Modeling of Mechanical Properties of Clay-Reinforced Polymer Nanocomposites Using Deep Neural Network

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Nanocomposites

2.3. Characterization

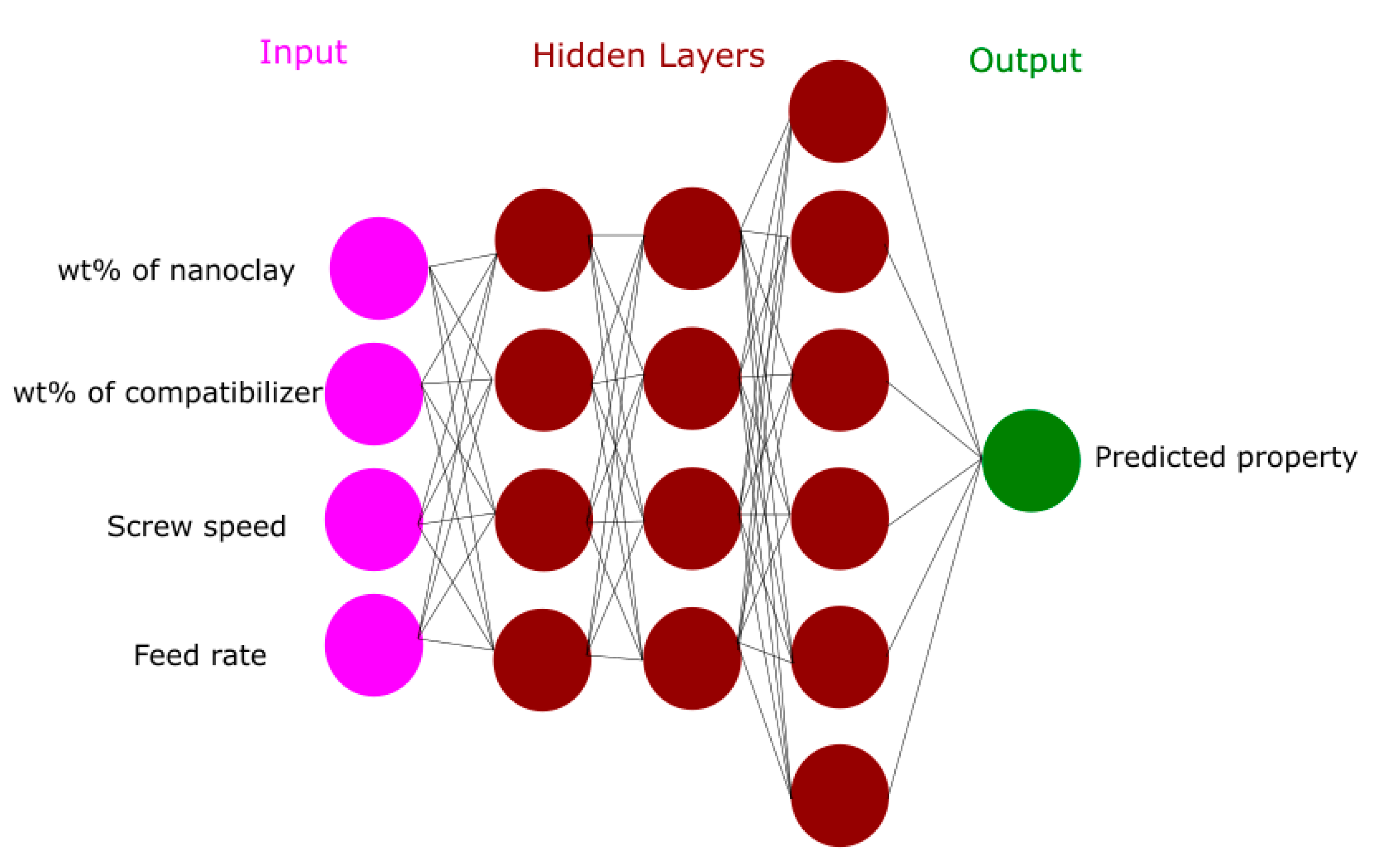

3. Deep Neural Network

4. Results and Discussion

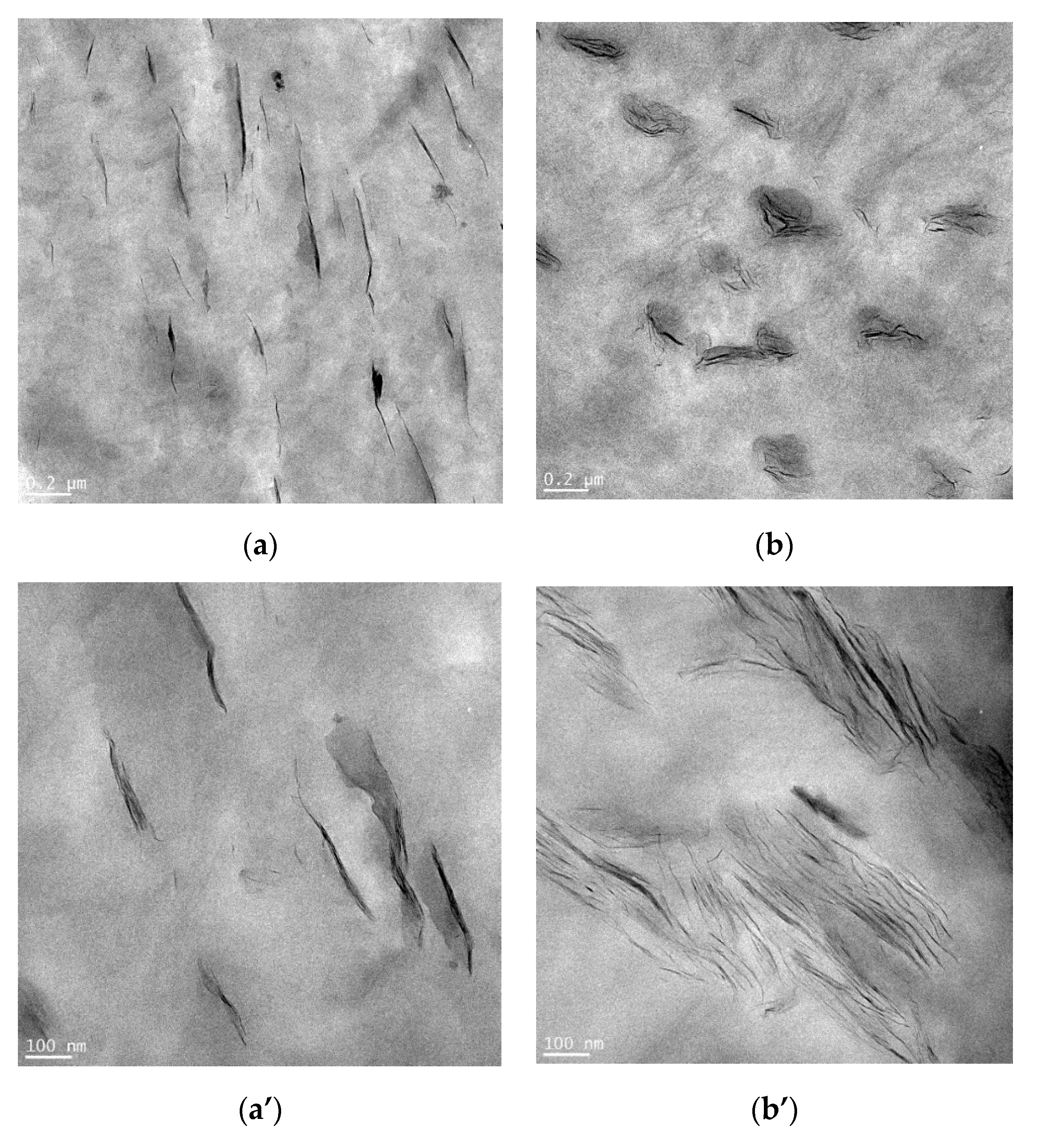

4.1. Microstructure Analysis

