3.1. Compressive Strength

The results of the compressive strength test of the specimens are shown in

Table 5 and

Figure 6. The averages were acquired by breaking four specimens at the age of 28 and 91 days.

By analyzing

Table 5 and

Figure 6, at 28 days with respect to the reference, concretes containing crystalline admixtures X, Y, and Z showed gains in strength of 15.4%, 30.9%, and 54.6%, respectively. The values obtained for the concrete with crystalline admixture Z were not considered due to the high coefficient of variation presented (13.2%). Roig-Flores et al. [

7] reported in their work an increase of 15% in the compressive strength of concretes containing crystalline admixtures at 28 days when compared to a reference concrete. This increase in compressive strength may be related to the filler effect provided by crystalline admixtures, to the point of contributing to the filling of the matrix pores [

7]. Furthermore, crystalline admixtures may have acted as an activator of cement hydration and contributed to the densification of C-S-H in the cementitious matrix [

36].

Pazderka and Hájková [

39] did not obtain a significant gain regarding the compressive strength of concretes containing 2% crystalline admixtures at 28 days. Ferrara and Krelani [

40] observed the same behavior, whereby the content of 1% crystalline admixtures did not increase the compressive strength of concrete samples until 30 days when compared to samples without additions.

For the age of 91 days, it can be noted that the concretes containing the crystalline admixtures showed less resistance in the compressive test when compared to the reference. Likewise, Helene et al. [

41] demonstrated little contribution of crystalline admixtures to concrete compressive strength, for the same w/c ratios, at the age of 91 days. Munn, Chang, and Kao [

42] found that the addition of 0.8% and 1.2% crystalline admixtures did not significantly increase the compressive strength of concretes made with ordinary cement, but found an increase in strength at 28 and 91 days for concretes produced with pozzolanic cement and the addition 1.2% crystalline admixtures. Better results could have been observed if the specimens were exposed to another curing condition, such as complete immersion [

26,

43].

To study the significance of controllable variables, a variance analysis (ANOVA) was carried out with factors using the software Statistica 13 (StatSoft, Tulsa, OK, USA). The results are shown in

Table 6.

It can be seen that the influence of the controllable variables used was considered statistically significant. Thus, the use of crystalline admixtures and the increase in age of the concrete made a difference regarding the results of compressive strength.

3.2. Capillarity Water Absorption

The results obtained in the capillarity water absorption test are shown in

Table 7 and

Figure 7 and correspond to the average of the absorption values after 72 h of testing. The averages were obtained by testing four specimens at 28 and 91 days of age.

The capillarity water absorption mechanism is not only influenced by the characteristics of the liquid, such as density, surface tension, and viscosity, but also depends on the characteristics of the concrete, such as tortuosity, radius, and communication between the capillary pores; the absorption of water is more intense with a smaller diameter of the capillary pores and their connections [

23].

Thus, the greater water absorption by capillarity observed in the reference for both ages may be related to the cement used in the present study. CPII-F cement has filler in its composition, a material that is considered to have similar inertness and fineness to cement, acting in the densification of the concrete matrix, causing a reduction in the size of the capillary pores, which in turn increases absorption.

Regarding the effect provided by crystalline admixtures, it is possible to observe a reduction in the absorption of water by capillarity in concretes with these materials. At 28 days compared to the reference, concretes with additives X, Y, and Z showed a reduction of 7%, 41%, and 13%, respectively.

At 91 days, a more considerable effect was observed using these materials, where the reduction in absorption was 24%, 43%, and 31%, respectively, for the crystalline admixtures X, Y, and Z. It is also possible to notice that there was no reduction in absorption from 28 to 91 days in the reference concrete, indicating that the reduction in absorption perceived in other concretes was mainly due to the effect of the crystalline admixtures used.

In the study by Joa et al. [

20], 3% crystalline admixtures in mortars provided a reduction in porosity and water absorption. On the other hand, Hassani et al. [

16] found no considerable difference in the results of water absorption in concretes containing 1% crystalline admixtures at 28 days.

To study the significance of controllable variables, a variance analysis (ANOVA) was carried out with the software Statistica 13. The results for the capillarity water absorption are shown in

Table 8.

