The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures

Abstract

1. Introduction

2. Materials and Methods

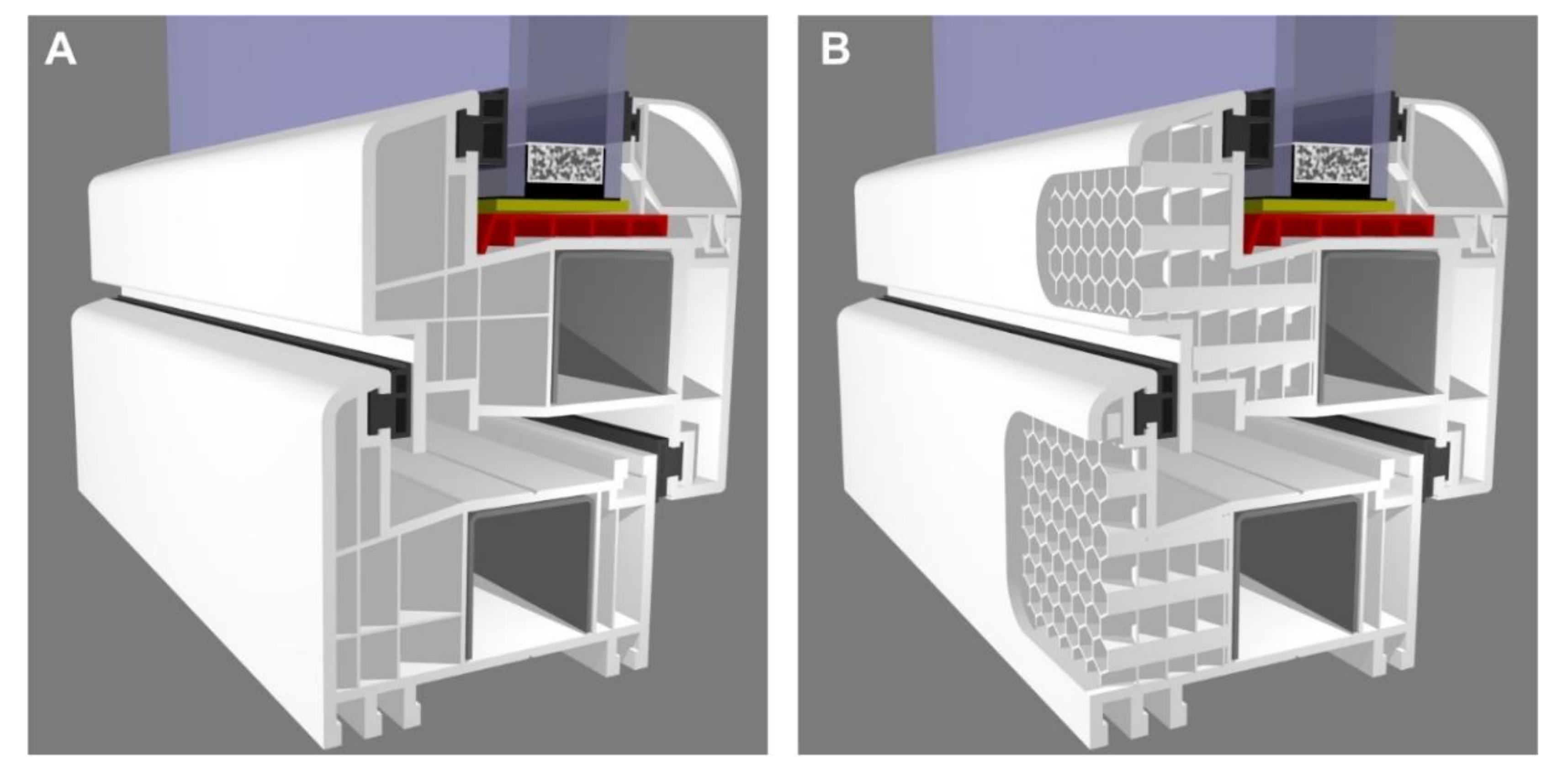

2.1. Practical Use Multilayer Insulation Material Made of Plastic with Thin Walls

