Influence of Metallic Oxide Nanoparticles on the Mechanical Properties of an A-TIG Welded 304L Austenitic Stainless Steel

Abstract

1. Introduction

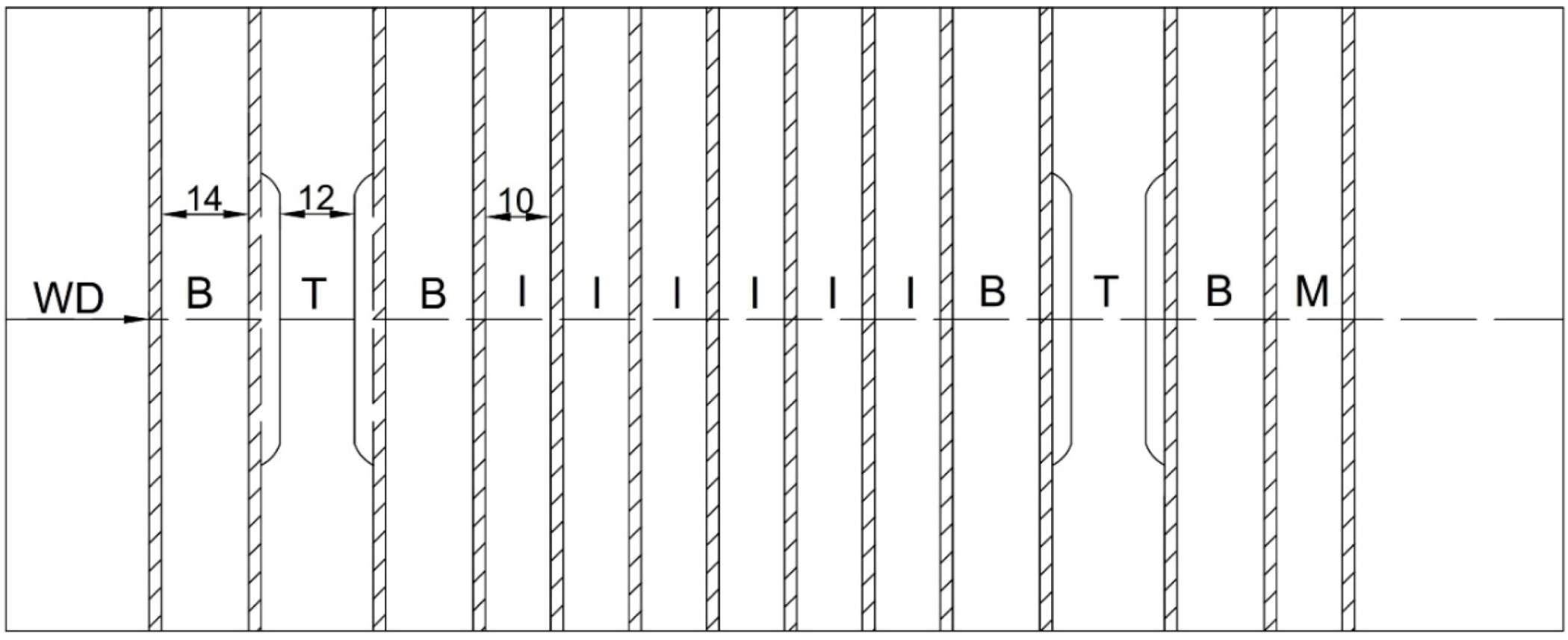

