The Characteristics of Swelling Pressure for Superabsorbent Polymer and Soil Mixtures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

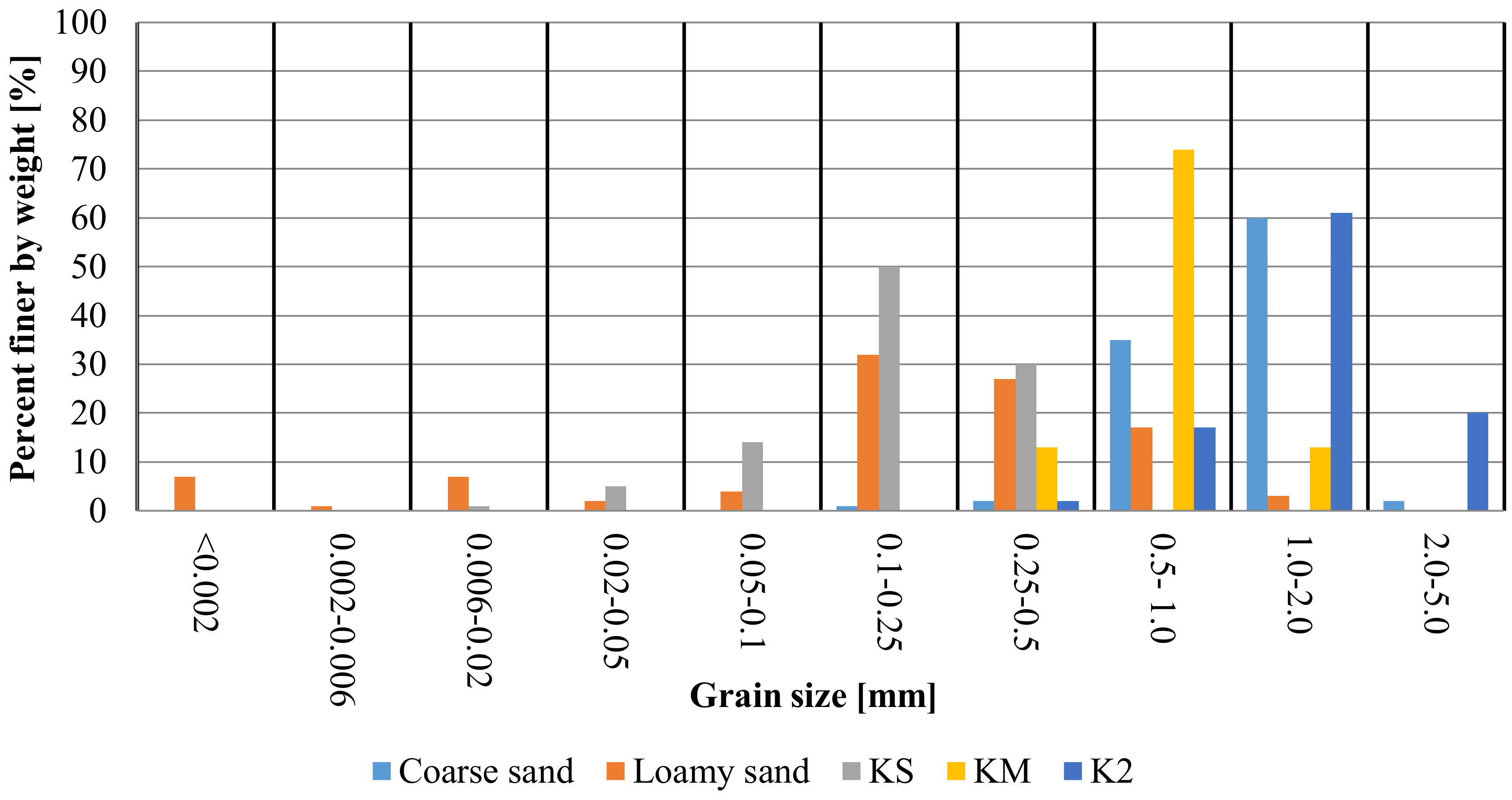

2.2. Physical Characteristics of Soils and Superabsorbent Polymers (SAPs)

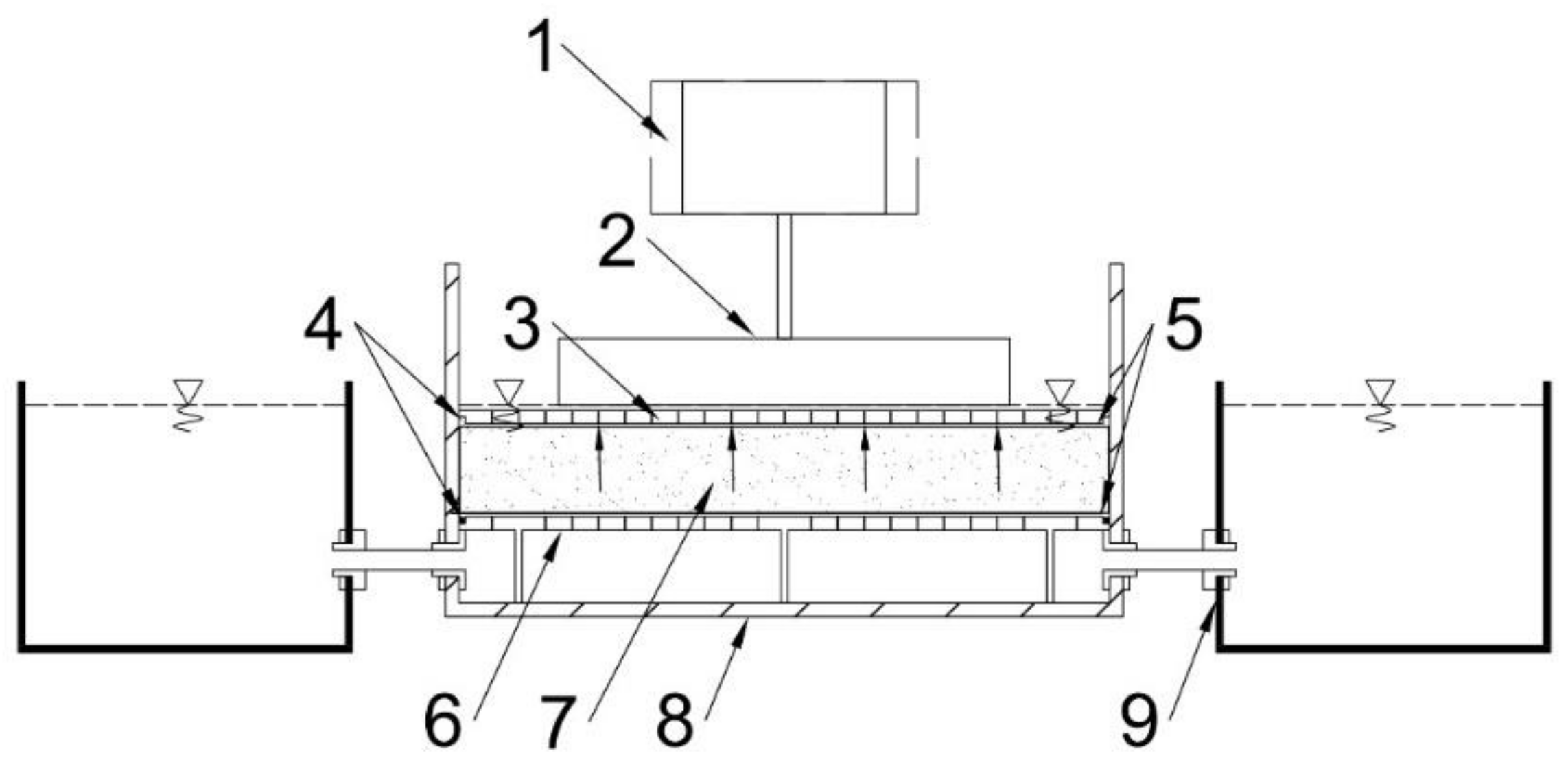

2.3. Swelling Pressure Measurement Procedure

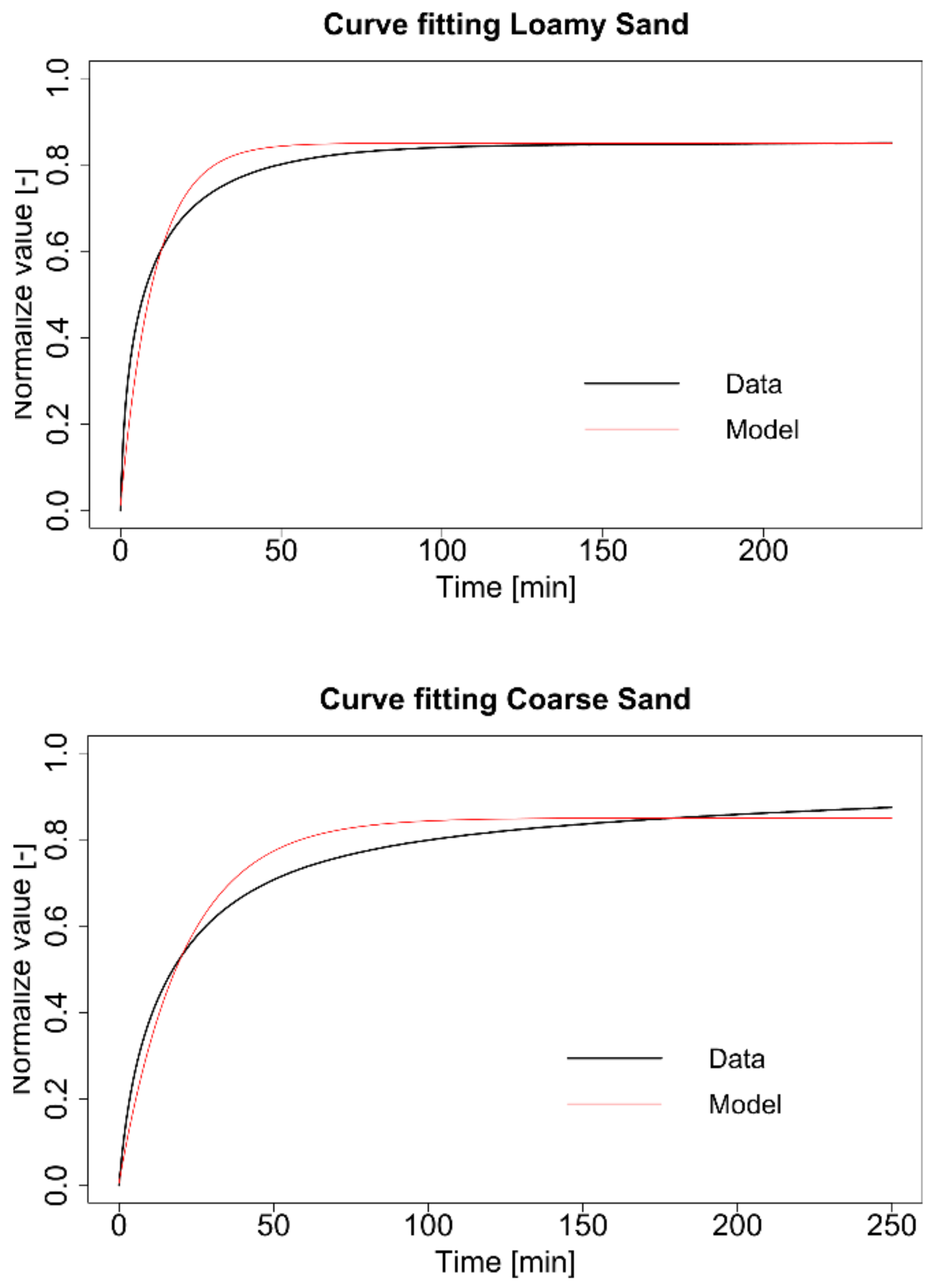

2.4. Model Estimation (Curve Fitting)