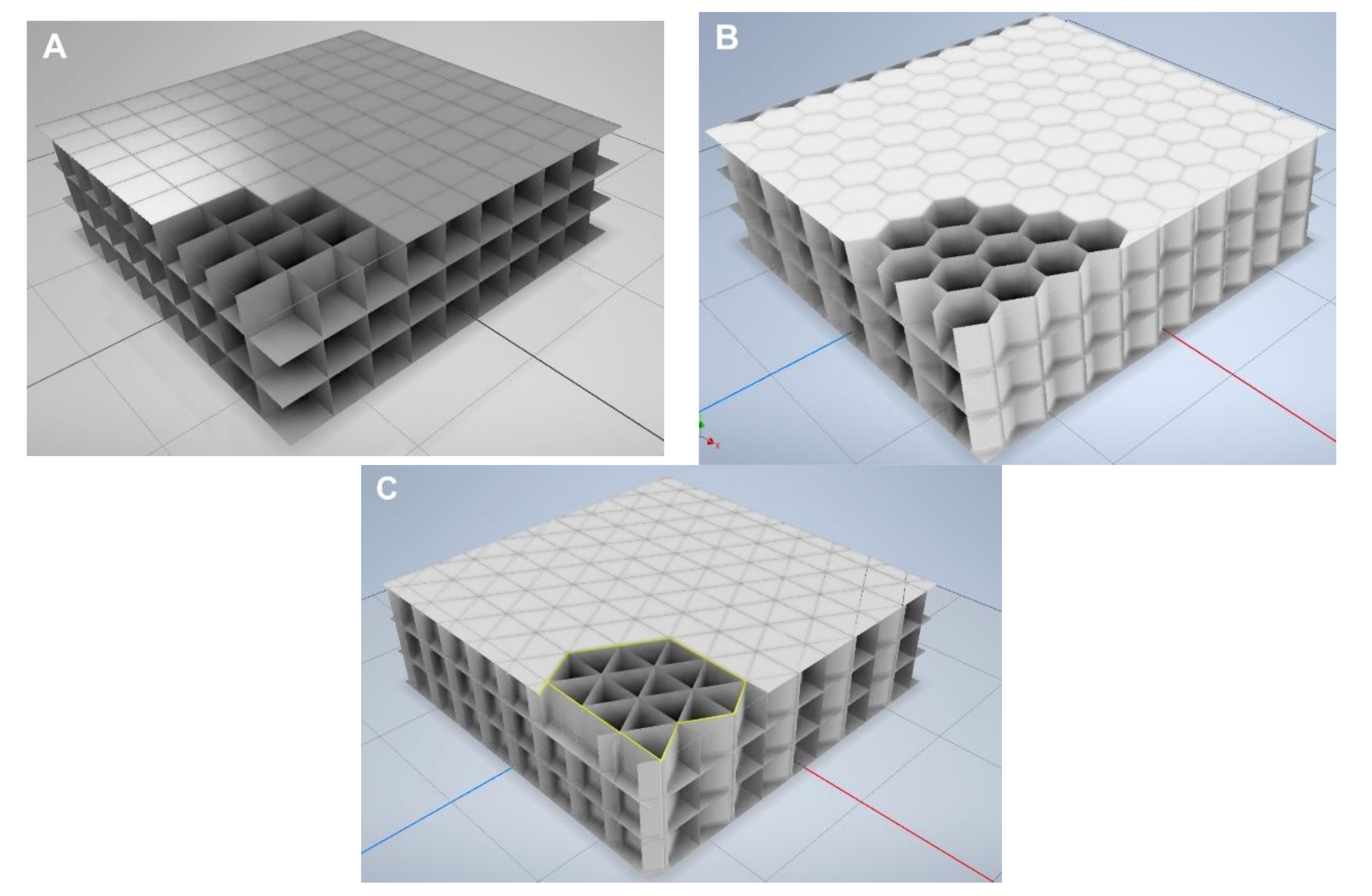

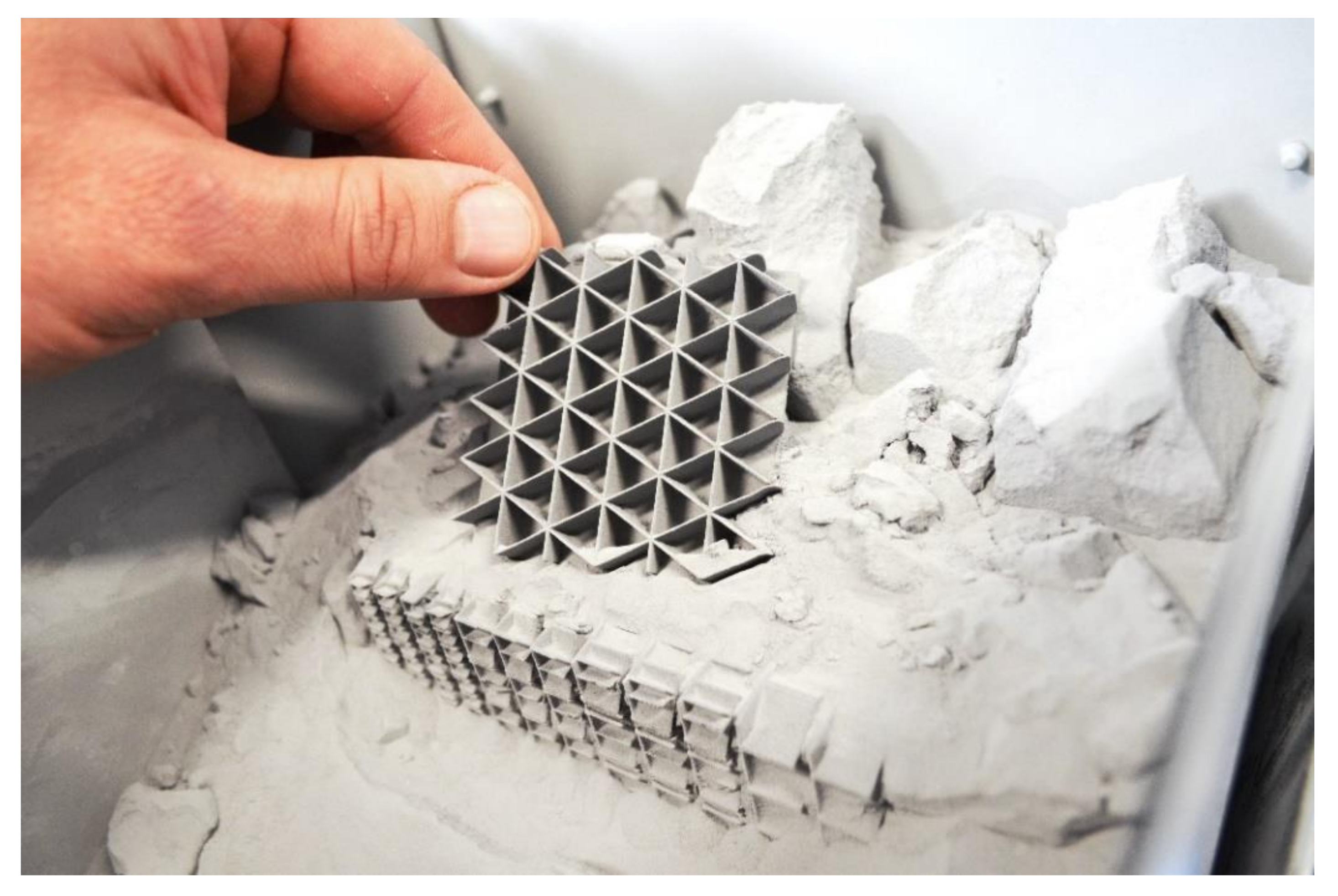

2.2. Design And 3D Printing of Multilayer Insulation

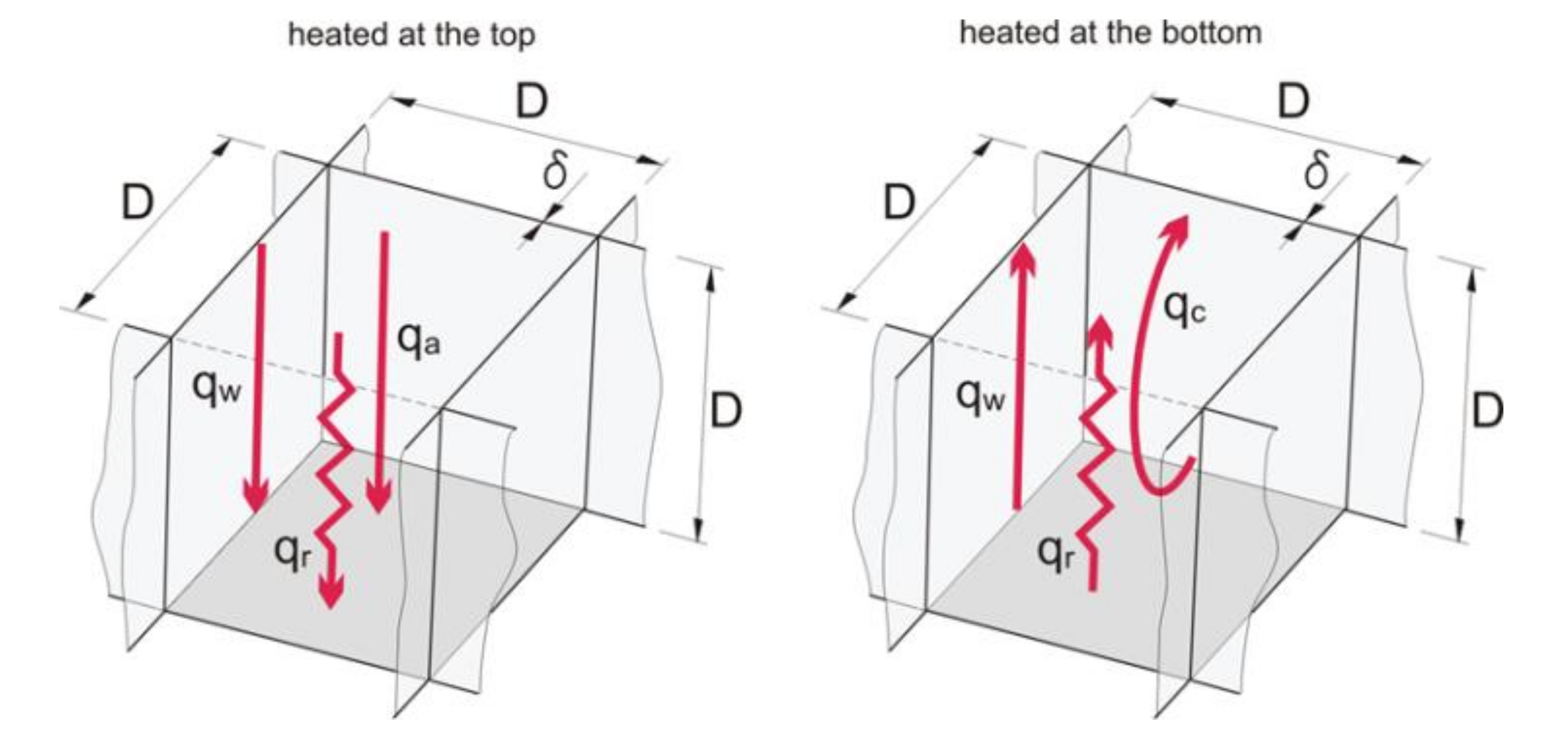

2.3. Mathematical Model

- qw—Heat conduction along plastic walls, W/m2,

- qa—Heat transfer through air,

- qc—Convective heat transfer, depending on the Rayleigh number value, W/m2,

- qr—radiation between layers, W/m2.

