Interlayer Hybridization of Virgin Carbon, Recycled Carbon and Natural Fiber Laminates

Abstract

1. Introduction

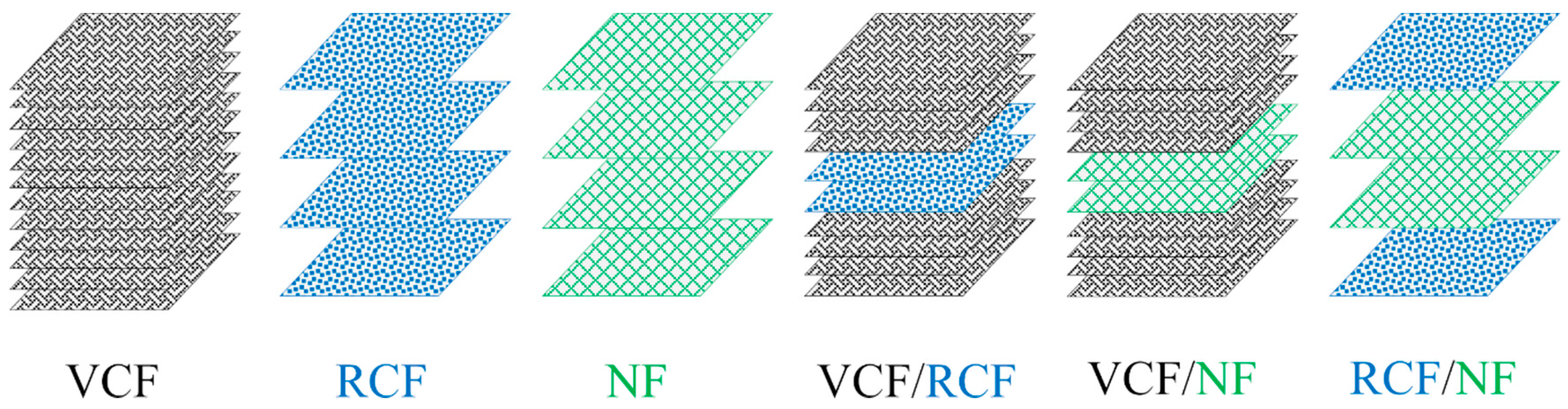

2. Materials and Methods

2.1. Materials

