Effect of APPT Treatment on Mechanical Properties and Durability of Green Composites with Woven Flax

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. APPT Treatment

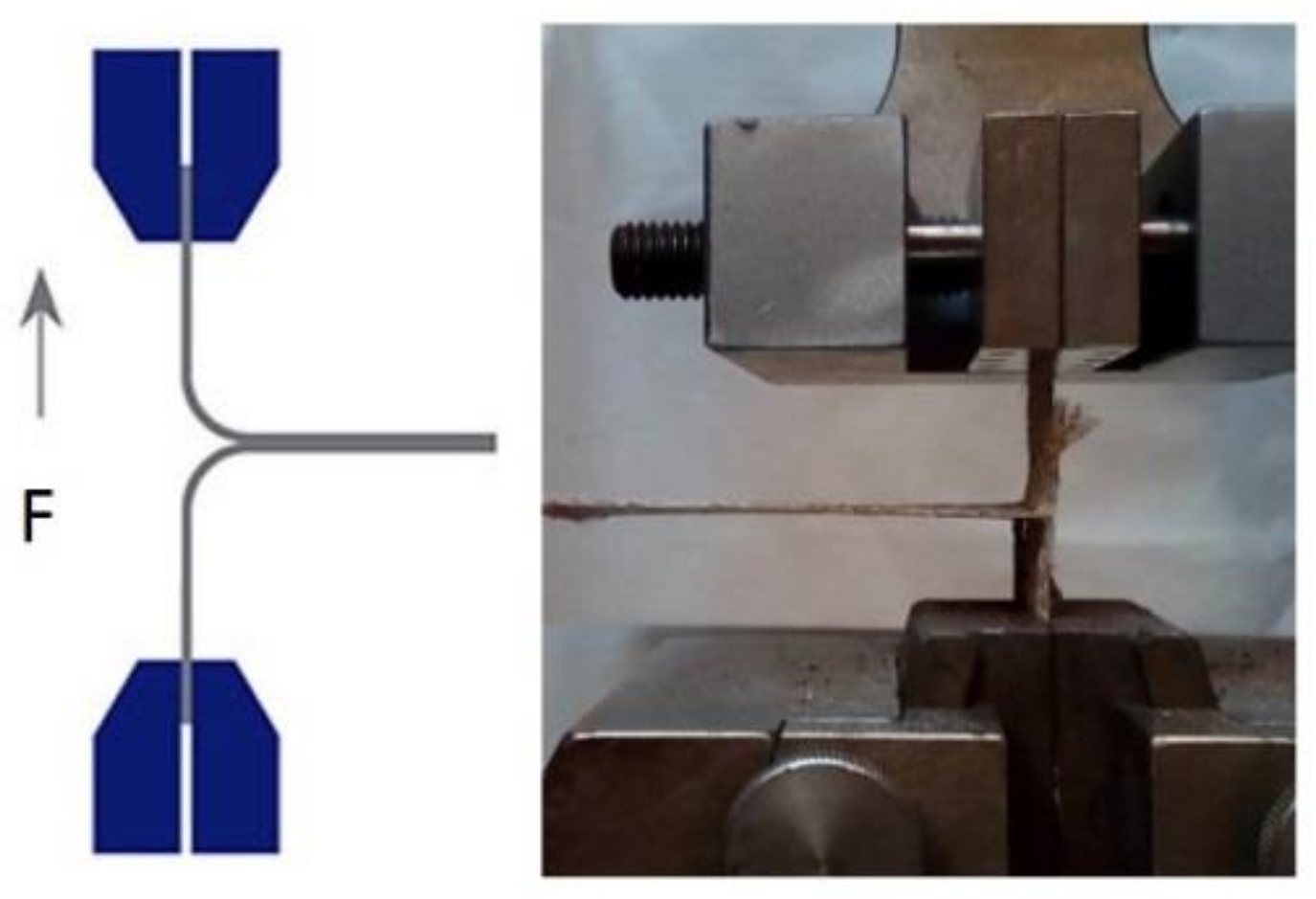

2.3. Tensile Tests

2.4. Peeling Tests

2.5. Moisture Absorption Tests

2.6. FTIR

3. Results

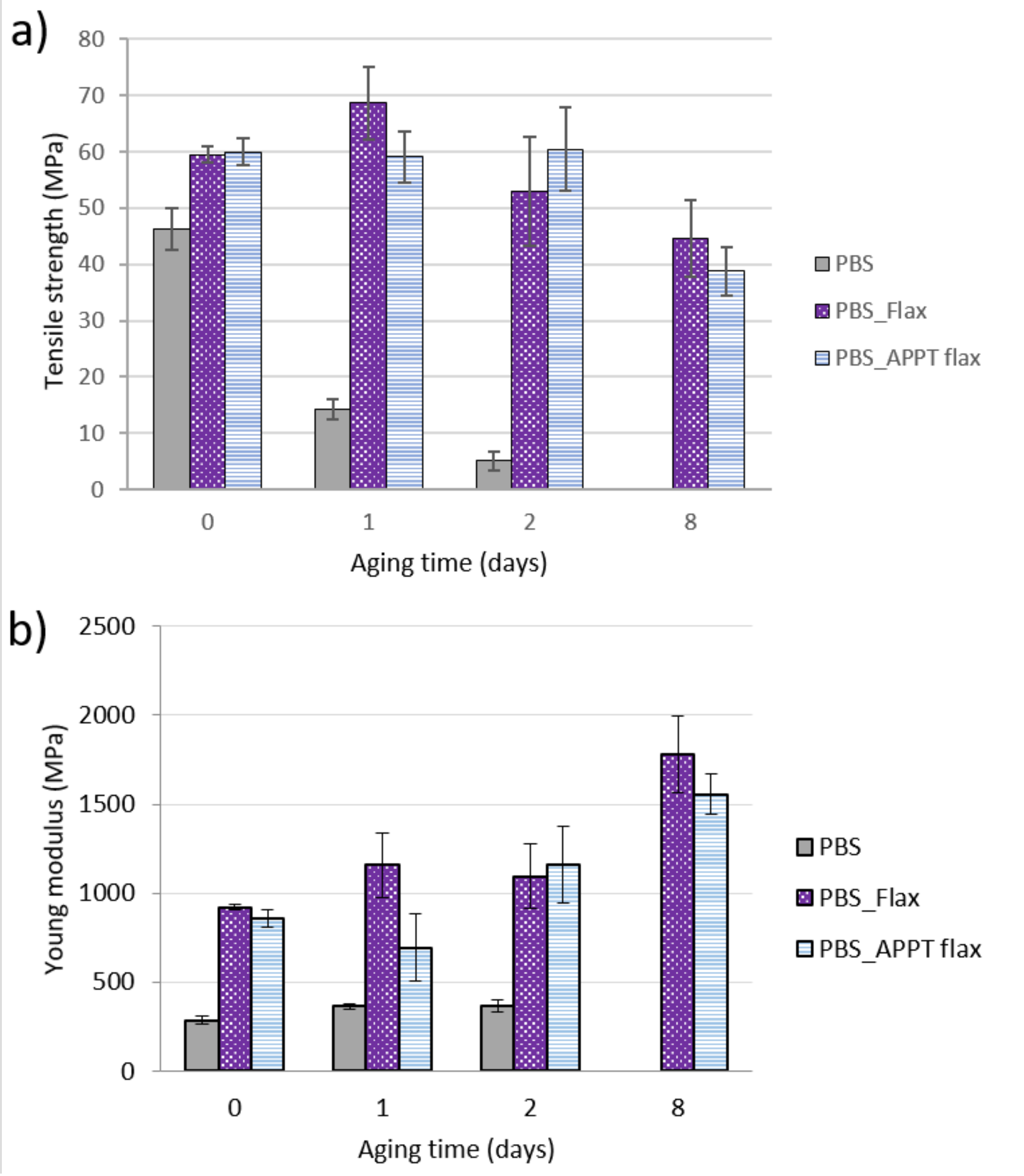

3.1. Mechanical Properties

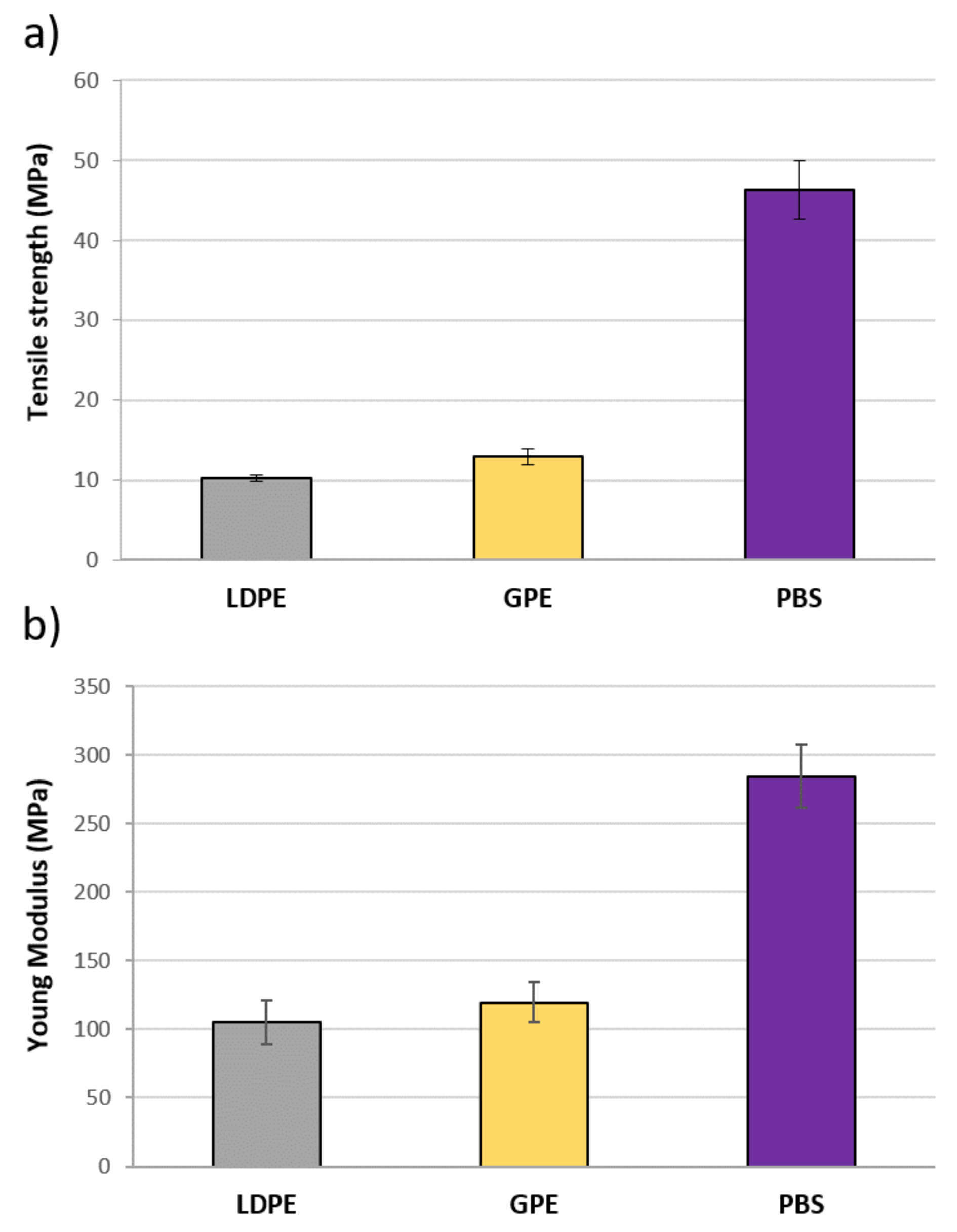

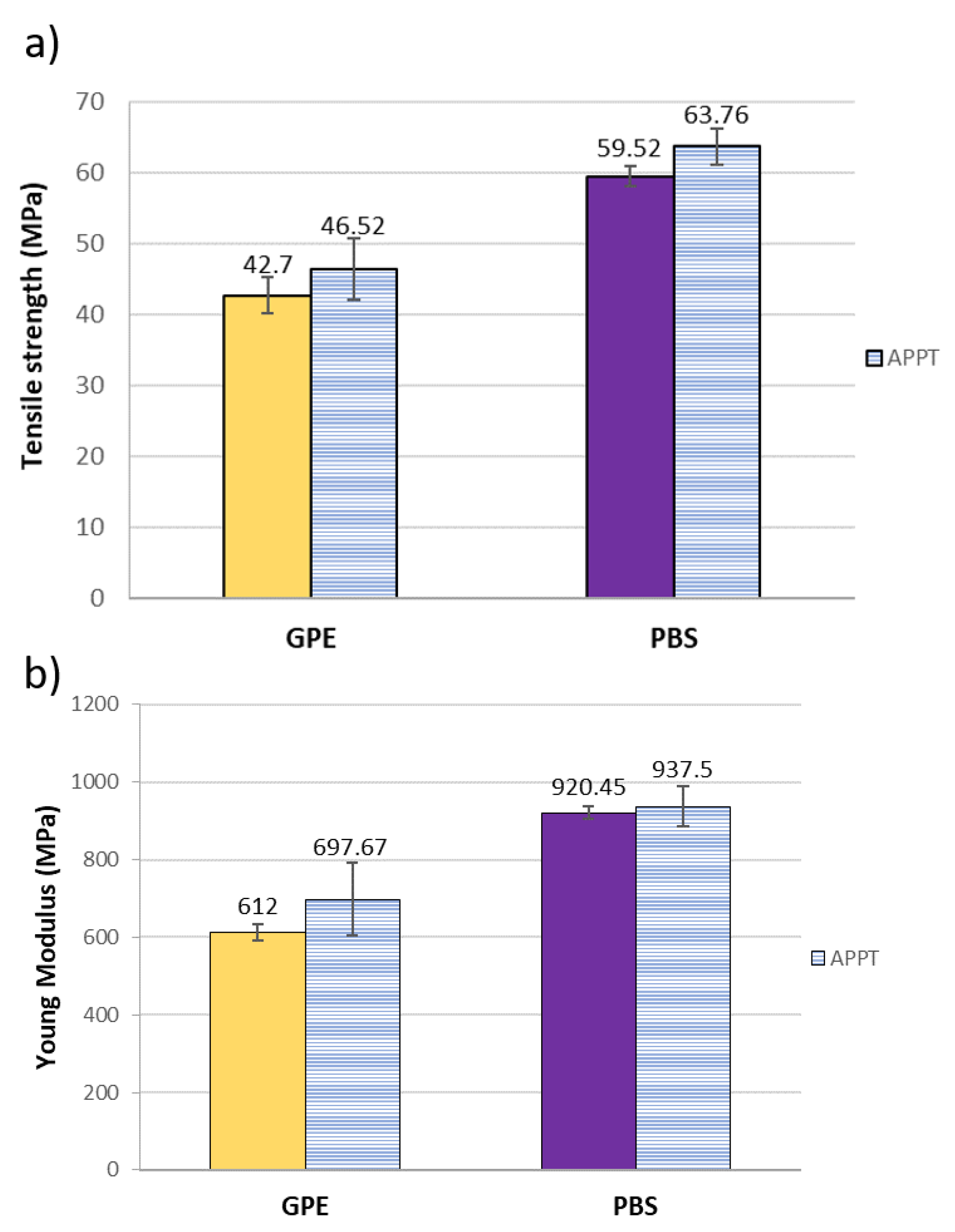

3.1.1. Mechanical Properties of Matrixes

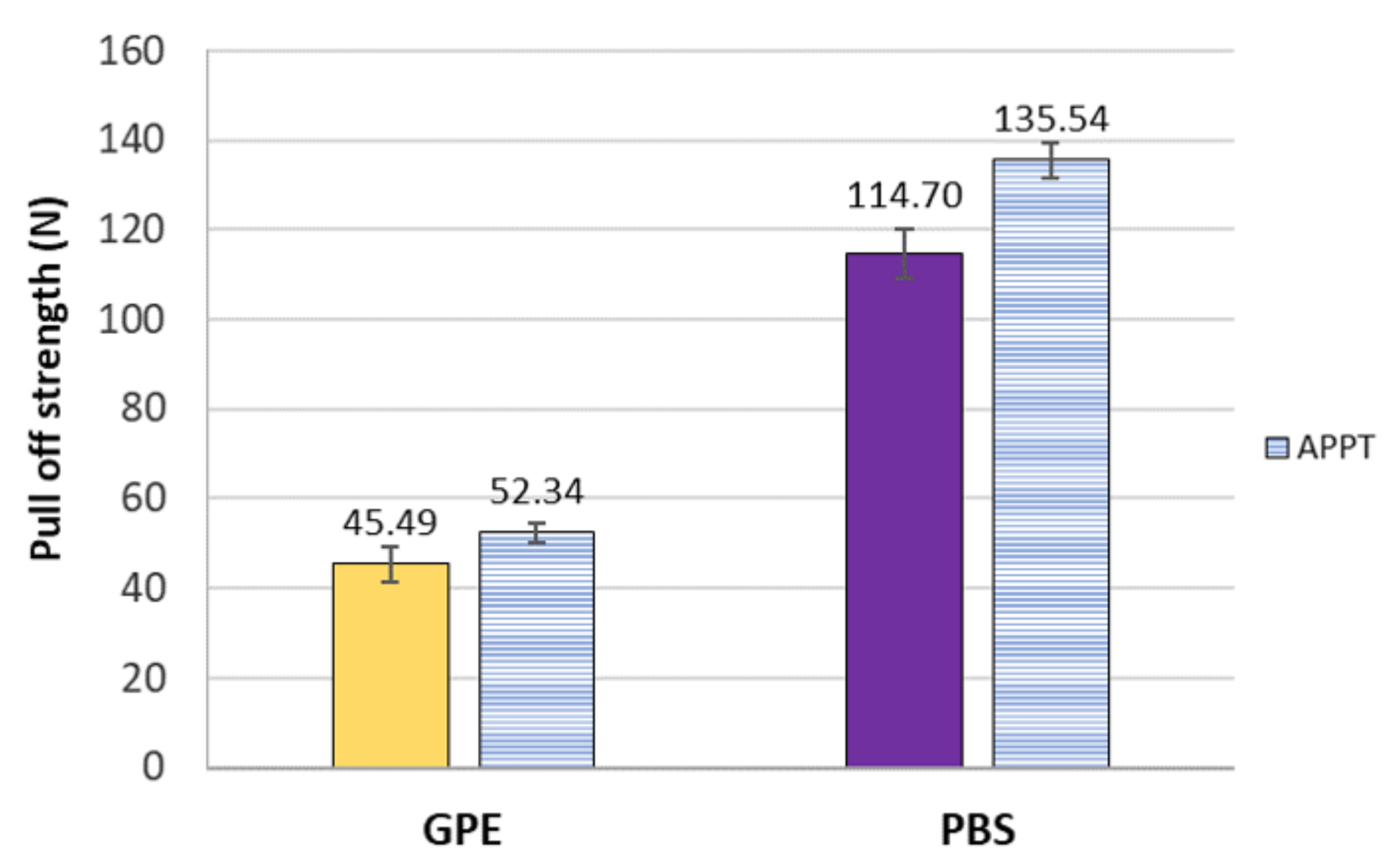

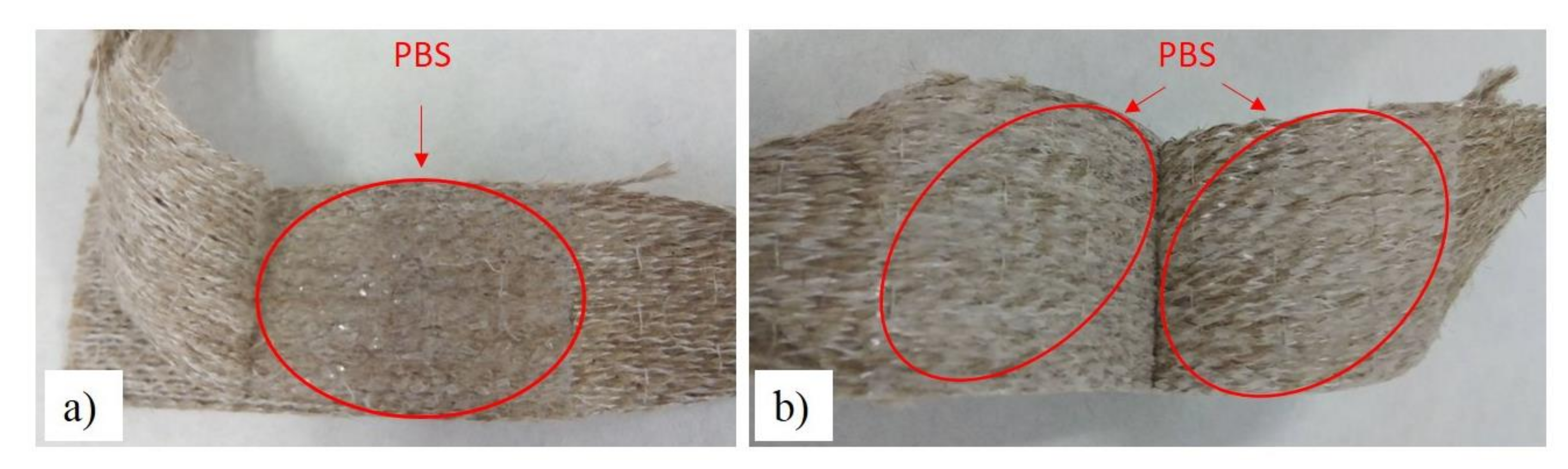

3.1.2. Mechanical Properties of Composites

3.2. Durability

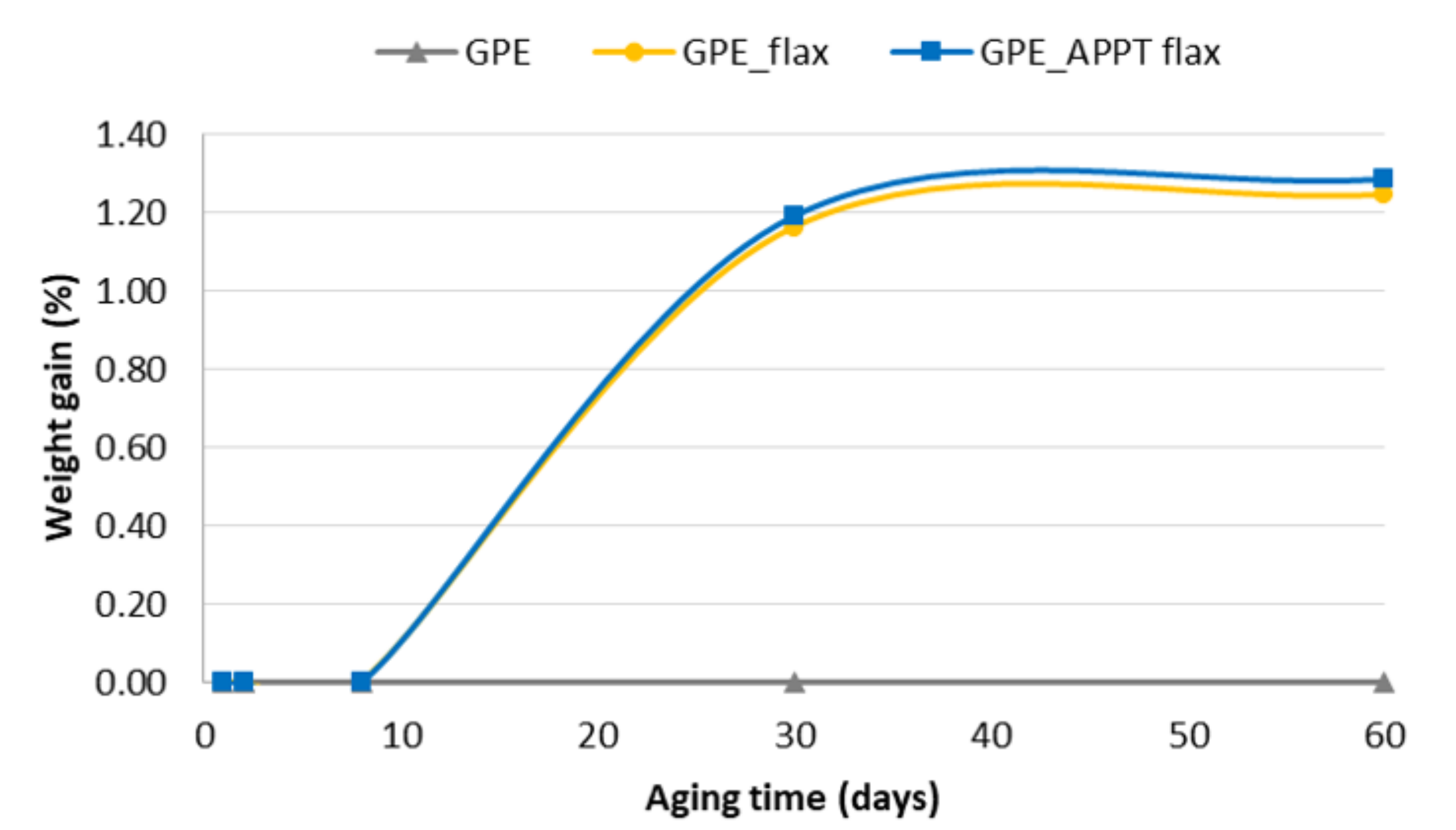

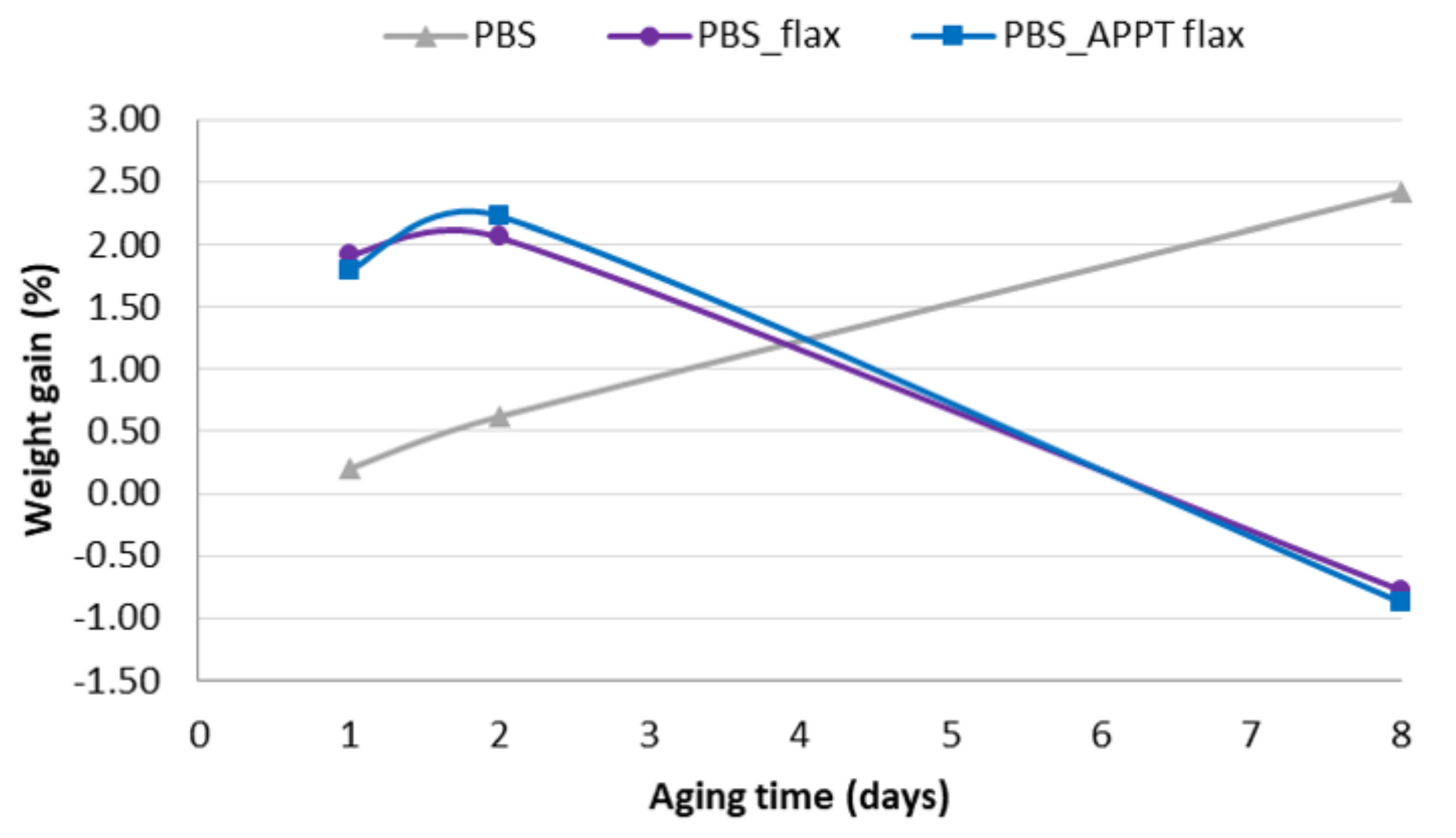

3.2.1. Moisture Absorption Tests

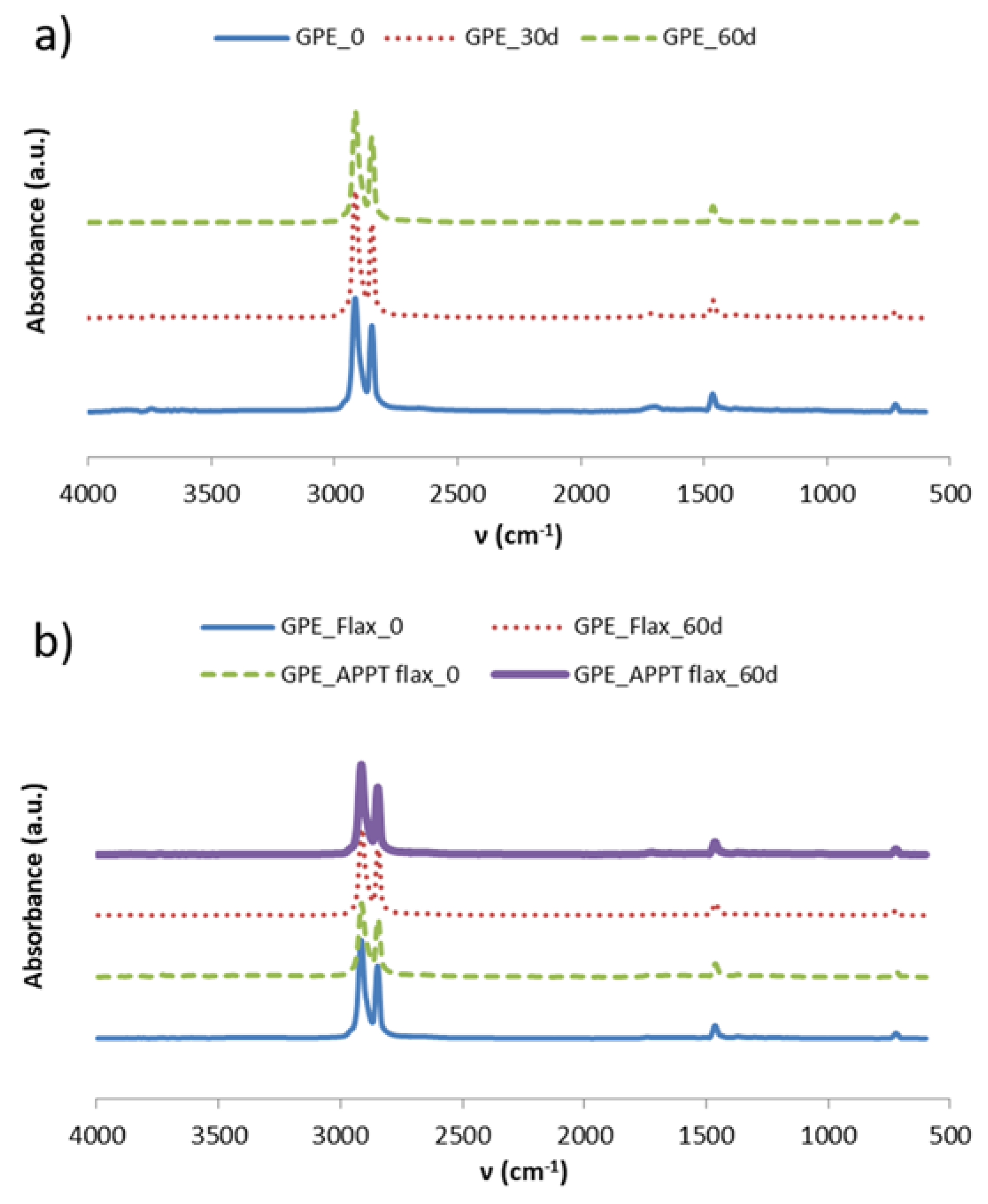