3.3. Crack Width Measurements Using Microscopy

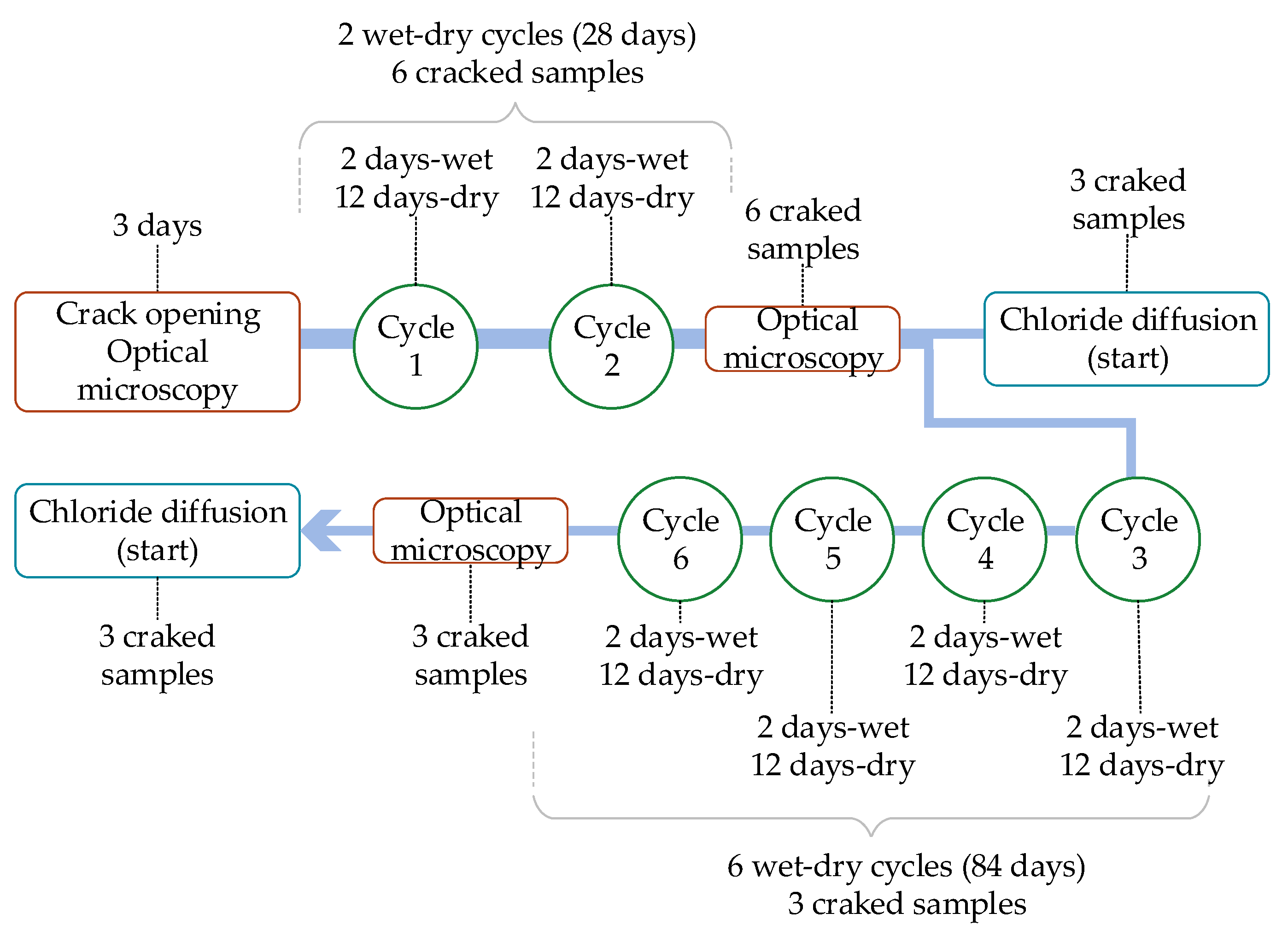

At 3 days, the crack thickness was measured on its surface, and images of the samples were collected using an optical microscope. Subsequently, after the wet–dry cycles, new images of the samples were collected to assess the crack self-healing rate. The test was performed on the same specimens used for the chloride diffusion test. The evolution of the self-healing of all evaluated samples is shown in

Figure 8.

