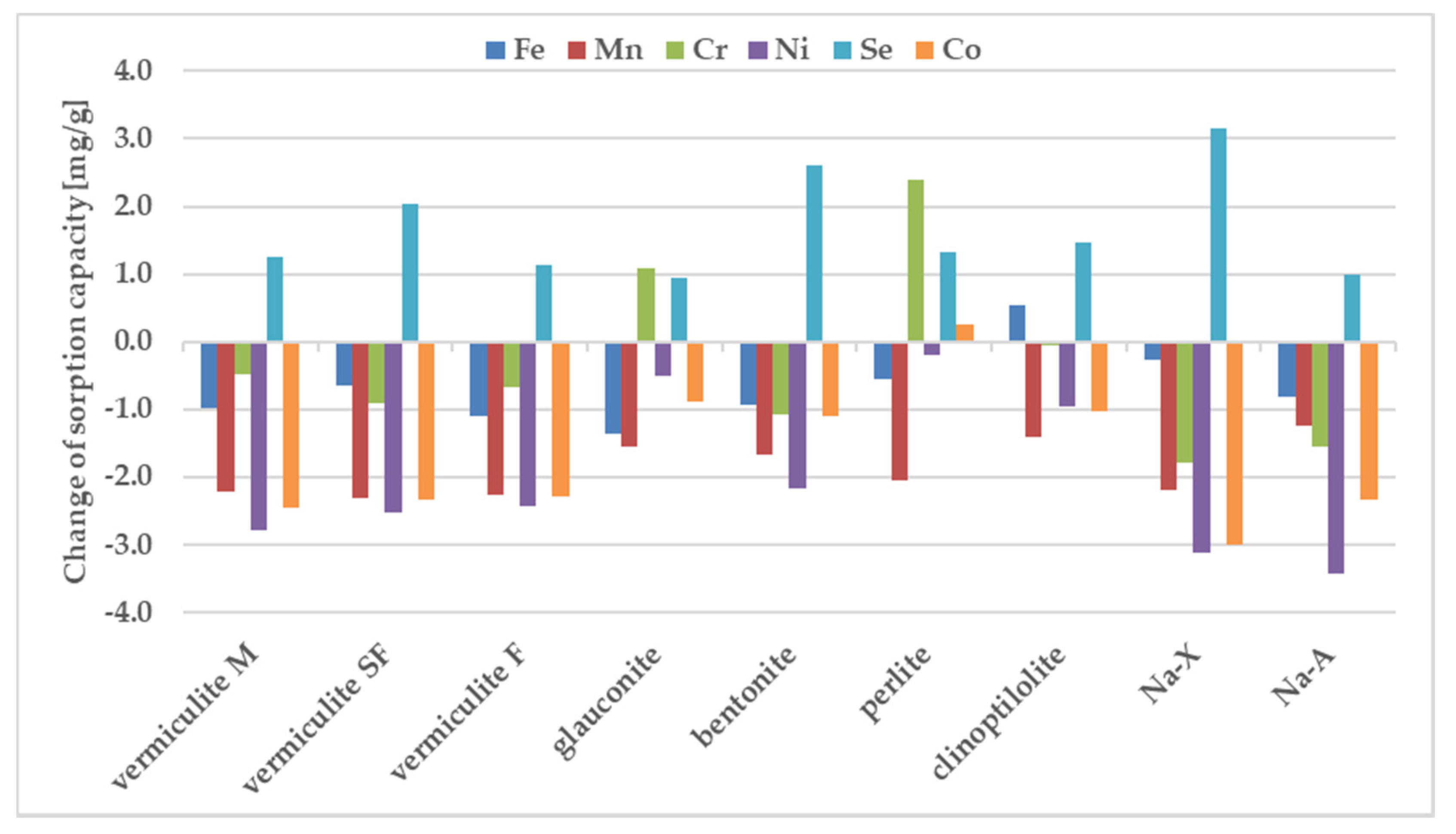

3.3. Sorption in Multi-Component Systems

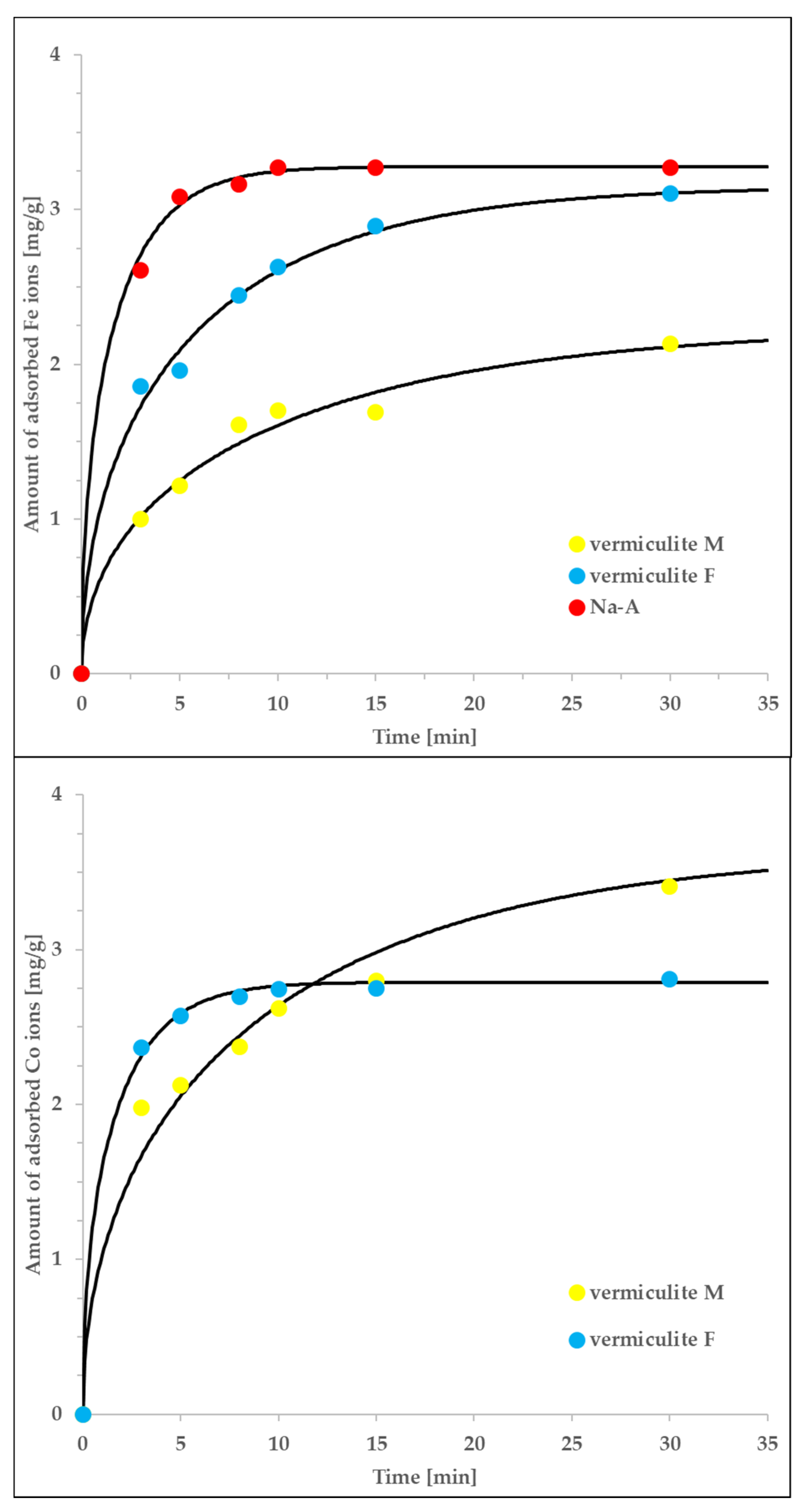

3.4. Sorption Kinetics