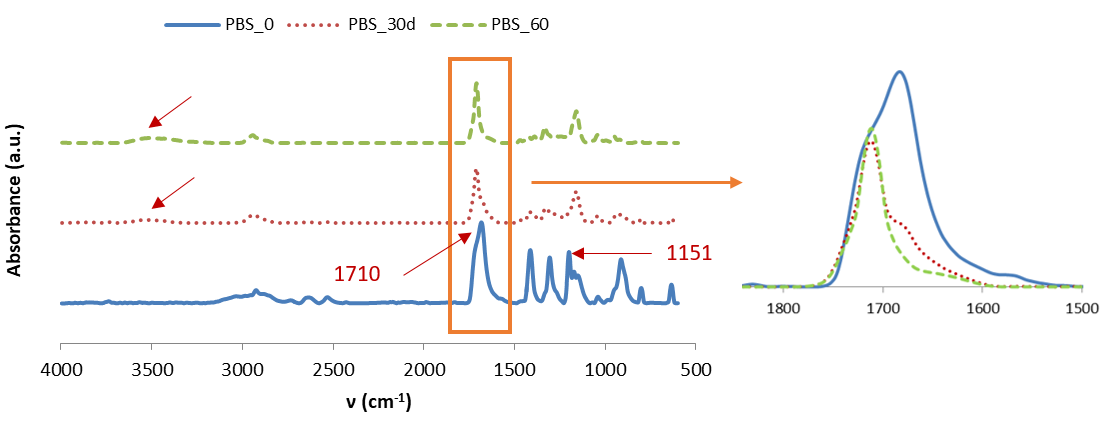

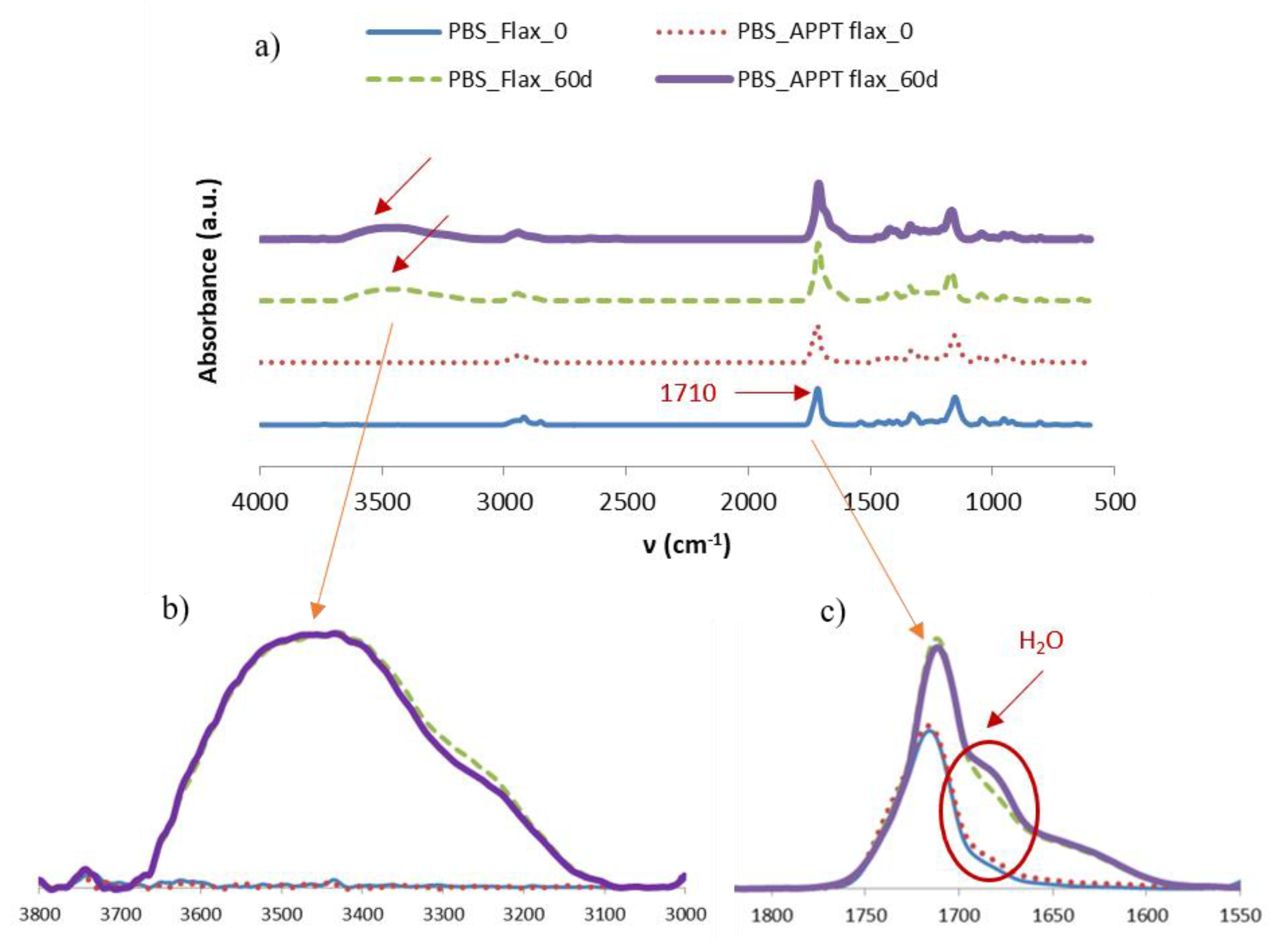

3.2.2. FTIR Analysis

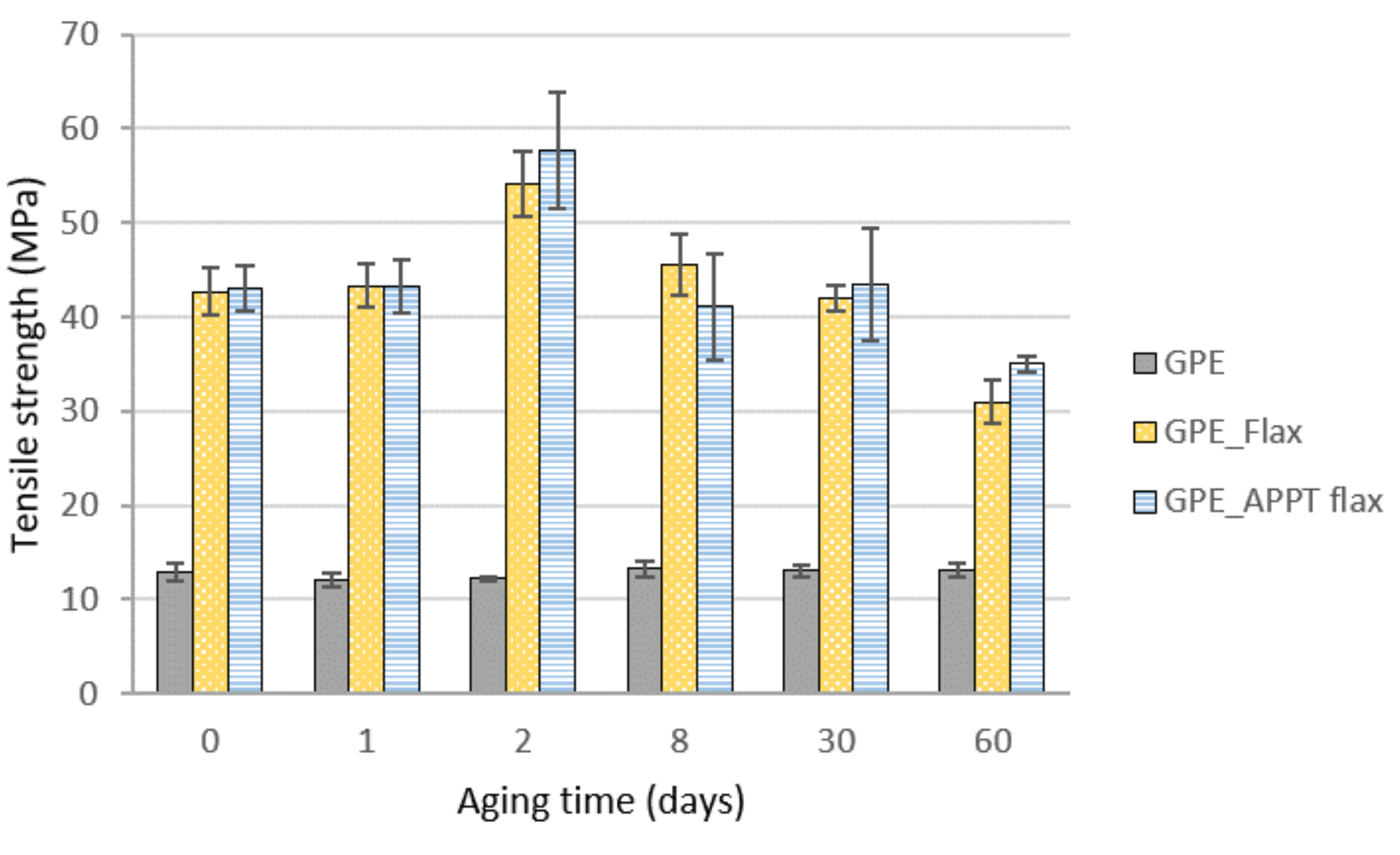

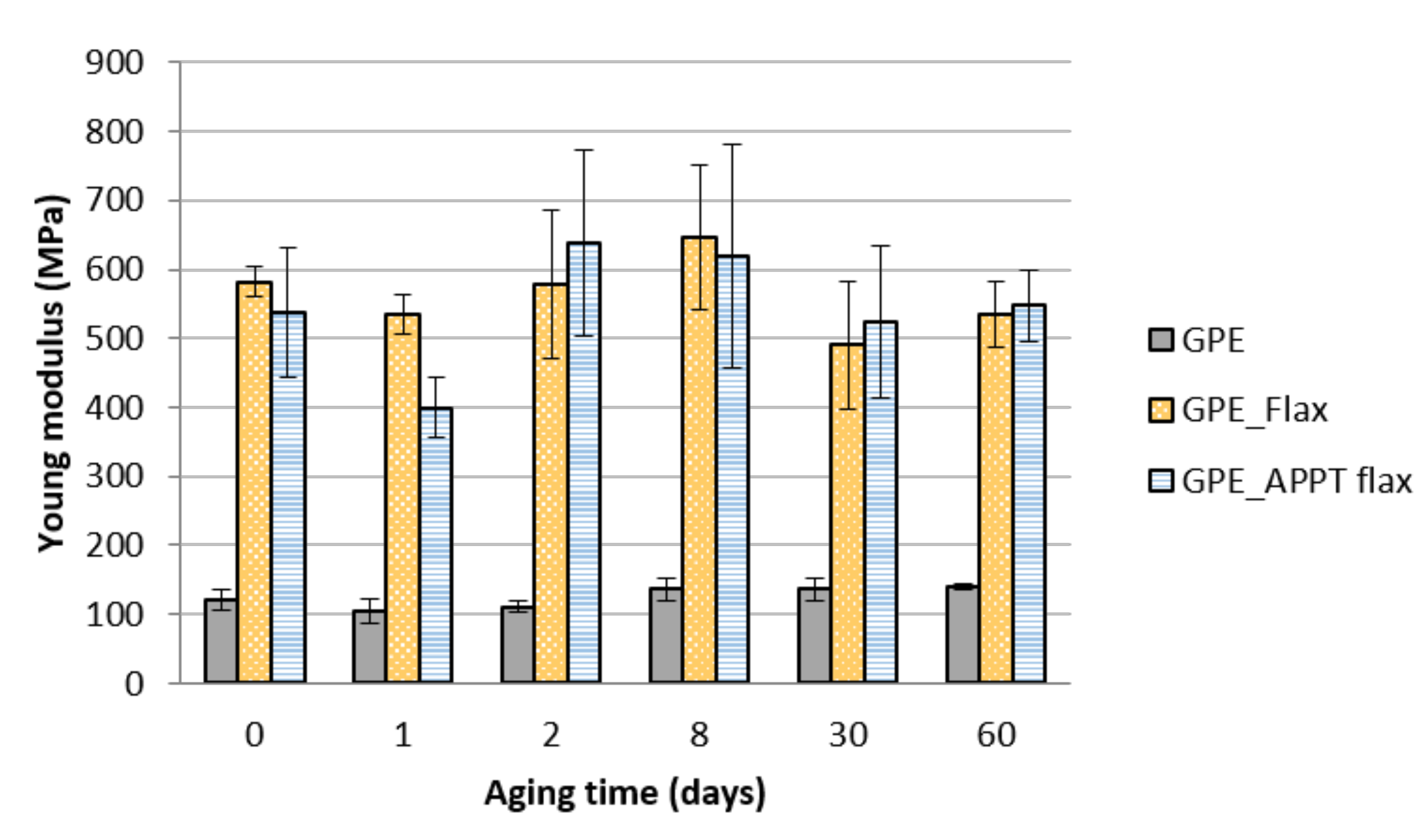

3.2.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lau, K.T.; Hung, P.Y.; Zhu, M.H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Jauhari, N.; Mishra, R.; Thakur, H. Natural Fibre Reinforced Composite Laminates—A Review. Mater. Today Proc. 2015, 2, 2868–2877. [Google Scholar] [CrossRef]

- Ahmad, F.; Choi, H.S.; Park, M.K. A review: Natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol. Mater. Eng. 2015, 300, 10–24. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural Fiber Reinforced Composites. Polym. Rev. 2012, 52, 259–320. [Google Scholar] [CrossRef]