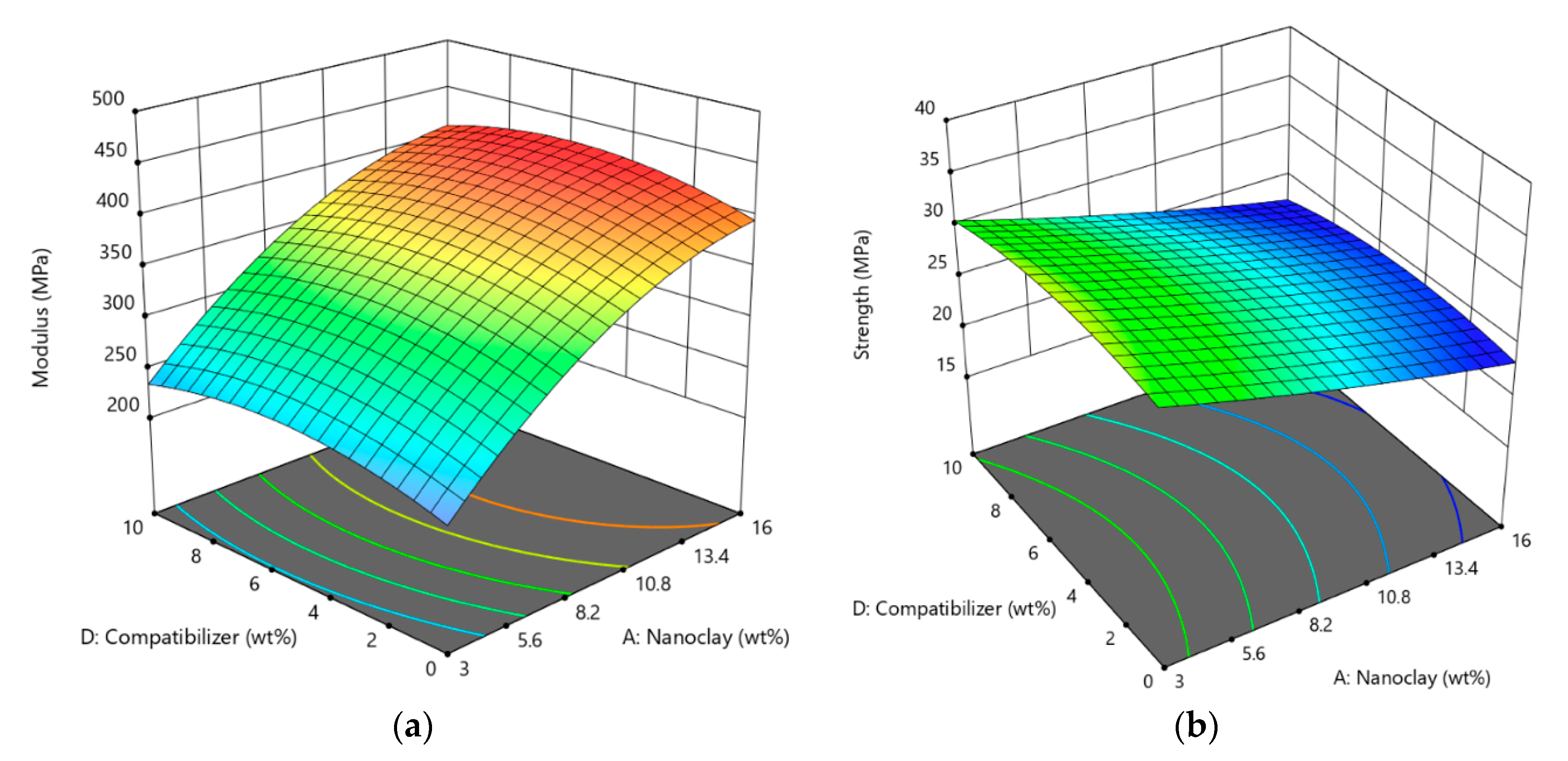

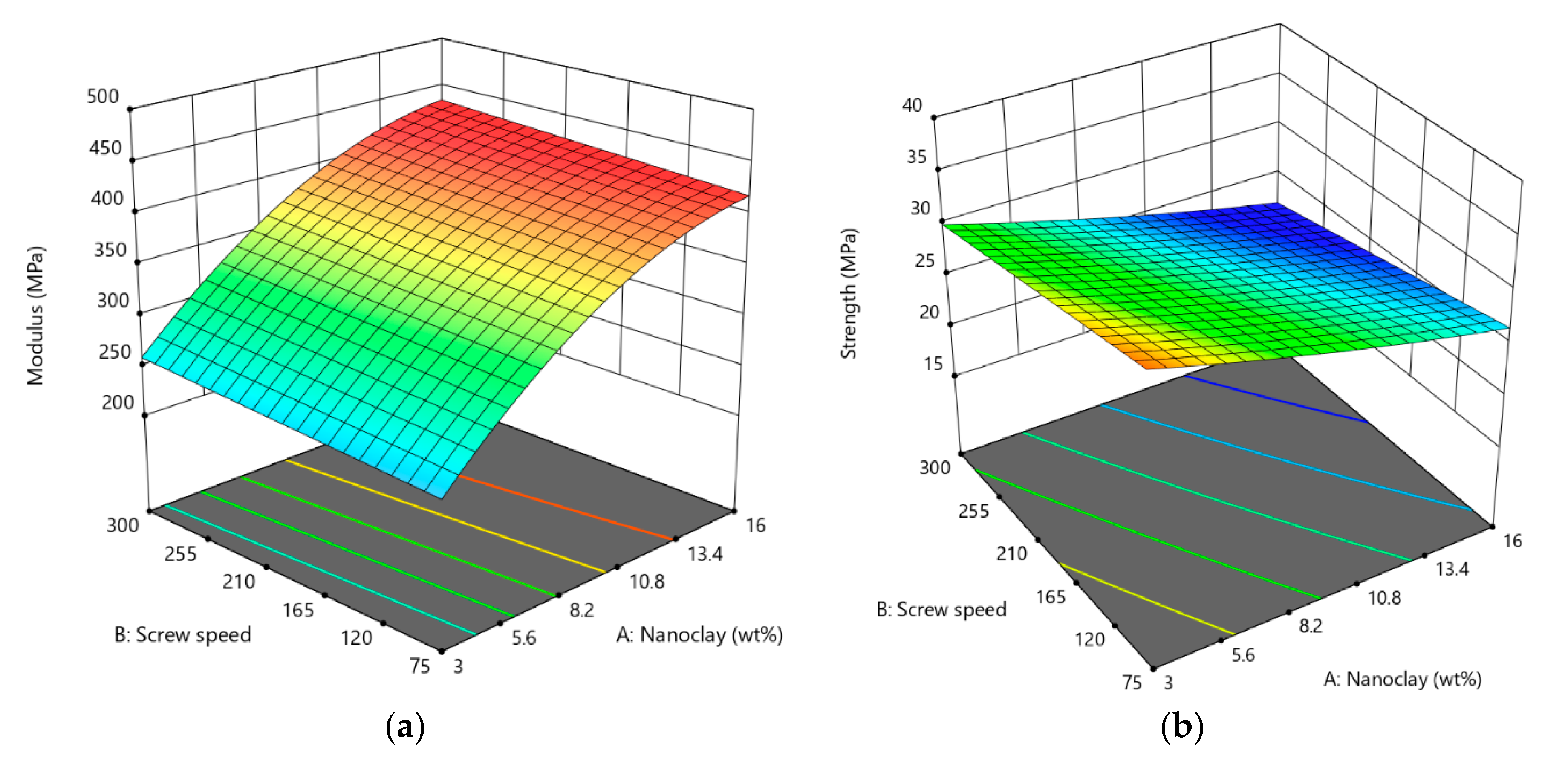

4.2. Mechanical Testing

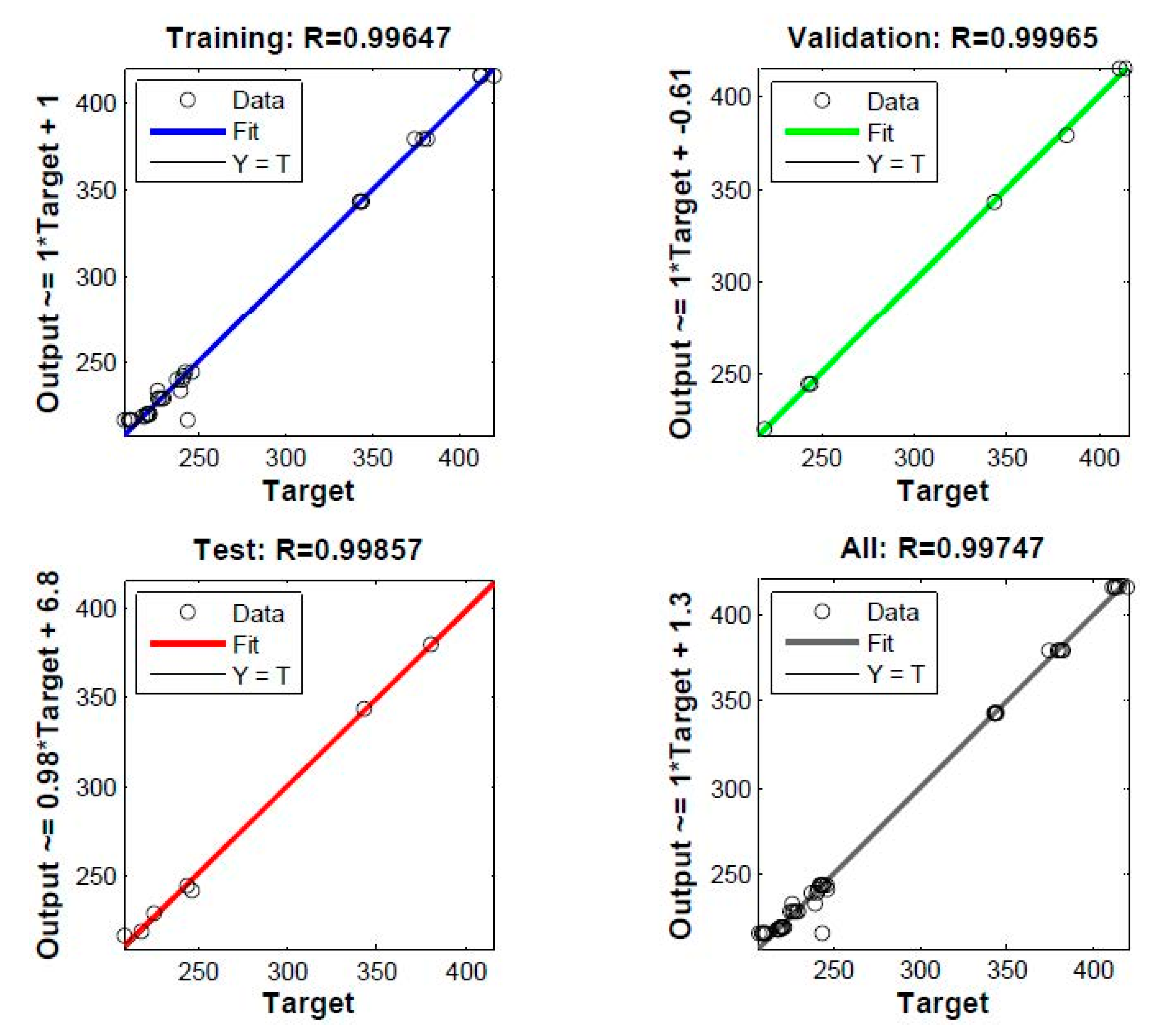

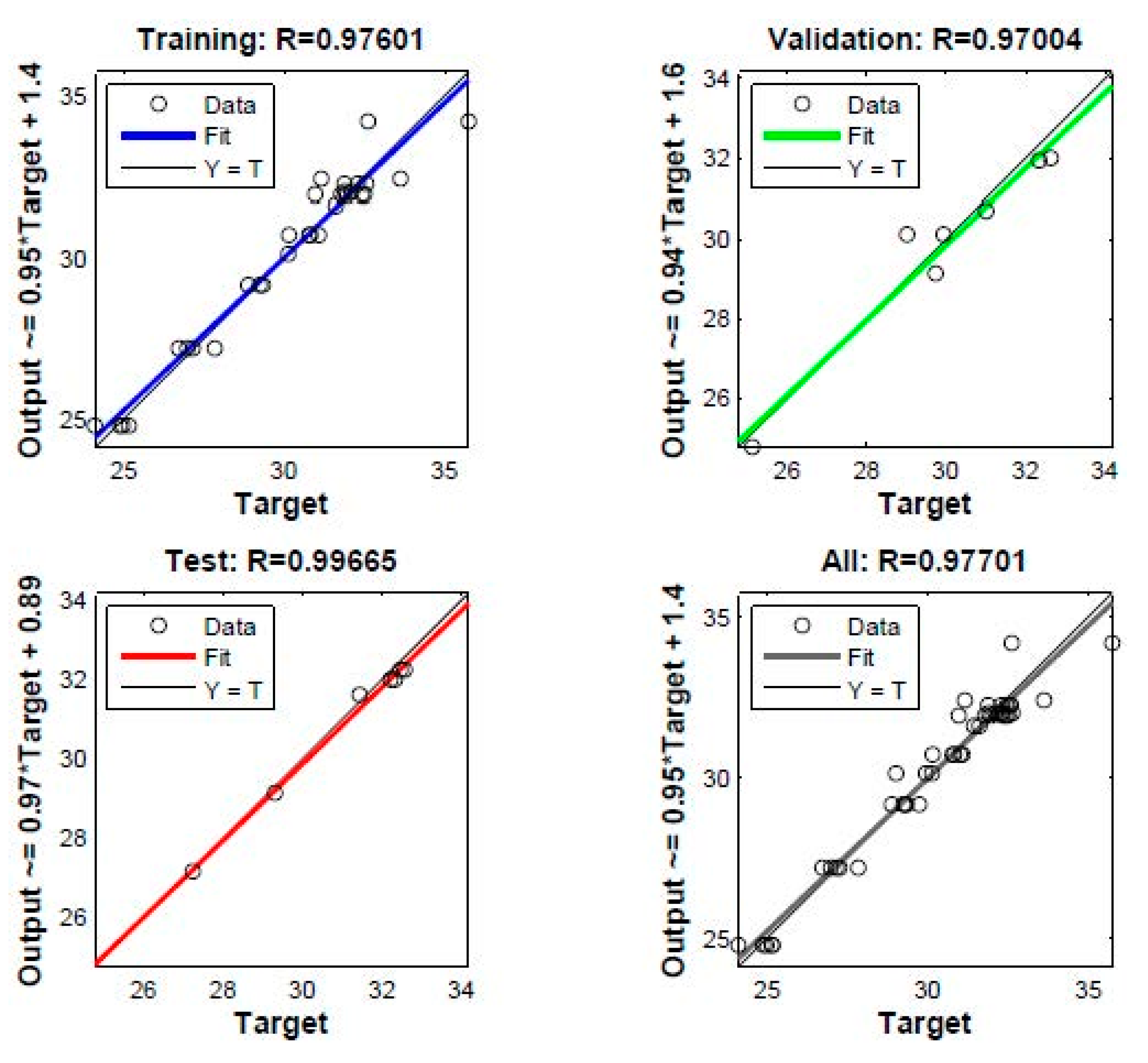

4.3. Validation of Neural Networks Model

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kawasumi, M.; Hasegawa, N.; Kato, M.; Usuki, A.; Okada, A. Preparation and mechanical