Characterisation of Wheat Straw Pellets Individually and in Combination with Cassava Starch or Calcium Carbonate under Various Compaction Conditions: Determination of Pellet Strength and Water Absorption Capacity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Material Moisture Content (MC)

2.3. Pellets Strength to Compressive Loads

2.4. Pellet Strength Parameters during Compression

2.5. Water Absorption

2.6. A Method for Optimising Compaction Conditions Due to the Pellets’ Strength and Their Water Absorption Capacity

2.7. Statistical Analysis

3. Results and Discussion

3.1. Research Results

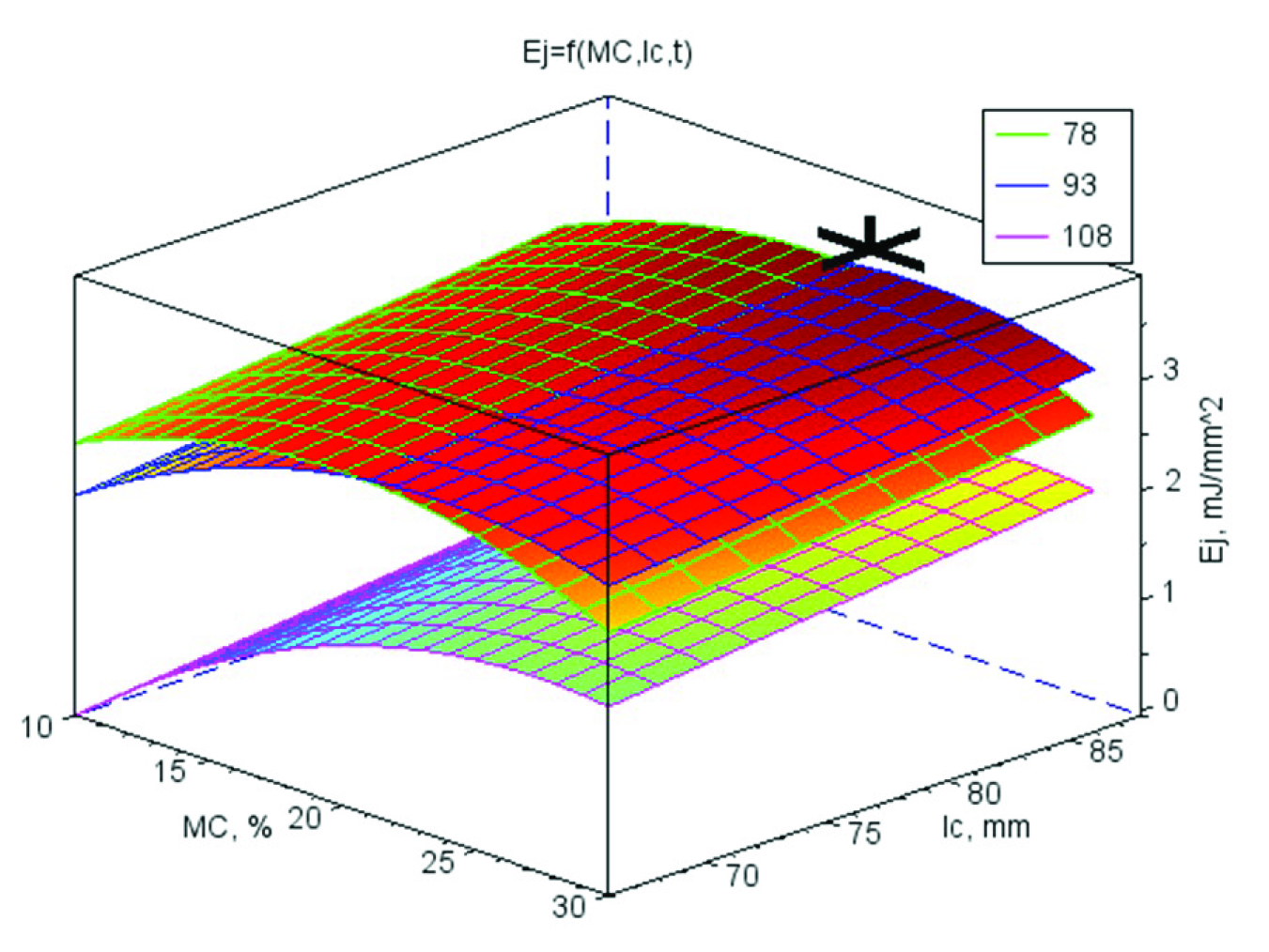

3.2. Specific Pellet Compression Work Ej

3.3. Elasticity Modulus for Pellet Compression E

3.4. Maximum Tensile Strength σc

3.5. Pellet Water Absorption k

3.6. Optimisation of Pelleting Conditions Due to Pellets Strength and Water Absorption

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | additive ratio (% wt/wt) |

| d | pellet diameter (mm) |

| E | elasticity modulus for pellet compression (MPa) |

| Ej | specific pellet compression work (mJ·mm−2) |

| F | compaction / compression force (N) |

| k | water absorption by crushed pellets (g H2O·g−1 DM) |

| lc | die height (mm) |

| lp | pellet length (mm) |

| MC | material moisture content (% w.b.) |

| pm | maximum agglomeration pressure (MPa) |

| t | material temperature (°C) |

| ρp | single pellet density (kg·m−3) |

| σc | maximum tensile strength (MPa) |

| CC | calcium carbonate |

| CS | cassava starch |

| WS | wheat straw |

References

- Bilgili, S.F.; Hess, J.B.; Blake, J.P.; Macklin, K.S.; Saenmahayak, B.; Sibley, J.L. Influence of bedding material on footpad dermatitis in broiler chickens. J. Appl. Poult. Res. 2009, 18, 583–589. [Google Scholar] [CrossRef]