2.5. A Model for Swelling Pressure

3. Results

3.1. Physical Characteristics of Soils and SAPs

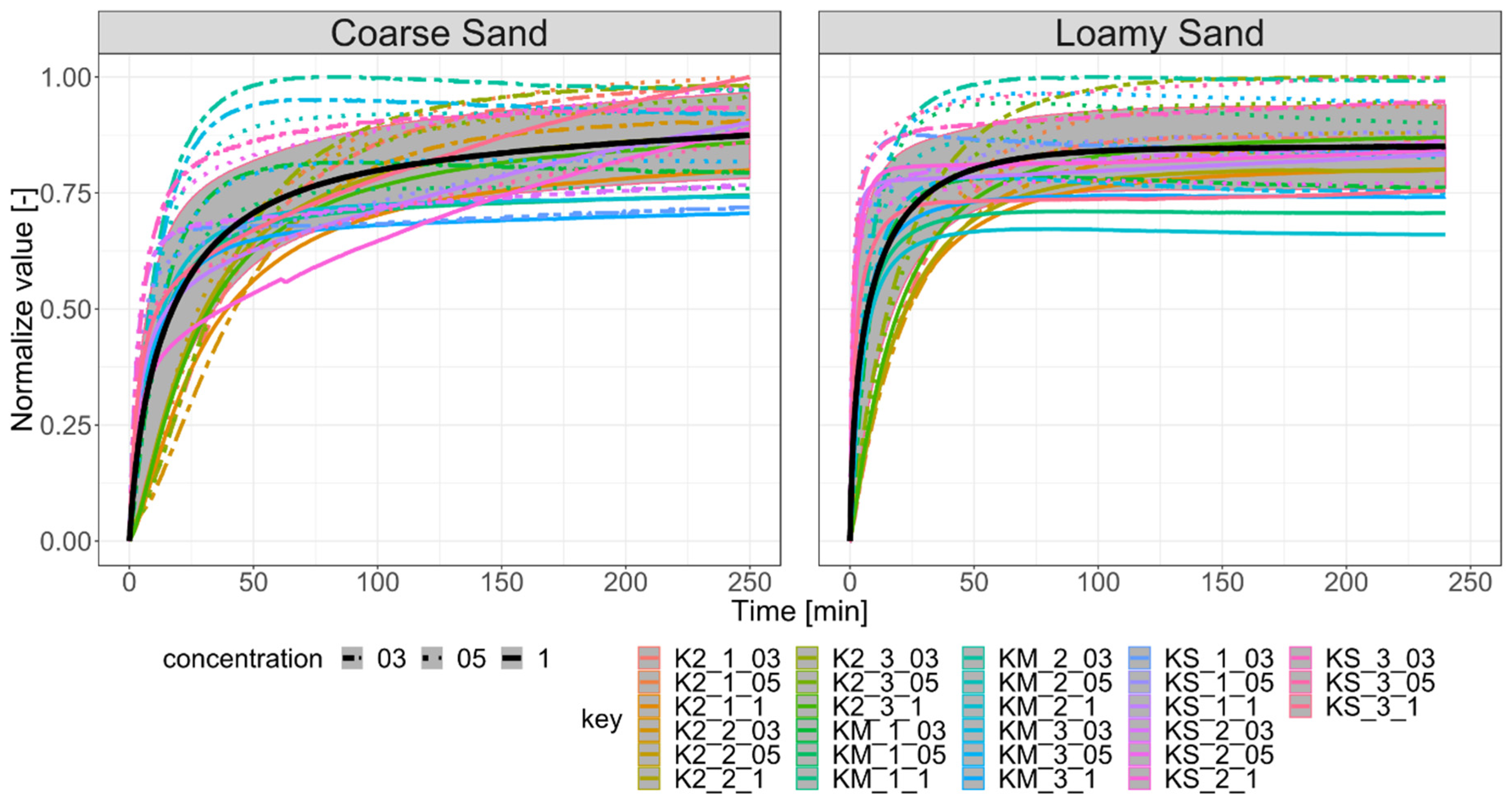

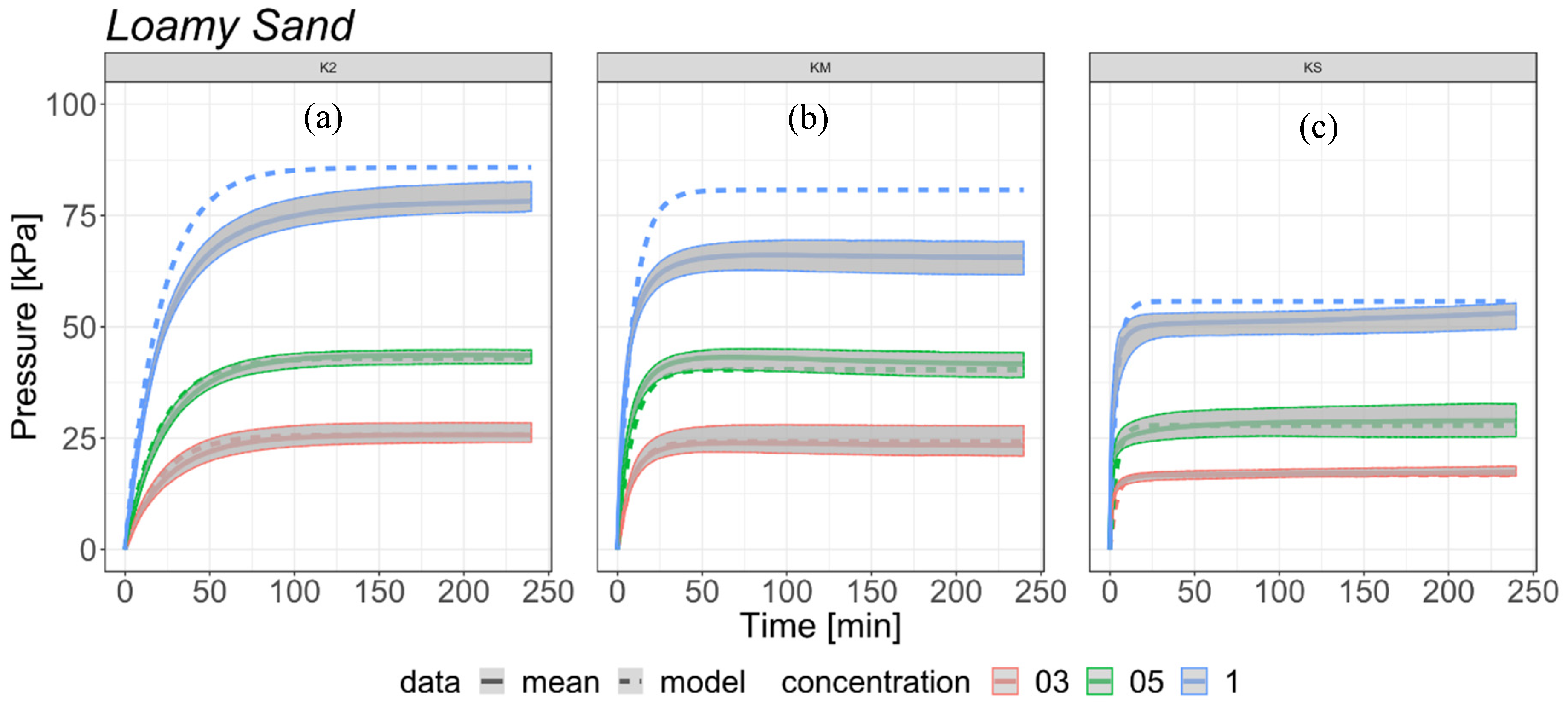

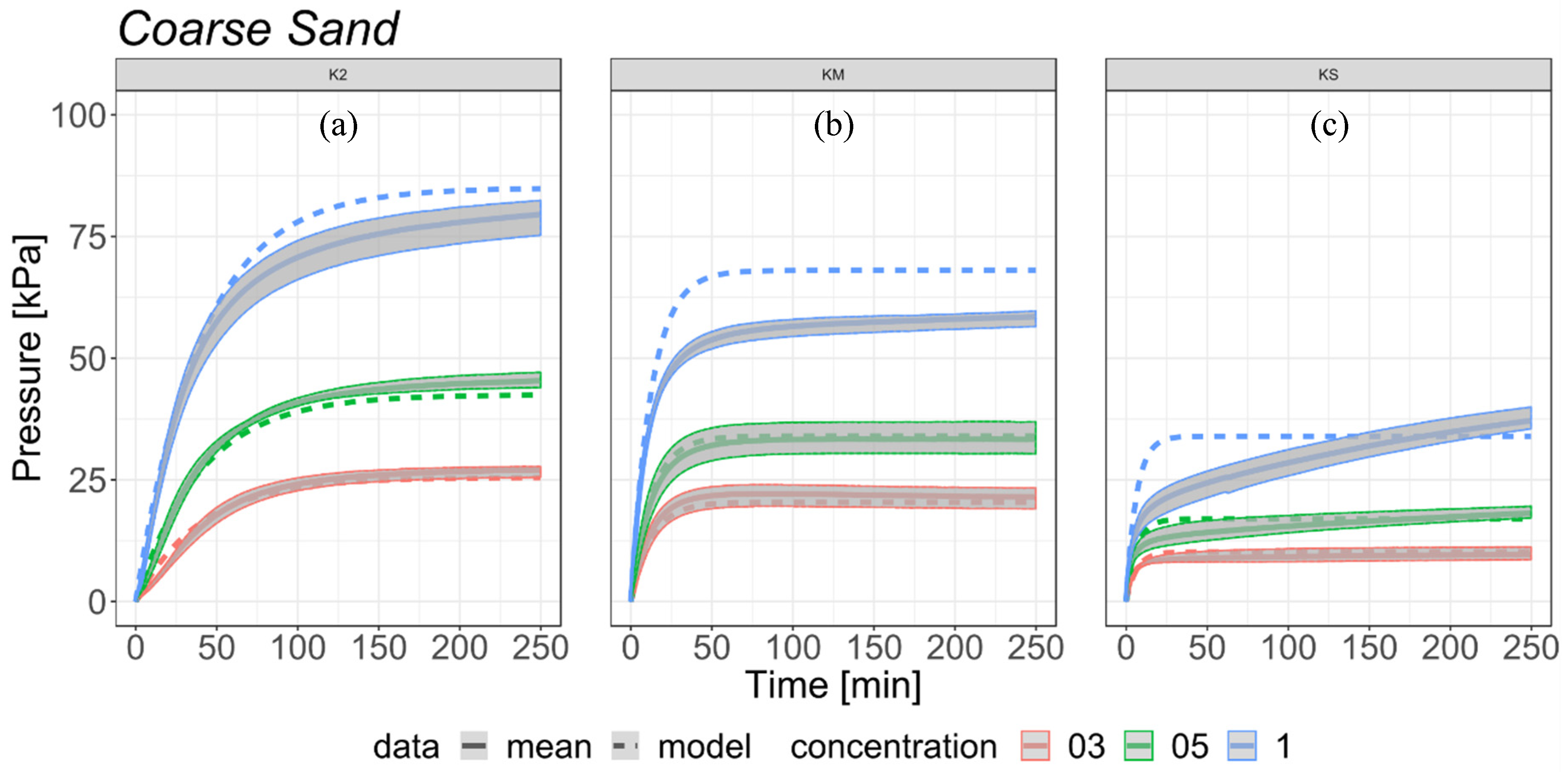

3.2. Results and Model Verification for Coarse Sand and Loamy Sand

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Maghchiche, A.; Haouam, A.; Immirzi, B. Use