- Malkapuram, R.; Kumar, V.; Negi, Y.S. Recent development in natural fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2009, 28, 1169–1189. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. The influence of fiber-surface treatment on the mechanical properties of jute-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 1997, 28, 1001–1005. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. Part B Eng. 2017, 114, 15–22. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly(lactic acid) (PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Conrads, H.; Schmidt, M. Plasma generation and plasma sources. Plasma Sources Sci. Technol. 2000, 9, 441–454. [Google Scholar] [CrossRef]

- Braithwaite, N. Introduction to Gas Discharges. Plasma Sources Sci. Technol. 2000, 9, 517–527. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Martínez, M.A. Influence of plasma treatment on the adhesion between a polymeric matrix and natural fibres. Cellulose 2017, 24, 1791–1801. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Paz, E.; Martínez, M.A. Influence of Low Pressure Plasma Treatment on the Durability of Thermoplastic Composites LDPE-flax/coconut under Thermal and Humidity Conditions. Fibers Polym. 2018, 19, 1327–1334. [Google Scholar] [CrossRef]

- Offringa, A.R. Thermoplastic applications composites-rapid processing applications. Compos. Part A 1996, 27, 329–336. [Google Scholar] [CrossRef]

- Ashter, S.A. Introduction to Bioplastics Engineering; Wiliam Andrew: Norwich, NY, USA, 2016. [Google Scholar]

- Pilla, S. Handbook of Bioplastics and Biocomposites Engineering Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Braskem. Available online: https://bioplasticsnews.com/braskem (accessed on 13 April 2020).