- Kheravii, S.K.; Swick, R.A.; Choct, M.; Wu, S.B. Potential of pelleted wheat straw as an alternative bedding material for broilers. Poult. Sci. 2017, 96, 1641–1647. [Google Scholar] [CrossRef] [PubMed]

- Pearson, E.G.; Leavengood, S.; Reeb, J.E. Comparison of the absorptive capacity of shavings of western juniper, western redcedar, and Douglas-fir for animal bedding. For. Prod. J. 2000, 50, 57–60. [Google Scholar]

- Cengiz, Ö.; Hess, J.B.; Bilgili, S.F. Effect of bedding type and transient wetness on footpad dermatitis in broiler chickens. J. Appl. Poult. Res. 2011, 20, 554–560. [Google Scholar] [CrossRef]

- Makovskis, K.; Lazdina, D.; Arsanica, A.; Solodovniks, V. Mechanical durability and water absorption of pellets made from different tree species-a case study. Agron. Res. 2016, 14, 134–142. [Google Scholar]

- Zamri, M.H.; Akil, H.M.; Bakar, A.A.; Ishak, Z.A.M.; Cheng, L.W. Effect of water absorption on pultruded jute/glass fiber-reinforced unsaturated polyester hybrid composites. J. Compos. Mater. 2012, 46, 51–61. [Google Scholar] [CrossRef]

- Podlaski, S.Z.; Wzorek, H.; Chomontowski, C.M. Effects of the physicochemical properties of pellets on the germination of pelleted sugar beet seeds. Int. Agrophys. 2019, 33, 175–183. [Google Scholar] [CrossRef]

- Farhadi, D. Evaluation of the Physical and Chemical Properties of Some Agricultural Wastes as Poultry Litter Material. Glob. J. Anim. Sci. Res. J. Homepage 2014, 2, 270–276. [Google Scholar]

- White, M.; McLeod, J., III. Properties of Shredded Wood Pallets. For. Prod. J. 1989, 39, 50–54. [Google Scholar]

