Effect of WEDM Process Parameters on Surface Morphology of Nitinol Shape Memory Alloy

Abstract

1. Introduction

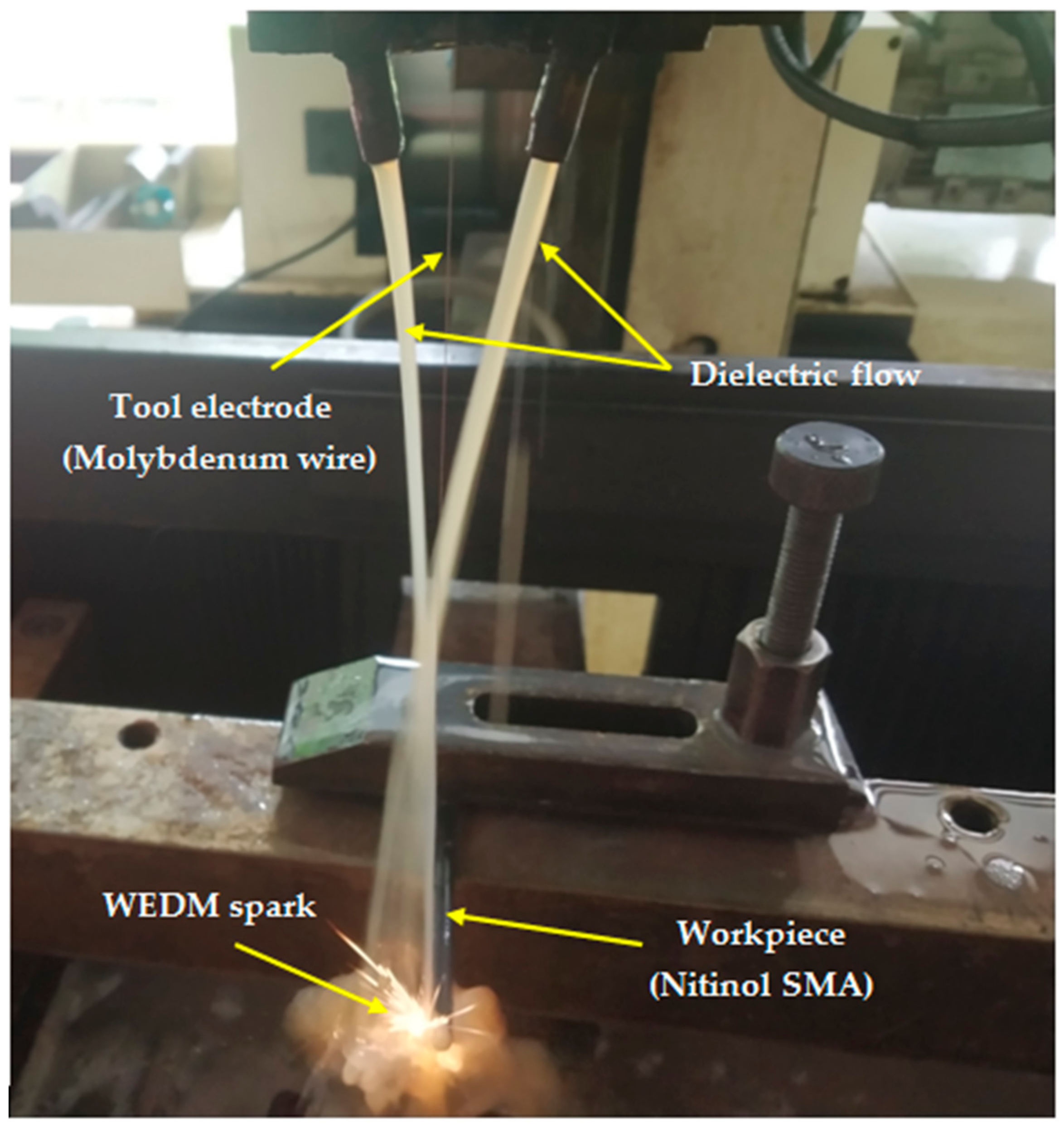

2. Materials and Methods

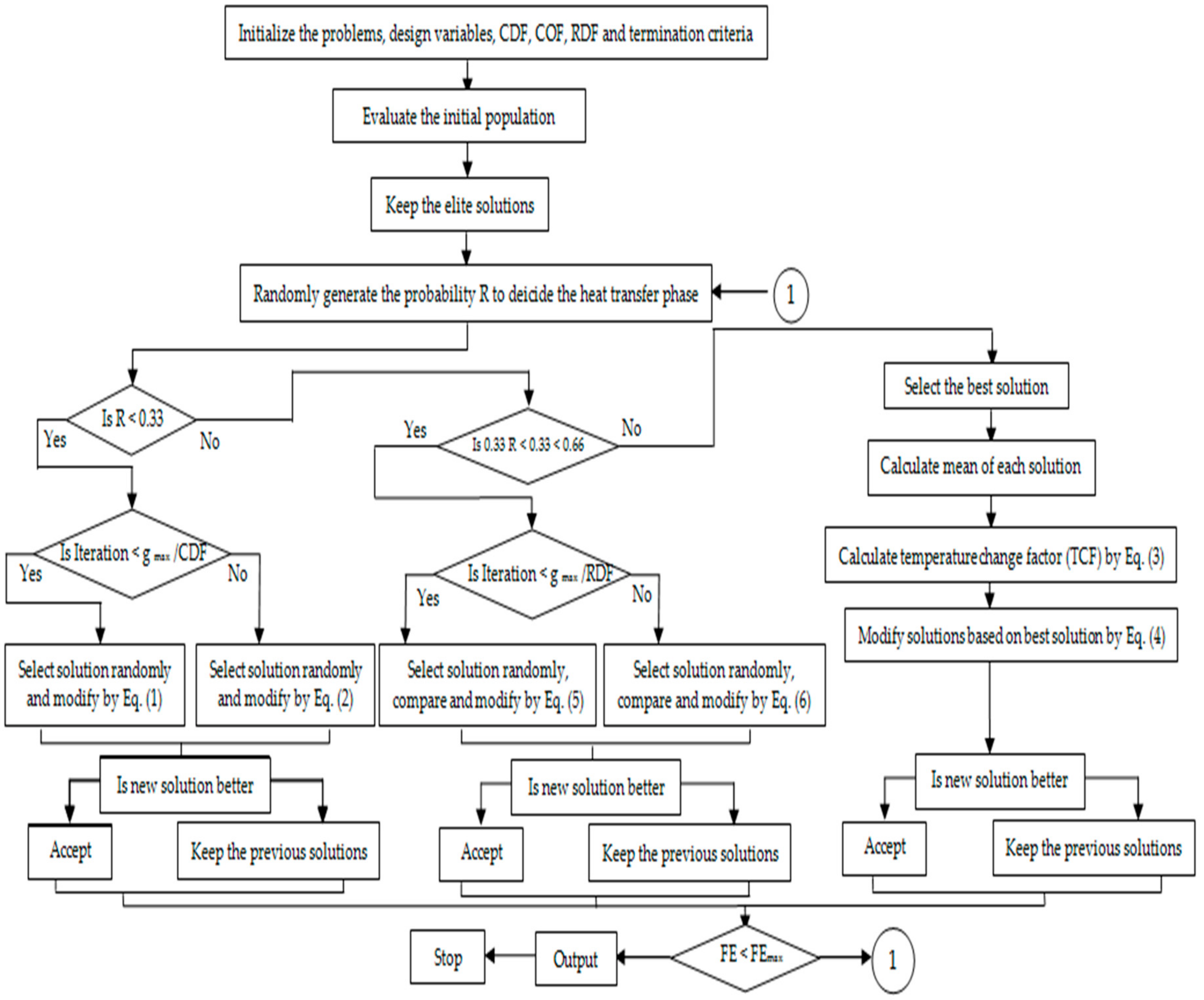

2.1. Conduction Phase

2.2. Convection Phase

2.3. Radiation Phase

- Pulse on time: 35 µs ≤ Ton ≤ 55 µs;

- Pulse off time: 10 µs ≤ Toff ≤ 20 µs;

- Current: 2 A ≤ I ≤ 4 A.

- Pulse on time: 1 µs ≤ Ton ≤ 110 µs;

- Pulse off time: 1 µs ≤ Toff ≤ 32 µs;

- Current: 1 A ≤ I ≤ 6 A.

