Optimizing Laser Powder Bed Fusion Parameters for IN-738LC by Response Surface Method

Abstract

1. Introduction

2. Methodology

2.1. Response Surface Method

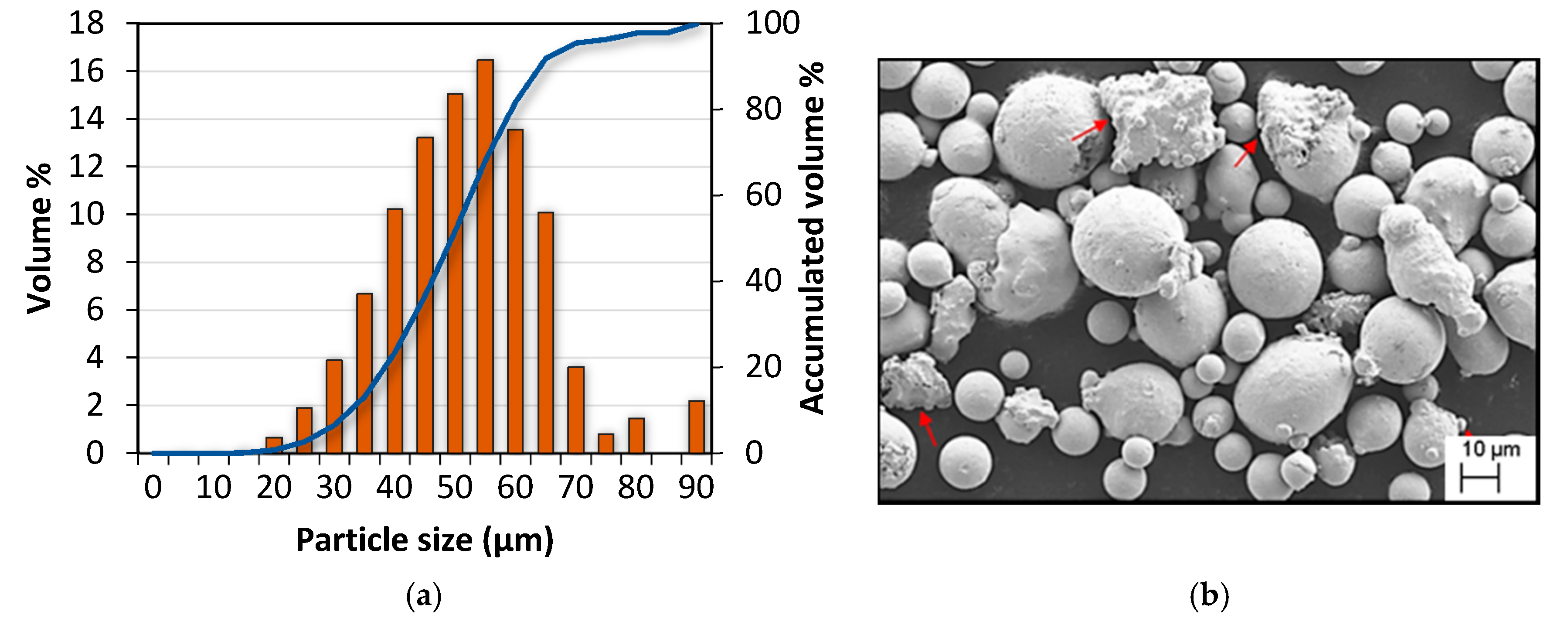

2.2. Materials

