Real-Time Optimization of Anti-Reflective Coatings for CIGS Solar Cells

Abstract

1. Introduction

2. Materials and Methods

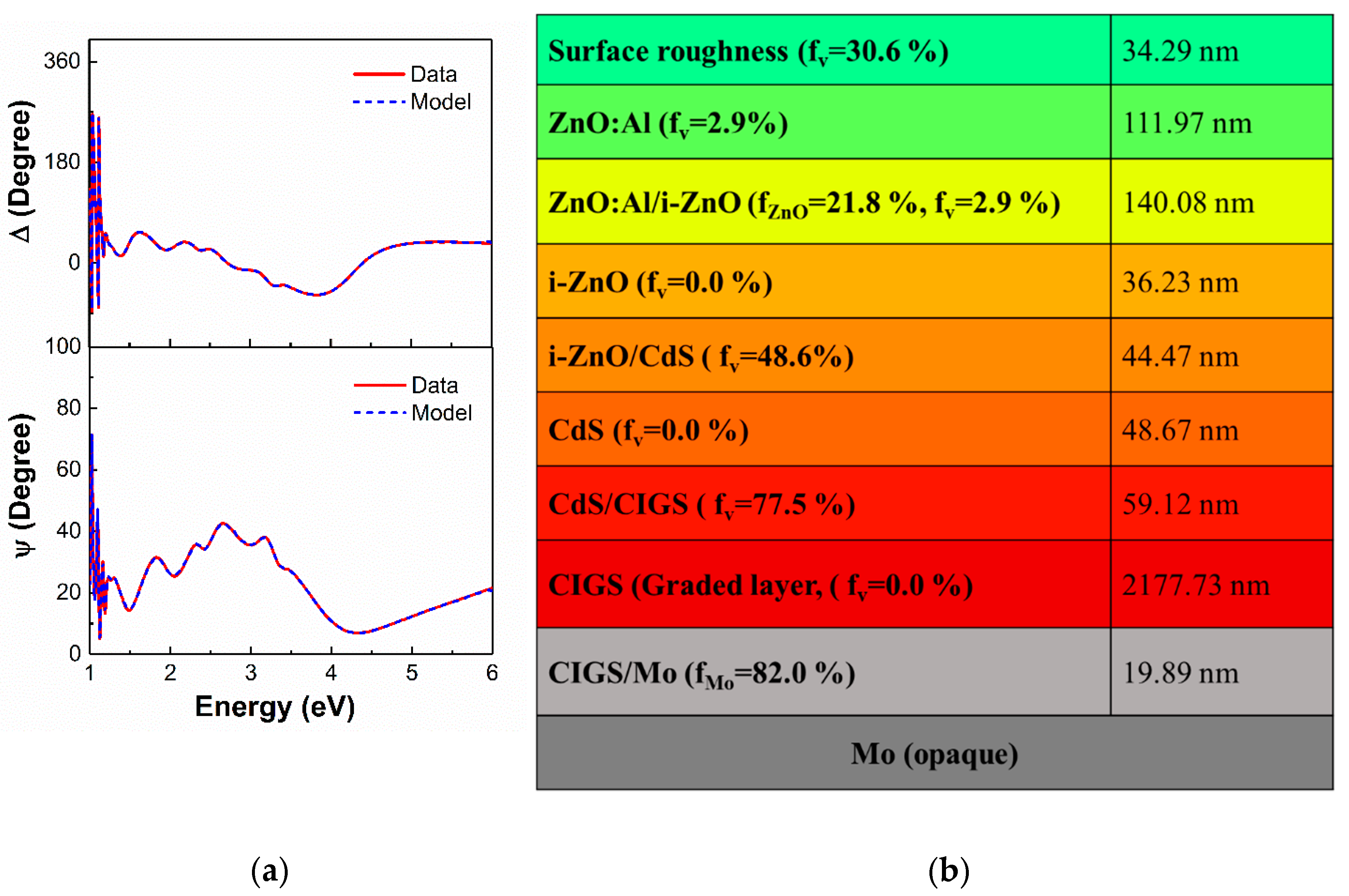

2.1. Spectroscopic Ellipsometry Measurements and Data Analysis

