The Significance of Coherent Transformation on Grain Refinement and Consequent Enhancement in Toughness

Abstract

1. Introduction

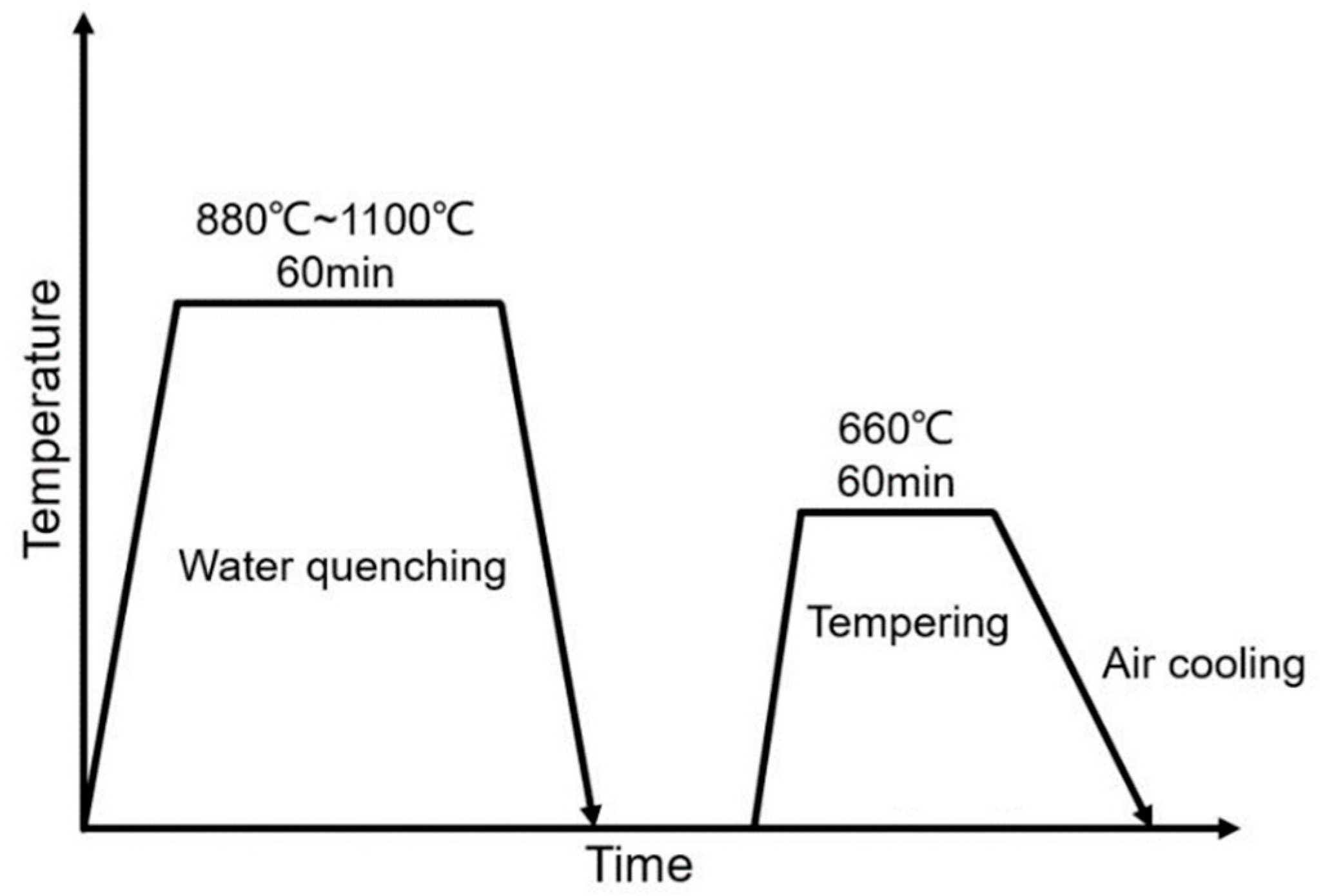

2. Experimental Procedure

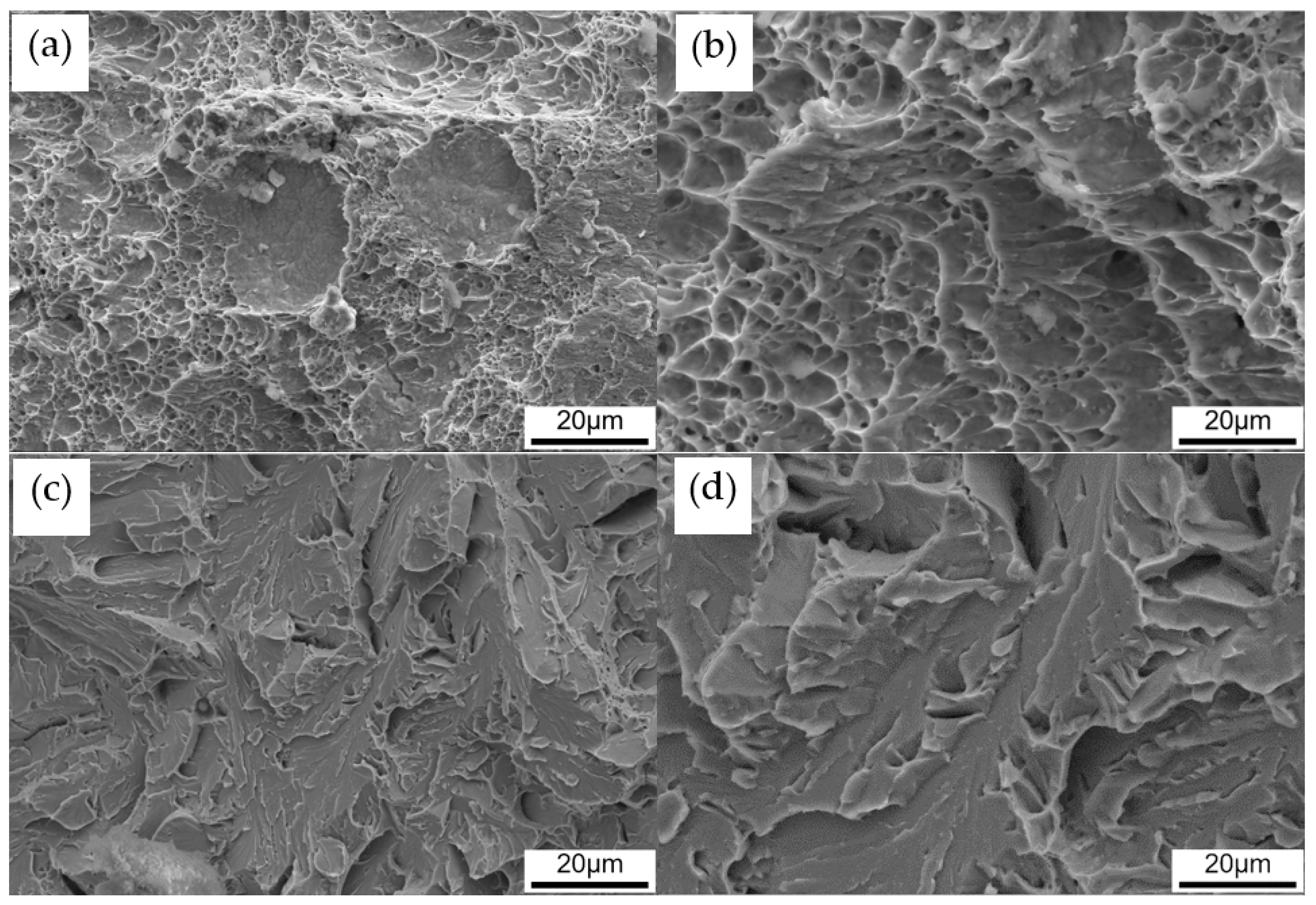

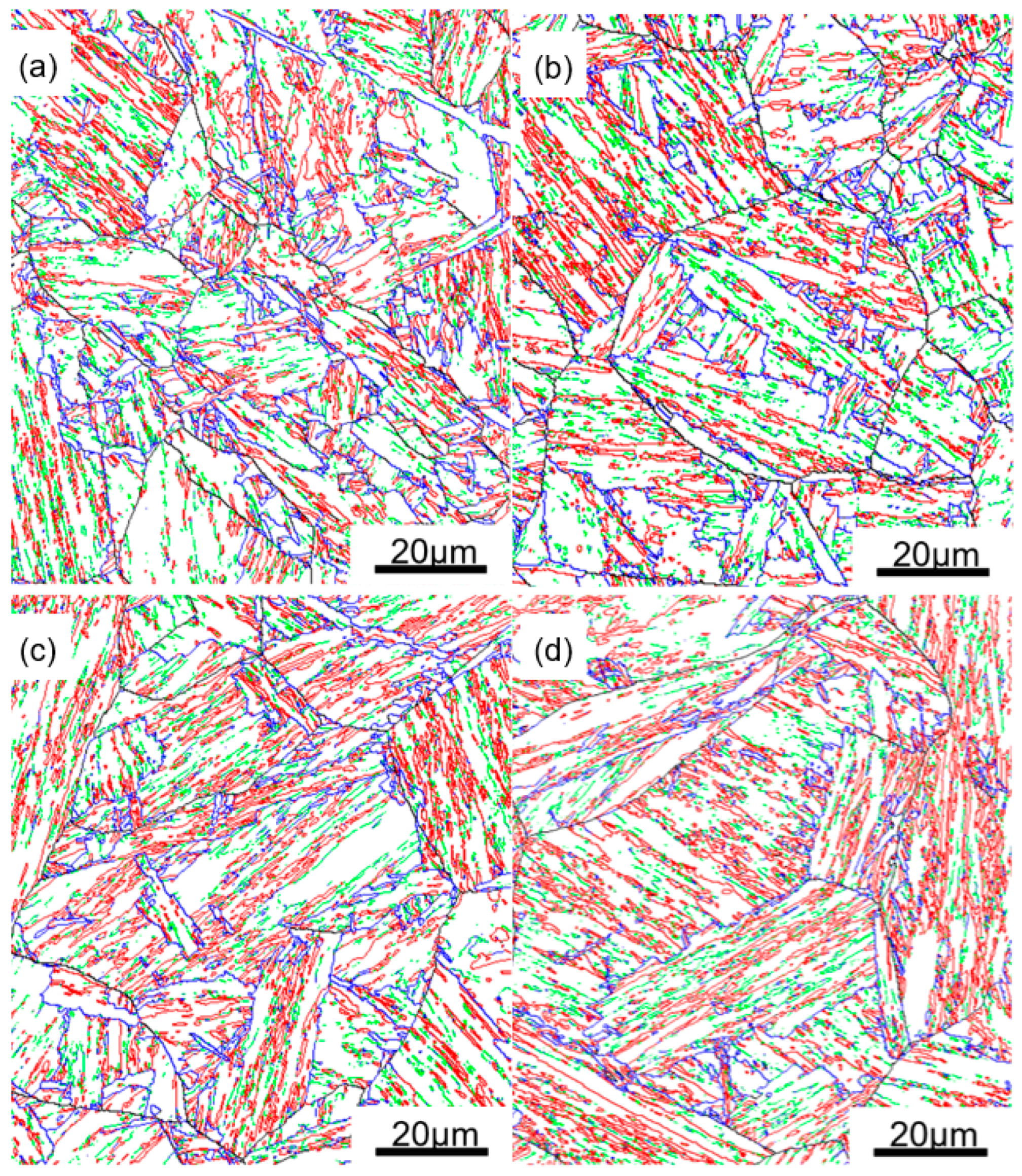

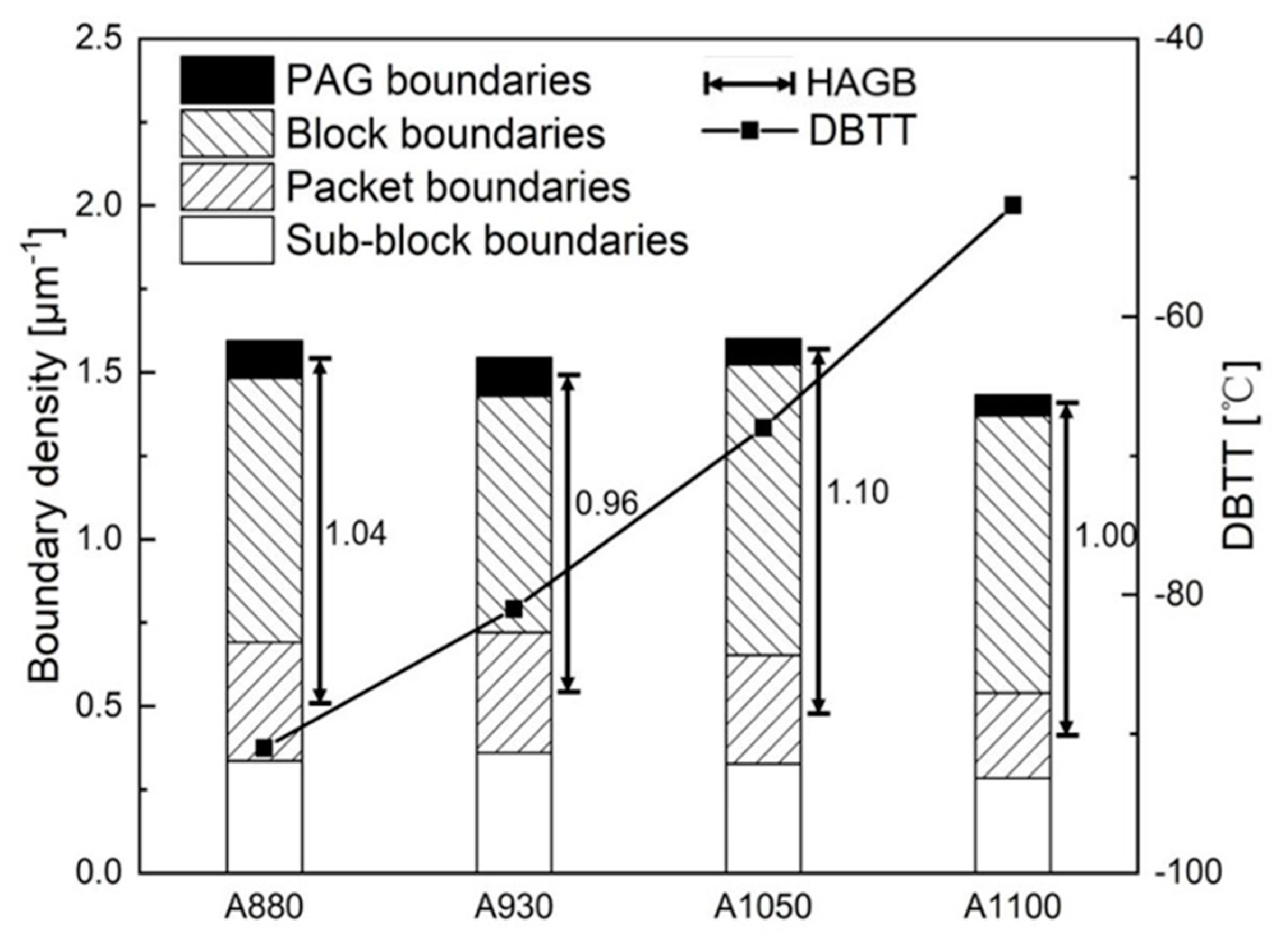

3. Results and Discussion

4. Conclusions

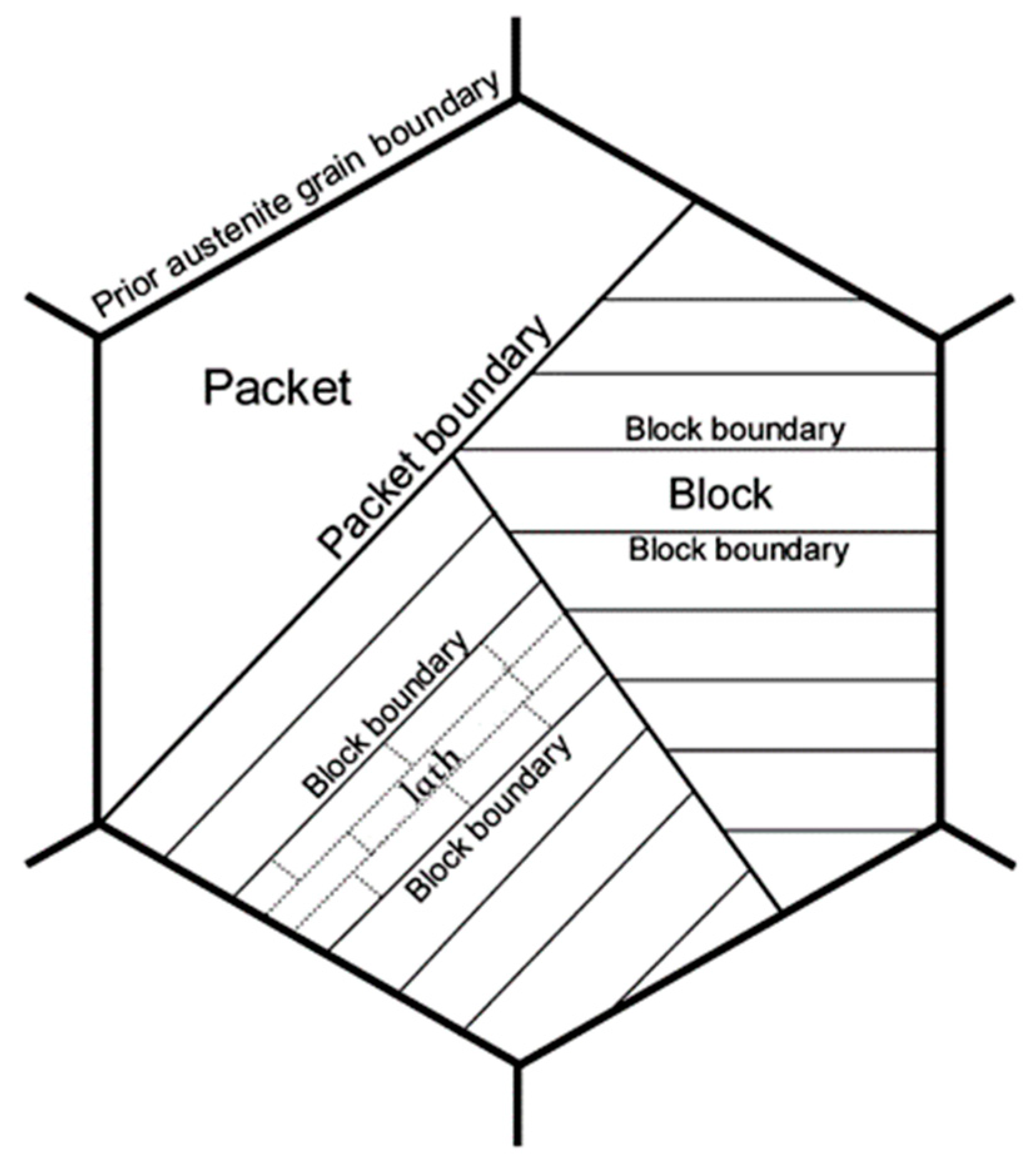

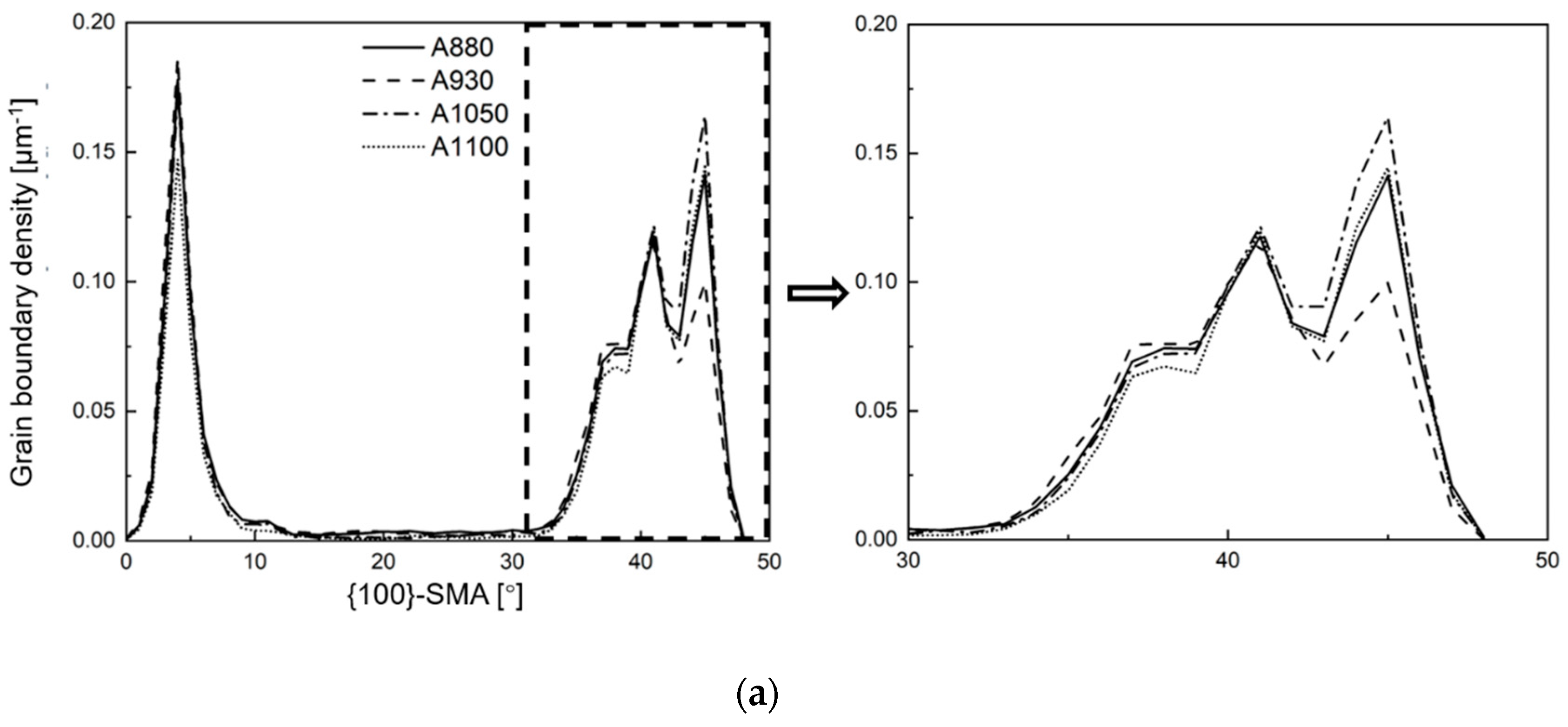

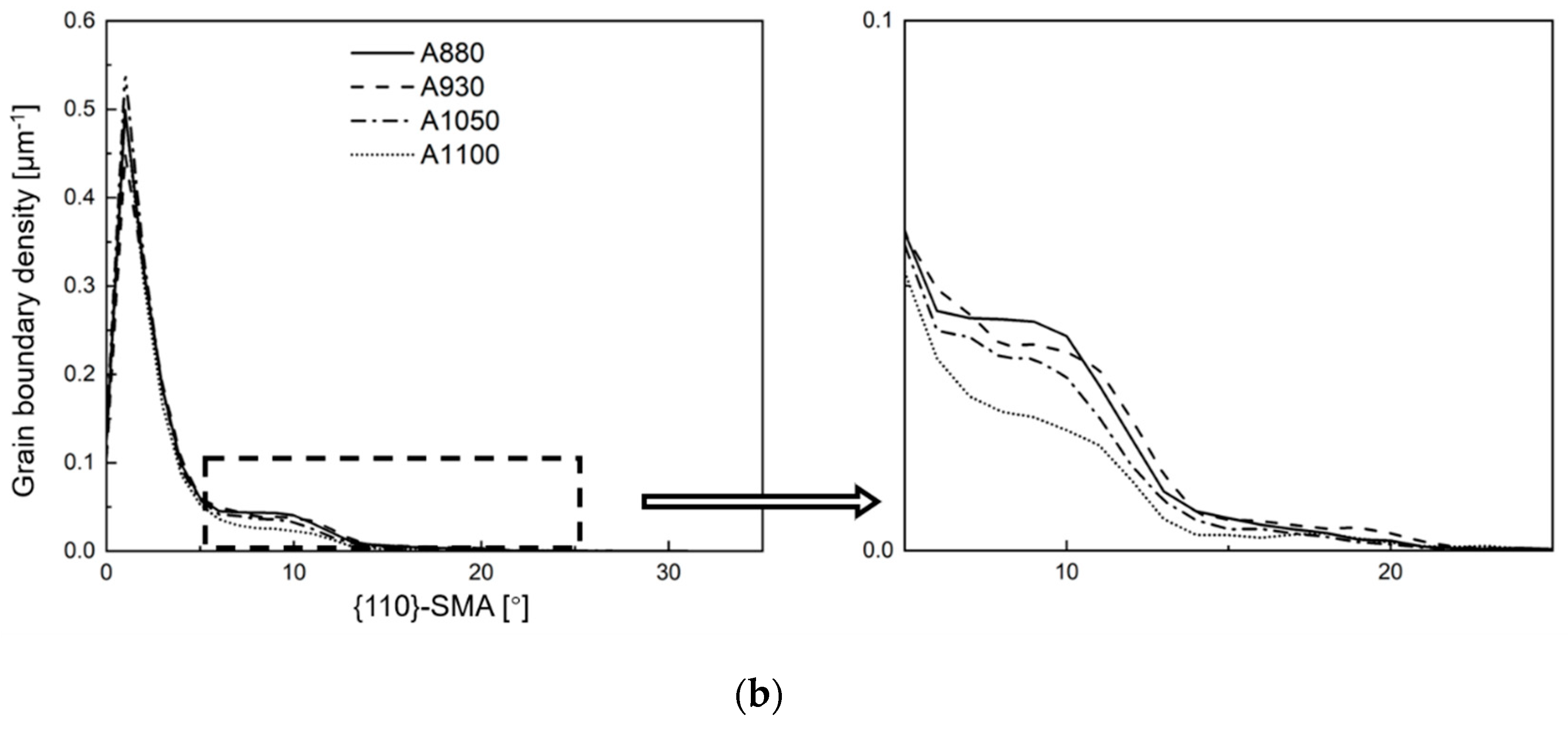

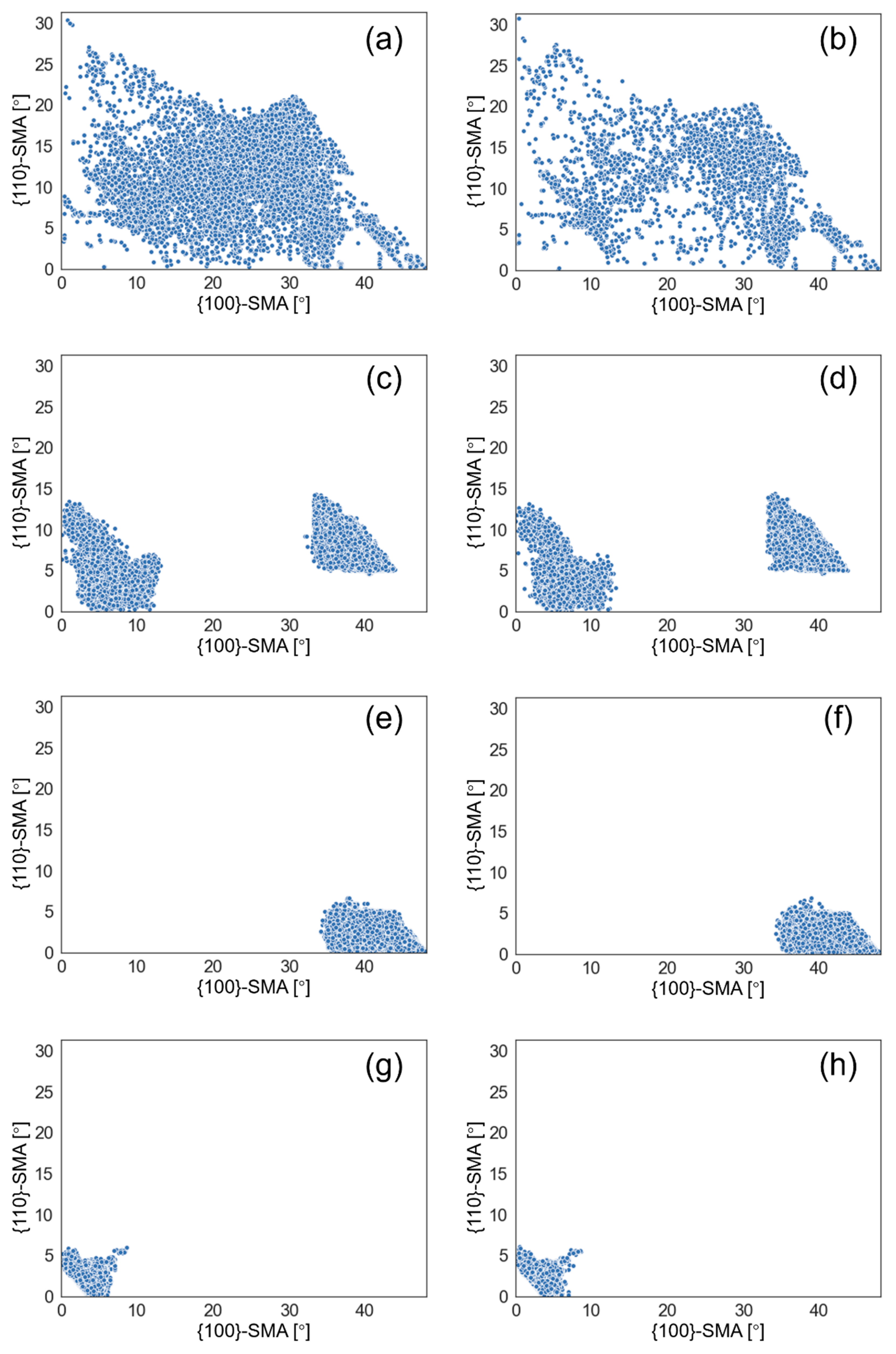