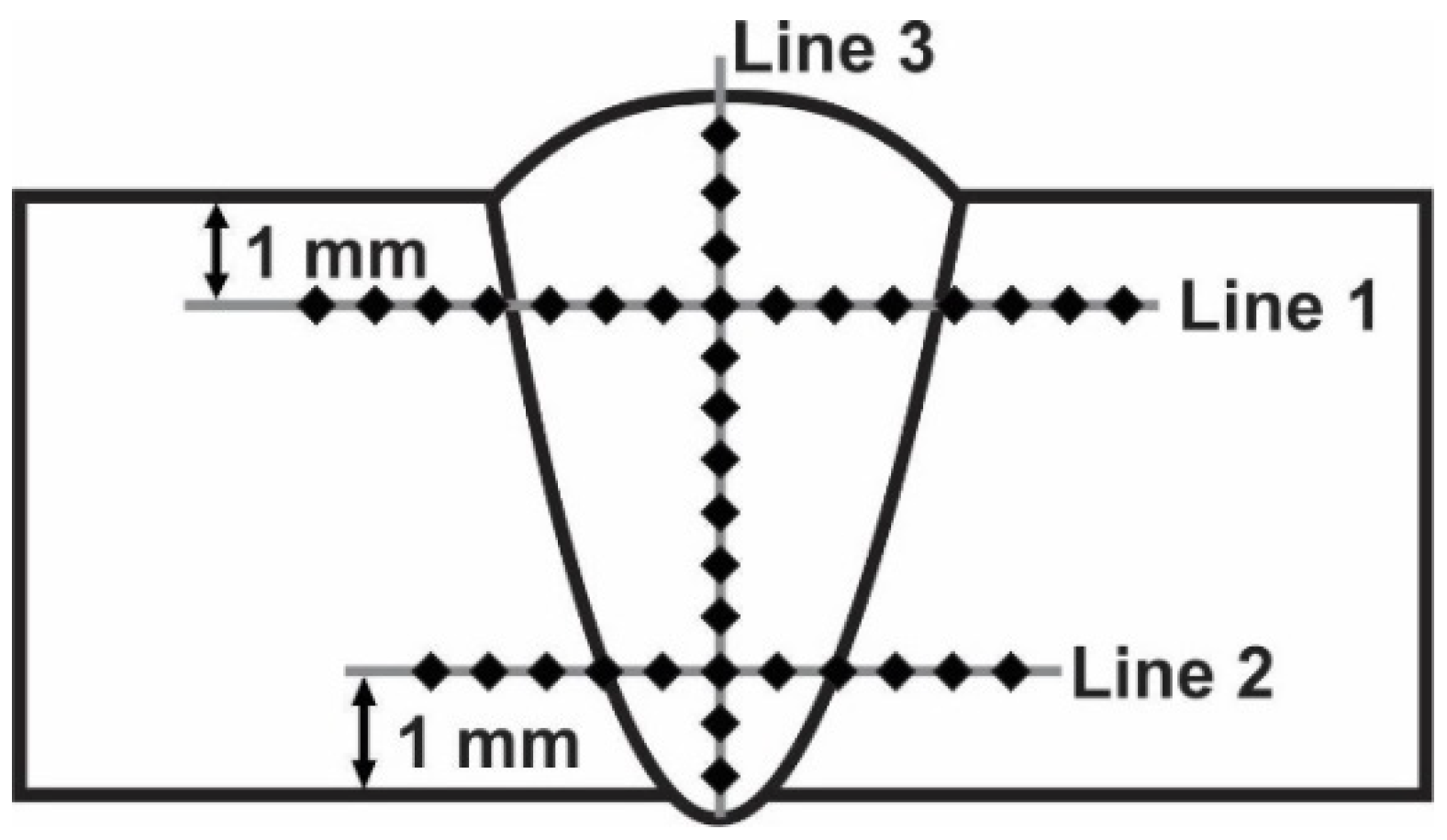

2. Materials and Methods

3. Results and Discussion

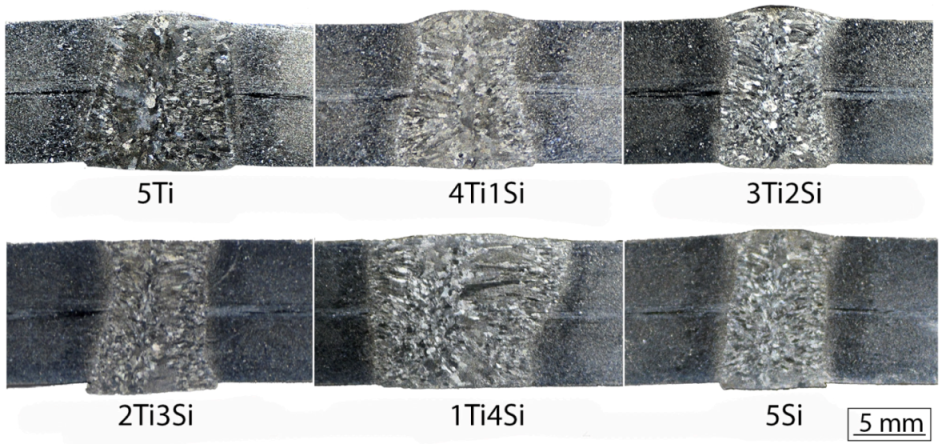

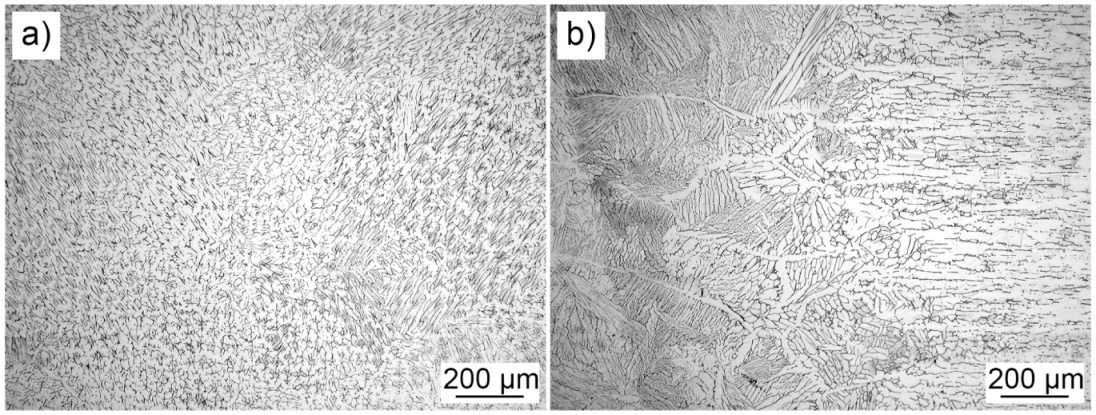