- TH—Temperature of hot side, K

- TC—Temperature of cold side, K

- n—Number of layers,

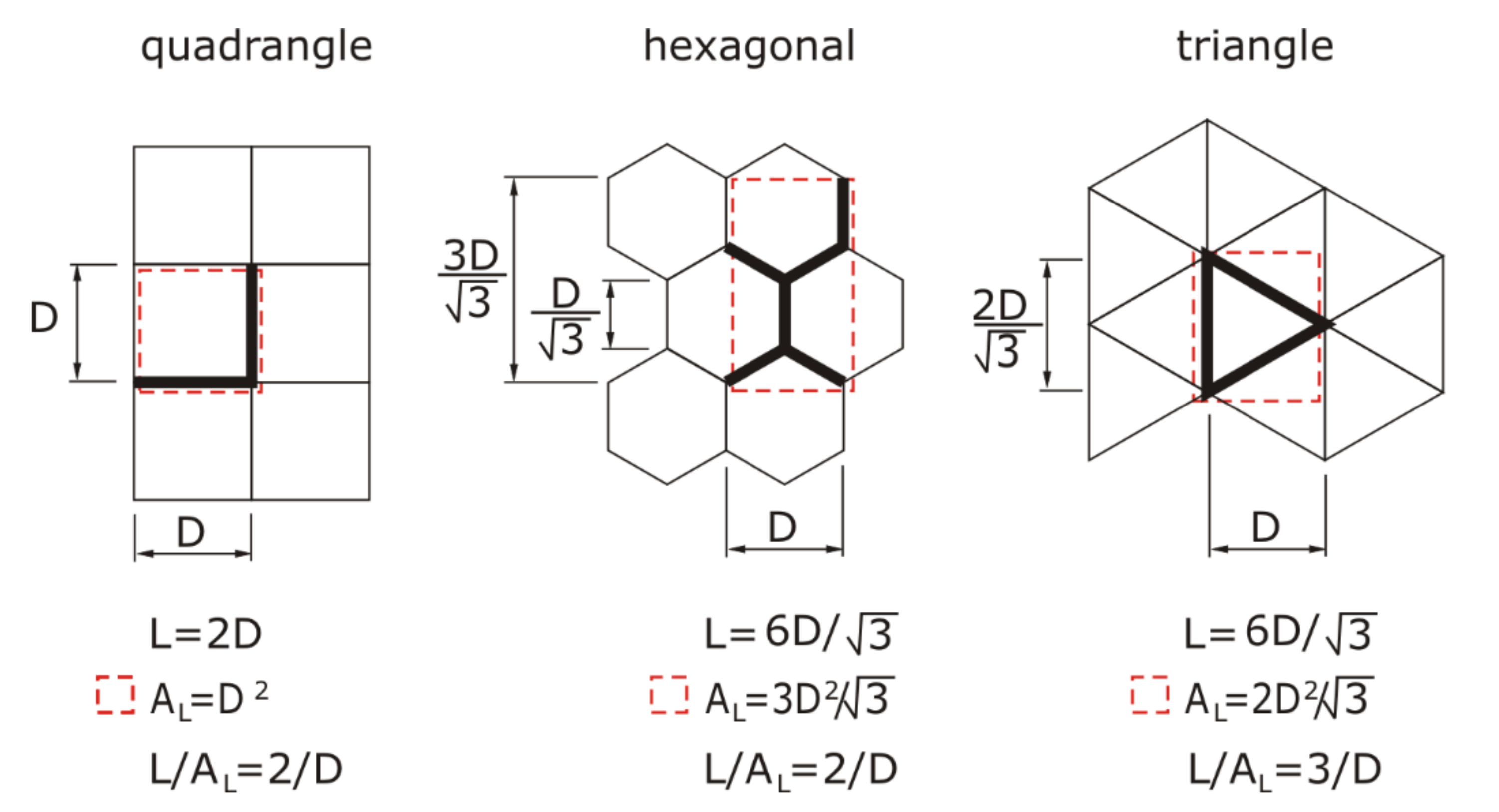

- D—Dimension of structure closure, m

- R—Thermal resistance, m2·K/W

- L—Wall length, m

- AL—Heat transfer area with walls that have length, L, m2

- Kw—Thermal conductivity of the wall material, W/(m·K)

- L/AL = 2/D for the quadrangle and hexagonal structures,

- L/AL = 3/D for the triangle structure.

- Ka—Thermal conductivity of air, W/(m·K)

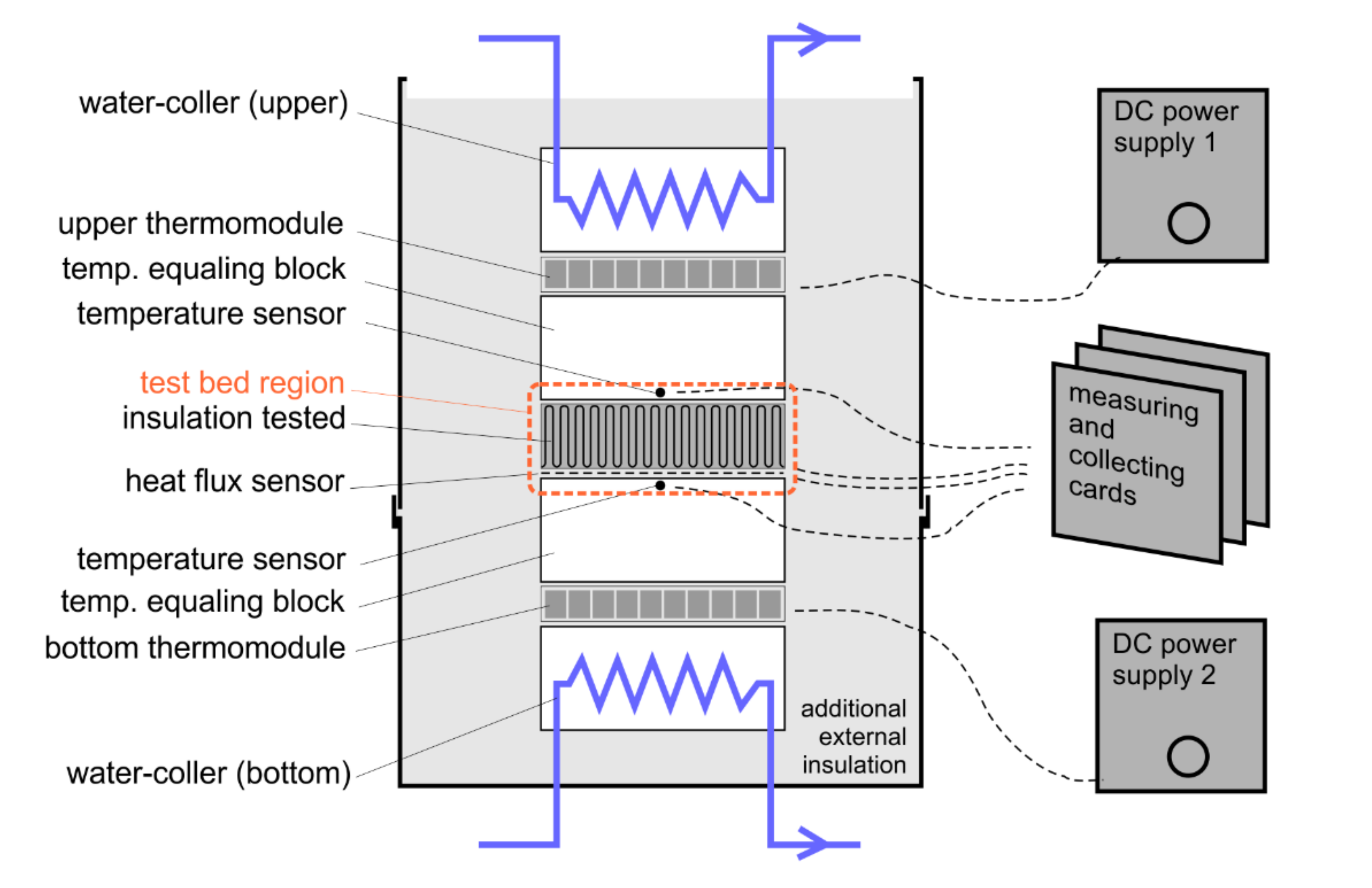

2.4. Experiments

- (a)

- heated at the top mode,

- (b)

- heated at the bottom mode.