Analyzing the results presented in

Figure 8, an increase in the self-healing rate of cracks could be seen for most of the studied concretes in the different wetting/drying cycles applied.

One reason for this increase in the rates of self-healing of cracks was the methodology for quantifying the thicknesses per pixel, using the ImageJ software. As explained in

Section 2.2.1 and

Section 2.2.2, the specimens were cut to obtain samples with dimensions of 95 mm in diameter and 30 mm in thickness, and then the cracks were created. As can be seen in

Figure 8, at 3 days, all samples showed a lower rate of self-healing, being higher after the wetting/drying cycles. It was found that, at 3 days, the crack edge region contained the presence of concrete cutoff remains, which resulted in the initial quantification being superficially lower in the first days.

Over time and with the application of the wetting/drying cycles, these remnants were removed, and an increase in the rate of self-healing was observed, leading to an increase in the crack region. In this way, to be perceived, the self-healing of a crack would need to be superior to the loose fines generated when cutting the specimens. However, this would not be perceived using optical microscopy if the samples were not cut and were molded directly into the dimensions required for testing [

24].

With crystalline admixtures, more significant self-healing was expected in most samples, including for greater crack thicknesses. However, a factor considered influential in this low formation of healing products was the lack of moisture, since the concretes were exposed to predominantly dry conditions, where each cycle was formed by only 2 days of wetting and 14 days of drying [

7,

12,

43]. On the other hand, wetting and drying cycles can effectively promote the self-healing of cracks when the sample immersion period is greater than or equal to the applied drying period [

12,

25,

44].

Given the above, it can be seen that, superficially, the self-healing of cracks was not observed. This result is related to the cracking methodology applied, which was not efficient in this work, as well as to the short wetting period that the concretes with crystalline admixtures were exposed to in the wetting/drying cycles.

As already mentioned, superficially, it was impossible to observe any point of self-healing of the cracks in all evaluated concretes. However, through optical microscopy, this behavior could not be confirmed for their internal region. The results showing the internal behavior of self-healing of cracks are presented below.