properties of polypropylene-clay hybrids. Macromolecules 1997, 30, 6333–6338. [Google Scholar] [CrossRef]

- Tan, H.; Yang, W. Toughening mechanisms of nano-composite ceramics. Mech. Mater 1998, 30, 111–123. [Google Scholar] [CrossRef]

- Han, Y.; Wang, Z.; Li, X.; Fu, J.; Cheng, Z. Polymer-layered Silicate Nanocomposites: Synthesis, Characterization, Properties and Applications. Curr. Trends Polym. Sci. 2001, 6, 1–16. [Google Scholar]

- Kornmann, X.; Lindberg, H.; Berglund, L.A. Synthesis of epoxy–clay nanocomposites: Influence of the nature of the clay on structure. Polymer 2001, 42, 1303–1310. [Google Scholar] [CrossRef]

- Utracki, L.; Kamal, M. Clay-containing polymeric nanocomposites. Arab. J. Sci. Eng. 2004, 27, 43–67. [Google Scholar]

- Hotta, S.; Paul, D. Nanocomposites formed from linear low density polyethylene and organoclays. Polymer 2004, 45, 7639–7654. [Google Scholar] [CrossRef]

- Zhao, K.; He, K. Dielectric relaxation of suspensions of nanoscale particles surrounded by a thick electric double layer. Phys. Rev. B 2006, 74, 205319. [Google Scholar] [CrossRef] [Green Version]