2.3. Porosity and Cracking Quantification

3. Results and Discussion

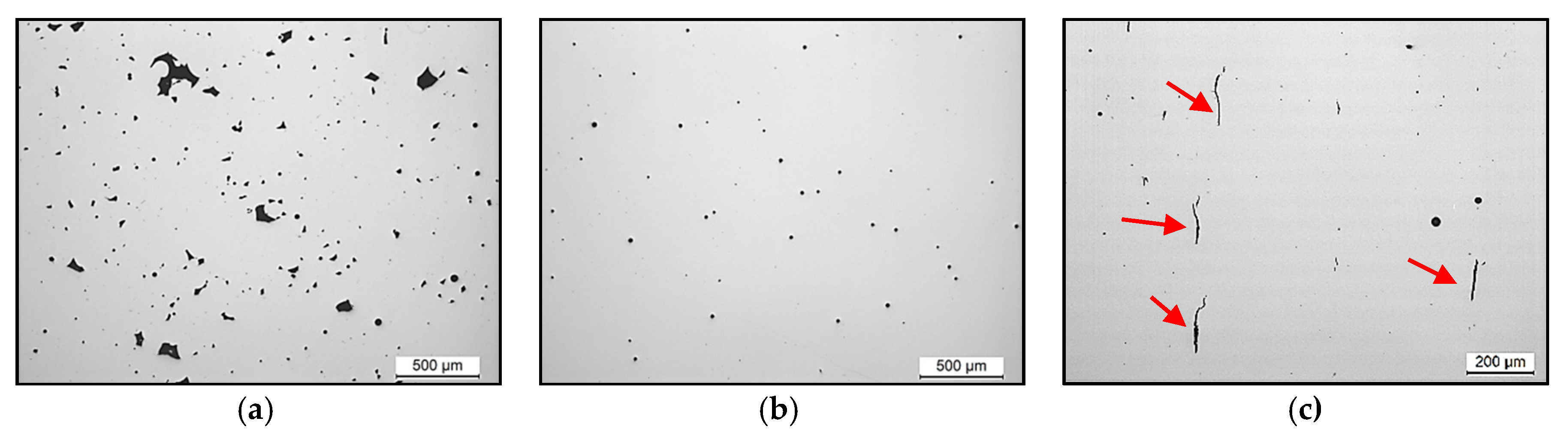

3.1. DoE and Sample Characterization

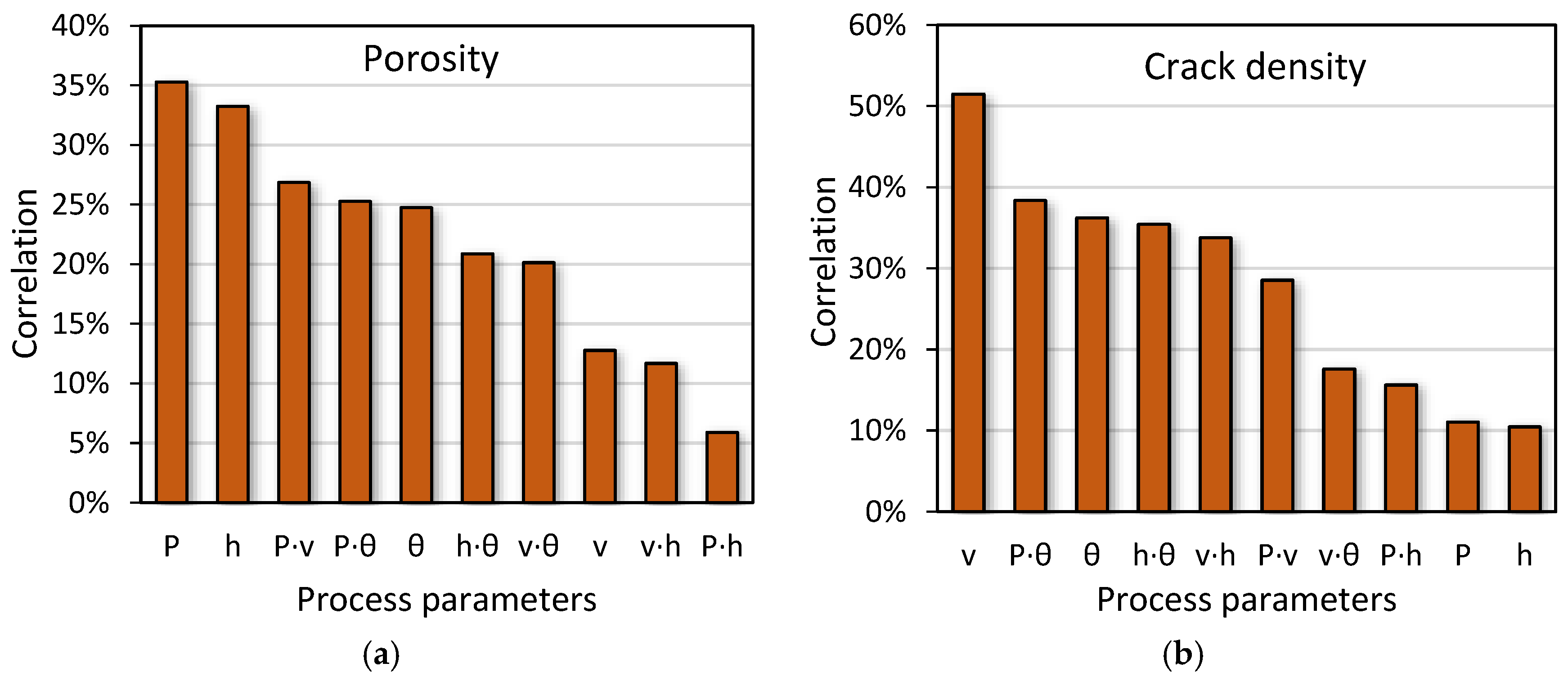

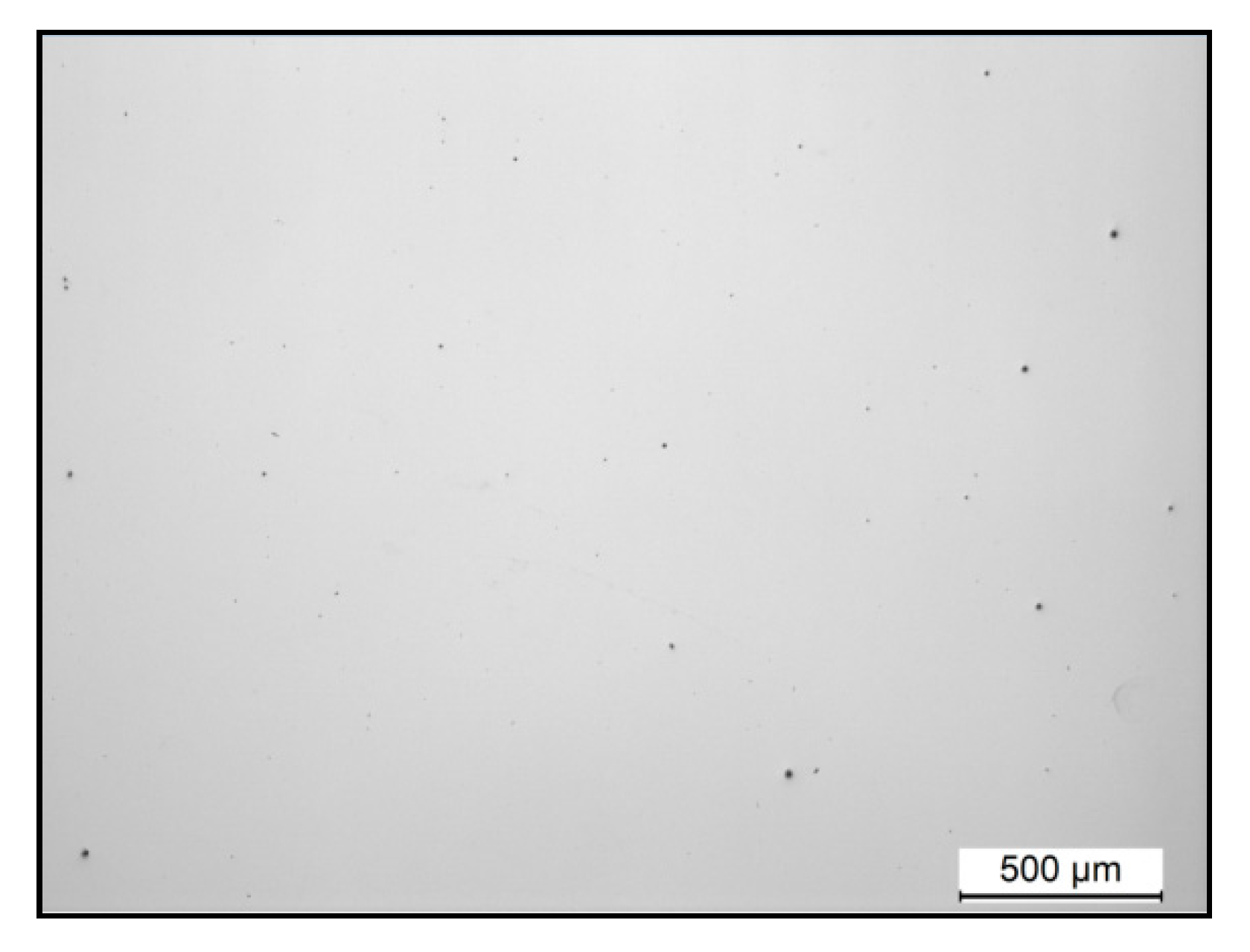

3.2. Influence of Process Parameters on Defectology

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. Laser Additive Manufacturing: Materials, Design, Technologies and Applications, 1st ed.; Elsevier Ltd.: Duxford, UK, 2016. [Google Scholar]