- In general, prior austenite grain boundaries have high {100}-plane misorientation angles and high {110}-plane misorientation angles, such that the refinement of prior austenite grains is an effective approach to improve toughness from the perspective of improving ductility and inhibiting cleavage fracture.

- Packet boundaries can also improve toughness from two perspectives, but only a proportion of packet boundaries can form very low {100}-plane misorientation angles, thus not all packet boundaries are very effective on inhibiting cleavage fracture.

- Block boundaries are characterized by high {100}-plane misorientation angles and low {110}-plane misorientation angles, and thus their contribution in inhibiting cleavage fracture is more significant than ductility improvement.

- Sub-block boundaries have low {100}-plane misorientation angles and low {110}-plane misorientation angles, and thus the contribution of sub-block boundaries on toughness improvement is significantly weaker.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Petch, N.J. The ductile-brittle transition in the fracture of α-iron: I. Philos. Mag. 1958, 3, 1128. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25. [Google Scholar]

- Hanamura, T.; Yin, F.; Nagai, K. Ductile-Brittle Transition Temperature of Ultrafine Ferrite/Cementite Microstructure in a Low Carbon Steel Controlled by Effective Grain Size. ISIJ Int. 2004, 44, 610. [Google Scholar] [CrossRef]

- Shanmugam, S.; Misra, R.D.K.; Mannering, T.; Panda, D.; Jansto, S. Impact toughness and microstructure relationship in niobium- and vanadium-microalloyed steels processed with varied cooling rates to similar yield strength. Mater. Sci. Eng. A 2006, 437, 436. [Google Scholar] [CrossRef]

- Zhao, M.-C.; Zeng, T.-Y.; Li, J.-L.; Xiaofang, H.; Zhao, Y.-C.; Atrens, A. Identification of the effective grain size responsible for the ductile to brittle transition temperature for steel with an ultrafine grain size ferrite/cementite microstructure with a bimodal ferrite grain size distribution. Mater. Sci. Eng. A 2011, 528, 4217. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279. [Google Scholar] [CrossRef]

- Sun, X.J.; Shang, C.J.; Miao, P.F.; Dong, L.L. Effect of austenitizing temperature on microstructure and properties of low carbon and low crack sensitivity offshore steel. Mater. Heat Treat. 2020, 41, 50. [Google Scholar]