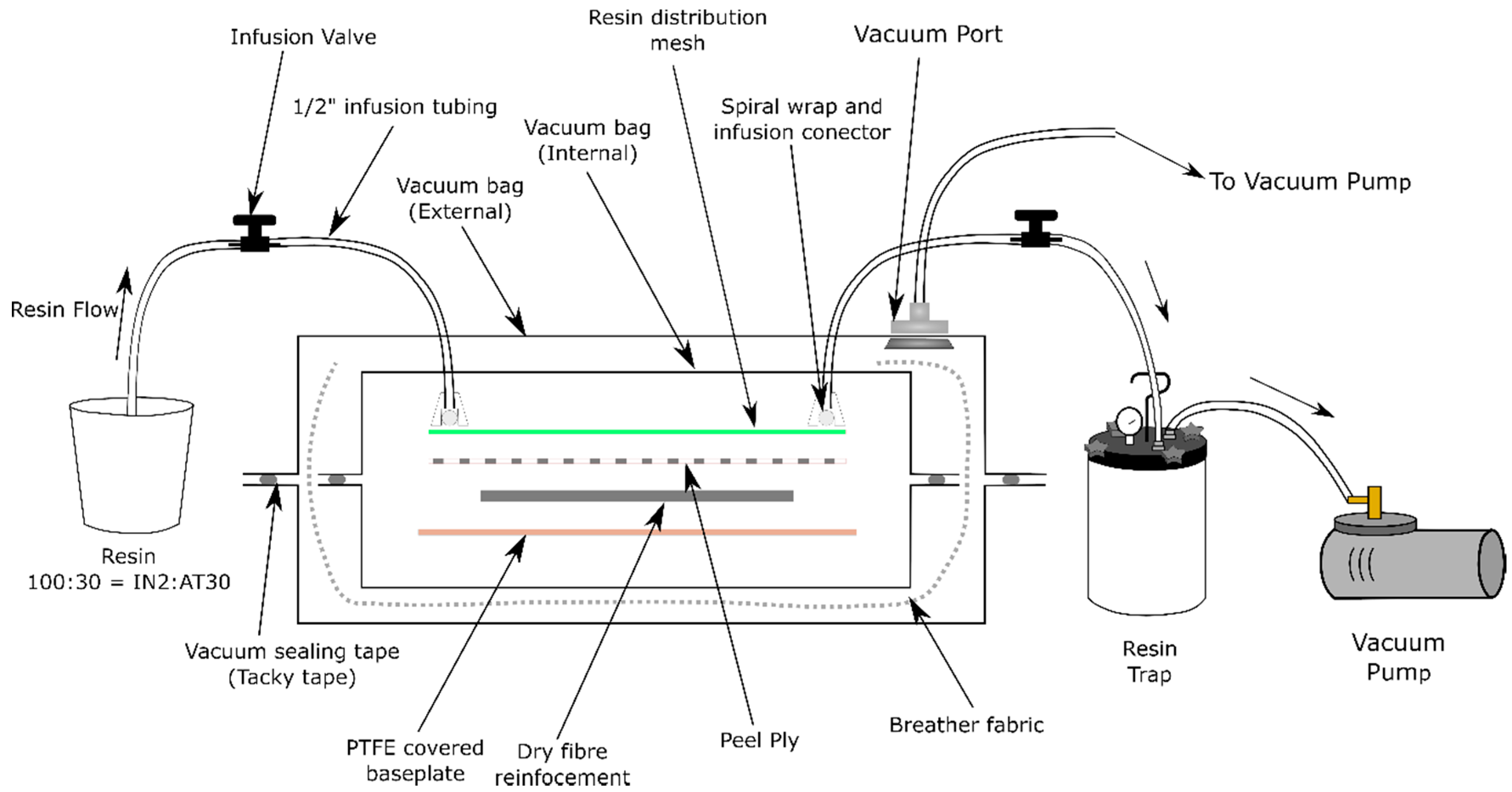

2.2. Double Bag Vacuum Infusion

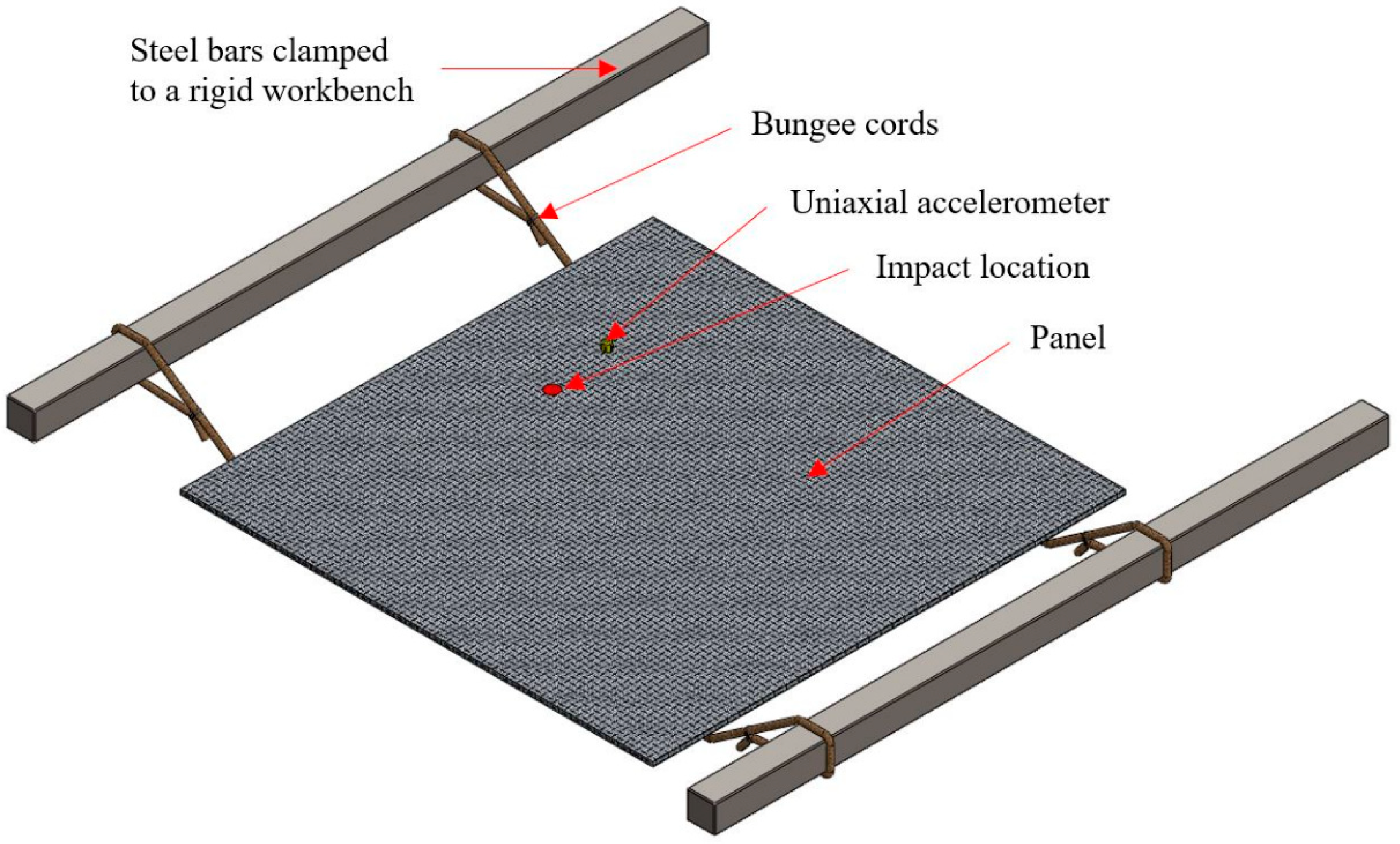

2.3. Experimental Modal Analysis Method

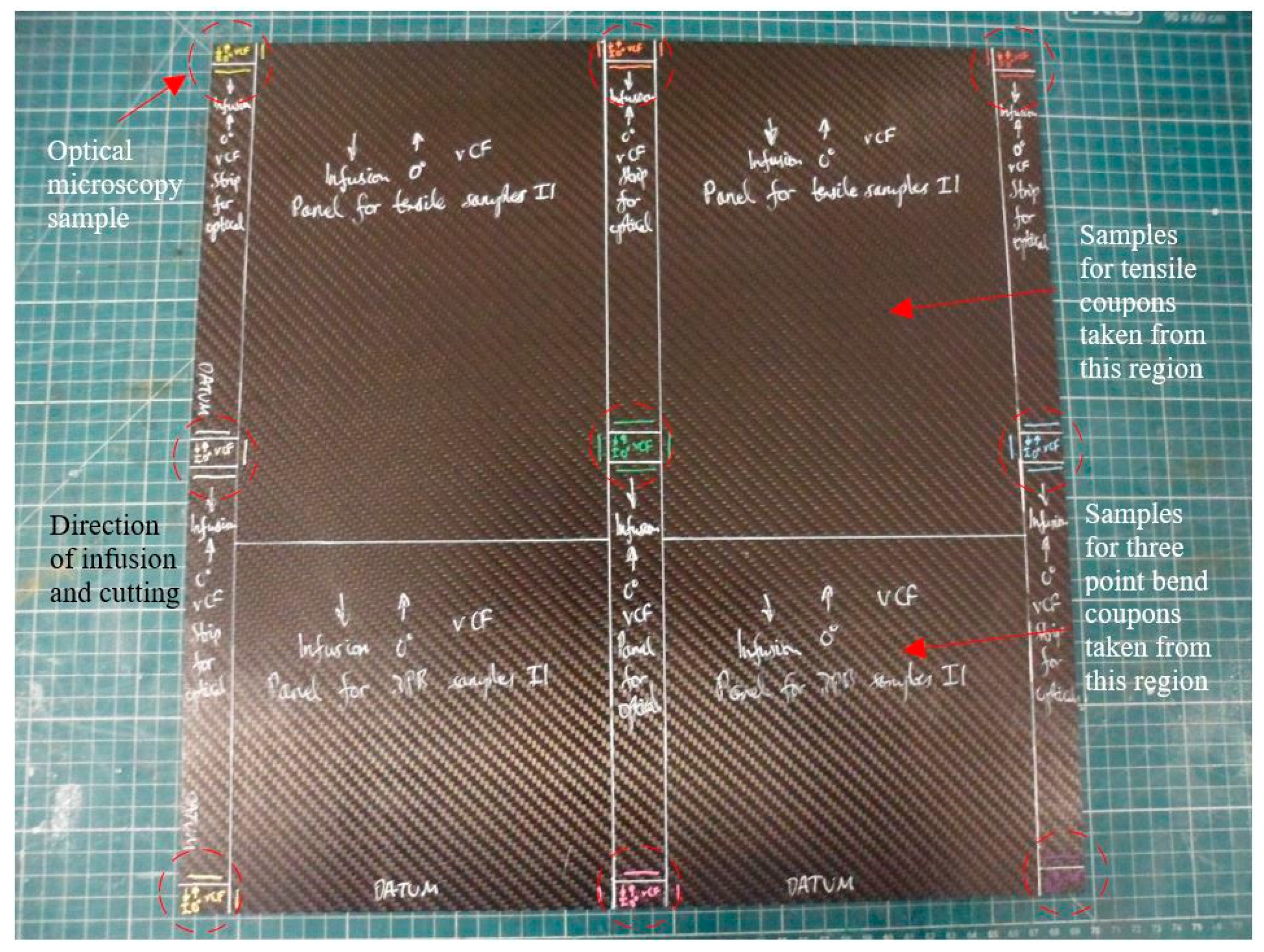