- Kempen, K. Expanding the Materials Palette for Selective Laser Melting of Metals; Ku Leuven: Leuven, Belgium, 2015. [Google Scholar]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Iturrioz, A.; Gil, E.; Petite, M.M.; Garciandia, F.; Mancisidor, A.M.; San Sebastian, M. Selective laser melting of AlSi10Mg alloy: Influence of heat treatment condition on mechanical properties and microstructure. Weld. World 2018, 62, 885–892. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc- and Zr- modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Ter Haar, G.M.; Becker, T.H. Selective laser melting produced Ti-6Al-4V: Post-process heat treatments to achieve superior tensile properties. Materials 2018, 11, 146. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Tong, X.; Huang, Y.; Li, J.; Ma, W.; Li, F.; Kuang, T. Microstructure and Mechanical Properties of 18Ni-300 Maraging Steel Fabricated by Selective Laser Melting. In Proceedings of the 2016 6th International Conference on Advanced Design and Manufacturing Engineering, Zhuhai, China, 23–24 July 2016; pp. 404–410. [Google Scholar] [CrossRef]

- Takaichi, A.; Suyalatu; Nakamoto, T.; Joko, N.; Nomura, N.; Tsutsumi, Y.; Migita, S.; Doi, H.; Kurosu, S.; Chiba, A.; et al. Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental applications. J. Mech. Behav. Biomed. Mater. 2013, 21, 67–76. [Google Scholar] [CrossRef]

- Uchida, S.; Kimura, T.; Nakamoto, T.; Ozaki, T.; Miki, T.; Takemura, M.; Oka, Y.; Tsubota, R. Microstructures and electrical and mechanical properties of Cu-Cr alloys fabricated by selective laser melting. Mater. Des. 2019, 175, 107815. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Tomus, D.; Rometsch, P.A.; Heilmaier, M.; Wu, X. Effect of minor alloying elements on crack-formation characteristics of Hastelloy-X manufactured by selective laser melting. Addit. Manuf. 2017, 16, 65–72. [Google Scholar] [CrossRef]

- Xu, J.; Lin, X.; Zhao, Y.; Guo, P.; Wen, X.; Li, Q.; Yang, H.; Dong, H.; Xue, L.; Huang, W. HAZ Liquation Cracking Mechanism of IN-738LC Superalloy Prepared by Laser Solid Forming. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 2018, 49, 5118–5136. [Google Scholar] [CrossRef]

- Rickenbacher, L.; Etter, T.; Hövel, S.; Wegener, K. High temperature material properties of IN738LC processed by selective laser melting (SLM) technology. Rapid Prototyp. J. 2013, 19, 282–290. [Google Scholar] [CrossRef]

- Xu, J.; Lin, X.; Guo, P.; Dong, H.; Wen, X.; Li, Q.; Xue, L.; Huang, W. The initiation and propagation mechanism of the overlapping zone cracking during laser solid forming of IN-738LC superalloy. J. Alloys Compd. 2018, 749, 859–870. [Google Scholar] [CrossRef]

- Cloots, M.; Uggowitzer, P.J.; Wegener, K. Investigations on the microstructure and crack formation of IN738LC samples processed by selective laser melting using Gaussian and doughnut profiles. Mater. Des. 2016, 89, 770–784. [Google Scholar] [CrossRef]

- Wang, N.; Mokadem, S.; Rappaz, M.; Kurz, W. Solidification cracking of superalloy single- and bi-crystals. Acta Mater. 2004, 52, 3173–3182. [Google Scholar] [CrossRef]

- DuPont, J.N.; Lippold, J.C.; Kiser, S.D. Welding Metallurgy and Weldabilidy of Nickel Based Alloys; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar] [CrossRef]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloys Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Perevoshchikova, N.; Rigaud, J.; Sha, Y.; Heilmaier, M.; Finnin, B.; Labelle, E.; Wu, X. Optimisation of selective laser melting parameters for the Ni-based superalloy IN-738 LC using Doehlert’s design. Rapid Prototyp. J. 2017, 23, 881–892. [Google Scholar] [CrossRef]

- Wang, G.; Huang, L.; Liu, Z.; Qin, Z.; He, W.; Liu, F.; Chen, C.; Nie, Y. Process optimization and mechanical properties of oxide dispersion strengthened nickel-based superalloy by selective laser melting. Mater. Des. 2020, 188, 108418. [Google Scholar] [CrossRef]