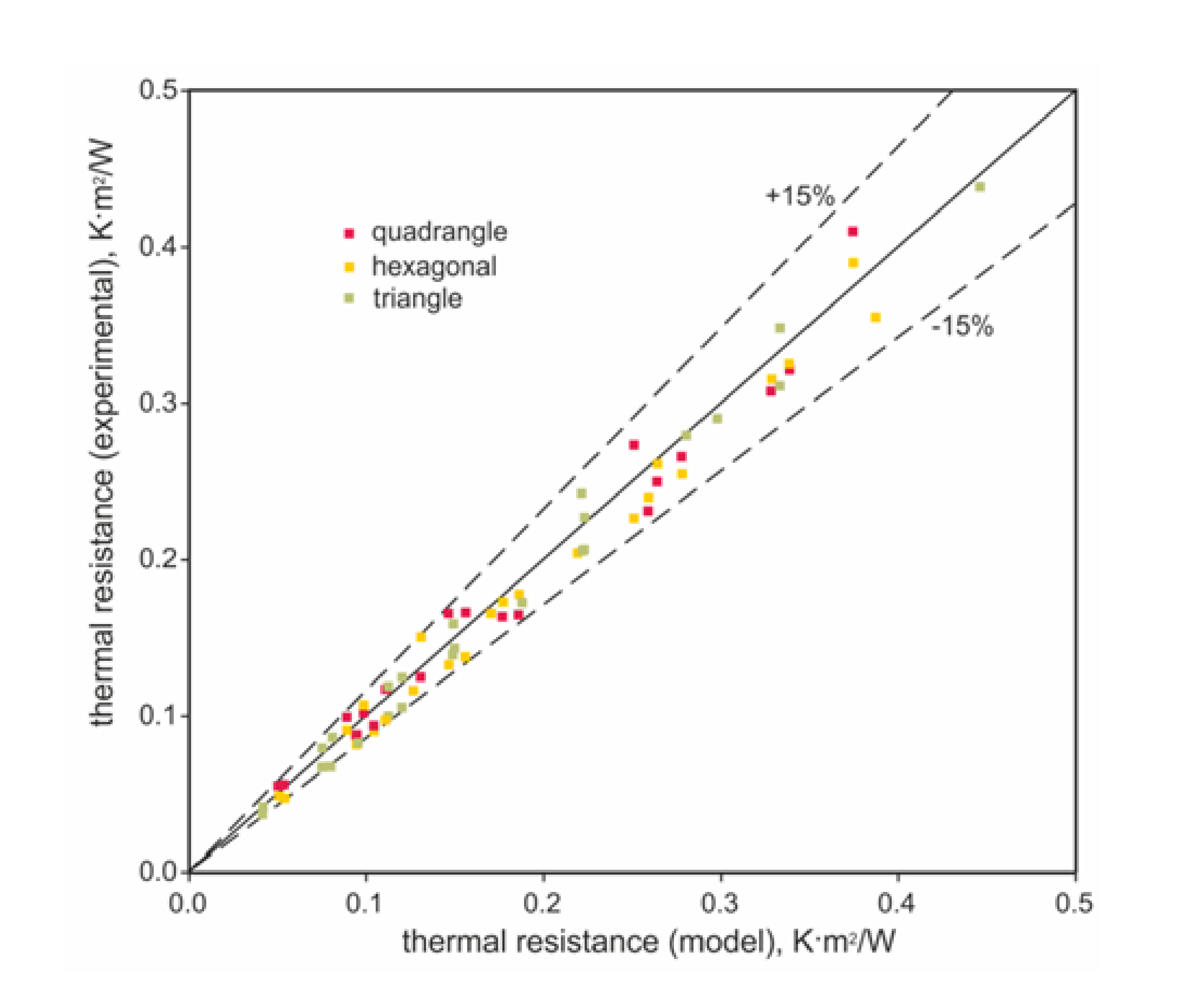

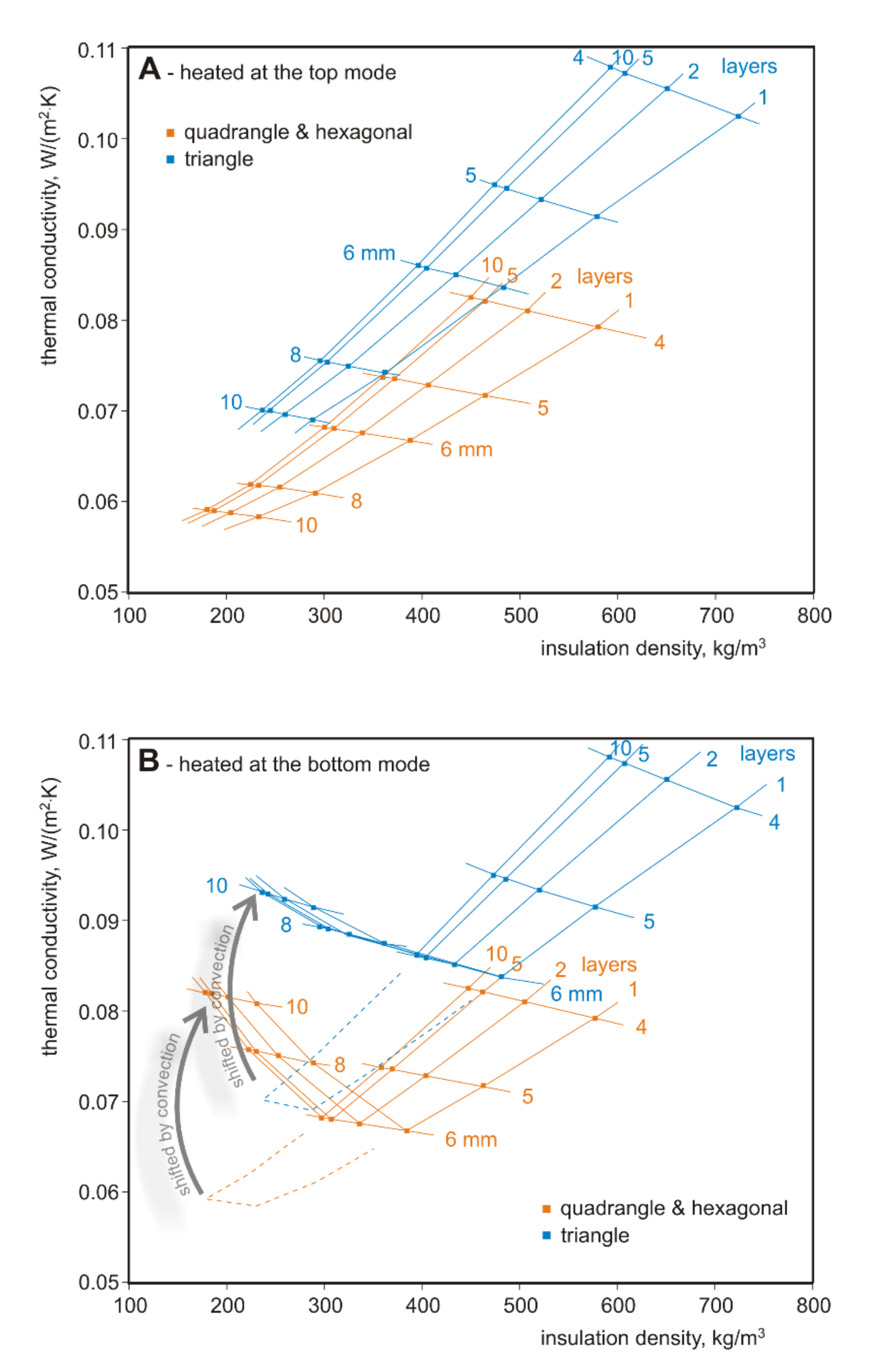

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| A | area of heat transfer, m2 |

| D | dimension of structure closure, m |

| H | multilayer insulation thickness, m |

| K | thermal conductivity, W/(m·K) |

| L | wall length, m |

| R | thermal resistance, m2·K/W |

| T | temperature, K |

| q | heat flux, W/m2 |

| Greek symbols | |

| δ | plastic wall thickness, m |

| ε | emissivity of plastic material |

| σ | Stefan–Boltzmann constant |

| Subscripts | |

| a | air |

| C | cooled side |

| c | convection |

| H | heated side |

| HB | heated at the bottom |

| HT | heated at the top |

| i | insulation |

| L | related to walls that have length L |

| n | number of layers |

| p | plastic |

| r | radiation |

| w | wall |

References

- Hasanzadeh, R.; Azdast, T.; Doniavi, A.; Eungkee, L.R. Thermal Conductivity of Low Density Polyethylene Foams Part I: Comprehensive Study of Theoretical Models. J. Therm. Sci. 2019, 28, 745–754. [Google Scholar]

- Hasanzadeh, R.; Azdast, T.; Doniavi, A. Thermal Conductivity of Low-Density Polyethylene Foams Part II: Deep Investigation using Response Surface Methodology. J. Therm. Sci. 2020, 29, 159–168. [Google Scholar] [CrossRef]

- Park, S.; Song, S.-Y. Evaluation of Alternatives for Improving the Thermal Resistance of Window Glazing Edges. Energies 2019, 12, 244. [Google Scholar] [CrossRef]