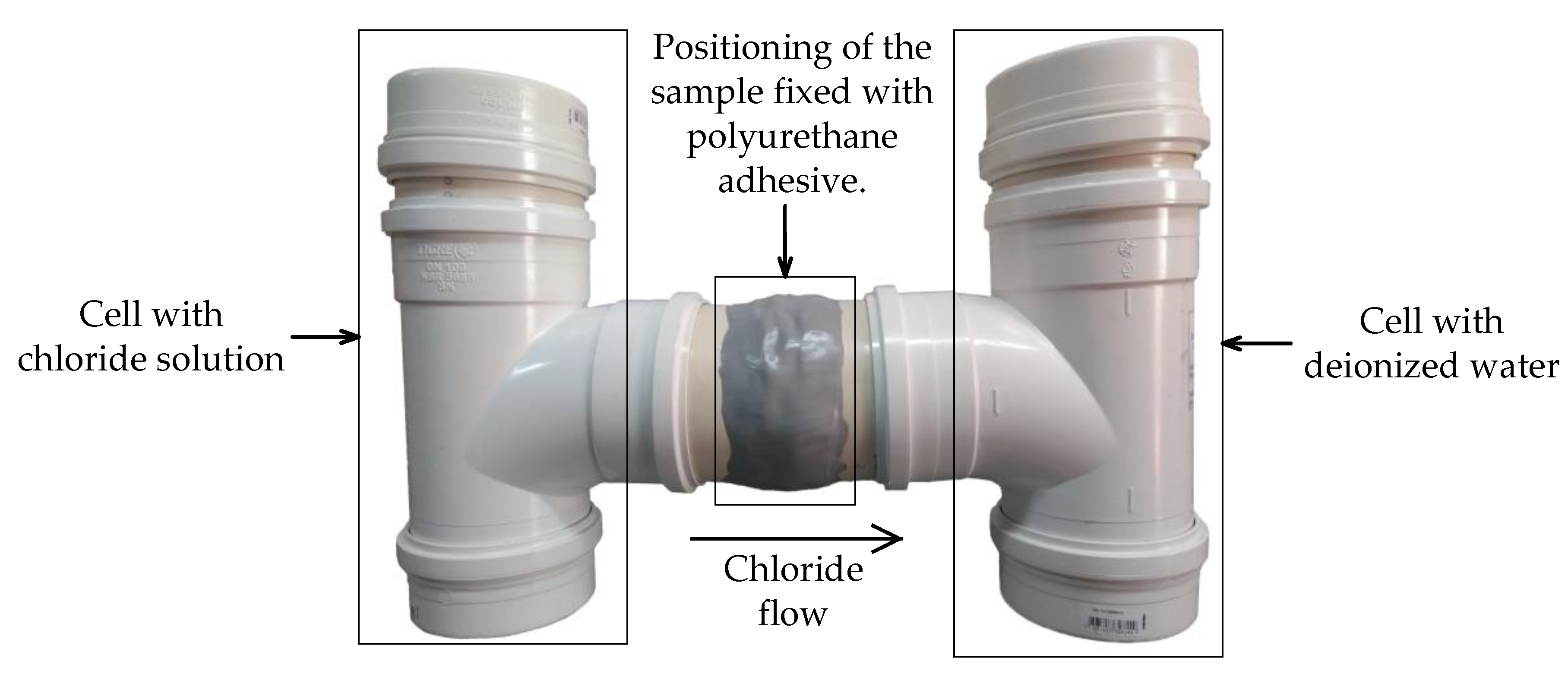

3.4. Chloride Diffusion

The chloride diffusion test was used to check the internal self-healing of cracks. This test started after two and six cycles of wetting and drying, with three cracked samples of each concrete, i.e., the same samples being used in optical microscopy.

Figure 9 presents the results obtained for the diffusion of chlorides from the samples submitted to the two wetting and drying cycles (28 days).

It can be observed that, among the crystalline admixtures, X and Z presented the lowest chloride passage over time. The crystalline admixture Y had the worst result during the test, with a more significant passage of chlorides over time, showing itself to be inferior even to the performance of the reference concrete. This result presented by the crystalline admixture Y may be related to its greater granulometry, thereby delaying the hydration reactions of this material before the start of the diffusion test [

45].

Concretes with crystalline admixtures X and Z showed a reduction of 35.55% and 58.53%, respectively, in relation to the reference, while the crystalline admixture Y showed an increase in this passage over time by 52.44%. In this sense, Borg et al. [

46] evaluated the self-healing of cracks in concretes with crystalline admixtures as facilitating agents for self-healing when exposed to chloride-rich environments. The authors found that a high hydrophilic reactivity of crystalline admixtures led to the best performance for most of the investigated exposure conditions, even for the sealing of cracks up to 0.3 mm thick.

Figure 10 shows the specimen results at the start of the chloride diffusion test after six wetting and drying cycles (84 days).

Analyzing

Figure 9 and

Figure 10, it can be seen that the cracked samples with crystalline admixtures did not wholly prevent the passage of chlorides through the cracks in the concretes but reduced this passage compared to the reference. In this case, the wetting/drying cycles were not wholly effective in activating and accelerating the crystalline admixture reactions causing the complete self-healing of the cracks before the specimens were subjected to the chloride diffusion test. These results can be related to the predominantly dry cycles applied to the concrete samples (12 days of drying) and to the short wetting period (2 days). It can be noted that, among crystalline admixtures, the most significant reduction in the passage of chlorides through the crack was provided by crystalline admixture Y (66.02%), showing that this additive requires a longer time for hydration reactions due to its greater granulometry.

However, as can be seen, all crystalline admixtures provided a reduction in the passage of chlorides. That is, they acted in reducing the internal thickness of the crack. In this sense, Huang [

6] found that the filling of cracks with hydration products was 28% after curing in water for 200 h. This demonstrates that the self-healing of cracks can significantly reduce the entry of aggressive agents through cracks and, thus, prolong the life of concrete structures, even if the cracks are not completely filled with hydration products.

Jacobsen, Marchand, and Boisvert [

47] verified the self-healing of cracks in concrete samples after 3 months of immersion in water, observing a reduction in the chloride migration rate. The reduction was 28% to 35% compared to the migration of freshly cracked samples. This effect agrees with the findings of Şahmaran [

48], who observed a reduced chloride diffusion coefficient and a slower penetration rate due to the effects of self-healing of cracks.