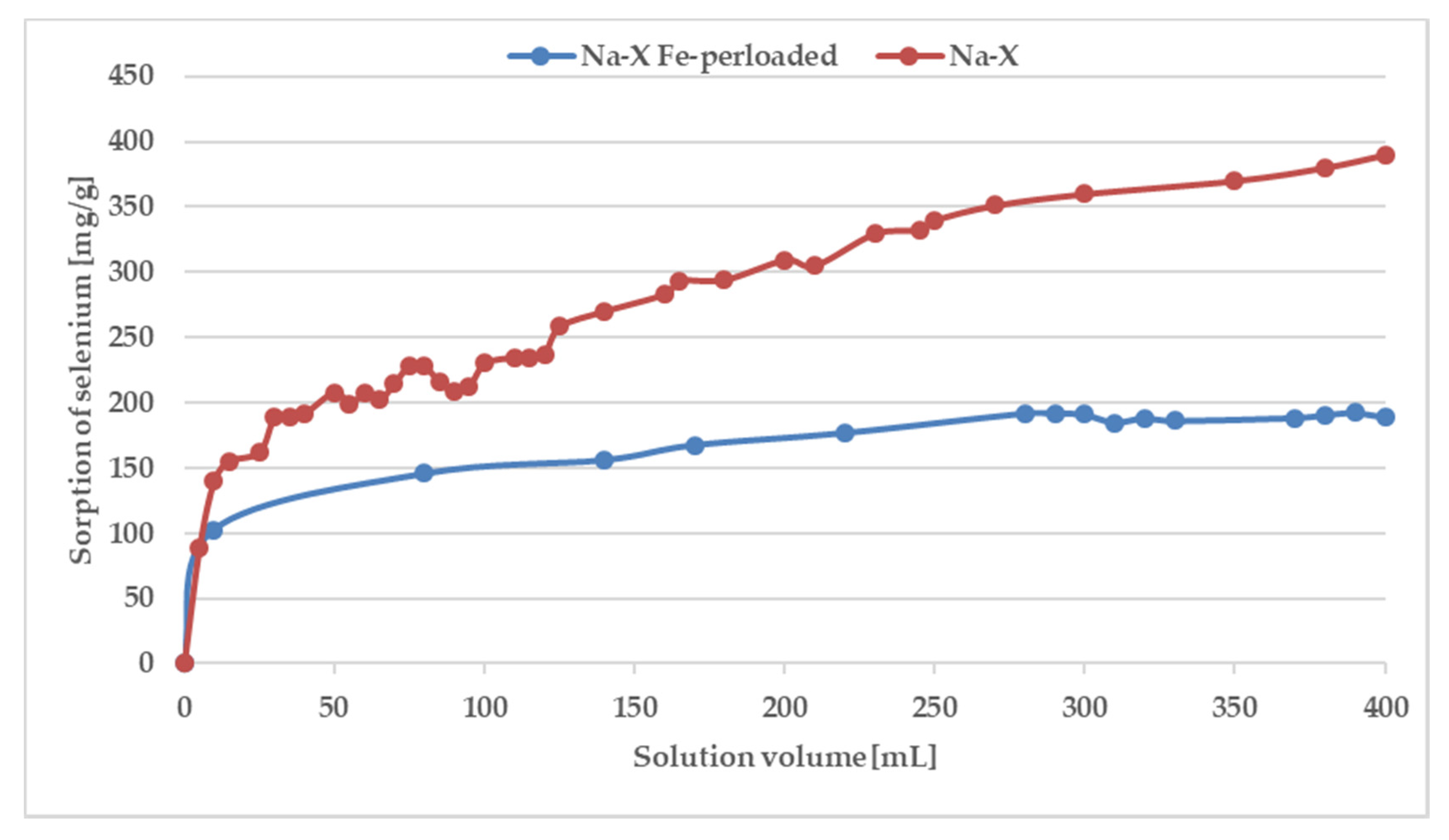

3.5. Fixed Bed Column Study

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- El-Shahawi, M.S.; Al-Saidi, H.M. Dispersive liquid-liquid microextraction for chemical speciation and determination of ultra-trace concentrations of metal ions. Tractrends Anal. Chem. 2013, 44, 12–24. [Google Scholar] [CrossRef]