- Awaji, H.; Nishimura, Y.; Choi, S.M.; Takahashi, Y.; Goto, T.; Hashimoto, S. Toughening mechanism and frontal process zone size of ceramics. J. Ceram. Soc. Jpn. 2009, 117, 623–629. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Chen, G. Relaxation behavior study of silicone rubber crosslinked network under static and dynamic compression by electric response. Polym. Compos. 2009, 30, 101–106. [Google Scholar] [CrossRef]

- Kim, P.; Doss, N.M.; Tillotson, J.P.; Hotchkiss, P.J.; Pan, M.J.; Marder, S.R.; Li, J.; Calame, J.P.; Perry, J.W. High energy density nanocomposites based on surface-modified BaTiO3 and a ferroelectric polymer. ACS Nano 2009, 3, 2581–2592. [Google Scholar] [CrossRef]

- Salom, C.; Prolongo, M.G.; Toribio, A.; Martínez-Martínez, A.J.; de Cárcer, I.A.; Prolongo, S.G. Mechanical properties and adhesive behavior of epoxy-graphene nanocomposites. Int. J. Adhes. Adhes. 2018, 84, 119–125. [Google Scholar] [CrossRef]

- Ajayan, P.M. Nanotubes from carbon. Chem. Rev. 1999, 99, 1787–1800. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Fan, Z.; Zhang, Z.; Niu, W.; Li, C.; Yang, N.; Chen, B.; Zhang, H. Two-dimensional metal nanomaterials: Synthesis, properties, and applications. Chem. Rev. 2018, 118, 6409–6455. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Chhowalla, M.; Liu, Z. 2D nanomaterials: Graphene and transition metal dichalcogenides. Chem. Soc. Rev. 2018, 47, 3015–3017. [Google Scholar] [CrossRef] [PubMed]

- Osman, M.A.; Rupp, J.E.P.; Suter, U.W. Tensile properties of polyethylene-layered silicate nanocomposites. Polymer 2005, 46, 1653–1660. [Google Scholar] [CrossRef]

- Varela, C.; Rosales, C.; Perera, R.; Matos, M.; Poirier, T.; Blunda, J.; Rojas, H. Functionalized polypropylenes in the compatibilization and dispersion of clay nanocomposites. Polym. Compos. 2006, 27, 451–460. [Google Scholar] [CrossRef]

- López-Quintanilla, M.; Sánchez-Valdés, S.; De Valle, L.R.; Miranda, R.G. Preparation and mechanical properties of PP/PP-g-MA/Org.-MMT nanocomposites with different MA content. Polym. Bull. 2006, 57, 385–393. [Google Scholar]

- Diaconescu, R.-M.; Barbuta, M.; Harja, M. Prediction of properties of polymer concrete composite with tire rubber using neural networks. Mater. Sci. Eng. B 2013, 178, 1259–1267. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A.; Ozsahin, S. Artificial neural network modeling to effect of reinforcement properties on the physical and mechanical properties of Al2024–B₄C composites produced by powder metallurgy. Composites 2013, 54, 224–233, ISSN:1359-8368. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A.; Ozsahin, S. Prediction of effect of reinforcement content, flake size and flake time on the density and hardness of flake AA2024-SiC nanocomposites using neural networks. J. Alloys. Compd. 2018, 739, 1005–1014. [Google Scholar] [CrossRef]

- Hassani, A.; Khataee, A.; Fathinia, M.; Karaca, S. Photocatalytic ozonation of ciprofloxacin from aqueous solution using TiO2/MMT nanocomposite: Nonlinear modeling and optimization of the process via artificial neural network integrated genetic algorithm. Process Saf. Environ. Prot. 2018, 116, 365–376. [Google Scholar] [CrossRef]

- Khan, W.S.; Hamadneh, N.N.; Khan, W.A. Prediction of thermal conductivity of polyvinylpyrrolidone (PVP) electrospun nanocomposite fibers using artificial neural network and prey-predator algorithm. PLoS ONE 2017, 12, e0183920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakhaei, M.R.; Mostafapour, A.; Naderi, G. Optimization of mechanical properties of PP/EPDM/clay nanocomposite fabricated by friction stir processing with response surface methodology and neural networks. Polym. Compos. 2017, 38, E421–E432. [Google Scholar] [CrossRef]

- Khademi, F.; Akbari, M.; Jamal, S.M.; Nikoo, M. Multiple linear regression, artificial neural network, and fuzzy logic prediction of 28 days compressive strength of concrete. Front. Struct. Civ. Eng. 2017, 11, 90–99. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Z.; Liu, Z. Application of artificial neural networks for catalysis: A review. Catalysts 2017, 7, 306. [Google Scholar] [CrossRef]

- Askari, H.; Ghaedi, M.; Dashtian, K.; Azghandi, M.H.A. Rapid and high-capacity ultrasonic assisted adsorption of ternary toxic anionic dyes onto MOF-5-activated carbon: Artificial neural networks, partial least squares, desirability function and isotherm and kinetic study. Ultrason. Sonochem. 2017, 37, 71–82. [Google Scholar] [CrossRef] [PubMed]

- Bayraktar, Ö.; Uzun, G.; Çakiroğlu, R.; Guldas, A. Experimental study on the 3D-printed plastic parts and predicting the mechanical properties using artificial neural networks. Polym. Adv. Technol. 2017, 28, 1044–1051. [Google Scholar] [CrossRef]