of polymers and biopolymers for water retaining and soil stabilization in arid and semiarid regions. J. Taibah Univ. Sci. 2010, 4, 9–16. [Google Scholar] [CrossRef]

- Hüttermann, A.; Orikiriza, L.J.B.; Agaba, H. Application of Superabsorbent Polymers for Improving the Ecological Chemistry of Degraded or Polluted Lands. CLEAN Soil Air Water 2009, 37, 517–526. [Google Scholar] [CrossRef]

- Garbowski, M.; Brown, C.S.; Johnston, D.B. Soil amendment interacts with invasive grass and drought to uniquely influence aboveground versus belowground biomass in aridland restoration. Restor. Ecol. 2020, 28, A13–A23. [Google Scholar] [CrossRef]

- Banedjschafie, S.; Durner, W. Water retention properties of a sandy soil with superabsorbent polymers as affected by aging and water quality. J. Plant Nutr. Soil Sci. 2015, 178, 798–806. [Google Scholar] [CrossRef]

- León, O.; Soto, D.; González, J.; Piña, C.; Muñoz-Bonilla, A.; Fernandez-García, M. Environmentally Friendly Fertilizers Based on Starch Superabsorbents. Materials 2019, 12, 3493. [Google Scholar] [CrossRef]

- Basak, B.B.; Pal, S.; Datta, S.C. Use of modified clays for retention and supply of water and nutrients. Curr. Sci. 2012, 102, 1272. [Google Scholar]