- Gustavsen, A.; Arasteh, D.; Jelle, B.P.; Curcija, C.; Kohler, C. Developing Low-conductance Window Frames: Capabilities and Limitations of Current Window Heat Transfer Design Tools—State-of-the-Art Review. J. Build. Phys. 2008, 2, 32. [Google Scholar] [CrossRef]

- Canessa, E.; Fonda, C.; Zennaro, M. Low Cost 3-D Printing for Science, Education & Sustainable Development; ICTP: Trieste, Italy, 2013. [Google Scholar]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Muülhaupt, R. Polymers for 3D Printing and Customized Additive. Manufacturing 2017, 117, 10212–10290. [Google Scholar]

- Yazdani Sarvestani, H.; Akbarzadeh, A.H.; Niknam, H.; Hermenean, K. 3D printed architected polymeric sandwich panels: Energy absorption and structural performance. Compos. Struct. 2018, 200, 886–909. [Google Scholar] [CrossRef]

- Tyczyński, P.; Siemiatkowski, Z.; Bąk, P.; Warzocha, K.; Rucki, M.; Szumiata, T. Performance of Maraging Steel Sleeves Produced by SLM with Subsequent Age Hardening. Materials 2020, 13, 3408. [Google Scholar] [CrossRef]

- Zhang, D.; Dong, Q. Fracturing and Damage of 3D-Printed Materials with Two Intermittent Fissures under Compression. Materials 2020, 13, 1607. [Google Scholar] [CrossRef]

- Park, S.A.; Lee, S.H.; Kim, W.D. Fabrication of porous polycaprolactone-hydroxyapatite (PCLHA) blend scaffolds using a 3D plotting system for bone tissue engineering. Bioprocess. Biosyst. Eng. 2011, 34, 505–513. [Google Scholar] [CrossRef]