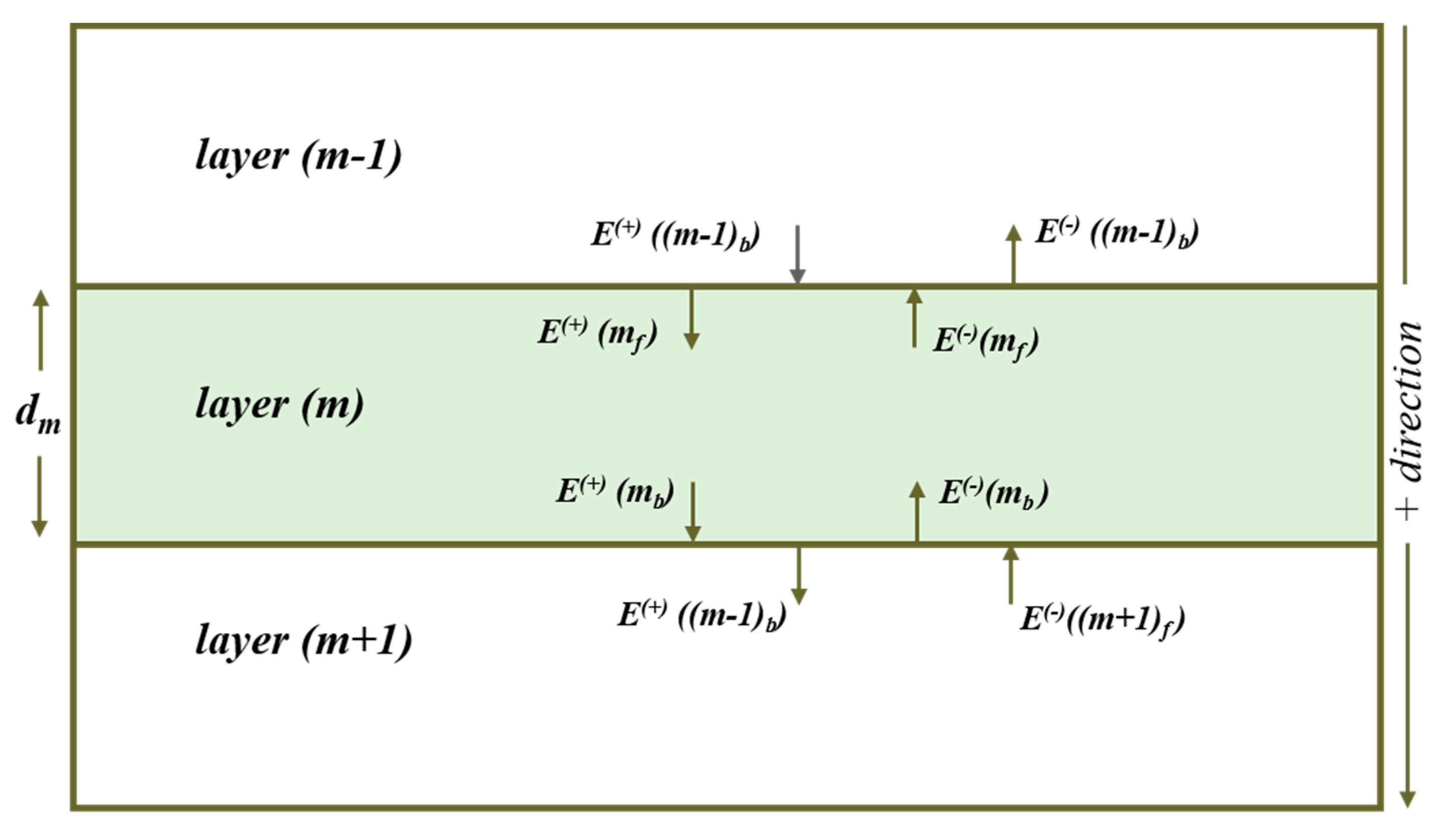

2.2. Transfer Matrix Theory Modeling

3. Results and Discussion

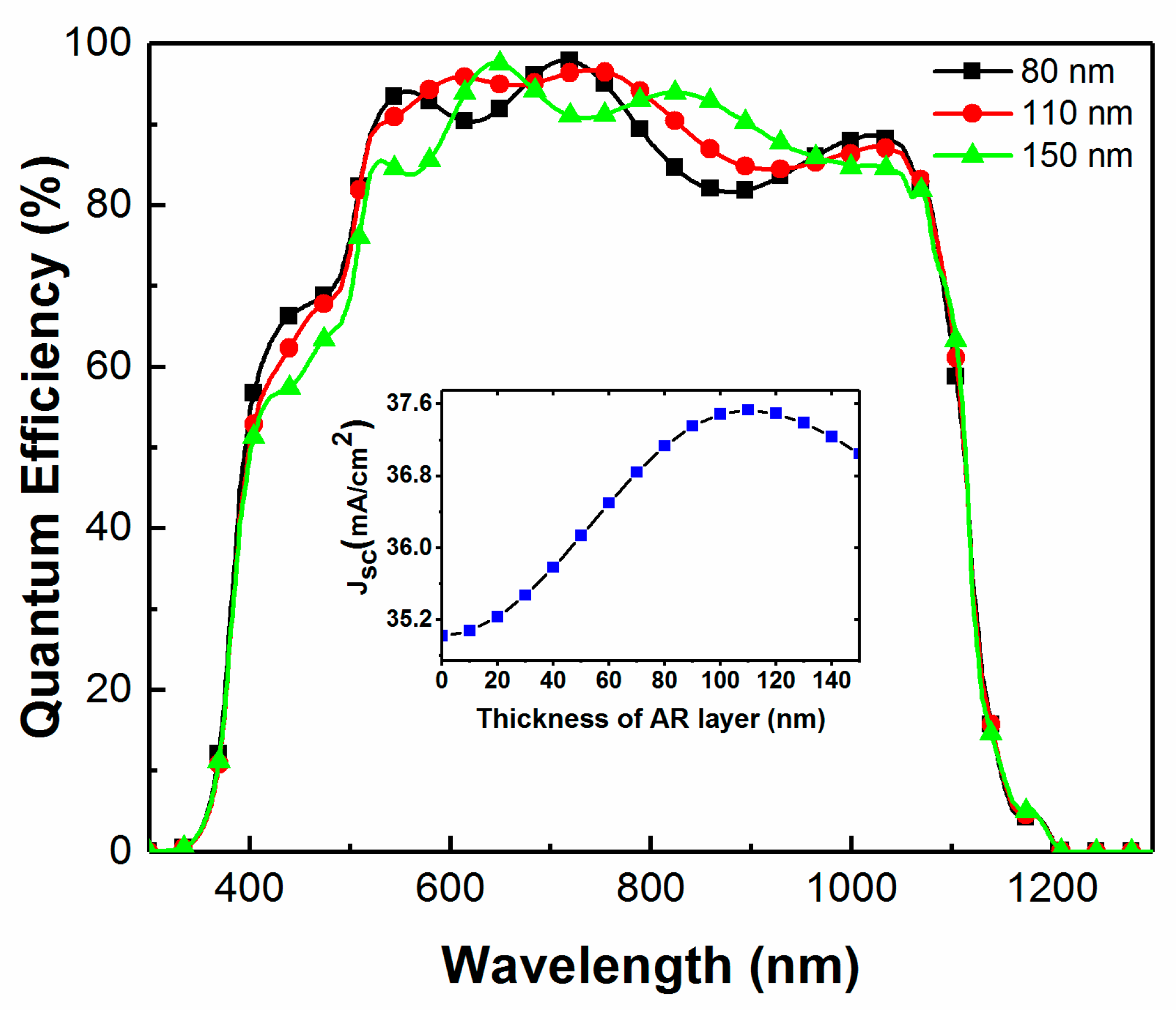

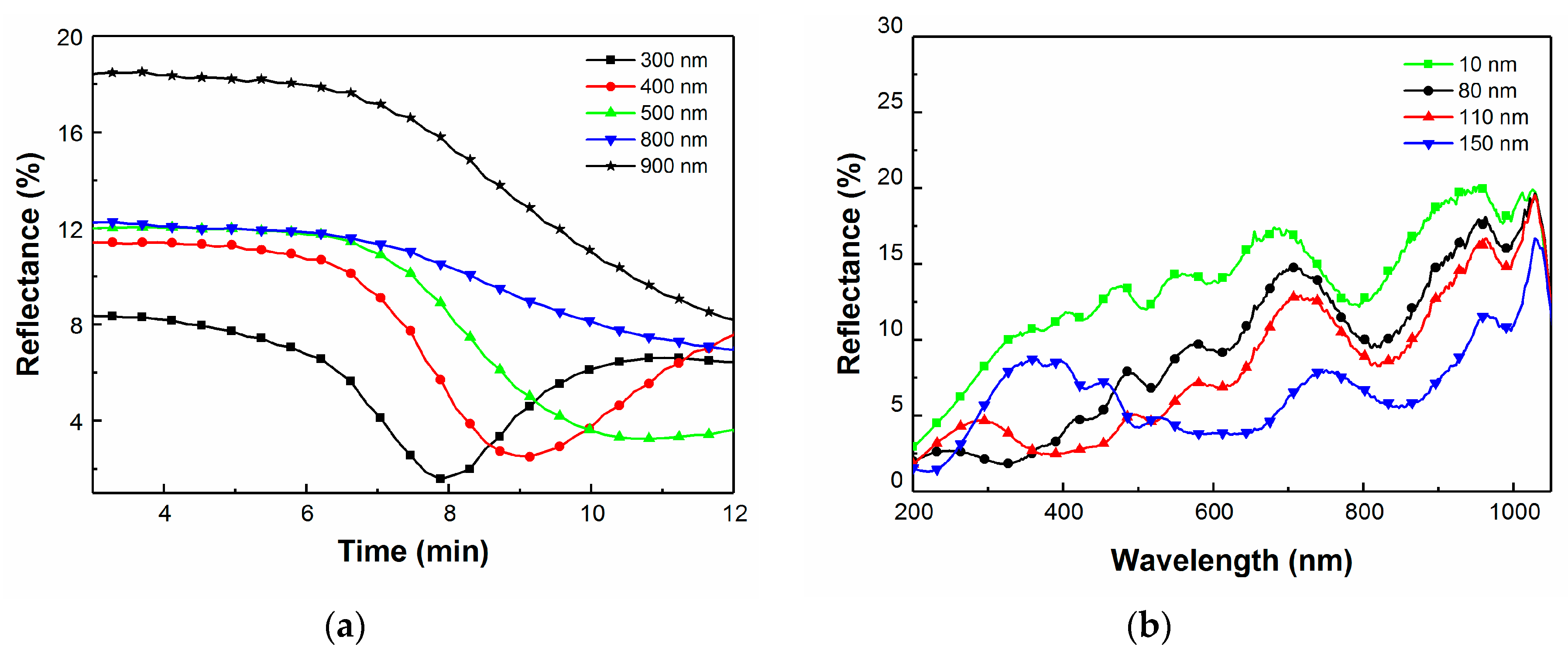