- Nakhli, S.A.A.; Delkash, M.; Bakhshayesh, B.E.; Kazemian, H. Application of Zeolites for Sustainable Agriculture: A Review on Water and Nutrient Retention. Water Air Soil Pollut. 2017, 228, 464. [Google Scholar] [CrossRef]

- Śpitalniak, M.; Lejcuś, K.; Dąbrowska, J.; Garlikowski, D.; Bogacz, A. The Influence of a Water Absorbing Geocomposite on Soil Water Retention and Soil Matric Potential. Water 2019, 11, 1731. [Google Scholar] [CrossRef]

- Gates, W.P.; Aldridge, L.P.; Carnero-Guzman, G.G.; Mole, R.A.; Yu, D.; Iles, G.N.; Klapproth, A.; Bordallo, H.N. Water desorption and absorption isotherms of sodium montmorillonite: A QENS study. Appl. Clay Sci. 2017, 147, 97–104. [Google Scholar] [CrossRef]

- Wan, T.; Wang, X.; Yuan, Y.; He, W. Preparation of a kaolinite-poly(acrylic acid acrylamide) water superabsorbent by photopolymerization. J. Appl. Polym. Sci. 2006, 102, 2875–2881. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, L.; Chen, Y. Synthesis and characterization of starch-g-Poly(acrylic acid)/Organo-Zeolite 4A superabsorbent composites with respect to their water-holding capacities and nutrient-release behavior. Polym. Compos. 2017, 38, 1838–1848. [Google Scholar] [CrossRef]

- Han, Y.; Yu, X.; Yang, P.; Li, B.; Xu, L.; Wang, C. Dynamic study on water diffusivity of soil with super-absorbent polymer application. Environ. Earth Sci. 2013, 69, 289–296. [Google Scholar] [CrossRef]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [PubMed]

- Savaskan Yilmaz, S.; Yildirim, N.; Misir, M.; Misirlioglu, Y.; Celik, E. Synthesis, Characterization of a New Polyacrylic Acid Superabsorbent, Some Heavy Metal Ion Sorption, the Adsorption Isotherms, and Quantum Chemical Investigation. Materials 2020, 13, 4390. [Google Scholar] [CrossRef] [PubMed]

- Varaprasad, K.; Raghavendra, G.M.; Jayaramudu, T.; Yallapu, M.M.; Sadiku, R. A mini review on hydrogels classification and recent developments in miscellaneous applications. Mater. Sci. Eng. C 2017, 79, 958–971. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, P.; Ding, H.; Le, C. Experimental Study on the Permeability of SAP Modified Concrete. Materials 2020, 13, 3368. [Google Scholar] [CrossRef]

- Fennell, E.; Huyghe, J.M. Chemically responsive hydrogel deformation mechanics: A review. Molecules 2019, 24, 3521. [Google Scholar] [CrossRef]

- Oksińska, M.P.; Magnucka, E.G.; Lejcuś, K.; Pietr, S.J. Biodegradation of the cross-linked copolymer of acrylamide and potassium acrylate by soil bacteria. Environ. Sci. Pollut. Res. 2016, 23, 5969–5977. [Google Scholar] [CrossRef]

- Zohuriaan-Mehr, M.J.; Kabiri, K. Superabsorbent polymer materials: A review. Iran. Polym. J. 2008, 17, 451–477. [Google Scholar]

- Drozdov, A.D. Swelling of thermo-responsive hydrogels. Eur. Phys. J. E 2014, 37, 93. [Google Scholar] [CrossRef]

- Ullah, F.; Othman, M.B.H.; Javed, F.; Ahmad, Z.; Akil, H.M. Classification, processing and application of hydrogels: A review. Mater. Sci. Eng. C 2015, 57, 414–433. [Google Scholar] [CrossRef] [PubMed]

- Iwata, M.; Koda, S.; Nomura, H. Theory of Compression and Expansion of Hydrogels. J. Chem. Eng. Jpn. 1999, 32, 684–688. [Google Scholar] [CrossRef]

- Chester, S.A.; Anand, L. A coupled theory of fluid permeation and large deformations for elastomeric materials. J. Mech. Phys. Solids 2010, 58, 1879–1906. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, R.; Li, A.; Wang, A. Preparation, swelling behaviors and application of polyacrylamide/attapulgite superabsorbent composites. Polym. Adv. Technol. 2006, 17, 12–19. [Google Scholar] [CrossRef]

- Rosa, F.; Bordado, J.; Casquilho, M. Ground particle size influence on the swelling of a copolymer of AA/AMPS in water. J. Appl. Polym. Sci. 2008, 107, 3413–3418. [Google Scholar] [CrossRef]

- Parvathy, P.C.; Jyothi, A.N. Water sorption kinetics of superabsorbent hydrogels of saponified cassava starch-graft-poly(acrylamide). Starch 2012, 64, 803–812. [Google Scholar] [CrossRef]

- Kiatkamjornwong, S.; Mongkolsawat, K.; Sonsuk, M. Synthesis and property characterization of cassava starch grafted poly[acrylamide-co-(maleic acid)] superabsorbent via γ-irradiation. Polymer 2002, 43, 3915–3924. [Google Scholar] [CrossRef]