- Little, J.P.; Horn, T.J.; Marcellin-Little, D.J.; Harrysson, O.L.A.; West, H.A., II. Development and validation of a canine radius replica for mechanical testing of orthopedic implants. Am. J. Vet. Res. 2012, 73, 27–33. [Google Scholar] [CrossRef]

- Tarafder, S.; Balla, V.K.; Davies, N.M.; Bandyopadhyay, A.; Bose, S. Microwave-sintered 3D printed tricalcium phosphate scaffolds for bone tissue engineering. J. Tissue Eng. Regen. Med. 2013, 7, 631–641. [Google Scholar] [CrossRef] [PubMed]

- Honiball, J.R. The Application of 3D Printing in Reconstructive Surgery. Master’s Thesis, University of Stellenbosch, Stellenbosch, South Africa, 2010. [Google Scholar]

- Tarfaoui, M.; Nachtane, M.; Goda, I.; Qureshi, Y.; Benyahia, H. 3D Printing to Support the Shortage in Personal Protective Equipment Caused by COVID-19 Pandemic. Materials 2020, 13, 3339. [Google Scholar] [CrossRef]

- Grabowska, B.; Kasperski, J. Modeling of thermal properties of thermal insulation layered with transparent, opaque and reflective film. J. Therm. Sci. 2018, 27, 463–469. [Google Scholar] [CrossRef]

- Wadley, H.N. Multifunctional periodic cellular metals. Phil. Trans. R. Soc. A 2006, 364, 31–68. [Google Scholar] [CrossRef]

- Petras, A.; Sutcliffe, M. Failure mode maps for honeycomb sandwich panels. Compos. Struct. 1999, 44, 237–252. [Google Scholar] [CrossRef]

- Rathbun, H.; Radford, D.D.; Xue, Z.; He, M.Y.; Yang, J.; Deshpande, V.; Fleck, N.A.; Hutchinson, J.W.; Zok, F.W.; Evans, A.G. Performance of metallic honeycomb-core sandwich beams under shock loading. Int. J. Solids Struct. 2006, 43, 1746–1763. [Google Scholar] [CrossRef]

- Buitrago, B.L.; Santiuste, C.; Sanchez-Saez, S.; Barbero, E. Modelling of composite sandwich structures with honeycomb core subjected to high- velocity impact. Compos. Struct. 2010, 92, 2090–2096. [Google Scholar] [CrossRef]

- Masters, I.; Evans, K. Models for the elastic deformation of honeycombs. Compos. Struct. 1996, 35, 403–422. [Google Scholar] [CrossRef]

- Meraghni, F.; Desrumaux, F.; Benzeggagh, M. Mechanical behaviour of cellular core for structural sandwich panels. Compos. A Appl. Sci. Manuf. 1999, 30, 767–779. [Google Scholar] [CrossRef]

- Becker, W. Closed-form analysis of the thickness effect of regular honeycomb core material. Compos. Struct. 2000, 48, 67–70. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Carter, W.B. Architected cellular materials. Annu. Rev. Mater. Res. 2016, 46, 187–210. [Google Scholar] [CrossRef]

- Bitzer, T. Honeycomb Technology: Materials, Design, Manufacturing, Applications and Testing; Springer Science & Business Media: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Abueidda, D.W.; Elhebeary, M.; Shiang, C.-S.; Pang, S.; Abu Al-Rub, R.K.; Jasiuk, I.M. Mechanical properties of 3D printed polymeric Gyroid cellular structures: Experimental and finite element study. Mater. Des. 2019, 165, 107597. [Google Scholar] [CrossRef]

- Kinstlinger, I.S.; Bastian, A.; Paulsen, S.J.; Hwang, D.H.; Ta, A.H.; Yalacki, D.R.; Schmidt, T.; Miller, J.S. Open-Source Selective Laser Sintering (OpenSLS) of Nylon and Biocompatible Polycaprolactone. PLoS ONE 2016, 2, 3. [Google Scholar] [CrossRef] [PubMed]

- Pelanconi, M.; Barbatoa, M.; Zavattoni, S.; Vignoles, G.L.; Ortona, A. Thermal design, optimization and additive manufacturing of ceramic regular structures to maximize the radiative heat transfer. Mater. Des. 2019, 163, 107539. [Google Scholar] [CrossRef]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—a new processing route for architects and builders. HAL 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Kasperski, J.; Grabowska, B. Optimizing the thermal effectiveness of an insulation wrap with internal folded polypropylene film for the transportation of frozen food. Int. J. Refrig. 2016, 67, 1–21. [Google Scholar] [CrossRef]

- Kasperski, J.; Grabowska, B. Effect of plastic film transmittance on heat transfer of a multi-layer structure made of rectangular air cells. Int. J. Refrig. 2018, 92, 1–21. [Google Scholar] [CrossRef]

- Roshenow, W.M.; Hartnett, J.P.; Cho, Y.I. Handbook of Heat Transfer; McGraw-Hill Education: New York, NY, USA, 1998. [Google Scholar]

| Structure | Quadrangle | Hexagonal | Triangle | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of layers | Dimension of closure, mm | Dimension of closure, mm | Dimension of closure, mm | |||||||||||

| 4 | 6 | 8 | 10 | 4 | 6 | 8 | 10 | 4 | 6 | 8 | 10 | |||

| Thermal resistance, m2K/W | Thermal resistance, m2K/W | Thermal resistance, m2K/W | ||||||||||||

| Heated at the top | Model | 1 | 0.050 | 0.090 | 0.131 | 0.171 | 0.050 | 0.090 | 0.131 | 0.171 | 0.039 | 0.072 | 0.108 | 0.144 |

| 2 | 0.099 | 0.178 | 0.260 | 0.340 | 0.099 | 0.178 | 0.260 | 0.340 | 0.076 | 0.141 | 0.213 | 0.287 | ||