- Siracusa, V.; Lotti, N.; Munari, A.; Dalla Rosa, M. Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: Gas barrier properties after stressed treatments. Polym. Degrad. Stab. 2015, 119, 35–45. [Google Scholar] [CrossRef]

- Phua, Y.J.; Lau, N.S.; Sudesh, K.; Chow, W.S.; Mohd Ishak, Z.A. Biodegradability studies of poly(butylene succinate)/organo-montmorillonite nanocomposites under controlled compost soil conditions: Effects of clay loading and compatibiliser. Polym. Degrad. Stab. 2012, 97, 1345–1354. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Hinchcliffe, S.A.; Hess, K.M.; Srubar, W.V. Experimental and theoretical investigation of prestressed natural fiber-reinforced polylactic acid (PLA) composite materials. Compos. Part B Eng. 2016, 95, 346–354. [Google Scholar] [CrossRef]

- ISO. UNE-EN ISO 527-1:2012. Plásticos. Determinación de las Propiedades en Tracción. Parte 1: Principios Generals; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- ISO. UNE EN ISO 11339:2010. Adhesivos. Ensayo de Pelado en T para Uniones Encoladas Flexible sobre Flexible; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Rissanen, M.; Ramamoorthy, S.K. Mechanical and thermal characterization of compression moulded polylactic acid natural fiber composites reinforced with hemp and lyocell fibers. J. Appl. Polym. Sci. 2014, 131, 1–10. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Hydrolytic degradation of biodegradable polyesters under simulated environmental conditions. J. Appl. Polym. Sci. 2015, 132, 1–13. [Google Scholar] [CrossRef]