- Bouklas, N.; Huang, R. Swelling kinetics of polymer gels: Comparison of linear and nonlinear theories. Soft Matter 2012, 8, 8194. [Google Scholar] [CrossRef]

- Hong, W.; Zhao, X.; Zhou, J.; Suo, Z. A theory of coupled diffusion and large deformation in polymeric gels. J. Mech. Phys. Solids 2008, 56, 1779–1793. [Google Scholar] [CrossRef]

- Sauerwein, M.; Steeb, H. A modified effective stress principle for chemical active multiphase materials with internal mass exchange. Geomech. Energy Environ. 2018, 15, 19–34. [Google Scholar] [CrossRef]

- Pourjavadi, A.; Seidi, F.; Salimi, H.; Soleyman, R. Grafted CMC/silica gel superabsorbent composite: Synthesis and investigation of swelling behavior in various media. J. Appl. Polym. Sci. 2008, 108, 3281–3290. [Google Scholar] [CrossRef]

- Lejcuś, K.; Śpitalniak, M.; Dabrowska, J. Swelling Behaviour of Superabsorbent Polymers for Soil Amendment under Different Loads. Polymers (Basel) 2018, 10, 271. [Google Scholar] [CrossRef]

- Bryk, M. Resolving compactness index of pores and solid phase elements in sandy and silt loamy soils. Geoderma 2018, 318, 109–122. [Google Scholar] [CrossRef]

- Kim, D.J.; Angulo Jaramillo, R.; Vauclin, M.; Feyen, J.; Choi, S.I. Modeling of soil deformation and water flow in a swelling soil. Geoderma 1999, 92, 217–238. [Google Scholar] [CrossRef]

- Misiewicz, J.; Lejcuś, K.; Dąbrowska, J.; Marczak, D. The Characteristics of Absorbency Under Load (AUL) for Superabsorbent and Soil Mixtures. Sci. Rep. 2019, 9, 18098. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.; Cai, S.; Suo, Z.; Hayward, R.C. Poroelastic swelling kinetics of thin hydrogel layers: Comparison of theory and experiment. Soft Matter 2010, 6, 6004. [Google Scholar] [CrossRef]

- Deisenroth, M.P.; Faisal, A.A.; Ong, C.S. Mathematics for Machine Learning; Cambridge University Press: Cambridge, UK, 2020. [Google Scholar]

- Brockwell, P.J.; Davis, R.A. (Eds.) Introduction to Time Series and Forecasting; Springer Texts in Statistics; Springer: New York, NY, USA, 2002; ISBN 978-0-387-95351-9. [Google Scholar]

- Borchers, H.W. Pracma: Practical Numerical Math Functions; Version 2.2.9.; R Foundation for Statistical Computing: Vienna, Austria, 2019. [Google Scholar]

- Woodall, W.H.; Wheeler, D.J.; Chambers, D.S. Understanding Statistical Process Control. Technometrics 1986, 28, 402. [Google Scholar] [CrossRef]

- Adamonytė, I.; Grybauskienė, V.; Vyčienė, G. The influence of biological additives on the moisture retention of soil. In Proceedings of the International Scientific Conference “Rural Development” 2017, Akademija, Lithuania, 23–24 November 2017; Volume 3230, pp. 1–5. [Google Scholar]

- Davis, C.R.; Kelly, S.L.; Erk, K.A. Comparing laser diffraction and optical microscopy for characterizing superabsorbent polymer particle morphology, size, and swelling capacity. J. Appl. Polym. Sci. 2018, 135, 46055. [Google Scholar] [CrossRef]

- Chen, J.J.; Ng, P.L.; Chu, S.H.; Guan, G.X.; Kwan, A.K.H. Ternary blending with metakaolin and silica fume to improve packing density and performance of binder paste. Constr. Build. Mater. 2020, 252, 119031. [Google Scholar] [CrossRef]

- Horoshenkov, K.V.; Mohamed, M.H.A. Experimental investigation of the effects of water saturation on the acoustic admittance of sandy soils. J. Acoust. Soc. Am. 2006, 120, 1910–1921. [Google Scholar] [CrossRef]

- Pourjavadi, A.; Jahromi, P.E.; Seidi, F.; Salimi, H. Synthesis and swelling behavior of acrylatedstarch-g-poly (acrylic acid) and acrylatedstarch-g-poly (acrylamide) hydrogels. Carbohydr. Polym. 2010, 79, 933–940. [Google Scholar] [CrossRef]

- Agaba, H.; Baguma Orikiriza, L.J.; Osoto Esegu, J.F.; Obua, J.; Kabasa, J.D.; Hüttermann, A. Effects of Hydrogel Amendment to Different Soils on Plant Available Water and Survival of Trees under Drought Conditions. CLEAN Soil Air Water 2010, 38, 328–335. [Google Scholar] [CrossRef]

- Yu, J.; Shi, J.G.; Ma, X.; Dang, P.F.; Yan, Y.L.; Mamedov, A.I.; Shainberg, I.; Levy, G.J. Superabsorbent Polymer Properties and Concentration Effects on Water Retention under Drying Conditions. Soil Sci. Soc. Am. J. 2017, 81, 889–901. [Google Scholar] [CrossRef]