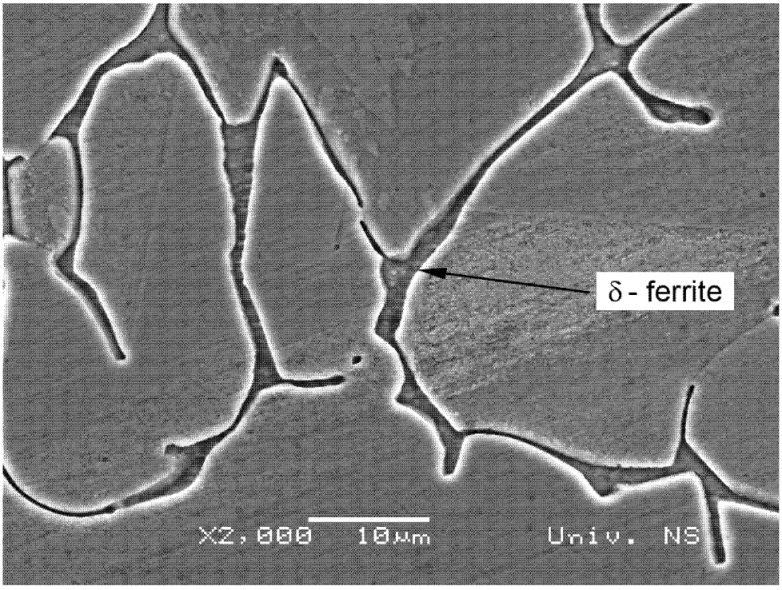

3.1. Metallographic Testing and Chemical Compositions

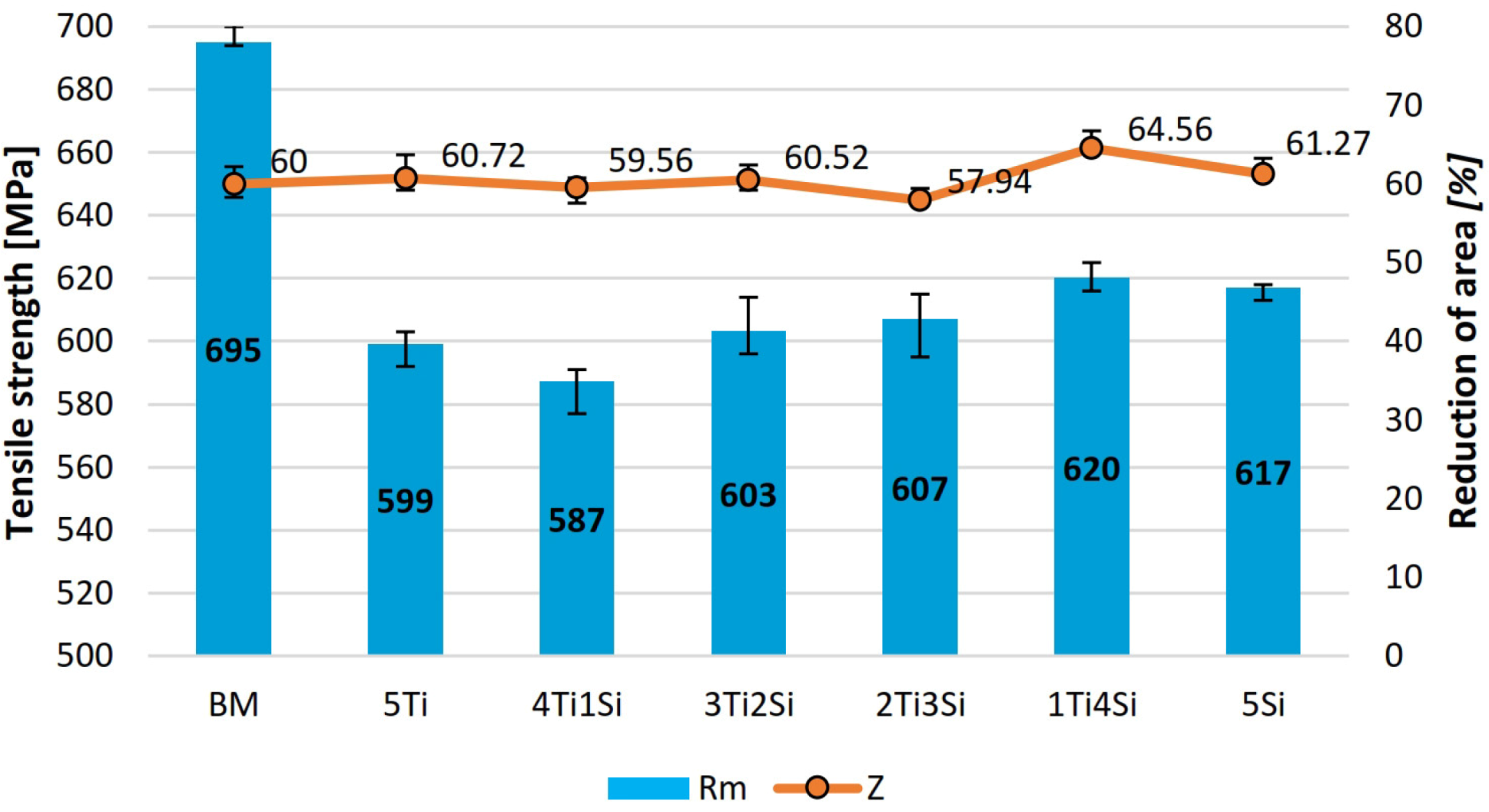

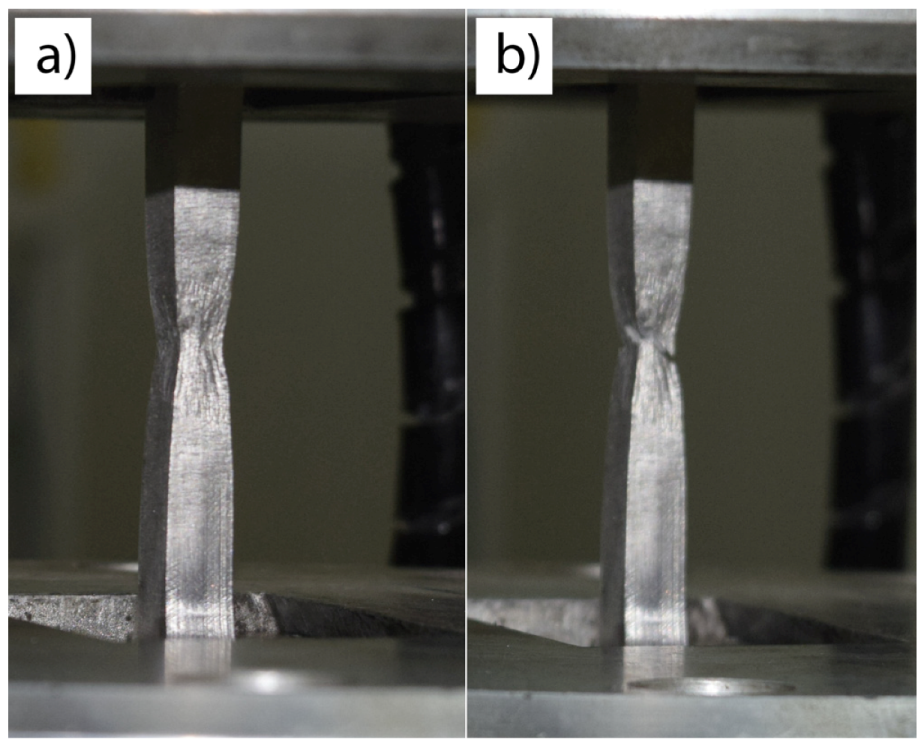