2.4. Mechanical and Optical Sample Preparation

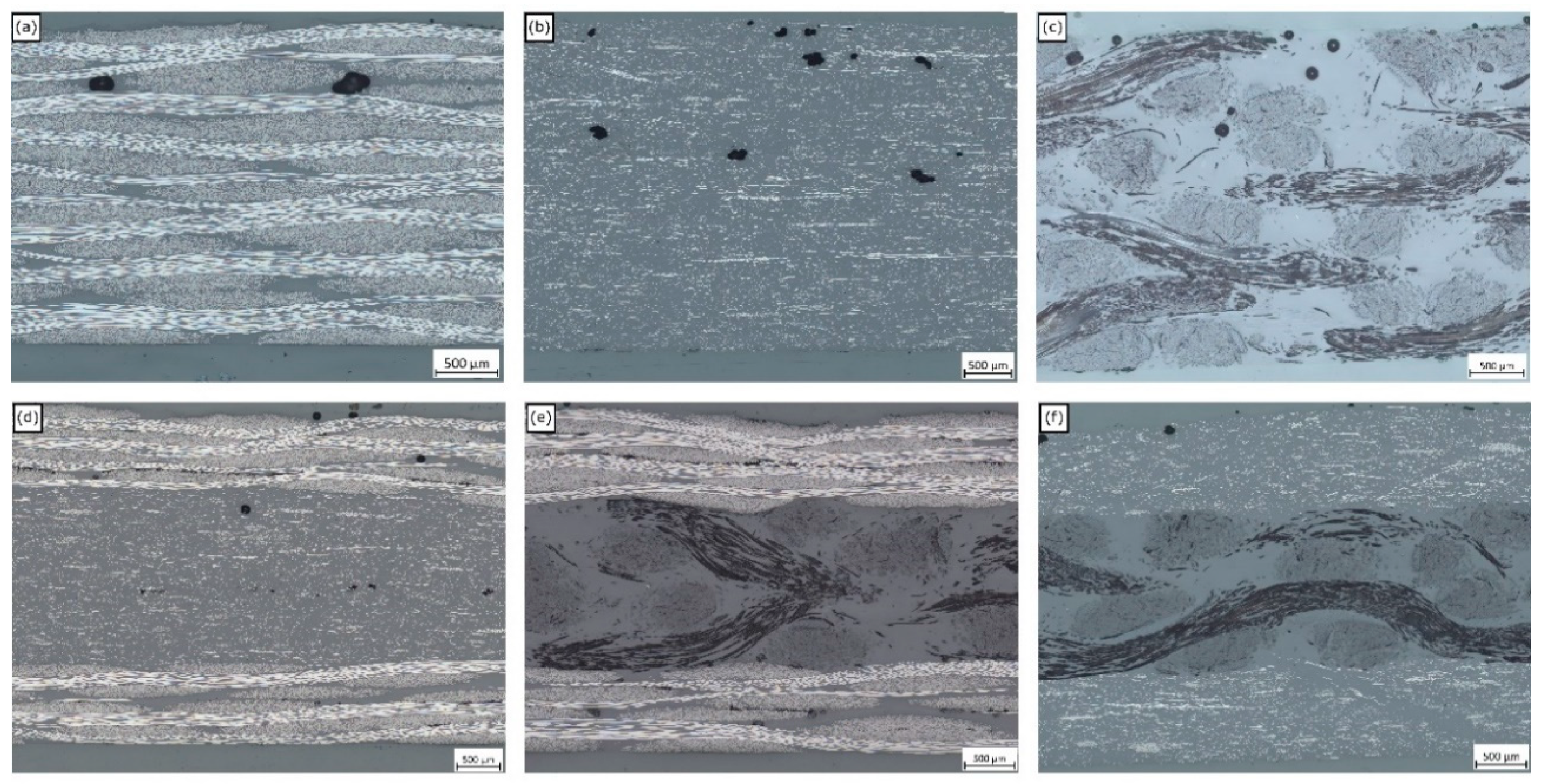

2.5. Optical Microscopy

2.6. Tensile Testing

2.6.1. 3D Stereo Digital Image Correlation (DIC)