- Kara, D.; Fisher, A.; Hill, S.J. Preconcentration and determination of trace elements with 2,6-diacetylpyridine functionalized Amberlite XAD-4 by flow injection and atomic spectroscopy. Analyst 2005, 130, 1518–1523. [Google Scholar] [CrossRef]

- Applegate, L.E. Membrane separation processes. Chem. Eng. 1984, 91, 64–89. [Google Scholar]

- Yu, Z.; Qi, T.; Qu, J.; Wang, L.; Chu, J. Removal of Ca(II) and Mg(II) from potassium chromate solution on Amberlite IRC 748 synthetic resin by ion exchange. J. Hazard. Mater. 2009, 167, 406–412. [Google Scholar] [CrossRef]

- Geselbarcht, J. Micro Filtration/Reverse Osmosis Pilot Trials for Livermore, California, Advanced Water Reclamation. In Proceedings of the 1996 Water Reuse Conference Proceedings, AWWA, San Diego, CA, USA, 25–28 February 1996; p. 187. [Google Scholar]

- Schnoor, J.L. Phytoremediation, Technology Evaluation Report TE-97-01; Ground-Water Remediation Technologies Analysis Center: Pittsburgh, PA, USA, 1997; pp. 1–37. [Google Scholar]

- Macingova, E.; Luptakova, A. Recovery of Metals from Acid Mine Drainage. Chem. Eng. Trans. 2012, 28, 109–114. [Google Scholar]

- Babel, S.; Kurniawan, T.A. Low-cost adsorbents for heavy metals uptake from contaminated water: A review. J. Hazard. Mater. 2003, 97, 219–243. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. Industrial wastes as low-cost potential adsorbents for the treatment of wastewater laden with heavy metals. Adv. Colloid Interface Sci. 2011, 166, 36–59. [Google Scholar] [CrossRef] [PubMed]

- Franus, M.; Bandura, L. Sorption of heavy metal ions from aqueous solution by glauconite. Fresenius Environ. Bull. 2014, 23, 825–839. [Google Scholar]

- Ezzeddine, Z.; Batonneau-Gener, I.; Pouilloux, Y.; Hamad, H.; Saad, Z. Synthetic NaX Zeolite as a Very Efficient Heavy Metals Sorbent in Batch and Dynamic Conditions. Colloids Interfaces 2018, 2, 22. [Google Scholar] [CrossRef]

- Erdem, E.; Karapinar, N.; Donat, R. The removal of heavy metal cations by natural zeolites. J. Colloid Interface Sci. 2004, 280, 309–314. [Google Scholar] [CrossRef] [PubMed]

- Belova, T.P. Adsorption of heavy metal ions (Cu2+, Ni2+, Co2+ and Fe2+) from aqueous solutions by natural zeolite. Heliyon 2019, 5, e02320. [Google Scholar] [CrossRef] [PubMed]

- Kovacova, Z.; Demcak, S.; Balintova, M.; Pla, C.; Zinicovscaia, I. Influence of Wooden Sawdust Treatments on Cu(II) and Zn(II) Removal from Water. Materials 2020, 13, 3575. [Google Scholar] [CrossRef] [PubMed]

- Zinicovscaia, I.; Yushin, N.; Abdusamadzoda, D.; Grozdov, D.; Shvetsova, M. Efficient Removal of Metals from Synthetic and Real Galvanic Zinc–Containing Effluents by Brewer’s Yeast Saccharomyces cerevisiae. Materials 2020, 13, 3624. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Ma, X.; Xu, L.; Wang, L.; Liu, G.; Xu, Q.; Lu, J.; Zhang, Y. Applications of chelating resin for heavy metal removal from wastewater. e-Polymers 2015, 15, 161–167. [Google Scholar] [CrossRef]

- Otunola, B.O.; Ololade, O.O. Review on the application of clay minerals as heavy metal adsorbents for remediation purposes. Environ. Technol. Innov. 2020, 18, 100692. [Google Scholar] [CrossRef]