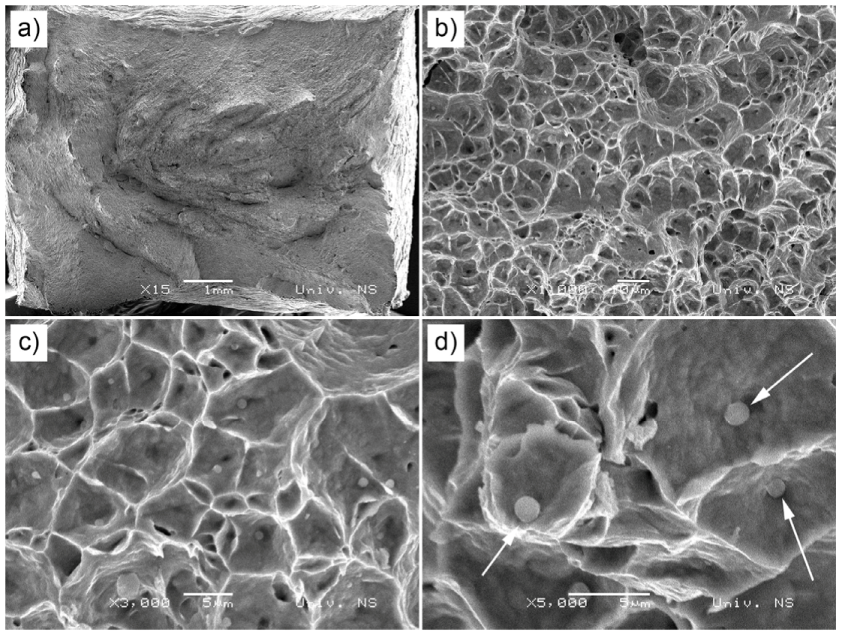

3.2. Mechanical Properties of Welds

4. Conclusions

- Chemical compositions of the weld metals are not dependent on the composition of the flux.