2.6.2. Image Correlation Analysis

2.7. Three-Point Bend Testing

3. Results and Discussion

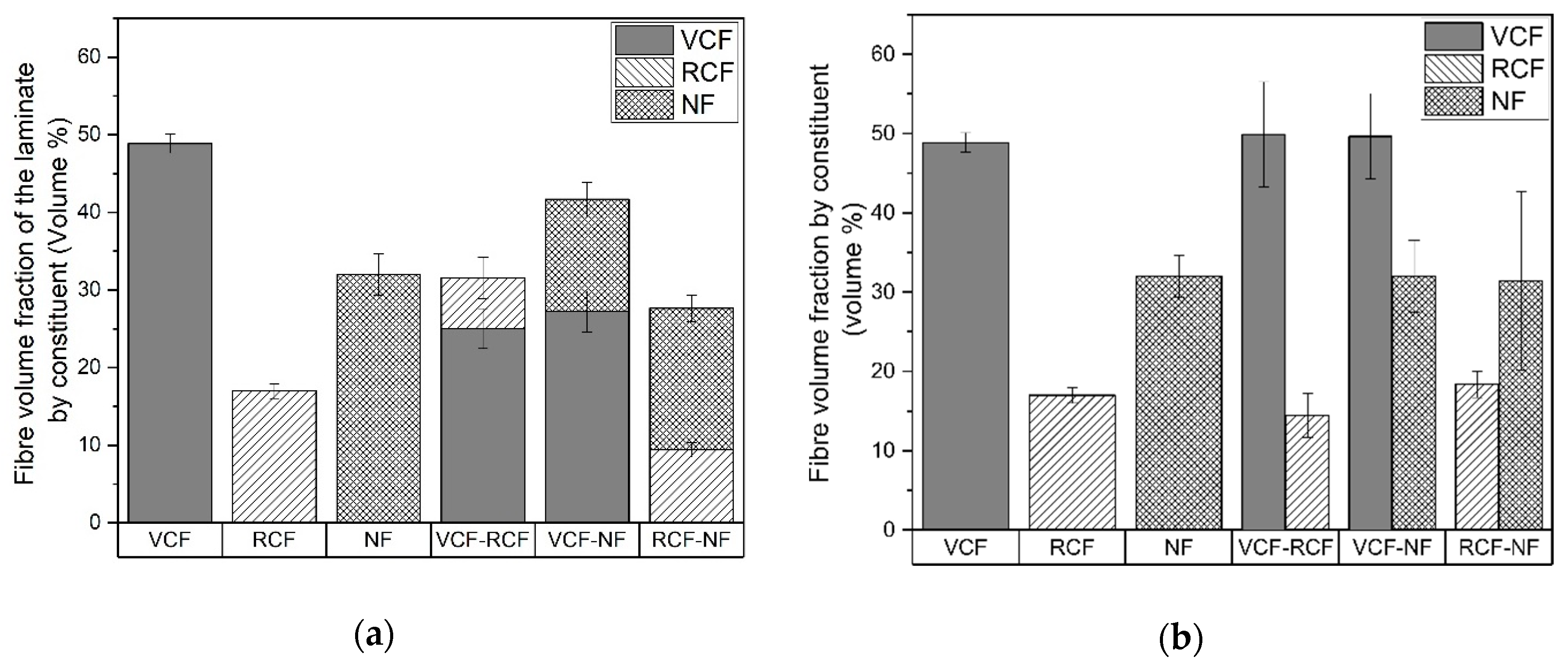

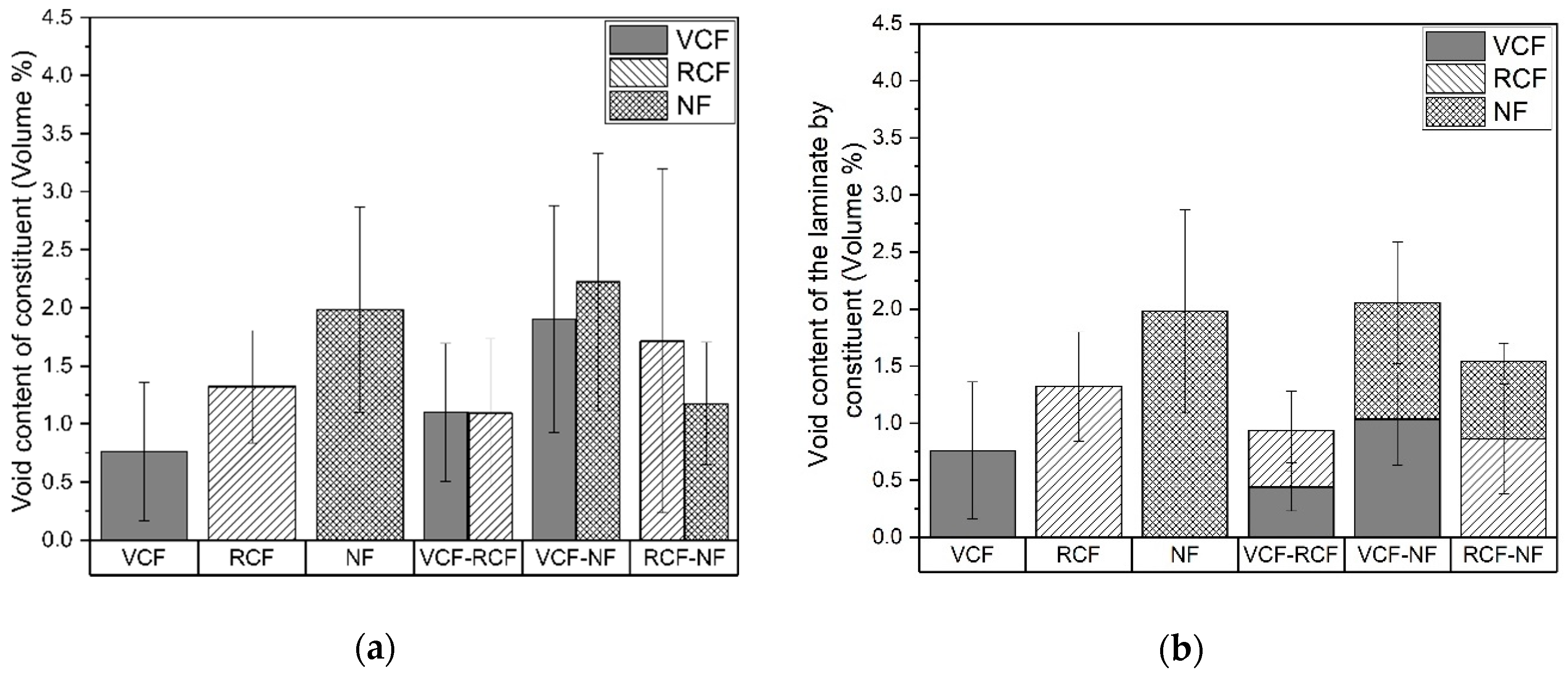

3.1. Optical Microscopy: Fiber Volume Fraction, Void Content

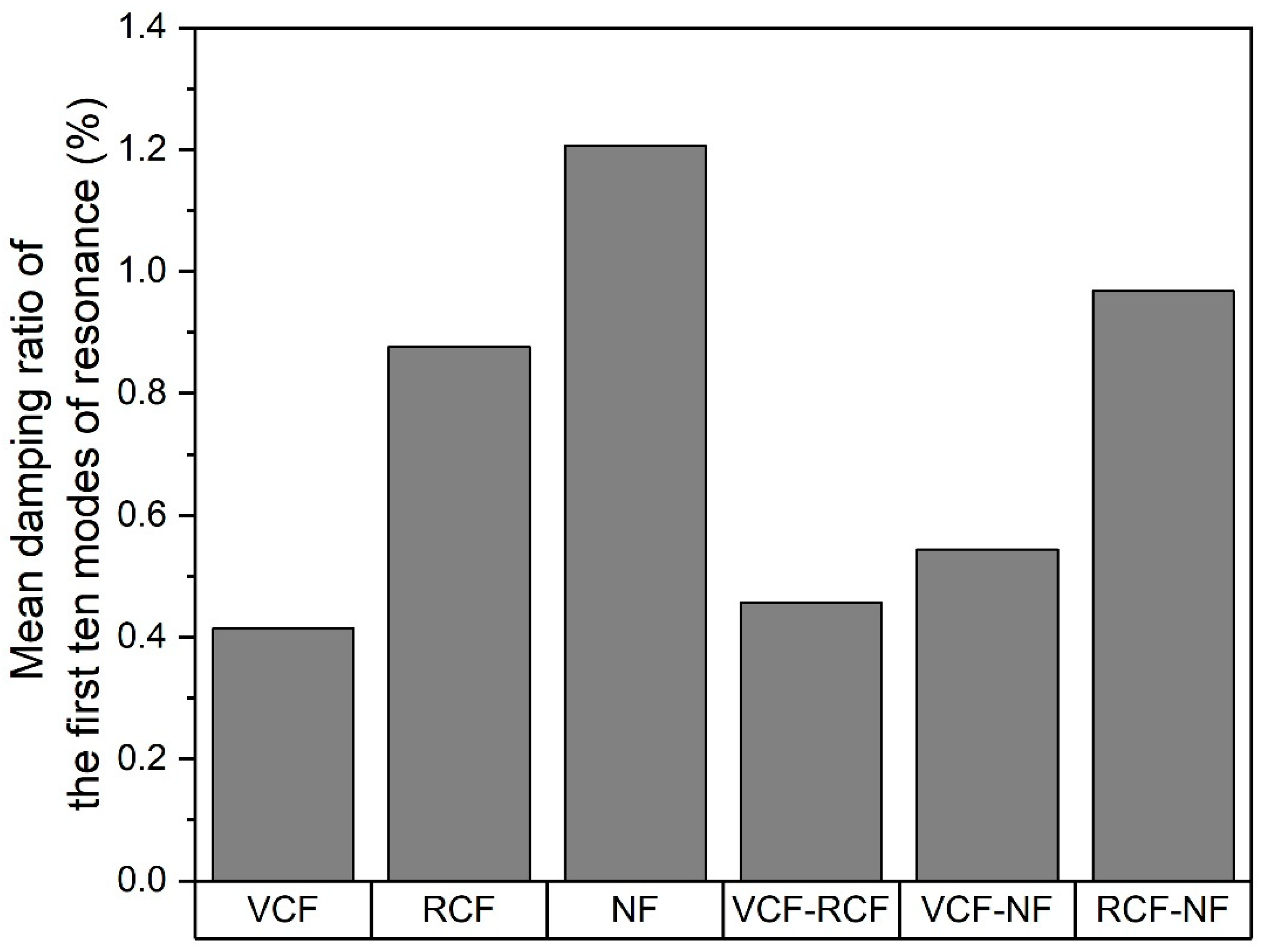

3.2. Experimental Modal Analysis

3.3. Mechanical Testing

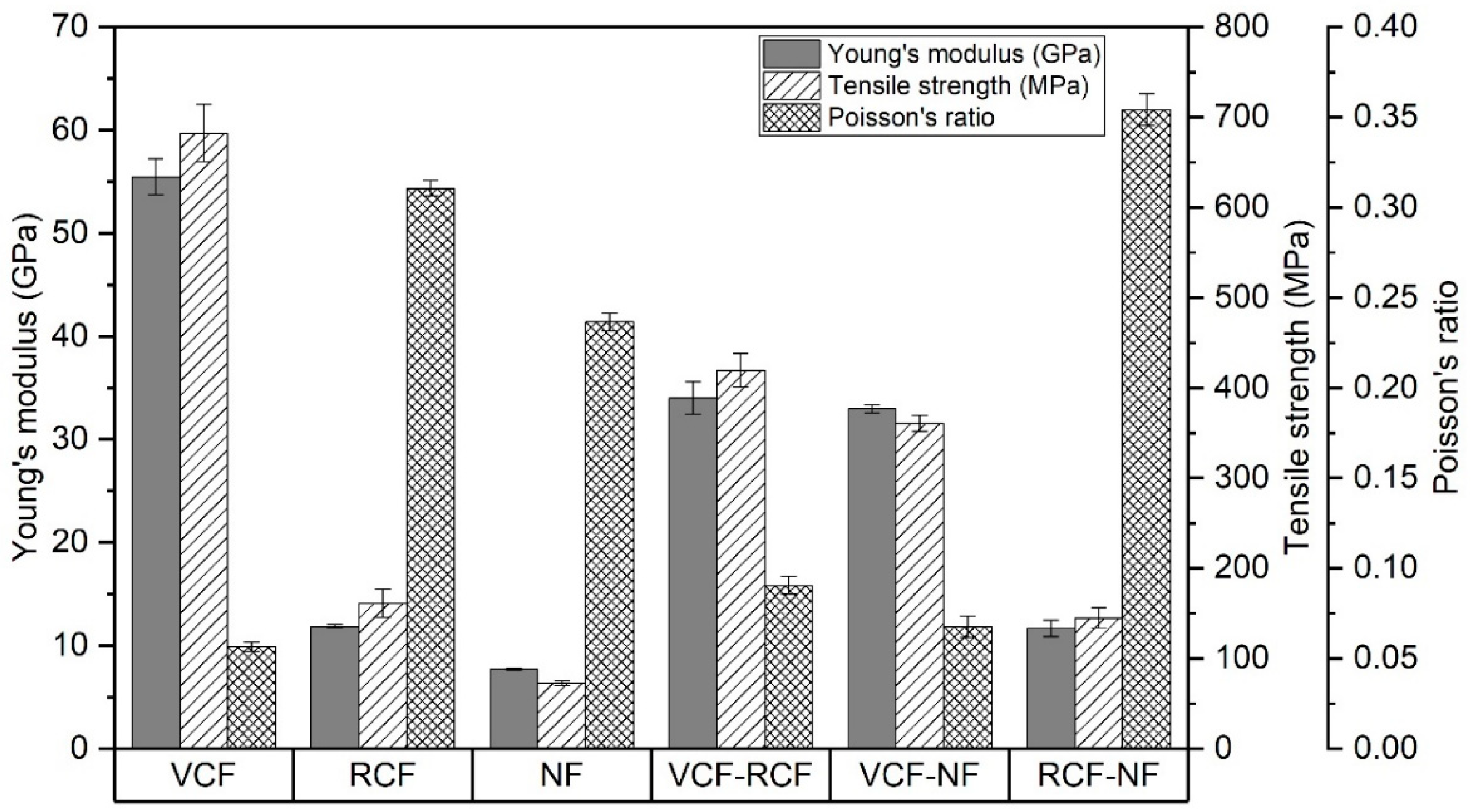

3.3.1. Tensile Properties

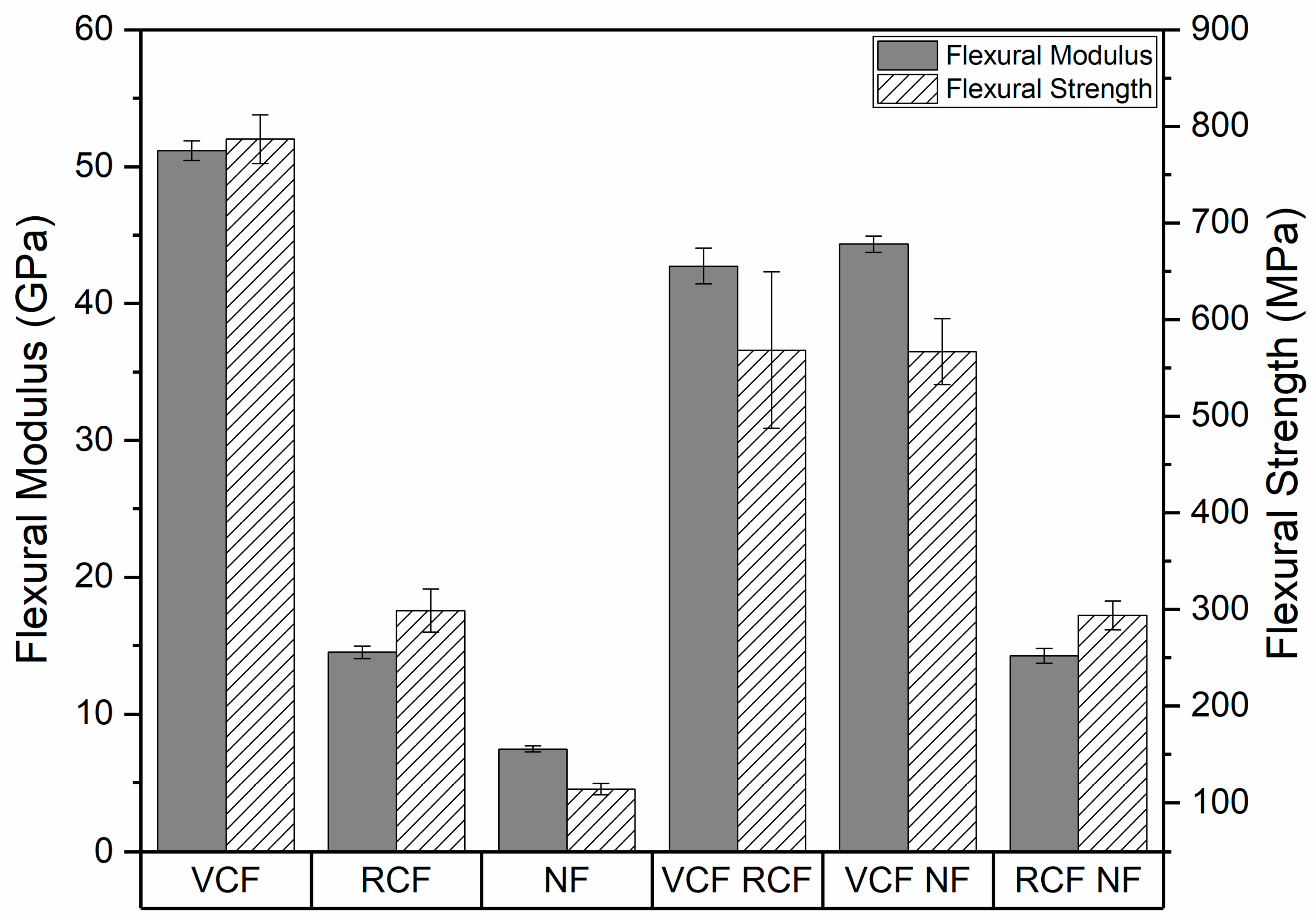

3.3.2. Flexural Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Meng, F.; McKechnie, J.; Pickering, S.J. An assessment of financial viability of recycled carbon fiber in automotive applications. Compos. Part A Appl. Sci. Manuf. 2018, 109, 207–220. [Google Scholar] [CrossRef]

- Longana, M.; Ondra, V.; Yu, H.; Potter, K.; Hamerton, I. Reclaimed Carbon and Flax Fiber Composites: Manufacturing and Mechanical Properties. Recycling 2018, 3, 52. [Google Scholar] [CrossRef]