- Li, X.; Ma, X.; Subramanian, S.; Shang, C.; Misra, R. Influence of prior austenite grain size on martensite–austenite constituent and toughness in the heat affected zone of 700 MPa high strength linepipe steel. Mater. Sci. Eng. A 2014, 616, 141. [Google Scholar] [CrossRef]

- Bouyne, E.; Flower, H.; Lindley, T.; Pineau, A. Use of EBSD technique to examine microstructure and cracking in a bainitic steel. Scr. Mater. 1998, 39, 295. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M.; Shi, J.; Hui, W.; Dong, H. Effect of microstructural refinement on the toughness of low carbon martensitic steel. Scr. Mater. 2008, 58, 492. [Google Scholar] [CrossRef]

- Wang, C.F.; Wang, M.Q.; Shi, J.; Hui, W.J.; Dong, H. Microstructural characterization and its effect on strength of low carbon martensitic steel. J. Mater. Sci. Technol. 2007, 23, 659. [Google Scholar]

- Liu, D.S.; Luo, M.; Cheng, B.G.; Cao, R.; Chen, J.H. Microstructural Evolution and Ductile-to-Brittle Transition in a Low-Carbon MnCrMoNiCu Heavy Plate Steel. Metall. Mat. Trans. A 2018, 49, 4918. [Google Scholar] [CrossRef]

- Luo, Z.-J.; Shen, J.-C.; Su, H.; Ding, Y.-H.; Yang, C.-F.; Zhu, X. Effect of Substructure on Toughness of Lath Martensite/Bainite Mixed Structure in Low-Carbon Steels. J. Iron Steel Res. Int. 2010, 17, 40. [Google Scholar] [CrossRef]

- Luo, H.; Wang, X.; Liu, Z.; Yang, Z. Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel. J. Mater. Sci. Technol. 2020, 51, 130–136. [Google Scholar] [CrossRef]

- Long, S.-L.; Liang, Y.-L.; Jiang, Y.; Liang, Y.; Yang, M.; Yi, Y.-L. Effect of quenching temperature on martensite multi-level microstructures and properties of strength and toughness in 20CrNi2Mo steel. Mater. Sci. Eng. A 2016, 676, 38. [Google Scholar] [CrossRef]

- Hwang, B.; Kim, Y.G.; Lee, S.; Kim, Y.M.; Kim, N.J.; Yoo, J.Y. Effective grain size and charpy impact properties of high-toughness X70 pipeline steels. Met. Mater. Trans. A 2005, 36, 2107. [Google Scholar] [CrossRef]

- Miao, C.; Shang, C.J.; Wang, X.; Zhang, L.; Subramanian, M. Microstructure and Toughness of Haz in X80 Pipeline Steel with High nb Content. Acta Met. Sin. 2010, 46, 541. [Google Scholar] [CrossRef]

- You, Y.; Shang, C.; Wenjin, N.; Subramanian, S. Investigation on the microstructure and toughness of coarse grained heat affected zone in X-100 multi-phase pipeline steel with high Nb content. Mater. Sci. Eng. A 2012, 558, 692. [Google Scholar] [CrossRef]

- You, Y.; Wang, X.; Shang, C. Influence of Austenitizing Temperature on the Microstructure and Impact Toughness of a High Strength Low Alloy HSLA100 Steel. Acta Met. Sin. 2012, 48, 1290. [Google Scholar] [CrossRef]

- Gourgues, A.-F.; Flower, H.M.; Lindley, T.C. Electron backscattering diffraction study of acicular ferrite, bainite, and martensite steel microstructures. Mater. Sci. Technol. 2000, 16, 26. [Google Scholar] [CrossRef]

- Li, X.; Zhao, J.; Wang, J.; Wang, X.; Liu, S.; Shang, C. Effect of boundaries on toughness in high-strength low-alloy steels from the view of crystallographic misorientation. Mater. Lett. 2020, 259, 126841. [Google Scholar] [CrossRef]

- Li, X.; Ma, X.; Subramanian, S.V.; Misra, R.D.K.; Shang, C. Structure–Property–Fracture Mechanism Correlation in Heat-Affected Zone of X100 Ferrite−Bainite Pipeline Steel. Met. Mater. Trans. E 2015, 2, 1. [Google Scholar] [CrossRef]

- Lambert-Perlade, A.; Gourgues-Lorenzon, A.-F.; Pineau, A. Austenite to bainite phase transformation in the heat-affected zone of a high strength low alloy steel. Acta Mater. 2004, 52, 2337. [Google Scholar] [CrossRef]

- Furuhara, T.; Kawata, H.; Morito, S.; Miyamoto, G.; Maki, T. Variant Selection in Grain Boundary Nucleation of Upper Bainite. Met. Mater. Trans. A 2008, 39, 1003. [Google Scholar] [CrossRef]

- Morris, J.J.W.; Lee, C.S.; Guo, Z. The Nature and Consequences of Coherent Transformations in Steel. ISIJ Int. 2003, 43, 410. [Google Scholar] [CrossRef]

- Ghosh, A.; Kundu, S.C.; Chakrabarti, D. Effect of crystallographic texture on the cleavage fracture mechanism and effective grain size of ferritic steel. Scr. Mater. 2014, 81, 8. [Google Scholar] [CrossRef]

- Guo, Z.; Lee, C.; Morris, J. On coherent transformations in steel. Acta Mater. 2004, 52, 5511. [Google Scholar] [CrossRef]

- Yang, S.; Shang, C.; Wang, X.; He, X. Abnormally turning of fine lath-like microstructures in low carbon microalloyed steel during mono-axis tension. Acta Metall. Sin. 2003, 39, 579. [Google Scholar]

- Liu, S.; Li, X.; Guo, H.; Yang, S.; Wang, X.; Shang, C.; Misra, R.D.K. Selective role of bainitic lath boundary in influencing slip systems and consequent deformation mechanisms and delamination in high-strength low-alloy steel. Philos. Mag. 2018, 98, 934. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, S.; Wan, F. Competition mechanism of brittle–ductile transition of metals under tensile condition. Mech. Mater. 2019, 137, 103138. [Google Scholar] [CrossRef]

- Beladi, H.; Rohrer, G.S.; Rollett, A.D.; Tari, V.; Hodgson, P.D. The distribution of intervariant crystallographic planes in a lath martensite using five macroscopic parameters. Acta Mater. 2014, 63, 86. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Ma, X.; Subramanian, S.; Xie, Z.; Shang, C.; Li, X. Analysis of impact toughness scatter in simulated coarse-grained HAZ of E550 grade offshore engineering steel from the aspect of crystallographic structure. Mater. Charact. 2018, 140, 312. [Google Scholar] [CrossRef]