- Iroba, K.L.; Tabil, L.G.; Sokhansanj, S.; Meda, V. Producing durable pellets from barley straw subjected to radio frequency-alkaline and steam explosion pretreatments. Int. J. Agric. Biol. Eng. 2014, 7, 68–82. [Google Scholar] [CrossRef]

- van Dam, J.; van den Oever, M.J.A.; Teunissen, W.; Keijsers, E.R.P.; Peralta, A.G. Process for production of high density/high performance binderless boards from whole coconut husk. Part 1: Lignin as intrinsic thermosetting binder resin. Ind. Crop. Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Lehtikangas, P. Quality properties of pelletised sawdust, logging residues and bark. Biomass Bioenergy 2001, 20, 351–360. [Google Scholar] [CrossRef]

- Donghui, L.; Lope, T.G.; Decheng, W.; Guanghui, W.; Zhiqin, W. Optimization of binder addition and compression load for pelletization of wheat straw using response surface methodology. Int. J. Agric. Biol. Eng. 2014, 7, 67–78. [Google Scholar] [CrossRef]

- Matkowski, P.; Lisowski, A.; Świętochowski, A. Effect of compacted dose of pure straw and blends of straw with calcium carbonate or cassava starch on pelletising process and pellet quality. J. Clean. Prod. 2020, 277, 124006. [Google Scholar] [CrossRef]

- Matkowski, P.; Lisowski, A.; Świętochowski, A. Pelletising pure wheat straw and blends of straw with calcium carbonate or cassava starch at different moisture, temperature, and die height values: Modelling and optimisation. J. Clean. Prod. 2020, 272, 122955. [Google Scholar] [CrossRef]

- Probst, K.; Ambrose, K.; Pinto, R.L.; Bali, R.; Krishnakumar, P.; Ileleji, K. The effect of moisture content on the grinding performance of corn and corncobs by hammer milling. Am. Soc. Agric. Eng. 2013, 56, 1025–1033. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, K.; Sun, Y. Pelletizing Properties of Wheat Straw Blending with Rice Straw. Energy Fuels 2017, 31, 5126–5134. [Google Scholar] [CrossRef]

- Xia, X.; Zhang, K.; Xiao, H.; Xiao, S.; Song, Z.; Yang, Z. Effects of additives and hydrothermal pretreatment on the pelleting process of rice straw: Energy consumption and pellets quality. Ind. Crop. Prod. 2019, 133, 178–184. [Google Scholar] [CrossRef]

- Lisowski, A.; Olendzki, D.; Świętochowski, A.; Dąbrowska, M.; Mieszkalski, L.; Ostrowska-Ligęza, E.; Stasiak, M.; Klonowski, J.; Piątek, M. Spent coffee grounds compaction process: Its effects on the strength properties of biofuel pellets. Renew. Energy 2019, 142, 173–183. [Google Scholar] [CrossRef]

- Lisowski, A.; Pajor, M.; Świętochowski, A.; Dąbrowska, M.; Klonowski, J.; Mieszkalski, L.; Ekielski, A.; Stasiak, M.; Piątek, M. Effects of moisture content, temperature, and die thickness on the compaction process, and the density and strength of walnut shell pellets. Renew. Energy 2019, 141, 770–781. [Google Scholar] [CrossRef]

- Gilvari, H.; de Jong, W.; Schott, D.L. Quality parameters relevant for densification of bio-materials: Measuring methods and affecting factors—A review. Biomass Bioenergy 2019, 120, 117–134. [Google Scholar] [CrossRef]

- Gope, P.C. Maximum tangential stress coupled with probabilistic aspect of fracture toughness of hybrid bio-composite. Eng. Sci. Technol. Int. J. 2018, 21, 201–214. [Google Scholar] [CrossRef]