- Abedi-Koupai, J.; Sohrab, F.; Swarbrick, G. Evaluation of Hydrogel Application on Soil Water Retention Characteristics. J. Plant Nutr. 2008, 31, 317–331. [Google Scholar] [CrossRef]

- Saha, A.; Rattan, B.; Sekharan, S.; Manna, U. Quantifying the interactive effect of water absorbing polymer (WAP)-soil texture on plant available water content and irrigation frequency. Geoderma 2020, 368, 114310. [Google Scholar] [CrossRef]

- Wróblewska, K.; Chohura, P.; Dębicz, R.; Lejcuś, K.; Dąbrowska, J. Water absorbing geocomposite: A novel method improving water and fertilizer efficiency in Brunnera macrophylla cultivation, Part I: Plant growth. Acta Sci. Pol. Hortorum Cultus 2018, 17, 49–56. [Google Scholar] [CrossRef]

- Kordas, L.; Kuc, P.; Lejcuś, K. Biological stabilisation of tailing pond coasts with use of mineral and organic substances and water-absorbing geocomposites. Pol. J. Environ. Stud. 2018, 27, 2089–2095. [Google Scholar] [CrossRef]

- Lejcuś, K.; Dąbrowska, J.; Garlikowski, D.; Śpitalniak, M. The application of water-absorbing geocomposites to support plant growth on slopes. Geosynth. Int. 2015, 22, 452–456. [Google Scholar] [CrossRef]

| Physical Properties | Soil/SAP | |||||

|---|---|---|---|---|---|---|

| Coarse Sand | Loamy Sand | K2 | KM | KS | ||

| Specific Weight [g/cm3] | 2.65 | 2.65 | 1.10 | 1.10 | 1.10 | |

| Bulk Density [g/cm3] | 1.8 | 2.05 | NA | NA | NA | |

| Porosity [-] | 0.32 | 0.23 | NA | NA | NA | |

| Grain Size Distribution [%] | Gravel (>2.00 mm) | 2 | 0 | 20 | 0 | 0 |

| Sand (0.05 mm–2.00 mm) | 98 | 83 | 80 | 100 | 94 | |

| Silt (0.002 mm–0.05 mm) | 0 | 10 | 0 | 0 | 6 | |

| Clay (<0.002 mm) | 0 | 7 | 0 | 0 | 0 | |

| Soil | SAP | SAP-Soil Proportion [%] | MAX Swelling Pressure [kPa] | Time-90% Max Pressure [min] | Standard Deviation of Sample [kPa] |

|---|---|---|---|---|---|

| Coarse Sand | K2 | 0.30 | 27.00 | 103.00 | 0.250 |

| 0.50 | 45.37 | 100.00 | 0.235 | ||

| 1.00 | 79.53 | 106.50 | 0.195 | ||

| KM | 0.30 | 21.49 | 25.50 | 0.158 | |

| 0.50 | 33.35 | 32.83 | 0.146 | ||

| 1.00 | 62.22 | 43.83 | 0.107 | ||

| KS | 0.30 | 9.67 | 29.00 | 0.119 | |

| 0.50 | 18.68 | 134.00 | 0.133 | ||

| 1.00 | 37.16 | 174.00 | 0.162 | ||

| Loamy Sand | K2 | 0.30 | 25.71 | 60.50 | 0.194 |

| 0.50 | 43.28 | 56.67 | 0.186 | ||

| 1.00 | 78.23 | 64.00 | 0.162 | ||

| KM | 0.30 | 23.39 | 18.83 | 0.148 | |

| 0.50 | 41.63 | 16.83 | 0.118 | ||

| 1.00 | 65.67 | 18.15 | 0.083 | ||

| KS | 0.30 | 17.39 | 8.83 | 0.070 | |

| 0.50 | 28.98 | 17.33 | 0.102 | ||

| 1.00 | 53.15 | 10.17 | 0.067 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Misiewicz, J.; Głogowski, A.; Lejcuś, K.; Marczak, D. The Characteristics of Swelling Pressure for Superabsorbent Polymer and Soil Mixtures. Materials 2020, 13, 5071. https://doi.org/10.3390/ma13225071

Misiewicz J, Głogowski A, Lejcuś K, Marczak D. The Characteristics of Swelling Pressure for Superabsorbent Polymer and Soil Mixtures. Materials. 2020; 13(22):5071. https://doi.org/10.3390/ma13225071

Chicago/Turabian StyleMisiewicz, Jakub, Arkadiusz Głogowski, Krzysztof Lejcuś, and Daria Marczak. 2020. "The Characteristics of Swelling Pressure for Superabsorbent Polymer and Soil Mixtures" Materials 13, no. 22: 5071. https://doi.org/10.3390/ma13225071

APA StyleMisiewicz, J., Głogowski, A., Lejcuś, K., & Marczak, D. (2020). The Characteristics of Swelling Pressure for Superabsorbent Polymer and Soil Mixtures. Materials, 13(22), 5071. https://doi.org/10.3390/ma13225071