- Deng, Y.; Mao, Z.; Yang, N.; Niu, X.; Lu, X. Collaborative Optimization of Density and Surface Roughness of 316L Stainless Steel in Selective Laser Melting. Materials 2020, 13, 1601. [Google Scholar] [CrossRef] [PubMed]

- Terner, M.; Ricordel, T.; Cho, J.; Lee, J. The Response Surface Methodology for Optimizing the Process Parameters of Selective Laser Melting. Weld. World 2019, 37, 27–39. [Google Scholar] [CrossRef]

- Harrington, E.C. The Desirability Function. Ind. Qual. Control 1965, 21, 494–498. [Google Scholar]

- Escribano-García, R.; Lostado-Lorza, R.; Fernández-Martínez, R.; Villanueva-Roldán, P.; Mac Donald, B.J. Improvement in Manufacturing Welded Products through Multiple Response Surface Methodology and Data Mining Techniques. In International Joint Conference SOCO’14-CISIS’14-ICEUTE’14; Springer International Publishing: Cham, Switzerland, 2014; pp. 301–310. [Google Scholar] [CrossRef]

- Lostado-Lorza, R.; Escribano-García, R.; Martínez Calvo, M.; Múgica Vidal, R. Improvement in the Design of Welded Joints of EN 235JR Low Carbon Steel by Multiple Response Surface Methodology. Metals 2016, 6, 205. [Google Scholar] [CrossRef]

- Derringer, G.; Suich, R. Simultaneous Optimization of Several Response Variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar] [CrossRef]

- Carter, L.N.; Wang, X.; Read, N.; Khan, R.; Aristizabal, M.; Essa, K.; Attallah, M.M. Process optimisation of selective laser melting using energy density model for nickel based superalloys. Mater. Sci. Technol. 2016, 32, 657–661. [Google Scholar] [CrossRef]

- Carter, L.N.; Attallah, M.M.; Reed, R.C. Laser Powder Bed Fabrication of Nickel-Base Superalloys: Influence of Parameters; Characterisation, Quantification and Mitigation of Cracking. Superalloys 2012, 577–586. [Google Scholar] [CrossRef]

- Darvish, K.; Chen, Z.W.; Phan, M.A.L.; Pasang, T. Selective laser melting of Co-29Cr-6Mo alloy with laser power 180–360 W: Cellular growth, intercellular spacing and the related thermal condition. Mater. Charact. 2018, 135, 183–191. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Y.; Wen, W.; Ge, J.; Liang, J. Effect of hatch spacing on melt pool and as-built quality during selective laser melting of stainless steel: Modeling and experimental approaches. Materials 2018, 12, 50. [Google Scholar] [CrossRef]

- R: A Language and Environment for STATISTICAL Computing. Available online: https://www.r-project.org/ (accessed on 20 July 2020).

- Kuhn, M. Desirability: Function Optimization and Ranking via Desirability Functions. Available online: https://cran.r-project.org/web/packages/desirability/vignettes/desirability.pdf (accessed on 29 October 2020).

- Bertsekas, D.P. Nonlinear Programming, 2nd ed.; Athena Scientific: Belmont, MA, USA, 1999. [Google Scholar]