- Longana, M.L.; Ong, N.; Yu, H.; Potter, K.D. Multiple closed loop recycling of carbon fiber composites with the HiPerDiF (High Performance Discontinuous Fiber) method. Compos. Struct. 2016, 153, 271–277. [Google Scholar] [CrossRef]

- Tapper, R.J.; Longana, M.L.; Hamerton, I.; Potter, K.D. A closed-loop recycling process for discontinuous carbon fiber polyamide 6 composites. Compos. Part B Eng. 2019, 179, 107418. [Google Scholar] [CrossRef]

- Tapper, R.J.; Longana, M.L.; Yu, H.; Hamerton, I.; Potter, K. Development of a closed-loop recycling process for discontinuous carbon fibre polypropylene composites. Compos. Part B Eng. 2018, 146, 222–231. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Joshi, S.; Drzal, L.; Mohanty, A.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Dissanayake, N.P.J.; Summerscales, J.; Grove, S.M.; Singh, M.M. Energy Use in the Production of Flax Fiber for the Reinforcement of Composites. J. Nat. Fibers 2009, 6, 331–346. [Google Scholar] [CrossRef]

- Pil, L.; Bensadoun, F.; Pariset, J.; Verpoest, I. Why are designers fascinated by flax and hemp fibre composites? Compos. Part A Appl. Sci. Manuf. 2016, 83, 193–205. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Krishnaraj, V.; Kumar, M.S.; Zitoune, R. Sound and Vibration Damping Properties of Flax Fiber Reinforced Composites. Procedia Eng. 2014, 97, 573–581. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.; Wong, K.H.; Pickering, S.J. Environmental Aspects of Use of Recycled Carbon Fiber Composites in Automotive Applications. Environ. Sci. Technol. 2017, 51, 12727–12736. [Google Scholar] [CrossRef] [PubMed]

- Budhwani, K.; Janney, M.; Vaidya, U. Vibration-based Nondestructive Testing to Determine Viability of Parts Produced with Recycled Thermoplastic Composites. Mater. Eval. 2016, 74, 181–193. [Google Scholar]

- Pimenta, S.; Pinho, S. The influence of micromechanical properties and reinforcement architecture on the mechanical response of recycled composites. Compos. Part A Appl. Sci. Manuf. 2014, 56, 213–225. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef]