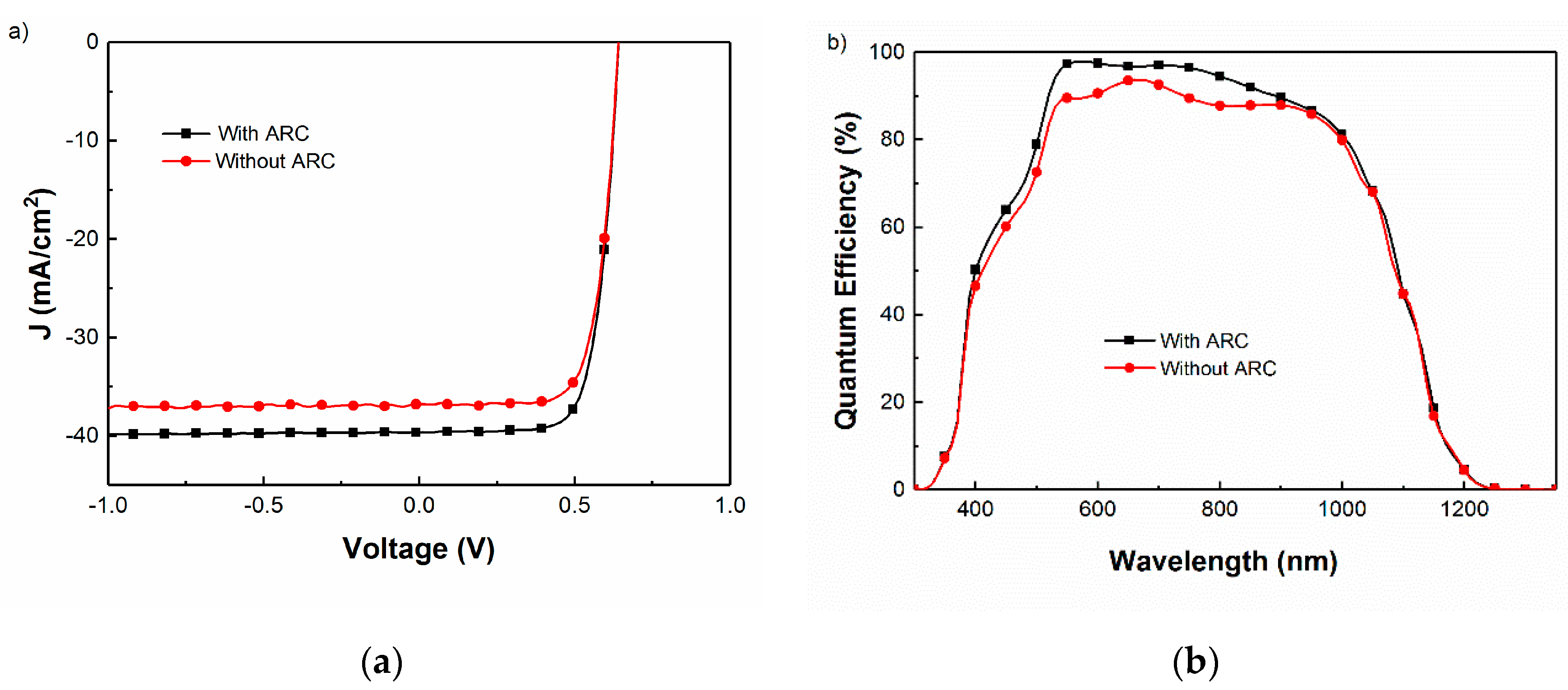

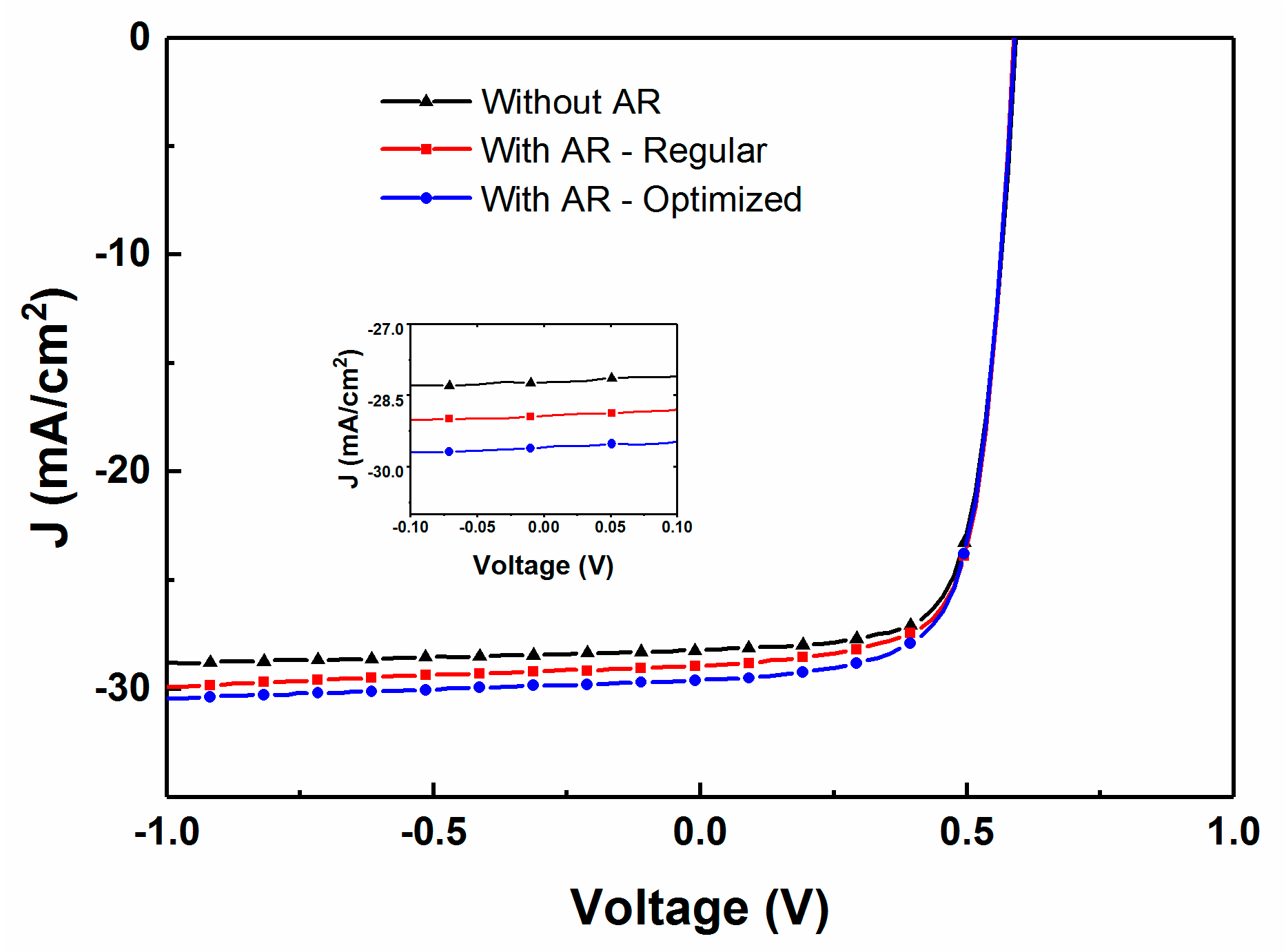

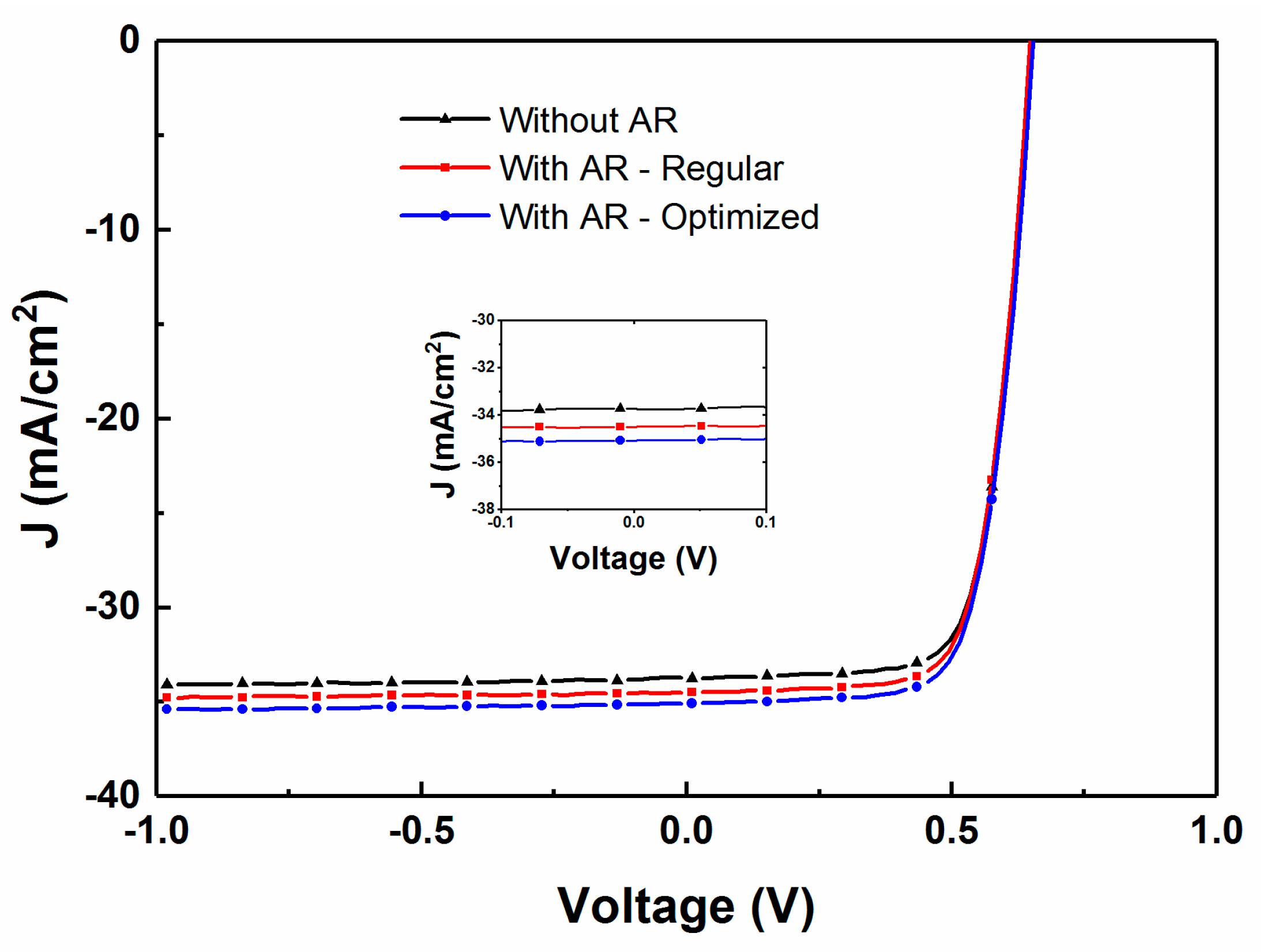

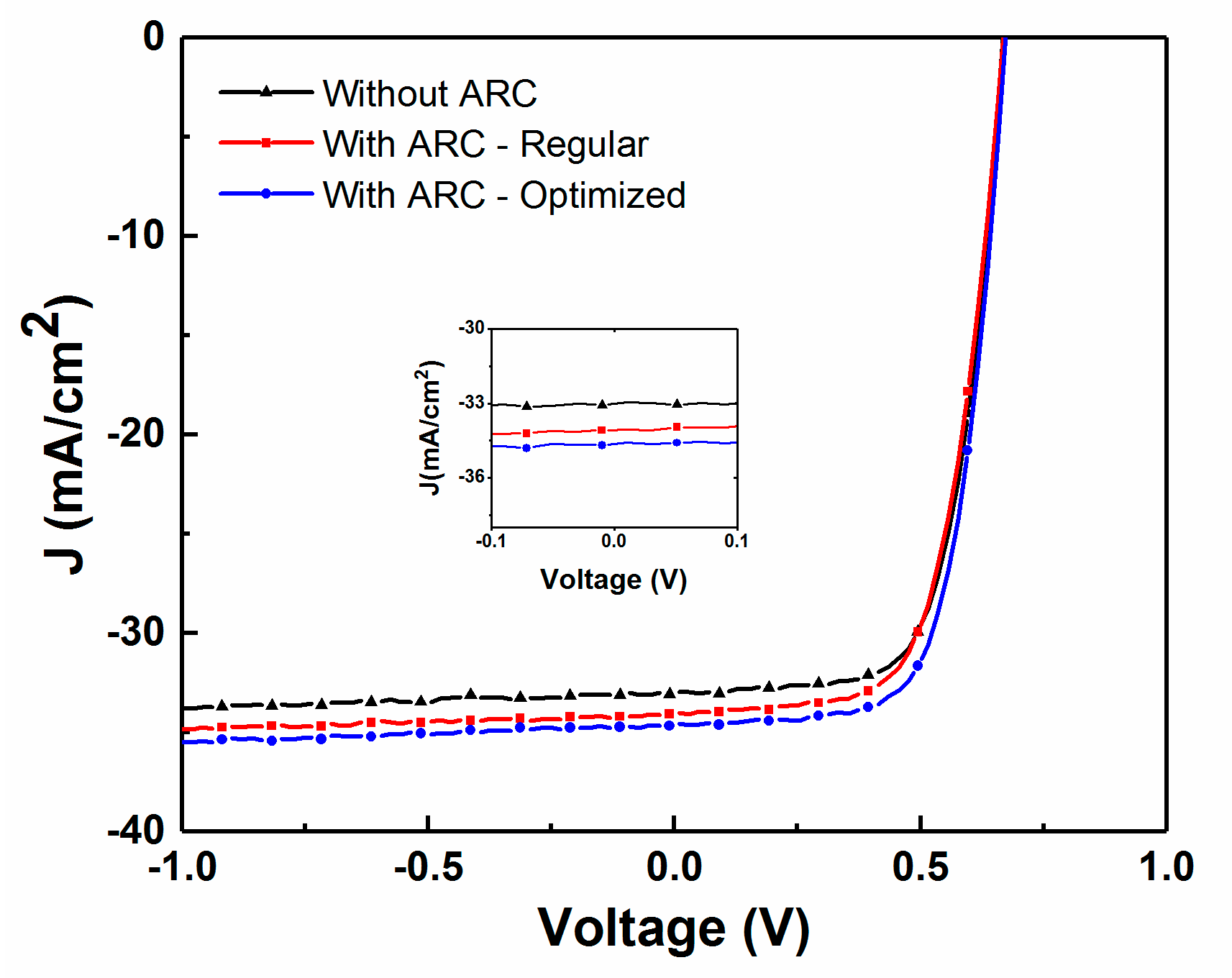

3.1. Real-Time Optimization of Thickness of AR Layer via In-Situ RTSE