| Element | Cr | Co | W | Ti | Al | Ta | Mo | Fe | Nb |

| wt% | 15.8 | 8.6 | 2.7 | 3.3 | 3.6 | 1.8 | 1.8 | 0.04 | 0.8 |

| Element | Si | Zr | Mn | B | C | O | N | Ni | |

| wt% | 0.02 | 0.04 | 0.002 | 0.0009 | 0.1 | 0.02 | 0.006 | Bal. | |

| Factor | Symbol | Range | Unit | |

|---|---|---|---|---|

| Min | Max | |||

| Laser power | P | 180 | 280 | W |

| Laser scan speed | v | 700 | 1100 | mm/s |

| Hatch distance | h | 0.08 | 0.12 | mm |

| Scan strategy | θ | 0 | 90 | ° |

| n | Inputs | Outputs | Defect | ||||

|---|---|---|---|---|---|---|---|

| P | v | h | θ | ϕ | CD * | Type | |

| 1 | 180 | 700 | 0.08 | 0 | 0.15 | 0.00 | P |

| 2 | 280 | 700 | 0.08 | 0 | - | - | |

| 3 | 180 | 1100 | 0.08 | 0 | 0.23 | 0.00 | P |

| 4 | 280 | 1100 | 0.08 | 0 | 0.09 | 0.00 | P |

| 5 | 180 | 700 | 0.12 | 0 | 1.26 | 0.16 | LOF/P/C |

| 6 | 280 | 700 | 0.12 | 0 | 0.11 | 0.16 | P/C |

| 7 | 180 | 1100 | 0.12 | 0 | 13.74 | 0.00 | LOF |

| 8 | 280 | 1100 | 0.12 | 0 | 0.17 | 0.00 | P |

| 9 | 180 | 700 | 0.08 | 90 | 0.15 | 0.64 | P/C |

| 10 | 280 | 700 | 0.08 | 90 | 0.13 | 0.45 | P/C |

| 11 | 180 | 1100 | 0.08 | 90 | 0.21 | 0.04 | P/C |

| 12 | 280 | 1100 | 0.08 | 90 | 0.10 | 0.08 | P/C |

| 13 | 180 | 700 | 0.12 | 90 | 0.24 | 0.10 | P/C |

| 14 | 280 | 700 | 0.12 | 90 | 0.10 | 0.68 | P/C |

| 15 | 180 | 1100 | 0.12 | 90 | 12.21 | 0.33 | LOF |

| 16 | 280 | 1100 | 0.12 | 90 | 0.40 | 0.11 | P/C |

| 17 | 180 | 900 | 0.10 | 67 | 0.27 | 0.03 | P/C |

| 18 | 280 | 900 | 0.10 | 67 | 0.04 | 0.00 | P |

| 19 | 230 | 700 | 0.10 | 67 | 0.09 | 0.06 | P/C |

| 20 | 230 | 1100 | 0.10 | 67 | 0.25 | 0.01 | P/C |

| 21 | 230 | 900 | 0.08 | 67 | 0.16 | 0.00 | P |

| 22 | 230 | 900 | 0.12 | 67 | 0.20 | 0.26 | P/C |

| 23 | 230 | 900 | 0.10 | 0 | 0.11 | 0.00 | P |

| 24 | 230 | 900 | 0.10 | 90 | 0.07 | 0.09 | P/C |

| Defect Type | p-Value | MAE | RMSE |

|---|---|---|---|

| ϕ | 0.07 | 10.1% | 13.6% |

| CD | 0.02 | 3.6% | 5.5% |

| Process Parameter and Defect Type | Target | Value | Desirability |

|---|---|---|---|

| P | In range | 272.60 W | 1.00 |

| v | In range | 799.50 mm/s | 1.00 |

| h | In range | 0.11 mm | 1.00 |

| θ | In range | 1.54° | 1.00 |

| ϕ | Minimize | 0.07% | 0.94 |

| CD | Minimize | 0.00 mm/mm2 | 1.00 |

| Overall desirability: | 0.97 | ||

| Process Parameter and Defect Type | Calculated | Experimental | Difference |

|---|---|---|---|

| P (W) | 272.6 | 273.0 | 0.4 |

| v (mm/s) | 799.5 | 800.0 | 0.5 |

| h (mm) | 0.11 | 0.11 | 0.00 |

| θ (°) | 1.54 | 0.00 | −1.54 |

| ϕ (%) | 0.07 | 0.09 ± 0.01 | 0.02 |

| CD (mm−1) | 0.00 | 0.00 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilanova, M.; Escribano-García, R.; Guraya, T.; San Sebastian, M. Optimizing Laser Powder Bed Fusion Parameters for IN-738LC by Response Surface Method. Materials 2020, 13, 4879. https://doi.org/10.3390/ma13214879

Vilanova M, Escribano-García R, Guraya T, San Sebastian M. Optimizing Laser Powder Bed Fusion Parameters for IN-738LC by Response Surface Method. Materials. 2020; 13(21):4879. https://doi.org/10.3390/ma13214879

Chicago/Turabian StyleVilanova, Mireia, Rubén Escribano-García, Teresa Guraya, and Maria San Sebastian. 2020. "Optimizing Laser Powder Bed Fusion Parameters for IN-738LC by Response Surface Method" Materials 13, no. 21: 4879. https://doi.org/10.3390/ma13214879

APA StyleVilanova, M., Escribano-García, R., Guraya, T., & San Sebastian, M. (2020). Optimizing Laser Powder Bed Fusion Parameters for IN-738LC by Response Surface Method. Materials, 13(21), 4879. https://doi.org/10.3390/ma13214879