3. Results and Discussion

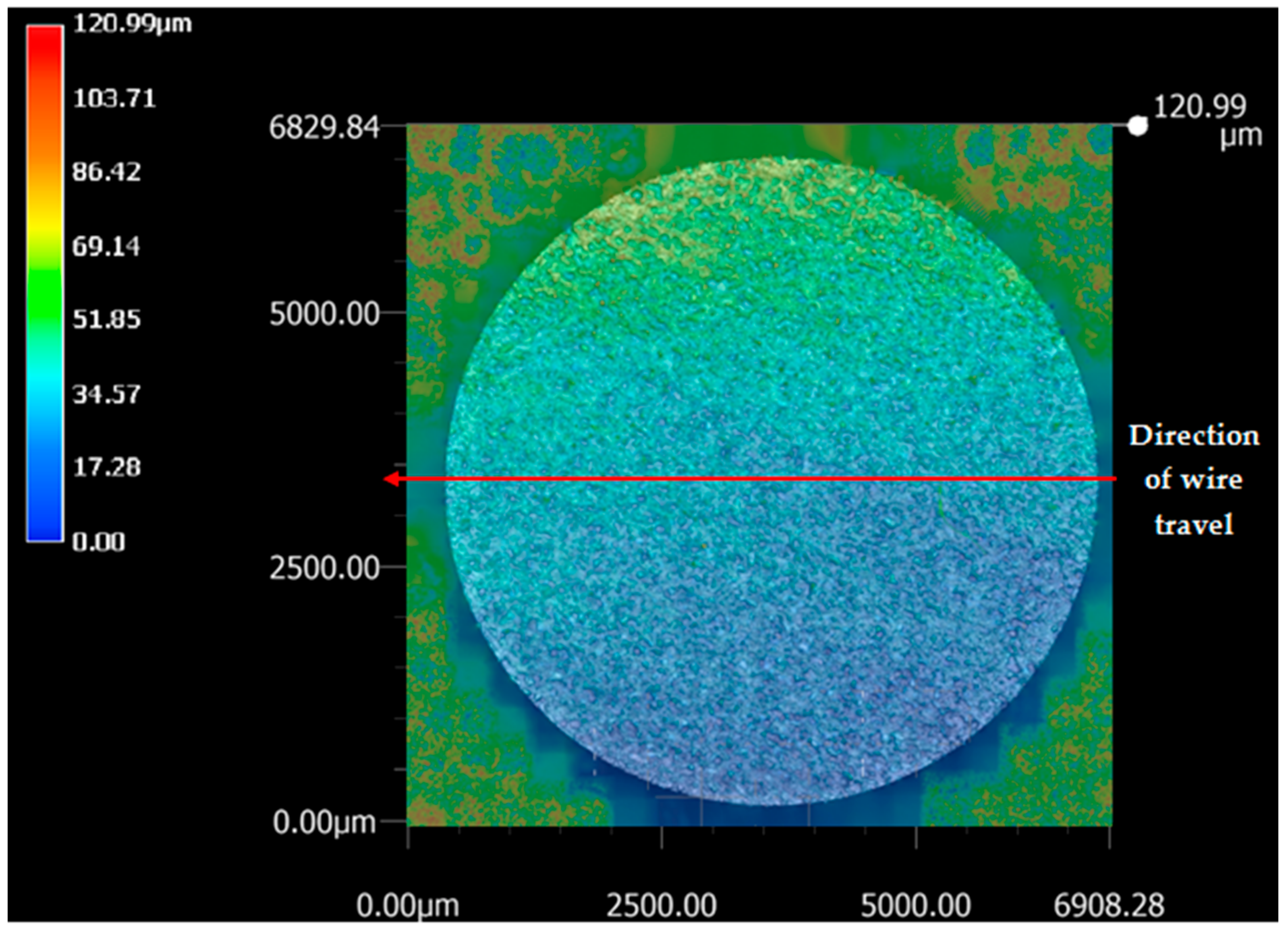

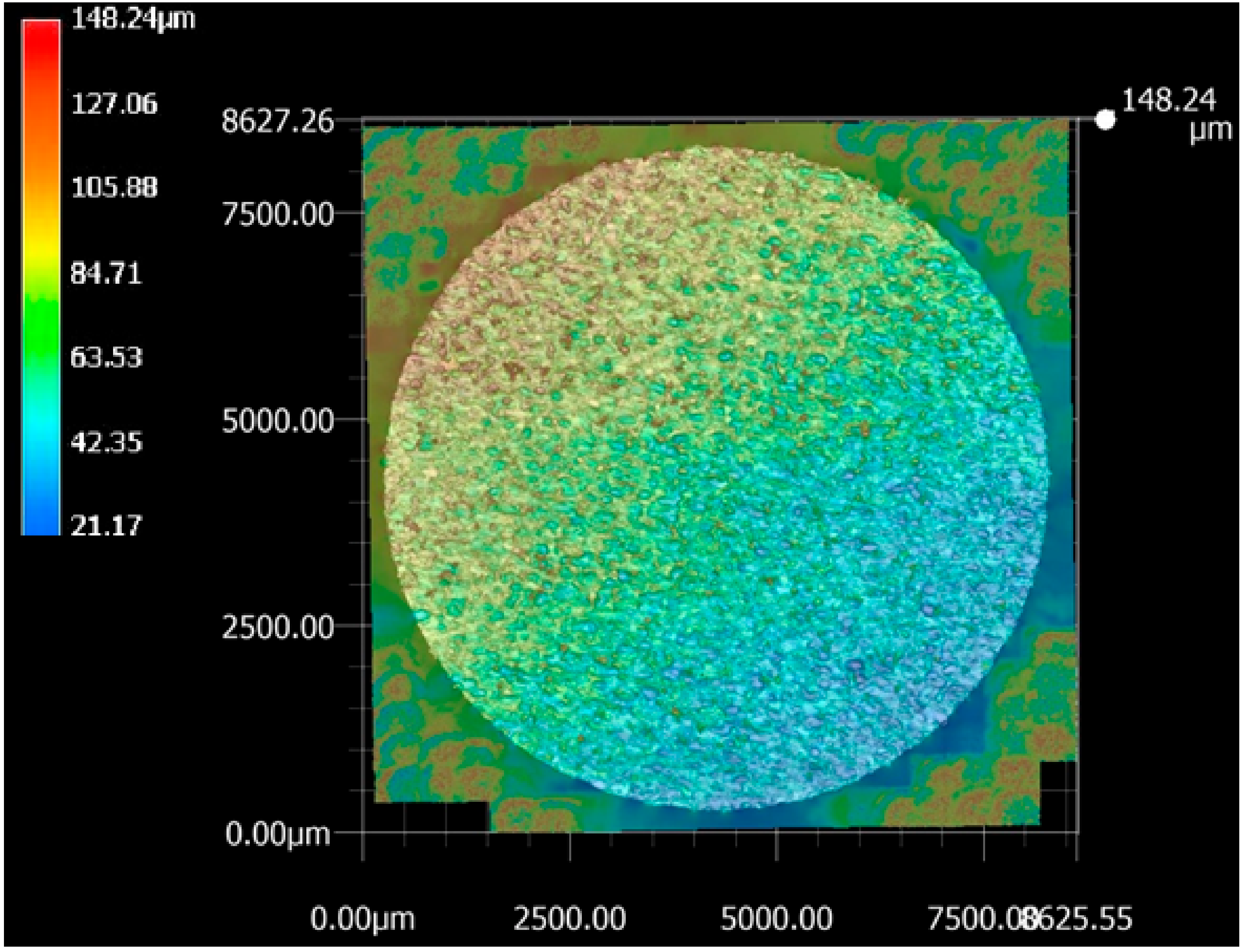

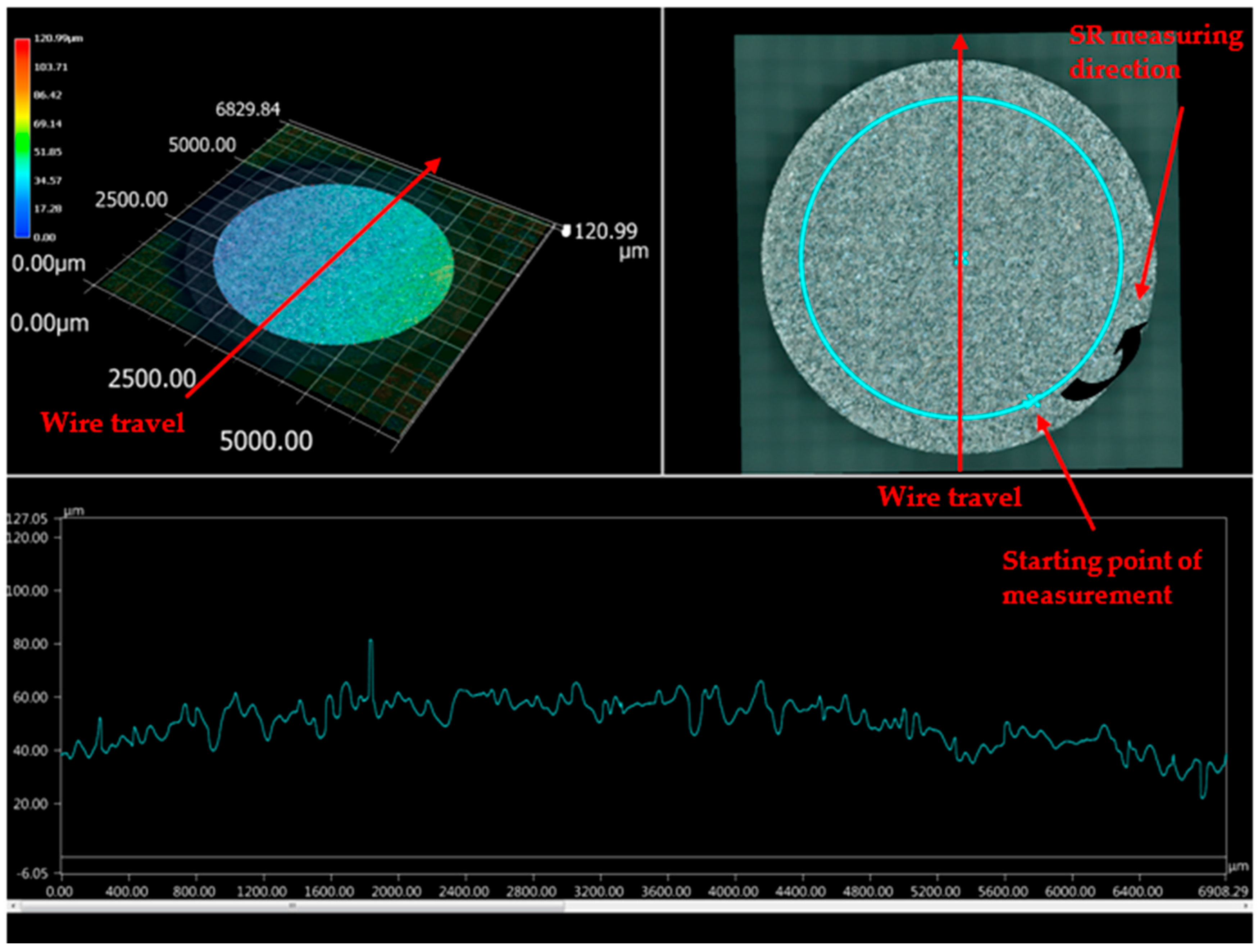

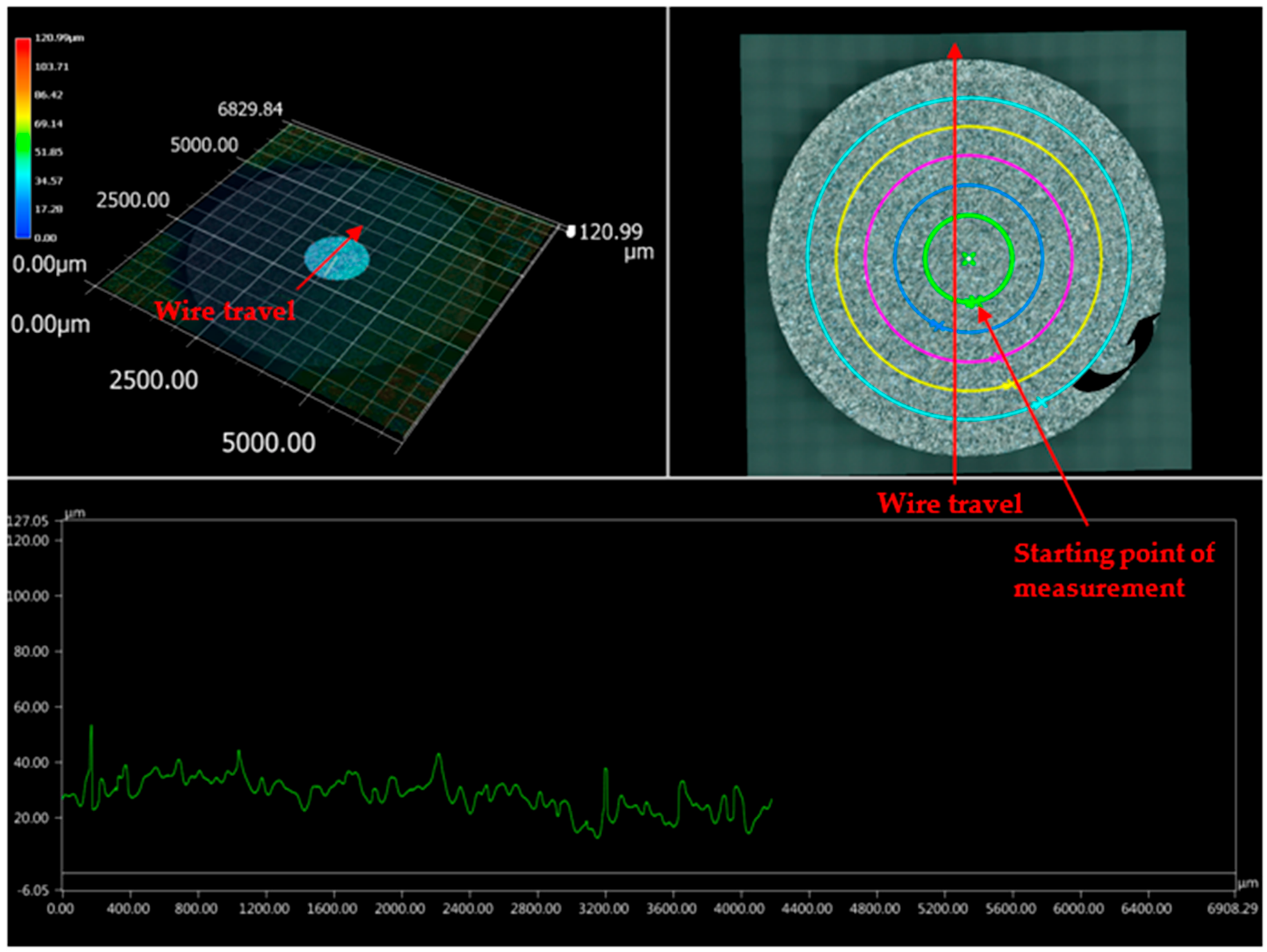

3.1. Analysis of SR Using 3D Digital Microscope