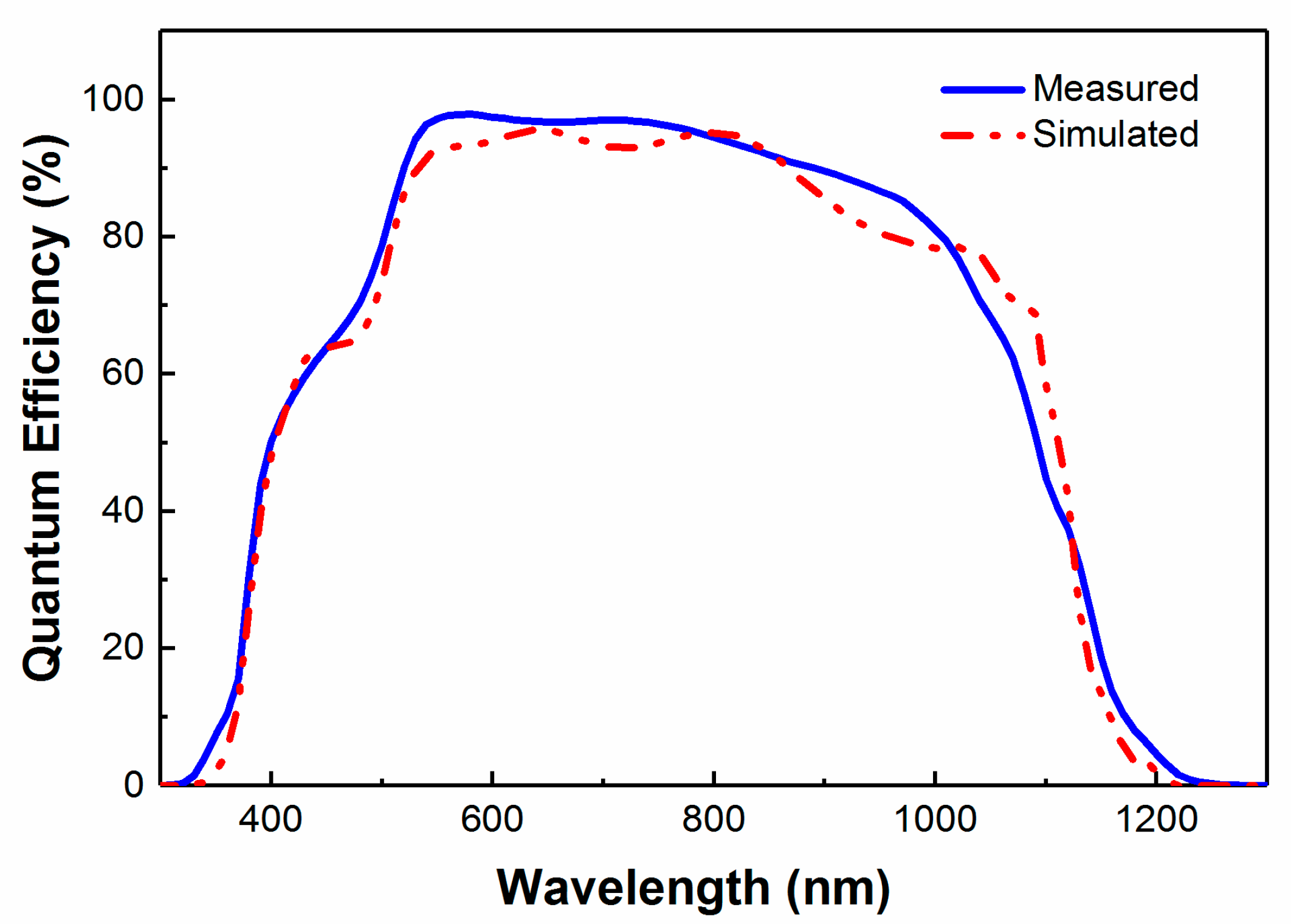

3.2. Real-Time Optimization of Thickness of AR Layer via Transfer Matrix Theory Modeling and In-Situ RTSE for Variation in Multilayer Structure