As previously mentioned, the wetting and drying cycles were not fully effective in causing the cracks to close, mainly due to the short wetting period that the specimens were exposed to. However, after these cycles, the direct contact of concretes containing crystalline admixtures with the water during the diffusion test may have positively influenced the reduction of the passage of chloride ions from the continuous hydration reaction of the crystalline admixtures with the water of the test. This is in line with the results observed by Borg et al. [

46], who verified that the ability to seal cracks in concrete continued to occur for samples submerged in water with chlorides. The authors also pointed out that this self-healing may prove to be more efficient than in water without chlorides.

The crack internal morphology is another factor that may have contributed to the greater or lesser passage of chlorides. The cracked specimens used in this work were selected by image analysis; thus, only the crack’s external surface and not its internal configuration was known. According to Roig-Flores et al. [

7], a crack’s internal morphology may be responsible for the greater efficiency of self-healing when initiating this phenomenon in internal areas that present lesser thickness of the cracks, even in cases where greater thicknesses are verified on the surface of the samples.

From the chloride diffusion test and Equation (3) describing Fick’s second law, it was possible to calculate the chloride diffusion coefficient for each studied concrete, a parameter that characterizes the concrete’s resistance to the passage of chlorides. Thus, through

Figure 11, it is possible to identify the average results of the chloride diffusion coefficients.

Analyzing

Figure 11, it can be seen that, for specimens submitted to two wetting/drying cycles, the diffusion coefficients of concretes with crystalline admixtures X and Z showed a reduction of 42.82% and 63.29%, respectively, with respect to the reference concrete. As previously discussed, concretes with the crystalline admixture Y showed lower resistance to chloride passage during the diffusion test and, thus, obtained a diffusion coefficient of 35.08% higher than the reference. For the six wetting/drying cycles, the three crystalline admixtures with a percentage reduction in relation to the reference stand out, denoting a greater resistance to the entry of chlorides.

Azarsa, Gupta, and Biparva [

4] investigated, through different methodologies, the effectiveness of crystalline admixtures in promoting improvements in the self-healing in concretes, in addition to improvements in chloride penetration and water permeability. Regarding the penetration of chlorides, the results indicated that the concrete samples treated with the crystalline admixtures had a lower diffusion coefficient at the two curing ages (28 and 56 days) compared to the control mixture, suggesting the formation of crystalline structures inside the concrete acting as a physical barrier to the passage of chlorides.

Analysis of variance (ANOVA) was performed with the software Statistica 13. The results of the diffusion coefficients are shown in

Table 9.

The predicted useful life of concrete structures corresponds to the period that chlorides take to pass through the concrete covering layer until they reach to and dissipate in the reinforcement, which can start corrosion. Therefore, the prediction of useful life is totally influenced by the diffusion coefficient. A higher diffusion coefficient suggests a lower resistance of the concrete to the passage of chlorides and, consequently, a lower calculated useful life.

Thus, through the diffusion coefficients found for the concretes, the useful life was forecast using Equation (3), with the results shown in

Figure 12 for concretes subjected to two wetting and drying cycles.

Considering the 4 cm coverage recommended by the NBR 6118 [

49], the reference concrete presented a useful life forecast of 19.6 years until the chlorides would reach the reinforcement. The concrete with crystalline admixture X had a useful life forecast of 28 years, representing an increase of 42.80% with respect to the reference. Among the crystalline admixtures, the worst performance can be noted for Y, with a 13 year life expectancy, showing a 35% reduction in relation to the reference, while crystalline admixture Z showed greater efficiency, with a predicted lifetime of 32 years (an increase of 63.30%). The predicted useful life of concretes subjected to six wetting/drying cycles is shown in

Figure 13.

It can be noted that the reference concrete had a useful life forecast of 17.6 years. A better result was noted for concrete with crystalline admixture X (37 years), while concretes with crystalline admixtures Y and Z showed similar performance (approximately 28 years), with a gain of 57% in the time before reaching the reinforcement.

Thus, it can be observed that the use of crystalline admixtures provided a reduction in the passage of chlorides through the concretes during the diffusion test and, consequently, to an extension of the time until these aggressive agents would reach the reinforcement, thereby causing the corrosion to start. It is worth mentioning that the results presented refer to cracked concretes, which allow a more accelerated movement of chlorides through the interior of the cementitious matrix and, as a result, less time for depassivation of the reinforcement.