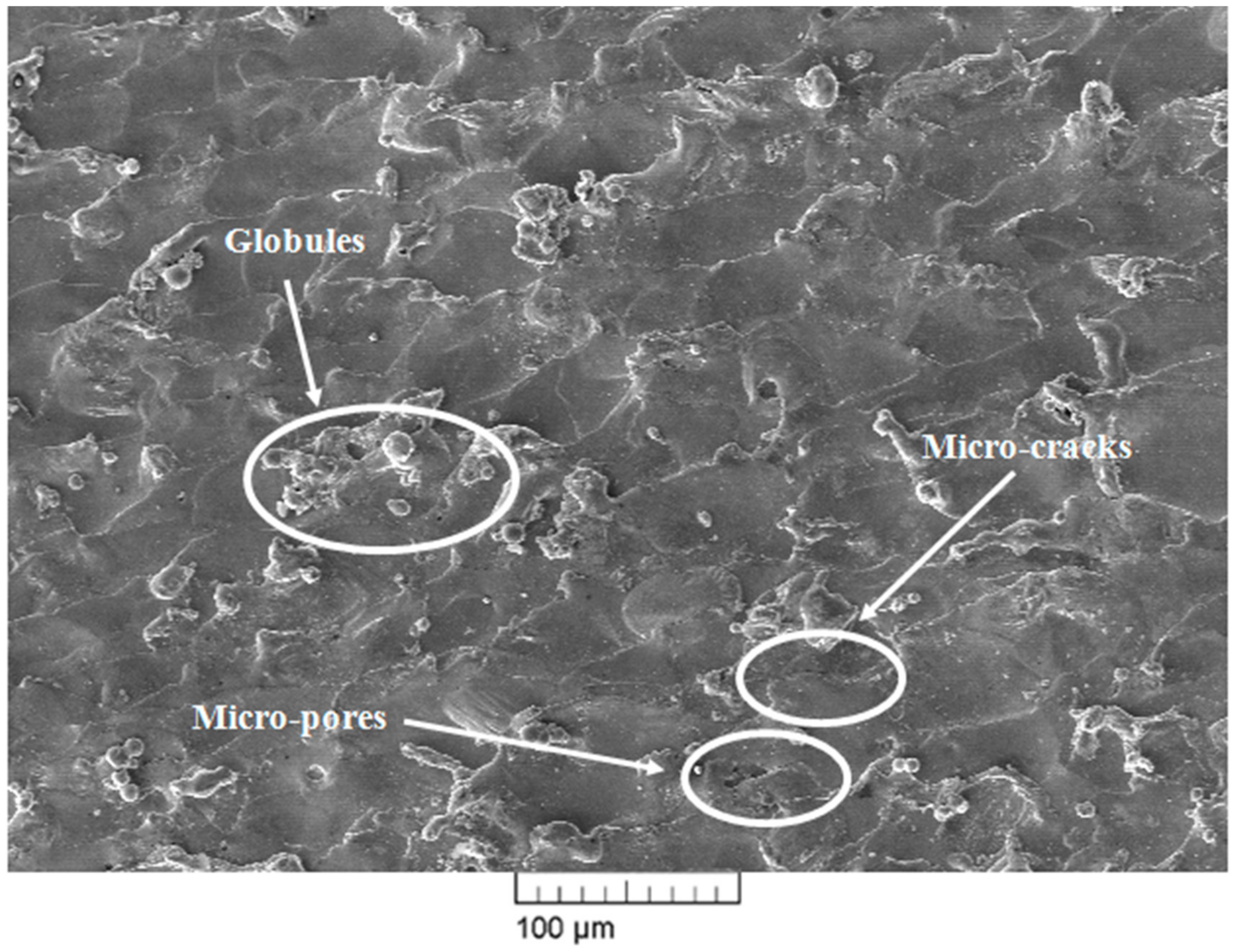

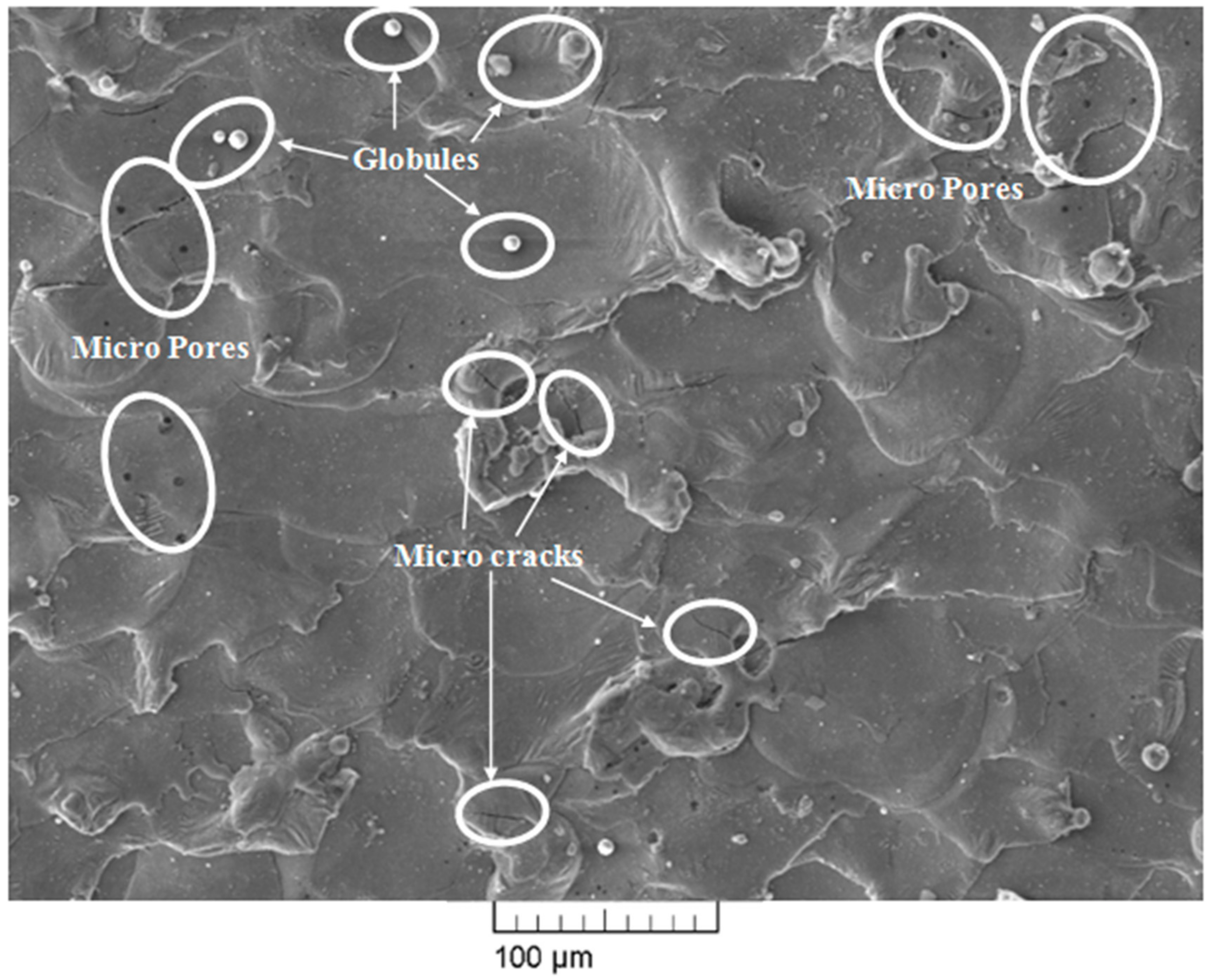

3.2. Analysis of Surface Defects

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Ölander, A. An electrochemical investigation of solid cadmium-gold alloys. J. Am. Chem. Soc. 1932, 54, 3819–3833. [Google Scholar] [CrossRef]

- Khanna, S.; Utsav; Patel, R.; Marathey, P.; Chaudari, R.; Vora, J.; Banerjee, R.; Ray, A.; Mukhopadhyay, I. Growth of titanium dioxide nanorod over shape memory material using chemical vapor deposition for energy conversion application. Mater. Today Proc. 2020, 28, 475–479. [Google Scholar] [CrossRef]

- Safranski, D.; Dupont, K.; Gall, K. Pseudoelastic NiTiNOL in Orthopaedic Applications. Shape Mem. Superelasticity 2020, 6, 332–341. [Google Scholar] [CrossRef]