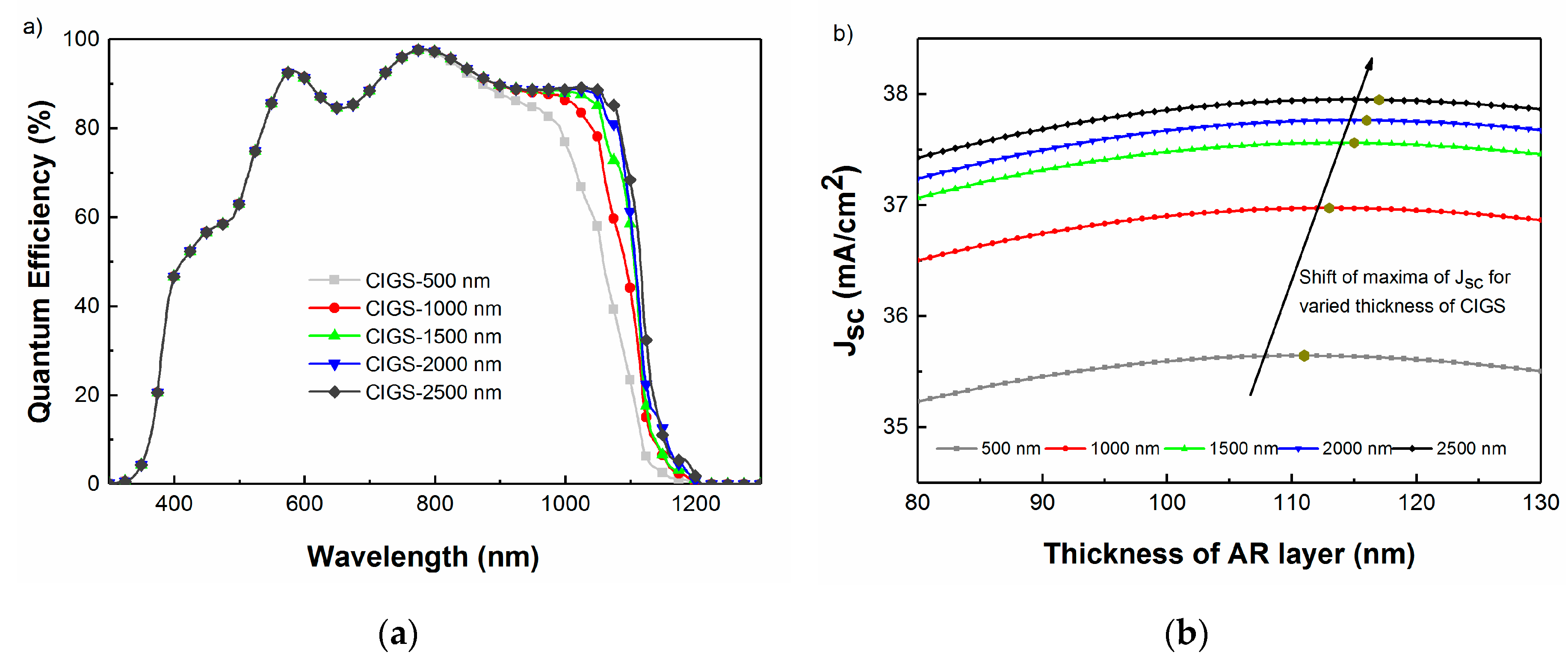

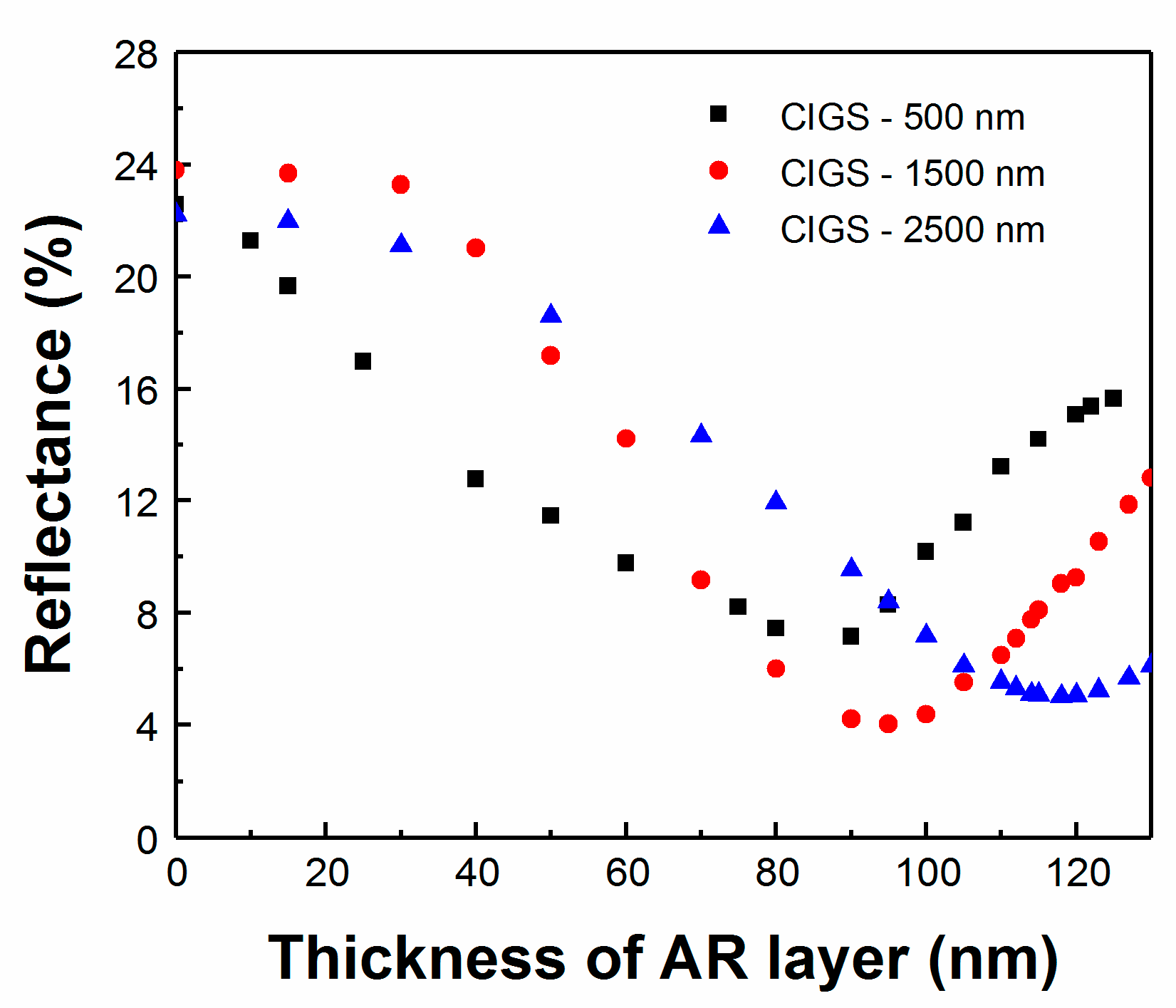

3.2.1. Optimizing the AR Layer as a Function of the CIGS Layer Thickness

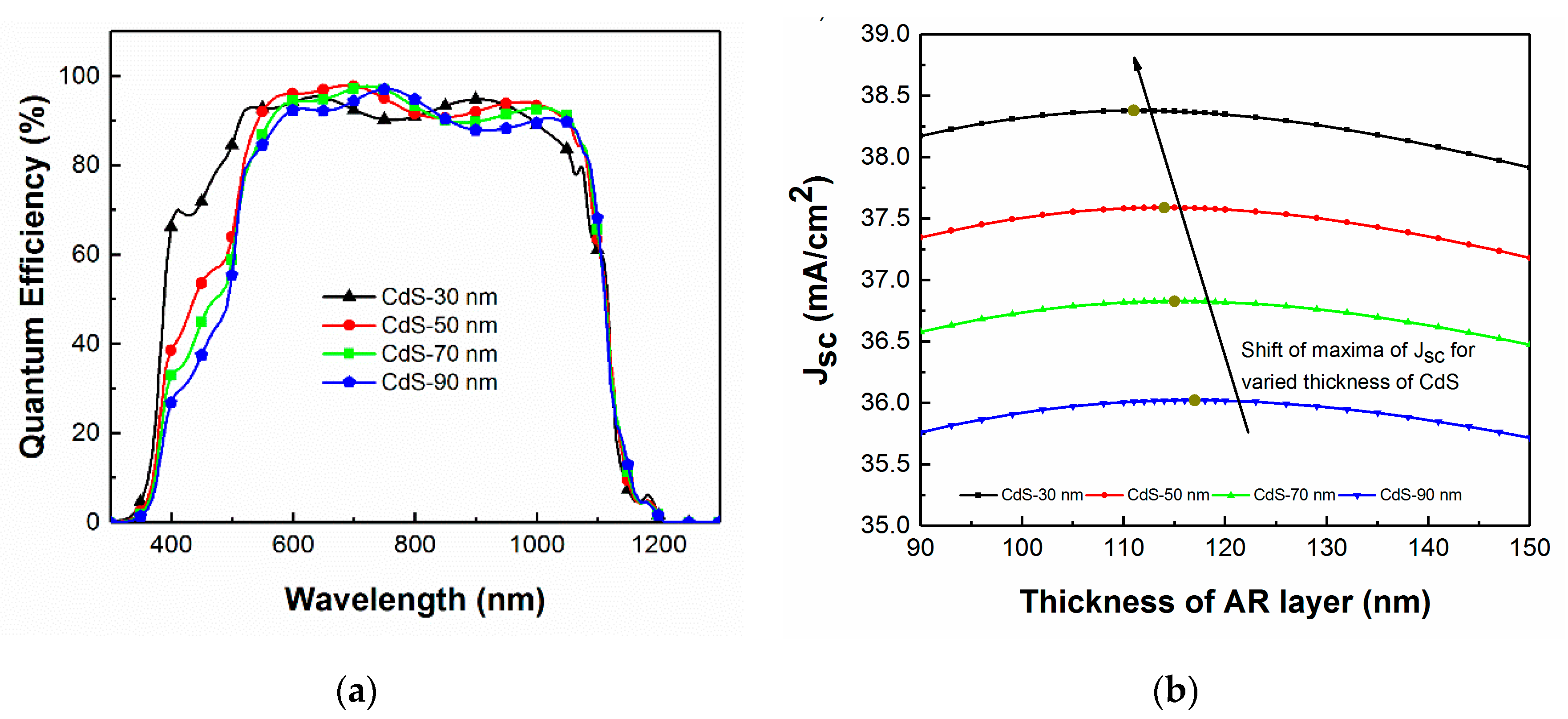

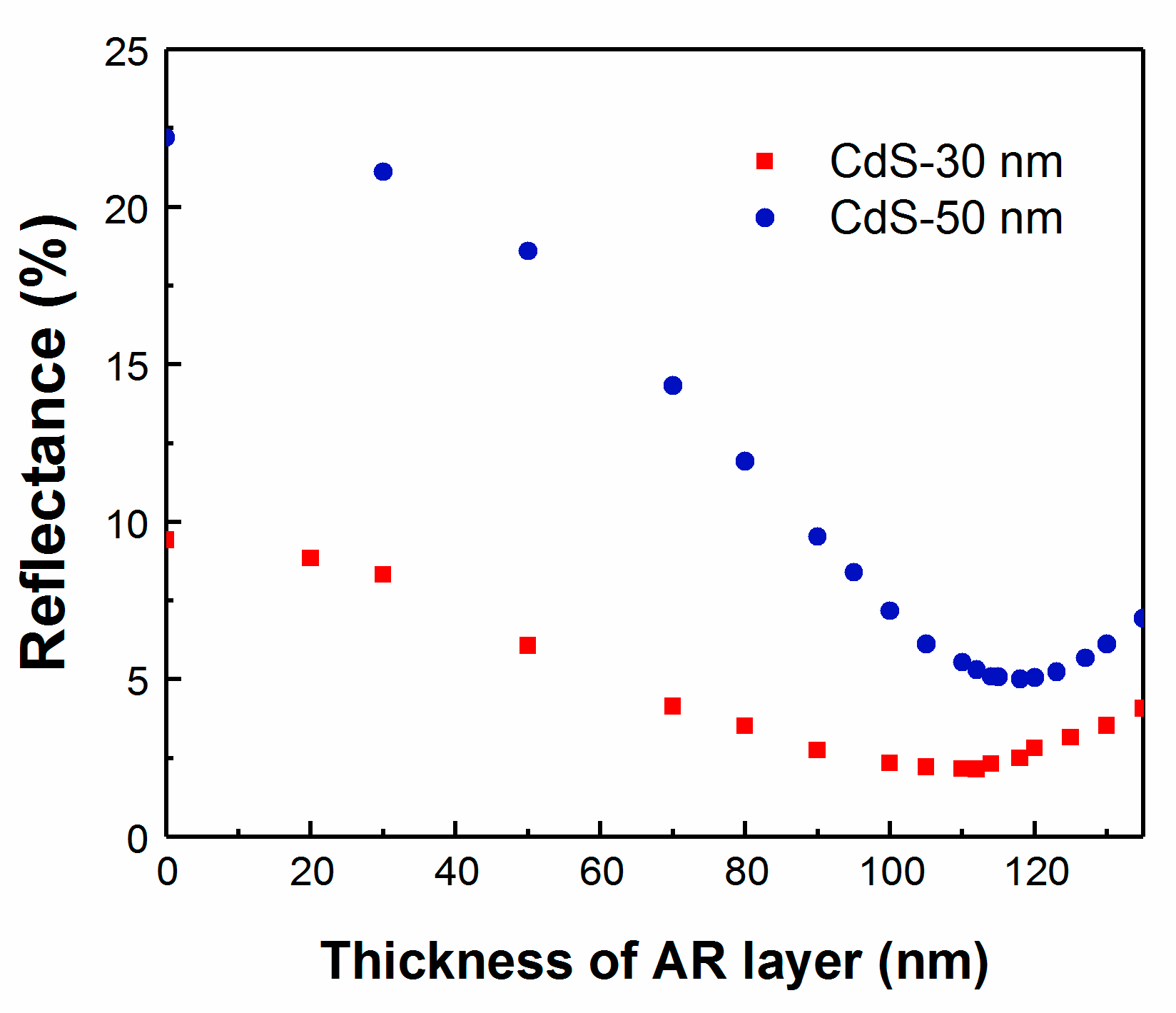

3.2.2. Optimizing the AR Layer as a Function of the CdS Layer Thickness

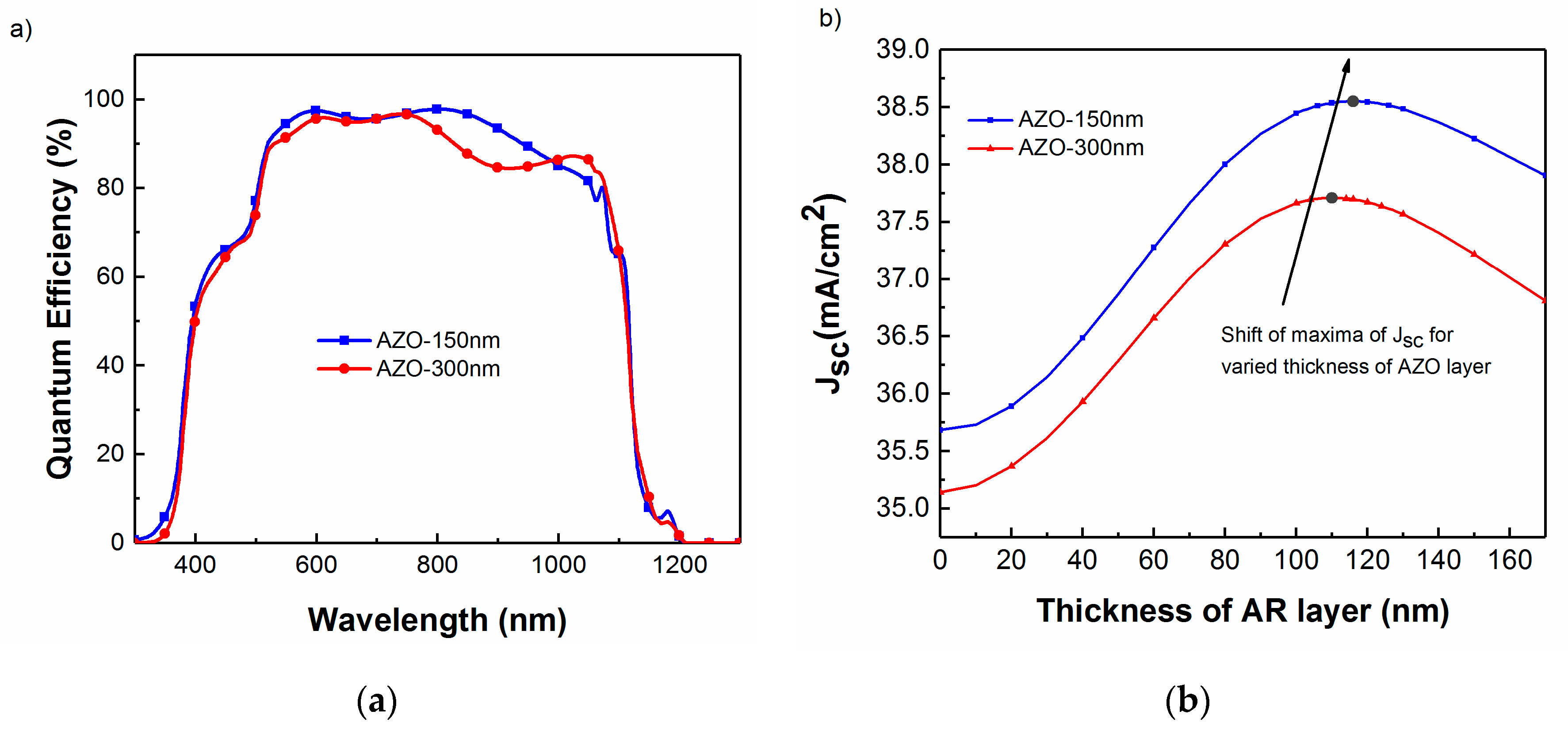

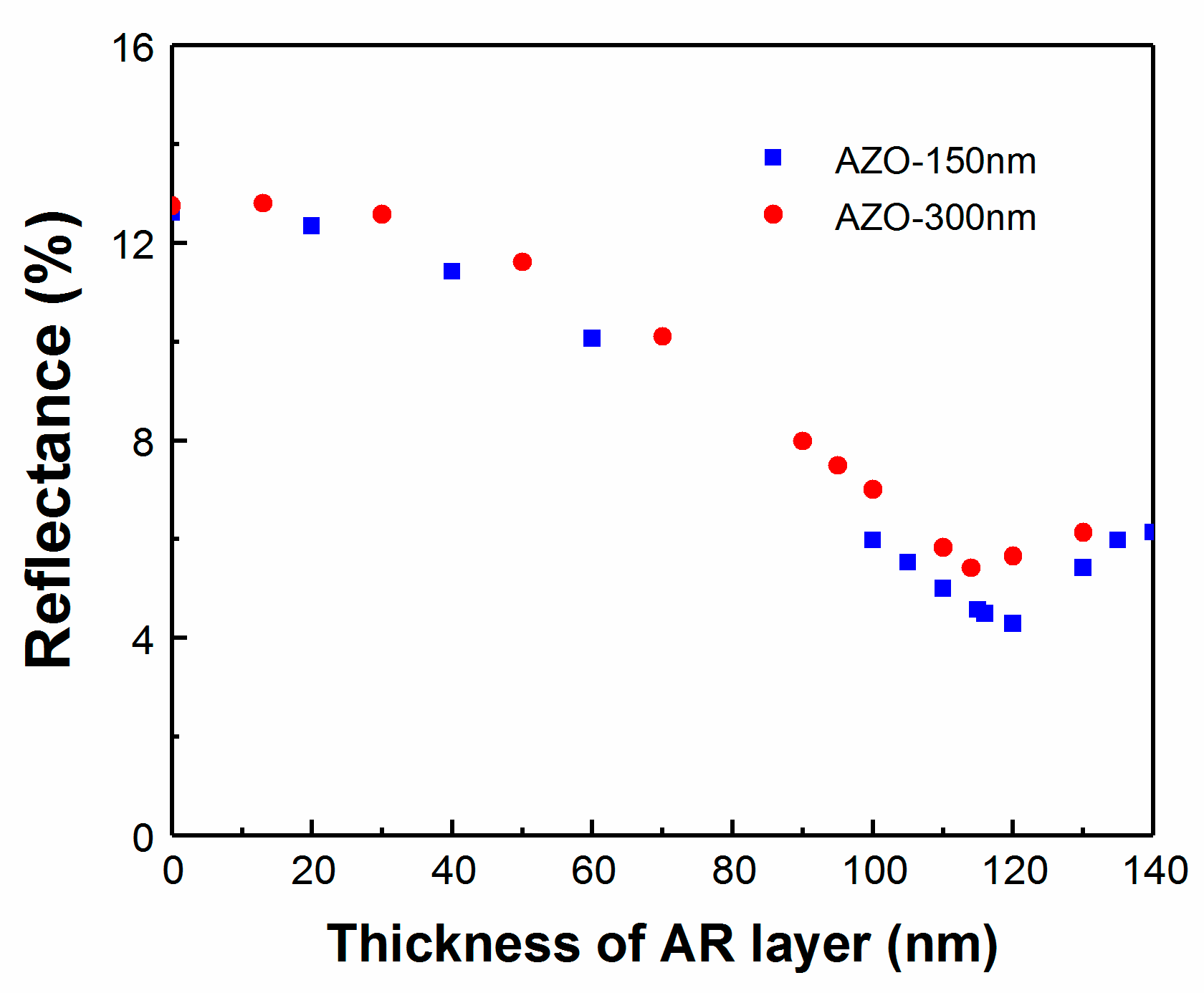

3.2.3. Optimizing the AR Layer as a Function of the AZO Layer Thickness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jackson, P.; Wuerz, R.; Hariskos, D.; Lotter, E.; Witte, W.; Powalla, M. Effects of heavy alkali elements in Cu(In,Ga)Se2 solar cells with efficiencies up to 22.6%. Phys. Status Solidi RRL Rapid Res. Lett. 2016, 10, 583–586. [Google Scholar] [CrossRef]