- Heidari, B.S.; Oliaei, E.; Shayesteh, H.; Davachi, S.M.; Hejazi, I.; Seyfi, J.; Bahrami, M.; Rashedi, H. Simulation of mechanical behavior and optimization of simulated injection molding process for PLA based antibacterial composite and nanocomposite bone screws using central composite design. J. Mech. Behav. Biomed. Mater. 2017, 65, 160–176. [Google Scholar] [CrossRef]

- Thapliyal, A.; Khar, R.K.; Chandra, A. Artificial Neural Network Modelling of Green Synthesised Silver Nanoparticles in Bentonite/Starch Bio-nanocomposite. Curr. Nanosci. 2018, 14, 239–251. [Google Scholar] [CrossRef]

- Zeraati, M.; Khayati, G.R. Optimization of micro hardness of nanostructure Cu-Cr-Zr alloys prepared by the mechanical alloying using artificial neural networks and genetic algorithm. J. Ultrafine Grained Nanostruct. Mater. 2018, 51, 183–192. [Google Scholar]

- Vogl, T.P.; Mangis, J.K.; Rigler, A.K.; Zink, W.T.; Alkon, D.L. Accelerating the convergence of the back-propagation method. Biol. Cybern. 1988, 59, 257–263. [Google Scholar] [CrossRef]

- Rojas, R. Neural Networks—A Systematic Introduction; Springer: New York, NY, USA, 1996. [Google Scholar]

- Pater, L. Application of artificial neural networks and genetic algorithms for crude fractional distillation process modeling. arXiv 2016, arXiv:1605.00097. [Google Scholar]

- Ghaboussi, J.; Wu, X.; Kaklauskas, G. Neural Network Material Modelling. Statyba 1999, 5, 250–257. [Google Scholar] [CrossRef] [Green Version]

- Marquardt, D.W. An algorithm for least-squares estimation of nonlinear parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Zazoum, B.; David, E.; Ngô, A.D. LDPE/HDPE/Clay Nanocomposites: Effects of Compatibilizer on the Structure and Dielectric Response. J. Nanotechnol. 2013, 2013, 138457. [Google Scholar] [CrossRef] [Green Version]

- Venkatesh, G.; Deb, A.; Karmarkar, A.; Chauhan, S.S. Effect of nanoclay content and compatibilizer on viscoelastic properties of montmorillonite/polypropylene nanocomposites. Mater. Des. 2012, 37, 285–291. [Google Scholar] [CrossRef]

- Huitric, J.; Ville, J.; Mederic, P.; Aubry, T. Solid-state mechanical properties of PE/PA blends filled with organoclay or compatibilized by a graft co-polymer: A comparative study. Polym. Test. 2018, 70, 208–214. [Google Scholar] [CrossRef]

- Uhl, F.M.; Davuluri, S.P.; Wong, S.C.; Webster, D.C. Organically modified montmorillonites in UV curable urethane acrylate films. Polymer 2004, 45, 6175–6187. [Google Scholar] [CrossRef]

- Taguet, A.; Huneault, M.A.; Favis, B.D. Interface/morphology relationships in polymer blends with thermoplastic starch. Polymer 2009, 50, 5733–5743. [Google Scholar] [CrossRef]

| Specimen Number | LLDPE Fraction (wt.%) | Nanoclay Fraction (wt.%) | Compatibilizer Fraction (wt.%) | Screw Speed (rpm) | Feed Rate (kg/h) | Tensile Strength (MPa) | Tensile Modulus (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 97 | 3 | 0 | 150 | 0.8 | 29.94 | 219.36 |