- Baschek, G. Effect of water absorption in polymers at low and high temperatures. Polymer 1999, 40, 3433–3441. [Google Scholar] [CrossRef]

- Gulmine, J.V.; Janissek, P.R.; Heise, H.M.; Akcelrud, L. Polyethylene characterization by FTIR. Polym. Test. 2002, 21, 557–563. [Google Scholar] [CrossRef]

- Phua, Y.J.; Chow, W.S.; Mohd Ishak, Z.A. The hydrolytic effect of moisture and hygrothermal aging on poly(butylene succinate)/organo-montmorillonite nanocomposites. Polym. Degrad. 2011, 96, 1194–1203. [Google Scholar] [CrossRef]

- Kanemura, C.; Nakashima, S.; Hotta, A. Mechanical properties and chemical structures of biodegradable poly(butylene-succinate) for material reprocessing. Polym. Degrad. Stab. 2012, 97, 972–980. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enciso, B.; Abenojar, J.; Martínez, M.A. Effect of APPT Treatment on Mechanical Properties and Durability of Green Composites with Woven Flax. Materials 2020, 13, 4762. https://doi.org/10.3390/ma13214762

Enciso B, Abenojar J, Martínez MA. Effect of APPT Treatment on Mechanical Properties and Durability of Green Composites with Woven Flax. Materials. 2020; 13(21):4762. https://doi.org/10.3390/ma13214762

Chicago/Turabian StyleEnciso, Belén, Juana Abenojar, and Miguel Angel Martínez. 2020. "Effect of APPT Treatment on Mechanical Properties and Durability of Green Composites with Woven Flax" Materials 13, no. 21: 4762. https://doi.org/10.3390/ma13214762

APA StyleEnciso, B., Abenojar, J., & Martínez, M. A. (2020). Effect of APPT Treatment on Mechanical Properties and Durability of Green Composites with Woven Flax. Materials, 13(21), 4762. https://doi.org/10.3390/ma13214762