- Ndazi, B.; Tesha, J.V.; Bisanda, E.T.N. Some opportunities and challenges of producing bio-composites from non-wood residues. J. Mater. Sci. 2006, 41, 6984–6990. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Buyuksari, U.; Avci, E.; Koc, E. Utilization of pine (Pinus pinea L.) cone in manufacture of wood based composite. For. Ecol. Manag. 2009, 259, 65–70. [Google Scholar] [CrossRef]

- Breuninger, W.F.; Piyachomkwan, K.; Sriroth, K. Tapioca/Cassava Starch: Production and Use. In Starch; Elsevier Inc.: Amsterdam, The Netherlands, 2009; pp. 541–568. ISBN 9780127462752. [Google Scholar]

- Xu, H.; Zhou, S.; Jin, X.; Liu, Y. Monte Carlo simulation of the induction time and particle size distribution in the nucleation of calcium carbonate. Powder Technol. 2014, 253, 242–246. [Google Scholar] [CrossRef]

- Lisowski, A.; Dąbrowska-Salwin, M.; Ostrowska-Ligęza, E.; Nawrocka, A.; Stasiak, M.; Świętochowski, A.; Klonowski, J.; Sypuła, M.; Lisowska, B. Effects of the biomass moisture content and pelleting temperature on the pressure-induced agglomeration process. Biomass Bioenergy 2017, 107, 376–383. [Google Scholar] [CrossRef]

- Ishii, K.; Furuichi, T. Influence of moisture content, particle size and forming temperature on productivity and quality of rice straw pellets. Waste Manag. 2014, 34, 2621–2626. [Google Scholar] [CrossRef]

- Lam, P.Y.; Lam, P.S.; Sokhansanj, S.; Bi, X.T.; Lim, C.J.; Melin, S. Effects of pelletization conditions on breaking strength and dimensional stability of Douglas fir pellet. Fuel 2014, 117, 1085–1092. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. Bioresources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- Lisowski, A.; Kostrubiec, M.; Dąbrowska-Salwin, M.; Świętochowski, A. The Characteristics of Shredded Straw and Hay Biomass—Part 1—Whole Mixture. Waste Biomass Valoriz. 2018, 9, 853–859. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Larsson, S.H.; Samuelsson, R. Prediction of ISO 17831-1:2015 mechanical biofuel pellet durability from single pellet characterization. Fuel Process. Technol. 2017, 163, 8–15. [Google Scholar] [CrossRef]

- Temmerman, M.; Rabier, F.; Jensen, P.D.; Hartmann, H.; Böhm, T. Comparative study of durability test methods for pellets and briquettes. Biomass Bioenergy 2006, 30, 964–972. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, V.R. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Sedláček, P.; Mucha, N.; Pečtová, I.; Fečko, P. Ekologické pelety z hnědého uhlí a biomasy. Acta Montan. Slovaca Ročník 2007, 12, 274–277. [Google Scholar]

- Hammes, F.; Boon, N.; de Villiers, J.; Verstraete, W.; Siciliano, S.D. Strain-specific ureolytic microbial calcium carbonate precipitation. Appl. Environ. Microbiol. 2003, 69, 4901–4909. [Google Scholar] [CrossRef]

- Burt, C.D.; Cabrera, M.L.; Rothrock, M.J.; Kissel, D.E. Urea Hydrolysis and Calcium Carbonate Precipitation in Gypsum-Amended Broiler Litter. J. Environ. Qual. 2018, 47, 162–169. [Google Scholar] [CrossRef]