| 2 | 97 | 3 | 0 | 150 | 0.8 | 30.12 | 218.11 |

| 3 | 97 | 3 | 0 | 150 | 0.8 | 29.01 | 217.67 |

| 4 | 97 | 3 | 0 | 150 | 1.2 | 32.34 | 209.52 |

| 5 | 97 | 3 | 0 | 150 | 1.2 | 32.43 | 211.42 |

| 6 | 97 | 3 | 0 | 150 | 1.2 | 31.98 | 208.74 |

| 7 | 97 | 3 | 0 | 150 | 1.2 | 31.78 | 207.15 |

| 8 | 97 | 3 | 0 | 150 | 1.2 | 30.96 | 210.12 |

| 9 | 97 | 3 | 0 | 150 | 1.6 | 32.22 | 220.34 |

| 10 | 97 | 3 | 0 | 150 | 1.6 | 32.10 | 221.87 |

| 11 | 97 | 3 | 0 | 150 | 1.6 | 32.32 | 219.23 |

| 12 | 97 | 3 | 0 | 150 | 1.6 | 32.63 | 220.91 |

| 13 | 97 | 3 | 0 | 150 | 1.6 | 31.89 | 220.17 |

| 14 | 95 | 3 | 2 | 150 | 1.2 | 32.61 | 246.45 |

| 15 | 92 | 3 | 5 | 150 | 1.2 | 31.15 | 237.27 |

| 16 | 87 | 3 | 10 | 150 | 1.2 | 31.43 | 226.12 |

| 17 | 97 | 3 | 0 | 150 | 1.2 | 32.51 | 243.48 |

| 18 | 95 | 3 | 2 | 150 | 1.2 | 35.75 | 241.15 |

| 19 | 92 | 3 | 5 | 150 | 1.2 | 33.63 | 240.27 |

| 20 | 87 | 3 | 10 | 150 | 1.2 | 31.61 | 239.37 |

| 21 | 95 | 3 | 2 | 75 | 0.8 | 32.57 | 228.48 |

| 22 | 95 | 3 | 2 | 75 | 0.8 | 32.30 | 227.12 |

| 23 | 95 | 3 | 2 | 75 | 0.8 | 32.47 | 225.17 |

| 24 | 95 | 3 | 2 | 75 | 0.8 | 31.88 | 226.72 |

| 25 | 95 | 3 | 2 | 75 | 0.8 | 32.56 | 229.82 |

| 26 | 95 | 3 | 2 | 300 | 1.6 | 30.82 | 243.65 |

| 27 | 95 | 3 | 2 | 300 | 1.6 | 31.01 | 245.87 |

| 28 | 95 | 3 | 2 | 300 | 1.6 | 30.78 | 242.72 |

| 29 | 95 | 3 | 2 | 300 | 1.6 | 31.08 | 244.14 |

| 30 | 95 | 3 | 2 | 300 | 1.6 | 30.14 | 242.12 |

| 31 | 90 | 8 | 2 | 150 | 1.2 | 29.23 | 343.23 |

| 32 | 90 | 8 | 2 | 150 | 1.2 | 29.34 | 344.23 |

| 33 | 90 | 8 | 2 | 150 | 1.2 | 29.73 | 342.89 |

| 34 | 90 | 8 | 2 | 150 | 1.2 | 28.87 | 342.75 |

| 35 | 90 | 8 | 2 | 150 | 1.2 | 29.30 | 343.10 |

| 36 | 86 | 12 | 2 | 150 | 1.2 | 27.15 | 380.26 |

| 37 | 86 | 12 | 2 | 150 | 1.2 | 27.24 | 378.98 |

| 38 | 86 | 12 | 2 | 150 | 1.2 | 26.98 | 382.17 |

| 39 | 86 | 12 | 2 | 150 | 1.2 | 27.83 | 381.42 |

| 40 | 86 | 12 | 2 | 150 | 1.2 | 26.72 | 374.23 |

| 41 | 82 | 16 | 2 | 150 | 1.2 | 25.15 | 412.37 |

| 42 | 82 | 16 | 2 | 150 | 1.2 | 25.13 | 414.23 |

| 43 | 82 | 16 | 2 | 150 | 1.2 | 24.97 | 411.87 |

| 44 | 82 | 16 | 2 | 150 | 1.2 | 24.09 | 420.00 |

| 45 | 82 | 16 | 2 | 150 | 1.2 | 24.87 | 410.72 |

| Specimen Number | 2 | 6 | 14 | 23 | 26 | 33 | 36 |

|---|---|---|---|---|---|---|---|

| Measured Modulus (MPa) | 218.11 | 208.74 | 246.45 | 225.17 | 243.65 | 342.89 | 380.26 |

| Predicted Modulus (MPa) | 218.57 | 216.17 | 241.61 | 228.79 | 244.17 | 343.33 | 379.32 |

| Relative Error (%) | 0.20 | 3.60 | 1.96 | 1.60 | 0.21 | 0.13 | 0.24 |

| Specimen Number | 9 | 11 | 16 | 21 | 23 | 35 | 37 |

|---|---|---|---|---|---|---|---|

| Measured Strength (MPa) | 32.22 | 32.32 | 31.43 | 32.57 | 32.47 | 29.3 | 27.24 |

| Predicted Strength (MPa) | 31.99 | 31.99 | 31.61 | 32.24 | 32.24 | 29.14 | 27.16 |

| Relative Error (%) | 0.70 | 1.00 | 0.57 | 0.99 | 0.69 | 0.52 | 0.26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zazoum, B.; Triki, E.; Bachri, A. Modeling of Mechanical Properties of Clay-Reinforced Polymer Nanocomposites Using Deep Neural Network. Materials 2020, 13, 4266. https://doi.org/10.3390/ma13194266

Zazoum B, Triki E, Bachri A. Modeling of Mechanical Properties of Clay-Reinforced Polymer Nanocomposites Using Deep Neural Network. Materials. 2020; 13(19):4266. https://doi.org/10.3390/ma13194266

Chicago/Turabian StyleZazoum, Bouchaib, Ennouri Triki, and Abdel Bachri. 2020. "Modeling of Mechanical Properties of Clay-Reinforced Polymer Nanocomposites Using Deep Neural Network" Materials 13, no. 19: 4266. https://doi.org/10.3390/ma13194266

APA StyleZazoum, B., Triki, E., & Bachri, A. (2020). Modeling of Mechanical Properties of Clay-Reinforced Polymer Nanocomposites Using Deep Neural Network. Materials, 13(19), 4266. https://doi.org/10.3390/ma13194266