- Different SiO2 to TiO2 ratios result in obtaining similarly shaped weld metals, with the same columnar structure, but with different widths.

- The widest weld resulted in the highest absolute amount of δ-ferrite, the widest space for deformation, resulting in the highest strength and ductility.

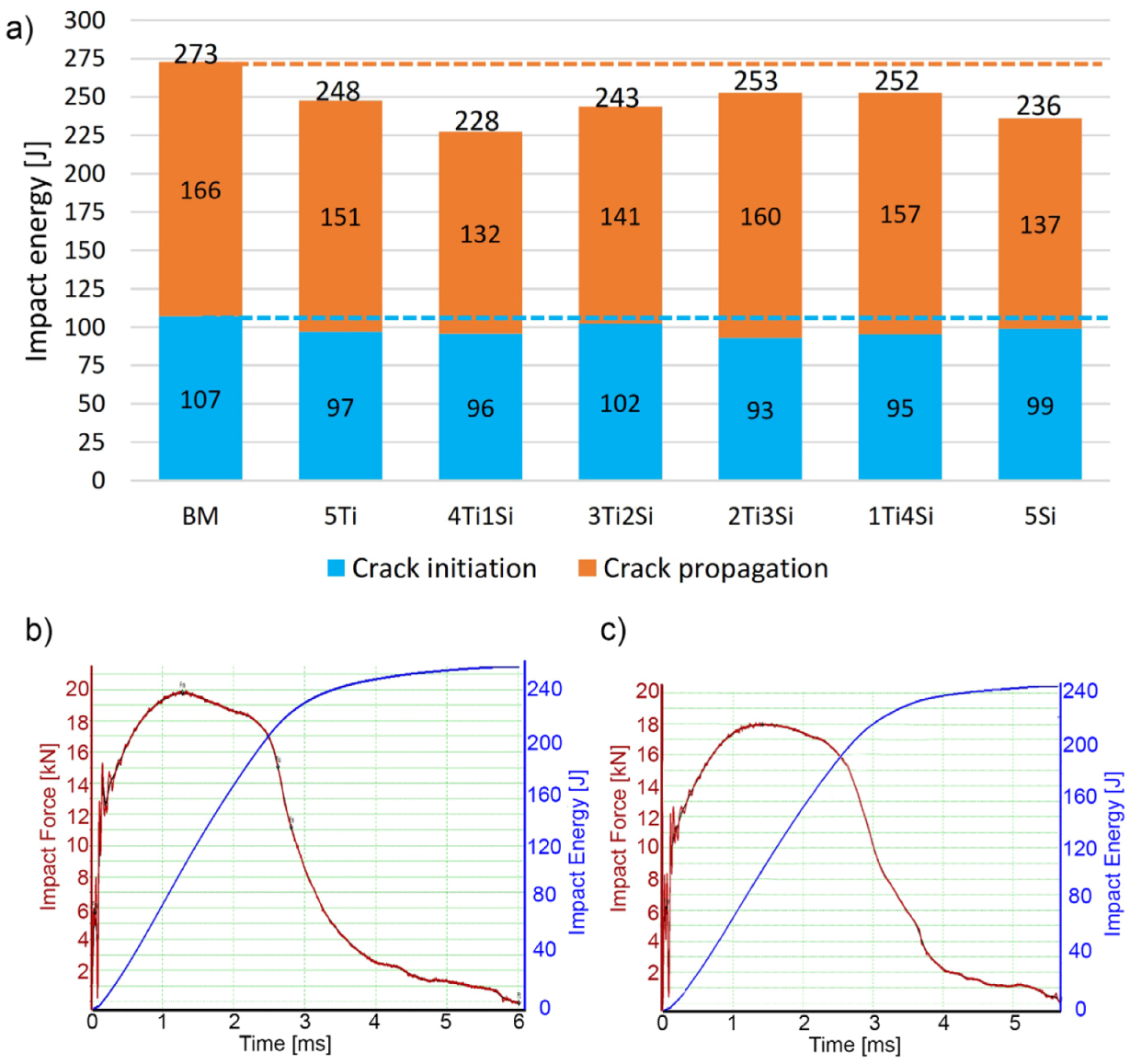

- Tensile properties and impact toughness of weldments were marginally lower compared to the base metal, due to the replacement of strain hardened polygonal austenite by the mixture of cast dendritic austenite.

- Tensile strength and reduction of area as well as impact toughness of the optimal specimen and the majority of other specimens, were within the limits set by the base metal standard limits.