- Magnus, A.E.; Ini, D.C.; Ayoade, K. Characterisation and comparison of rice husk briquettes with cassava peels and cassava starch as binders. Biofuels 2016, 7, 671–675. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Oyewusi, T.F.; Osunbitan, J.A.; Ogunjimi, L.A.O. Effect of binder type, binder concentration and compacting pressure on some physical properties of carbonized corncob briquette. Energy Rep. 2019, 5, 909–918. [Google Scholar] [CrossRef]

| Level | Moisture Content, MC, % w.b. | Material Temperature, t, °C | Die Height, lc, mm | Additive Ratio, A, % | Additive Type |

|---|---|---|---|---|---|

| 1 | 10 | 78 | 66 | 0 | CS |

| 2 | 20 | 93 | 76 | 2 | CC |

| 3 | 30 | 108 | 86 | 6 | – |

| 4 | – | – | – | 10 | – |

| Factor | ρp, kg m−3 | Ej, mJ·mm−2 | E, MPa | σc, MPa | k, g H2O·g−1 DM |

|---|---|---|---|---|---|

| p-value | |||||

| Additive | 0.0285 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| A | <0.0001 | 0.0523 | 0.5438 | 0.2428 | <0.0001 |

| MC | <0.0001 | 0.0002 | <0.0001 | <0.0001 | <0.0001 |

| lc | <0.0001 | <0.0001 | 0.4100 | <0.0001 | <0.0001 |

| t | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Mean and ± SD for type of additive | |||||

| WS | 490 c* ± 23 | 2.53 b ± 0.19 | 4.62 b ± 0.30 | 1.95 b ± 0.17 | 5.45 c ± 0.16 |

| CS | 405 a ± 11 | 1.28 a ± 0.08 | 7.42 c ± 0.26 | 1.23 a ± 0.09 | 2.24 a ± 0.04 |

| CC | 475 b ± 18 | 2.66 b ± 0.20 | 2.39 a ± 0.12 | 2.11 b ± 0.15 | 4.80 b ± 0.11 |

| Mean and ± SD for additive ratio A (% wt/wt) | |||||

| 0 | 490 c ± 23 | 2.53 c ± 0.19 | 4.62 a ± 0.30 | 1.95 a ± 0.17 | 5.45 c ± 0.16 |

| 2 | 446 b ± 18 | 2.07 b ± 0.19 | 5.19 a ± 0.32 | 1.75 a ± 0.15 | 3.56 b ± 0.15 |

| 6 | 430 a ± 18 | 1.92 a ± 0.19 | 4.80 a ± 0.31 | 1.68 a ± 0.15 | 3.69 b ± 0.15 |

| 10 | 443 ab ± 19 | 1.92 a ± 0.21 | 4.73 a ± 0.32 | 1.58 a ± 0.15 | 3.30 a ± 0.12 |

| Mean and ± SD for material moisture content MC (% w.b.) | |||||

| 10 | 372 a ± 15 | 1.12 a ± 0.11 | 4.12 a ± 0.24 | 0.85 a ± 0.09 | 4.40 c ± 0.14 |

| 20 | 495 c ± 19 | 2.51 b ± 0.20 | 4.73 b ± 0.25 | 1.98 b ± 0.15 | 3.35 a ± 0.11 |

| 30 | 479 b ± 14 | 2.57 b ± 0.17 | 5.71 c ± 0.32 | 2.31 c ± 0.14 | 3.64 b ± 0.14 |

| Mean and ± SD for die height lc (mm) | |||||

| 66 | 402 a ± 15 | 1.81 a ± 0.17 | 4.75 a ± 0.30 | 1.43 a ± 0.13 | 4.00 c ± 0.15 |

| 76 | 479 c ± 17 | 2.12 b ± 0.18 | 4.98 a ± 0.27 | 1.83 b ± 0.14 | 3.83 b ± 0.14 |

| 86 | 466 b ± 17 | 2.28 b ± 0.17 | 4.84 a ± 0.26 | 1.90 b ± 0.14 | 3.56 a ± 0.12 |

| Mean and ± SD for material temperature t (°C) | |||||

| 78 | 542 c ± 18 | 2.60 b ± 0.19 | 5.25 b ± 0.28 | 2.25 b ± 0.15 | 3.35 a ± 0.12 |

| 93 | 494 b ± 16 | 2.57 b ± 0.19 | 5.83 c ± 0.27 | 2.11 b ± 0.15 | 3.60 b ± 0.12 |