- Aboudi Mana, S.C.; Hanafiah, M.M.; Chowdhury, A.J.K. Environmental characteristics of clay and clay-based minerals. Geol. Ecol. Landsc. 2017, 1, 155–161. [Google Scholar] [CrossRef]

- Vhahangwele, M.; Mugera, G.W. The potential of ball-milled South African bentonite clay for attenuation of heavy metals from acidic waste waters: Simultaneous sorption of Co2+, Cu2+, Ni2+, Pb2+, and Zn2+ ions. J. Environ. Chem. Eng. 2015, 3, 2416–2425. [Google Scholar] [CrossRef]

- Sis, H.; Uysal, T. Removal of heavy metal ions from aqueous medium using Kuluncak (Malatya) vermiculites and effect of precipitation on removal. Appl. Clay Sci. 2014, 95, 1–8. [Google Scholar] [CrossRef]

- Malandrino, M.; Abollino, O.; Giacomino, A.; Aceto, M.; Mentasti, E. Adsorption of heavy metals on vermiculite: Influence of pH and organic ligands. J. Colloid Interface Sci. 2006, 299, 537–546. [Google Scholar] [CrossRef]

- Franus, M.; Bandura, L.; Madej, J. Mono and Poly-Cationic Adsorption of Heavy Metals Using Natural Glauconite. Minerals 2019, 9, 470. [Google Scholar] [CrossRef]

- Bouazza, D.; Miloudi, H.; Adjdir, M.; Tayeb, A.; Boos, A. Competitive adsorption of Cu (II) and Zn (II) on impregnate raw Algerian bentonite and efficiency of extraction. Appl. Clay Sci. 2018, 151, 118–123. [Google Scholar] [CrossRef]

- Uddin, M.K. A review on the adsorption of heavy metals by clay minerals, withspecial focus on the past decade. Chem. Eng. J. 2017, 308, 438–462. [Google Scholar] [CrossRef]

- Saja, S.; Bouazizi, A.; Achiou, B.; Ouammou, M.; Albizane, A.; Bennazha, J.; Younssi, S.A. Elaboration and characterization of low-cost ceramic membrane made from natural Moroccan perlite for treatment of industrial wastewater. J. Environ. Chem. Eng. 2018, 6, 451–458. [Google Scholar] [CrossRef]

- Styczeń, J.; Barnat-Hunek, D.; Panek, R.; Franus, W. The microstructural and physical properties of renovation renders with clinoptilolite, Na-P1 and Na-X zeolites. Constr. Build. Mater. 2020, 261, 120016. [Google Scholar] [CrossRef]

- Ahmed, I.M.; Hamed, M.M.; Metwally, S.S. Experimental and mathematical modeling of Cr(VI) removal usingnano-magnetic Fe3O4-coated perlite from the liquid phase. Chin. J. Chem. Eng. 2020, 28, 1582–1590. [Google Scholar] [CrossRef]

- RizkI, H.E.; Ahmed, I.M.; Metwally, S.S. Selective sorption and separation of molybdenum ion from some fission products by impregnated perlite. Chem. Eng. Process. Process Intensif. 2018, 124, 131–136. [Google Scholar] [CrossRef]

- Athanasiadis, K.; Helmreich, B. Influence of chemical conditioning on the ion exchange capacity and on kinetic of zinc uptake by clinoptilolite. Water Res. 2005, 39, 1527–1532. [Google Scholar] [CrossRef]

- Bandura, L.; Franus, M.; Panek, R.; Woszuk, A.; Franus, W. Characterization of zeolites and their use as adsorbents of petroleum substances. Przem. Chem. 2015, 3, 323–327. [Google Scholar]

- Barer, R.M. Zeolites and Clay Minerals as Sorbent and Molecular Sieves; Academic Press: New York, NY, USA, 1987. [Google Scholar]

- Katoh, M.; Horiuchi, K.; Satoh, A.; Aoyagi, K.; Sugiyama, S. Alkali Treatment of Commercial Silicoaluminophosphate Molecular Sieves (SAPO-34) Enhances the Water Adsorption and Desorption Properties. J. Encaps. Ads. Sci. 2019, 9, 149–158. [Google Scholar]