- Yoneyama, T.; Miyazaki, S. Shape Memory Alloys for Biomedical Applications; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Hamann, I.; Hempel, U.; Rotsch, C.; Leimert, M. Biological Cell Investigation of Structured Nitinol Surfaces for the Functionalization of Implants. Materials 2020, 13, 3264. [Google Scholar] [CrossRef]

- Kulkarni, V.N.; Gaitonde, V.; Karnik, S.; Manjaiah, M.; Davim, J.P. Machinability Analysis and Optimization in Wire EDM of Medical Grade NiTiNOL Memory Alloy. Materials 2020, 13, 2184. [Google Scholar] [CrossRef]

- Rathi, P.; Ghiya, R.; Shah, H.; Srivastava, P.; Patel, S.; Chaudhari, R.; Vora, J. Multi-response Optimization of Ni55.8Ti Shape Memory Alloy Using Taguchi–Grey Relational Analysis Approach. In Innovations in Smart Cities Applications Edition 2; Springer: Berlin/Heidelberg, Germany, 2020; pp. 13–23. [Google Scholar]

- Lagoudas, D.; Rediniotis, O.K.; Khan, M.M.; Dassios, G.; I Fotiadis, D.; Massalas, C.V.; Kiriaki, K. Applications of shape memory alloys to bioengineering and biomedical technology. In Scattering Theory and Biomedical Engineering Modelling and Applications; World Scientific: Singapore, 2000; pp. 195–207. [Google Scholar]

- Chaudhari, R.; Vora, J.J.; Prabu, S.S.M.; Palani, I.A.; Patel, V.K.; Parikh, D.M.; De Lacalle, L.N.L. Multi-Response Optimization of WEDM Process Parameters for Machining of Superelastic Nitinol Shape-Memory Alloy Using a Heat-Transfer Search Algorithm. Materials 2019, 12, 1277. [Google Scholar] [CrossRef]

- Sheth, M.; Gajjar, K.; Jain, A.; Shah, V.; Patel, H.; Chaudhari, R.; Vora, J. Multi-objective Optimization of Inconel 718 Using Combined Approach of Taguchi—Grey Relational Analysis. In Advances in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 229–235. [Google Scholar]

- Chaudhari, R.; Vora, J.J.; Pramanik, A.; Parikh, D. Optimization of Parameters of Spark Erosion Based Processes. In Spark Erosion Machining; CRC Press: Boca Raton, FL, USA, 2020; pp. 190–216. [Google Scholar]

- Chaudhari, R.; Vora, J.; Parikh, D.M.; Wankhede, V.; Khanna, S. Multi-response Optimization of WEDM Parameters Using an Integrated Approach of RSM–GRA Analysis for Pure Titanium. J. Inst. Eng. (India) Ser. D 2020, 101, 117–126. [Google Scholar] [CrossRef]

- Lalwani, V.; Sharma, P.; Pruncu, C.I.; Unune, D.R. Response Surface Methodology and Artificial Neural Network-Based Models for Predicting Performance of Wire Electrical Discharge Machining of Inconel 718 Alloy. J. Manuf. Mater. Process. 2020, 4, 44. [Google Scholar]

- Theisen, W.; Schuermann, A. Electro discharge machining of nickel-titanium shape memory alloys. Mater. Sci. Eng. A 2004, 378, 200–204. [Google Scholar] [CrossRef]

- Majumder, H.; Maity, K. Application of GRNN and multivariate hybrid approach to predict and optimize WEDM responses for Ni-Ti shape memory alloy. Appl. Soft Comput. 2018, 70, 665–679. [Google Scholar] [CrossRef]

- Soni, H.; Sannayellappa, N.; Rangarasaiah, R.M. An experimental study of influence of wire electro discharge machining parameters on surface integrity of TiNiCo shape memory alloy. J. Mater. Res. 2017, 32, 3100–3108. [Google Scholar] [CrossRef]

- Tosun, N. The effect of the cutting parameters on performance of WEDM. KSME Int. J. 2003, 17, 816–824. [Google Scholar] [CrossRef]

- Sánchez, J.A.; Ortega, N.; De Lacalle, L.N.L.; Lamikiz, A.; Marañon, J.A.; De Lacalle, L.N.L.; Lamikiz, A. Analysis of the electro discharge dressing (EDD) process of large-grit size cBN grinding wheels. Int. J. Adv. Manuf. Technol. 2005, 29, 688–694. [Google Scholar] [CrossRef]

- Reolon, L.W.; Laurindo, C.A.H.; Torres, R.D.; Amorim, F.L. WEDM performance and surface integrity of Inconel alloy IN718 with coated and uncoated wires. Int. J. Adv. Manuf. Technol. 2018, 100, 1981–1991. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Prabu, S.S.M.; Palani, I.A.; Patel, V.K.; Parikh, D.M. Pareto optimization of WEDM process parameters for machining a NiTi shape memory alloy using a combined approach of RSM and heat transfer search algorithm. Adv. Manuf. 2019, 40, 1–17. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Patel, V.; De Lacalle, L.N.L.; Parikh, D.M. Surface Analysis of Wire-Electrical-Discharge-Machining-Processed Shape-Memory Alloys. Materials 2020, 13, 530. [Google Scholar]

- Tosun, N.; Pihtili, H. The Effect of Cutting Parameters on Wire Crater Sizes in Wire EDM. Int. J. Adv. Manuf. Technol. 2003, 21, 857–865. [Google Scholar] [CrossRef]

- Bisaria, H.; Shandilya, P. Experimental investigation on wire electric discharge machining (WEDM) of Nimonic C-263 superalloy. Mater. Manuf. Process. 2018, 34, 83–92. [Google Scholar] [CrossRef]

- Ho, K.; Newman, S.; Rahimifard, S.; Allen, R. State of the art in wire electrical discharge machining (WEDM). Int. J. Mach. Tools Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Ghanem, F.; Braham, C.; Sidhom, H. Influence of steel type on electrical discharge machined surface integrity. J. Mater. Process. Technol. 2003, 142, 163–173. [Google Scholar] [CrossRef]

- Jangra, K.K. An experimental study for multi-pass cutting operation in wire electrical discharge machining of WC-5.3% Co composite. Int. J. Adv. Manuf. Technol. 2014, 76, 971–982. [Google Scholar] [CrossRef]

- Magabe, R.; Sharma, N.; Gupta, K.; Davim, J.P. Modeling and optimization of Wire-EDM parameters for machining of Ni55.8Ti shape memory alloy using hybrid approach of Taguchi and NSGA-II. Int. J. Adv. Manuf. Technol. 2019, 102, 1703–1717. [Google Scholar] [CrossRef]