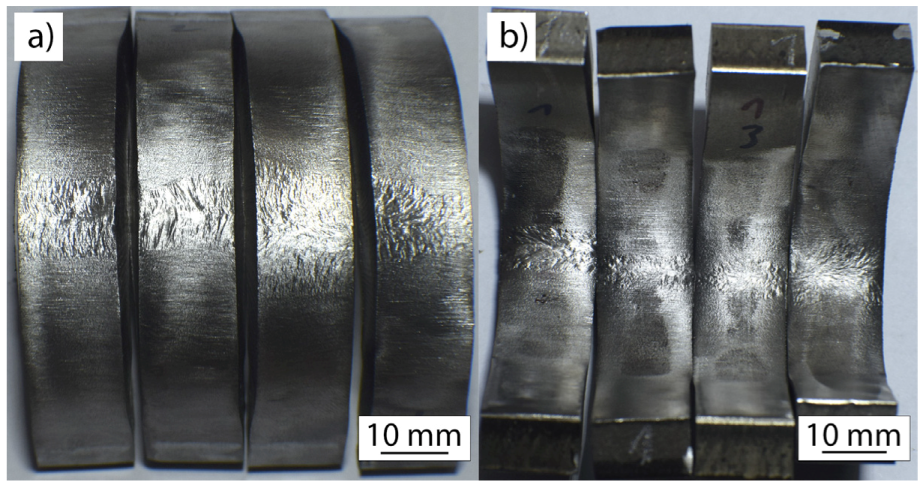

- Bend testing did not result in the occurrence of any cracks.

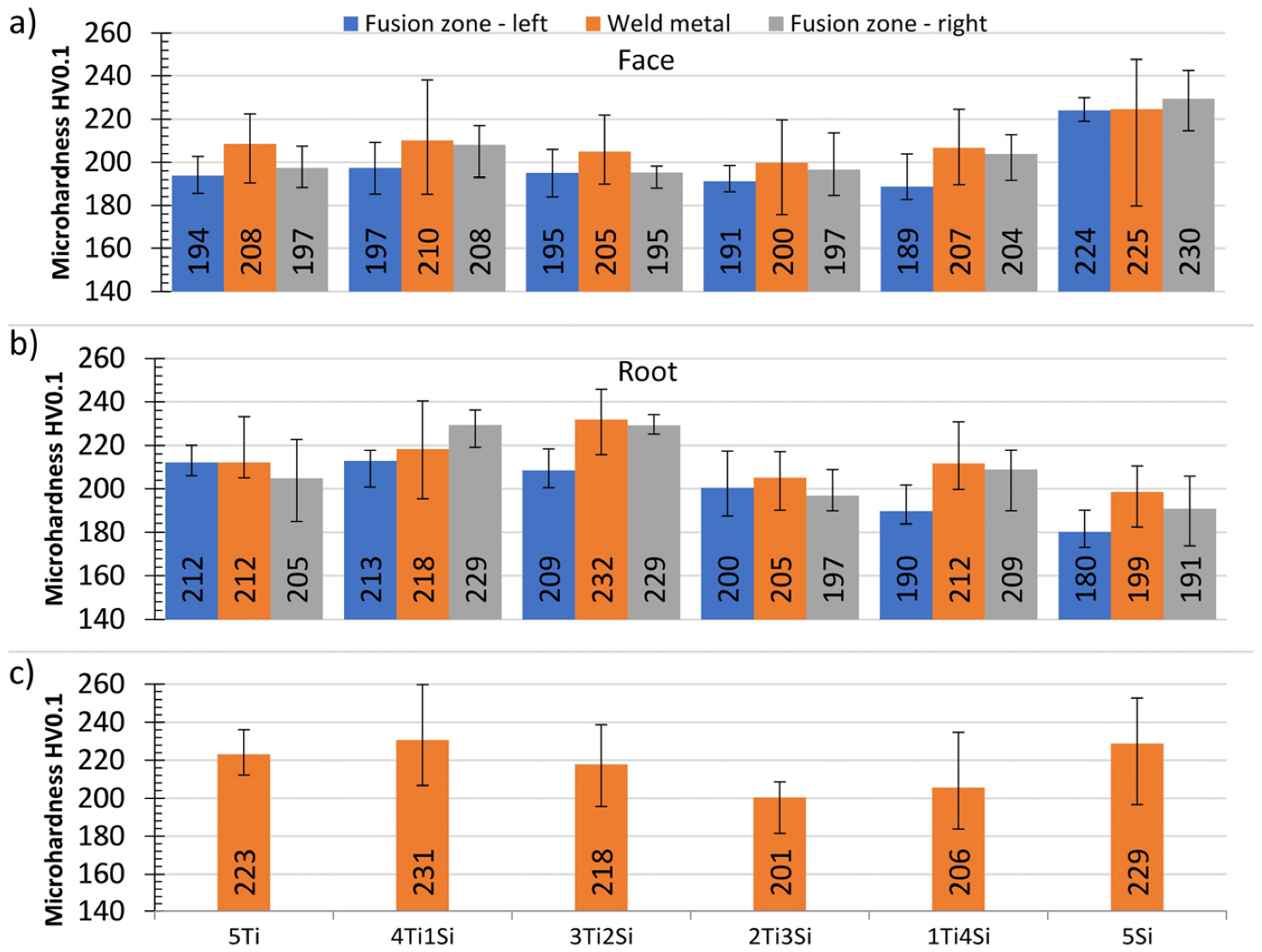

- Microhardness values in the weld metal in the majority of specimens were higher compared to the fusion zones. Additionally, specimens that had the lowest average microhardness had the highest tensile and impact toughness.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Baddoo, N.R. Stainless steel in construction: A review of research, applications, challenges and opportunities. J. Constr. Steel. Res. 2008, 64, 1199–1206. [Google Scholar] [CrossRef]