- Figmig, R.; Kováč, M. Study on utilization of zeolite in concrete precast industry. J. Civ. Eng. 2019, 14, 93–102. [Google Scholar] [CrossRef]

- Wang, S.; Peng, Y. Natural zeolites as effective adsorbents in water and wastewater treatment. Chem. Eng. J. 2010, 156, 11–24. [Google Scholar] [CrossRef]

- Franus, W.; Dudek, K. Clay minerals and clinoptilolite of variegated shales formation of the skole unit. Pol. Flysch Carpathians. Geol. Carpath. 1999, 50, 23–24. [Google Scholar]

- Bandura, L.; Panek, R.; Rotko, M.; Franus, W. Synthetic zeolites from fly ash for an effective trapping of BTX in gas stream. Microporous Mesoporous Mater. 2016, 223, 1–9. [Google Scholar] [CrossRef]

- Kunecki, P.; Panek, R.; Wdowin, M.; Franus, W. Synthesis of Faujasite (FAU) and Tschernichite (LTA) Type Zeolites as a Potential Direction of the Development of Lime Class C Fly Ash. Int. J. Miner. Process. 2017, 166, 69–78. [Google Scholar] [CrossRef]

- Joshi, M.S.; Mohan Rao, P. Cation sieve properties of natural heulandites. J. Colloid Interface Sci. 1983, 95, 131–134. [Google Scholar] [CrossRef]

- Oter, O.; Akcay, H. Use of natural clinoptilolite to improve, water quality: Sorption and selectivity studies of lead(II), copper(II), zinc(II), and nickel(II). Water Environ. Res. 2007, 79, 329–335. [Google Scholar] [CrossRef]

- Milosevic, S.; Tomasevic-Canovic, M. Modification of the surface of minerals for development the materials-adsorbents. In Proceedings of the 36th International October Conference on Mining and Metallurgy, Bor, Serbia and Montenegro, 2 September 2004. [Google Scholar]

- Stocker, K.; Ellersdorfer, M.; Lehner, M.; Raith, J.G. Characterization and Utilization of Natural Zeolites in Technical Applications. Bhm Berg-Und Hüttenmännische Mon. 2017, 162, 142–147. [Google Scholar] [CrossRef]

- Derkowski, A.; Środoń, J.; Franus, W.; Uhlik, P.; Banaś, M.; Zieliński, M.; Caplovicova, M.; Franus, M. Partial dissolution of glauconitic samples: Implications for the methodology of K-Ar and Rb-Sr dating. Clays Clay Miner. 2009, 57, 531–554. [Google Scholar] [CrossRef]

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and durability properties of concretes incorporating natural zeolite. Arch. Civ. Mech. Eng. 2016, 16, 554–562. [Google Scholar] [CrossRef]

- Kunecki, P.; Panek, R.; Wdowin, M.; Bień, T.; Franus, W. Influence of the fly ash fraction after grinding process on the hydrothermal synthesis efficiency of Na-A, Na-P1, Na-X and sodalite zeolite types. Int. J. Coal Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Kunecki, P.; Panek, R.; Koteja, A.; Franus, W. Influence of the reaction time on the crystal structure of Na-P1 zeolite obtained from coal fly ash microspheres. Microporous Mesoporous Mater. 2018, 266, 102–108. [Google Scholar] [CrossRef]

- Crank, J. Mathematics of Diffusion, 2nd ed.; Clarendon Press: Oxford, UK, 1975. [Google Scholar]

- Marcus, Y. Ionic Radii in Aqueous Solutions. Chem. Rev. 1988, 88, 1475–1498. [Google Scholar] [CrossRef]

- Suzuki, M. Adsorption Engineering; Kodansha, Elsevier: Tokyo, Japan, 1990. [Google Scholar]

- Séby, F.; Potin-Gautier, M.; Giffaut, E.; Borge, G.; Donard, O.F.X. A critical review of thermodynamic data for selenium species at 25 °C. Chem. Geol. 2001, 171, 173–194. [Google Scholar] [CrossRef]