- Sharma, N.; Gupta, K.; Davim, J.P. On wire spark erosion machining induced surface integrity of Ni55.8Ti shape memory alloys. Arch. Civ. Mech. Eng. 2019, 19, 680–693. [Google Scholar] [CrossRef]

- Bisaria, H.; Shandilya, P. The machining characteristics and surface integrity of Ni-rich NiTi shape memory alloy using wire electric discharge machining. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 233, 1068–1078. [Google Scholar] [CrossRef]

- Pirani, C.; Iacono, F.; Generali, L.; Sassatelli, P.; Nucci, C.; Lusvarghi, L.; Gandolfi, M.G.; Prati, C. HyFlex EDM: Superficial features, metallurgical analysis and fatigue resistance of innovative electro discharge machined NiTi rotary instruments. Int. Endod. J. 2015, 49, 483–493. [Google Scholar] [CrossRef]

- Azam, M.; Jahanzaib, M.; Abbasi, J.A.; Abbas, M.; Wasim, A.; Hussain, S. Parametric analysis of recast layer formation in wire-cut EDM of HSLA steel. Int. J. Adv. Manuf. Technol. 2016, 87, 713–722. [Google Scholar] [CrossRef]

- Newton, T.R.; Melkote, S.N.; Watkins, T.; Trejo, R.M.; Reister, L. Investigation of the effect of process parameters on the formation and characteristics of recast layer in wire-EDM of Inconel 718. Mater. Sci. Eng. A 2009, 513, 208–215. [Google Scholar] [CrossRef]

| Element | Ti | Ni | Co | Cu | Cr | Fe | Nb | C | H | O | N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt (%) | Balance | 55.78 | 0.005 | 0.005 | 0.005 | 0.012 | 0.005 | 0.039 | 0.001 | 0.034 | 0.001 |

| Researcher | Work Material | Input Parameters at High Discharge Energy Level | Input Parameters at Low Discharge Energy Level | Input Parameters at Optimized Parameters Settings | Remarks |

|---|---|---|---|---|---|

| Chaudhari et al. [22] | Superelastic Nitinol SMA | Ton = 110 μs, Toff = 32 μs, Current = 6 A | Not reported | Ton = 65 μs, Toff = 32 μs, Current = 6 A | 3D surface analysis shows higher value of SR (1 to 148 µm) on machined surface at optimized parameter settings (Figure 4). |

| Present study | Nitinol SMA | Ton = 110 μs, Toff = 1 μs, Current = 6 A | Ton = 1 μs, Toff = 32 μs, Current = 1 A | Ton = 40 μs, Toff = 12 μs, Current = 1 A | Figure 3 of 3D surface analysis shows lower value of SR (1 to 75 µm approx.) on machined surface at optimized parameter settings. This is due to less discharge energy at optimized parameter settings. |

| Researcher | Work Material | Input Parameters at High Discharge Energy Level | Input Parameters at Low Discharge Energy Level | Input Parameters at Optimized Parameters Settings | Remarks |