- Garrison, W.M. Ultrahigh-strength steels for aerospace applications. JOM 1990, 42, 20–24. [Google Scholar] [CrossRef]

- Wells, M.G.H. Advances in steels for aerospace applications. Key Eng. Mater. 1992, 77–78, 71–80. [Google Scholar] [CrossRef]

- Tseng, K.-H.; Hsu, C.-Y. Performance of activated TIG process in austenitic stainless steel welds. J. Mater. Process. Technol. 2011, 211, 503–512. [Google Scholar] [CrossRef]

- Klobčar, D.; Tušek, J.; Bizjak, M.; Simončič, S.; Lešer, V. Active flux tungsten inert gas welding Of austenitic stainless steel AISI 304. Metalurgija 2016, 55, 617–620. [Google Scholar]

- Vidyarthy, R.S.; Dwivedi, D.K. Activating flux tungsten inert gas welding for enhanced weld penetration. J. Manuf. Process. 2016, 22, 211–228. [Google Scholar] [CrossRef]

- Dramicanin, M.; Balos, S.; Janjatovic, P.; Zabunov, I.; Grabulov, V. Activated flux TIG welding of stainless steel pipes. Chem. Ind. Chem. Eng. Q. 2019, 25, 353–360. [Google Scholar] [CrossRef]

- Gurevich, S.M.; Zamkov, V.N.; Kushnirenko, N.A. Improving the penetration of titanium alloys when they are welded by argon tungsten arc process. Avtom. Svarka. 1965, 18, 1–5. [Google Scholar]

- Yangchuan, C.; Zhen, L.; Zunyue, H.; Yida, Z. Effect of cerium oxide flux on active flux TIG welding of 800 MPa super steel. J. Mater. Process. Technol. 2016, 230, 80–87. [Google Scholar]

- Vora, J.J.; Badheka, J.B. Experimental investigation on mechanism and weld morphology of activated TIG welded bead-on-plate weldments of reduced activation ferritic/martensitic steel using oxide fluxes. J. Manuf. Process. 2015, 20, 224–233. [Google Scholar] [CrossRef]

- Tseng, K.-H.; Lin, P.-Y. UNS S31603 stainless steel tungsten inert gas welds made with microparticle and nanoparticle oxides. Materials 2014, 7, 4755–4772. [Google Scholar] [CrossRef] [PubMed]

- Balos, S.; Dramicanin, M.; Janjatovic, P.; Zabunov, I.; Klobcar, D.; Busic, M.; Luisa Grilli, M. Metal oxide nanoparticle-based coating as a catalyzer for A-TIG welding: Critical raw material perspective. Metals 2019, 9, 567. [Google Scholar] [CrossRef]

- Balos, S.; Dramicanin, M.; Janjatovic, P.; Zabunov, I.; Pilic, B.; Goel, S.; Szutkowska, M. Suppressing the use of critical raw materials in joining of AISI 304 stainless steel using activated tungsten inert gas welding. Metals 2019, 9, 1187. [Google Scholar] [CrossRef]

- Takeuchi, Y.; Takagi, R.; Shinoda, T. Effect of bismuth on weld joint penetration in austenitic stainless steel. Weld. Res. Suppl. 1992, 71, 283–290. [Google Scholar]

- Mills, K.C.; Keene, B.J.; Brooks, R.F.; Shirali, A. Marangoni effects in welding. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 1998, 356, 911–925. [Google Scholar] [CrossRef]

- Skvortsov, E.A. Role of electronegative elements in contraction of the arc discharge. Weld Int. 1998, 12, 471–475. [Google Scholar] [CrossRef]

- Tanaka, M.; Shimizu, T.; Terasaki, T.; Ushio, M.; Koshiishi, F.; Terasaki, H. Effects of activating flux on arc phenomena in gas tungsten arc welding. Sci. Technol. Weld Join. 2000, 5, 397–402. [Google Scholar] [CrossRef]

- Thakur, P.P.; Chapgaon, A.N. A review on effects of GTAW process parameters on weld. IJRASET 2016, 4, 136–140. [Google Scholar]

- Cibi, A.J.; Thilagham, K.T. High frequency gas tungsten arc welding process for dressing of weldment. IJAERS 2017, 4, 229–235. [Google Scholar]