- Giorgini, L.; Benelli, T.; Brancolini, G.; Mazzocchetti, L. Recycling of carbon fiber reinforced composite waste to close their life cycle in a cradle-to-cradle approach. Curr. Opin. Green Sustain. Chem. 2020, 26. [Google Scholar] [CrossRef]

- Hagnell, M.; Åkermo, M. The economic and mechanical potential of closed loop material usage and recycling of fibre-reinforced composite materials. J. Clean. Prod. 2019, 223, 957–968. [Google Scholar] [CrossRef]

- Holmes, M. Recycled carbon fiber composites become a reality. Reinf. Plast. 2018, 62, 148–153. [Google Scholar] [CrossRef]

- Tang, X.; Yan, X. Acoustic energy absorption properties of fibrous materials: A review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 360–380. [Google Scholar] [CrossRef]

- Kumar, K.S.; Siva, I.; Jeyaraj, P.; Jappes, J.W.; Amico, S.; Rajini, N. Synergy of fiber length and content on free vibration and damping behavior of natural fiber reinforced polyester composite beams. Mater. Des. 2014, 56, 379–386. [Google Scholar] [CrossRef]

- Munde, Y.S.; Ingle, R.B.; Siva, I. Vibration damping and acoustic characteristics of sisal fibre–reinforced polypropylene composite. Noise Vib. Worldw. 2018, 50, 13–21. [Google Scholar] [CrossRef]

- Rajesh, M.; Singh, S.P.; Pitchaimani, J. Mechanical behavior of woven natural fiber fabric composites: Effect of weaving architecture, intra-ply hybridization and stacking sequence of fabrics. J. Ind. Text. 2016, 47, 938–959. [Google Scholar] [CrossRef]

- Gupta, M.; Srivastava, R.K. Mechanical Properties of Hybrid Fibers-Reinforced Polymer Composite: A Review. Polym. Technol. Eng. 2015, 55, 626–642. [Google Scholar] [CrossRef]

- Dong, C. Review of natural fibre-reinforced hybrid composites. J. Reinf. Plast. Compos. 2017, 37, 331–348. [Google Scholar] [CrossRef]

- Meredith, J.; Coles, S.R.; Powe, R.; Collings, E.; Cozien-Cazuc, S.; Weager, B.; Müssig, J.; Kirwan, K. On the static and dynamic properties of flax and Cordenka epoxy composites. Compos. Sci. Technol. 2013, 80, 31–38. [Google Scholar] [CrossRef]

- Meredith, J.; Cozien-Cazuc, S.; Collings, E.; Carter, S.; Alsop, S.; Lever, J.; Coles, S.R.; Wood, B.M.; Kirwan, K. Recycled carbon fibre for high performance energy absorption. Compos. Sci. Technol. 2012, 72, 688–695. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillo, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Nisini, E.; Santulli, C.; Liverani, A. Mechanical and impact characterization of hybrid composite laminates with carbon, basalt and flax fibres. Compos. Part B Eng. 2017, 127, 92–99. [Google Scholar] [CrossRef]

- López-Alba, E.; Schmeer, S.; Díaz, F. Energy Absorption Capacity in Natural Fiber Reinforcement Composites Structures. Materials 2018, 11, 418. [Google Scholar] [CrossRef]

- Derusova, D.A.; Vavilov, V.; Sfarra, S.; Sarasini, F.; Druzhinin, N. Applying ultrasonic resonance vibrometry for the evaluation of impact damage in natural/synthetic fibre reinforced composites. Polym. Test. 2018, 68, 70–76. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Naqvi, S.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Tse, B.; Yu, X.; Gong, H.; Soutis, C. Flexural Properties of Wet-Laid Hybrid Nonwoven Recycled Carbon and Flax Fibre Composites in Poly-Lactic Acid Matrix. Aerospace 2018, 5, 120. [Google Scholar] [CrossRef]

- Bachmann, J.; Wiedemann, M.; Wierach, P. Flexural Mechanical Properties of Hybrid Epoxy Composites Reinforced with Nonwoven Made of Flax Fibers and Recycled Carbon Fibers. Aerospace 2018, 5, 107. [Google Scholar] [CrossRef]

- Cihan, M.; Sobey, A.; Blake, J. Mechanical and dynamic performance of woven flax/E-glass hybrid composites. Compos. Sci. Technol. 2019, 172, 36–42. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of flax/carbon fiber hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef]

- Duc, F.; Bourban, P.; Plummer, C.; Månson, J.-A. Damping of thermoset and thermoplastic flax fibre composites. Compos. Part A Appl. Sci. Manuf. 2014, 64, 115–123. [Google Scholar] [CrossRef]

- Ashworth, S.; Rongong, J.; Wilson, P.; Meredith, J. Mechanical and damping properties of resin transfer moulded jute-carbon hybrid composites. Compos. Part B Eng. 2016, 105, 60–66. [Google Scholar] [CrossRef]

- Le Guen, M.J.; Newman, R.H.; Fernyhough, A.; Emms, G.W.; Staiger, M.P. The damping–modulus relationship in flax–carbon fibre hybrid composites. Compos. Part B Eng. 2016, 89, 27–33. [Google Scholar] [CrossRef]

- Assarar, M.; Zouari, W.; Ayad, R.; Kebir, H.; Berthelot, J.-M. Improving the damping properties of carbon fibre reinforced composites by interleaving flax and viscoelastic layers. Compos. Part B Eng. 2018, 152, 248–255. [Google Scholar] [CrossRef]

- Li, Y.; Cai, S.; Huang, X. Multi-scaled enhancement of damping property for carbon fiber reinforced composites. Compos. Sci. Technol. 2017, 143, 89–97. [Google Scholar] [CrossRef]

- Pingulkar, P.; Suresha, B. Free Vibration Analysis of Laminated Composite Plates Using Finite Element Method. Polym. Polym. Compos. 2016, 24, 529–538. [Google Scholar] [CrossRef]

- Kureemun, U.; Ravandi, M.; Tran, L.; Teo, W.; Tay, T.; Lee, H. Effects of hybridization and hybrid fibre dispersion on the mechanical properties of woven flax-carbon epoxy at low carbon fibre volume fractions. Compos. Part B Eng. 2018, 134, 28–38. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, H.; Kumar, A. Influence of Stacking sequence and thickness on the free vibrational behaviour of Carbon/epoxy laminates. Mater. Today Proc. 2018, 5, 7701–7707. [Google Scholar] [CrossRef]

- Treviso, A.; Van Genechten, B.; Mundo, D.; Tournour, M. Damping in composite materials: Properties and models. Compos. Part B Eng. 2015, 78, 144–152. [Google Scholar] [CrossRef]