- Raut, H.K.; Ganesh, V.A.; Nairb, A.S.; Ramakrishna, S. Anti-reflective coatings: A critical, in-depth review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Kaminski, P.; Lisco, F.; Walls, J. Multilayer broadband antireflective coatings for more efficient thin film CdTe solar cells. IEEE J. Photovolt. 2014, 4, 452–456. [Google Scholar] [CrossRef]

- Nubile, P. Analytical design of antireflection coatings for silicon photovoltaic devices. Thin Solid Films 1999, 342, 257–261. [Google Scholar] [CrossRef]

- Hara, T.; Maekawa, T.; Minoura, S.; Sago, Y.; Niki, S.; Fujiwara, H. Quantitative assessment of optical gain and loss in submicron-textured CuInGaSe2 solar cells fabricated by three-stage coevaporation. Phys. Rev. Appl. 2014, 2, 034012. [Google Scholar] [CrossRef]

- Ibdah, A.; Koirala, P.; Aryal, P.; Pradhan, P.; Marsillac, S.; Rockett, A.; Podraza, N.; Collins, R. Spectroscopic ellipsometry for analysis of polycrystalline thin-film photovoltaic devices and prediction of external quantum efficiency. Appl. Surf. Sci. 2017, 421, 601–607. [Google Scholar] [CrossRef]

- Ibdah, A.; Koirala, P.; Aryal, P.; Pradhan, P.; Heben, M.; Podraza, N.; Marsillac, S.; Collins, R. Optical simulation of external quantum efficiency spectra of CuIn1−xGaxSe2 solar cells from spectroscopic ellipsometry inputs. J. Energy Chem. 2018, 27, 1151–1169. [Google Scholar] [CrossRef]

- Woollam, J.A. Guide to Using WVASE 32: Spectroscopic Ellipsometry Data Acquisition and Analysis Software; J. A. Woollam Company Inc.: Lincoln, NE, USA, 2008. [Google Scholar]

- Tompkins, H.; Irene, E.A. Handbook of Ellipsometry; William Andrew: Norwich, NY, USA, 2005. [Google Scholar]