- Sharma, P.; Dwivedi, D.K. Comparative study of activated flux-GTAW and multipass-GTAW dissimilar P92 steel-304H ASS joints. Mater. Manuf. Process. 2019, 34, 1–10. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Bajpai, A.; Raghuvanshi, S.; Singh, A.; Chandrasekhar, A.; Arivarasu, M.; Arivazhagan, N. Investigations on structure–property relationships of activated flux TIG weldments of super-duplex/austenitic stainless steels. Mater. Sci. Eng. A 2015, 638, 60–68. [Google Scholar] [CrossRef]

- Hdhibi, A.; Touileb, K.; Djoudjou, R.; Ouis, A.; Bouzazi, M.L.; Chakhari, J. Effect of single oxide fluxes on morphology and mechanical properties of ATIG on 316 L austenitic stainless steel welds. Eng. Technol. Appl. Sci. Res. 2018, 8, 3064–3072. [Google Scholar]

- Huang, H.-Y. Effects of shielding gas composition and activating flux on GTAW weldments. Mater. Des. 2009, 30, 2404–2409. [Google Scholar] [CrossRef]

- Sabiha, A.; Nemes, J.A. Internal ductile failure mechanisms in steel cold heading process. J. Mater. Process. Technol. 2009, 209, 4292–4311. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | P | S | Fe |

|---|---|---|---|---|---|---|---|

| 0.02 | 0.042 | 1.55 | 18.63 | 8.23 | 0.032 | 0.0004 | balance |

| Material Specifications | Tensile Properties | Impact Energy | |||||

|---|---|---|---|---|---|---|---|

| Yield Strength Rp (MPa) | Ultimate Tensile Strength Rm (MPa) | Elongation A (%) | Reduction of Area Z (%) | Crack Formation (J) | Crack Propagation (J) | Impact Energy (J) | |

| Base metal | 474 | 697 | 57 | 60 | 107 | 166 | 273 |

| 304L nominal values | >170 | >485 | >40 | – | – | – | >100 |

| Specimen | 5Ti | 4Ti1Si | 3Ti2Si | 2Ti3Si | 1Ti4Si | 5Si | |

|---|---|---|---|---|---|---|---|

| Weld width (mm) | Face | 10.5 | 9.9 | 7.7 | 8.7 | 14.0 | 6.7 |

| Root | 9.4 | 8.5 | 8.5 | 8.6 | 10.8 | 8.8 | |

| Specimen | C | Si | Mn | Cr | Ni | P | S | Fe |

|---|---|---|---|---|---|---|---|---|

| 5Ti | 0.02 | 0.45 | 1.5 | 18.57 | 8.29 | 0.032 | 0.0006 | balance |

| 4Ti1Si | 0.02 | 0.45 | 1.51 | 18.55 | 8.24 | 0.032 | 0.0006 | balance |

| 3Ti2Si | 0.02 | 0.45 | 1.53 | 18.56 | 8.2 | 0.03 | 0.0007 | balance |

| 2Ti3Si | 0.02 | 0.45 | 1.51 | 18.57 | 8.24 | 0.032 | 0.0007 | balance |

| 1Ti4Si | 0.025 | 0.45 | 1.53 | 18.6 | 8.26 | 0.032 | 0.0006 | balance |

| 5Si | 0.025 | 0.44 | 1.55 | 18.63 | 8.23 | 0.031 | 0.0004 | balance |

| AISI 304L | 0.02 | ≤0.045 | ≤1.55 | 18.63 | 8.23 | 0.032 | 0.0004 | balance |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balos, S.; Dramicanin, M.; Janjatovic, P.; Kulundzic, N.; Zabunov, I.; Pilic, B.; Klobčar, D. Influence of Metallic Oxide Nanoparticles on the Mechanical Properties of an A-TIG Welded 304L Austenitic Stainless Steel. Materials 2020, 13, 4513. https://doi.org/10.3390/ma13204513

Balos S, Dramicanin M, Janjatovic P, Kulundzic N, Zabunov I, Pilic B, Klobčar D. Influence of Metallic Oxide Nanoparticles on the Mechanical Properties of an A-TIG Welded 304L Austenitic Stainless Steel. Materials. 2020; 13(20):4513. https://doi.org/10.3390/ma13204513

Chicago/Turabian StyleBalos, Sebastian, Miroslav Dramicanin, Petar Janjatovic, Nenad Kulundzic, Ivan Zabunov, Branka Pilic, and Damjan Klobčar. 2020. "Influence of Metallic Oxide Nanoparticles on the Mechanical Properties of an A-TIG Welded 304L Austenitic Stainless Steel" Materials 13, no. 20: 4513. https://doi.org/10.3390/ma13204513

APA StyleBalos, S., Dramicanin, M., Janjatovic, P., Kulundzic, N., Zabunov, I., Pilic, B., & Klobčar, D. (2020). Influence of Metallic Oxide Nanoparticles on the Mechanical Properties of an A-TIG Welded 304L Austenitic Stainless Steel. Materials, 13(20), 4513. https://doi.org/10.3390/ma13204513