- Torres, J.; Pintos, V.; Domínguez, S.; Kremer, C.; Kremer, E. Selenite and Selenate Speciation in Natural Waters: Interaction with Divalent Metal Ions. J. Solut. Chem. 2010, 39, 1–10. [Google Scholar] [CrossRef]

- Skorek, R.; Turek, E.; Zawisza, B.; Marguí, E.; Queralt, I.; Stempin, M.; Kucharski, P.; Sitko, R. Determination of selenium by X-ray fluorescence spectrometry using dispersive solid-phase microextraction with multiwalled carbon nanotubes as solid sorbent. J. Anal. At. Spectrom. 2012, 27, 1688–1693. [Google Scholar] [CrossRef][Green Version]

- Bleiman, N.; Mishael, Y.G. Selenium removal from drinking water by adsorption to chitosan–clay composites and oxides: Batch and columns tests. J. Hazard. Mater. 2010, 183, 590–595. [Google Scholar] [CrossRef]

- Gezer, N.; Gulfen, M.; Aydın, A.O. Adsorption of selenite and selenate ions onto thiourea formaldehyde resin. J. Appl. Polym. Sci. 2011, 122, 1134–1141. [Google Scholar] [CrossRef]

- Opiso, E.; Sato, T.; Yoneda, T. Adsorption and co-precipitation behavior of arsenate, chromate, selenate and boric acid with synthetic allophane-like materials. J. Hazard. Mater. 2009, 170, 79–86. [Google Scholar] [CrossRef]

- Tokunaga, K.; Takahashi, Y. Effective removal of selenite and selenate ions from aqueous solution by barite. Environ. Sci. Technol. 2017, 51, 9194–9201. [Google Scholar] [CrossRef]

- Prieto, M.; Astilleros, J.M.; Fernandez-Diaz, L. Environmental remediation by crystallization of solid solutions. Elements 2013, 9, 195–201. [Google Scholar] [CrossRef]

- Urbankova, K.; Moos, M.; Mach, J.; Sommer, L. Simultaneous determination of inorganic arsenic, antimony, selenium and tellurium by ICP-MS in environmental waters using SPE preconcentration on modified silica. Int. J. Environ. Anal. Chem. 2011, 91, 1077–1087. [Google Scholar] [CrossRef]

- Liu, Q. Determination of ultra-trace amounts of inorganic selenium species in natural water by ion chromatography-inductively coupled plasma-mass spectrometry coupled with nano-Al2O3 solid phase extraction. Open Chem. 2010, 8, 326–330. [Google Scholar] [CrossRef]

- Tsoi, Y.-K.; Leung, K.S.Y. Toward the use of surface modified activated carbon in speciation: Selective preconcentration of selenite and selenate in environmental waters. J. Chromatogr. A 2011, 1218, 2160–2164. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.; He, M.; Hu, B. On-line separation and preconcentration of inorganic arsenic and selenium species in natural water samples with CTAB-modified alkyl silica microcolumn and determination by inductively coupled plasma-optical emission spectrometry. Talanta 2008, 76, 772–779. [Google Scholar] [CrossRef]

- Lin, T.-S. Inorganic selenium speciation in groundwaters by solid phase extraction on Dowex 1X2. J. Hazard. Mater. 2007, 149, 80–85. [Google Scholar] [CrossRef]

- Arpadjan, S.; Vuchkova, L.; Kostadinova, E. Sorption of arsenic, bismuth, mercury, antimony, selenium and tin on dithiocarbamate loaded polyurethane foam as a preconcentration method for their determination in water samples by simultaneous inductively coupled plasma atomic emission spectrometry and electrothermal atomic absorption spectrometry. Analyst 1997, 122, 243–246. [Google Scholar]

- Chwastowska, J.; Skwara, W.; Dudek, J.; Sterlińska, E.; Pszonicki, L. Speciation analysis of selenium in mineral waters by graphite furnace atomic absorption spectrometry after separation on dithizone sorbent. Chem. Anal. 2007, 52, 253–263. [Google Scholar]