- Muralidhar, B.A. Study of flax hybrid preforms reinforced epoxy composites. Mater. Des. 2013, 52, 835–840. [Google Scholar] [CrossRef]

- Assarar, M.; Zouari, W.; Sabhi, H.; Ayad, R.; Berthelot, J.-M. Evaluation of the damping of hybrid carbon–flax reinforced composites. Compos. Struct. 2015, 132, 148–154. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Amico, S.C.; Botelho, E.C.; Amado, F.D.R. Hybridization effect on the mechanical properties of curaua/glass fiber composites. Compos. Part B Eng. 2013, 55, 492–497. [Google Scholar] [CrossRef]

- Kassapoglou, C. Review of Classical Laminated Plate Theory. Des. Anal. Compos. Struct. 2010, 2010, 33–53. [Google Scholar] [CrossRef]

- Kretsis, G. A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites 1987, 18, 13–23. [Google Scholar] [CrossRef]

- Song, J.H. Pairing effect and tensile properties of laminated high-performance hybrid composites prepared using carbon/glass and carbon/aramid fibers. Compos. Part B Eng. 2015, 79, 61–66. [Google Scholar] [CrossRef]

- Wang, T.; Song, B.; Qiao, K.; Ding, C.; Wang, L. Influence of the hybrid ratio and stacking sequence on mechanical and damping properties of hybrid composites. Polym. Compos. 2018, 40, 2368–2380. [Google Scholar] [CrossRef]

- Marom, G.; Fischer, S.; Tuler, F.R.; Wagner, H.D. Hybrid effects in composites: Conditions for positive or negative effects versus rule-of-mixtures behaviour. J. Mater. Sci. 1978, 13, 1419–1426. [Google Scholar] [CrossRef]

- Gardiner, G. Double-Bag Infusion: 70% Fiber Volume? Compos World. 2010. Available online: https://www.compositesworld.com/articles/double-bag-infusion-70-fiber-volume (accessed on 1 May 2020).

- Williams, C.; Summerscales, J.; Grove, S. Resin Infusion under Flexible Tooling (RIFT): A review. Compos. Part A Appl. Sci. Manuf. 1996, 27, 517–524. [Google Scholar] [CrossRef]

- Gardiner, G. Double Bagging Through Three Decades. Compos World. 2010. Available online: https://www.compositesworld.com/articles/double-bagging-through-three-decades (accessed on 1 May 2020).

- Avitabile, P. Introduction to experimental modal analysis: A simple non-mathematical presentation. In Modal Testing: A Practitioner’s Guide; The Society for Experimental Mechanics and John Wiley & Sons Ltd.: Chichester, UK, 2018; p. 6. [Google Scholar]

- BSI Standards Publication. Part 4: Test conditions for isotropic and orthotropic fiber-reinforced plastic composites. In ISO 527-4:1997 Plastics—Determination of Tensile Properties; BSI Standards Publication: London, UK, 1997. [Google Scholar]

- BSI Standards Publication. Part 1: General principles. In BS EN ISO 527-1: 2012 Determination of Tensile Properties; BSI Standards Publication: London, UK, 2012. [Google Scholar]

- BSI Standards Publication. BS EN ISO 14125:1998+A1:2011 Fiber-Reinforced Plastic Composites. Determination of Flexural Properties; BSI Standards Publication: London, UK, 1998. [Google Scholar]

- Kabir, M.M.; Wang, H.; Aravinthan, T.; Cardona, F.; Lau, K.-T. Effects of natural fiber surface on composite properties: A review. In Proceedings of the 1st International Postgraduate Conference on Engineering, Designing and Developing the Built Environment for Sustainable Wellbeing (eddBE2011), Brisbane, Australia, 27–29 April 2011; pp. 94–99. [Google Scholar]

| Type | Reinforcement | Designated | Lay-up Sequence (degrees) | Mass (kg) | Thickness (mm) |

|---|---|---|---|---|---|

| Pure | Toray T300 carbon fiber | VCF | [(0/90)VCF]3s | 0.685 | 2.88 |

| Carbiso M SM45D carbon fiber | RCF | [(0/90)RCF]s | 0.773 | 3.45 | |

| Biotex flax fiber | NF | [(0/90)NF]s | 0.712 | 3.24 | |

| Hybrid | Toray T300 carbon fiber/Carbiso M SM45D carbon fiber | VCF-RCF | [(0/90/90/0)VCF(0)RCF]s | 0.874 | 3.69 |

| Toray T300 carbon fiber/Biotex flax fiber | VCF-NF | [(0/90/90/0)VCF(0)NF]s | 0.715 | 3.46 | |

| Carbiso M SM45D carbon fiber/Biotex flax fiber | RCF-NF | [(0)RCF(0)NF]s | 0.814 | 3.31 |

| Parameter | |

|---|---|

| Camera | Teledyne DALSA 12 M |

| Lens | Titanar 75 b |

| Camera angle/° | 24.47 |

| Frame rate/Hz | 1 |

| Working distance/mm | 533 |

| Pixel to mm | 1 pixel = 0.03 mm |

| Aperture | f/22 |

| Imaging window/pixels | 4096 × 3000 |

| Calibration Plate | CP20/90/D08713 |

| Measurement volume/mm2 | 125 mm × 95 mm × 75 mm |

| Facet size/pixels | 19 |

| Step size/pixels | 13 |

| Spatial resolution/mm | 0.57 |

| Displacement resolution/µm | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilson, P.R.; Ratner, A.; Stocker, G.; Syred, F.; Kirwan, K.; Coles, S.R. Interlayer Hybridization of Virgin Carbon, Recycled Carbon and Natural Fiber Laminates. Materials 2020, 13, 4955. https://doi.org/10.3390/ma13214955

Wilson PR, Ratner A, Stocker G, Syred F, Kirwan K, Coles SR. Interlayer Hybridization of Virgin Carbon, Recycled Carbon and Natural Fiber Laminates. Materials. 2020; 13(21):4955. https://doi.org/10.3390/ma13214955

Chicago/Turabian StyleWilson, Peter R., Alon Ratner, Gary Stocker, Frank Syred, Kerry Kirwan, and Stuart R. Coles. 2020. "Interlayer Hybridization of Virgin Carbon, Recycled Carbon and Natural Fiber Laminates" Materials 13, no. 21: 4955. https://doi.org/10.3390/ma13214955

APA StyleWilson, P. R., Ratner, A., Stocker, G., Syred, F., Kirwan, K., & Coles, S. R. (2020). Interlayer Hybridization of Virgin Carbon, Recycled Carbon and Natural Fiber Laminates. Materials, 13(21), 4955. https://doi.org/10.3390/ma13214955