- Li, X.; Ma, X.; Subramanian, S.V.; Shang, C. EBSD characterization of secondary microcracks in the heat affected zone of a X100 pipeline steel weld joint. Int. J. Fract. 2015, 193, 131. [Google Scholar] [CrossRef]

- Wu, B.; Huang, S.; Wang, Z.; Zhao, J.; Wang, C.; Shang, C.; Misra, R.D.K. Crystallography analysis of toughness in high strength ultra-heavy plate steel. Mater. Lett. 2019, 250, 55. [Google Scholar] [CrossRef]

- Qiao, Y.; Argon, A. Cleavage cracking resistance of high angle grain boundaries in Fe–3%Si alloy. Mech. Mater. 2003, 35, 313. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T.; Yin, F.; Tsuzaki, K. Inverse Temperature Dependence of Toughness in an Ultrafine Grain-Structure Steel. Science 2008, 320, 1057. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Li, C.; Yuan, G.; Wang, G.-D. Improvement of strength and toughness for hot rolled low-carbon bainitic steel via grain refinement and crystallographic texture. Mater. Lett. 2016, 175, 157. [Google Scholar] [CrossRef]

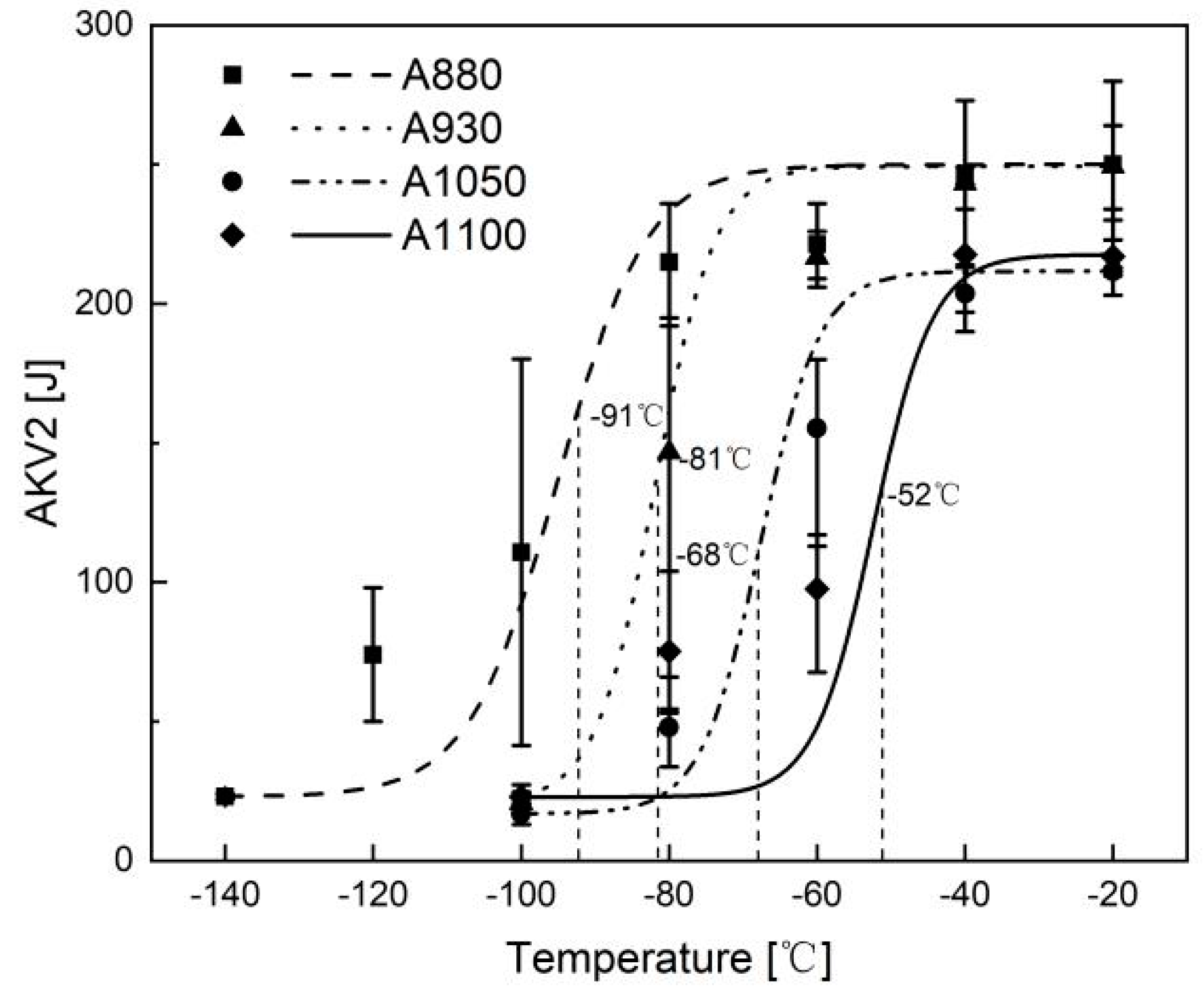

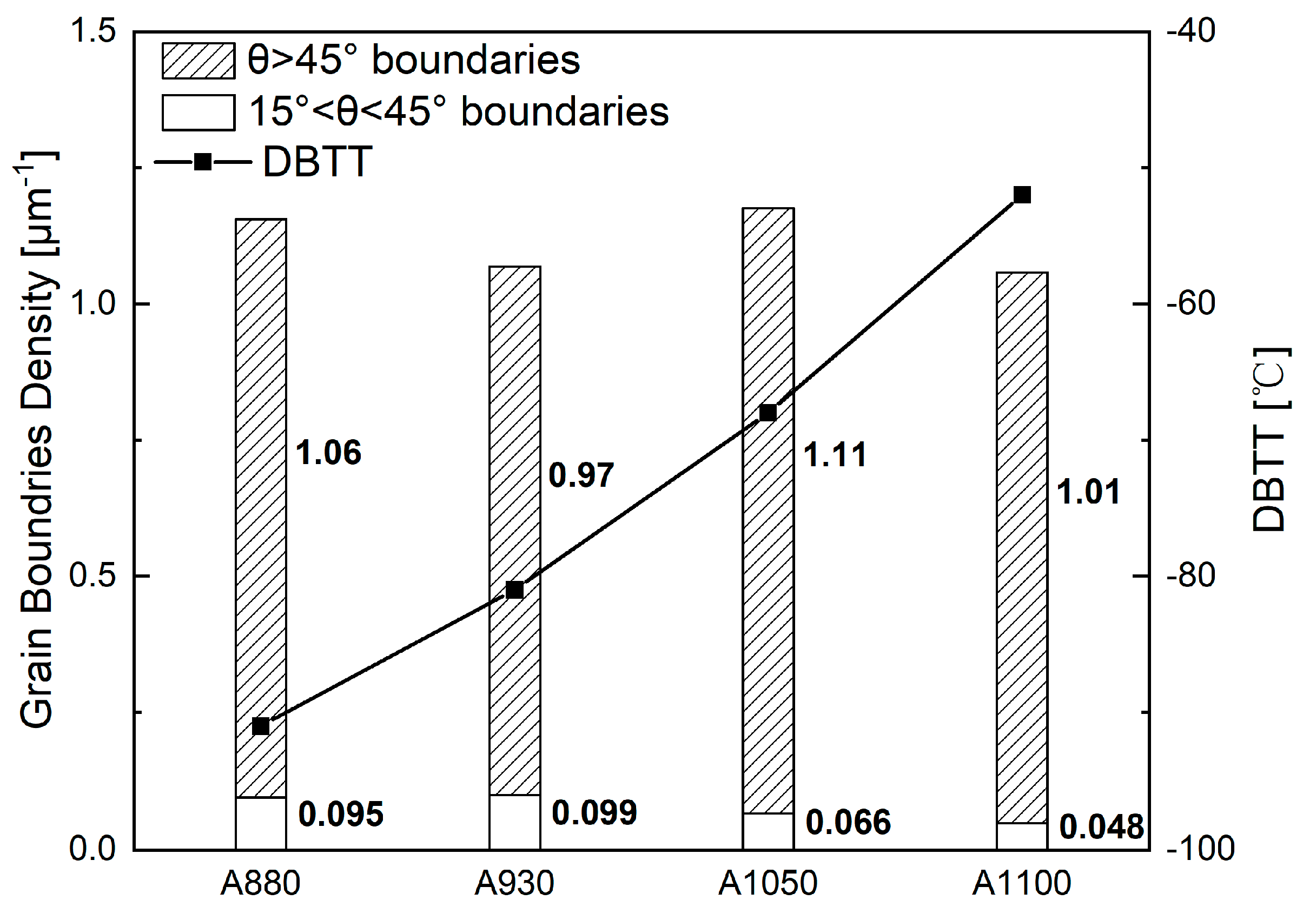

| Samples | Yield Strength/MPa | Tensile Strength/MPa | Total Elongation/% | DBTT/°C |

|---|---|---|---|---|

| A880 | 716 | 782 | 23.4 | −97 |

| A930 | 693 | 756 | 23.3 | −81 |

| A1050 | 626 | 741 | 22.0 | −68 |

| A1100 | 639 | 727 | 21.3 | −52 |

| Variant No. | Misorientation Angle/° | Plane Parallel (CP Group) | Directional Parallel | Bain Group |

|---|---|---|---|---|

| V1 | - | (1 1 1)fcc//(0 1 1)bcc (CP1) | [−1 0 1]fcc//[−1 −1 1]bcc | B1 |

| V2 | 60.00 | [−1 0 1]fcc//[−1 1 −1]bcc | B2 | |

| V3 | 60.00 | [0 1 −1]fcc//[−1 −1 1]bcc | B3 | |

| V4 | 10.52 | [0 1 −1]fcc//[−1 1 −1]bcc | B1 | |

| V5 | 60.00 | [1 −1 0]fcc//[−1 −1 1]bcc | B2 | |

| V6 | 49.48 | [1 −1 0]fcc//[−1 1 −1]bcc | B3 | |

| V7 | 49.47 | (1 −1 1)fcc//(0 1 1)bcc (CP2) | [1 0 −1]fcc//[−1 −1 1]bcc | B2 |

| V8 | 10.53 | [1 0 −1]fcc//[−1 1 −1]bcc | B1 | |