| 3 | 0.147 | 0.265 | 0.389 | 0.509 | 0.147 | 0.265 | 0.389 | 0.509 | 0.113 | 0.210 | 0.318 | 0.429 | ||

| Experimental | 1 | 0.055 | 0.099 | 0.125 | 0.165 | 0.048 | 0.091 | 0.151 | 0.166 | 0.042 | 0.079 | 0.118 | 0.143 | |

| 2 | 0.102 | 0.163 | 0.230 | 0.320 | 0.106 | 0.172 | 0.238 | 0.324 | 0.086 | 0.158 | 0.226 | 0.289 | ||

| 3 | 0.166 | 0.248 | 0.354 | 0.470 | 0.132 | 0.260 | 0.354 | 0.476 | 0.124 | 0.242 | 0.310 | 0.437 | ||

| Discrepancies *, % | 1 | −8 | −9 | 5 | 4 | 5 | −1 | −13 | 3 | −7 | −10 | −9 | 1 | |

| 2 | −3 | 9 | 13 | 6 | −7 | 3 | 9 | 5 | −12 | −11 | −6 | −1 | ||

| 3 | −12 | 7 | 10 | 8 | 11 | 2 | 10 | 7 | −9 | −13 | 3 | −2 | ||

| Heated at the bottom | Model | 1 | 0.050 | 0.090 | 0.108 | 0.124 | 0.050 | 0.090 | 0.108 | 0.124 | 0.039 | 0.072 | 0.091 | 0.109 |

| 2 | 0.099 | 0.178 | 0.213 | 0.245 | 0.099 | 0.178 | 0.213 | 0.245 | 0.076 | 0.141 | 0.181 | 0.217 | ||

| 3 | 0.147 | 0.265 | 0.319 | 0.367 | 0.147 | 0.265 | 0.319 | 0.367 | 0.113 | 0.210 | 0.270 | 0.324 | ||

| Experimental | 1 | 0.056 | 0.087 | 0.116 | 0.116 | 0.047 | 0.078 | 0.097 | 0.116 | 0.036 | 0.067 | 0.082 | 0.099 | |

| 2 | 0.090 | 0.164 | 0.202 | 0.272 | 0.087 | 0.177 | 0.203 | 0.226 | 0.067 | 0.138 | 0.171 | 0.205 | ||

| 3 | 0.165 | 0.265 | 0.306 | 0.408 | 0.136 | 0.253 | 0.314 | 0.388 | 0.098 | 0.205 | 0.278 | 0.347 | ||

| Discrepancies *, % | 1 | −10 | 3 | −8 | 7 | 7 | 15 | 10 | 7 | 7 | 7 | 11 | 10 | |

| 2 | 10 | 8 | 5 | −10 | 14 | 0 | 5 | 9 | 13 | 2 | 6 | 6 | ||

| 3 | −11 | 0 | 4 | −10 | 8 | 5 | 1 | −6 | 15 | 3 | −3 | −7 | ||

| Structure | Quadrangle and Hexagonal | Triangle | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of | Dimension of closure, mm | Dimension of closure, mm | |||||||||

| layers | 4 | 5 | 6 | 8 | 10 | 4 | 5 | 6 | 8 | 10 | |

| Thermal resistance, m2K/W | Thermal resistance, m2K/W | ||||||||||

| Heated at the top | 1 | 0.050 | 0.070 | 0.090 | 0.131 | 0.171 | 0.039 | 0.055 | 0.072 | 0.108 | 0.144 |

| 2 | 0.099 | 0.137 | 0.178 | 0.260 | 0.340 | 0.076 | 0.107 | 0.141 | 0.213 | 0.287 | |

| 5 | 0.244 | 0.340 | 0.441 | 0.647 | 0.848 | 0.186 | 0.264 | 0.349 | 0.529 | 0.713 | |

| 10 | 0.485 | 0.677 | 0.880 | 1.292 | 1.693 | 0.370 | 0.526 | 0.696 | 1.056 | 1.424 | |

| Heated at the bottom | 1 | 0.050 | 0.070 | 0.090 | 0.108 | 0.124 | 0.039 | 0.055 | 0.072 | 0.091 | 0.109 |

| 2 | 0.099 | 0.137 | 0.178 | 0.213 | 0.245 | 0.076 | 0.107 | 0.141 | 0.181 | 0.217 | |

| 5 | 0.244 | 0.340 | 0.441 | 0.529 | 0.610 | 0.186 | 0.264 | 0.349 | 0.449 | 0.538 | |

| 10 | 0.485 | 0.677 | 0.880 | 1.057 | 1.218 | 0.370 | 0.526 | 0.696 | 0.895 | 1.074 | |

| Density, kg/m3 | Density, kg/m3 | ||||||||||

| Density | 1 | 580.5 | 464.4 | 387.0 | 290.3 | 232.2 | 725.6 | 580.5 | 483.8 | 362.8 | 290.3 |

| 2 | 507.9 | 406.4 | 338.6 | 254.0 | 203.2 | 653.1 | 522.5 | 435.4 | 326.5 | 261.2 | |

| 5 | 464.4 | 371.5 | 309.6 | 232.2 | 185.8 | 609.5 | 487.6 | 406.4 | 304.8 | 243.8 | |

| 10 | 449.9 | 359.9 | 299.9 | 224.9 | 180.0 | 595.0 | 476.0 | 396.7 | 297.5 | 238.0 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grabowska, B.; Kasperski, J. The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures. Materials 2020, 13, 4400. https://doi.org/10.3390/ma13194400

Grabowska B, Kasperski J. The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures. Materials. 2020; 13(19):4400. https://doi.org/10.3390/ma13194400

Chicago/Turabian StyleGrabowska, Beata, and Jacek Kasperski. 2020. "The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures" Materials 13, no. 19: 4400. https://doi.org/10.3390/ma13194400

APA StyleGrabowska, B., & Kasperski, J. (2020). The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures. Materials, 13(19), 4400. https://doi.org/10.3390/ma13194400