- Rovira, M.; Giménez, J.; Martínez, M.; Martínez-Lladó, X.; de Pablo, J.; Martí, V.; Duro, L. Sorption of selenium(IV) and selenium(VI) onto natural iron oxides: Goethite and hematite. J. Hazard. Mater. 2008, 150, 279–284. [Google Scholar] [CrossRef]

- Kozai, N.; Ohnuki, T.; Komarneni, S. Selenium oxyanions: Highly selective uptake by a novel anion exchanger. J. Mater. Res. 2002, 17, 2993–2996. [Google Scholar] [CrossRef]

| Material | Na2O | MgO | Al2O3 | SiO2 | P2O5 | K2O | CaO | TiO2 | Fe2O3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| vermiculite M | 0.00 | 26.62 | 9.63 | 42.52 | 0.00 | 0.09 | 0.55 | 0.71 | 10.16 | 9.59 |

| vermiculite SF | 0.00 | 26.85 | 10.17 | 42.75 | 0.08 | 0.25 | 0.86 | 0.71 | 9.61 | 8.57 |

| vermiculite F | 0.00 | 27.09 | 10.14 | 44.02 | 0.00 | 1.20 | 0.48 | 0.65 | 10.55 | 5.69 |

| glauconite | 0.00 | 2.58 | 6.13 | 47.77 | 2.23 | 7.24 | 3.55 | 0.27 | 25.01 | 5.05 |

| bentonite | 0.00 | 17.96 | 6.65 | 56.17 | 0.00 | 2.12 | 3.11 | 0.45 | 3.71 | 9.67 |

| perlite | 1.92 | 0.00 | 11.05 | 73.82 | 0.00 | 7.47 | 1.56 | 0.22 | 2.32 | 1.55 |

| clinoptilolite | 0.00 | 0.53 | 9.54 | 71.67 | 0.02 | 3.77 | 3.59 | 0.21 | 1.85 | 8.69 |

| Na-X | 5.08 | 1.67 | 22.32 | 42.96 | 0.16 | 3.02 | 3.20 | 1.53 | 7.61 | 12.15 |

| Na-A | 2.56 | 0.07 | 31.59 | 48.64 | 0.03 | 1.63 | 2.84 | 0.59 | 2.19 | 9.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flieger, J.; Kawka, J.; Płaziński, W.; Panek, R.; Madej, J. Sorption of Heavy Metal Ions of Chromium, Manganese, Selenium, Nickel, Cobalt, Iron from Aqueous Acidic Solutions in Batch and Dynamic Conditions on Natural and Synthetic Aluminosilicate Sorbents. Materials 2020, 13, 5271. https://doi.org/10.3390/ma13225271

Flieger J, Kawka J, Płaziński W, Panek R, Madej J. Sorption of Heavy Metal Ions of Chromium, Manganese, Selenium, Nickel, Cobalt, Iron from Aqueous Acidic Solutions in Batch and Dynamic Conditions on Natural and Synthetic Aluminosilicate Sorbents. Materials. 2020; 13(22):5271. https://doi.org/10.3390/ma13225271

Chicago/Turabian StyleFlieger, Jolanta, Justyna Kawka, Wojciech Płaziński, Rafał Panek, and Jarosław Madej. 2020. "Sorption of Heavy Metal Ions of Chromium, Manganese, Selenium, Nickel, Cobalt, Iron from Aqueous Acidic Solutions in Batch and Dynamic Conditions on Natural and Synthetic Aluminosilicate Sorbents" Materials 13, no. 22: 5271. https://doi.org/10.3390/ma13225271

APA StyleFlieger, J., Kawka, J., Płaziński, W., Panek, R., & Madej, J. (2020). Sorption of Heavy Metal Ions of Chromium, Manganese, Selenium, Nickel, Cobalt, Iron from Aqueous Acidic Solutions in Batch and Dynamic Conditions on Natural and Synthetic Aluminosilicate Sorbents. Materials, 13(22), 5271. https://doi.org/10.3390/ma13225271