|---|---|---|---|---|---|

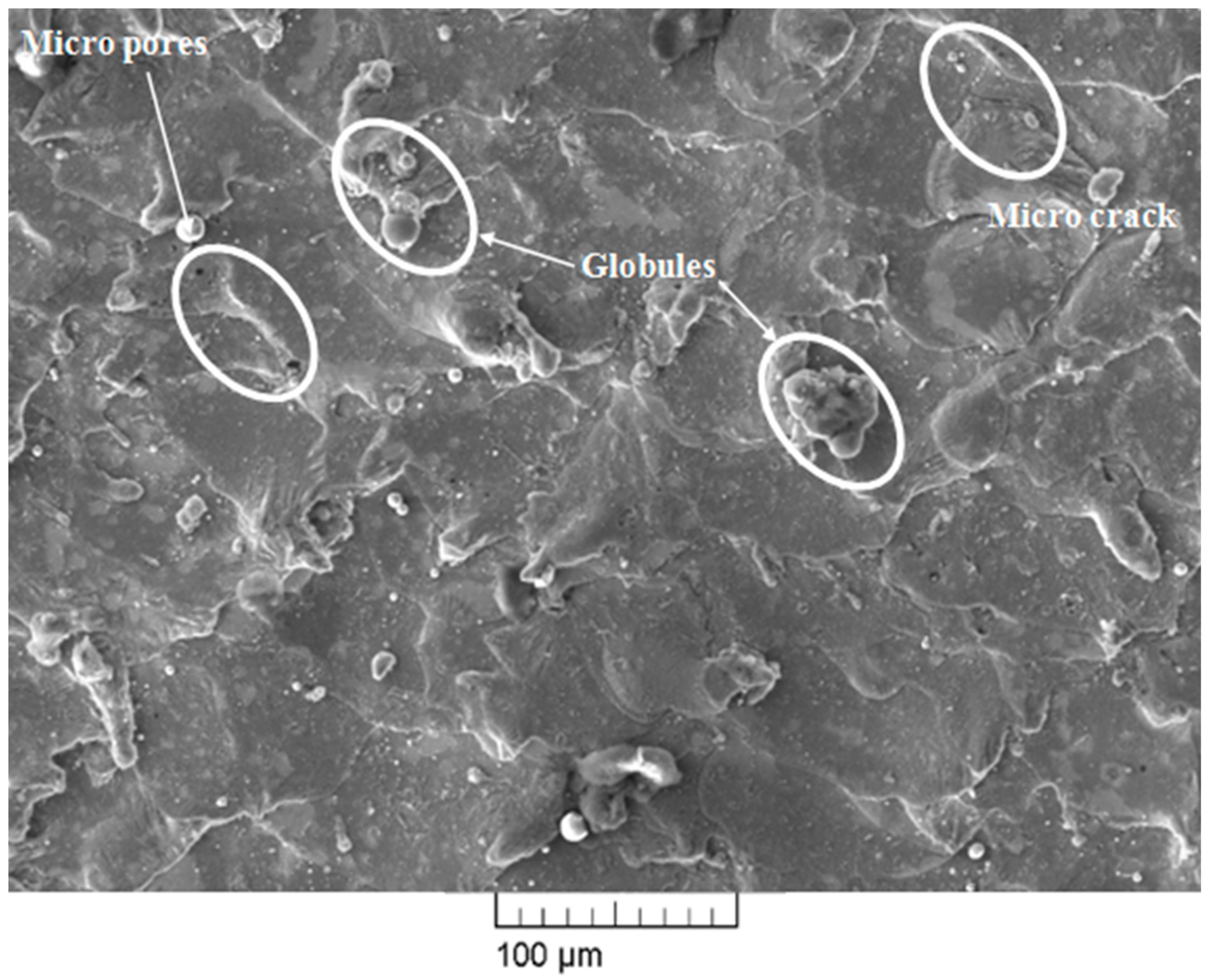

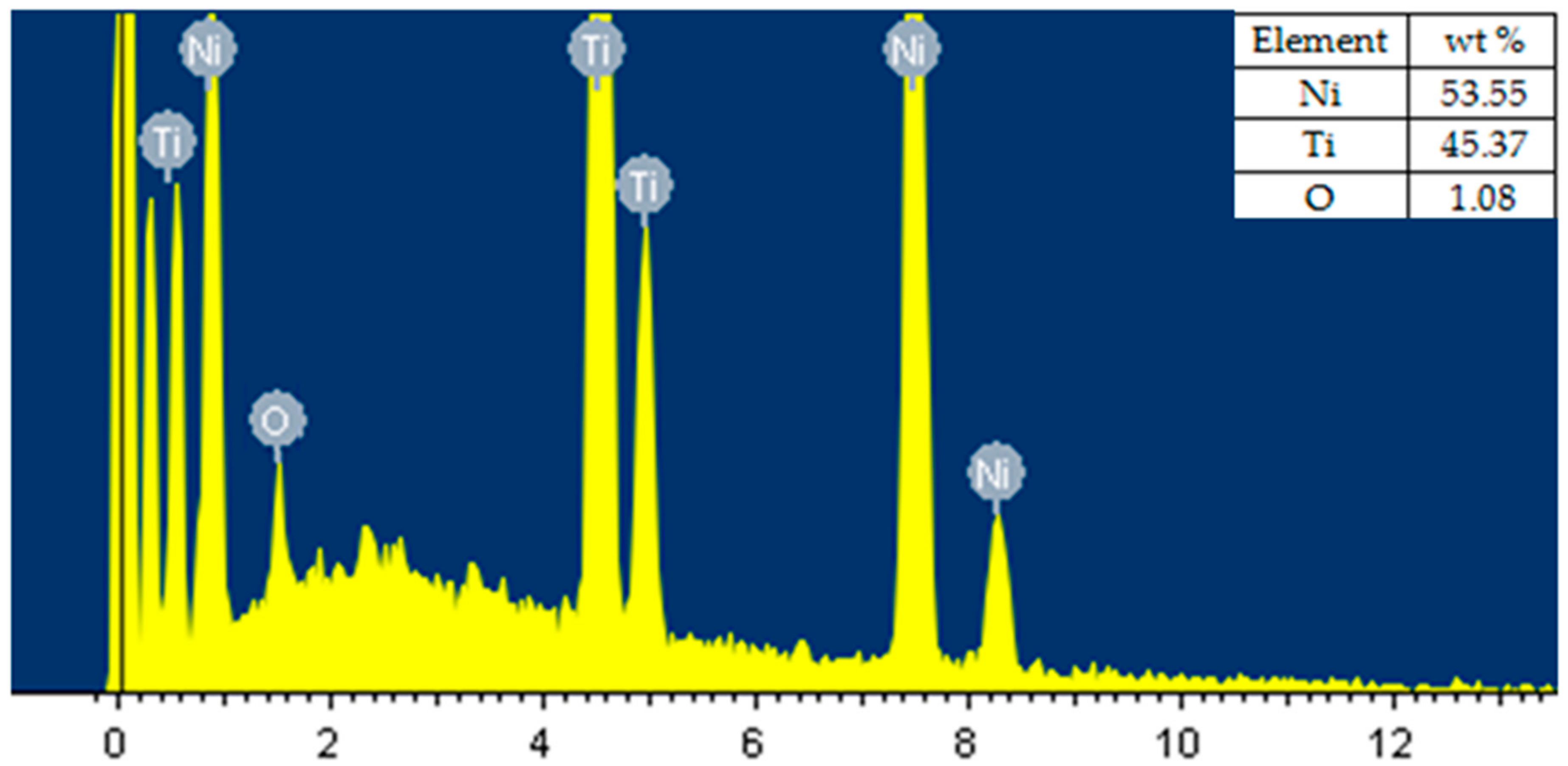

| Chaudhari et al. [22] | Superelastic Nitinol SMA | Ton = 110 μs, Toff = 32 μs, Current = 6 A | Not reported | Ton = 65 μs, Toff = 32 μs, Current = 6 A | SEM analysis showed a large number of microcracks, micropores, and globules at a high discharge energy level, and they were largely reduced at optimized parameter settings. EDX analysis showed the presence of nickel and titanium elements of the workpiece and little amount of oxygen. Work surface was observed to be without the deposition of wire material. |

| Present study | Nitinol SMA | Ton = 110 μs, Toff = 1 μs, Current = 6 A | Ton = 1 μs, Toff = 32 μs, Current = 1 A | Ton = 40 μs, Toff = 12 μs, Current = 1 A | Figure 8 of SEM analysis shows some larger cracks as compared to the past study due to a slightly higher discharge energy level due to a decrease in the value of Toff. However, reduction in other defects can be seen in Figure 9 at optimized parameter settings. Similar to past study, no wire material was found on the work surface, and the amount of oxygen was also reduced to 1.08% by wt. This is again due to less discharge energy in comparison to past results. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaudhari, R.; Vora, J.J.; Patel, V.; Lacalle, L.N.L.d.; Parikh, D.M. Effect of WEDM Process Parameters on Surface Morphology of Nitinol Shape Memory Alloy. Materials 2020, 13, 4943. https://doi.org/10.3390/ma13214943

Chaudhari R, Vora JJ, Patel V, Lacalle LNLd, Parikh DM. Effect of WEDM Process Parameters on Surface Morphology of Nitinol Shape Memory Alloy. Materials. 2020; 13(21):4943. https://doi.org/10.3390/ma13214943

Chicago/Turabian StyleChaudhari, Rakesh, Jay J. Vora, Vivek Patel, L. N. López de Lacalle, and D. M. Parikh. 2020. "Effect of WEDM Process Parameters on Surface Morphology of Nitinol Shape Memory Alloy" Materials 13, no. 21: 4943. https://doi.org/10.3390/ma13214943

APA StyleChaudhari, R., Vora, J. J., Patel, V., Lacalle, L. N. L. d., & Parikh, D. M. (2020). Effect of WEDM Process Parameters on Surface Morphology of Nitinol Shape Memory Alloy. Materials, 13(21), 4943. https://doi.org/10.3390/ma13214943