| V9 | 50.51 | [−1 −1 0]fcc//[−1 −1 1]bcc | B3 | |

| V10 | 50.51 | [−1 −1 0]fcc//[−1 1 −1]bcc | B2 | |

| V11 | 14.88 | [0 1 1]fcc//[−1 −1 1]bcc | B1 | |

| V12 | 57.22 | [0 1 1]fcc//[−1 1 −1]bcc | B3 | |

| V13 | 14.88 | (−1 1 1)fcc//(0 1 1)bcc (CP3) | [0 −1 1]fcc//[−1 −1 1]bcc | B1 |

| V14 | 50.51 | [0 −1 1]fcc//[−1 1 −1]bcc | B3 | |

| V15 | 57.21 | [−1 0 −1]fcc//[−1 −1 1]bcc’ | B2 | |

| V16 | 20.60 | [−1 0 −1]fcc//[−1 1 −1]bcc | B1 | |

| V17 | 51.73 | [1 1 0]fcc//[−1 −1 1]bcc | B3 | |

| V18 | 47.12 | [1 1 0]fcc//[−1 1 −1]bcc | B2 | |

| V19 | 50.51 | (1 1 −1)fcc//(0 1 1)bcc (CP4) | [−1 1 0]fcc//[−1 −1 1]bcc | B3 |

| V20 | 57.21 | [−1 1 0]fcc//[−1 1 −1]bcc | B2 | |

| V21 | 20.60 | [0 −1 −1]fcc//[−1 −1 1]bcc | B1 | |

| V22 | 47.12 | [0 −1 −1]fcc//[−1 1 −1]bcc | B3 | |

| V23 | 57.21 | [1 0 1]fcc//[−1 −1 1]bcc | B2 | |

| V24 | 21.05 | [1 0 1]fcc//[−1 1 −1]bcc | B1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhao, J.; Dong, L.; Misra, R.D.K.; Wang, X.; Wang, X.; Shang, C. The Significance of Coherent Transformation on Grain Refinement and Consequent Enhancement in Toughness. Materials 2020, 13, 5095. https://doi.org/10.3390/ma13225095

Li X, Zhao J, Dong L, Misra RDK, Wang X, Wang X, Shang C. The Significance of Coherent Transformation on Grain Refinement and Consequent Enhancement in Toughness. Materials. 2020; 13(22):5095. https://doi.org/10.3390/ma13225095

Chicago/Turabian StyleLi, Xiucheng, Jingxiao Zhao, Lili Dong, R. Devesh Kumar Misra, Xuemin Wang, Xuelin Wang, and Chengjia Shang. 2020. "The Significance of Coherent Transformation on Grain Refinement and Consequent Enhancement in Toughness" Materials 13, no. 22: 5095. https://doi.org/10.3390/ma13225095

APA StyleLi, X., Zhao, J., Dong, L., Misra, R. D. K., Wang, X., Wang, X., & Shang, C. (2020). The Significance of Coherent Transformation on Grain Refinement and Consequent Enhancement in Toughness. Materials, 13(22), 5095. https://doi.org/10.3390/ma13225095