- Aryal, P.; Ibdah, A.; Pradhan, P.; Attygalle, D.; Koirala, P.; Podraza, N.; Marsillac, S.; Collins, R.; Li, J. Parameterized complex dielectric functions of CuIn1−xGaxSe2: Applications in optical characterization of compositional non-uniformities and depth profiles in materials and solar cells. Prog. Photovolt. Res. Appl. 2016, 24, 1200–1213. [Google Scholar] [CrossRef]

- Aryal, K.; Khatri, H.; Collins, R.; Marsillac, S. In situ and ex situ studies of molybdenum thin films deposited by rf and dc magnetron sputtering as a back contact for CIGS solar cells. Int. J. Photoenergy 2012, 2012, 1–7. [Google Scholar] [CrossRef]

- Khatri, H.; Collins, R.; Marsillac, S. In-Situ and Ex-Situ Studies of Molybdenum Thin Films Deposited by rf and dc Magnetron Sputtering. In Proceedings of the 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; IEEE: New York, NY, USA, 2010. [Google Scholar]

- Aryal, K.; Rajan, G.; Erkaya, Y.; Hegde, N.; Boland, P.; Ranjan, V.; Collins, R.; Marsillac, S. Characterization of TCO Deposition for CIGS Solar Cells. In Proceedings of the 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; IEEE: New York, NY, USA, 2012. [Google Scholar]

- Santbergen, R.; Smets, A.; Zeman, M. Optical model for multilayer structures with coherent, partly coherent and incoherent layers. Opt. Express 2013, 21, A262–A267. [Google Scholar] [CrossRef]

- Chilwell, J.; Hodgkinson, I. Thin-films field-transfer matrix theory of planar multilayer waveguides and reflection from prism-loaded waveguides. J. Opt. Soc. Am. A 1984, 1, 742–753. [Google Scholar] [CrossRef]

- Prentice, J. Optical generation rate of electron-hole pairs in multilayer thin-film photovoltaic cells. J. Phys. D Appl. Phys. 1999, 32, 2146–2150. [Google Scholar] [CrossRef]

- Prentice, J. Coherent, partially coherent and incoherent light absorption in thin-film multilayer structures. J. Phys. D Appl. Phys. 2000, 33, 3139–3145. [Google Scholar] [CrossRef]

- Pettersson, L.; Roman, L.; Inganas, O. Modeling photocurrent action spectra of photovoltaic devices based on organic thin films. J. Appl. Phys. 1999, 86, 487–496. [Google Scholar] [CrossRef]

- Poruba, A.; Fejfar, A.; Remes, Z.; Springer, J.; Vanecek, M.; Kocka, J.; Meier, J.; Torres, P.; Shah, A. Optical absorption and light scattering in microcrystalline silicon thin films and solar cells. J. Appl. Phys. 2000, 88, 148–160. [Google Scholar] [CrossRef]

- Springer, J.; Poruba, A.; Vanecek, M. Improved three-dimensional optical model for thin-film silicon solar cells. J. Appl. Phys. 2004, 96, 5329–5337. [Google Scholar] [CrossRef]

- Contreras, M.; Egaas, B.; Ramanathan, K.; Hiltner, J.; Swartzlander, A.; Hasoon, F.; Noufi, R. Progress toward 20% efficiency in Cu(In,Ga)Se2 polycrystalline thin-film solar cells. Prog. Photovolt. Res. Appl. 1999, 7, 311–316. [Google Scholar] [CrossRef]

- Chirila, A.; Buecheler, S.; Pianezzi, F.; Bloesch, P.; Gretener, C.; Uhl, A.; Fella, C.; Kranz, L.; Perrenoud, J.; Seyrling, S.; et al. Highly efficient Cu(In,Ga)Se2 solar cells grown on flexible polymer films. Nat. Mater. 2011, 10, 857–861. [Google Scholar] [CrossRef]

- Jackson, P.; Hariskos, D.; Wuerz, R.; Kiowski, O.; Bauer, A.; Friedlmeier, T.; Powalla, M. Properties of Cu(In,Ga)Se2 solar cells with new record efficiencies up to 21.7%. Phys. Status Solidi RRL Rapid Res. Lett. 2015, 9, 28–31. [Google Scholar] [CrossRef]

- Rajan, G.; Ibdah, A.; Aryal, K.; Ashrafee, T.; Ranjan, V.; Pogue, A.; Rockett, A.; Collins, R.; Marsillac, S. Optical Enhancement of Ultra-Thin CIGS Solar Cells Using Multilayered Antireflection Coatings. In Proceedings of the 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; IEEE: New York, NY, USA, 2014. [Google Scholar]

- Koirala, P.; Li, J.; Yoon, H.; Aryal, P.; Marsillac, S.; Rockett, A.; Podraza, N.; Collins, R. Through-the-glass spectroscopic ellipsometry for analysis of CdTe thin-film solar cells in the superstrate configuration. Prog. Photovolt. Res. Appl. 2016, 24, 1055–1067. [Google Scholar] [CrossRef]

- Shafarman, W.; Birkmire, R.; Marsillac, S.; Marudachalam, M.; Orbey, N.; Russell, T. Effect of Reduced Deposition Temperature, Time, And Thickness on Cu (InGa)Se2 Films and Devices. In Proceedings of the 26th Photovoltaic Specialist Conference, Anaheim, CA, USA, 29 September–3 October 1997; IEEE: New York, NY, USA, 2014. [Google Scholar]

- Amory, C.; Bernede, J.; Marsillac, S. Study of a growth instability of γ-In2Se3. J. Appl. Phys. 2003, 94, 6945–6948. [Google Scholar]

- Rajan, G.; Aryal, K.; Ashrafee, T.; Karki, S.; Ibdah, A.; Ranjan, V.; Collins, R.; Marsillac, S. Optimization of Anti-Reflective Coatings for CIGS Solar Cells via Real Time Spectroscopic Ellipsometry. In Proceedings of the 42nd Photovoltaic Specialist Conference, New Orleans, LA, USA, 14–16 June 2015; IEEE: New York, NY, USA, 2015. [Google Scholar]

- Aryal, K.; Erkaya, Y.; Rajan, G.; Ashrafee, T.; Rockett, A.; Collins, R.; Marsillac, S. Comparative Study of ZnS Thin Films Deposited by CBD and ALD as a Buffer Layer for CIGS Solar Cell. In Proceedings of the 2013 39th Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013; IEEE: New York, NY, USA, 2013. [Google Scholar]

- Orgassa, K.; Rau, U.; Nguyen, Q.; Schock, H.; Werner, J. Role of the CdS buffer layer as an active optical element in Cu(In,Ga)Se2 thin-film solar cells. Prog. Photovolt. Res. Appl. 2002, 10, 457–463. [Google Scholar]

- Islam, M.; Ishizuka, S.; Yamada, A.; Matsubara, K.; Niki, S.; Sakurai, T.; Akimoto, K. Thickness study of Al:ZnO film for application as a window layer in Cu(In1−xGax)Se2 thin film solar cell. Appl. Surf. Sci. 2011, 257, 4026–4030. [Google Scholar]

| AR Coating | η (%) | Jsc (mA/cm2) | Voc (V) | FF (%) |

|---|---|---|---|---|

| Without AR | 16.7 | 35.6 | 0.64 | 73.4 |

| With MgF2 | 17.6 | 37.5 | 0.64 | 73.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajan, G.; Karki, S.; Collins, R.W.; Podraza, N.J.; Marsillac, S. Real-Time Optimization of Anti-Reflective Coatings for CIGS Solar Cells. Materials 2020, 13, 4259. https://doi.org/10.3390/ma13194259

Rajan G, Karki S, Collins RW, Podraza NJ, Marsillac S. Real-Time Optimization of Anti-Reflective Coatings for CIGS Solar Cells. Materials. 2020; 13(19):4259. https://doi.org/10.3390/ma13194259

Chicago/Turabian StyleRajan, Grace, Shankar Karki, Robert W. Collins, Nikolas J. Podraza, and Sylvain Marsillac. 2020. "Real-Time Optimization of Anti-Reflective Coatings for CIGS Solar Cells" Materials 13, no. 19: 4259. https://doi.org/10.3390/ma13194259

APA StyleRajan, G., Karki, S., Collins, R. W., Podraza, N. J., & Marsillac, S. (2020). Real-Time Optimization of Anti-Reflective Coatings for CIGS Solar Cells. Materials, 13(19), 4259. https://doi.org/10.3390/ma13194259