| 108 | 310 a ± 10 | 1.03 a ± 0.08 | 3.48 a ± 0.25 | 0.79 a ± 0.07 | 4.44 c ± 0.15 |

| ρp | Ej | E | σc | k | |

|---|---|---|---|---|---|

| Wheat straw (WS) | |||||

| MC, % | 13.2 | 30.0 | 23.2 | 30.0 | 10.0 |

| lc, mm | 86.0 | 86.0 | 86.0 | 86.0 | 66.0 |

| t, °C | 78.9 | 91.6 | 91.2 | 90.9 | 108 |

| Optimum value | 785 kg·m−3 | 4.64 mJ·mm−2 | 8.69 MPa | 3.56 MPa | 6.99 g H2O·g−1 DM |

| Wheat straw and cassava starch (WS + CS) | |||||

| A, % | 0.00 | 0.00 | 0.00 | 4.00 | 6.10 |

| MC, % | 30.0 | 30.0 | 30.0 | 30.0 | 10.0 |

| lc, mm | 73.3 | 71.0 | 66.0 | 76.1 | 66.0 |

| t, °C | 78.0 | 78.0 | 87.8 | 78.0 | 81.2 |

| Optimum value | 682 kg·m−3 | 2.30 mJ·mm−2 | 11.96 MPa | 3.16 MPa | 3.15 g H2O·g−1 DM |

| Wheat straw and calcium carbonate (WS + CC) | |||||

| A, % | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| MC, % | 18.1 | 16.1 | 10.0 | 16.9 | 10.0 |

| lc, mm | 86.0 | 71.0 | 86.0 | 71.0 | 66.0 |

| t, °C | 78.0 | 78.0 | 78.0 | 78.0 | 108.0 |

| Optimum value | 853 kg·m−3 | 6.10 mJ·mm−2 | 5.54 MPa | 4.17 MPa | 6.99 g H2O·g−1 DM |

| For all | |||||

| A, % | 4.00 | 0.00 | 4.00 | 4.00 | 0.00 |

| MC, % | 23.3 | 21.6 | 30.0 | 30.0 | 10.0 |

| lc, mm | 78.5 | 86.0 | 71.0 | 86.0 | 66.0 |

| t, °C | 80.2 | 86.0 | 88.5 | 87.6 | 108.0 |

| Optimum value | 633 kg·m−3 | 3.66 mJ·mm−2 | 6.77 MPa | 3.06 MPa | 6.28 g H2O·g−1 DM |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matkowski, P.; Lisowski, A.; Świętochowski, A. Characterisation of Wheat Straw Pellets Individually and in Combination with Cassava Starch or Calcium Carbonate under Various Compaction Conditions: Determination of Pellet Strength and Water Absorption Capacity. Materials 2020, 13, 4375. https://doi.org/10.3390/ma13194375

Matkowski P, Lisowski A, Świętochowski A. Characterisation of Wheat Straw Pellets Individually and in Combination with Cassava Starch or Calcium Carbonate under Various Compaction Conditions: Determination of Pellet Strength and Water Absorption Capacity. Materials. 2020; 13(19):4375. https://doi.org/10.3390/ma13194375

Chicago/Turabian StyleMatkowski, Patryk, Aleksander Lisowski, and Adam Świętochowski. 2020. "Characterisation of Wheat Straw Pellets Individually and in Combination with Cassava Starch or Calcium Carbonate under Various Compaction Conditions: Determination of Pellet Strength and Water Absorption Capacity" Materials 13, no. 19: 4375. https://doi.org/10.3390/ma13194375

APA StyleMatkowski, P., Lisowski, A., & Świętochowski, A. (2020). Characterisation of Wheat Straw Pellets Individually and in Combination with Cassava Starch or Calcium Carbonate under Various Compaction Conditions: Determination of Pellet Strength and Water Absorption Capacity. Materials, 13(19), 4375. https://doi.org/10.3390/ma13194375